Patents

Literature

341results about How to "Increase the mixing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

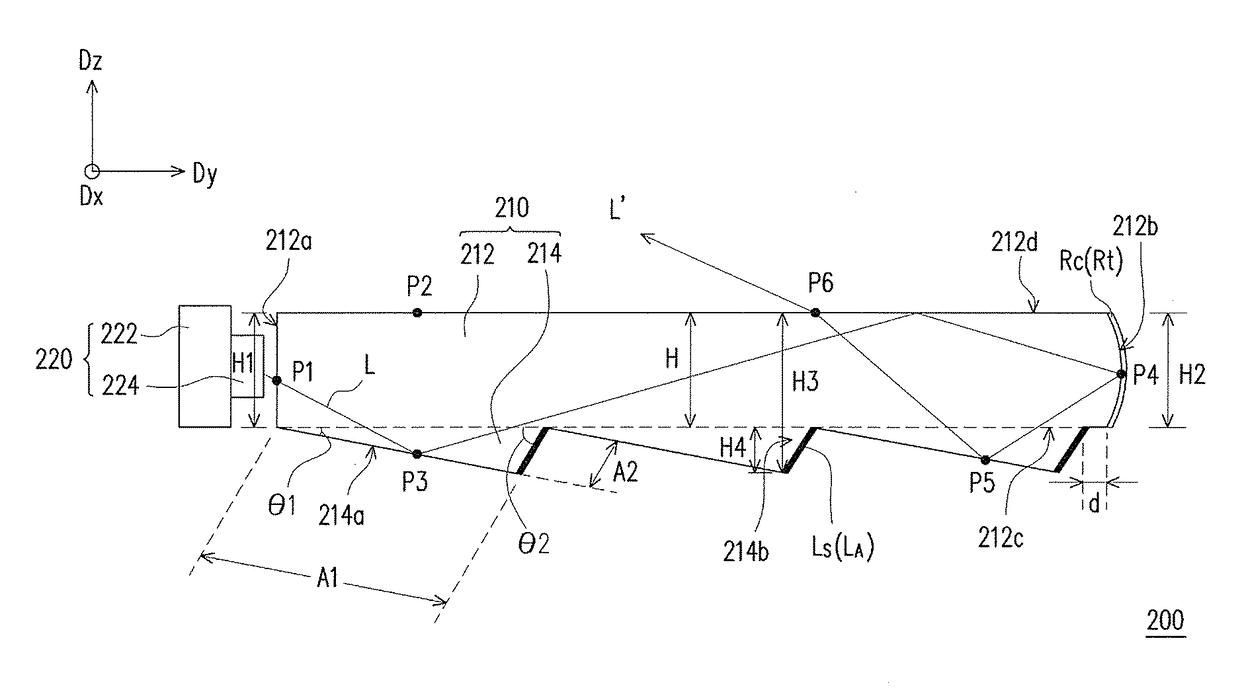

Planar light source

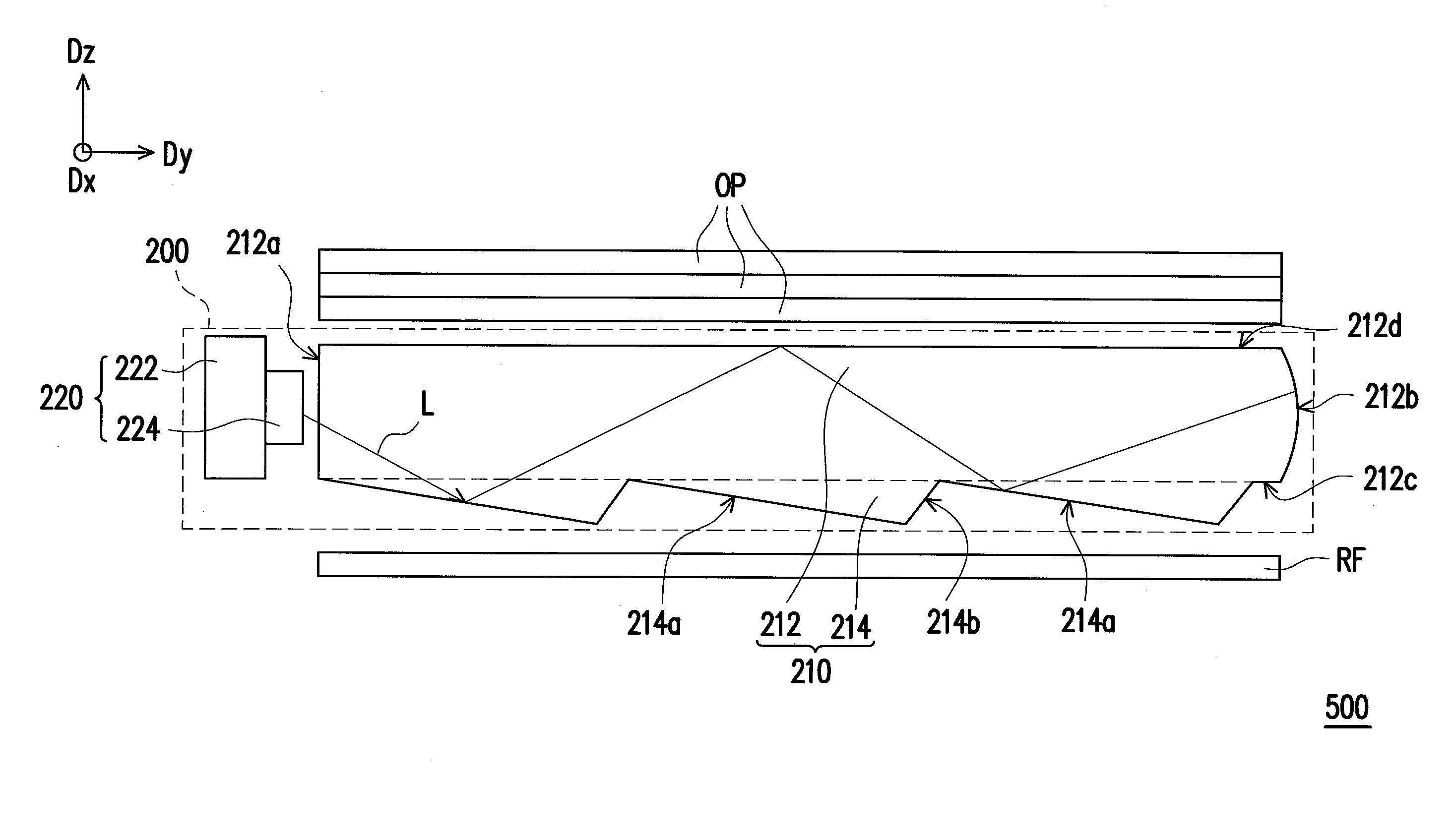

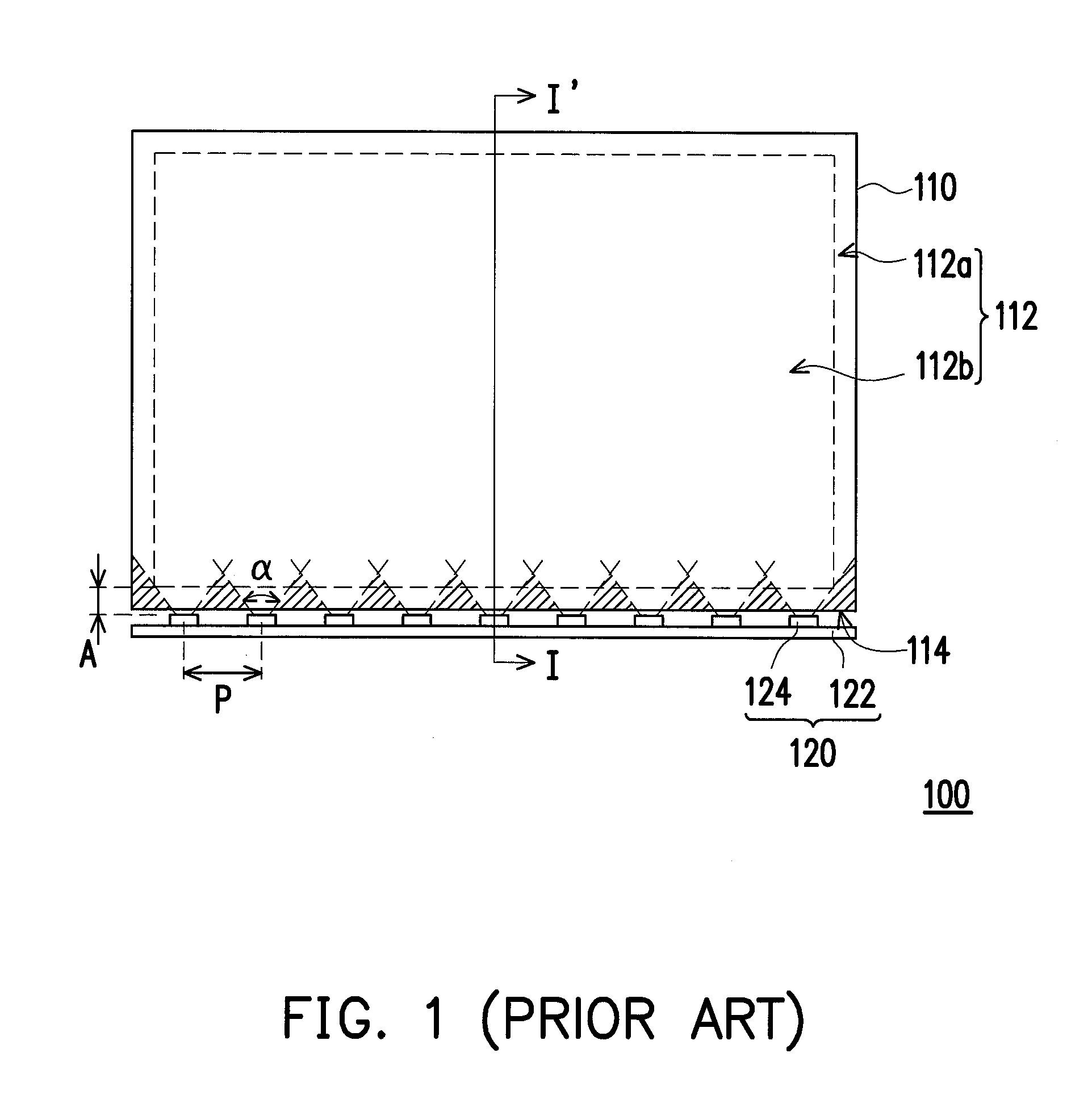

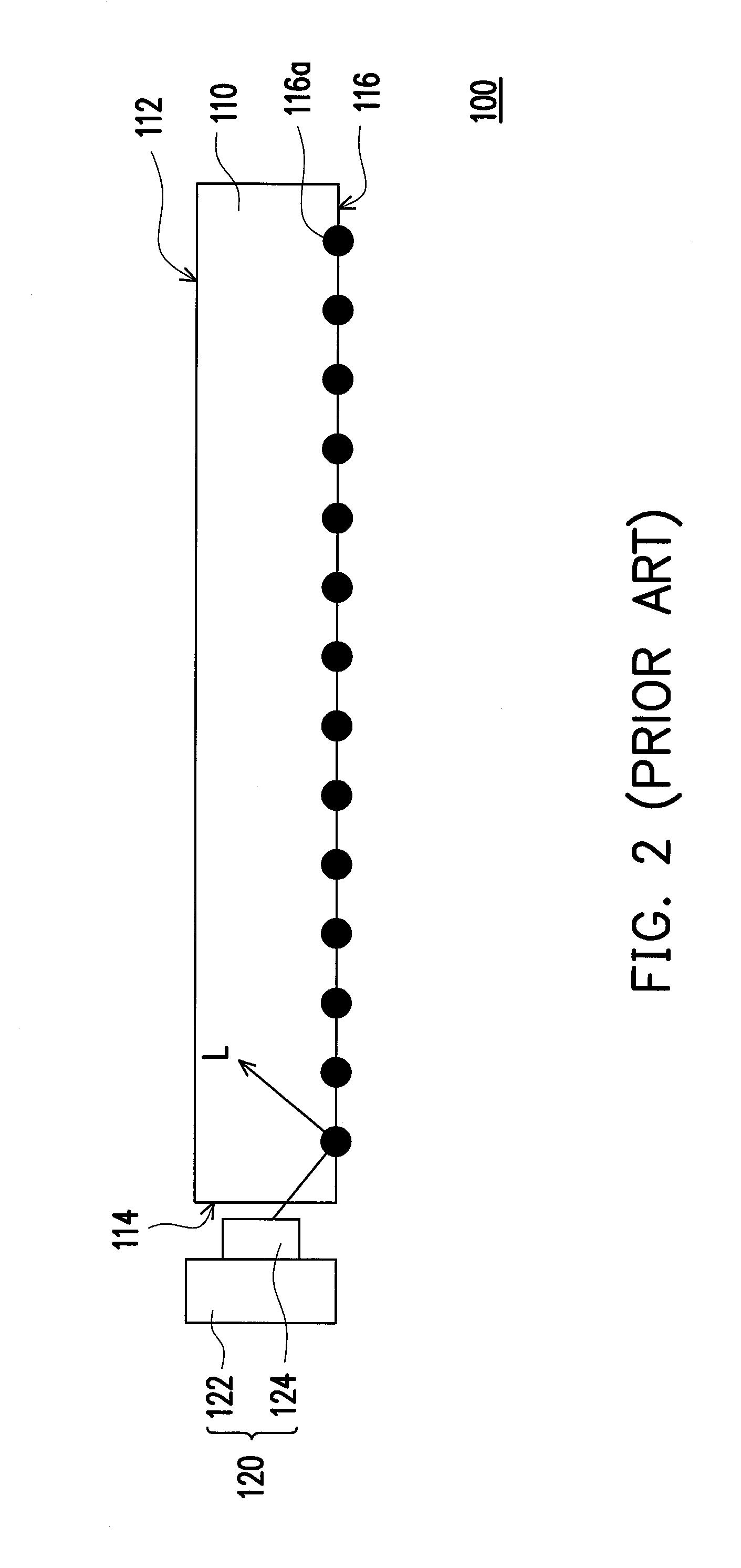

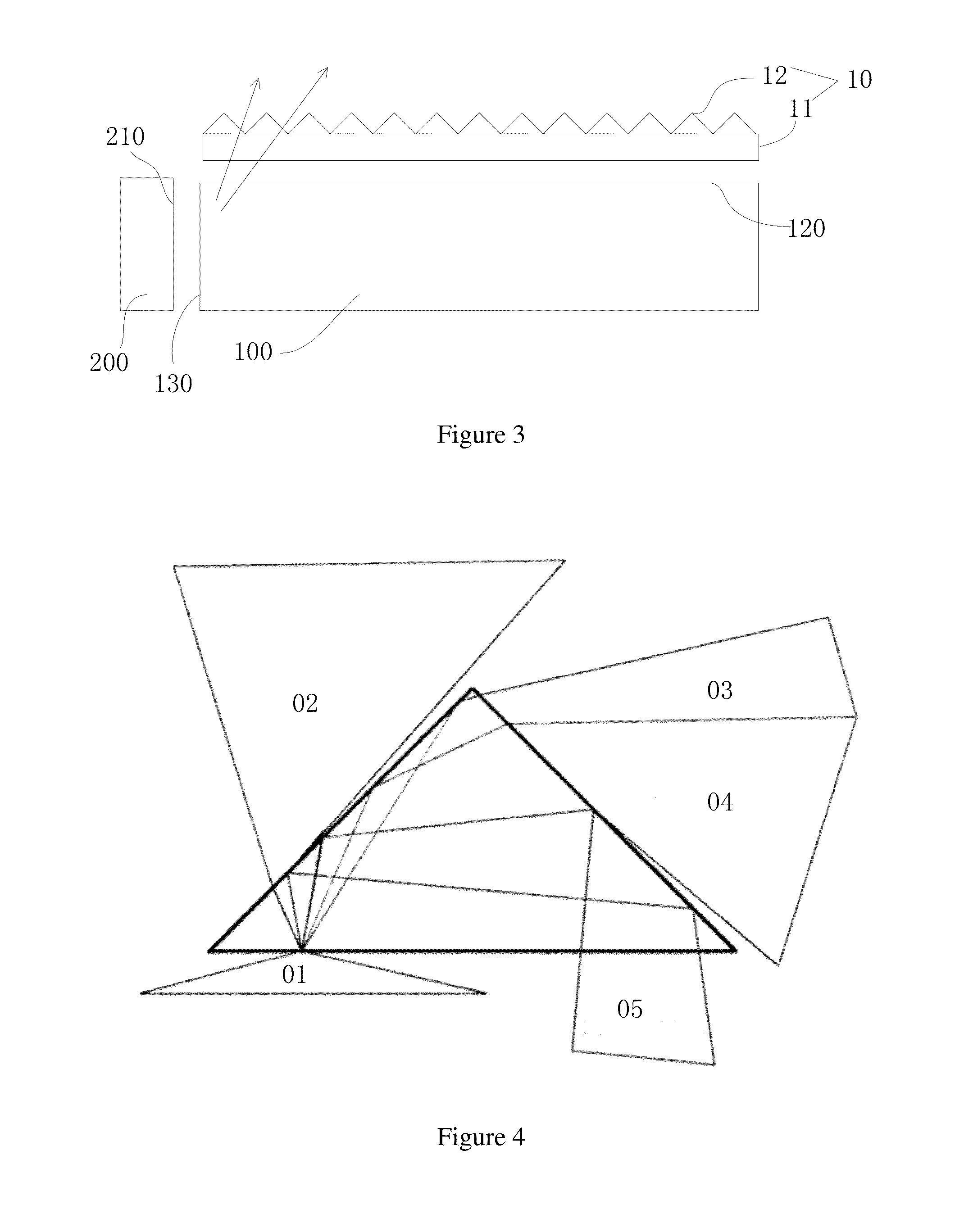

ActiveUS20140376258A1Improve light uniformityReduce usageMechanical apparatusPlanar/plate-like light guidesLight guideShortest distance

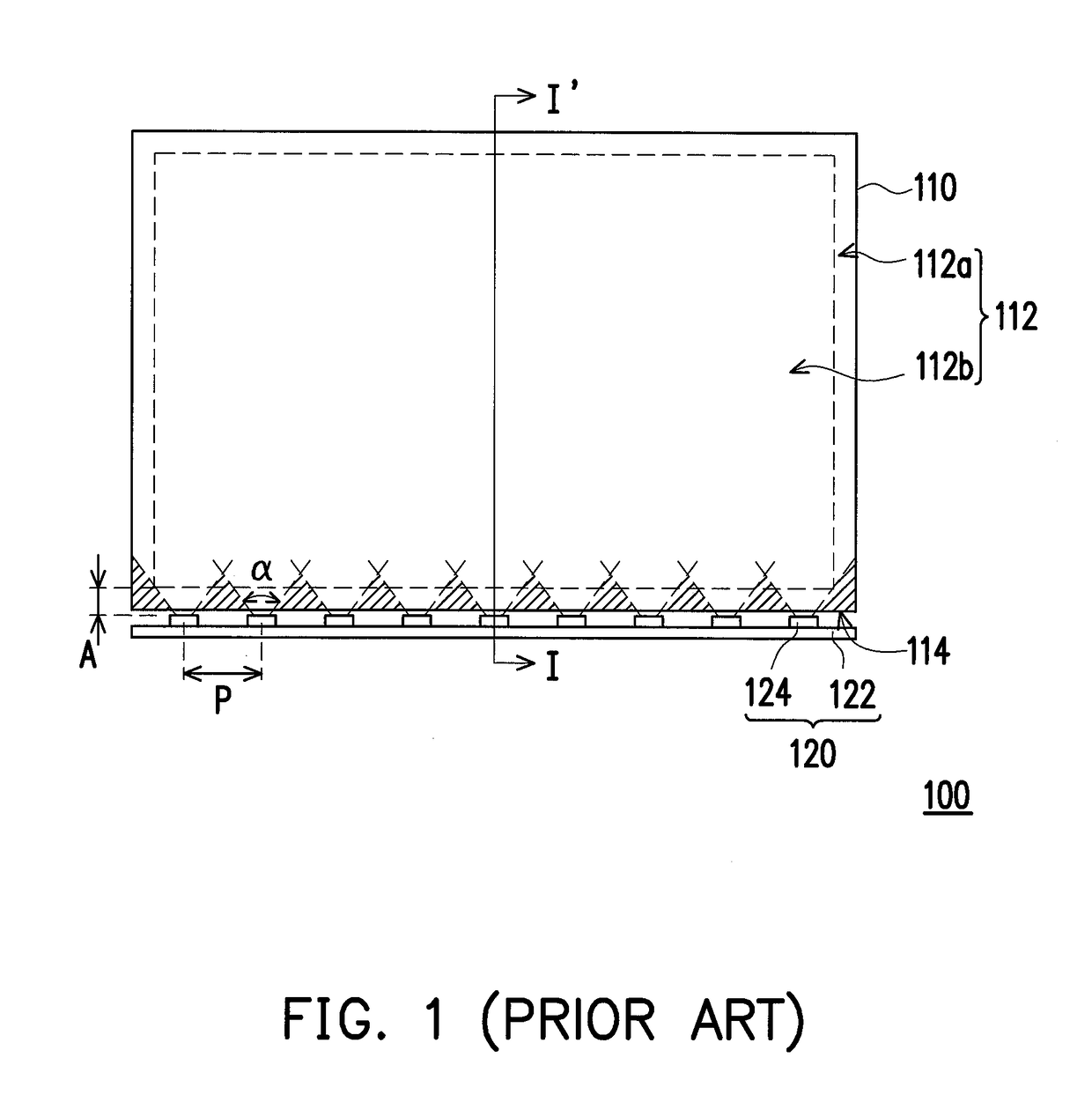

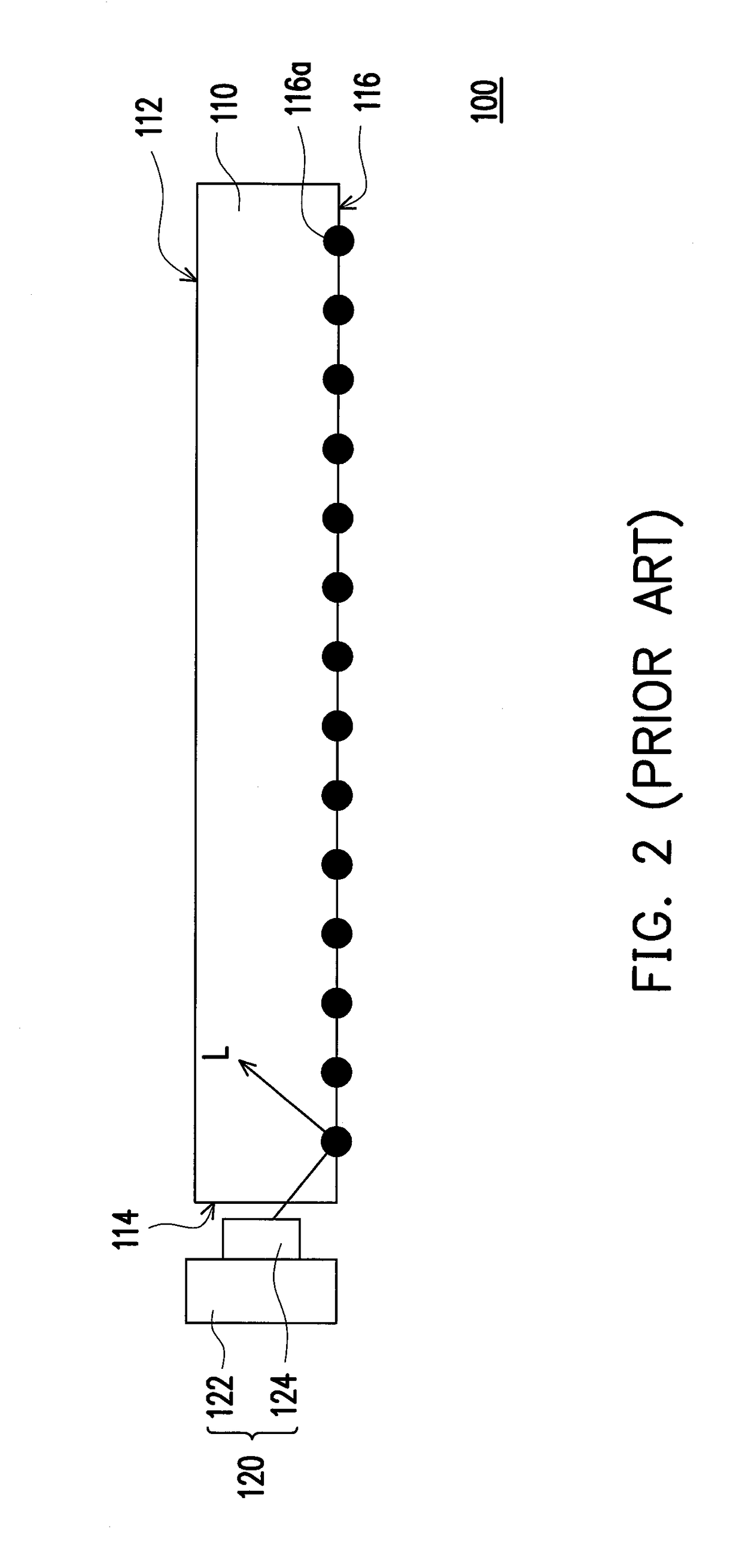

A planar light source including a light guide plate (LGP) and a light source device is provided. The LGP includes a plate portion and at least one prism portion. The plate portion has a light incident surface, a reflective surface, a bottom surface, and a light exiting surface. The prism portion is disposed on the bottom surface of the plate portion, and has a first plane and a second plane. An included angle between the first plane and the bottom surface is smaller than an included angle between the second plane and the bottom surface, and a shortest distance between the first plane and the light incident surface is smaller than a shortest distance between the second plane and the light incident surface. The light source device is disposed adjacent to the light incident surface. The disclosure provides planar light source with good light uniformity.

Owner:CORETRONIC

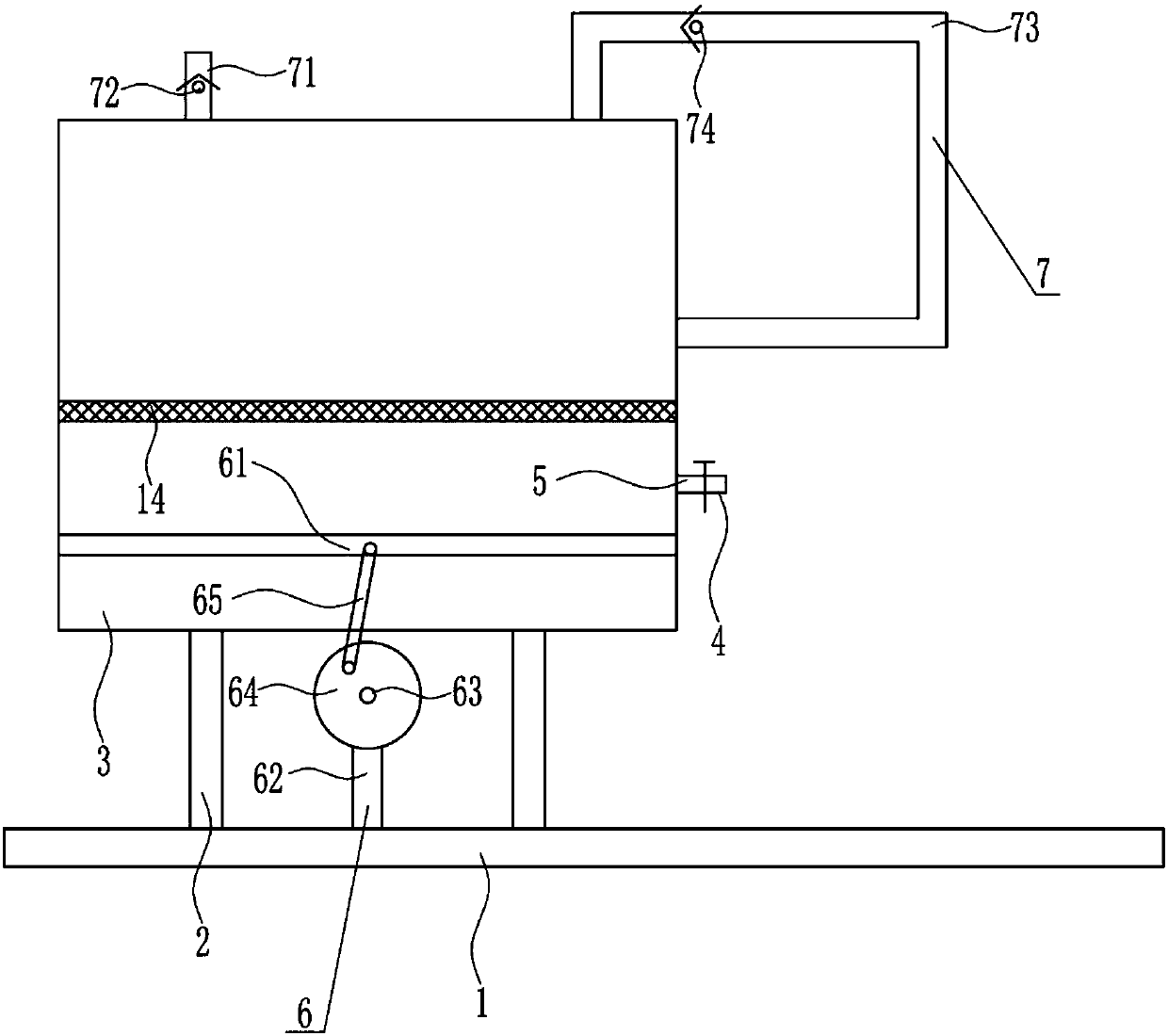

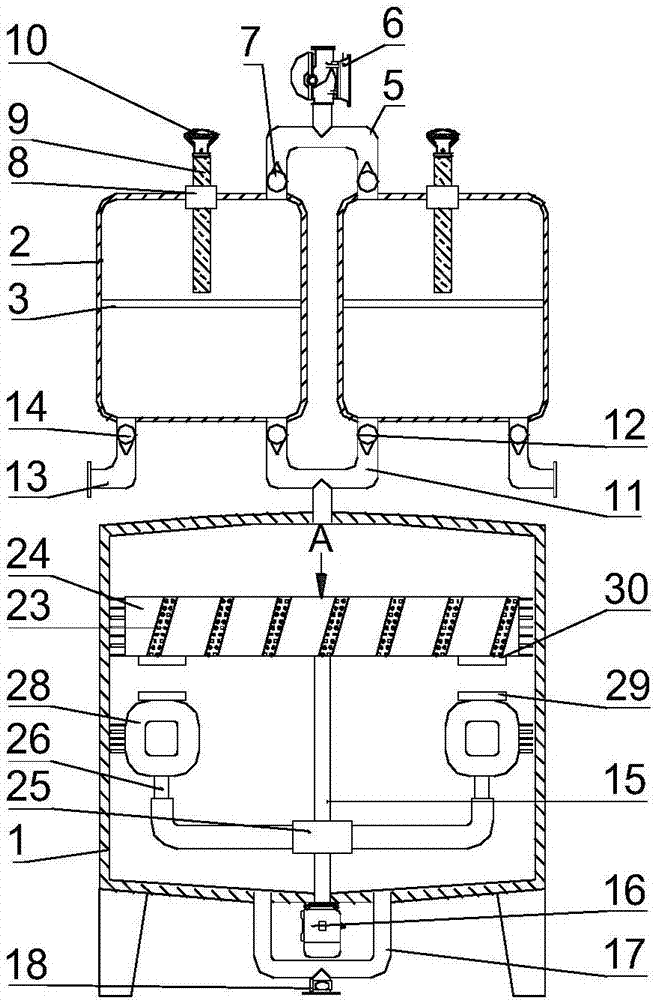

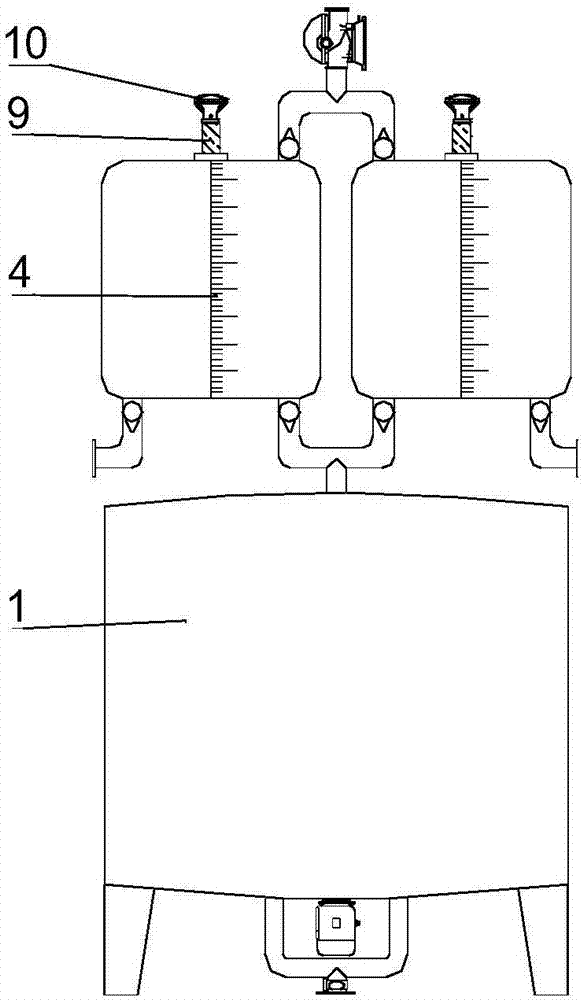

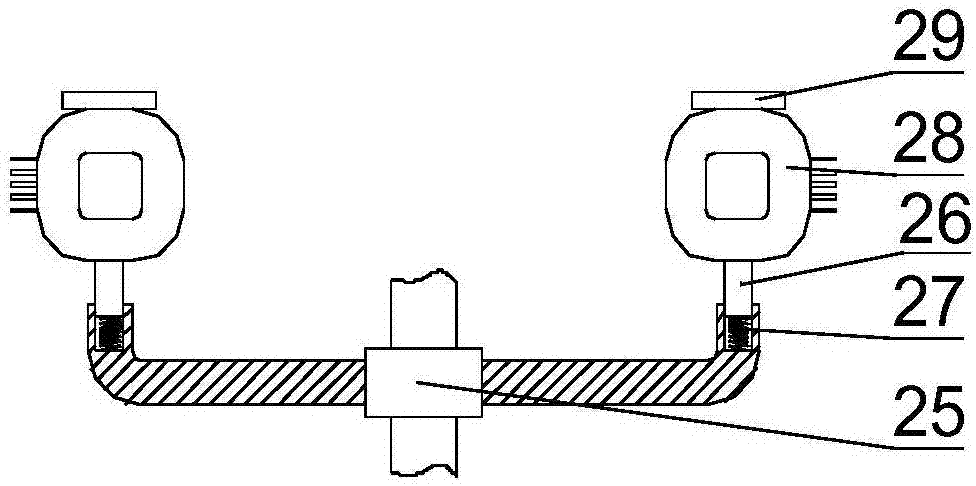

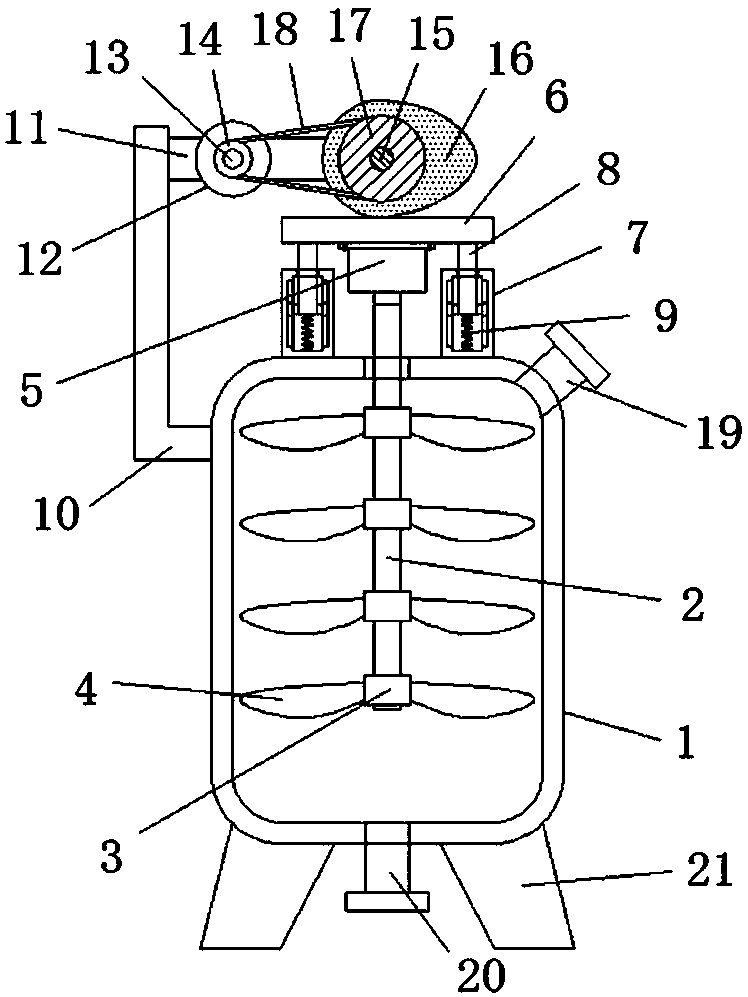

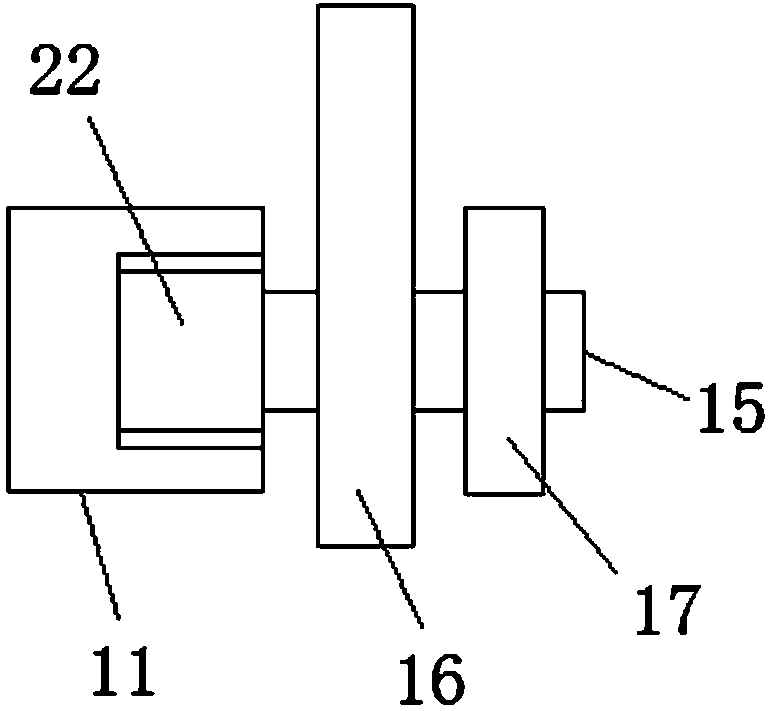

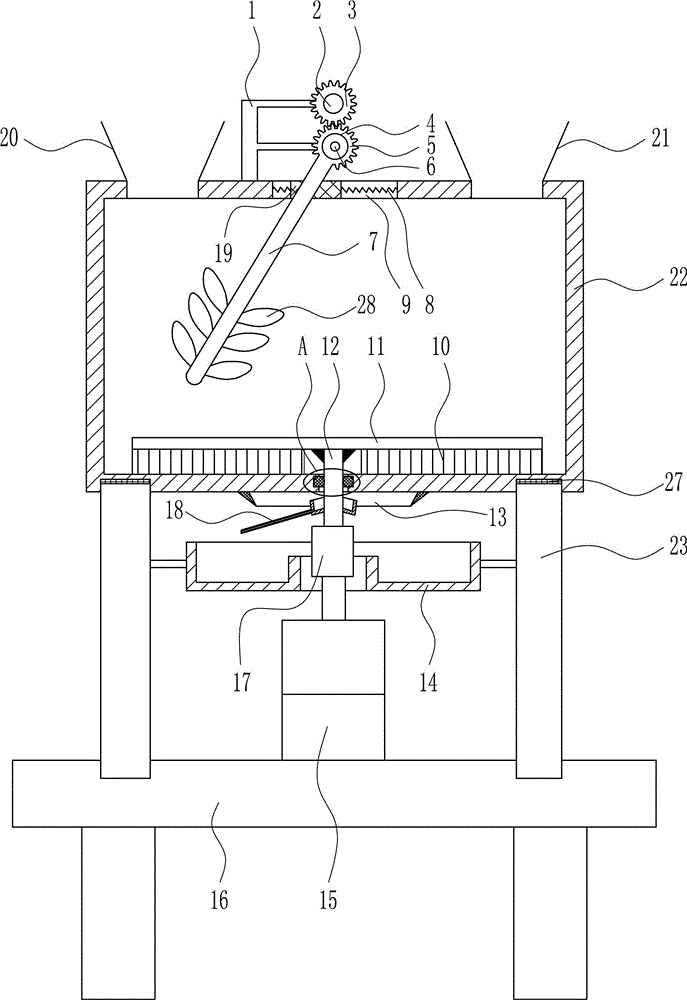

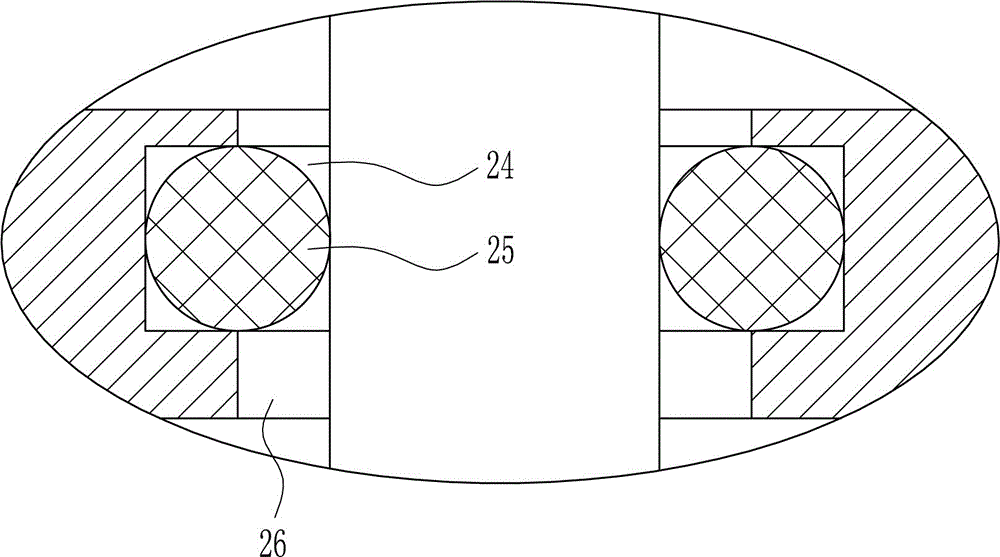

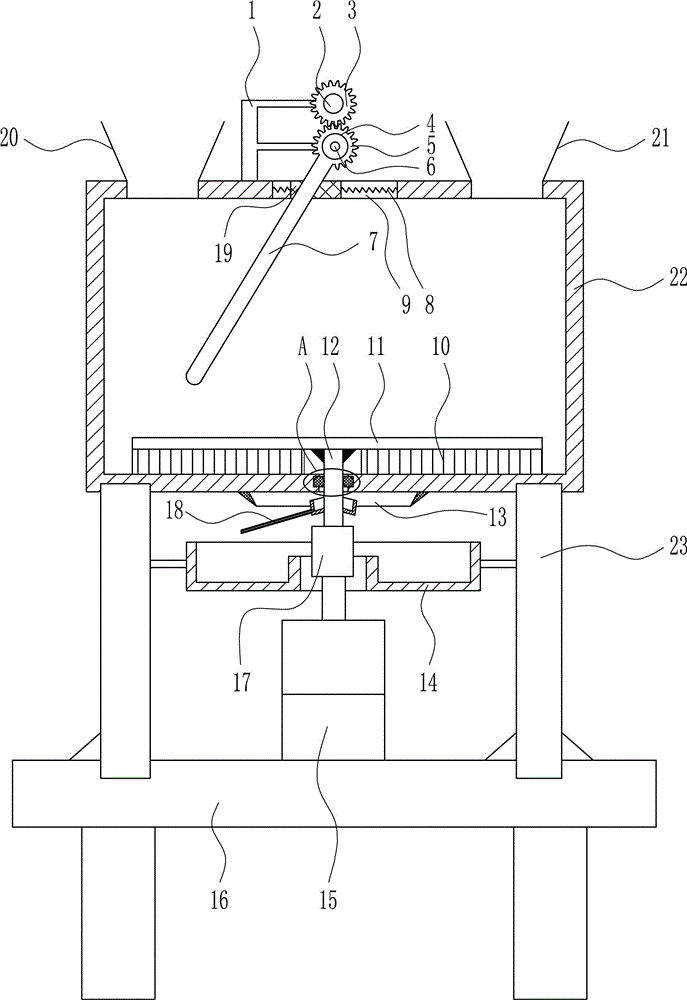

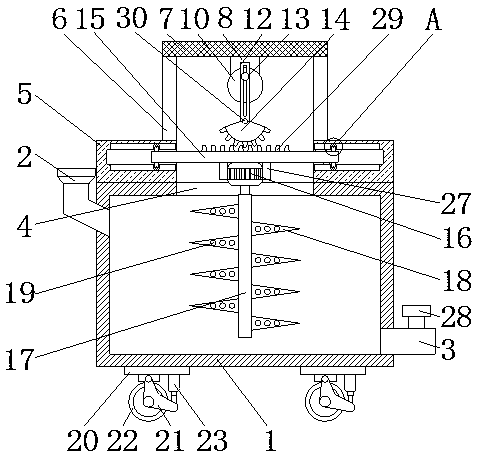

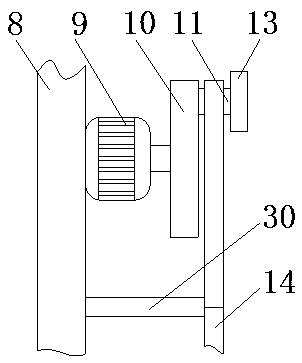

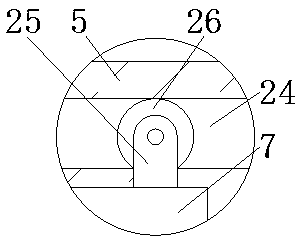

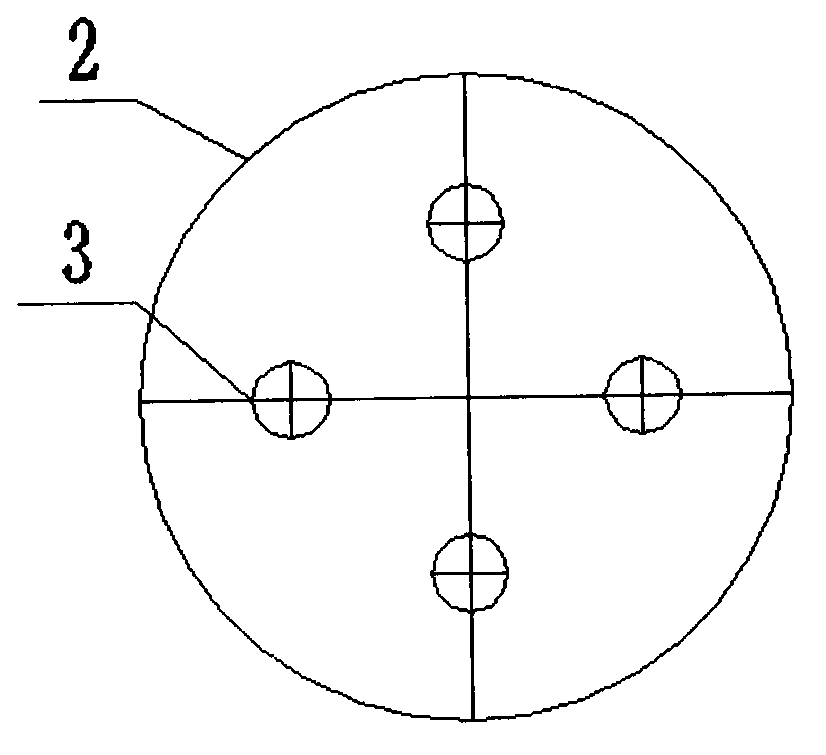

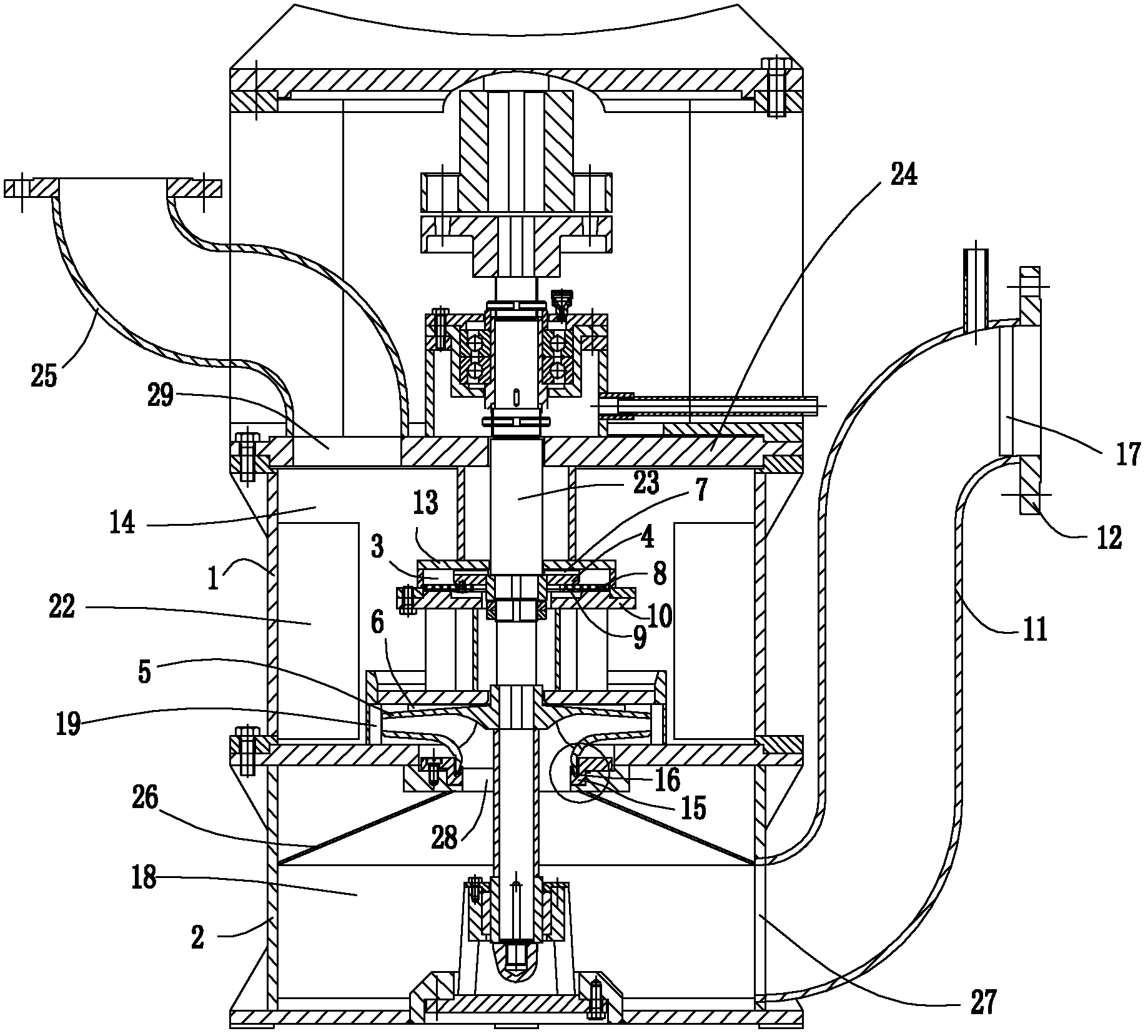

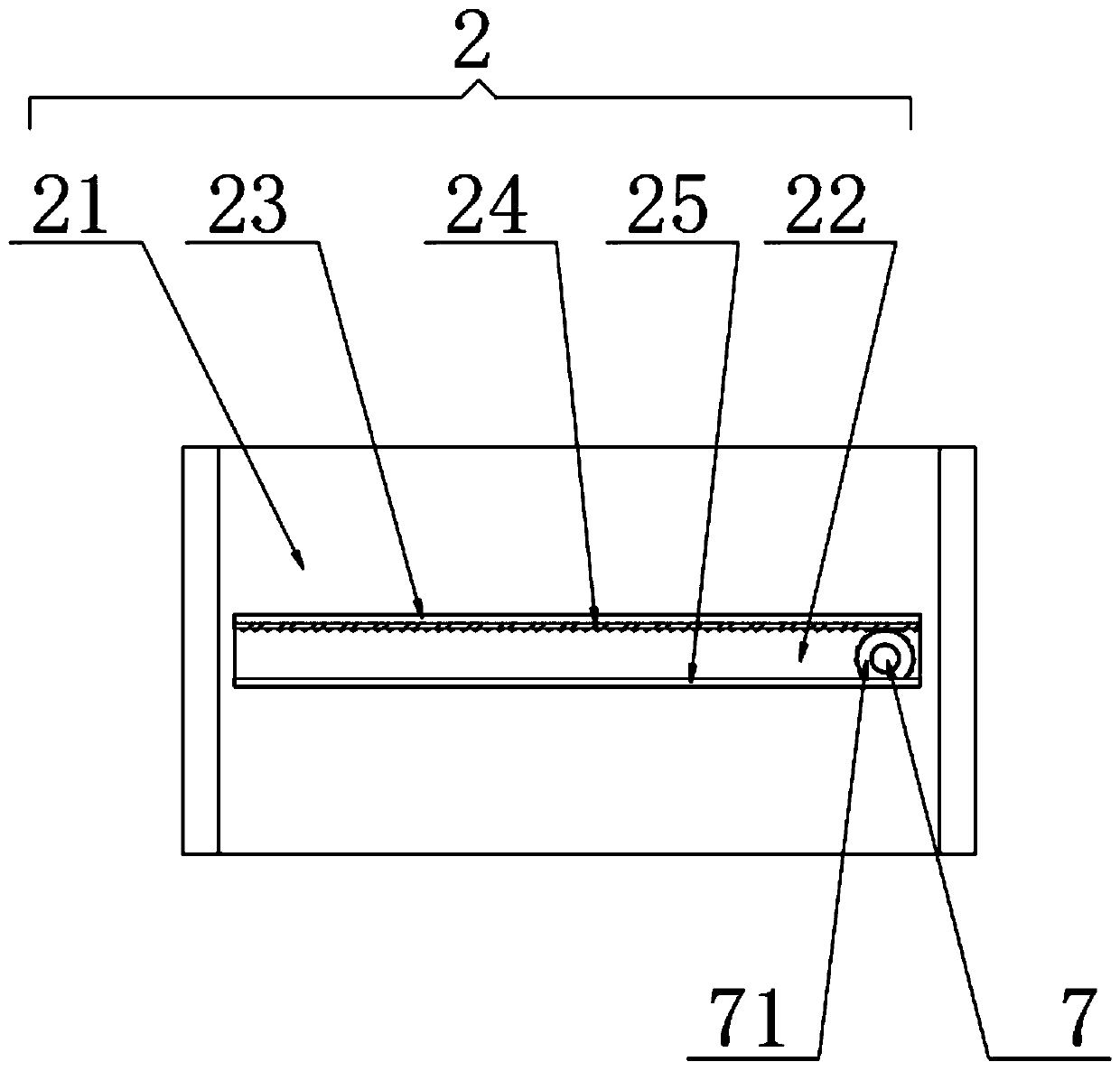

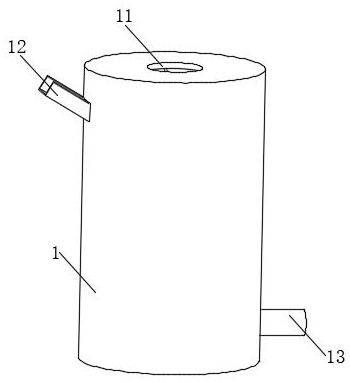

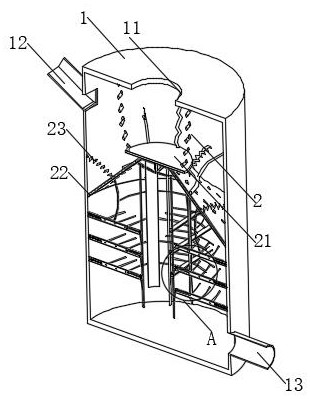

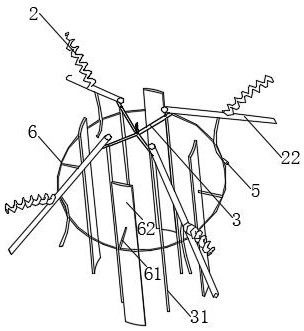

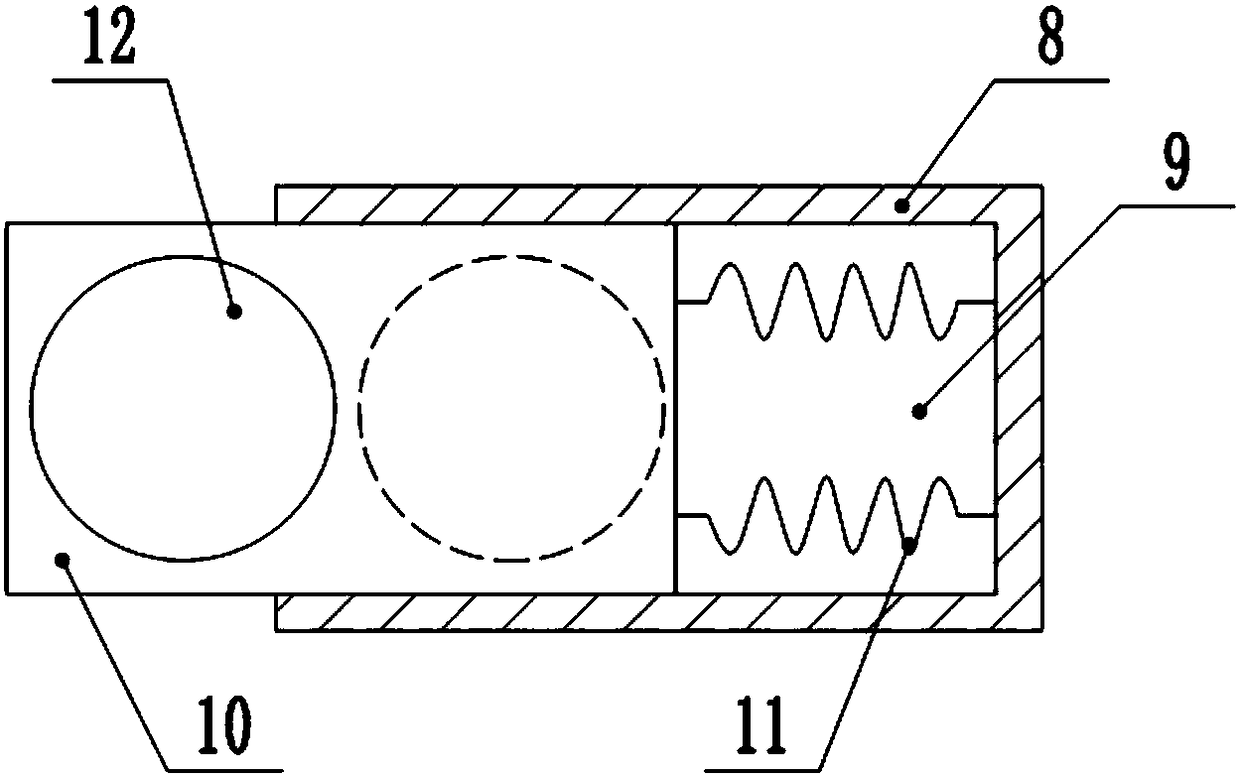

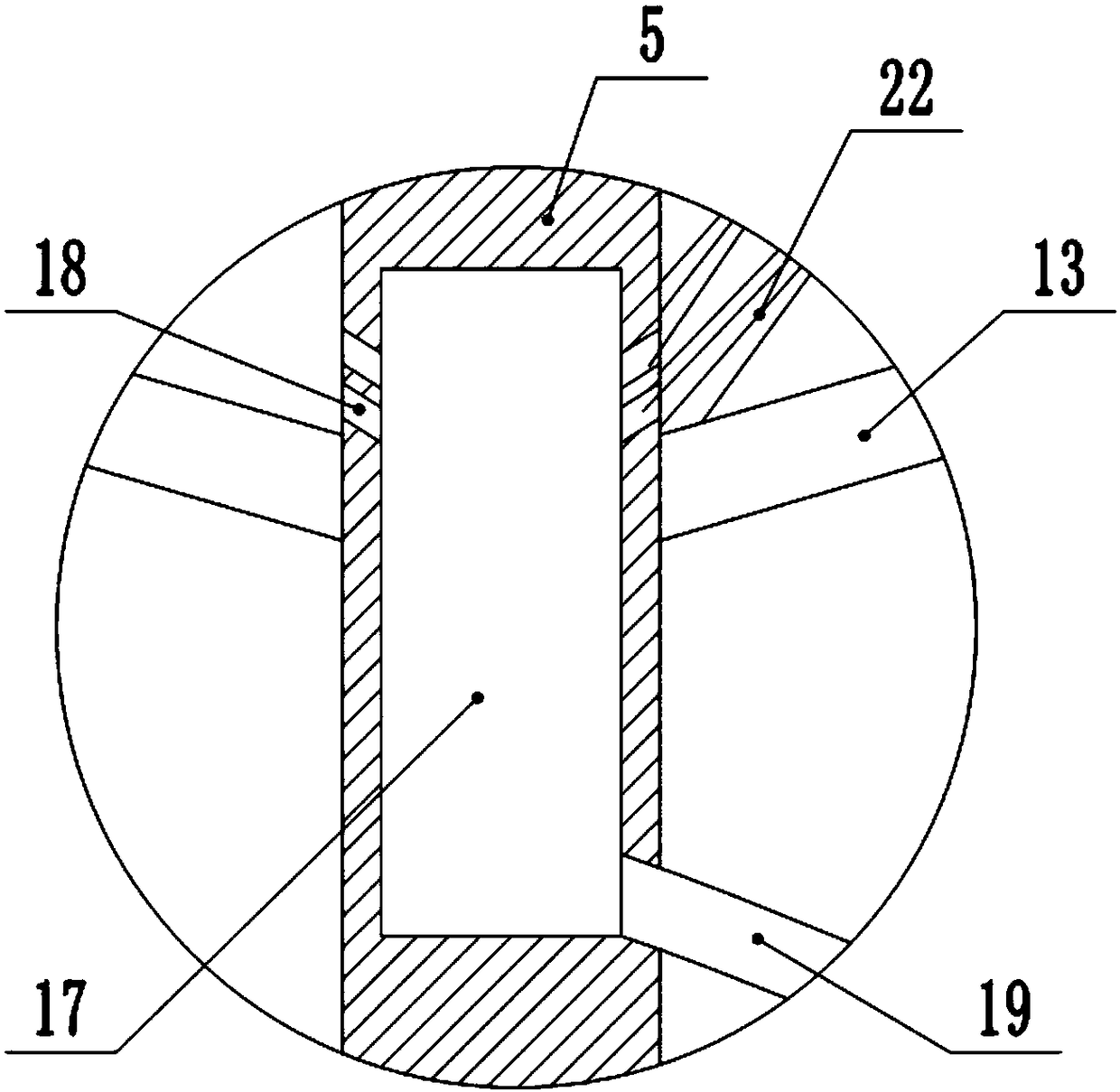

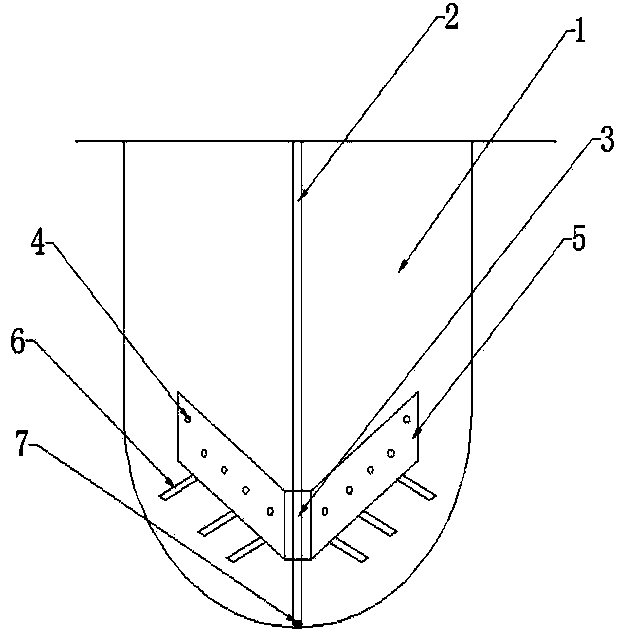

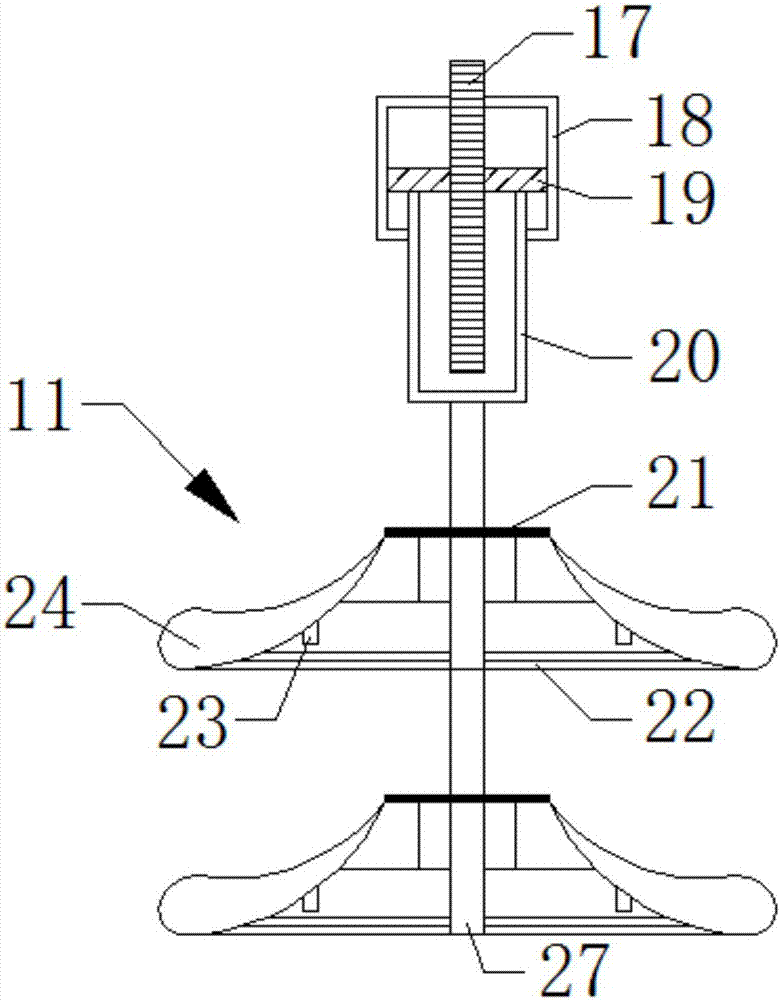

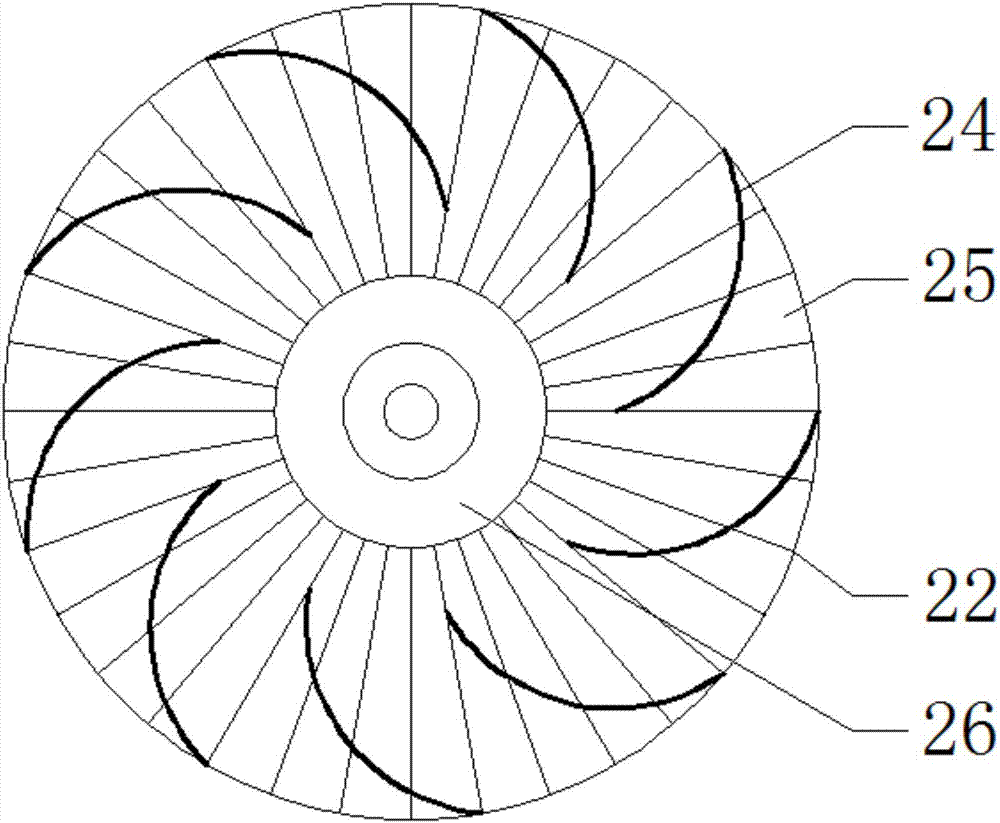

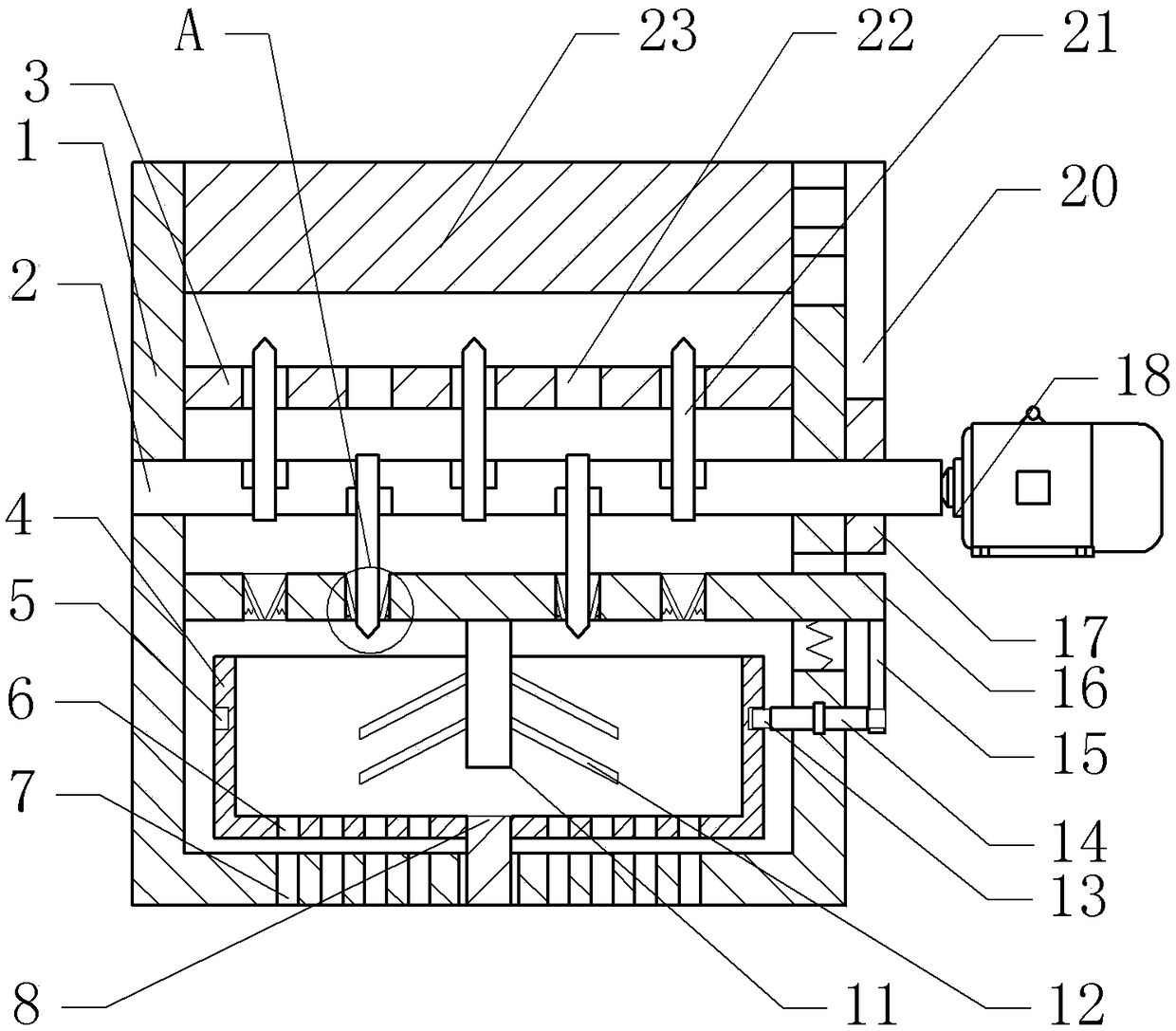

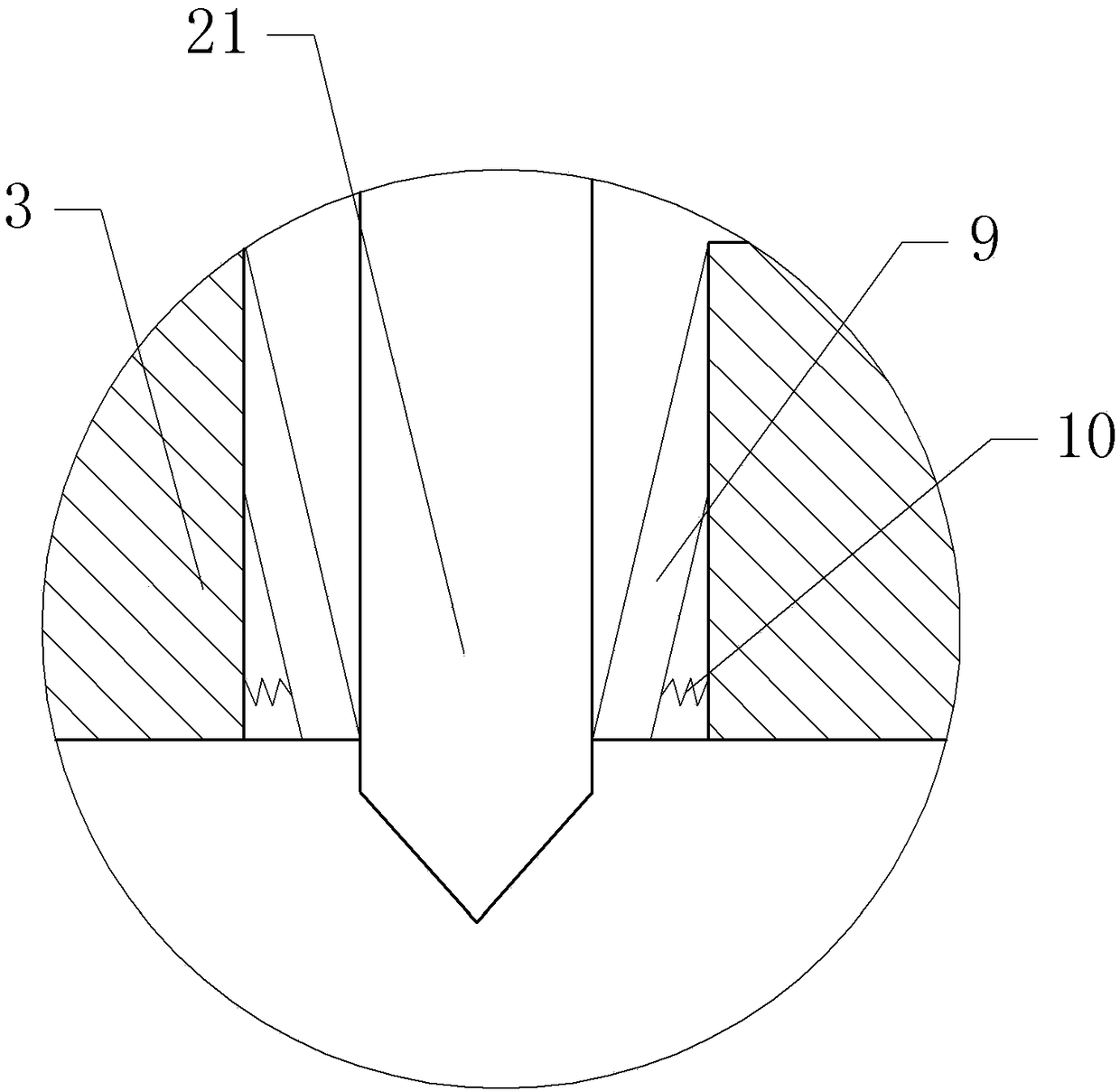

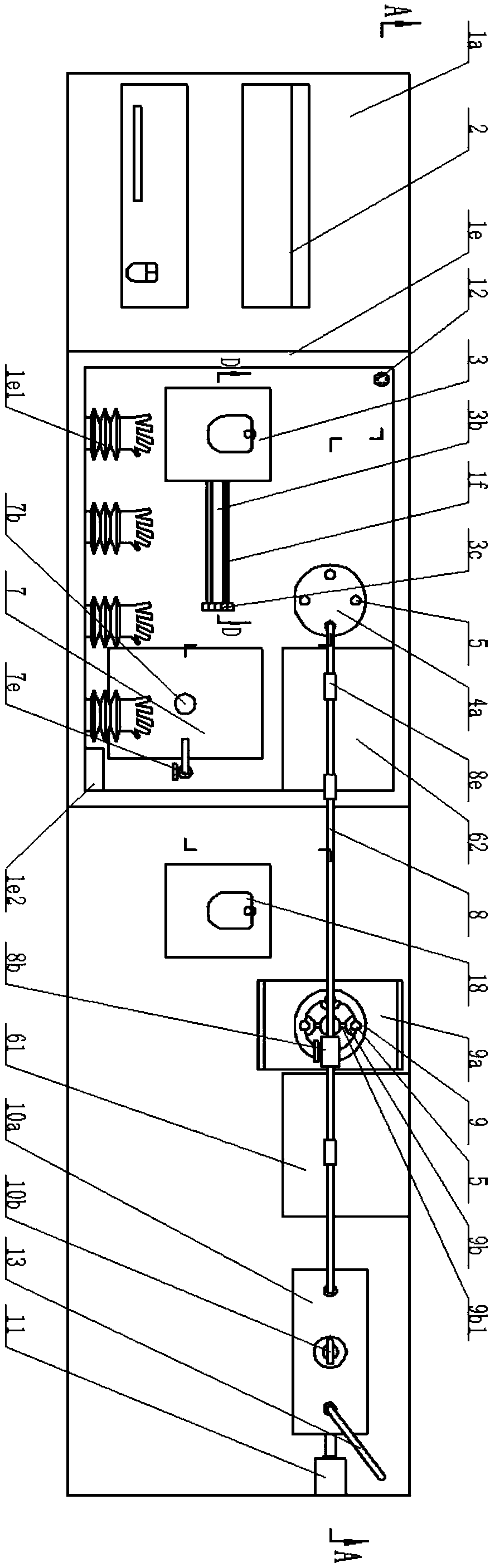

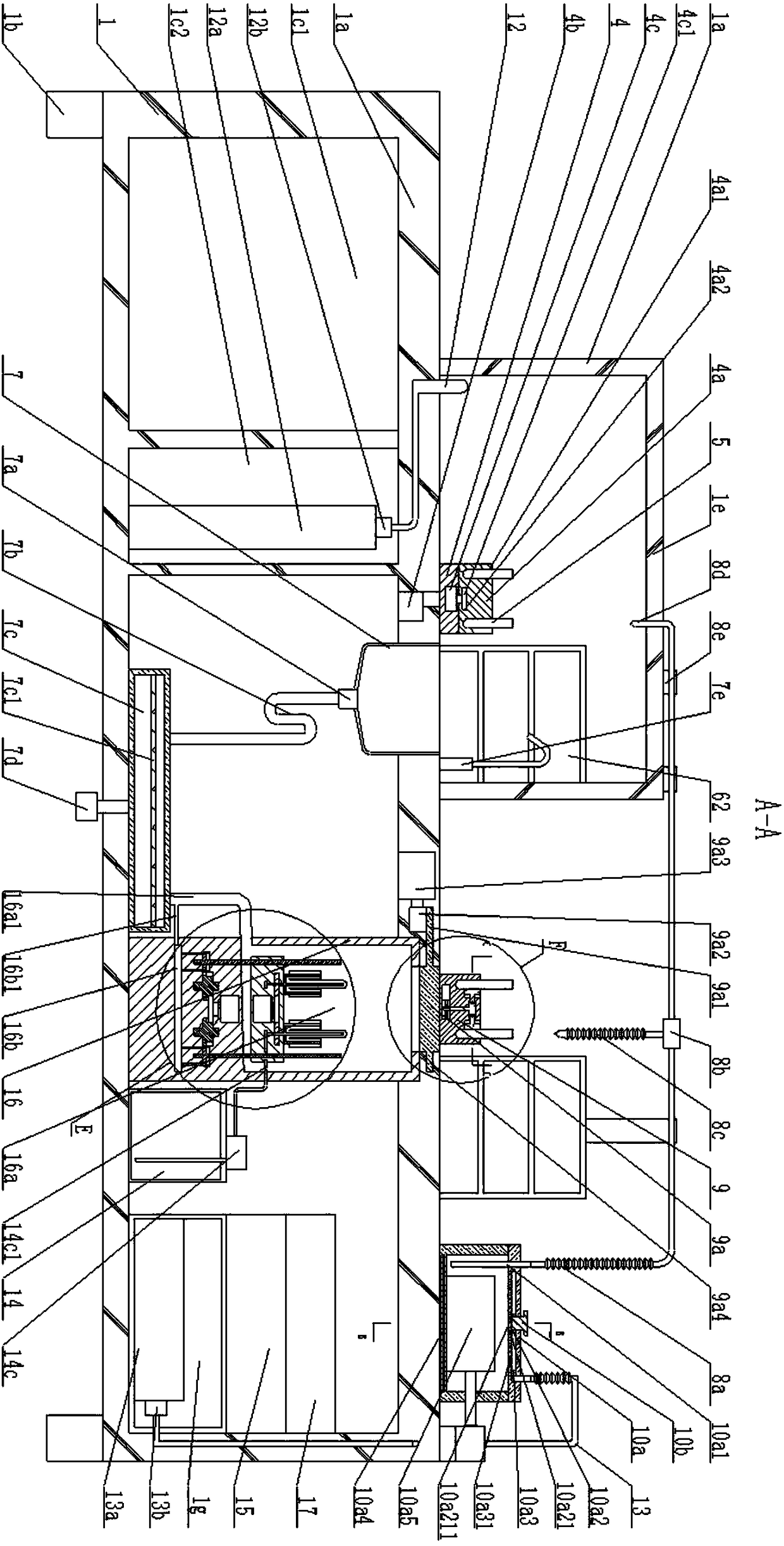

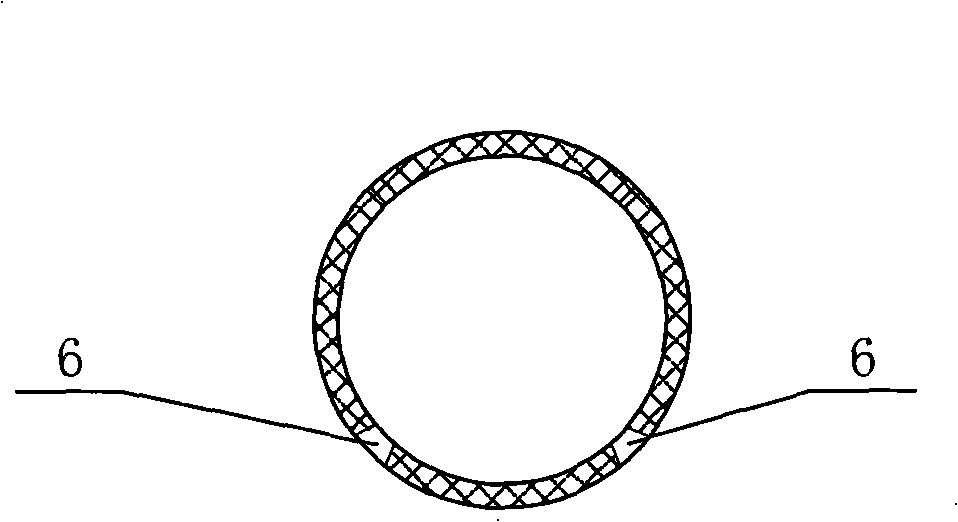

High-efficiency mixing device for raw material for producing brake clutch disc

InactiveCN107855065AImprove mixing efficiencyIncrease the mixing areaFlow mixersTransportation and packagingEngineeringUltimate tensile strength

The invention relates to a mixing device for a raw material, and particularly relates to a high-efficiency mixing device for a raw material for producing a brake clutch disc. The invention aims at solving the technical problem of providing a high-efficiency mixing device for the raw material for producing the brake clutch disc, which is uniform in mixing, low in labor intensity and quick in mixingspeed. In order to solve the technical problem, the invention provides such a high-efficiency mixing device for the raw material for producing the brake clutch disc. The high-efficiency mixing devicecomprises a bottom plate, supporting rods, a first box body, a first discharge pipe, a valve and the like, wherein the left and right sides of the bottom left side of the bottom plate are both provided with the supporting rods through a bolt connection way; the first box body is arranged at the tops of the supporting rods; the lower part of the right side of the first box body is provided with the first discharge pipe; the first discharge pipe is provided with the valve; the middle part in the first box body is provided with a reticular plate. The high-efficiency mixing device is used for realizing the effect of the high-efficiency mixing device for the raw material for producing the brake clutch disc, which is uniform in mixing, low in labor intensity and quick in mixing speed.

Owner:闫梦蝶

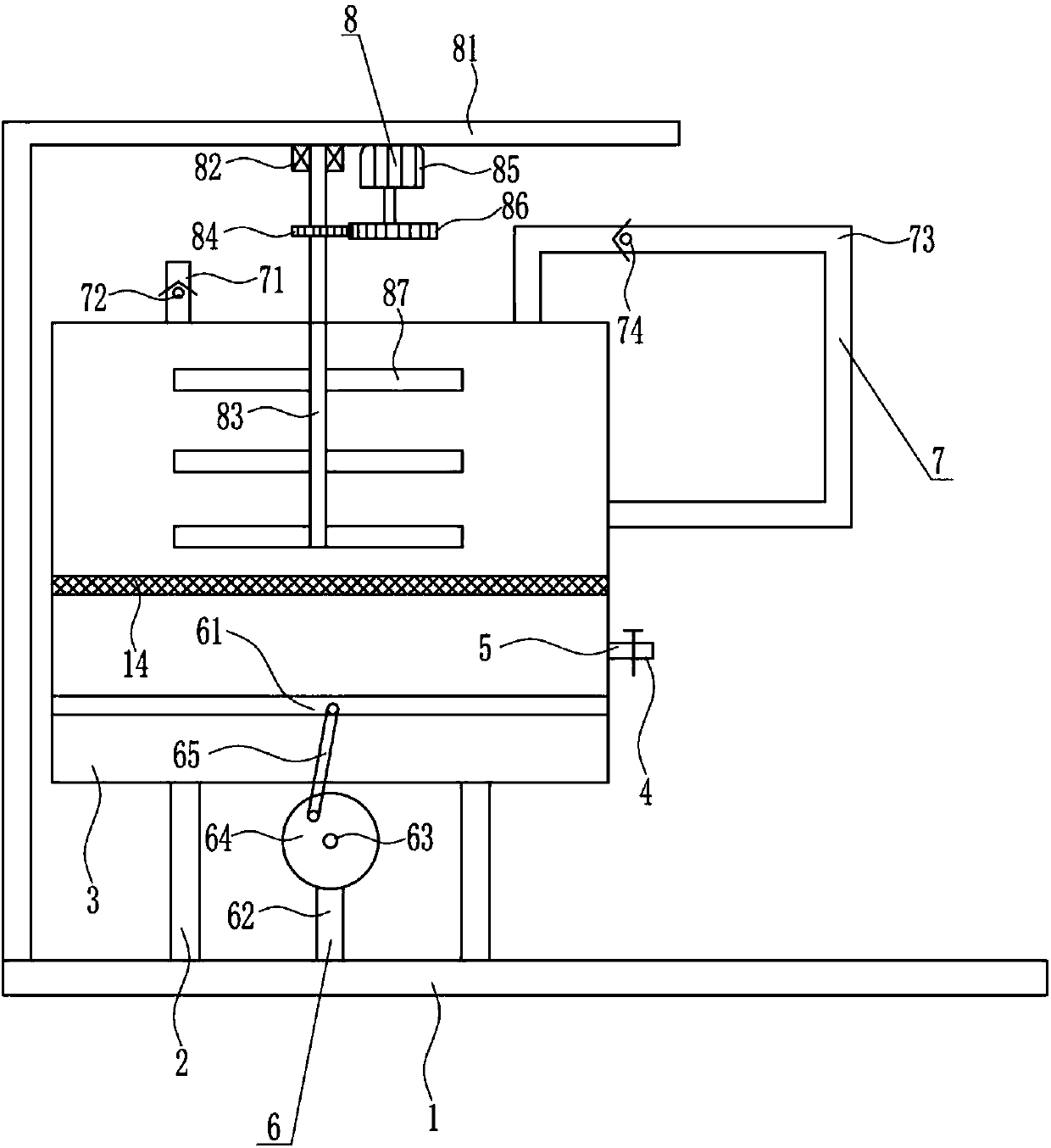

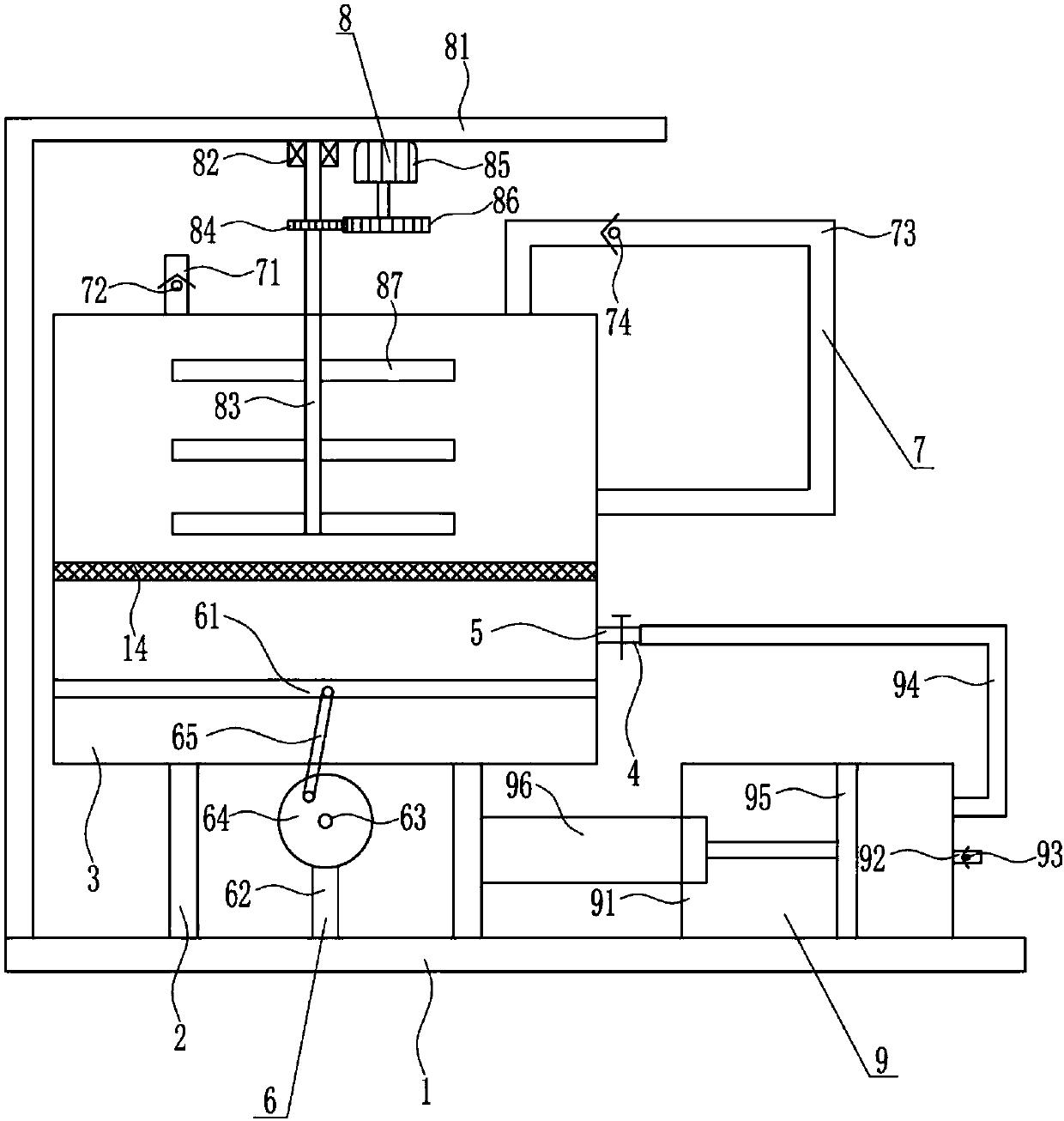

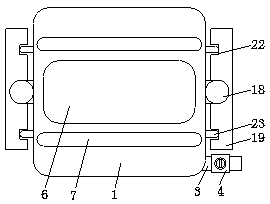

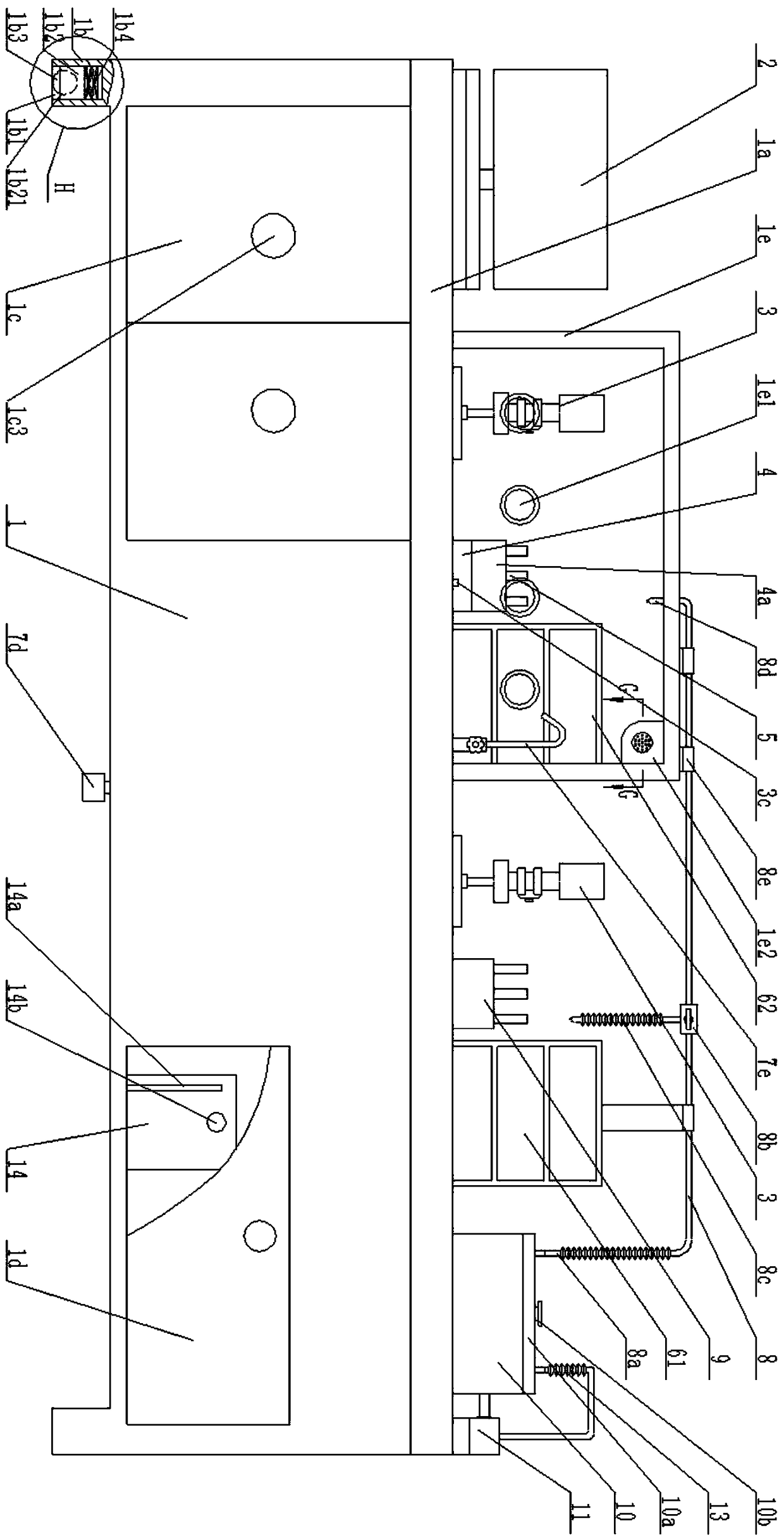

High efficiency printing ink mixing device used for printing production lines

InactiveCN107185444AIncrease the lengthWell mixedShaking/oscillating/vibrating mixersTransportation and packagingProduction linePrinting ink

The invention discloses a high efficiency printing ink mixing device used for printing production lines. The high efficiency printing ink mixing device comprises a pedestal, a support, a mixing barrel, and a mixing motor; the bottom of the mixing barrel is fixedly connected with the pedestal via first springs; two fixing supports are arranged on the left side and the right side of the mixing barrel symmetrically; a gear rack is fixedly arranged on the fixing support on the right side of the mixing barrel; the right side of the gear rack is provided with a semicircle gear matching the gear rack; the mixing motor is fixedly arranged on the top of the mixing barrel; an output terminal of the mixing motor is fixedly connected with a stirring shaft; a tunnel-shaped discharge port is arranged in the mixing barrel; the bottom of the discharge port is communicated with a liquid outlet pipe. The high efficiency printing ink mixing device is capable of increasing agitator arm length, increasing material mixing area, and realizing uniform mixing of printing ink; the high efficiency printing ink mixing device is provided with the mixing barrel capable of moving upward and downward, so that printing ink mixing uniformity is increased further; the discharge port is provided with a filter screen, so that discharge of impurities with printing ink is prevented, printing ink quality is improved, and printing quality is ensured.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

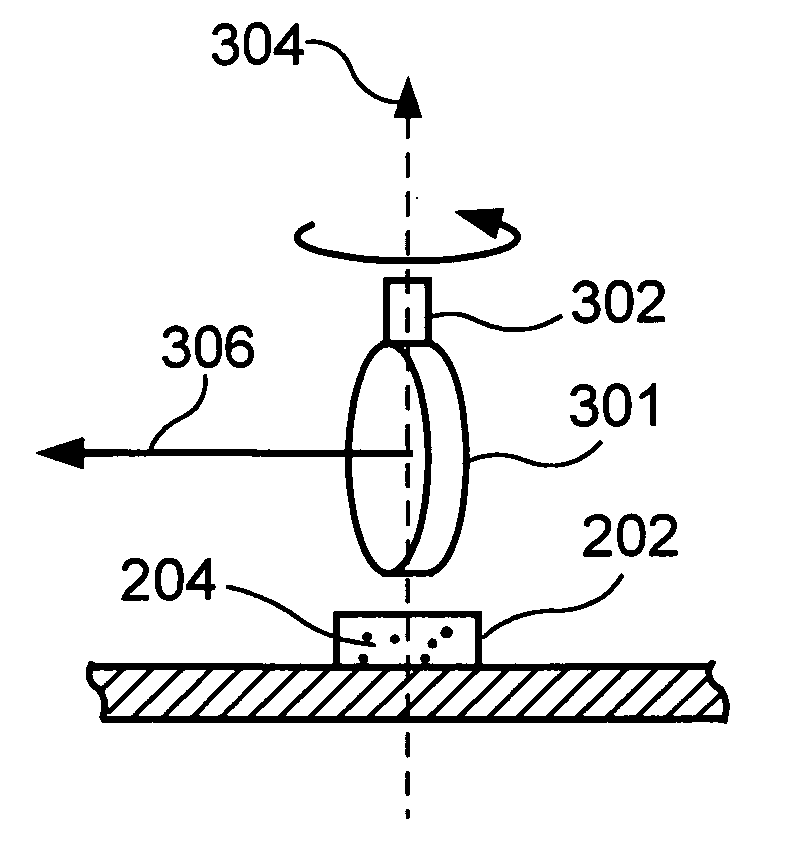

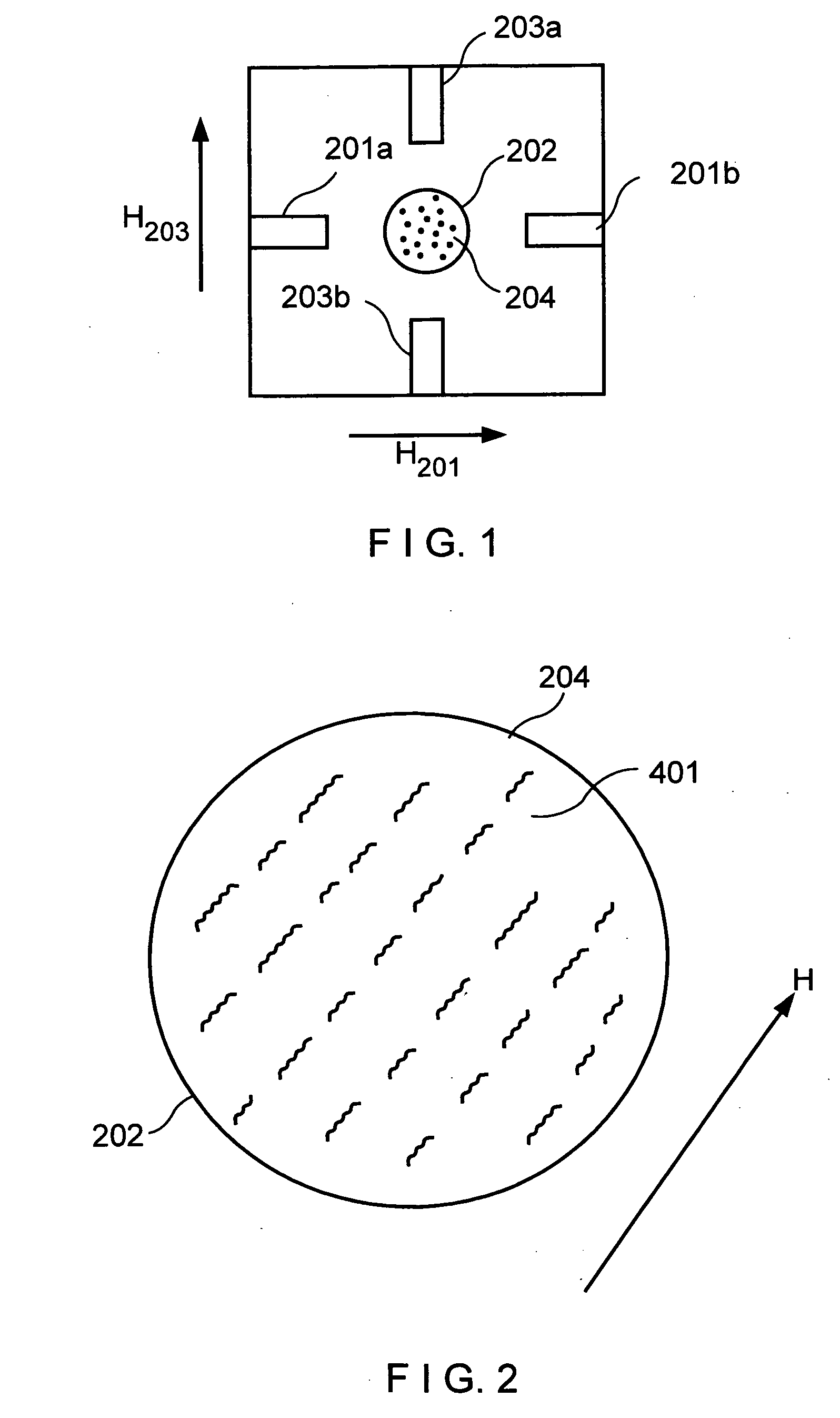

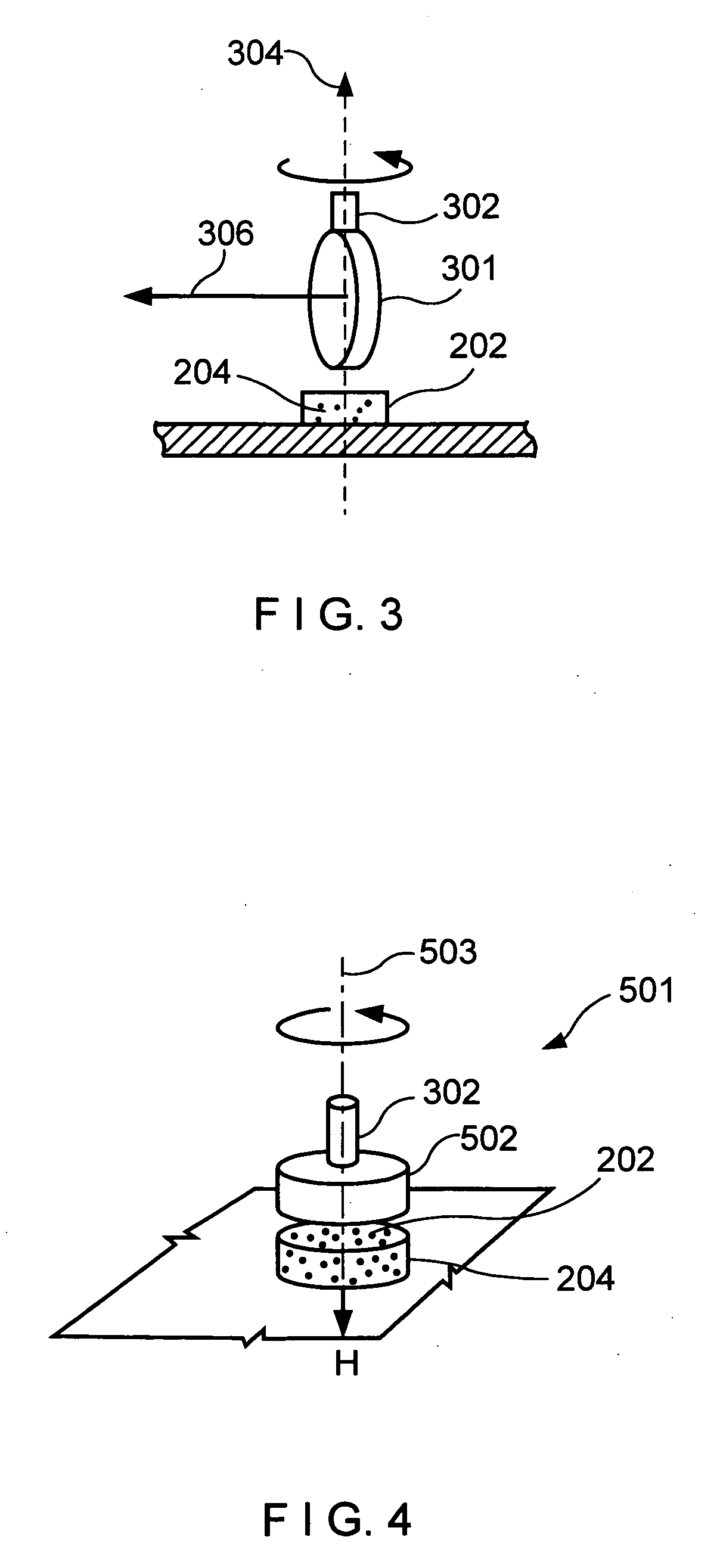

Method and arrangement of rotating magnetically inducible particles

InactiveUS20050286342A1Effective mixing actionLarge spanTransportation and packagingMixersSuspended particlesParticle chains

This invention provides a device and method for rotating magnetically inducible particles suspended in a fluid by rotating a multidirectional magnetic field through the suspended particles. A rare earth magnet is positioned adjacent to the suspended particles and oriented such that the axis of a magnetic field generated by the magnet passes through the suspension. The magnetic flux lines of the magnet's field radiate in multiple directions through the suspended particles, them to form long multidirectional chains. The magnet and the chains of suspended particles are rotated with respect to one another, the axis of the rotation being approximately parallel to the magnetic axis of the multidirectional magnetic field. This causes the particle chains to rotate about the magnetic axis, thus mixing the fluid.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Mixed paint fast proportioning device for building construction

InactiveCN107398216AEasy to scrape offIncrease the mixing areaRotary stirring mixersTransportation and packagingBristleReciprocating motion

The invention discloses a mixed paint fast proportioning device for building construction. The device consists of: proportioning tanks, a mixing tank, piston plates, threaded columns, threaded sleeves, a negative pressure pump, movable sleeves, L-shaped columns and a rotating ring. Stock solutions of different types are injected into the proportioning tanks according to needed capacity, the stock solutions in the proportioning tanks enter the mixing tank to enable proportioning of the stock solution according to a needed ratio, the centrifugal force makes stirring plates stretch outward to increase the stirring area and improve the mixing quality, first bristle and second bristle scrape off the mixed slurry adhered to the mixing tank inner wall to improve the mixing quality, when the mixed slurry adhered to the mixing tank inner wall is difficultly scraped off, the magnetic-south poles and magnetic-north poles of second magnets under a rotational state and first magnets under a stationary state are the same or opposite alternately, a frame body drives the second bristle to do reciprocating motion up and down, thus achieving easy scraping of the adhered mixed slurry, and further improving the mixing quality.

Owner:林红英

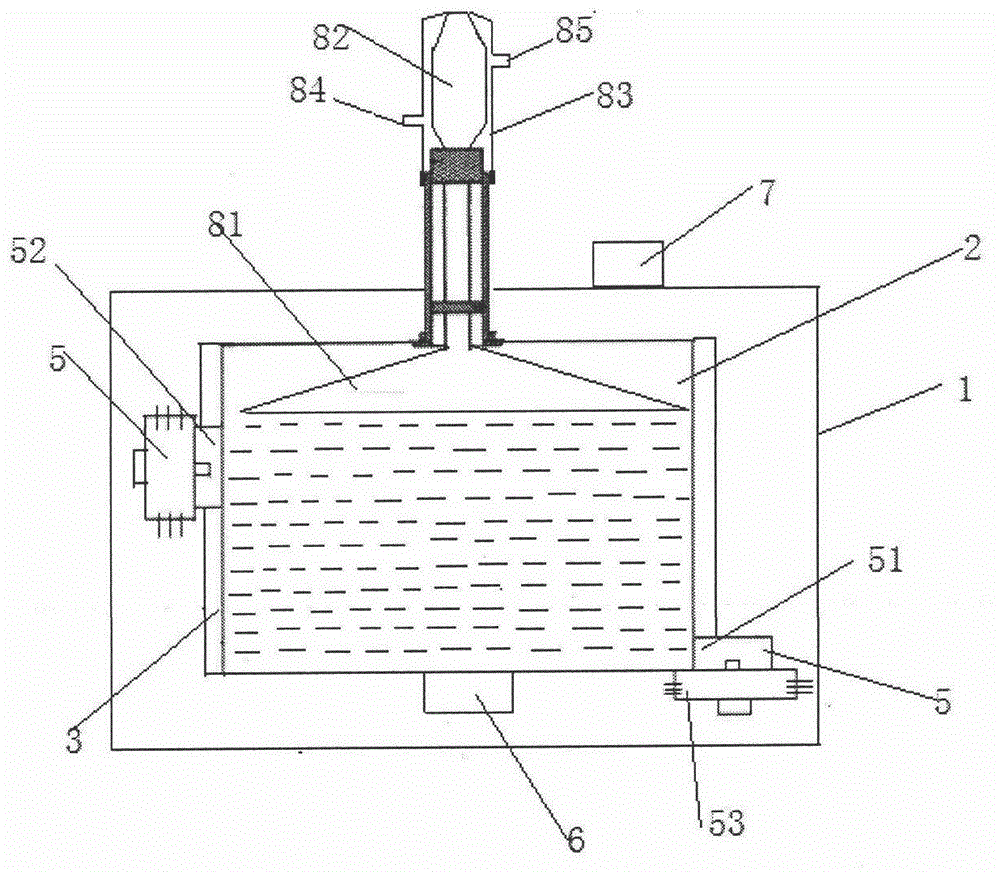

Ultrasonic wave and microwave extraction system with reflux devices

InactiveCN104014158AShear vibration field strengthExpand the vibration areaEnergy based chemical/physical/physico-chemical processesSolid solvent extractionStopped workMicrowave

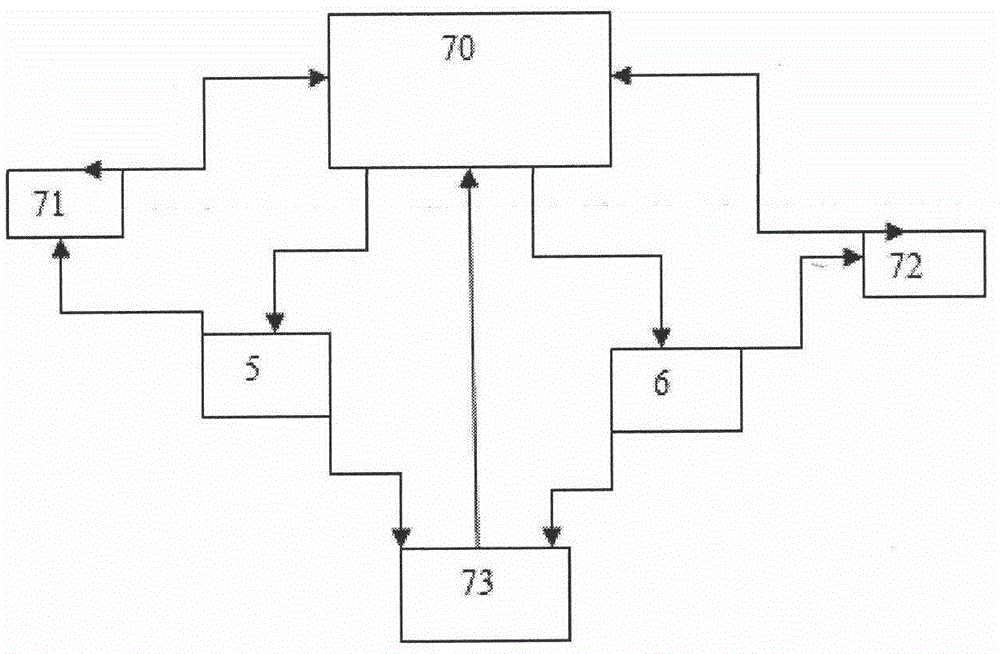

The invention provides an ultrasonic wave and microwave extraction system for traditional Chinese medicines. The system is provided with a coordinated regulation device, wherein a first alarm device, a second alarm device and a third alarm device are arranged on the coordinated regulation device; the coordinated regulation device firstly controls microwave lead-in devices to lead in microwaves, after a certain time, the first alarm device sends an alarm signal to the coordinated regulation device, and the coordinated regulation device controls an ultrasonic wave lead-in device to lead in ultrasonic waves; after a certain time, the second alarm device sends an alarm signal to the coordinated regulation device, and the coordinated regulation device controls the microwave lead-in devices and the ultrasonic wave lead-in device to change the operating powers to be respectively lower than the initial powers of the microwave lead-in devices and the ultrasonic wave lead-in device; the third alarm device sends an alarm signal to the coordinated regulation device after the microwave lead-in devices and the ultrasonic wave lead-in device work with the changed operating powers for a certain time, and the coordinated regulation device firstly controls the microwave lead-in devices to stop working and then controls the ultrasonic wave lead-in device to stop working. The best matching effects of ultrasonic waves and microwaves are achieved by arranging the coordinated regulation device to strictly control the lead-in time, lead-in order, lead-in powers and closing time of the ultrasonic waves and the microwaves.

Owner:王茜南

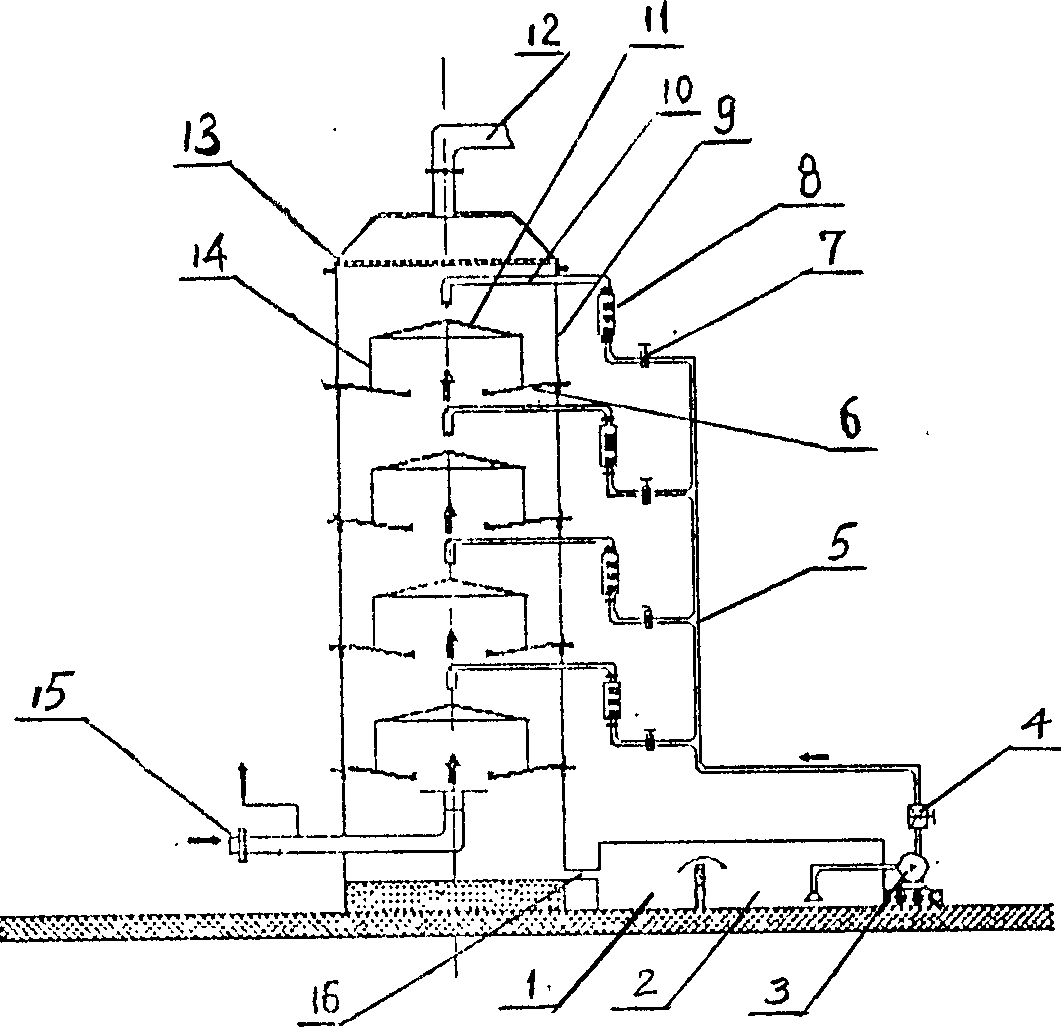

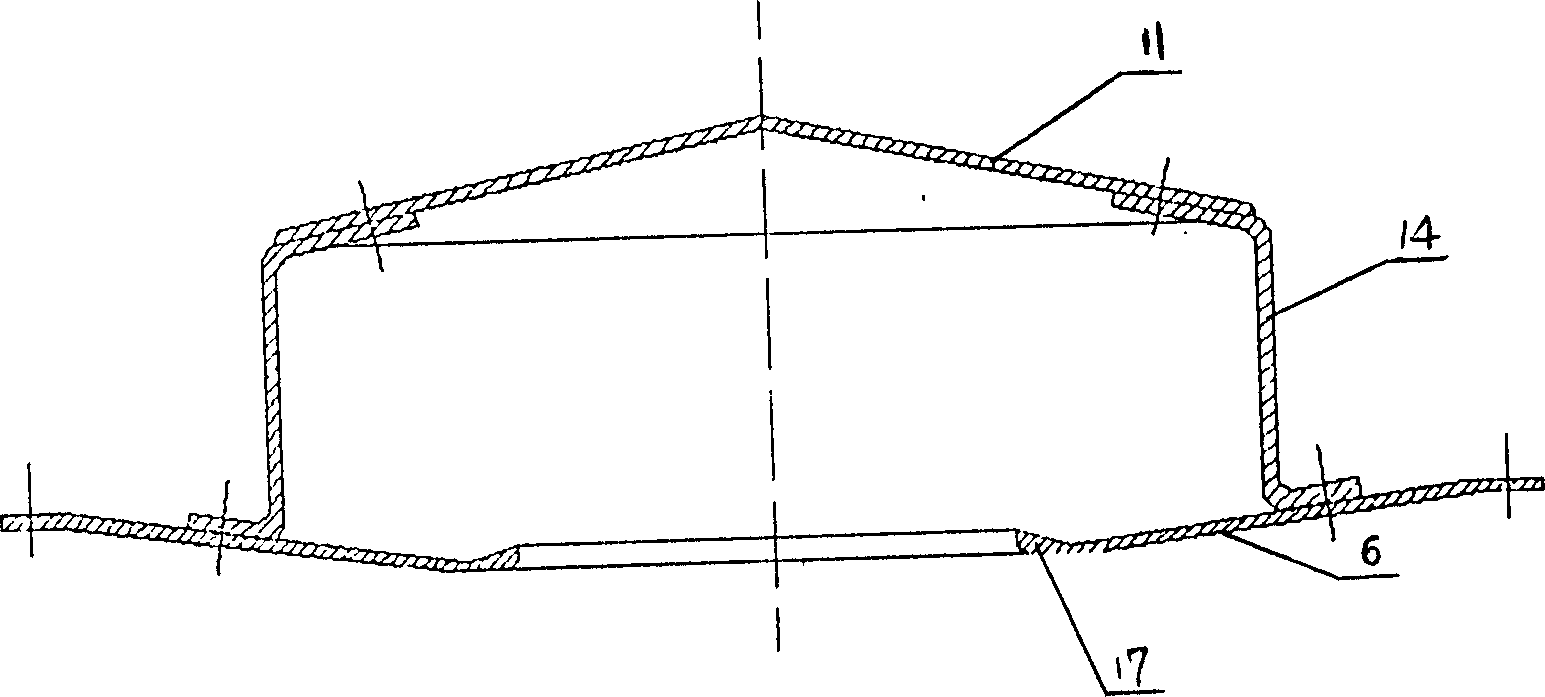

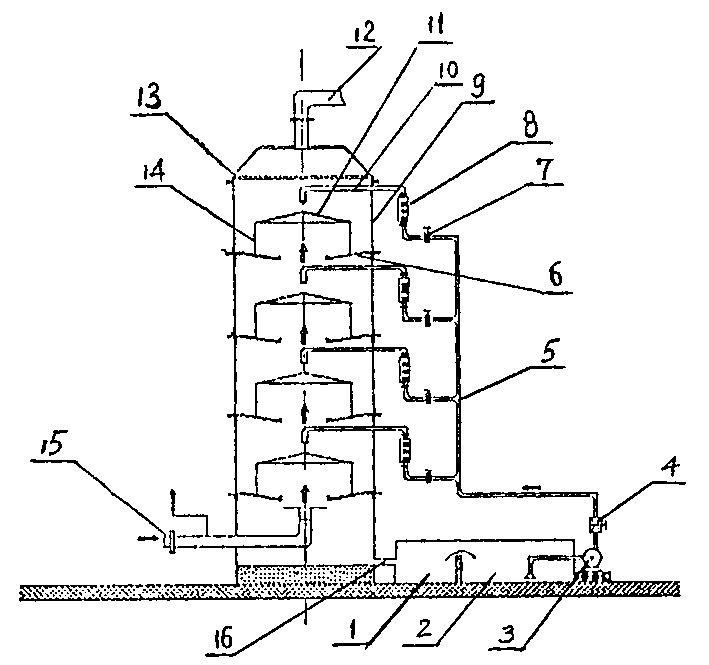

Multi-stage liquid curtain spray washing flue gas desulfurizing deivce

InactiveCN1419953AEasy to installEasy maintenanceDispersed particle separationFlue gasProcess engineering

A flue gas desulfurizing apparatus with multi-stage liquid curtain, spraying and washing is characterized that a multi-stage desulfurizing tower correspondent with multi-stage desulfurizing liquid spraying tubes is arranged in a cylindrical body, said desulfurizing tower has an internal barrier structure consisting of lower ring barriers and top covers, the flue gas flows from bottom to top, and the desulfurizing liquid flows from top to bottom. Its advantages are high mixing effect and high utilization rate of desulfurizing liquid.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +1

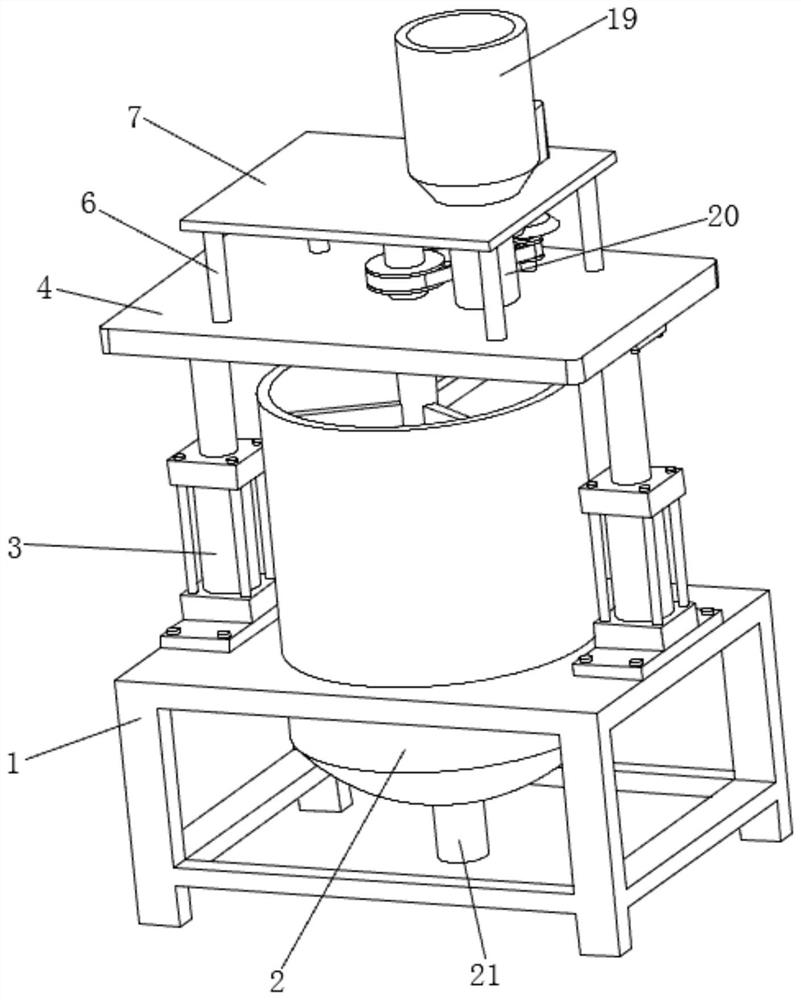

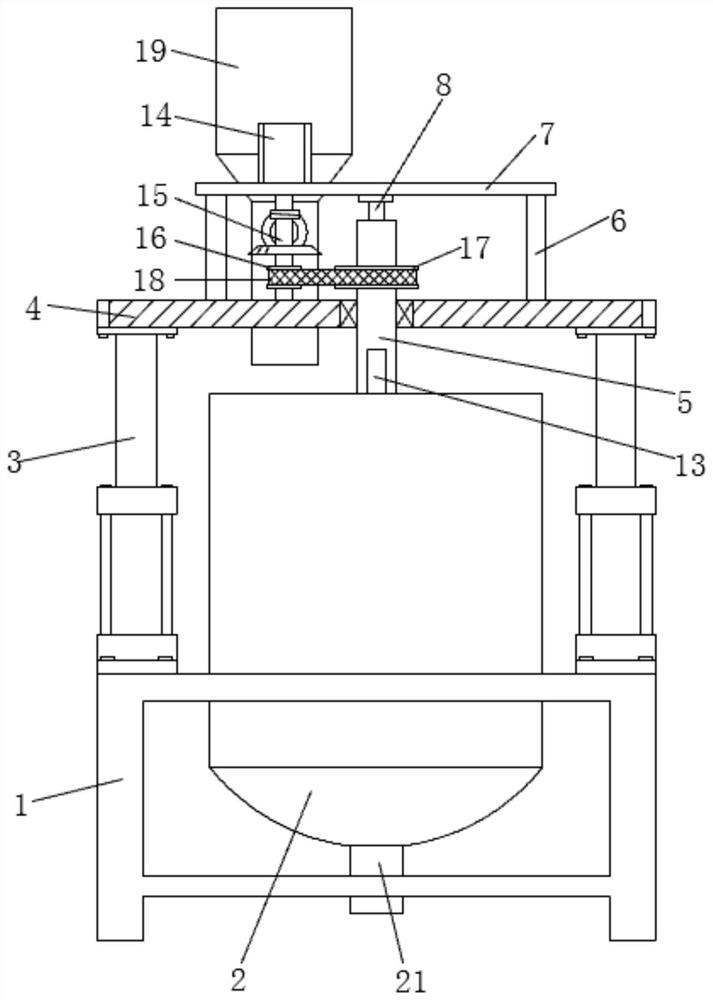

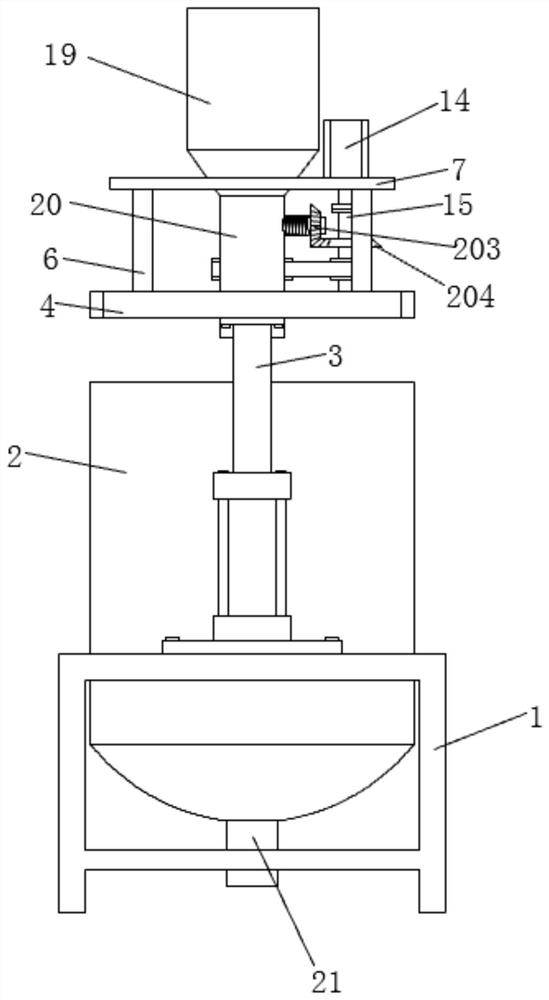

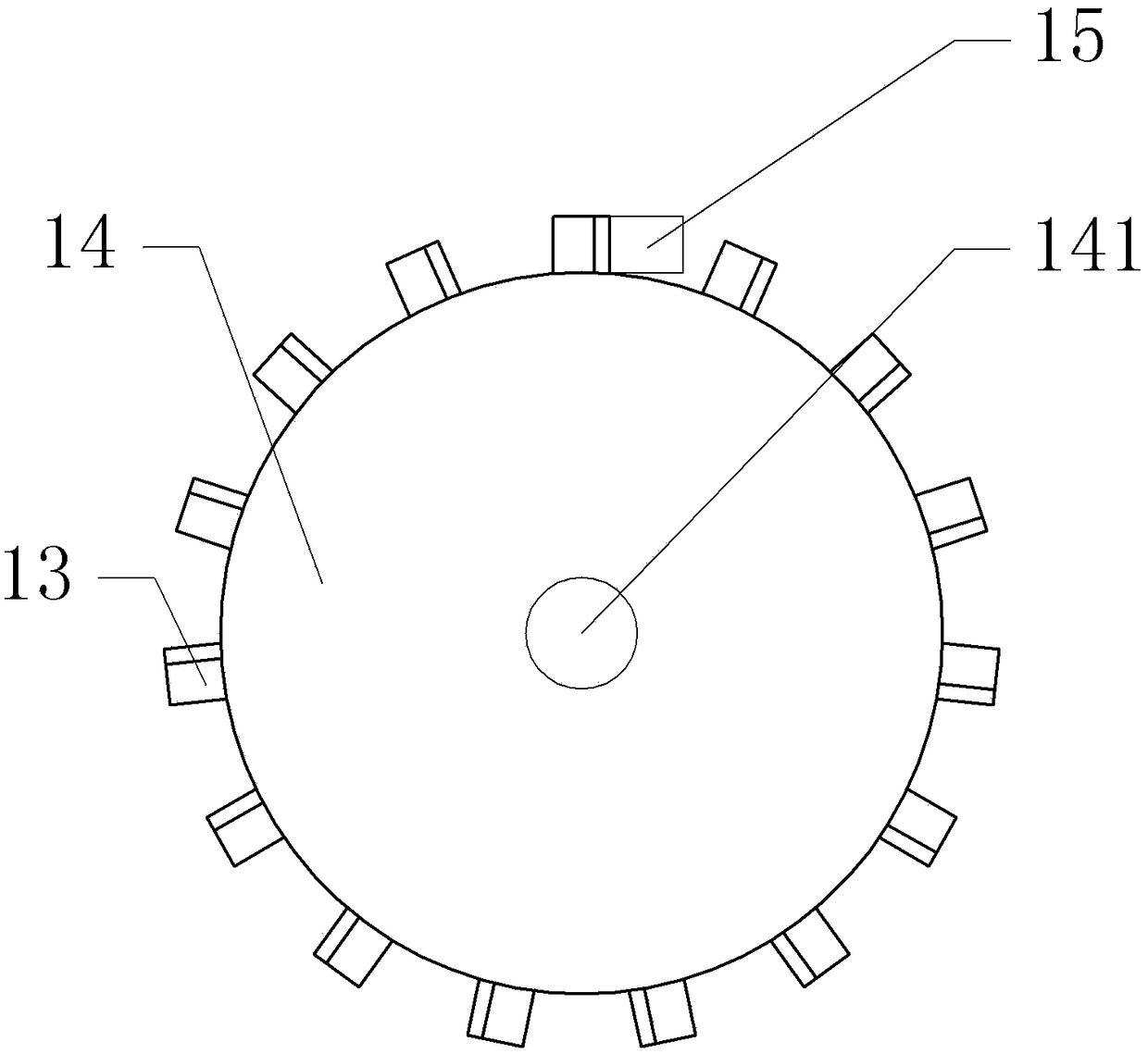

Diamond powder stirring and mixing device

InactiveCN112076655AIncrease the mixing areaAvoid uneven mixingTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention discloses a diamond powder stirring and mixing device comprising a stirring tank with an opening in the top, the stirring tank is plugged into the center of the inner cavity of a base; supporting columns are symmetrically and fixedly connected to the left side and the right side of the top of a base; a cover plate is fixedly connected to the tops of the supporting columns, and threesets of first hinge seats are fixedly connected to the outer wall, located below the cover plate, of a stirring shaft in the axial direction; and a first stirring rod is hinged to one end, away from the stirring shaft of each first hinge seat. The stirring shaft, the first stirring rods and a second stirring rod can be driven to rotate through a rotating motor, so that materials in the stirring tank are stirred, and the sliding block slides up and down along a reciprocating screw rod in a reciprocating mode; connecting rods drive the first stirring rods to swing up and down at an angle for stirring, so that the stirring areas of the first stirring rods and the second stirring rod are larger, the mixing effect is better, and uneven mixing caused by inertia centrifugal force generated by materials under the stirring action of the stirring shaft and the stirring rods can be avoided; therefore, the mixing effect can be further improved.

Owner:南安市鄂丰机械有限公司

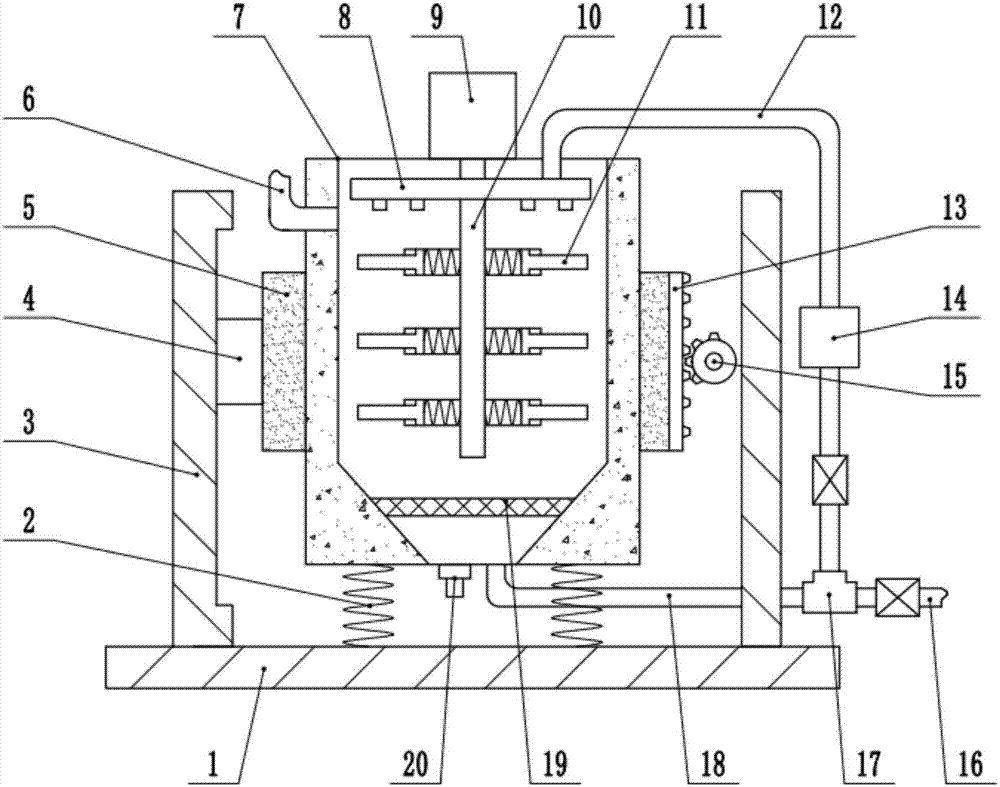

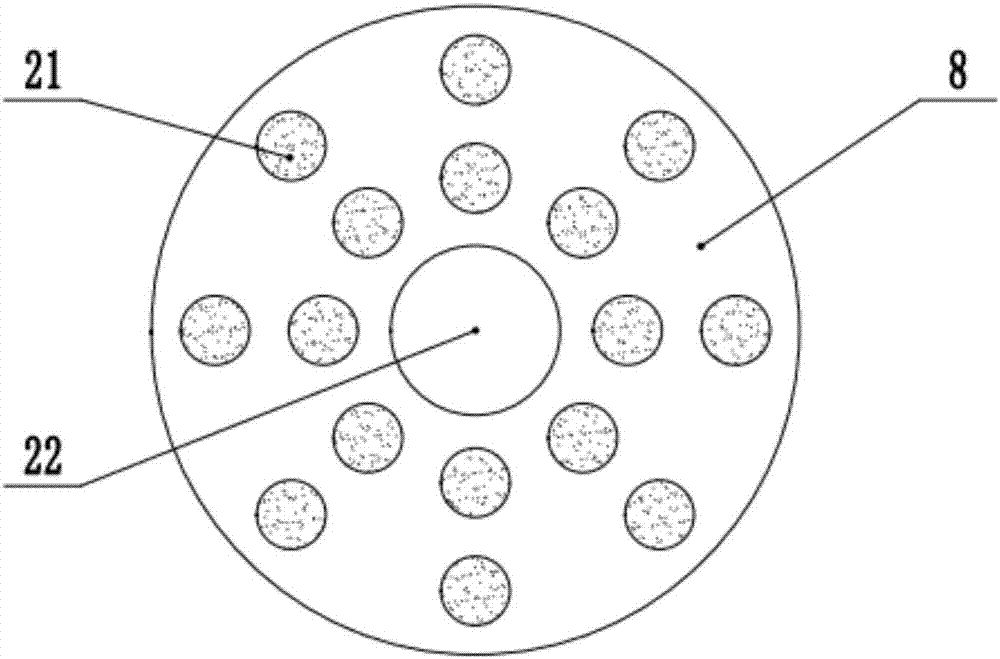

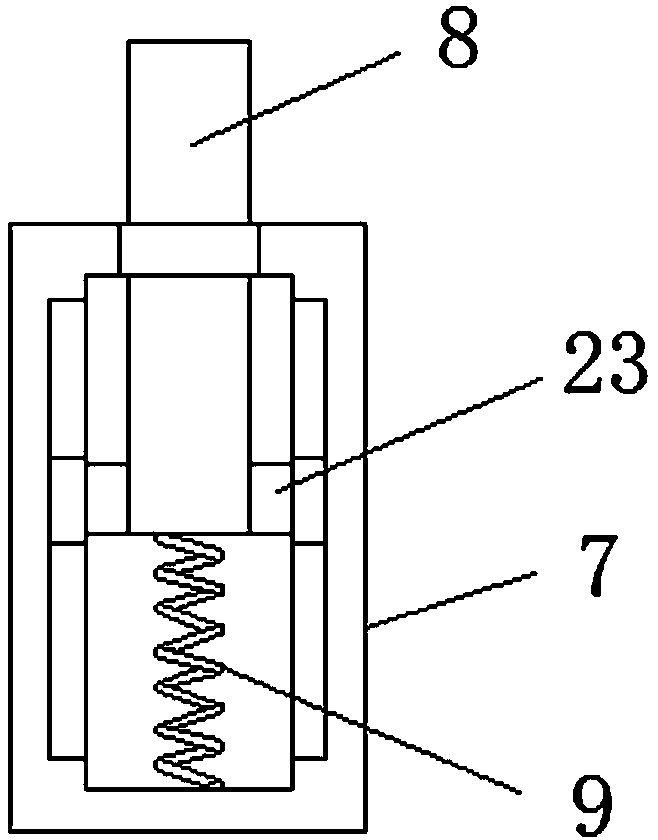

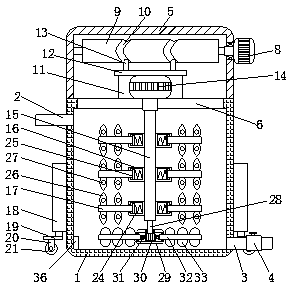

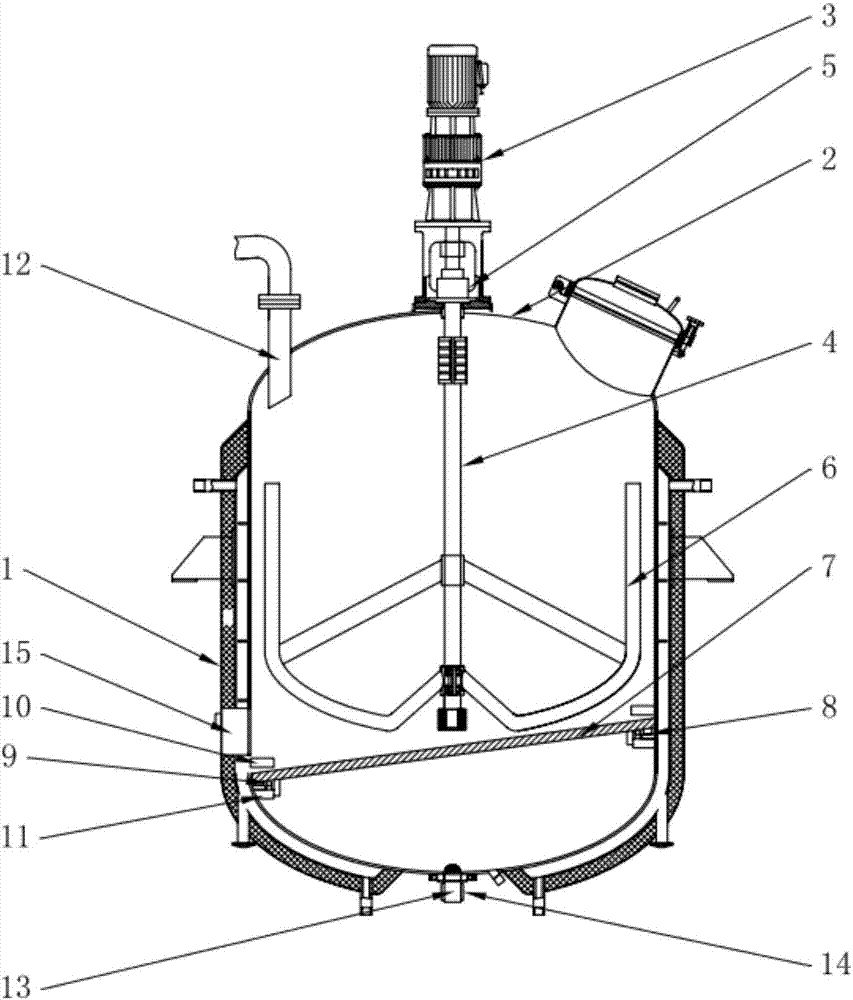

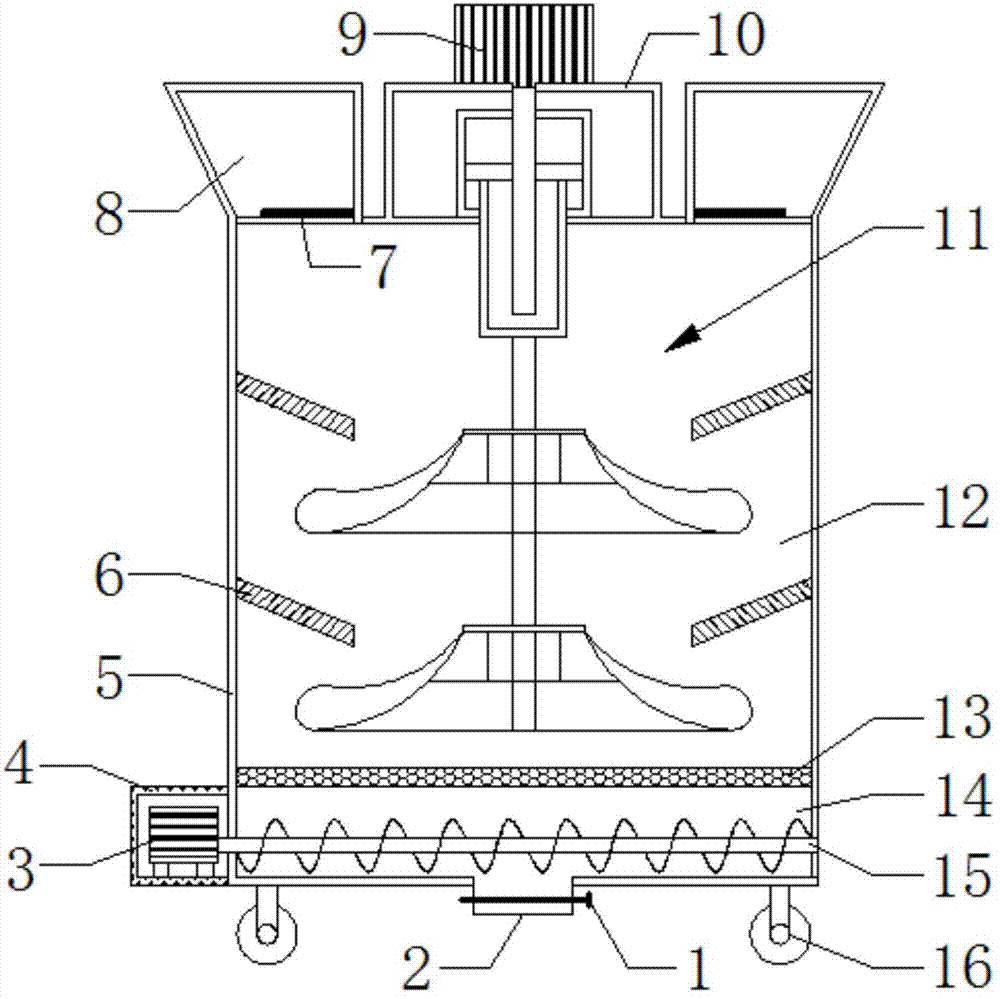

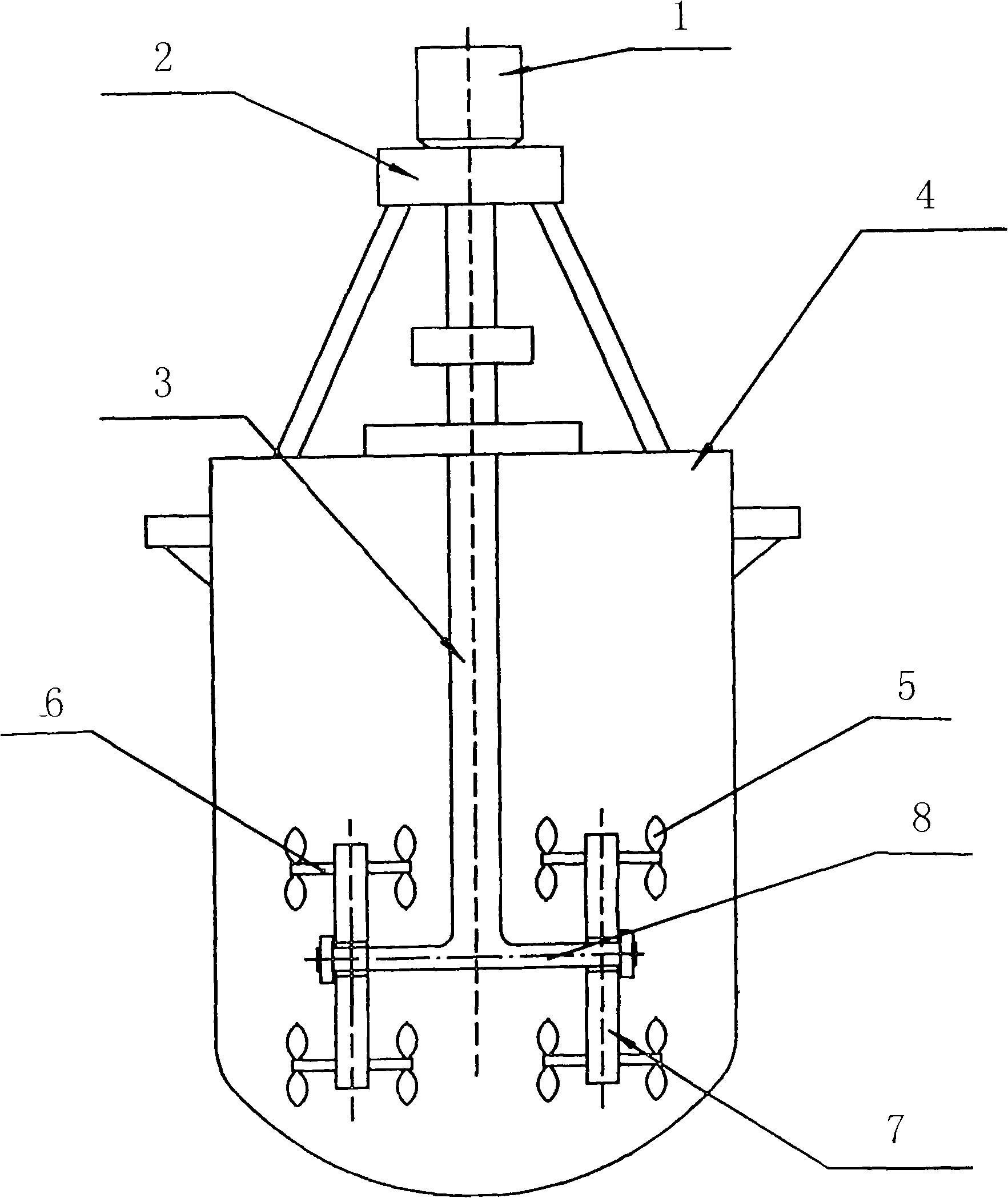

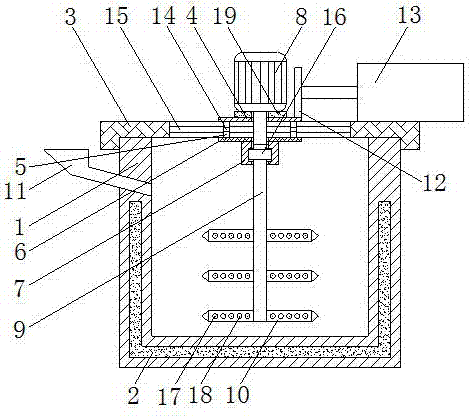

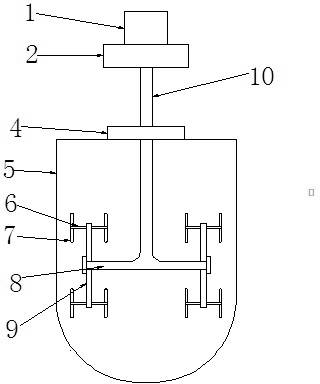

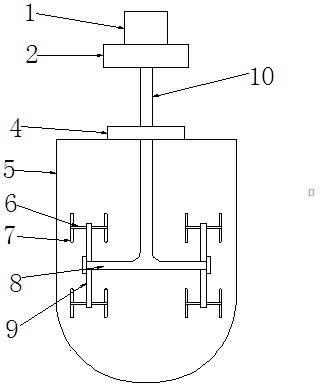

Reaction kettle for preparation of electrolyte of lithium battery

InactiveCN108654543AExpand the scope of work activitiesIncrease the mixing areaShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectrolyte

The invention discloses a reaction kettle for preparation of an electrolyte of a lithium battery. The reaction kettle comprises a casing of the reaction kettle, wherein a stirring shaft is movably arranged in the casing of the reaction kettle; a plurality of shaft sleeves fixedly sleeve the stirring shaft; a plurality of stirring blades are fixedly arranged on each shaft sleeve; a lifting plate ismovably arranged above the casing of the reaction kettle; a stirring motor is fixedly arranged at the bottom part of the lifting plate; the top end of the stirring shaft movably penetrates through the upper part of the casing of the reaction kettle, and is fixedly connected with an output shaft of the stirring motor; fixed columns are respectively arranged at both sides of the stirring motor andare fixedly arranged at the top part of the casing of the reaction kettle; each fixed column is of a hollow structure. The reaction kettle has the advantages that the whole structure is simple and clear; the working and movement scope of the stirring blades in the casing of the reaction kettle is increased; the stirring area is expanded; the oscillation amplitude of the electrolyte of the lithiumbattery in the casing of the reaction kettle is accelerated; the electrolyte of the lithium battery is more uniformly and fully stirred; the stirring efficiency is favorably improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

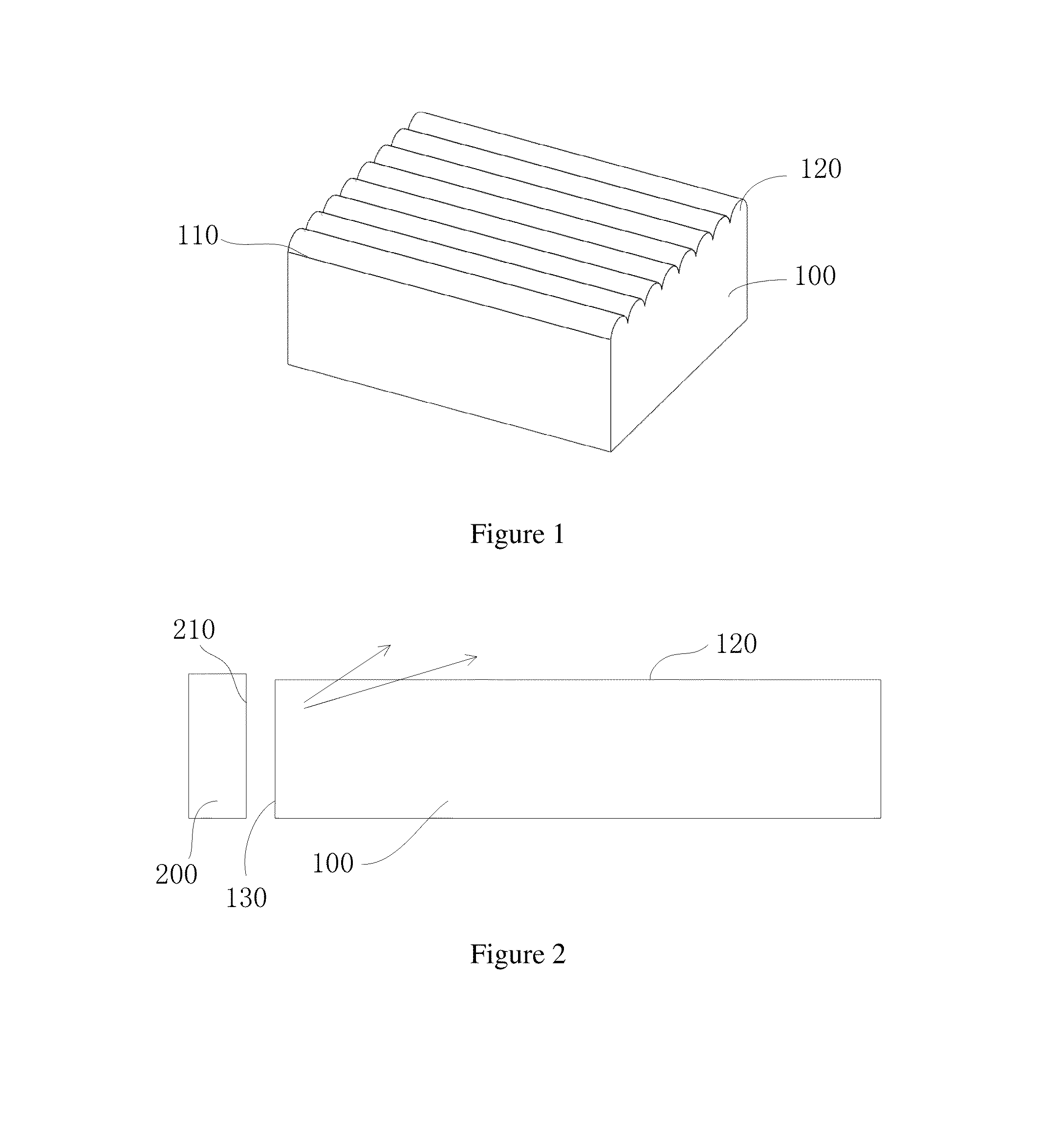

Planar light source

ActiveUS9703032B2Improve light uniformityReduce usageMechanical apparatusLight guides for lighting systemsShortest distanceLight guide

A planar light source including a light guide plate (LGP) and a light source device is provided. The LGP includes a plate portion and at least one prism portion. The plate portion has a light incident surface, a reflective surface, a bottom surface, and a light exiting surface. The prism portion is disposed on the bottom surface of the plate portion, and has a first plane and a second plane. An included angle between the first plane and the bottom surface is smaller than an included angle between the second plane and the bottom surface, and a shortest distance between the first plane and the light incident surface is smaller than a shortest distance between the second plane and the light incident surface. The light source device is disposed adjacent to the light incident surface. The disclosure provides planar light source with good light uniformity.

Owner:CORETRONIC

High-environment-friendliness industrial material mixing equipment

InactiveCN106621963AIncrease mixing speedReduce vibration effectsShaking/oscillating/vibrating mixersTransportation and packagingMixing tankPetroleum engineering

The invention relates to mixing equipment, in particular to high-environment-friendliness industrial material mixing equipment and aims to realize high mixing speed and mixing thoroughness of the high-environment-friendliness industrial material mixing equipment. The equipment comprises a first supporting frame, a rotating motor, a first gear, a bearing seat, a second gear, a first rotating shaft, an oscillating rod, an elastic part, a brush, a fixing plate, a second rotating shaft and the like. A left supporting rod and a right supporting rod are connected with a liquid receiving basin by means of adhesive connection, a mixing tank is connected to upper ends of the supporting rods by means of mortise joint, the bottom middle of the mixing tank is provided with a second through hole and an arc groove, and the diameter of the second through hole is smaller than that of the arc groove. The high-environment-friendliness industrial material mixing equipment has advantages of high mixing speed, thoroughness in mixing, simplicity in operation and simple structure.

Owner:刘德平

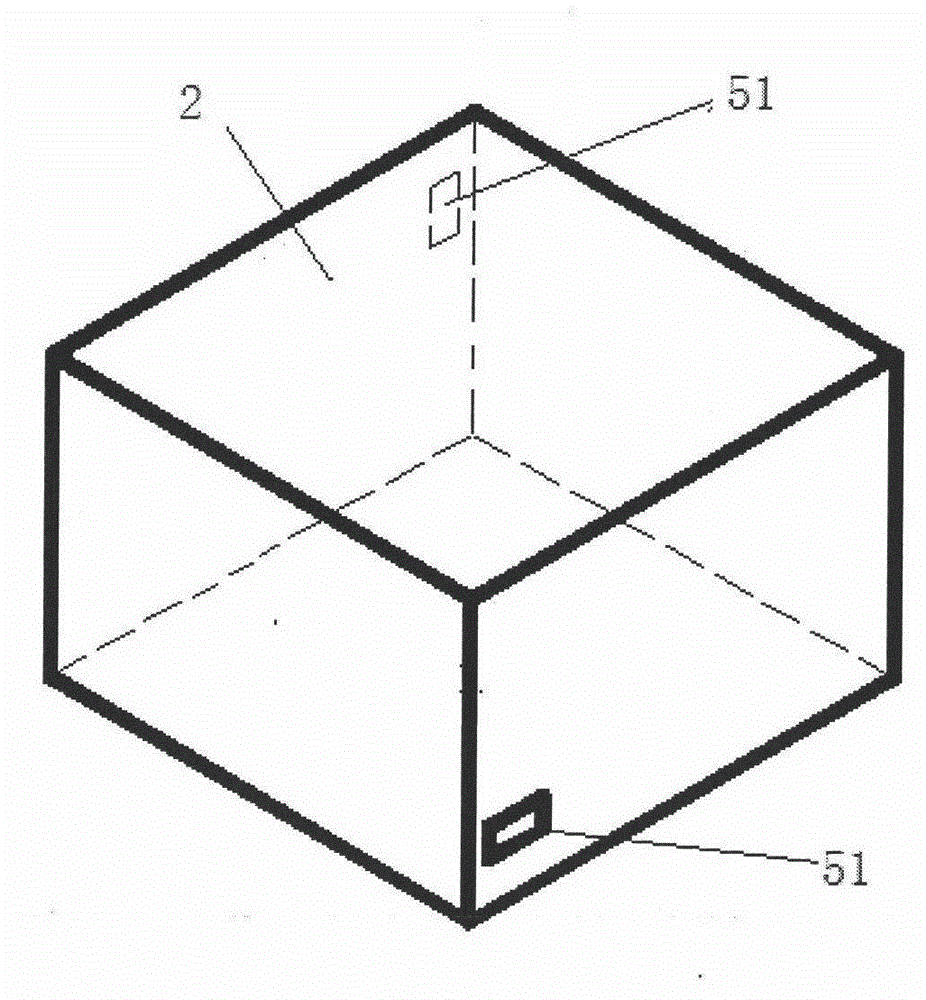

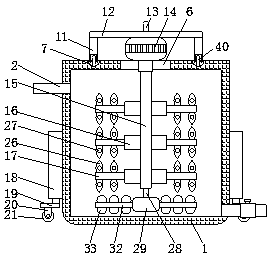

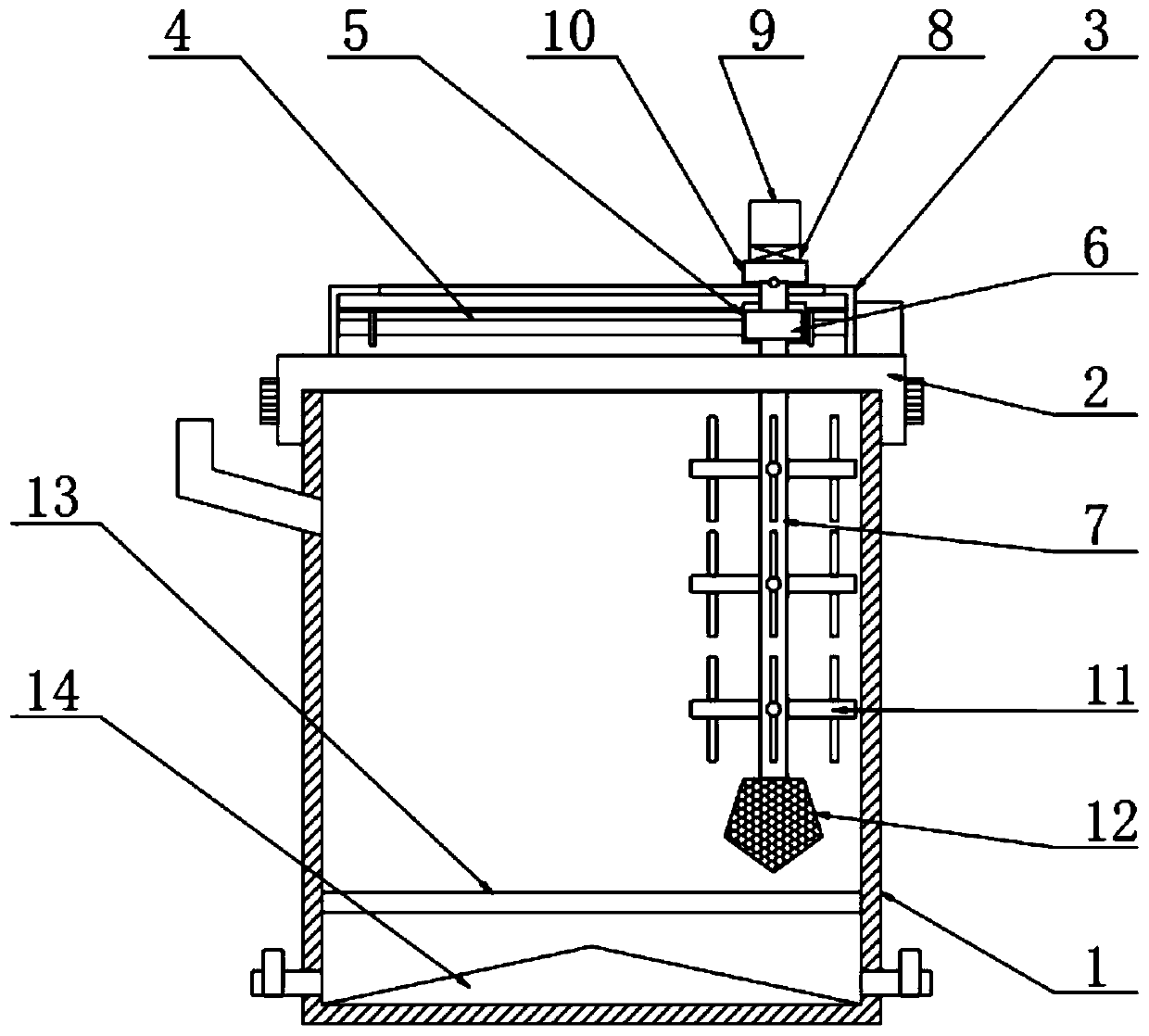

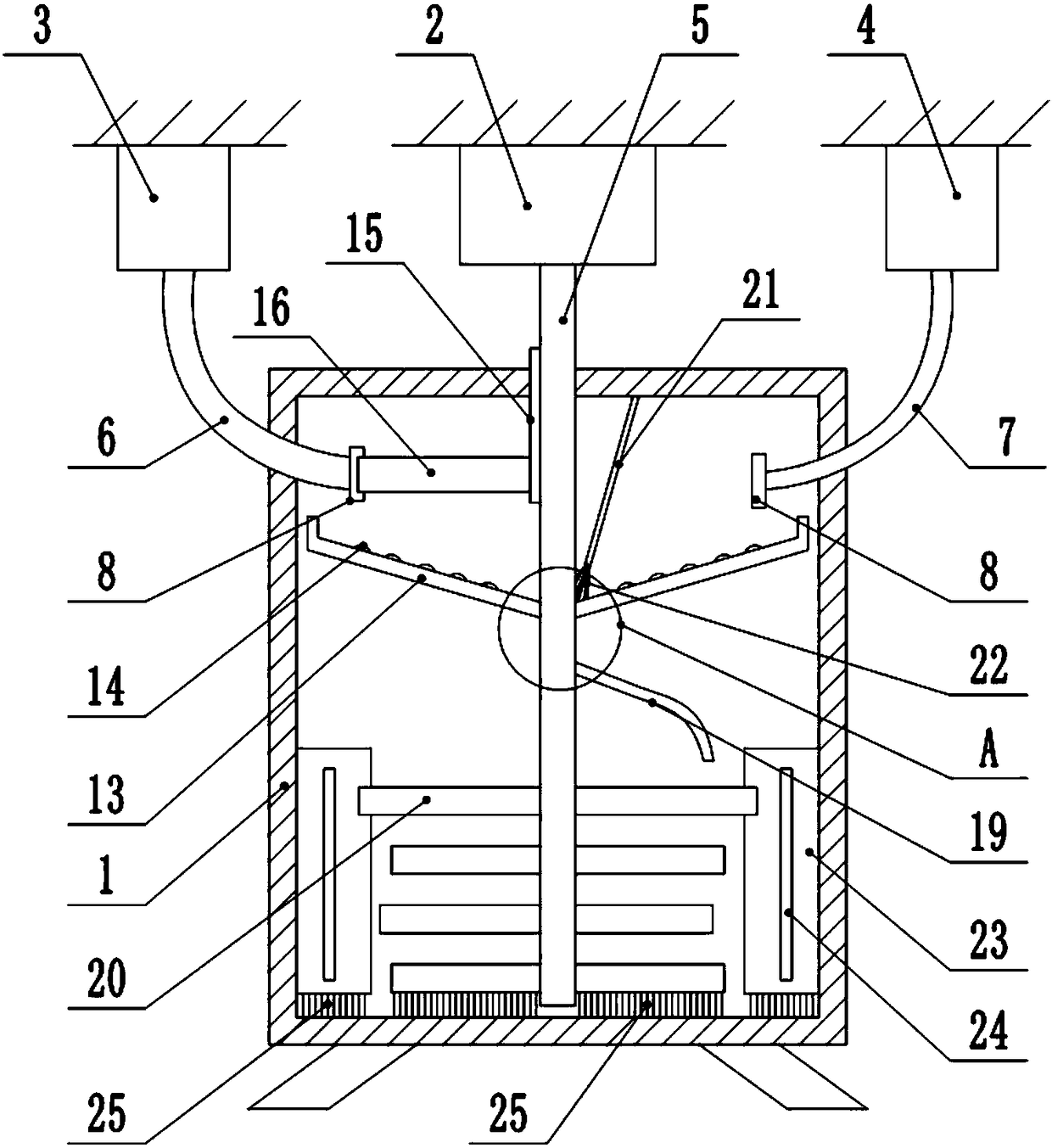

New energy battery electrolyte mixing processing device

InactiveCN109621798AIncrease the mixing areaImprove stirring efficiencyShaking/oscillating/vibrating mixersAssembling battery machinesElectrical batteryNew energy

The invention discloses a new energy battery electrolyte mixing processing device. The device comprises a box body, the top of the left side of the box body is communicated with a feeding pipe, the bottom of the right side of the box body is communicated with a discharging pipe, and a valve is arranged on the surface of the discharging pipe; a sealing box is fixedly connected to the top of the boxbody, and a square hole is formed in the top of the box body; long grooves are formed in the portions, on the front side and the rear side of the square hole, on the top of the box body respectively;the top of the right side of the sealing box is fixedly connected with a first motor. A stirring rod can transversely move in the process of electrolyte stirring, and the position of the stirring rodcan be adjusted, so that the stirring area of the stirring rod is increased, the electrolyte stirring efficiency is improved, and the production efficiency is improved. The problems that an existingstirring device for a new energy battery is relatively monotonous in stirring mode, the stirring area of the stirring rod is fixed, the position of the stirring rod cannot be adjusted, the electrolytestirring efficiency is reduced and the production efficiency is reduced are solved.

Owner:邵新祥

Potassium chlorate production stirring device

PendingCN107626248AIncrease the mixing areaReduce use costChloratesShaking/oscillating/vibrating mixersBiochemical engineeringMoving frame

The invention discloses a potassium chlorate production stirring device which comprises a tank body, wherein a feeding tube is connected with the left side of the top of the tank body; a discharge tube is communicated with the bottom of the right side of the tank body; a long hole is formed in the top of the tank body; casings are fixedly connected with both sides of the top of the tank body; support columns are fixedly connected with the tops of the casings; a transverse plate is fixedly connected with the tops of the support columns; a vertical plate is fixedly connected with the bottom of the transverse plate; a first motor is fixedly connected with the bottom of the front side of the vertical plate. Due to matched use of a second motor, a stirring rod and stirring blades, materials inside the inner cavity of the tank body can be stirred; due to matched use of the first motor, a round disc, a column, the moving frame, a moving frame, a circular plate, a fan-shaped gear and a transverse rod, the stirring rod is moved leftwards and rightwards, the stirring area of the stirring rod inside the inner cavity of the tank body is increased, then the device has the advantage of efficientstirring, the workload is reduced, the use cost of the user is reduced, and convenience of use is achieved.

Owner:LEIYANG JINYUE SCI & TECH DEV

Multi-nozzle steam jet type heat pump and operation method

InactiveCN102748330AReduce wasteHigh injection coefficientJet pumpsMachines/enginesSpray nozzleEvaporation

Owner:天津聚贤达科技有限公司

Anti-clogging reaction vessel

ActiveCN107185473AEasy to openAvoid cloggingChemical/physical/physico-chemical stationary reactorsStationary filtering element filtersElectricityMarine engineering

The invention relates to the field of a chemical industrial device, specifically to an anti-clogging reaction vessel. The reaction vessel includes a vessel body; a cover is mounted on the top of the vessel; a stirring mechanism is mounted on the cover; a filter screen adapted to a cross-section of the vessel body is mounted at the lower part of a stirring shaft; a gravity inductor is mounted at an edge of the filter screen; a vibrating component is arranged at the lower part of the gravity inductor and comprises a mounting base and a vibrator, which is internally provided with a circuit board, wherein the circuit board is in electrical connection to the gravity inductor; and the lower part of the vessel body is provided with a discharge port, which is provided with a hemispheric filtering blocking screen and is covered with a heating belt. The vessel is simple in structure and convenient to operate, prevents the phenomenon of super difficult movement of materials in the vessel, reduces large blocks in the materials, and can prevent the phenomenon that the discharge port is clogged due to temperature variation.

Owner:HENGYANG YISHUN CHEM CO LTD

Stirring device for textile materials

InactiveCN107413263AAvoid simple structuresEfficient mixingShaking/oscillating/vibrating mixersRotary stirring mixersReciprocating motionArchitectural engineering

The invention discloses a stirring device for textile materials. The stirring device comprises a base. An elongated slot is formed in the left side of the top of the base, a first electric telescopic rod is fixedly connected with the right side of the top of the base, a connecting block is fixedly connected with the left side of the first electric telescopic rod, a tank is arranged on the top of the base, the right side of the tank is fixedly connected with the left side of the connecting block, supports are fixedly connected with two sides of the bottom of the tank, and rollers are movably connected with the bottoms of the supports by rotary shafts. The stirring device has the advantages that the base, the elongated slot, the first electric telescopic rod, the connecting block, the tank, the supports, the rollers, second electric telescopic rods, a transverse plate, a motor, a first belt pulley, a rotary rod, a second belt pulley, a belt and stirring rods are used with one another, accordingly, the textile materials can be efficiently stirred by the stirring device, and the problems that existing stirring devices are simple in structure, existing tanks cannot carry out reciprocating movement, existing stirring rods only can carry out rotation movement, existing textile materials cannot be sufficiently uniformly stirred by the existing stirring devices and the stirring efficiency is deteriorated can be solved.

Owner:FOSHAN LIANZHI XINCHUANG TECH CO LTD

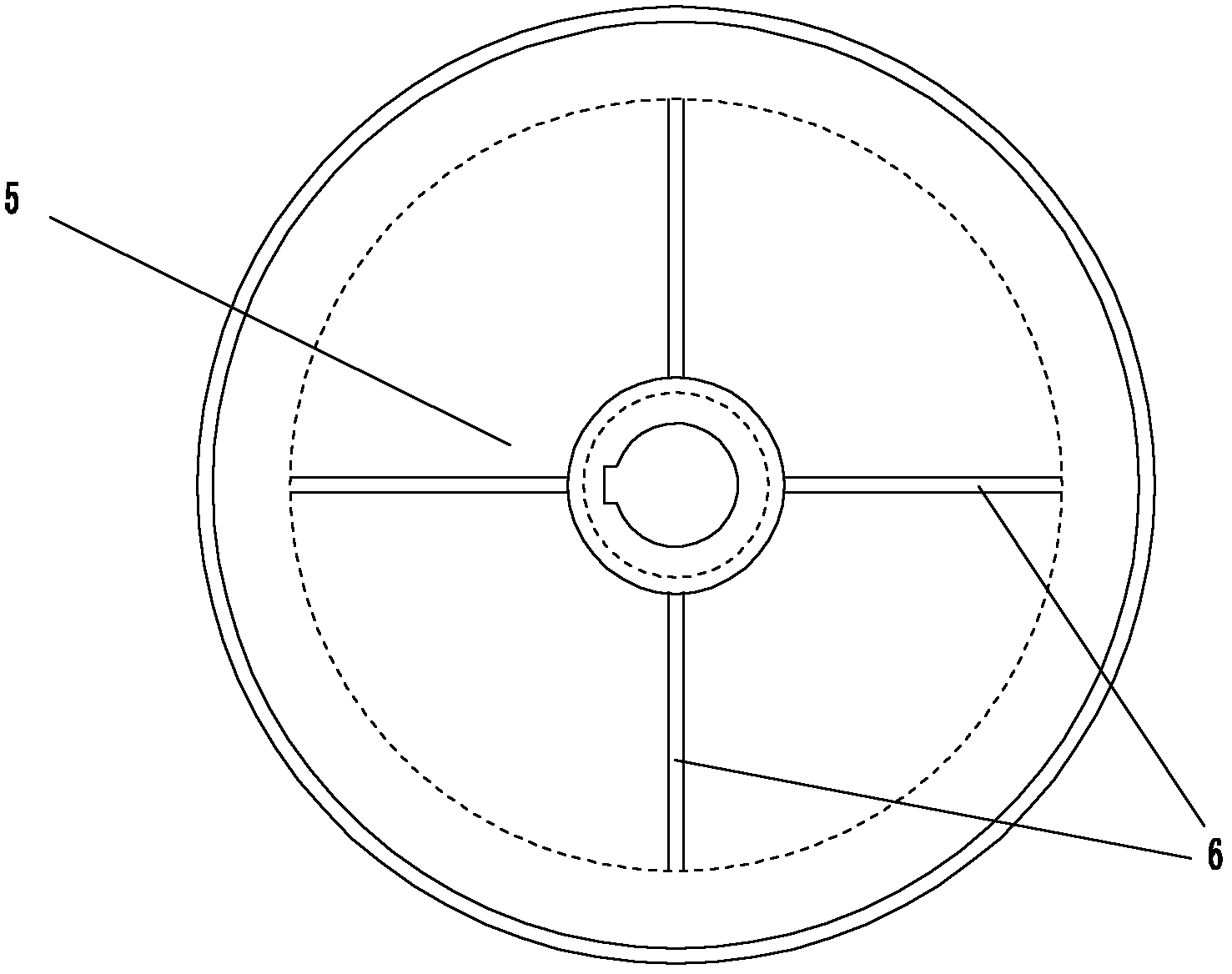

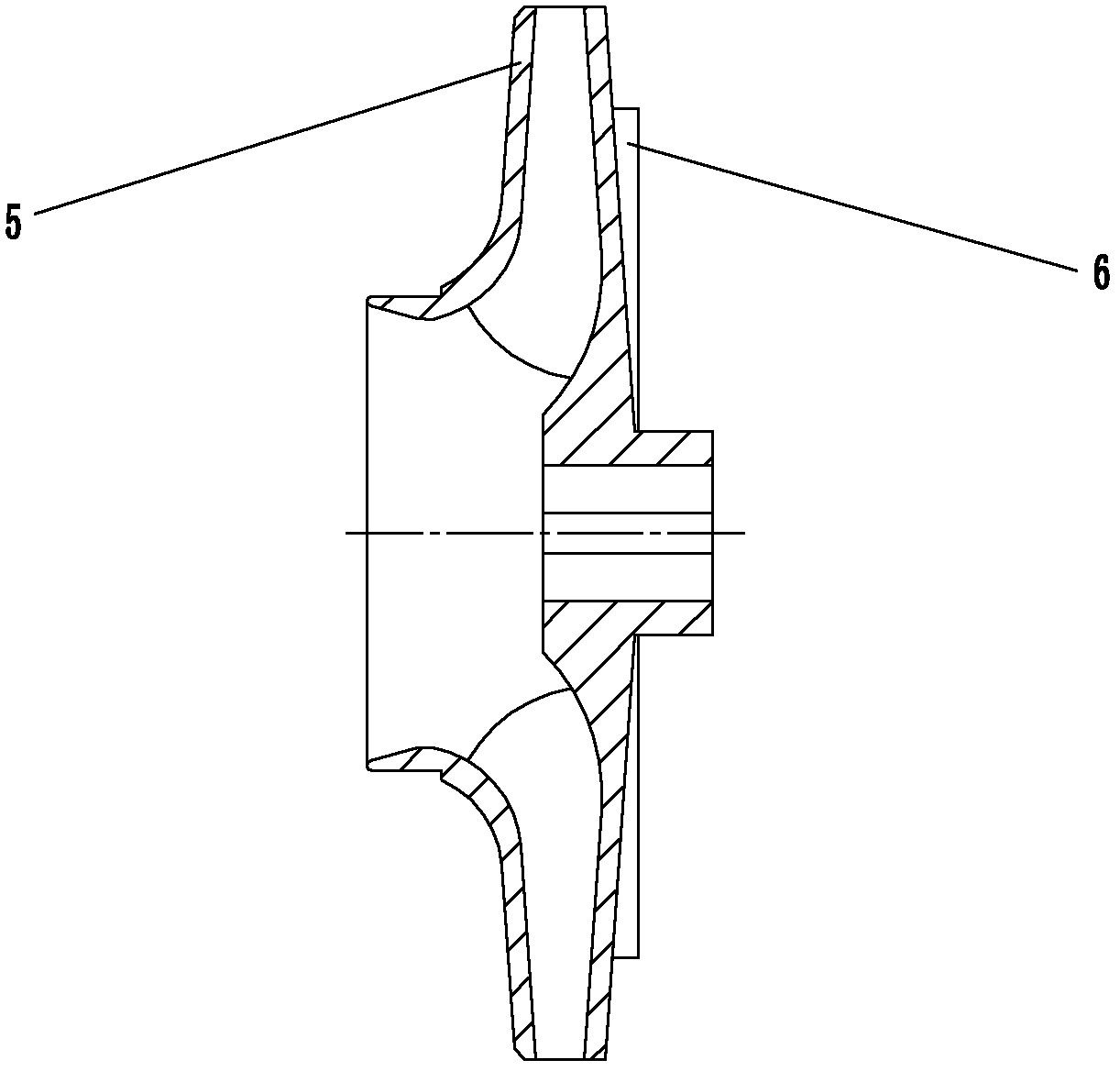

Vertical internal and external mixing shaft-seal-free self-sucking pump

ActiveCN102192157AFast separationImprove self-priming performancePump componentsPriming pumpImpellerEngineering

The invention discloses a vertical internal and external mixing shaft-seal-free self-sucking pump which comprises a pump body, a pump cover, a pump shaft, a main impellor, a main impellor seal chamber, an assistant impellor chamber, an assistant impellor, a water sucking chamber, a water outlet, a water inlet pipe, a water inlet pipe flange, a volute chamber and a gas-water separation chamber, wherein the top surface of the main impellor and the top surface of the assistant impellor are respectively provided with a radial main impellor balancing rib and a radial assistant impellor balancing rib; the outer edge at the bottom surface of the assistant impellor is fixedly provided with an annular seal pad; and the bottom surface of the assistant impellor chamber is provided with an annular supporting plate. Through the self-sucking pump provided by the invention, the issue of air intake of a shaft seal can be solved, high-vacuum continuous air exhaust can be kept all the time in the self-sucking process, the self-sucking capability is improved, and the self-sucking time is shortened.

Owner:GUANGZOU BAIYUN PUMP GROUP

Novel brine stirring machine for ice maker

InactiveCN109847627AIncrease the mixing areaImprove uniformityShaking/oscillating/vibrating mixersRotary stirring mixersPulp and paper industry

The invention discloses a novel brine stirring machine for an ice maker, and belongs to the technical field of stirring machines. The brine stirring machine comprises a shell and a quantitative discharging device; a lead screw is movably arranged between the left inner wall and the right inner wall of a mounting shell through bearings; the outer wall of the screw rod is sleeved with a movable block; the outer wall of a stirring rod is uniformly provided with branched stirring rods; a hollow block communicating with the bottom end of the stirring rod is arranged at the bottom end of the stirring rod; a material placing cylinder is arranged at the top of the quantitative discharging device; and a filter screen plate is transversely arranged in the inner cavity of the shell. The brine stirring machine is provided with the lead screw, the movable block, an assembly block, the stirring rod and the branched stirring rods, so that the branched stirring rods can move left and right, the stirring area of liquid inside the shell is increased, and uniformity is improved. Meanwhile, a gear and a gear rack are arranged to be matched with each other, so that the stirring rod can rotate during moving, the liquid located at each position in the shell can be mixed, and mixing quality is improved.

Owner:FOCUSUN REFRIGERATION JIANGSU

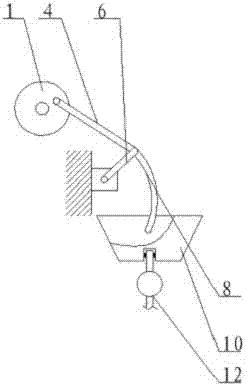

Food mixing machine

InactiveCN103110365ARealize automatic stirring functionImprove work efficiencyKitchen equipmentFood shapingEngineeringCurvilinear motion

The invention discloses a food mixing machine comprising a container used for holding food and a mixing rod arranged on the container. The food mixing machine is characterized by further comprising a movement device. The movement device comprises a slewing gear and a rocker. The slewing gear is driven to slew by a driving device. The rocker with one end fixedly hinged is arranged under the slewing gear. The slewing gear and the rocker are hinged with one connecting rod, and the lower end of the connecting rod is fixedly connected with the mixing rod. A crank and rocker mechanism comprise the slewing gear, the connecting rod and the rocker. When the slewing gear performs rotary motion, the connecting rod swings back and forth, and an endpoint of the mixing rod, fixedly connected on the connecting rod, performs closed curvilinear motion. According to the cycle, the food mixing machine realizes automatic mixing function and working efficiency is increased.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Premixed high-performance concrete material mixing device and material mixing method

ActiveCN113561325AEnhance the effect of mixingPrevent material impactCement mixing apparatusGrain treatmentsMixing effectCaking

The invention relates to the technical field of concrete production equipment, and discloses a premixed high-performance concrete material mixing device and a material mixing method. The premixed high-performance concrete material mixing device comprises a material mixing box, a water inlet is formed in the center axis position of the top of the material mixing box, a feeding hopper is arranged on the upper wall of the left side of the material mixing box, and the feeding hopper communicates with the side wall of the material mixing box. A discharging port is formed in the lower wall of the side, away from the feeding hopper, of the material mixing box, and the discharging opening communicates with the side wall of the material mixing box. According to the premixed high-performance concrete material mixing device and the material mixing method, when entering the material mixing box from a feeding port, solid materials fall onto an elastic screen firstly, and the elastic screen oscillates through the action of rotating rods under the extrusion of gravity. Furthermore, arc-shaped grinding rods can move along the outer surface of the elastic screen under the action of arc-shaped rotating rods, and therefore an agglomerated part in the materials can be crushed, and the subsequent material mixing effect can be enhanced.

Owner:南通欧本建筑科技有限公司

Xiang pig feed mixing equipment

ActiveCN108465426ARealize intermittent feedingImprove uniformityFeeding-stuffTransportation and packagingEngineeringFeed additive

The invention relates to the field of livestock breeding equipment and in particular discloses Xiang pig feed mixing equipment which comprises a mixing tank, a motor and two storage chambers, whereinthe motor is arranged above the mixing tank; the output end of the motor is coaxially fixedly connected with a rotating shaft; the storage chambers are connected with discharge tubes; control mechanisms are mounted at discharge holes of the discharge tubes; the rotating shaft is hinged with push plates for opening the control mechanisms; holding discs are arranged below the discharge holes; a cavity is formed inside the rotating shaft; feeding holes are formed in the side wall of the rotating shaft; the feeding holes are communicated with the cavity and the mixing tank; a third discharge tubeis communicated with the bottom of the cavity; the rotating shaft is coaxially fixedly connected with a plurality of stirring blades; a plurality of vertically arranged rotating plates are hinged withthe side wall of the mixing tank along the circumference of the mixing tank; the rotating plates are pushed to rotate in the rotation process of the stirring blades. By adopting the equipment, primary mixing of feed with feed additives can be achieved through the holding discs, secondary mixing can be achieved through the stirring blades, meanwhile, feed on the side wall of the mixing tank can bestirred and mixed through rotation of the rotating plates, and the uniformity degree of the feed and the feed additives can be increased.

Owner:湖南俊旺科技饲料有限公司

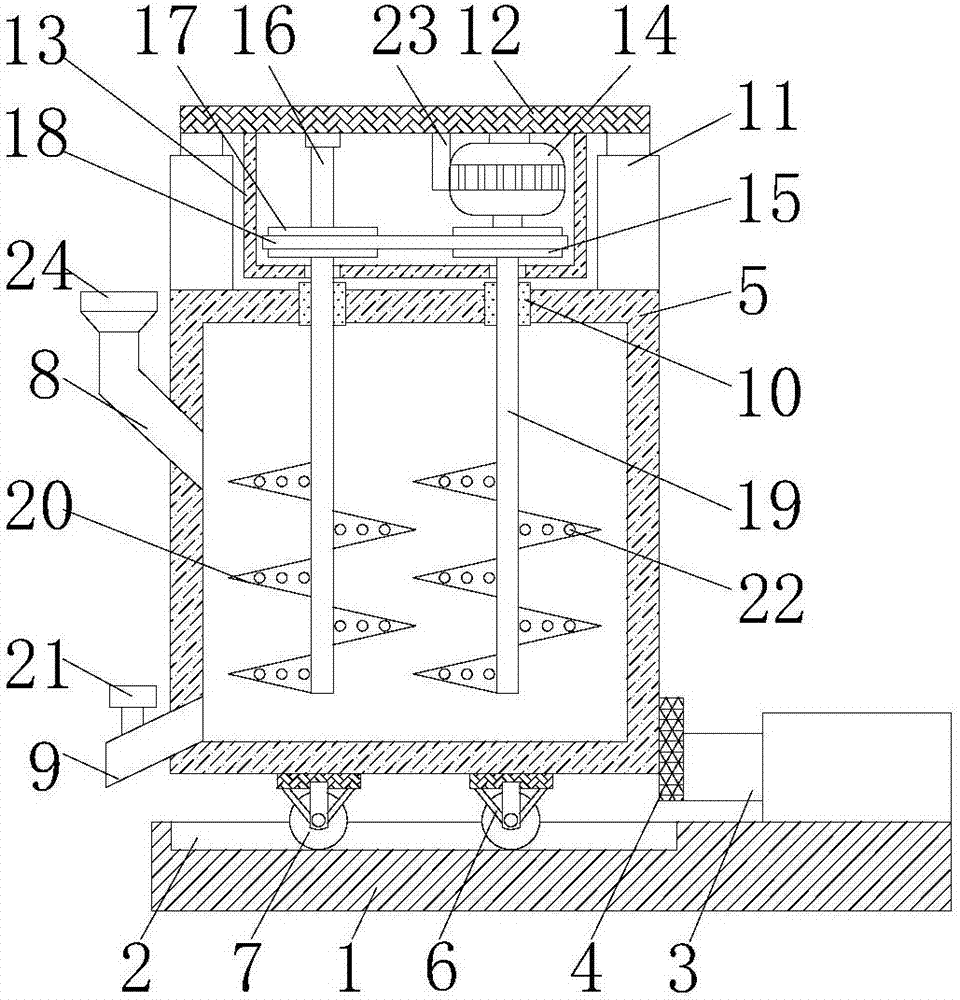

Novel stirring paddles

InactiveCN103418266AIncrease the mixing areaGuaranteed uniformityRotary stirring mixersEngineeringViscosity

The invention relates to novel stirring paddles which comprise a stirring material distributing tank, a stirring rod and stirring paddle bodies. The stirring material distributing tank is made of stainless steel and used for containing materials. The stirring rod is made of stainless steel and columnar. The bottom of the stirring rod is of a round ball body structure. The stirring paddle bodies are in a V shape, symmetrically arranged at the two ends of the bottom side of the stirring rod and composed of stirring blades and side blades. A certain number of small holes are formed in the stirring blades. The stirring blade bodies are in the V shape and symmetrically arranged at the two ends of the bottom side of the stirring rod. The stirring area of the novel stirring paddles is increased, uniformity of the materials is ensured, meanwhile, a certain number of small holes are formed in fracture surfaces of the stirring paddle bodies. Thus, the novel stirring paddle bodies can reduce flowing resistance in materials with large viscosity. The novel stirring paddles are good in structural stability, simple in structure, convenient to manufacture and capable of greatly improving working efficiency.

Owner:天津聚贤达科技有限公司

Material mixing device for civil engineering

The invention discloses a mixing and batching device for civil engineering, which comprises a box body, a screw mixer and a vertical mixer. A coarse mixing box is arranged at the inner upper end of the box body, and a fine mixing box is arranged at the lower end of the box body, wherein The screw mixer is fixedly connected to the inside of the fine mixing box, a first stirring motor is fixedly connected to one end surface of the fine mixing box, the lower end of the fine mixing box is provided with a discharge pipe, and the vertical mixer is fixed Connected inside the rough mixing box, the vertical mixer includes a stirring impeller, a stirring shaft and a screw, a feeding funnel is fixedly connected on both sides of the upper end of the box, and the two groups of feeding funnels are fixedly connected. There is a second stirring motor. The mixing and batching device for civil engineering realizes the use of mixing and batching by being provided with a box body, a screw mixer and a vertical mixer, and has high use value.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Smashing device used for pet snacks processing

The invention relates to the technical field of smashing, and discloses a smashing device used for pet snacks processing. The smashing device comprises a rack, a box and a motor, wherein a pressure block is connected into the box in a sliding way, a first sieve plate is arranged below the pressure block, and a first sieve slot is formed in the first sieve plate; a crankshaft is arranged below thefirst sieve plate, a cutter is fixed on a rod journal of the crankshaft, one end of the crankshaft is fixedly connected with the motor, a cam is fixed on the crankshaft, and a slide bar is arranged above the cam; a second sieve plate is arranged below the crankshaft, the second sieve plate can prop against the cam, a plurality of second sieve slots are formed in the second sieve plate, a reset spring is arranged at the bottom of the second sieve plate, sealing plates are hinged to two sides of the second sieve slots, compressed springs propping against the second sieve plate are fixed on the sealing plates, and discharge holes are formed in the bottom of the box. The smashing device is simple in structure, and can sufficiently stir and smash snacks of pets, so that the pet snacks can be smashed and stirred in multiple levels, and then the snacks can be conveniently eaten by pets.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

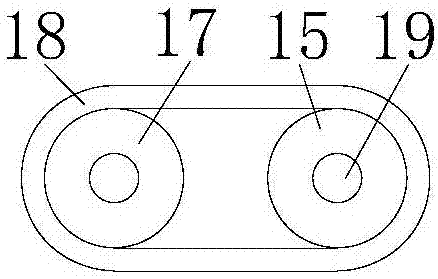

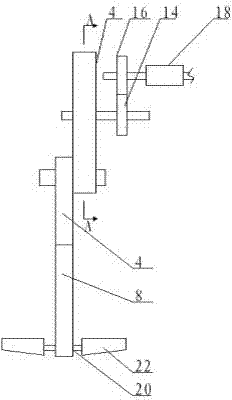

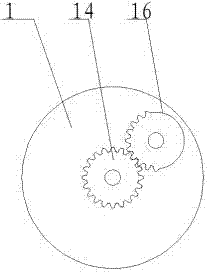

Multihead stirrer

InactiveCN101274236ASimple design principleEasy to installRotary stirring mixersReaction rateReducer

The invention provides a multi-head mixer, comprising a motor, a reducer, a mixing shaft and a mixing blade; the mixing blade is arranged at the end of the mixing shaft. The mixer is characterized in that the end of the mixing shaft is fixed with a transverse shaft; two ends of the transverse shaft are symmetrically and fixedly provided with two short shafts which are parallel to each other; two ends of each short shaft are symmetrically fixed with a connecting shaft; two ends of the connecting shaft are provided with a mixing blade. The multi-head mixer of the invention increases the mixing blades, enlarges the mixing area, leads the raw material to have good mixing effect in a reaction kettle, improves the mixing efficiency, speeds up the reaction rate and improves the yield. Meanwhile, the mixer of the invention has simple design principle, is convenient for processing, has convenient installation and usage, high mixing efficiency and saves the power energy.

Owner:徐先鹏 +1

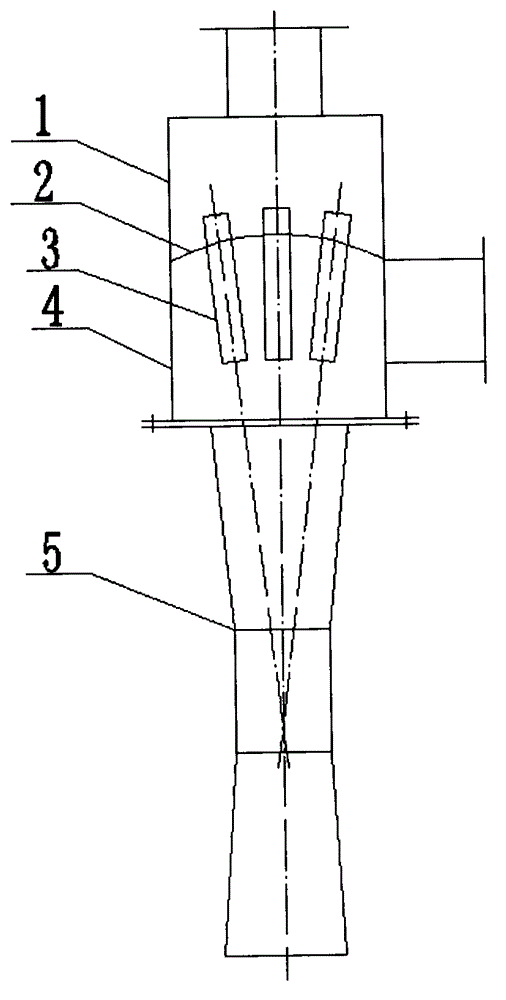

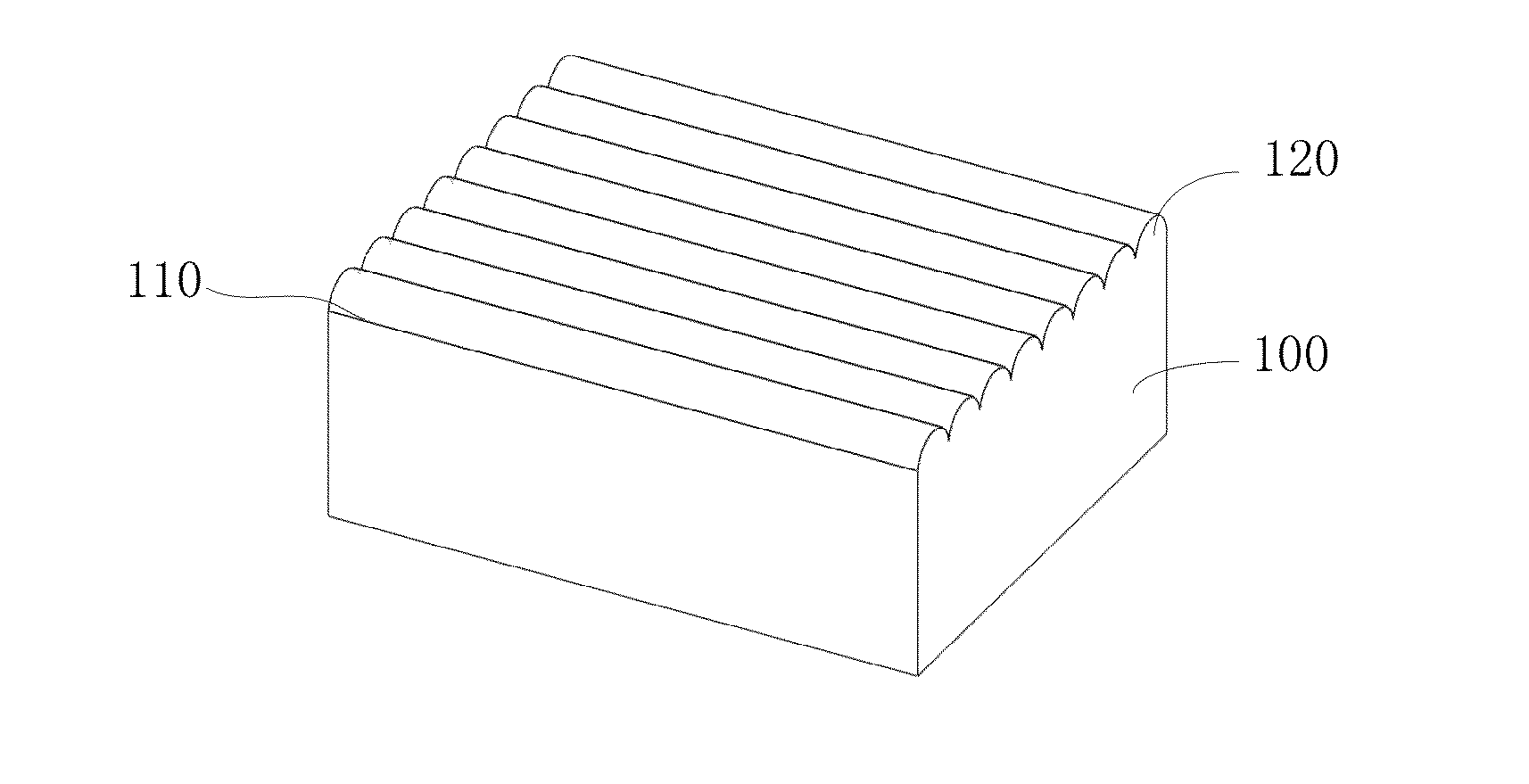

Backlight module

InactiveUS20140056029A1Increase light mixing areaImprove the display effectMechanical apparatusPlanar/plate-like light guidesLight guideLight beam

A backlight module comprises: a light emitting device; a light guide plate that has a plurality of light guide prisms; a first prism assembly that comprises a first base body and a plurality of first prisms arranged on the light emergent surface of the first base body; a second prism assembly that comprises a second base body and a plurality of second prisms, wherein the extending direction of the second prisms is vertical to that of the first prisms. By way of the light guide prisms of the light guide plate extending in the parallel direction to the extending direction of the first prisms, the light beam with a large angle propagating through the light guide plate will not be guided out by the prisms near the light incident side, so as to increase the light mixing area and subsequently avoid the presence of alternately dark and bright hotspot.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Multifunctional biological experiment table

ActiveCN108405011AConvenient experimentConducive to pollution preventionHollow article cleaningWater/sewage treatmentCrucibleElectron microscope

The invention relates to a multifunctional biological experiment table. The multifunctional biological experiment table comprises a cabinet, a table board, cabinet legs, an oxygen isolating cabinet, acomputer, a liquid delivery header pipe, a test tube fixing block II, a crucible, a motor V, a test tube cleaning device and the like. The four cabinet legs are fixed under the cabinet, the table board is arranged on the cabinet, the computer, the oxygen isolating cabinet, an electron microscope II, the test tube fixing block II, the crucible and the motor V are successively arranged on the tableboard from left to right, and the test tube cleaning device is arranged in the cabinet and positioned below the test tube fixing block II. The multifunctional biological experiment table is providedwith the oxygen isolating cabinet, experiments requiring oxygen isolation can be finished, meanwhile, test tubes can be cleaned automatically, and thus, the multifunctional biological experiment tableis convenient and speedy.

Owner:广东中智源实验室装备制造有限公司

Dissolving device capable of realizing efficient operation

InactiveCN107413245ADissolve fastImprove solubilityRotary stirring mixersTransportation and packagingEngineeringElectric heating

The invention discloses a dissolving device which can work efficiently. The dissolving device comprises a dissolving chamber, wherein the inner wall of the dissolving chamber is fixedly provided with an electric heating block; the top of the dissolving chamber is movably provided with a top cover; the top of the top cover is movably connected with a support block I; two sides of the bottom of the support block I are fixedly connected with connecting blocks; the bottom ends of the connecting blocks penetrate the top cover and are fixedly connected with a support block II located in the dissolving chamber; the bottom of the support block II is fixedly connected with a support block III; the top of the support block I is fixedly connected with a motor; a rotating shaft of the motor successively penetrates the support block I, the top cover and the support block II and is arranged in and movably connected with the support block III. According to the invention, through arrangement of the electric heating block, the motor, a transmission rod and a stirring rod, the effect of rapid dissolving of materials is achieved and materials in the dissolving chamber are allowed to be in motion state, so dissolving of the materials is accelerated and material dissolving efficiency is improve; and thus, the dissolving device meets current processing needs and is easy to use.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

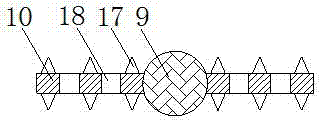

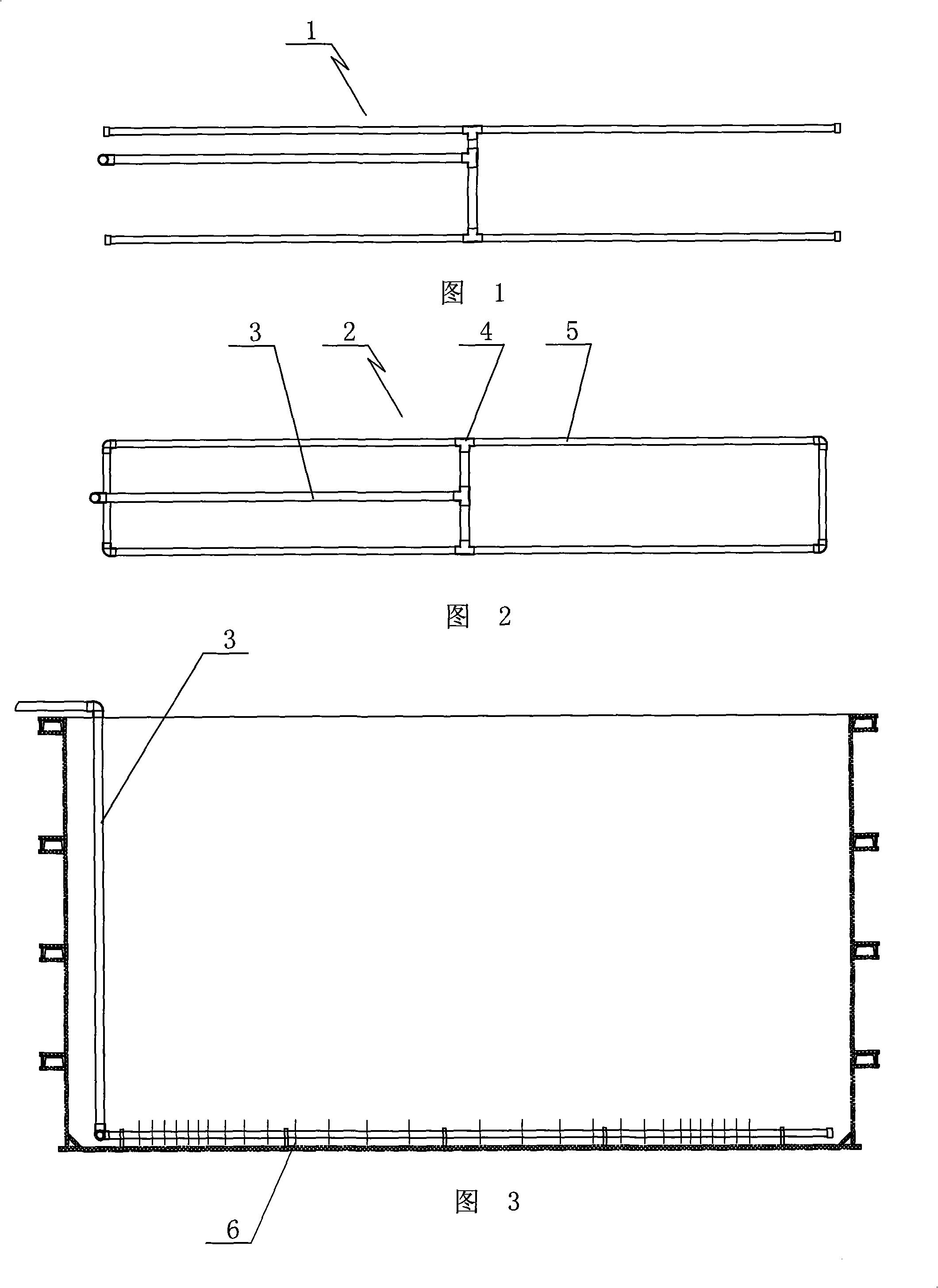

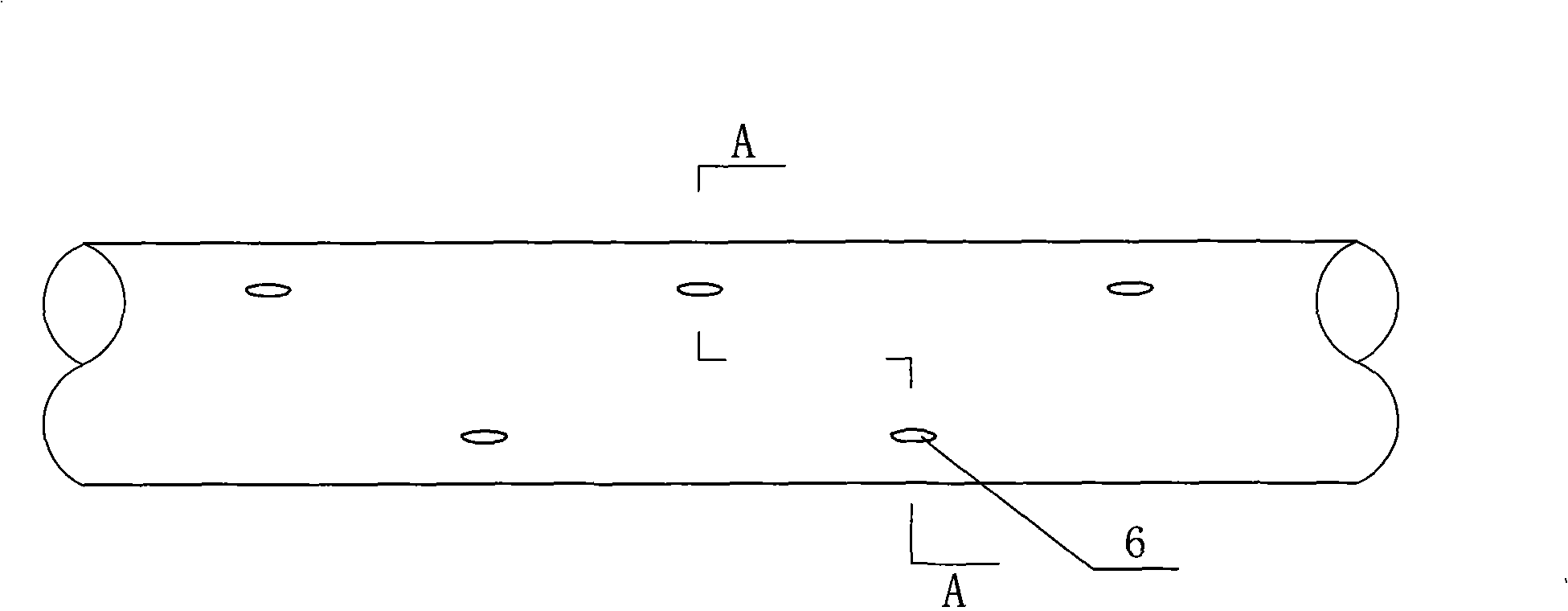

Air stirring pipe for electroplating production equipment

ActiveCN101403133AEvenly distributedIncrease the mixing areaCellsTransportation and packagingChinese charactersAir cavity

The invention relates to an air stirring pipe used for an electroplating production device. The stirring pipe can not only stir the solution uniformly, but also can save air flow. The stirring pipe comprises a stirring pipe body and is characterized in that the stirring pipe is assembled and connected by a pipe and a bend head into a shape of Chinese character 'ri', a middle crossing pipe is connected with an inlet manifold, and air outlet holes are distributed at the bottom of the stirring pipe outwards along the flowing direction of the air flow, and the amount of the air outlet holes is more and more.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Multiple-vane stirrer

InactiveCN102658051AStir wellImprove reaction efficiencyRotary stirring mixersTransportation and packagingTransverse axisDrive shaft

The invention relates to a multiple-vane stirrer, which comprises a motor, a reduction box and a drive shaft, wherein the motor, the reduction box and the drive shaft are arranged from top to bottom; and the drive shaft is connected with the output end of the reduction box and extends into a stirring drum in a centering mode. A transverse shaft is fixedly arranged at the bottom end of the drive shaft vertical to a drive shaft axis, and small shafts are symmetrically arranged at two ends of the transverse shaft in a mutually-parallel mode along a direction vertical to the transverse shaft. Connecting rods are also symmetrically arranged at two ends of each small shaft in the mutually-parallel mode, and two ends of each connecting rod are vertically connected with stirring vanes. A bearing block playing a role for supporting the drive shaft is arranged at the top of the stirring drum. Compared with the prior art, the multiple-vane stirrer is provided with multiple stirring vanes to increase the mixing area, so that materials are more fully stirred, the reaction efficiency is higher, and the accumulation and sedimentation of the materials are effectively prevented; the maintenance is reduced; the structure is simple; and the implementation is convenient and fast.

Owner:黄更生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com