Patents

Literature

103results about How to "Increase mixing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

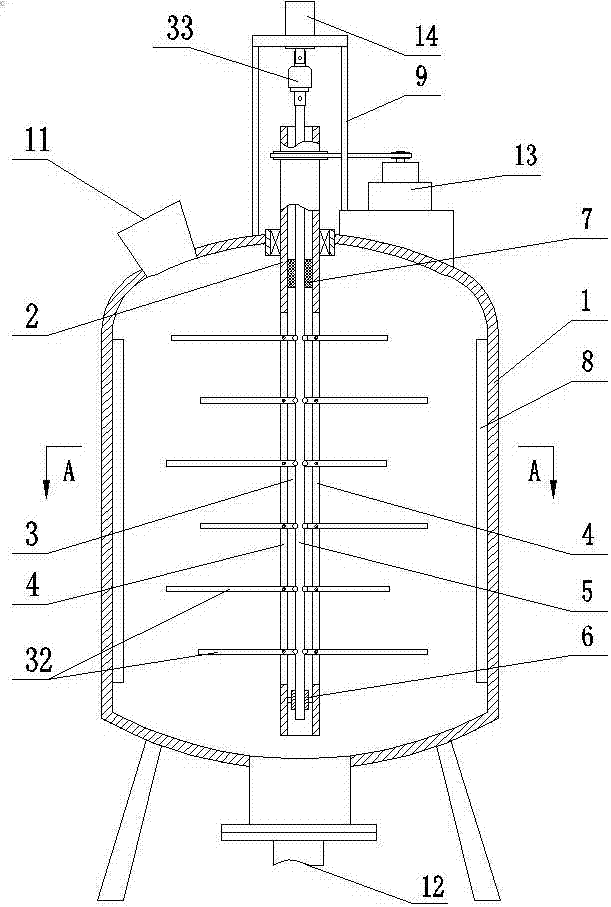

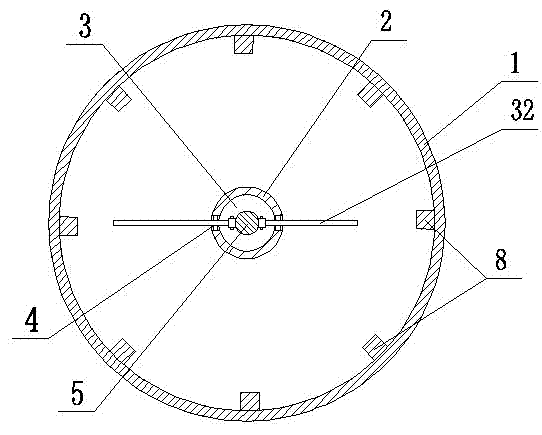

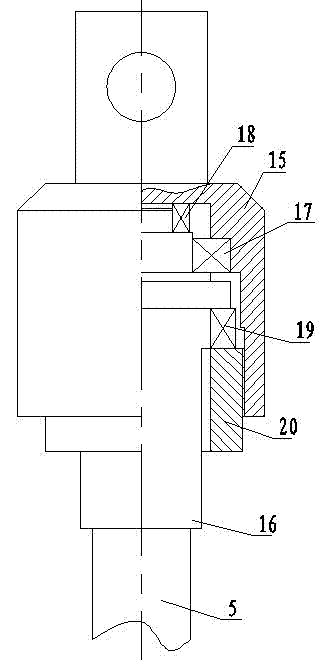

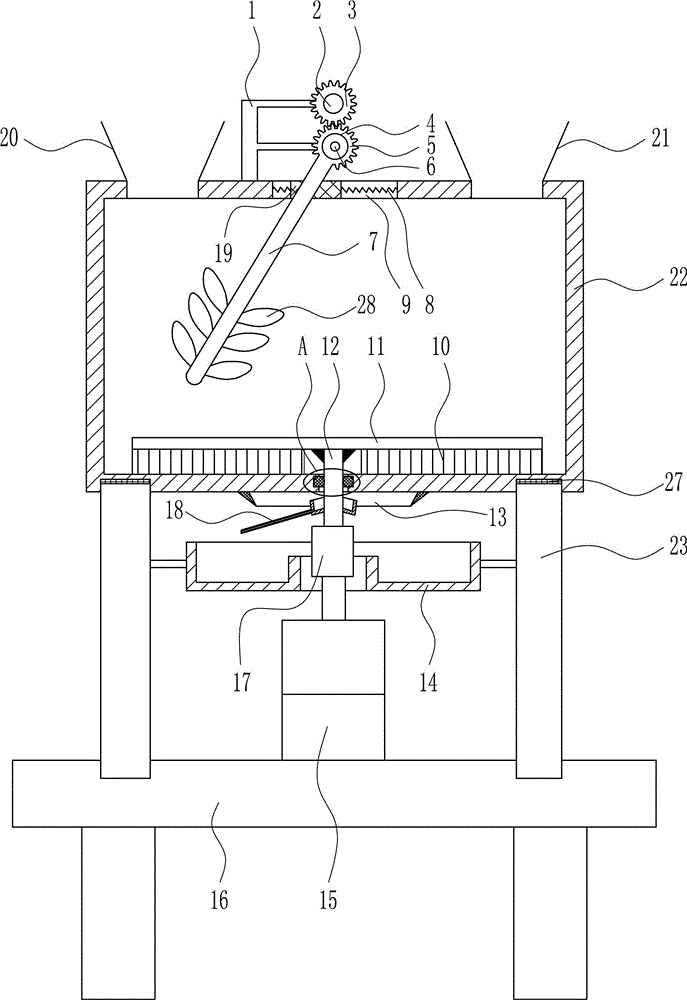

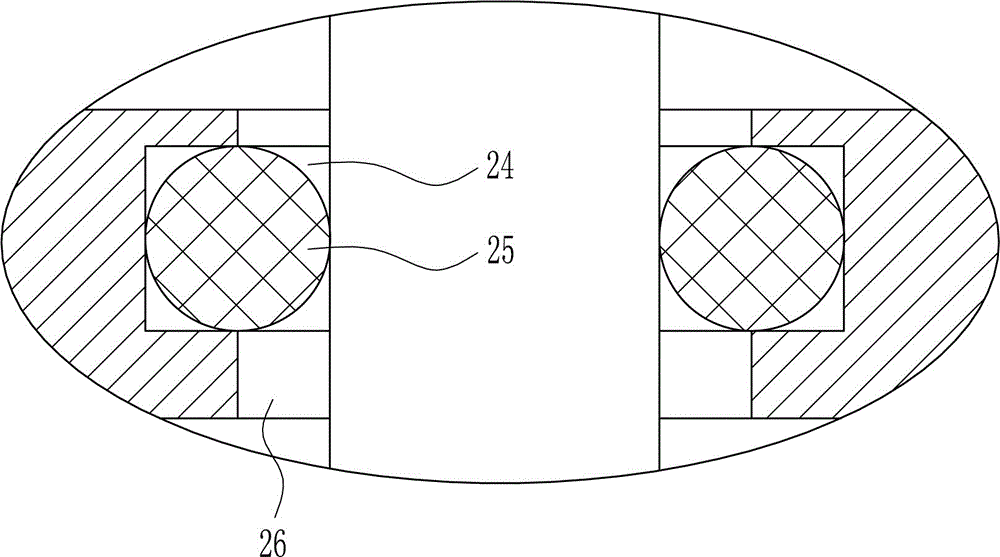

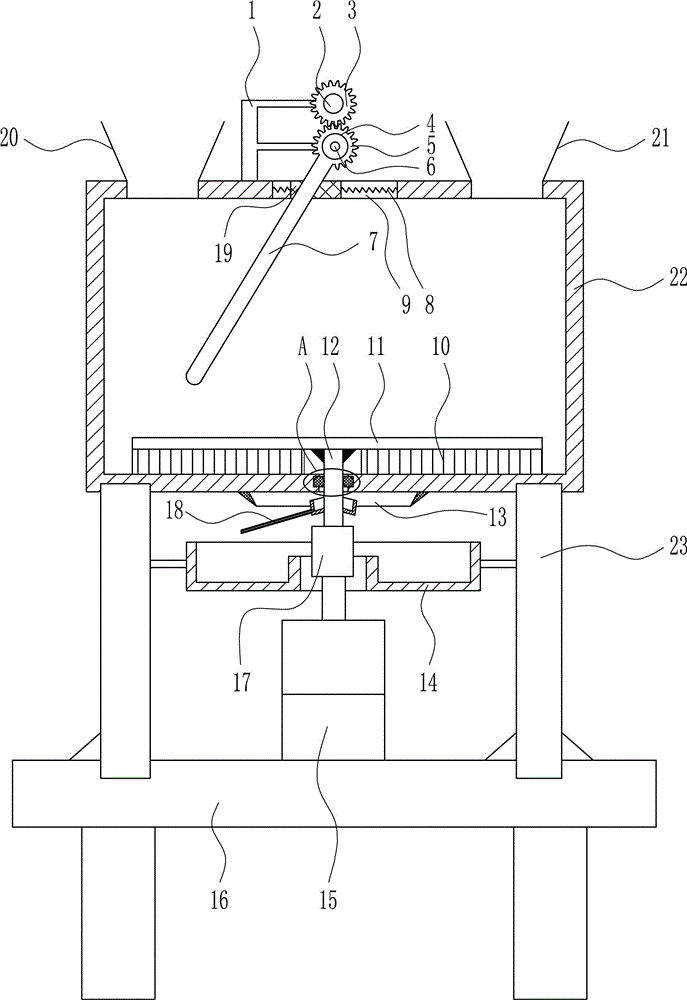

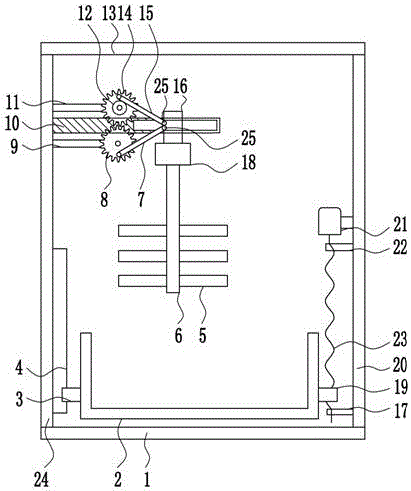

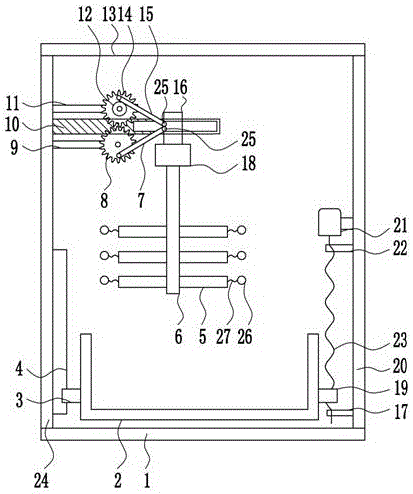

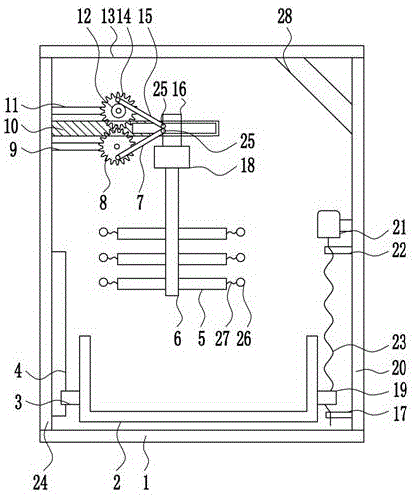

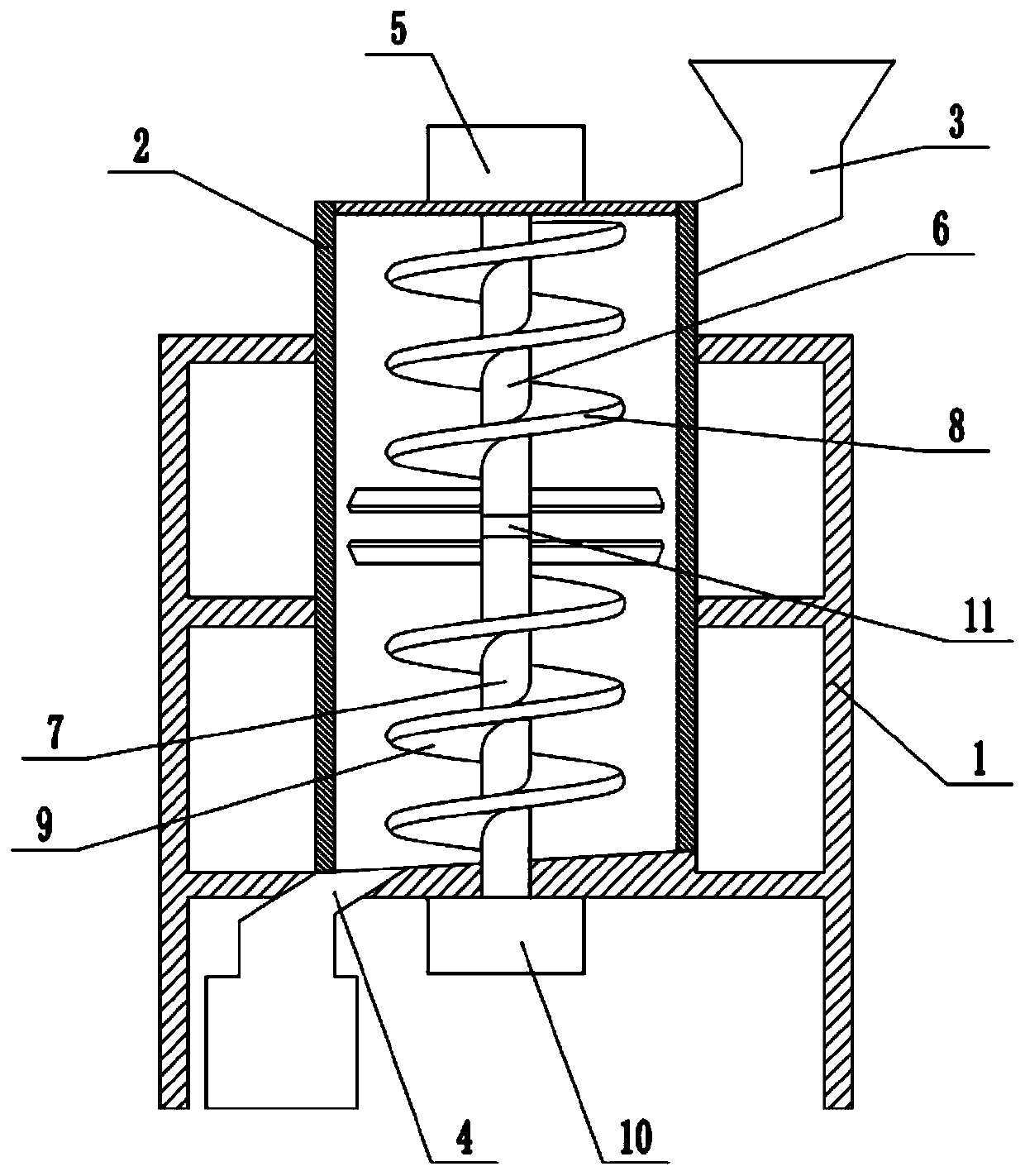

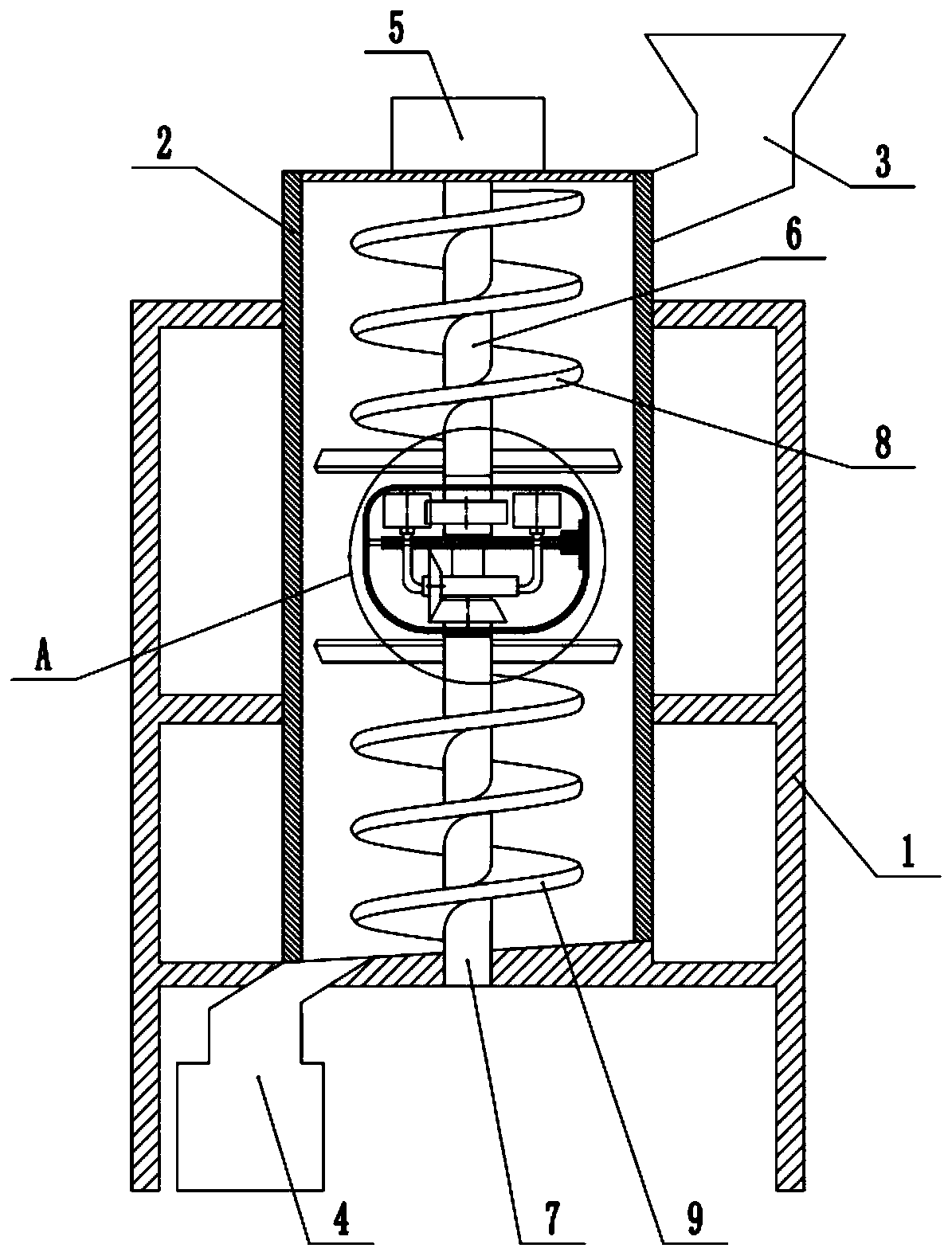

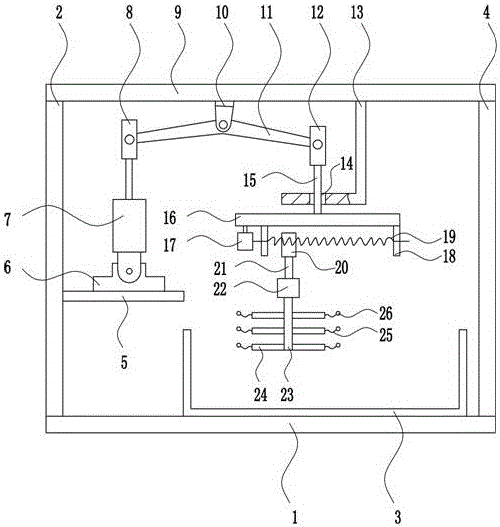

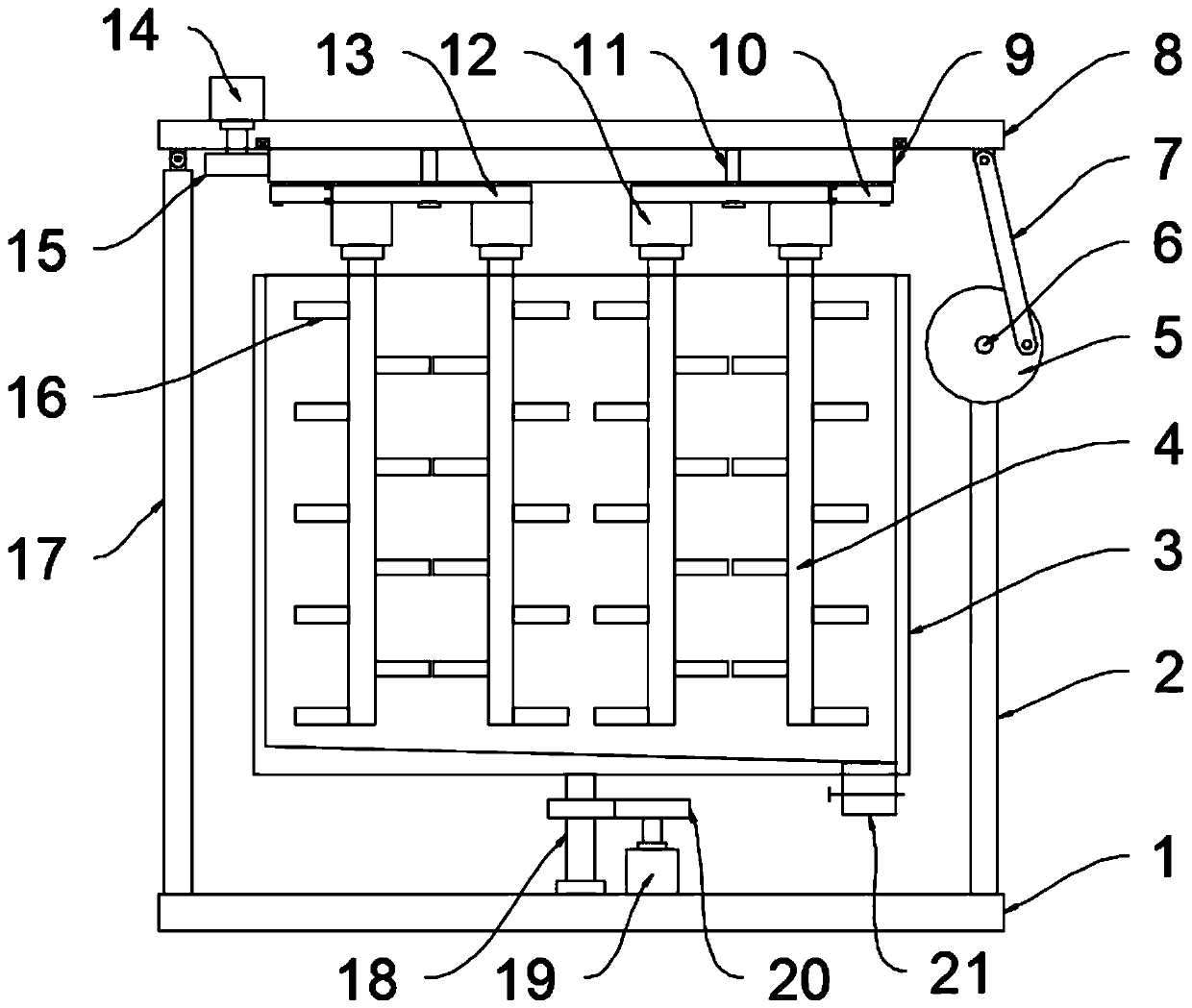

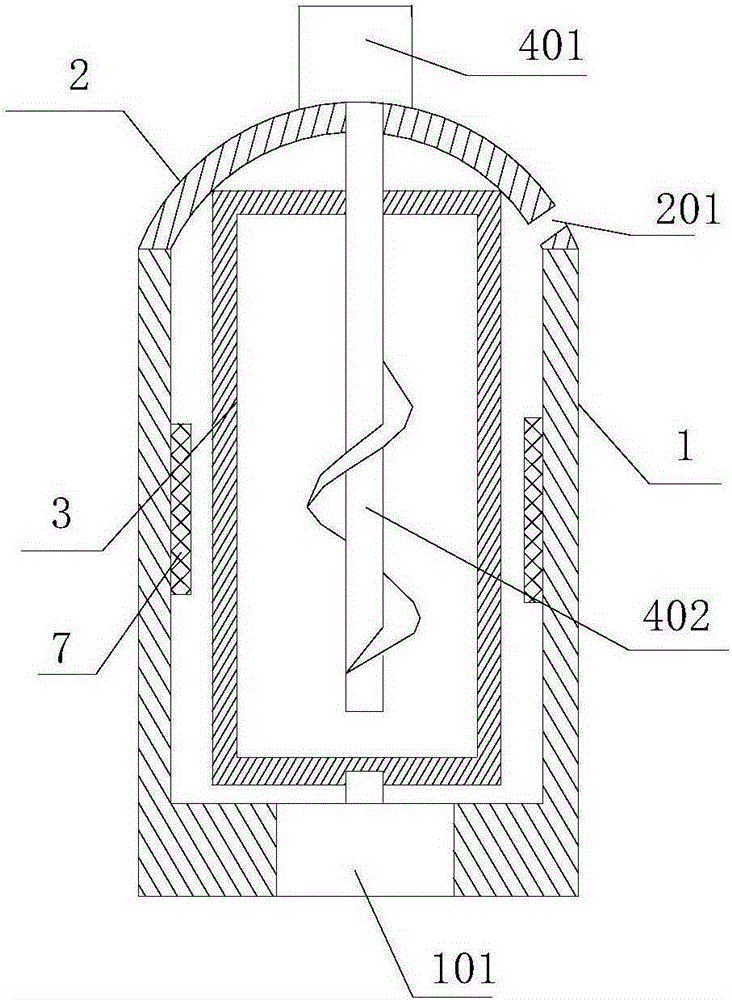

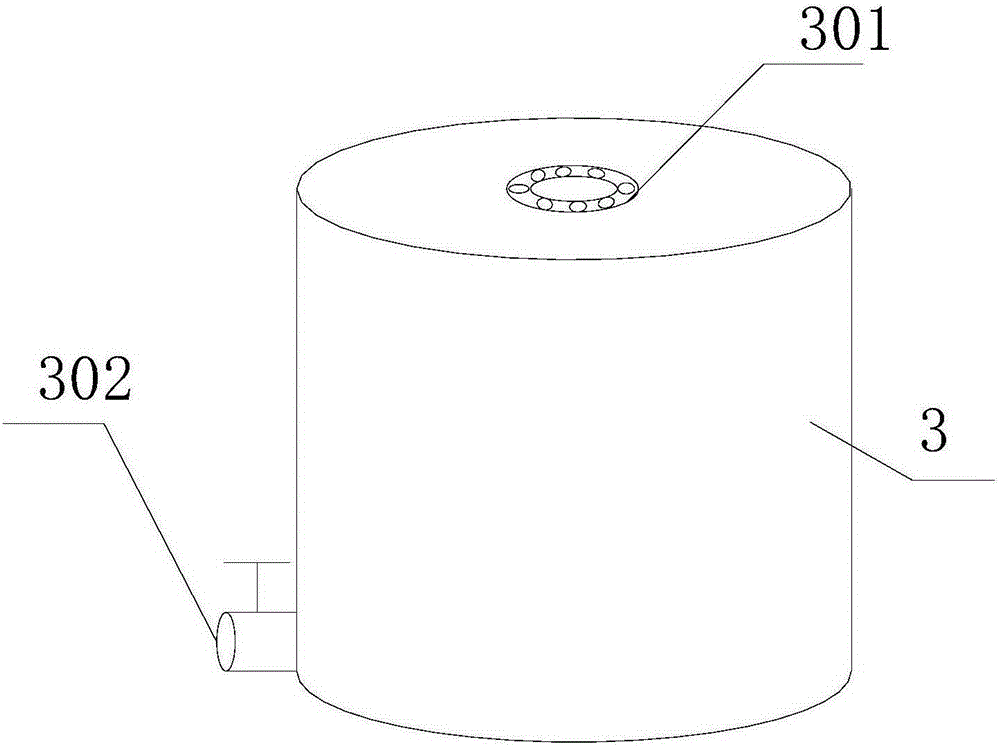

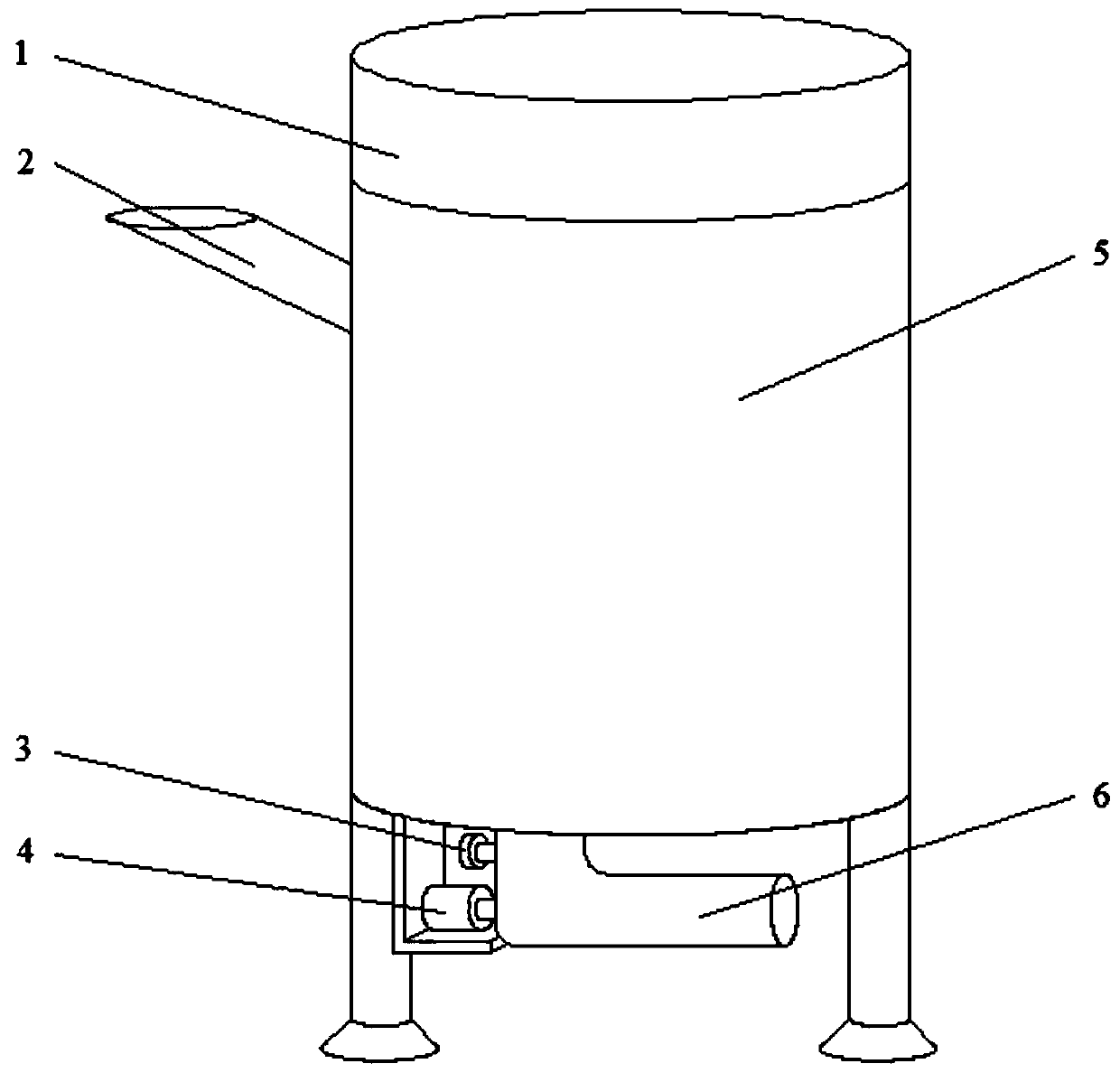

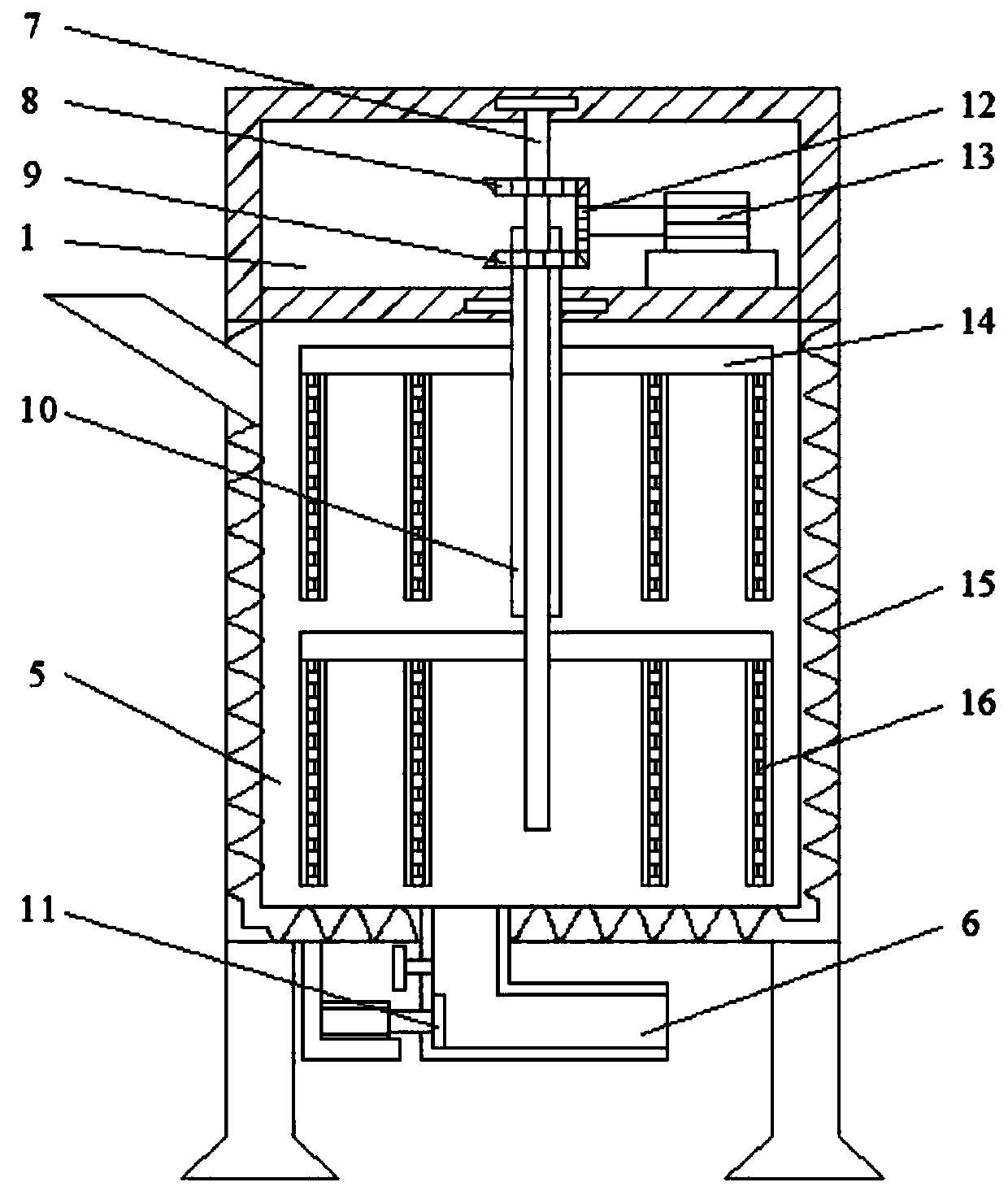

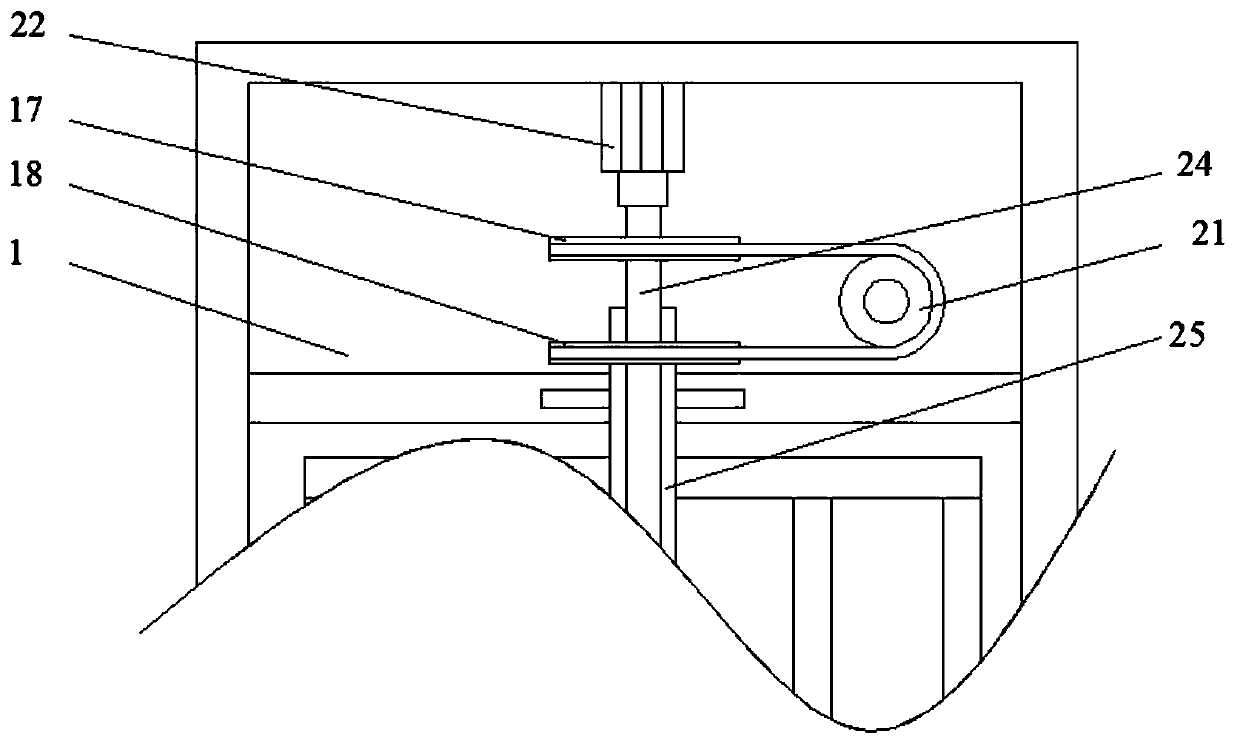

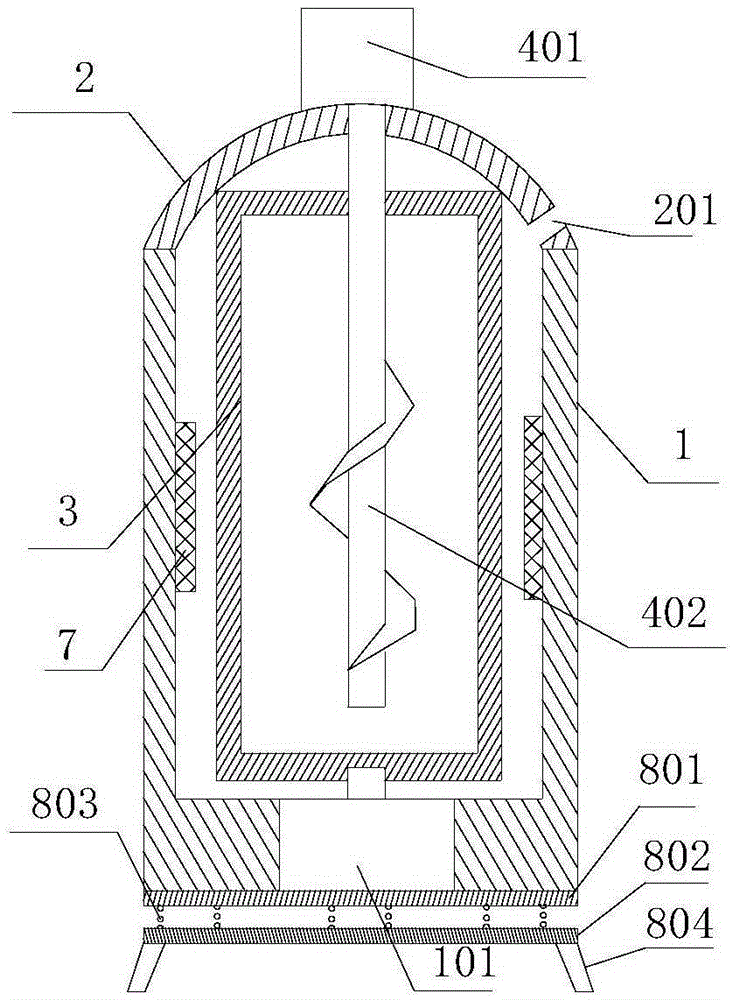

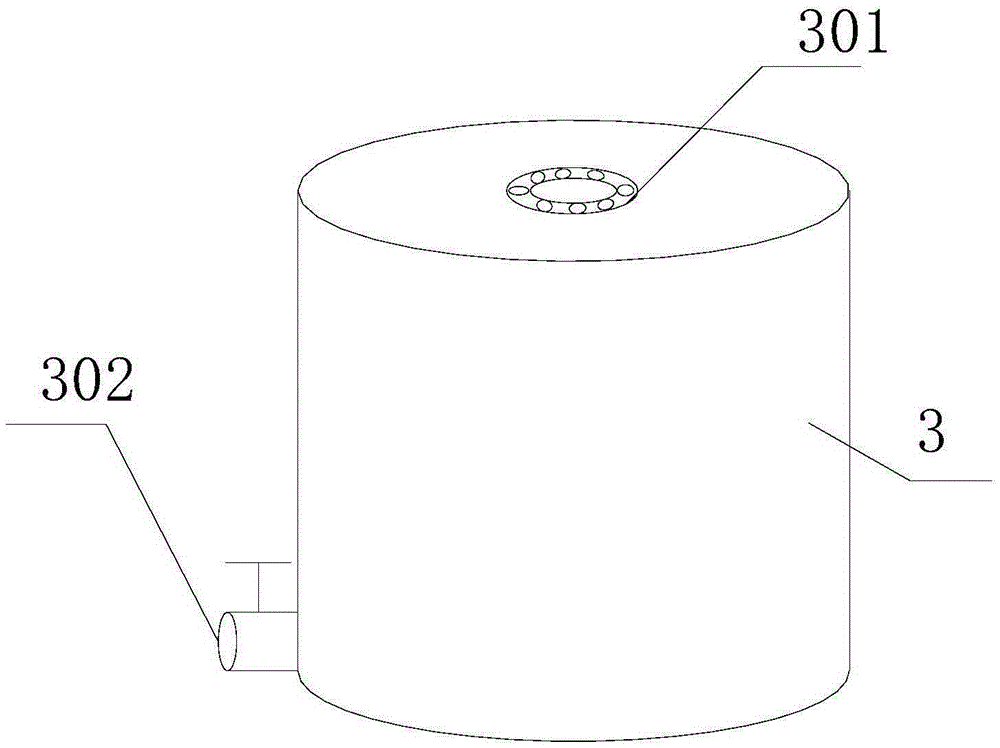

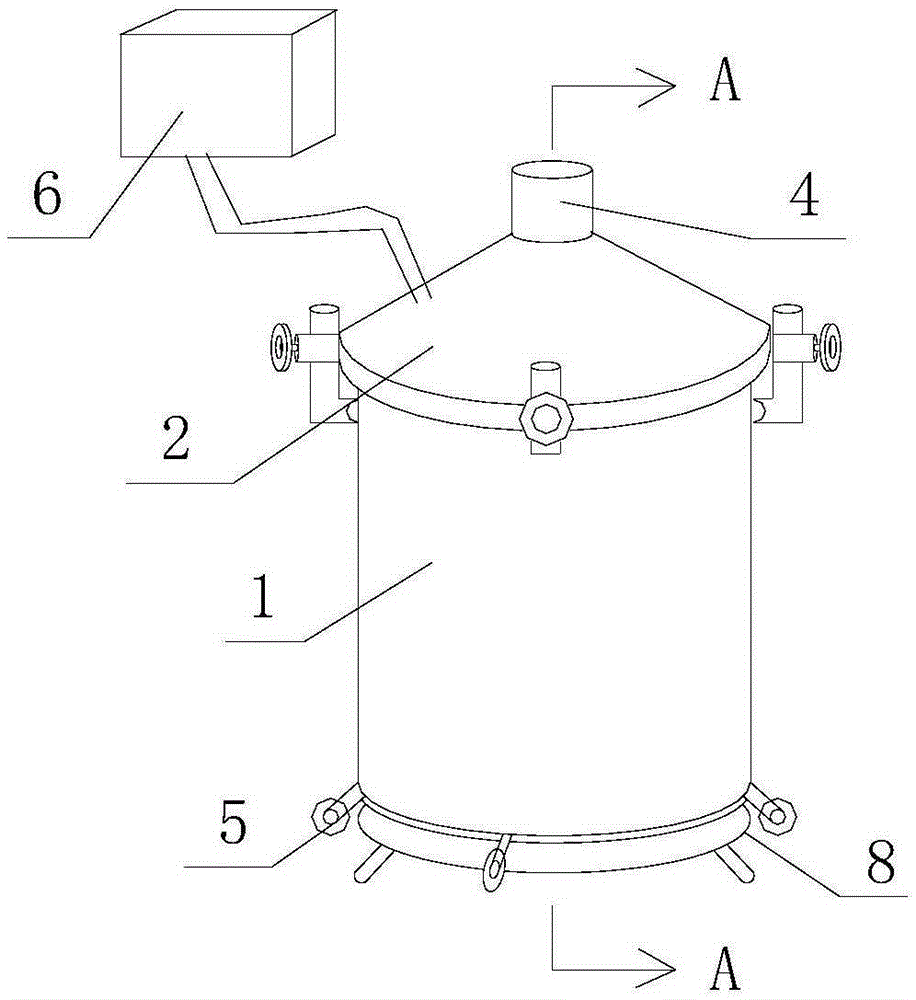

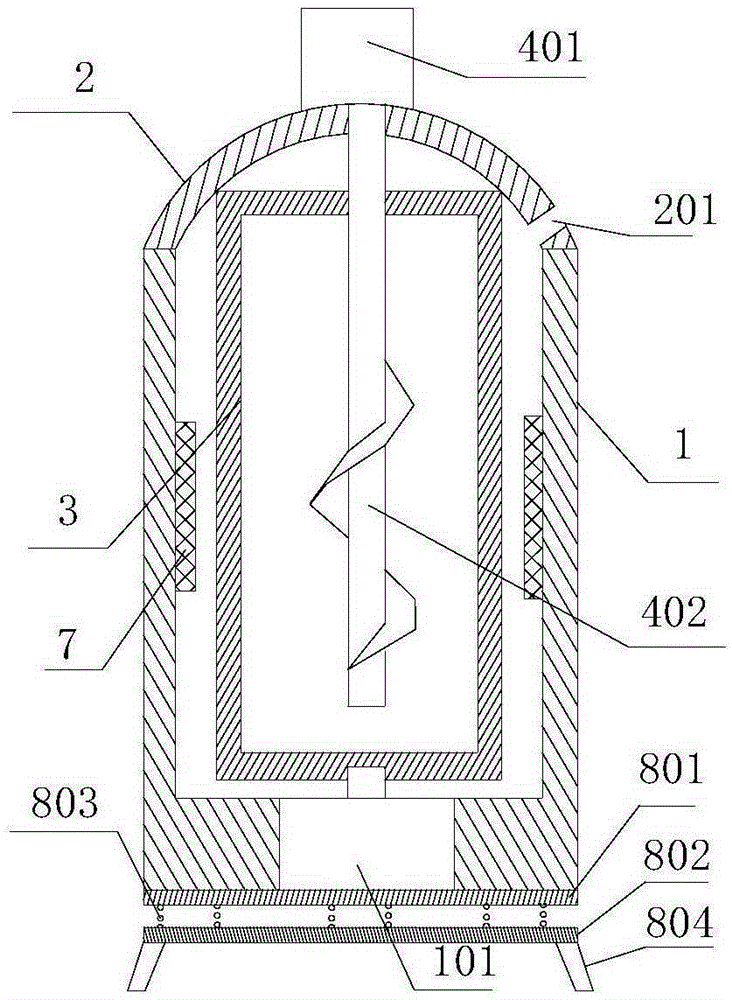

Reaction kettle with stirring arms capable of swinging

InactiveCN102962024ASpeed up the mixingLarge stirring rangeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsPush pullMixing effect

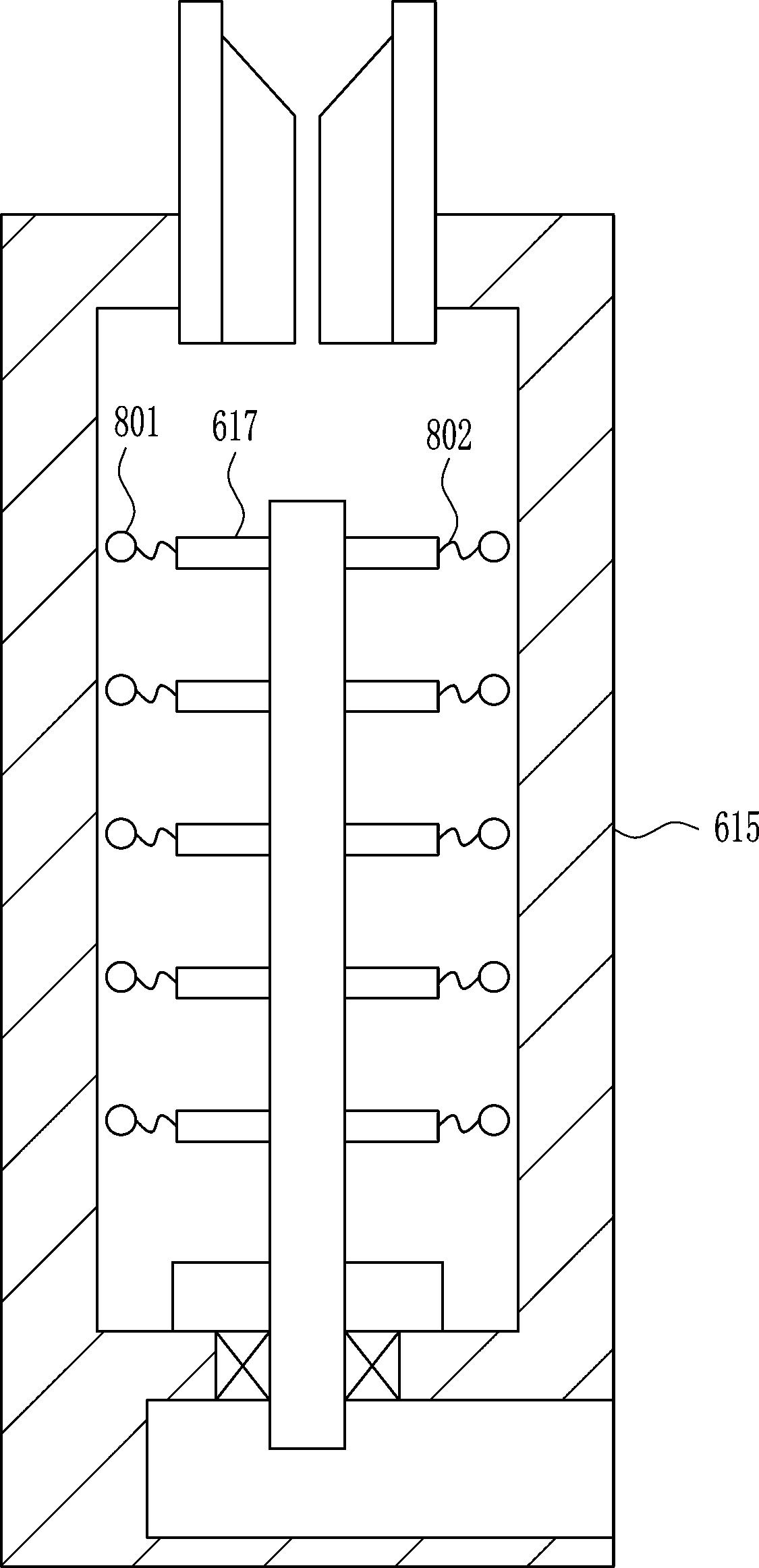

The invention discloses a reaction kettle with stirring arms capable of swinging. The reaction kettle comprises a kettle body and a stirring shaft, wherein the top of the kettle body is provided with a material inlet; the bottom of the kettle body is provided with a material outlet; the stirring shaft is rotatably connected on the top wall of the kettle body and divided into a kettle inside section and a kettle outside section; the kettle outside section of the stirring shaft is in power connection with a power device arranged at the top of the kettle body; the stirring shaft is provided with an axial through cavity; the kettle inside section of the stirring shaft is provided with an installation groove; the wall of the installation groove is hinged with a plurality of stirring arms which are arranged at intervals from top to bottom; the outer end of each stirring arm extends to the side wall of the kettle body and the inner end of each stirring arm is hinged with a pull rod which is slidably connected in the through cavity; the upper end of the pull rod extends out of the through cavity; and the extending end of the pull rod is in power connection with a push-pull device arranged at the top of the kettle body so as to realize up and down swinging of the stirring arms. The reaction kettle has the advantages of high speed of mixing liquid to uniform and excellent mixing effect and brings about the benefits of shortening the reaction time and improving the production efficiency.

Owner:SHANDONG TIANWEI MEMBRANE TECH

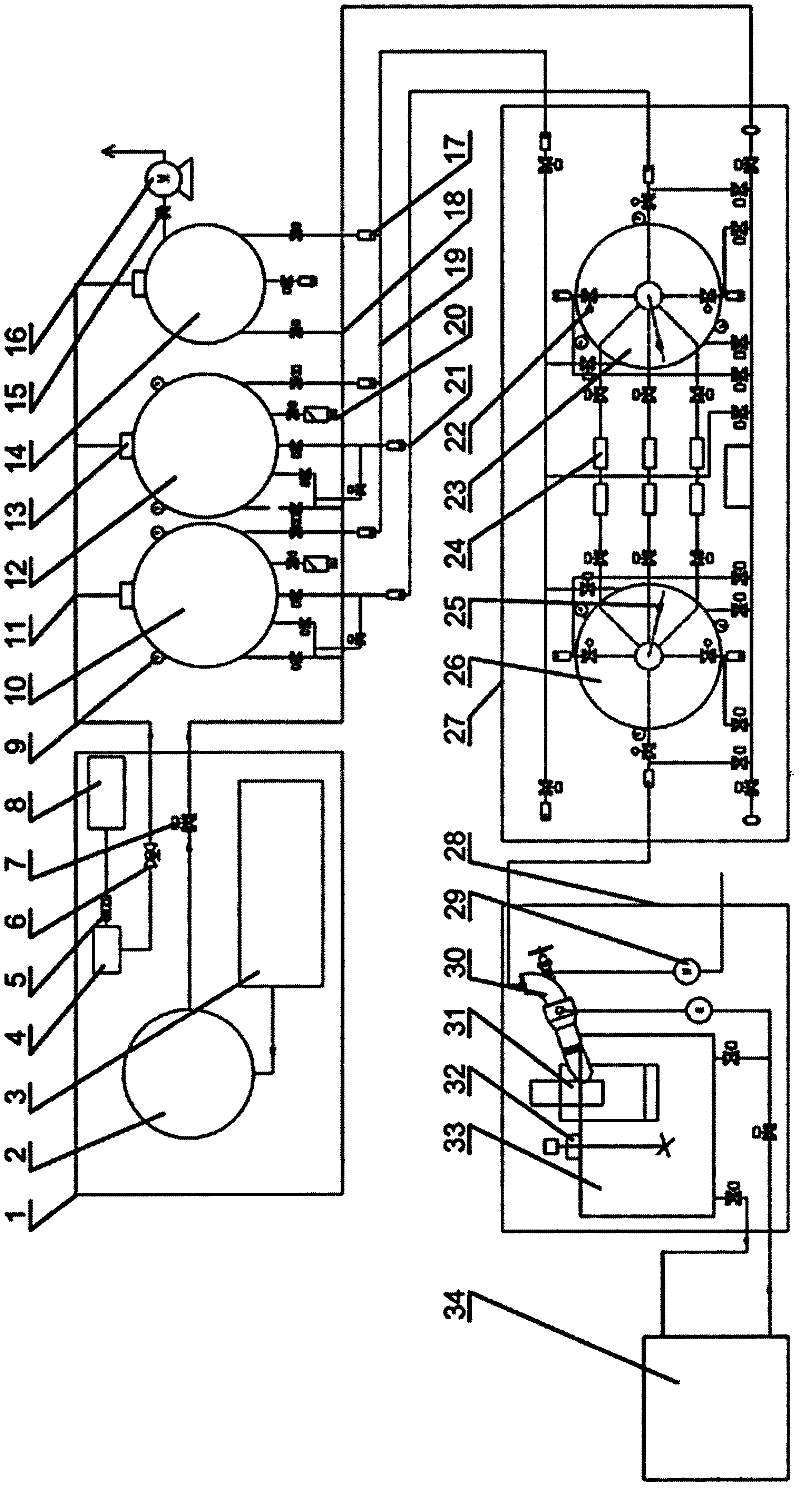

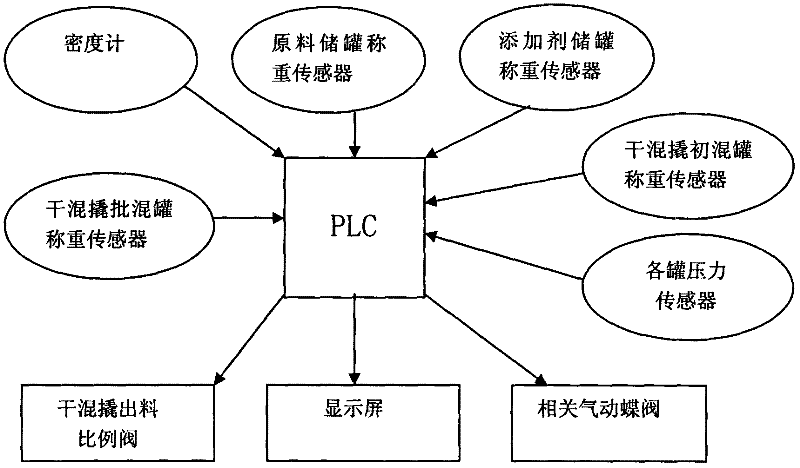

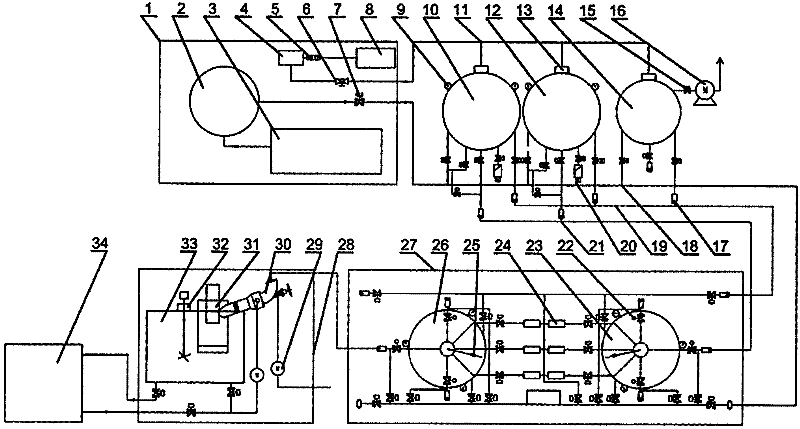

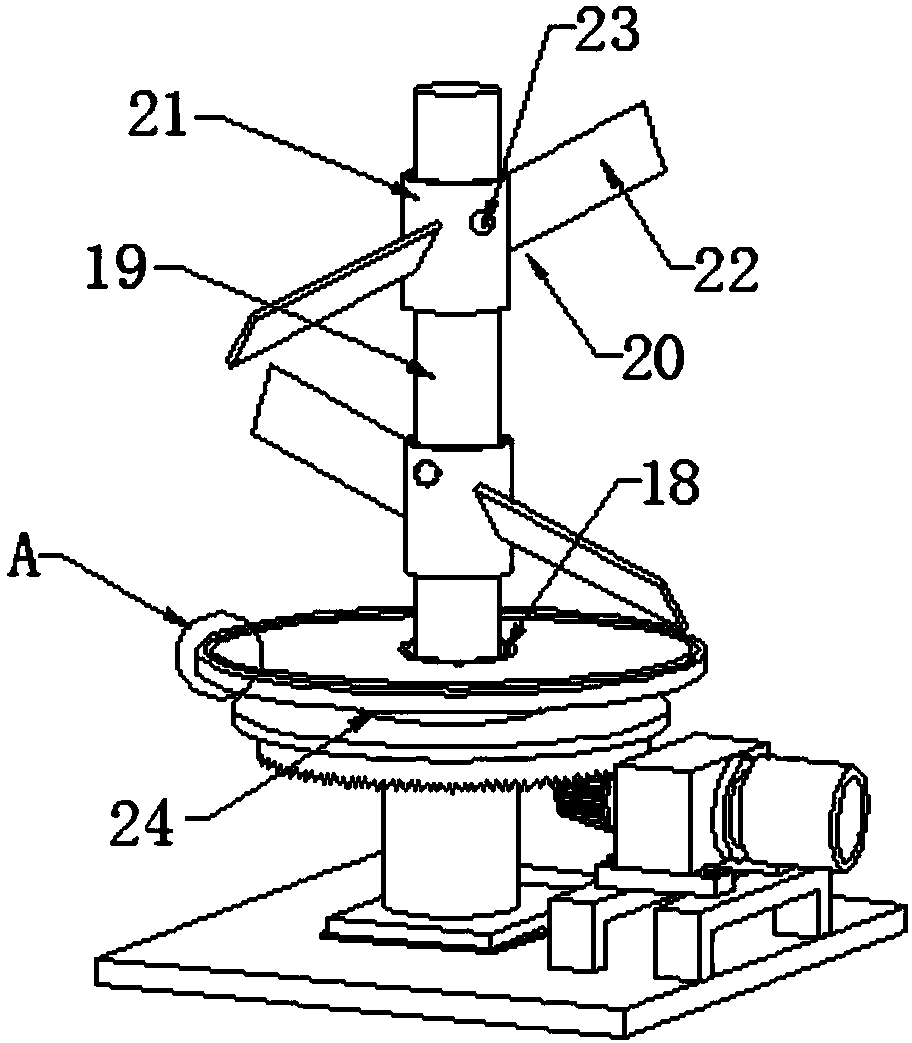

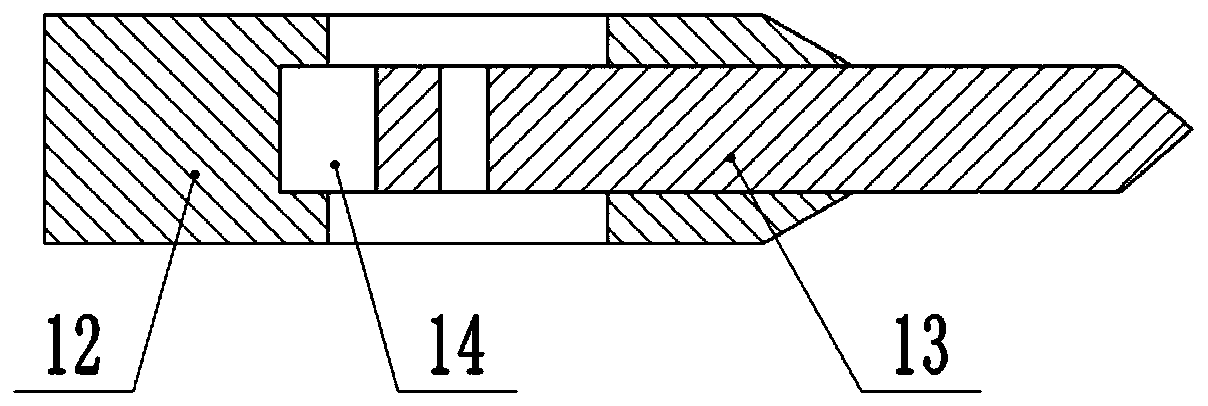

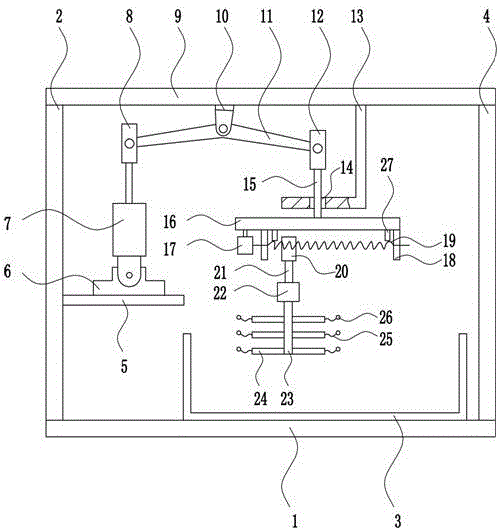

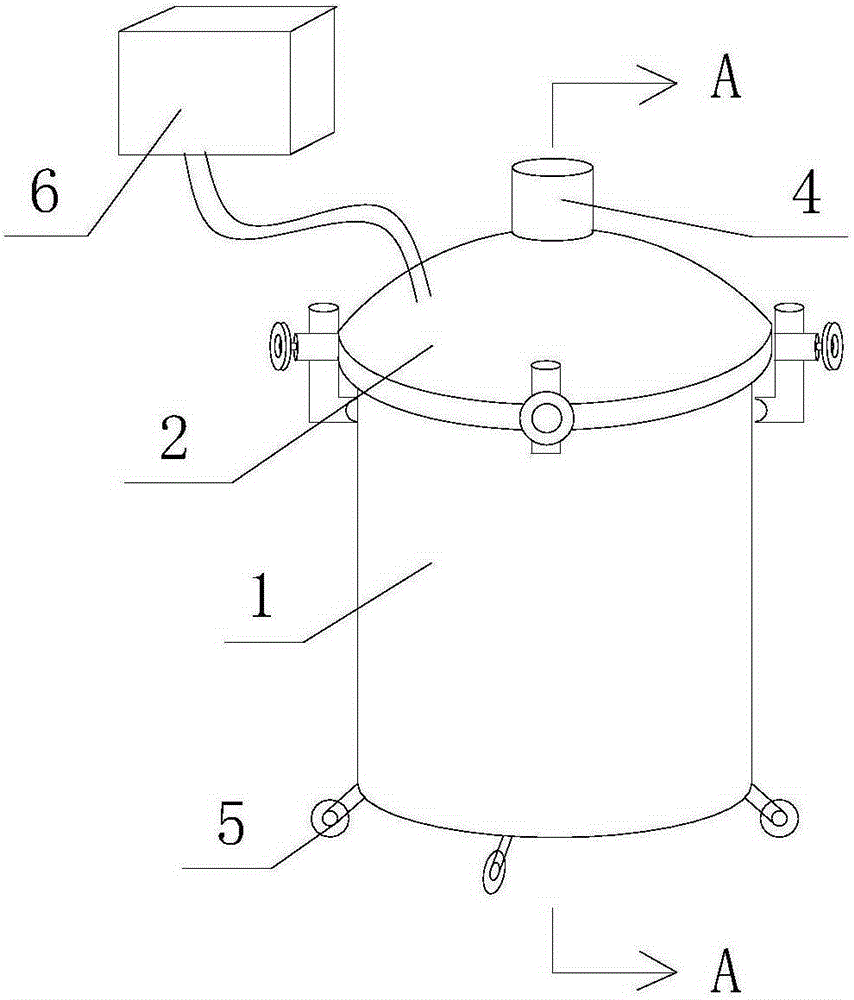

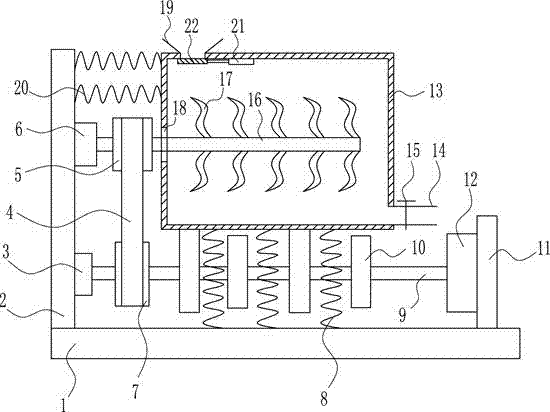

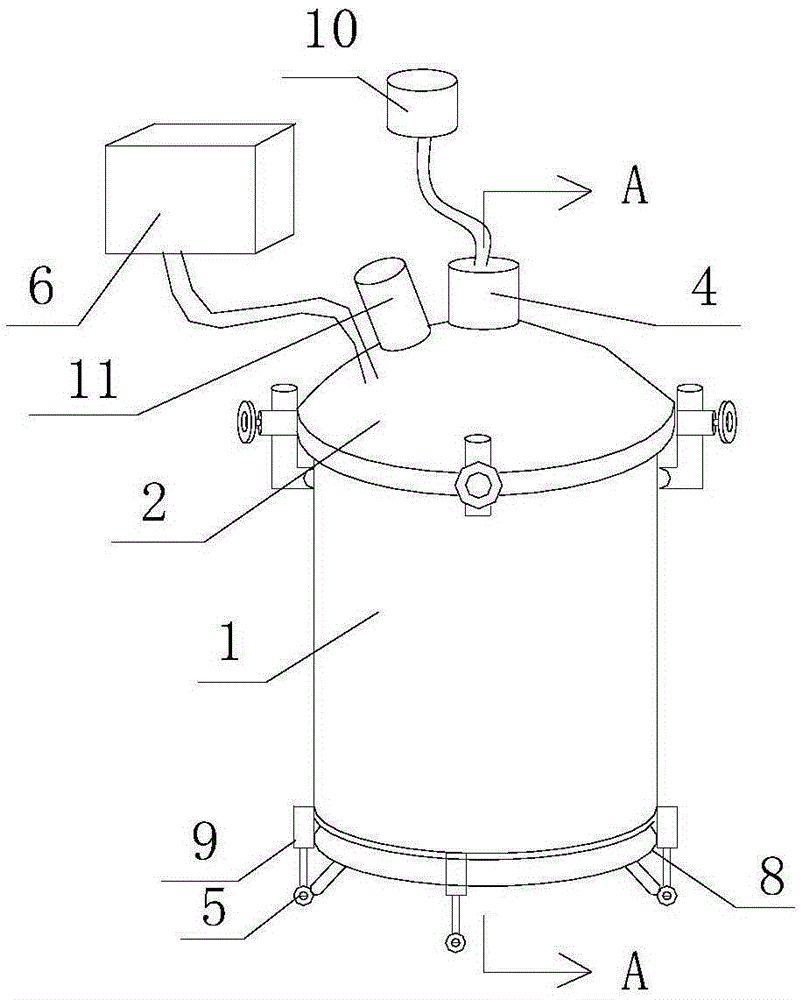

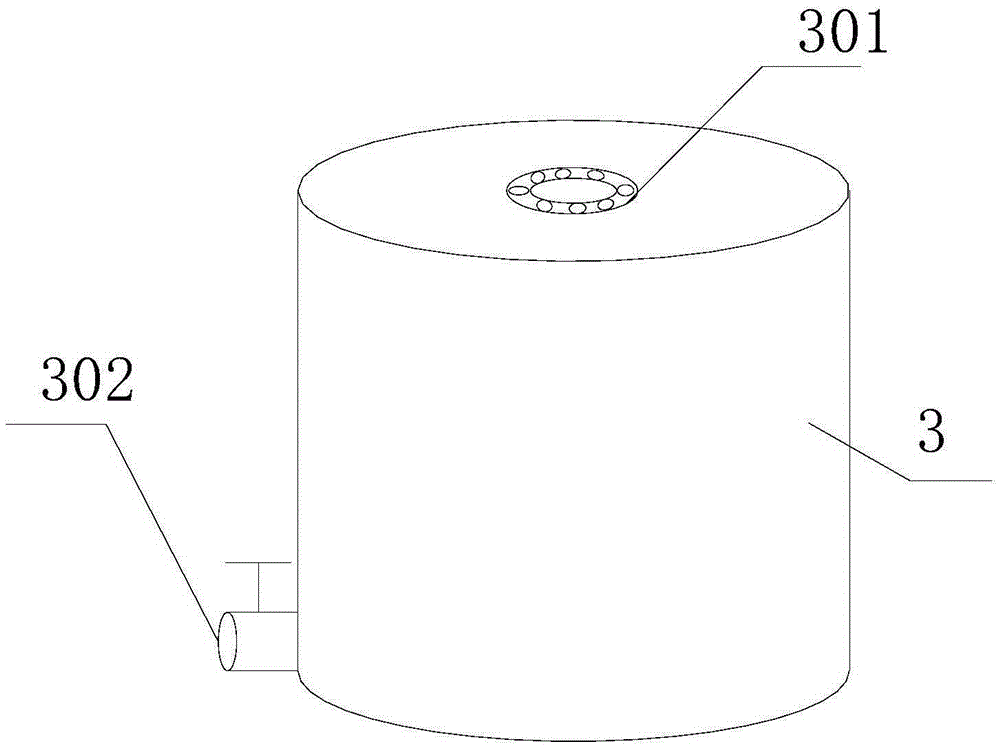

System for automatically and quickly distributing drilling liquid

InactiveCN102418484ASolve precise measurementSolve densityConstructionsMixer accessoriesAutomatic controlHigh energy

The invention discloses a system for automatically and quickly distributing drilling liquid. The system comprises a programmable logic controller (PLC) automatic control system, an air source system, a storage system, a dry mixing system and a slurry mixing system; the air source system comprises an air storage tank, a large-scale air compressor, a dry cooling machine, a small-scale air compressor and an air supply pipeline which are uniformly distributed on a forced draught fan package; the storage system comprises a raw material storage tank, an additive storage tank, a dust removal tank, weighing sensors which are arranged at bottoms of the raw material storage tank and the additive storage tank, a raw material gas conveying pipeline and a dust removal pipeline; the dry mixing system comprises a primary mixing tank and a batch mixing tank which are arranged on a dry mixing package, weighing sensors which are arranged at bottoms of the primary mixing tank and the batch mixing tank, a primary mixing pipeline, a batch mixing pipeline, and a primary mixing tank and batch mixing tank mixing circulation pipeline; and the slurry mixing system comprises a stirring pool, a stirrer which is arranged on the middle part of the stirring pool, a diffusion groove which is formed on one side of the stirrer, a high-energy mixer which is arranged on the upper part of the diffusion groove, a slurry mixing pipeline, a slurry conveying pipeline and a densitometer which is arranged on the slurry conveying pipeline; and all the systems are matched to realize automatic slurry distribution.

Owner:山东胜油固井工程技术有限公司

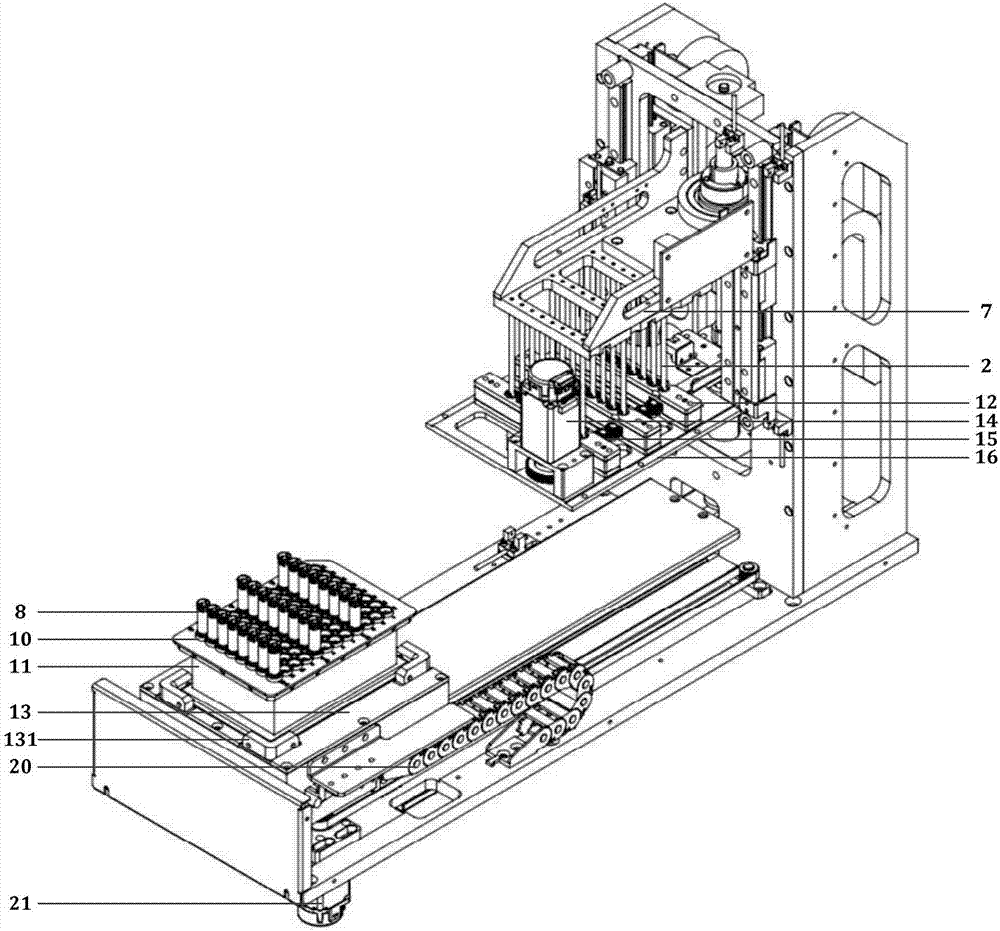

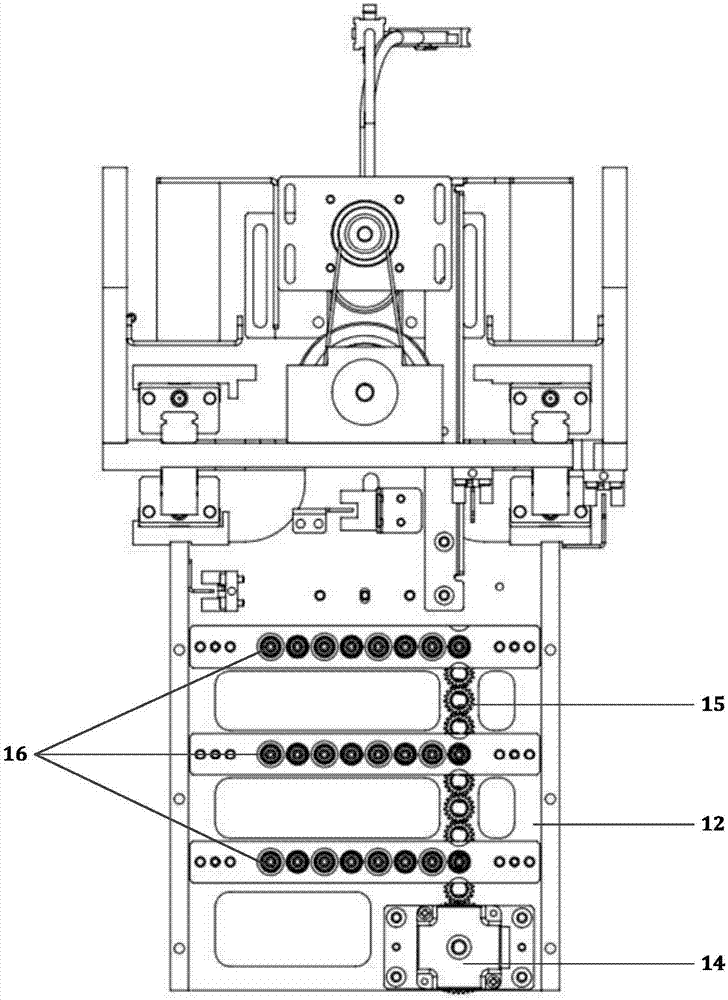

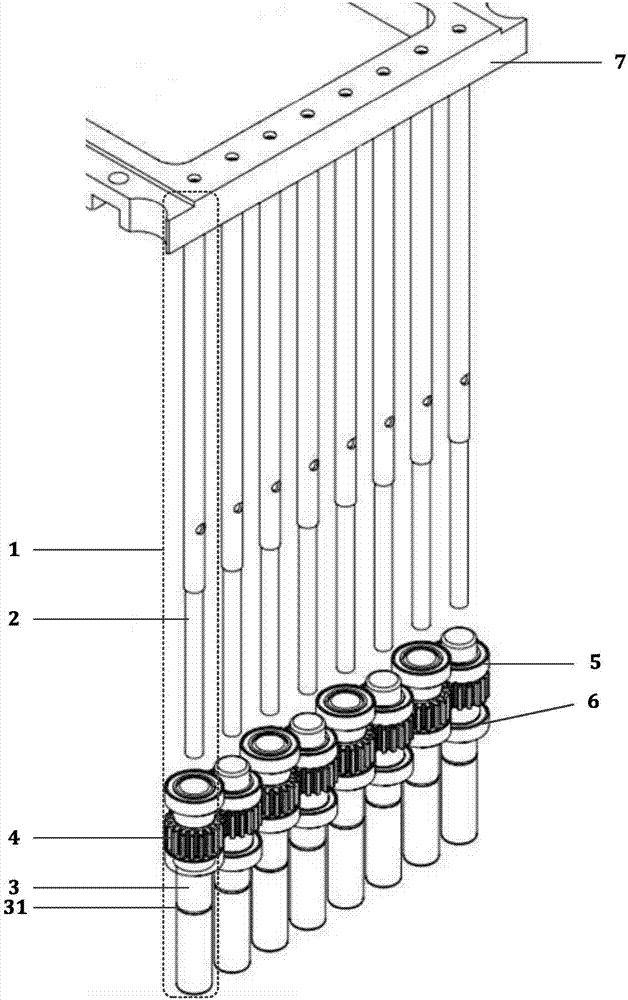

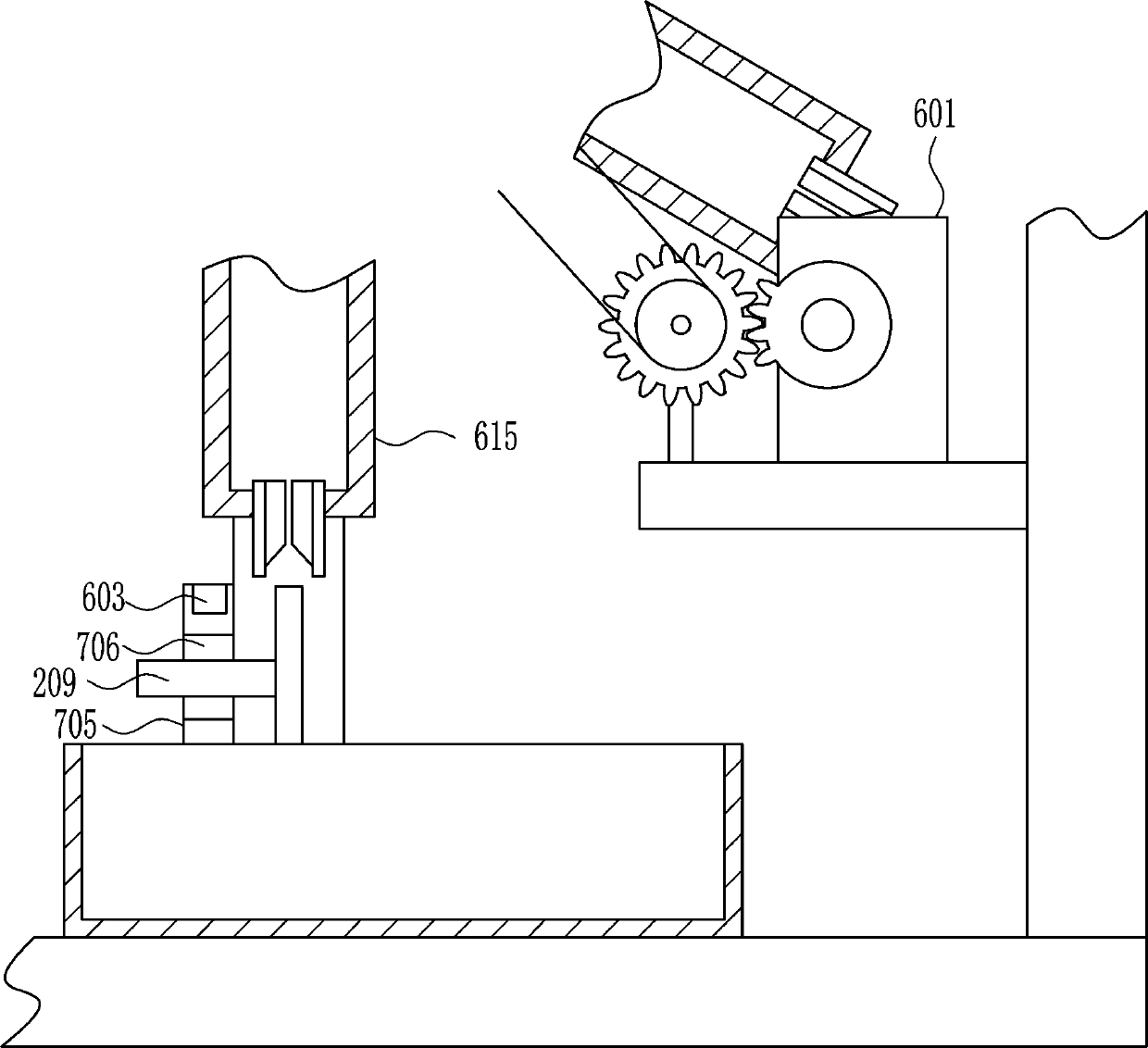

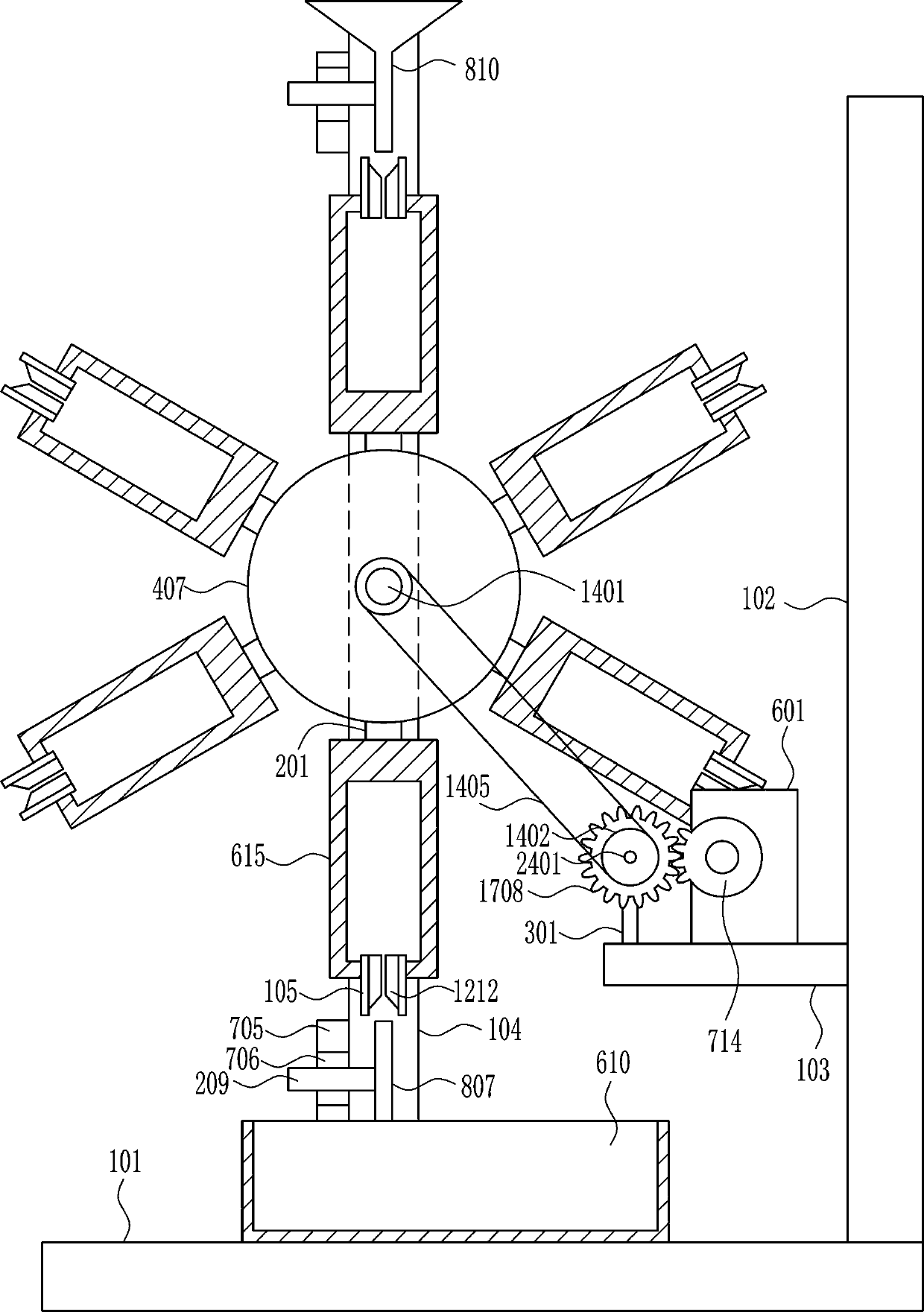

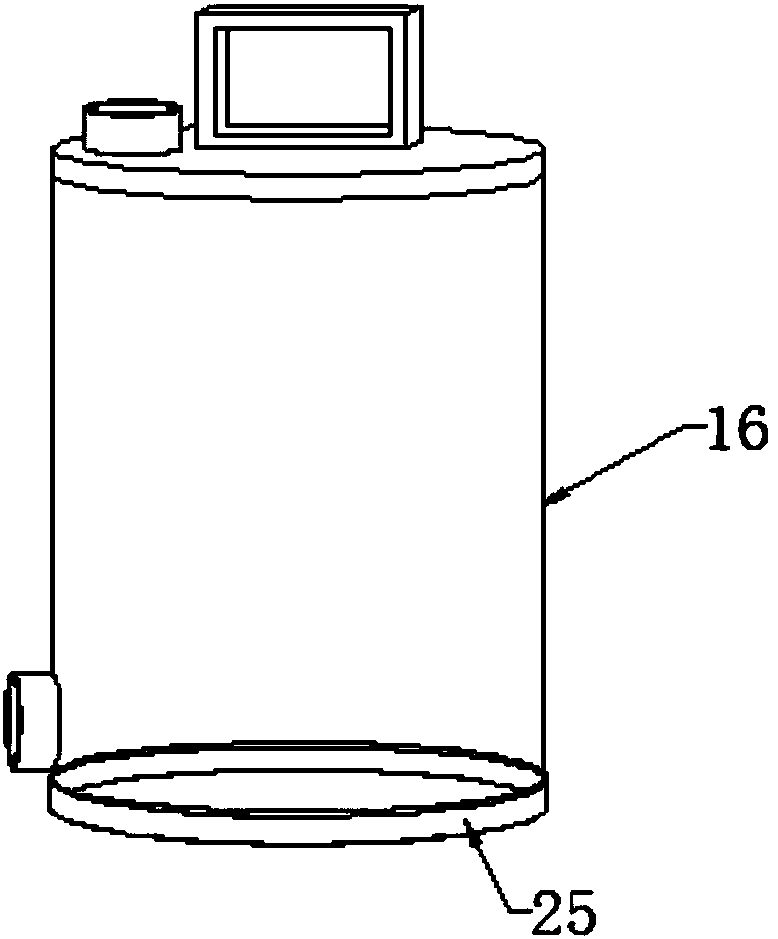

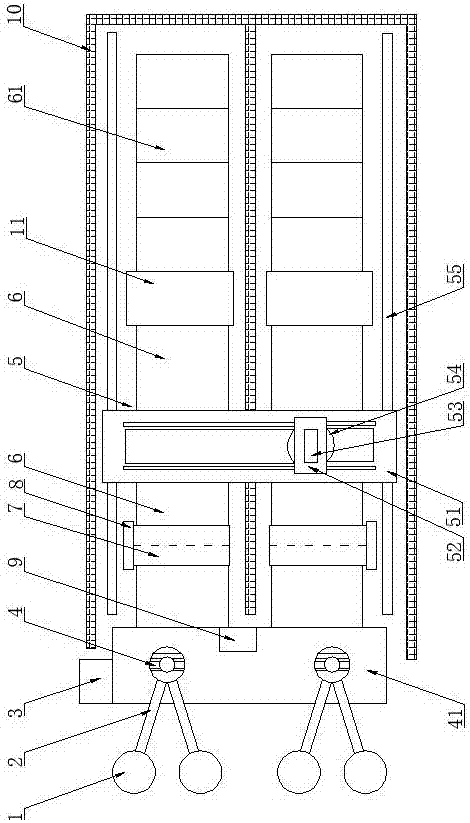

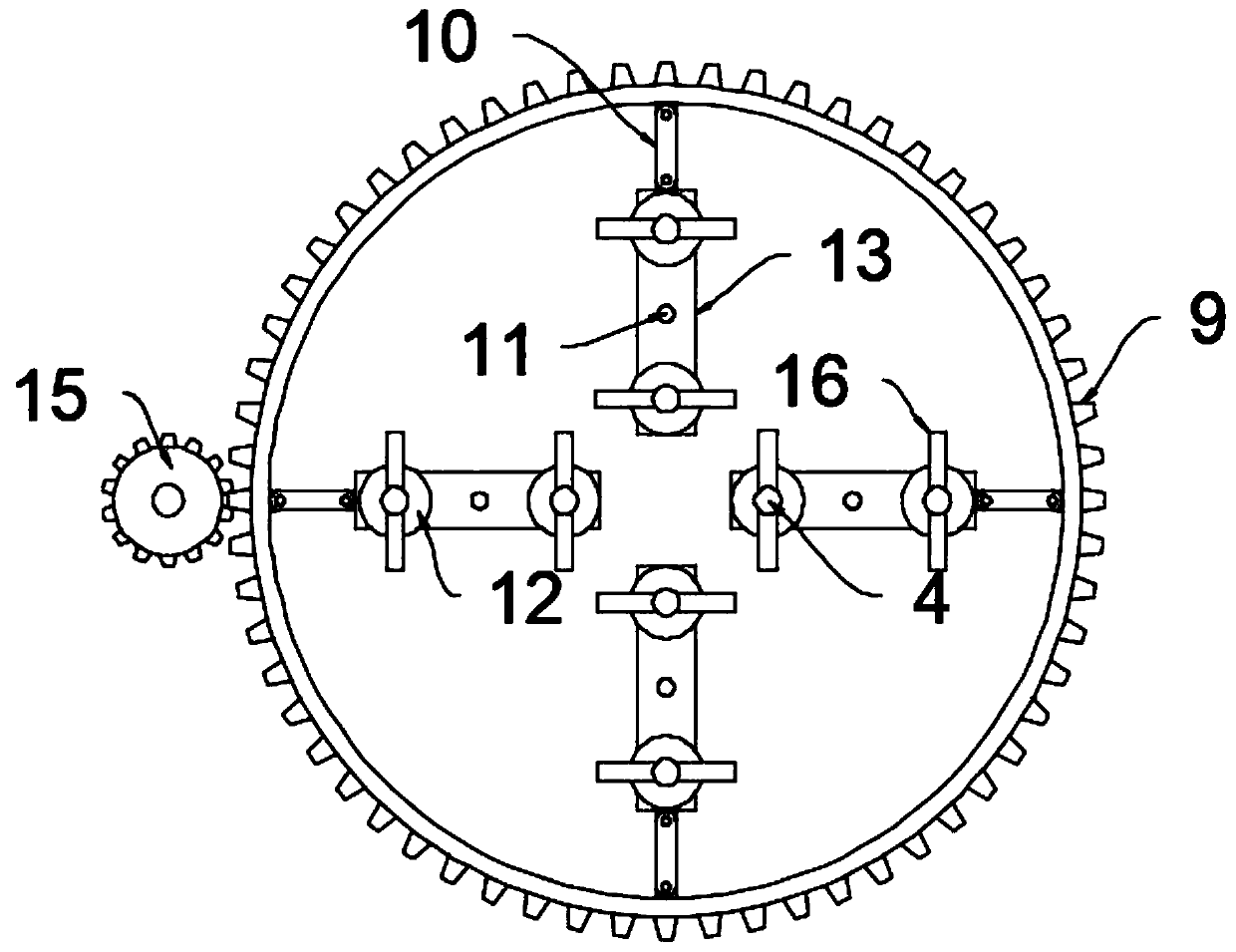

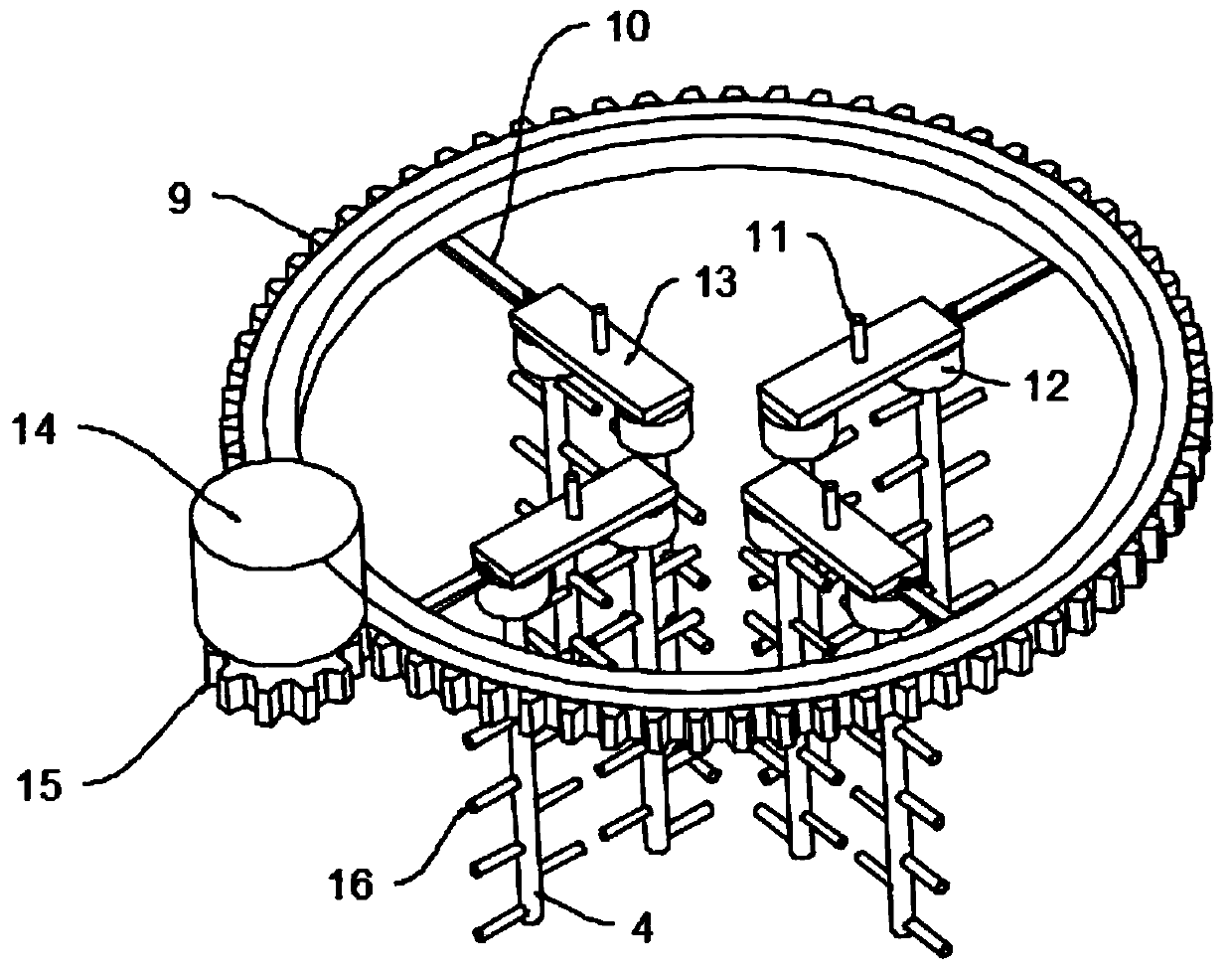

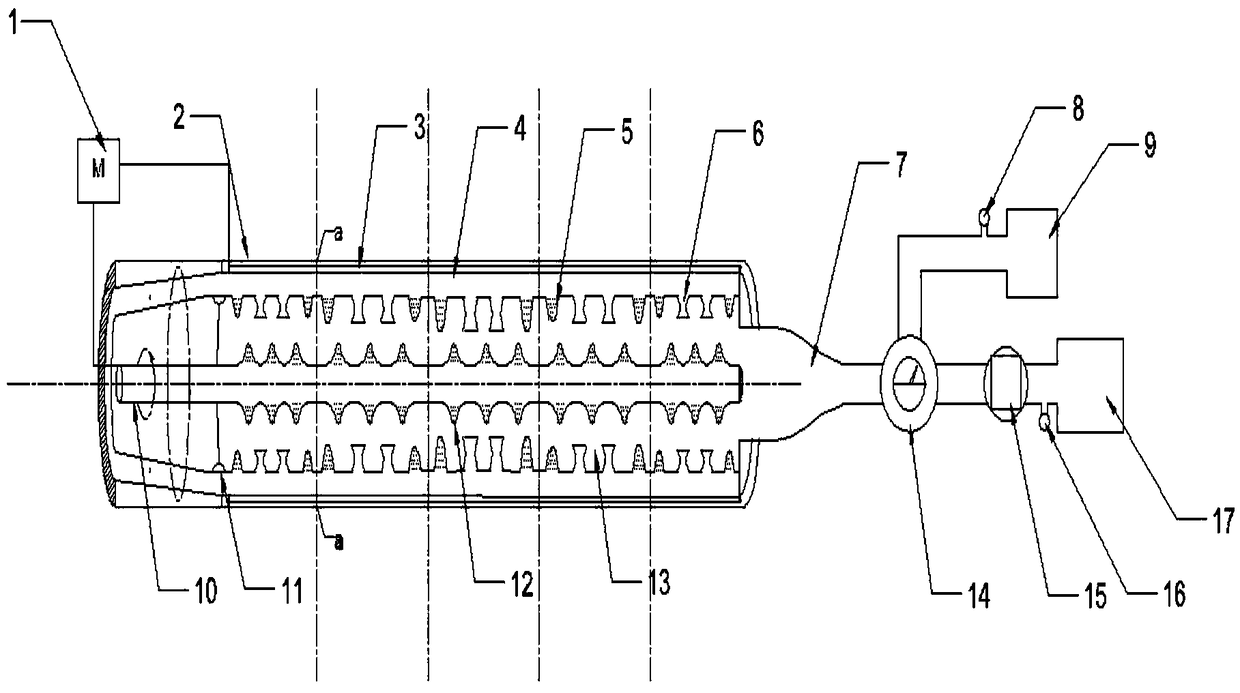

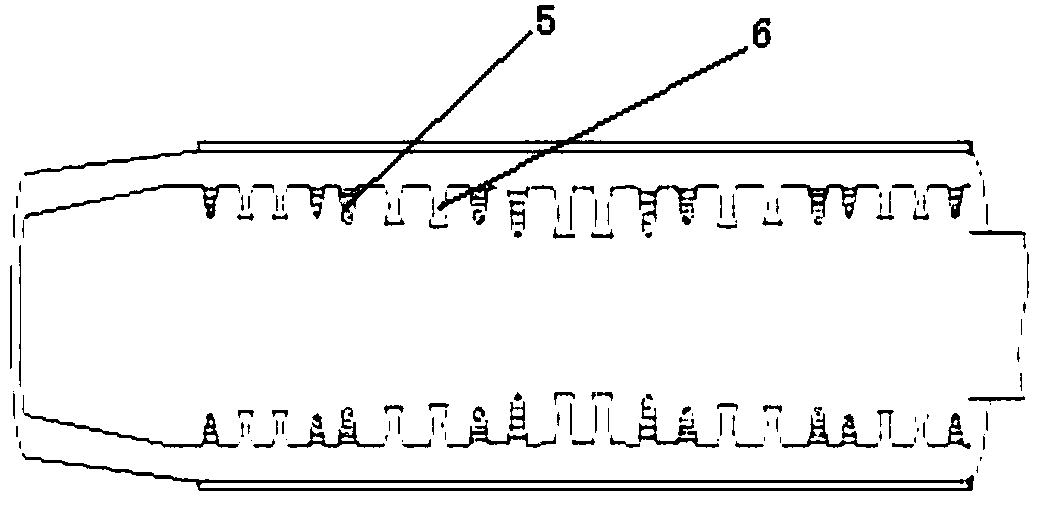

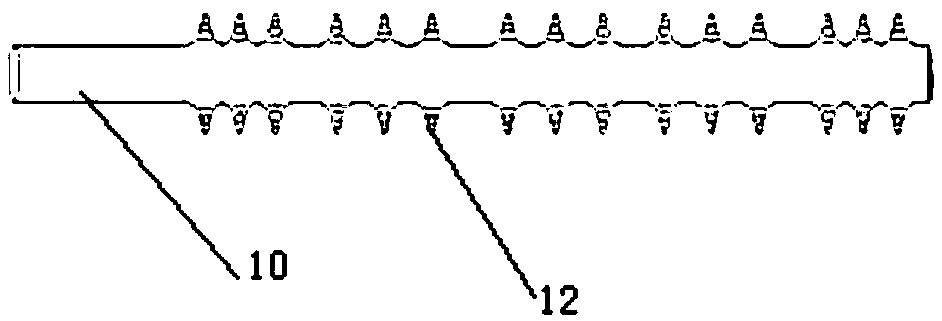

Rotary type nucleic acid extraction device and control method thereof

ActiveCN107058062AIncrease mixing speedImprove the mixing effectBioreactor/fermenter combinationsBiological substance pretreatmentsContamination rateEngineering

The invention discloses a rotary type nucleic acid extraction device and a control method thereof. The device comprises a multiflux extraction device, a plurality of extraction consumable components, a vertical device which is connected with the multiflux extraction device and a horizontal device which is connected with the extraction consumable components, wherein the multiflux extraction device adopts a rotary mode to mix samples and required extraction reagents uniformly, and the device can provide external force such as magnetic drawing, mixing and heating which is required by nucleic acid extraction and coordinate with a motion in a vertical and / or horizontal direction at the same time, so that the whole process of the nucleic acid extraction is achieved. According to the device, the blending efficiency of the samples and the required extraction reagents is improved, the cross contamination rate between extraction holes is lowered, and the length and the integrity degree of nucleic acid fragments in extraction product are guaranteed.

Owner:苏州天隆生物科技有限公司

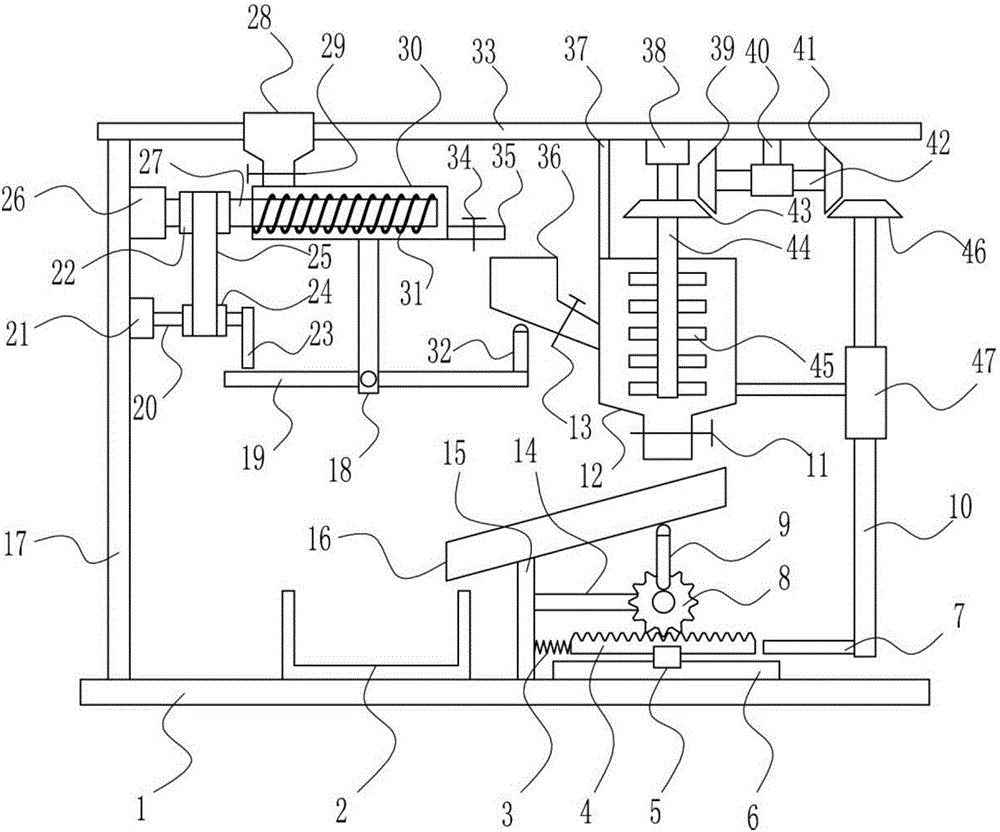

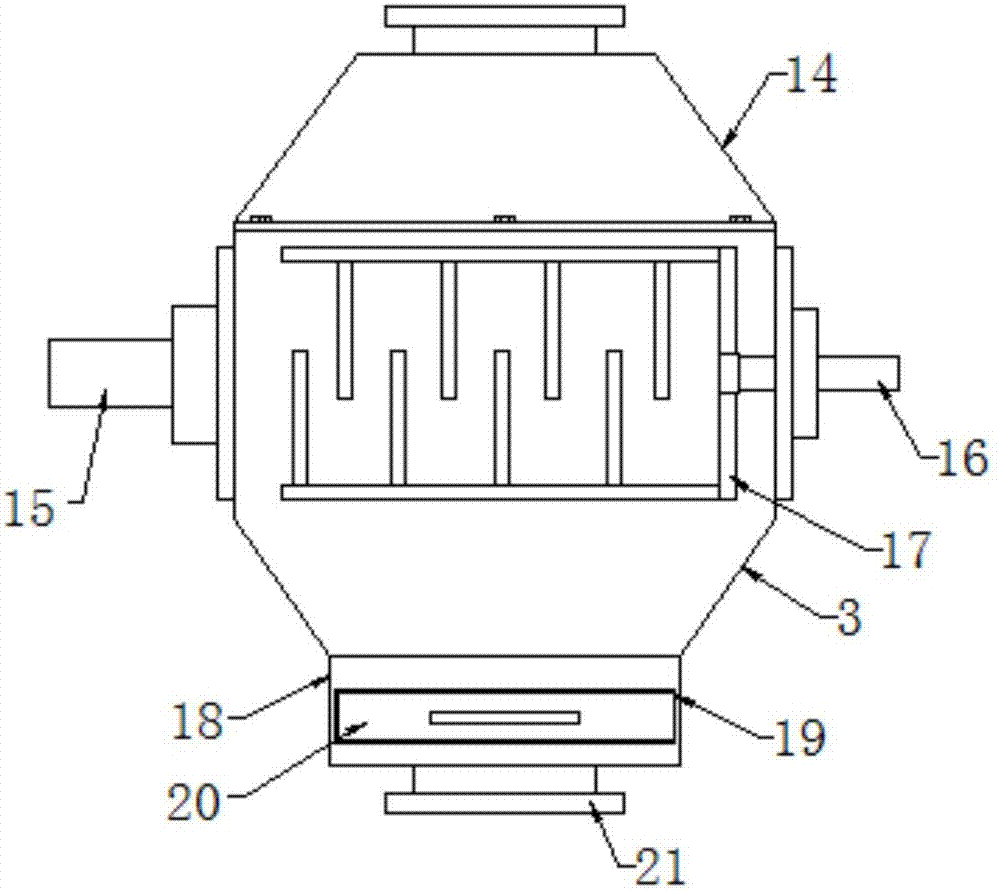

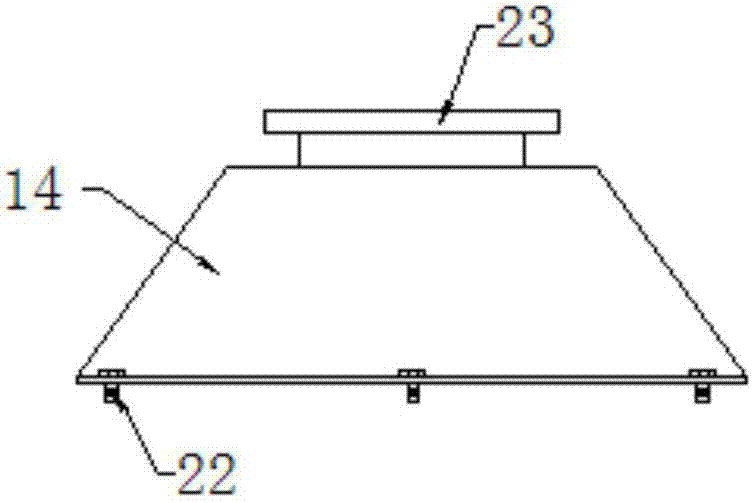

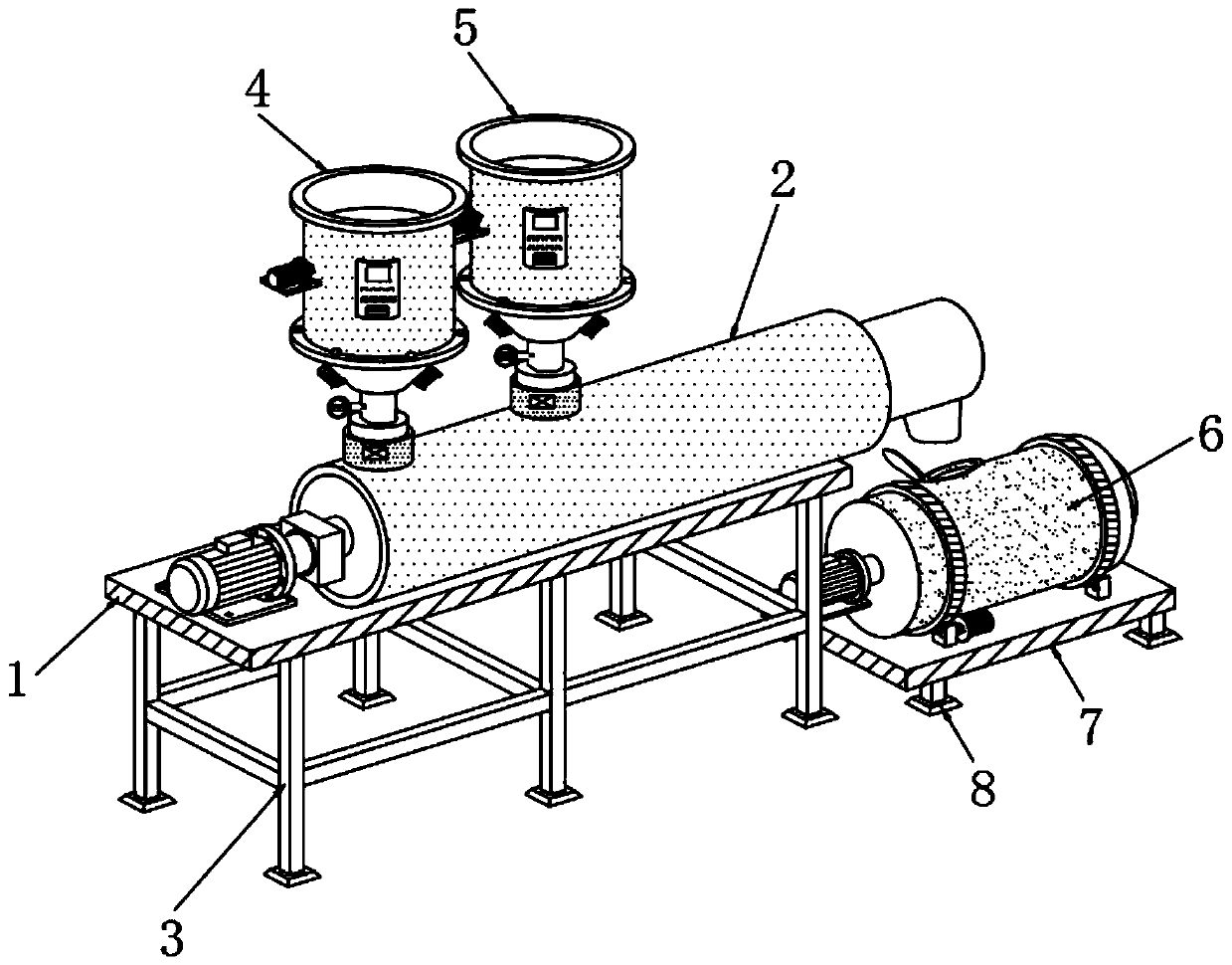

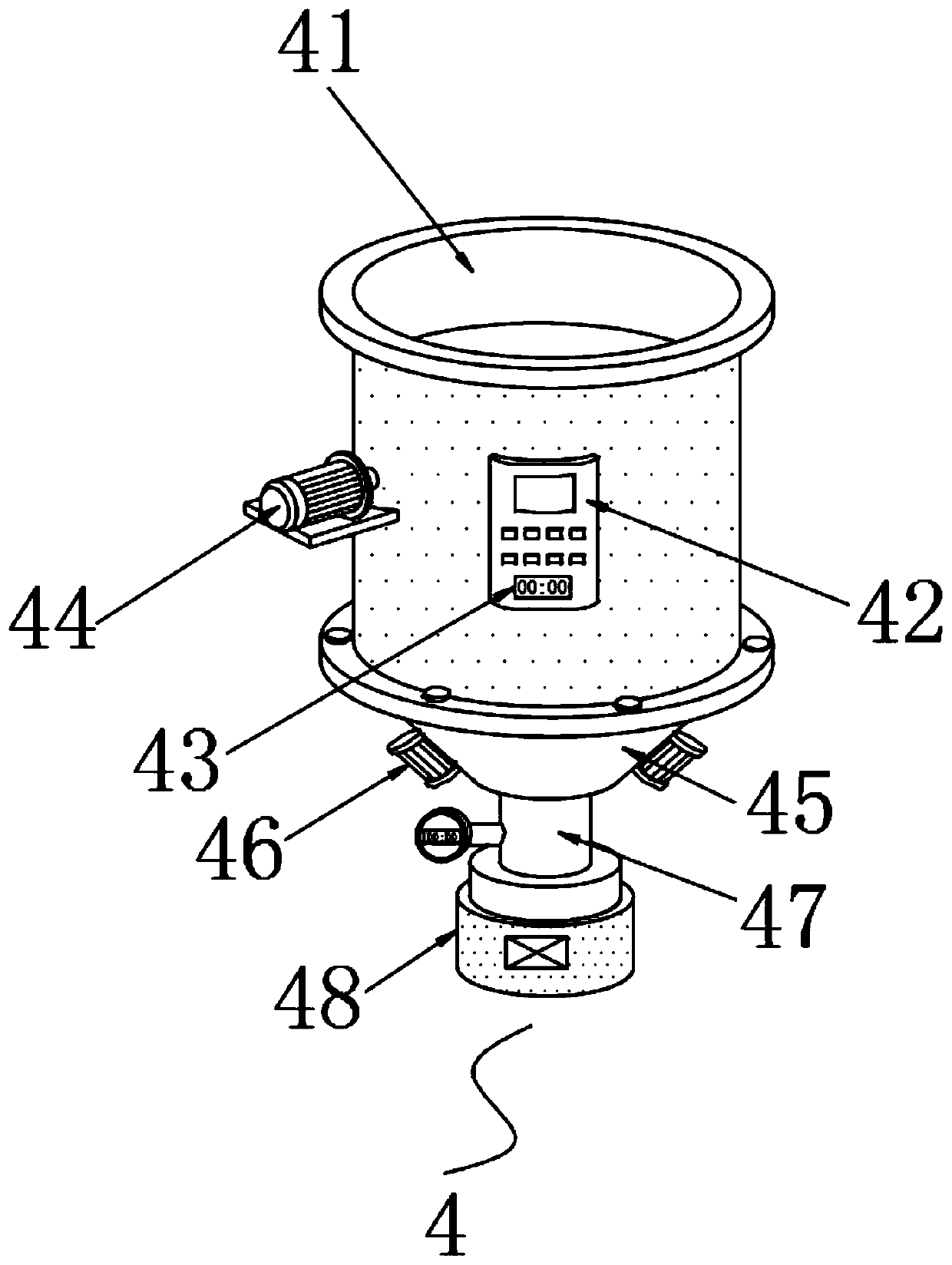

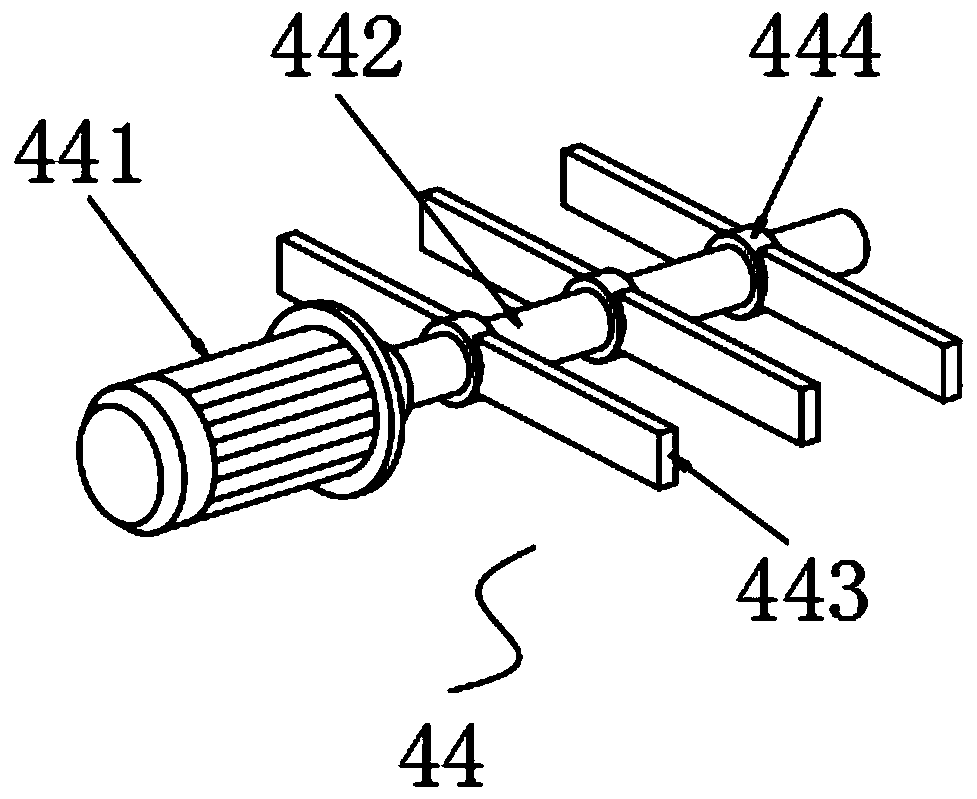

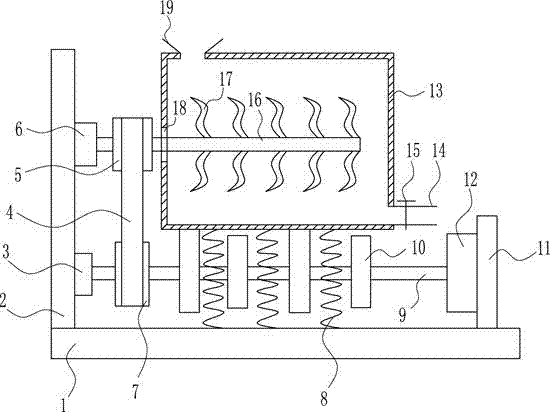

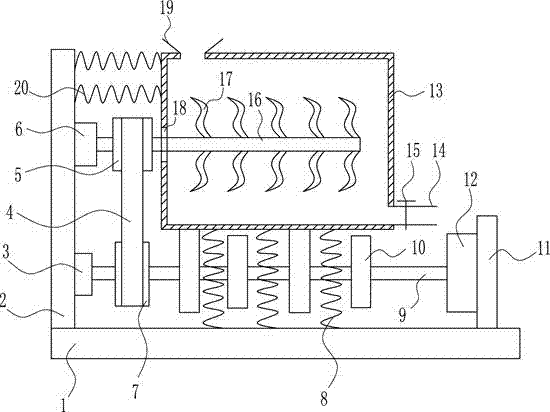

High-efficient mixing device for feed production of animal husbandry

InactiveCN107259620AWell mixedImprove mixing efficiencyShaking/oscillating/vibrating mixersFeeding-stuffEngineeringAnimal husbandry

The invention discloses a high-efficient mixing device for feed production of animal husbandry. The high-efficient mixing device comprises a bottom plate, a mixing frame, a rotating shaft, a first gear, a first rack, a first connecting rod, a second connecting rod, a motor, a knocking device, a moving cam, a second spring, a second support plate, a roller, a vertical rod, a spacing plate, third springs, a stirring shaft, stirring rods and a transmission mechanism. The high-efficient mixing device is provided with the first connecting rod, the second connecting rod, the first rack, the first gear and the knocking device, and the mixing frame is knocked unceasingly while the mixing frame is driven to rotate, so that feeds are mixed uniformly, and the stirring and mixing efficiency is improved; the moving cam, the second spring, the third springs, the vertical rod, the stirring shaft and the transmission mechanism are arranged, the stirring rods are driven by the moving cam, the second spring, the third springs, the vertical rod, the stirring shaft and the transmission mechanism to rotate, and the rotating direction of the stirring rods is opposite to that of the mixing frame, so that the stirring and mixing speed is high, and the stirring and mixing efficiency is further improved; and besides, the stirring rods are driven to move up and down, so that the stirring is thorough and uniform, and the stirring and mixing efficiency is further improved.

Owner:银川金帮手信息科技有限公司

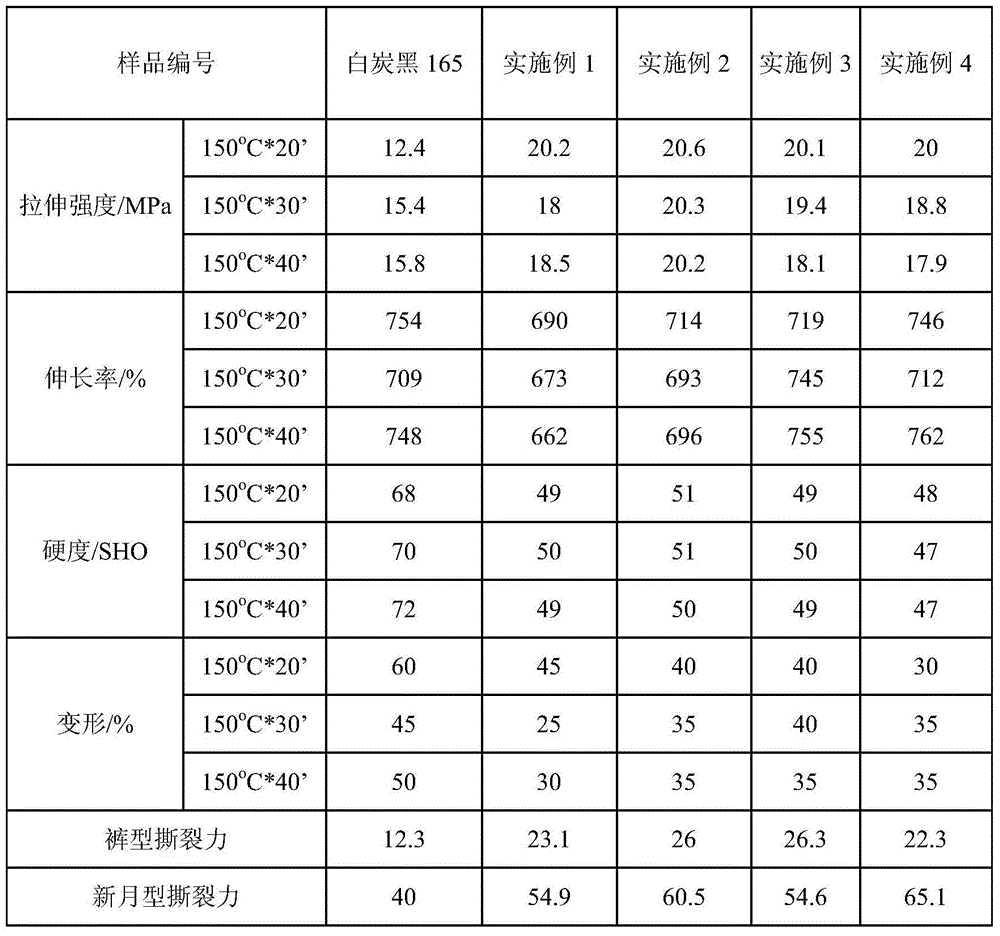

Preparation method for high-dispersion deposition white carbon black

ActiveCN105273442AImprove hydrophobicityImprove wear resistancePigment treatment with organosilicon compoundsRolling resistanceCoupling

The invention relates to a preparation method for white carbon black, and concretely relates to a preparation method for high-dispersion deposition white carbon black. A white carbon black suspension, an umbrella-shaped siloxane dispersant and a siloxane coupling agent containing sulfydryls or carbon-carbon double bonds are mixed, the pH value is adjusted to 2-7 after mixing, the mixture is heated to 30-79 DEG C and reacted for 1-6h, and high-dispersion deposition white carbon black is obtained. The umbrella-shaped siloxane dispersant and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The siloxane coupling agent and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The prepared white carbon black has superstrong hydrophobicity, the processing performance in subsequent preparation of rubber compounds can be raised effectively, dynamic mechanical properties of vulcanized rubber as tyre tread rubber can be improved effectively, the rolling resistance of tread rubber is lowered effectively, and the wear resistant performance of tread rubber is raised.

Owner:SHENYANG RES INST OF CHEM IND

High-environment-friendliness industrial material mixing equipment

InactiveCN106621963AIncrease mixing speedReduce vibration effectsShaking/oscillating/vibrating mixersTransportation and packagingMixing tankPetroleum engineering

The invention relates to mixing equipment, in particular to high-environment-friendliness industrial material mixing equipment and aims to realize high mixing speed and mixing thoroughness of the high-environment-friendliness industrial material mixing equipment. The equipment comprises a first supporting frame, a rotating motor, a first gear, a bearing seat, a second gear, a first rotating shaft, an oscillating rod, an elastic part, a brush, a fixing plate, a second rotating shaft and the like. A left supporting rod and a right supporting rod are connected with a liquid receiving basin by means of adhesive connection, a mixing tank is connected to upper ends of the supporting rods by means of mortise joint, the bottom middle of the mixing tank is provided with a second through hole and an arc groove, and the diameter of the second through hole is smaller than that of the arc groove. The high-environment-friendliness industrial material mixing equipment has advantages of high mixing speed, thoroughness in mixing, simplicity in operation and simple structure.

Owner:刘德平

Method for preparing reactive hot-press in-situ autogenesis aluminium-base composite material

The invention relates to a preparation technique of reaction heat pressing original position autogeny aluminium base material, relates to a preparation technique of a complex material. The invention resolves the problem that when prepare the complex material with external method, the performance of the material decreases and prepare ceramic complex material with original position reaction heat pressing method the raw material will easily cold welding when blended dry. The invention includes following steps: a, ball mill Al, B and TiO2 powder adding 8 to 21 ml ethanol and argon gas of 1 to 1.5 atmosphere, the weight ratio the blending material to milling material 1 to 10 : 1, the rotating speed is 100 to 400 round per minutes, the blending period lasts for 6 to 12 hours, dry off the material; b, cold shaping the dried blended powder to black lead mould and then sintering in vacuum heat pressing furnace. The technique is simple and easy operation.

Owner:HARBIN INST OF TECH

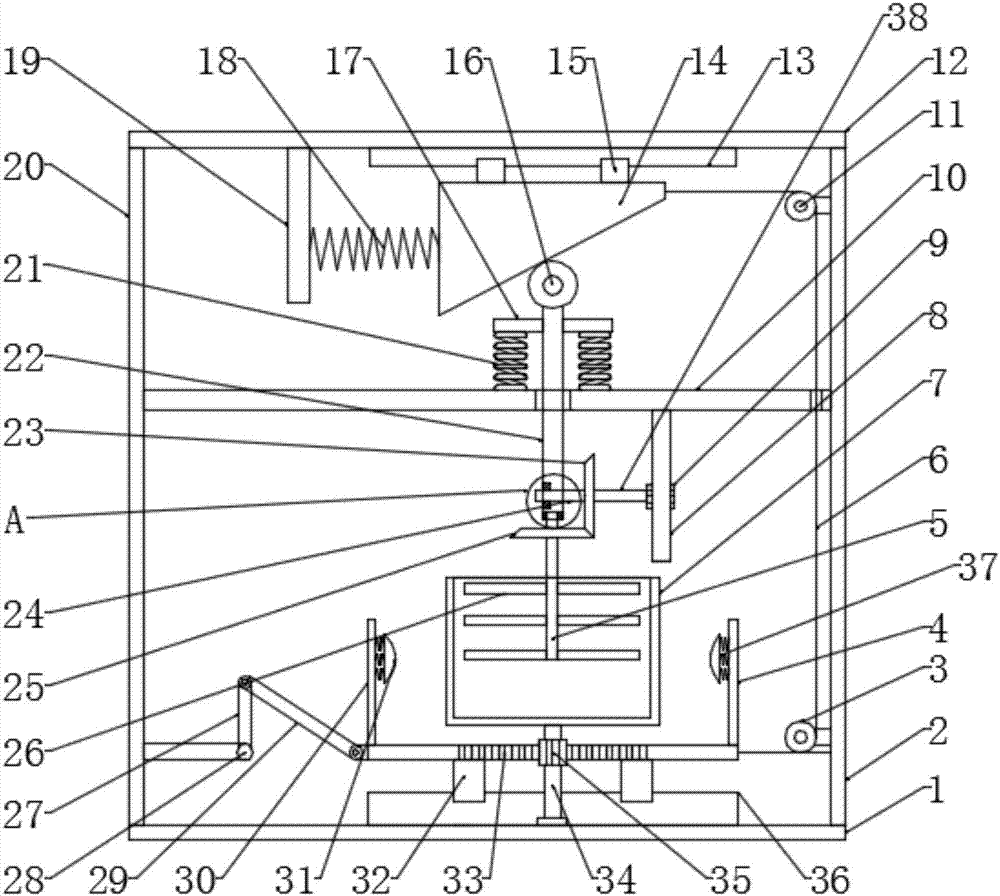

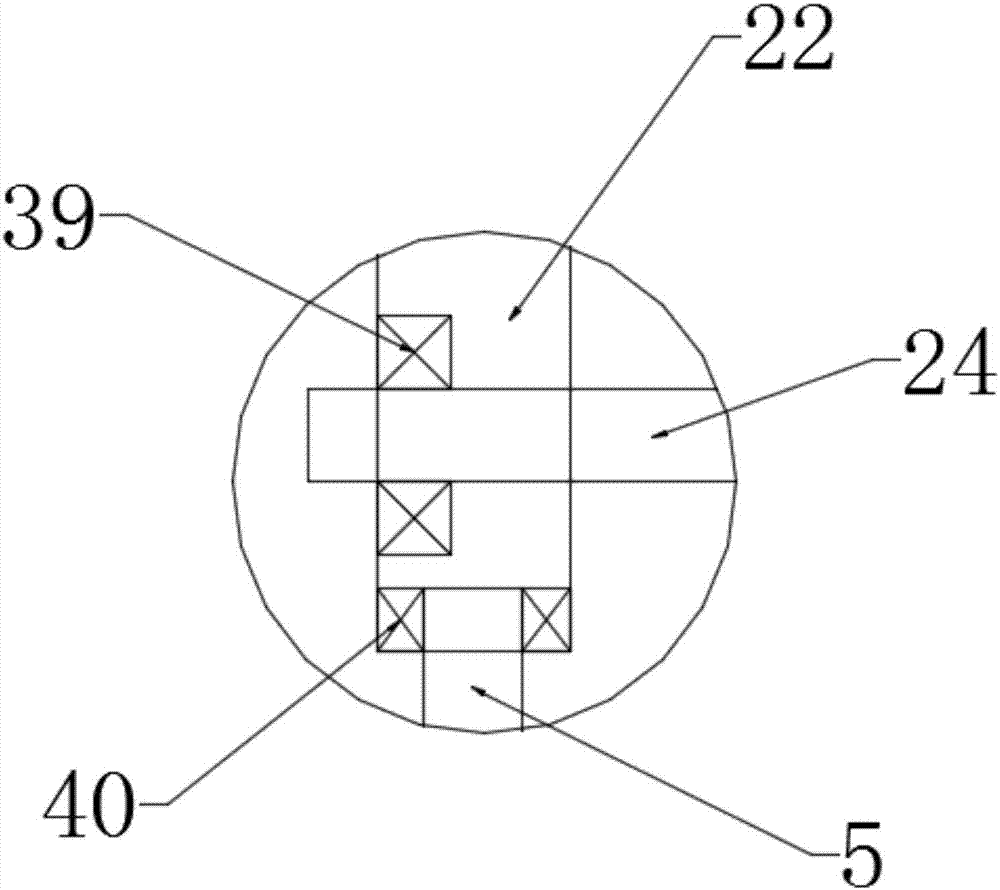

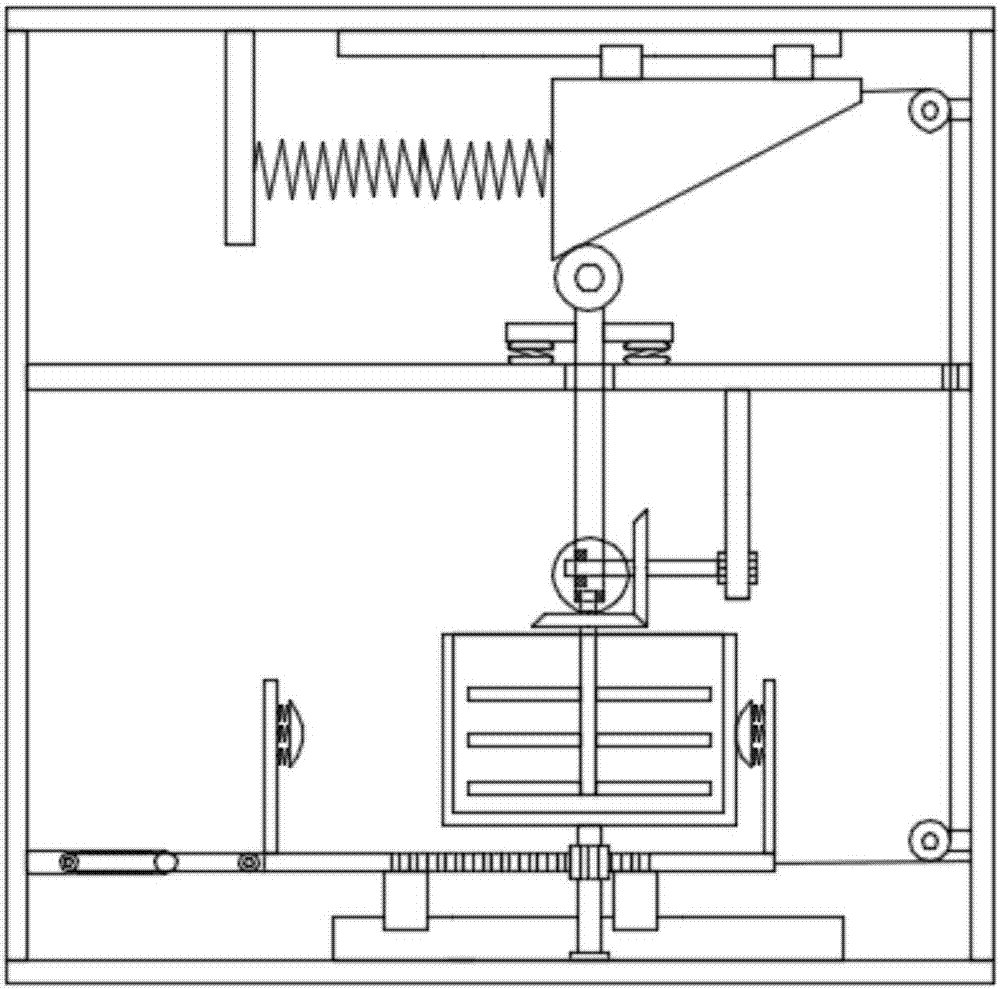

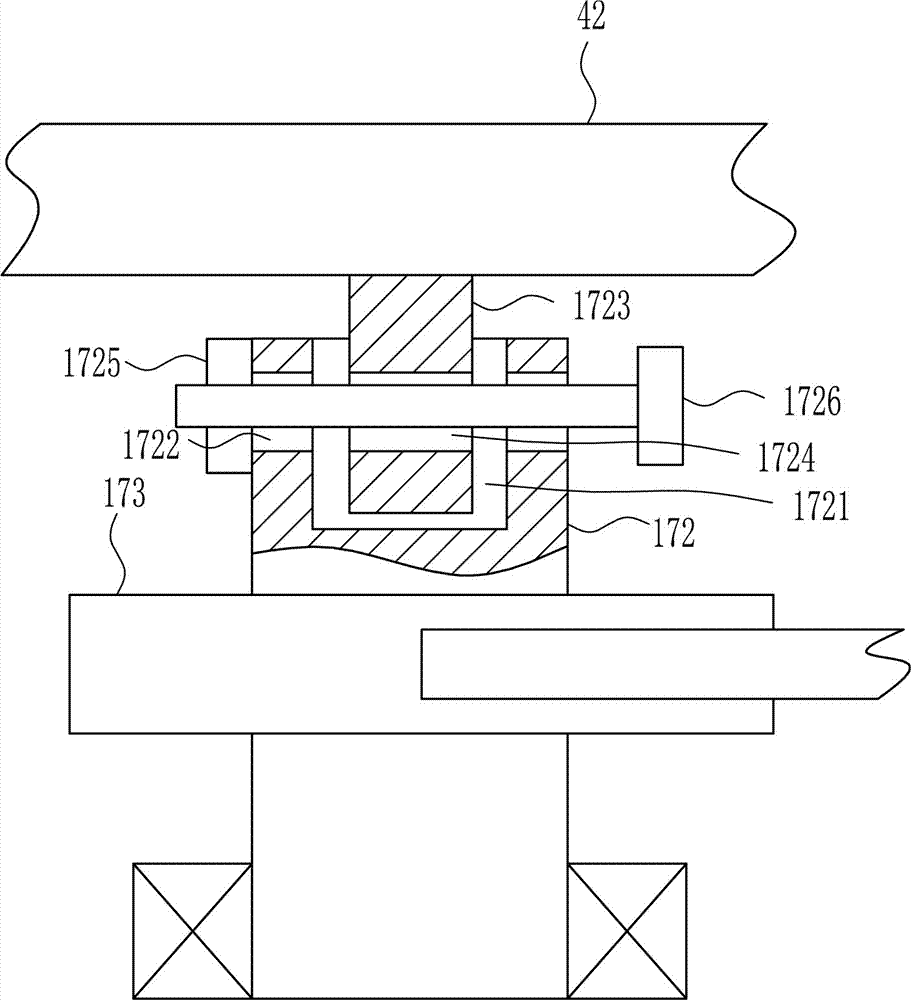

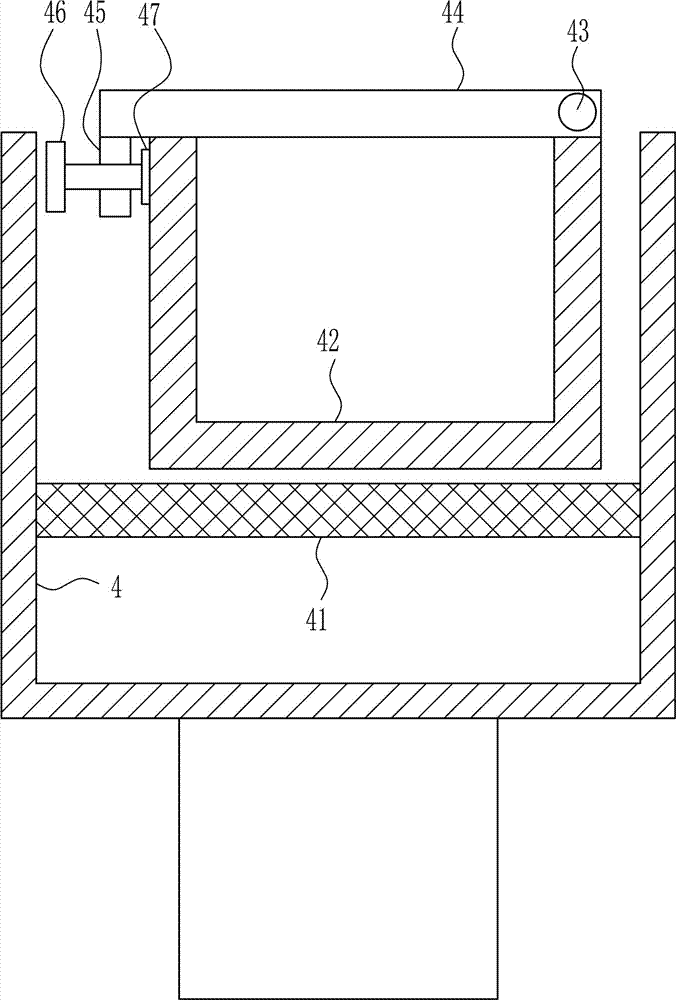

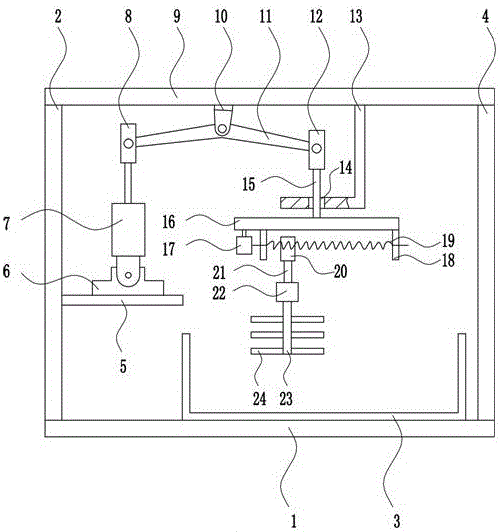

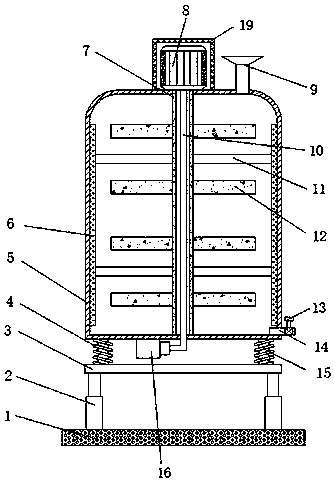

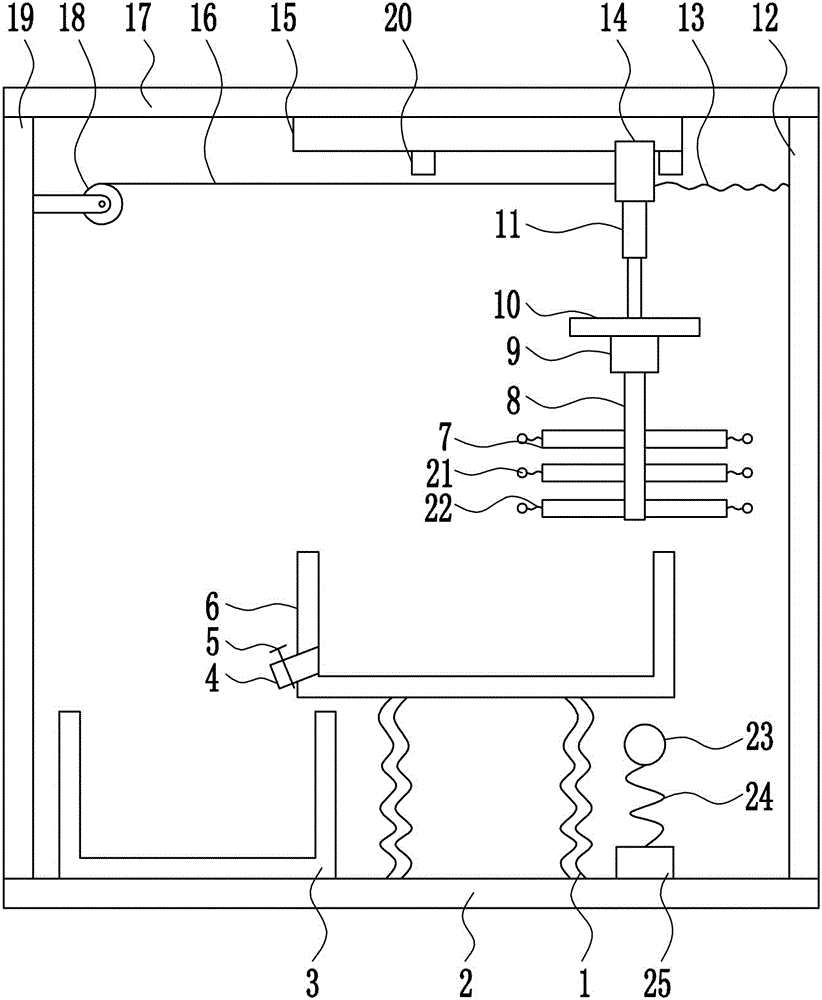

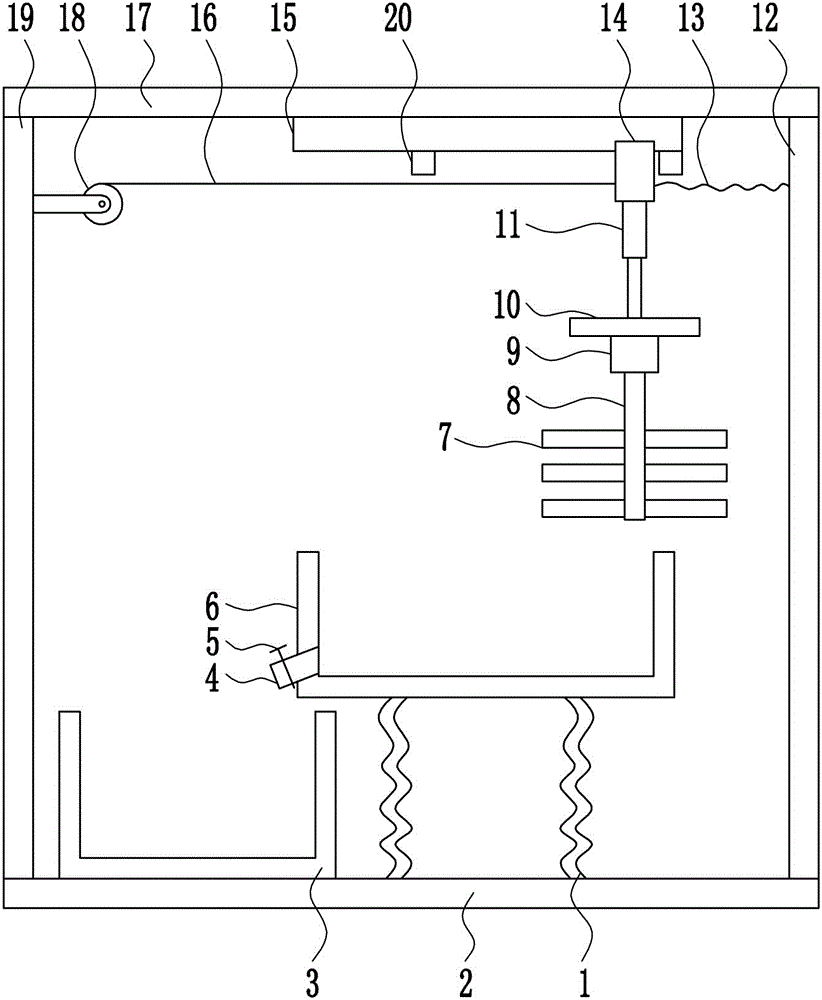

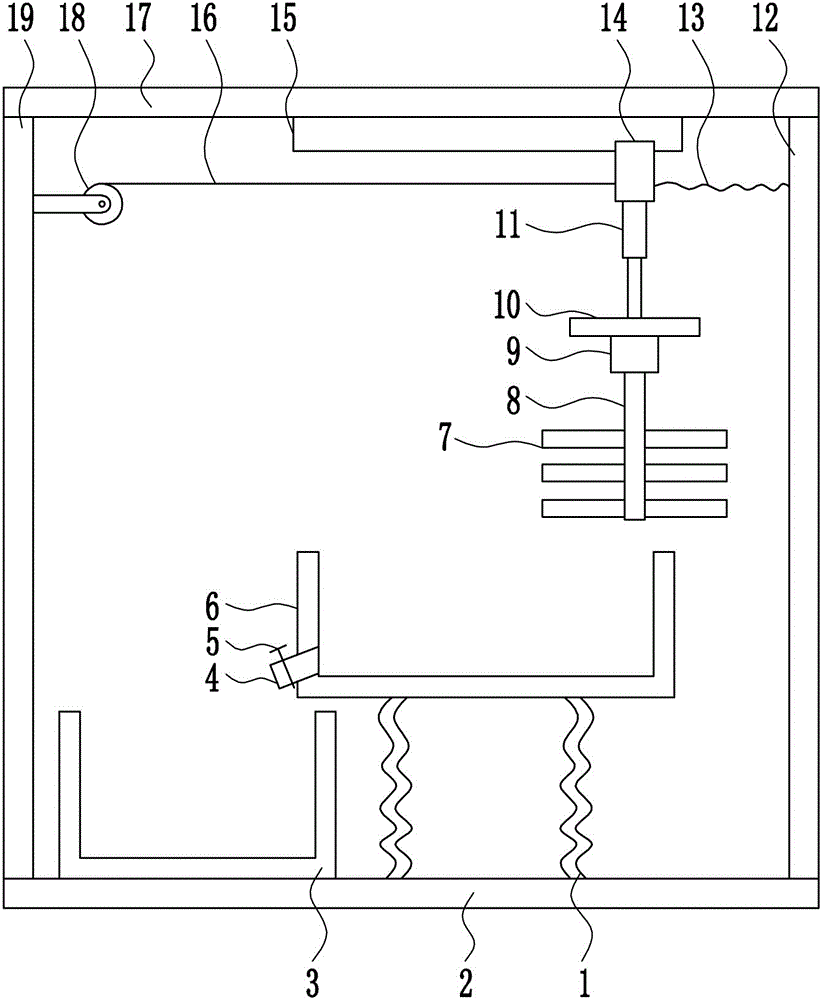

Medical medicinal liquid preparing mixing and stirring equipment with independent stirring container

InactiveCN108031361AWell mixedIncrease mixing speedRotating receptacle mixersTransportation and packagingEngineeringMedical treatment

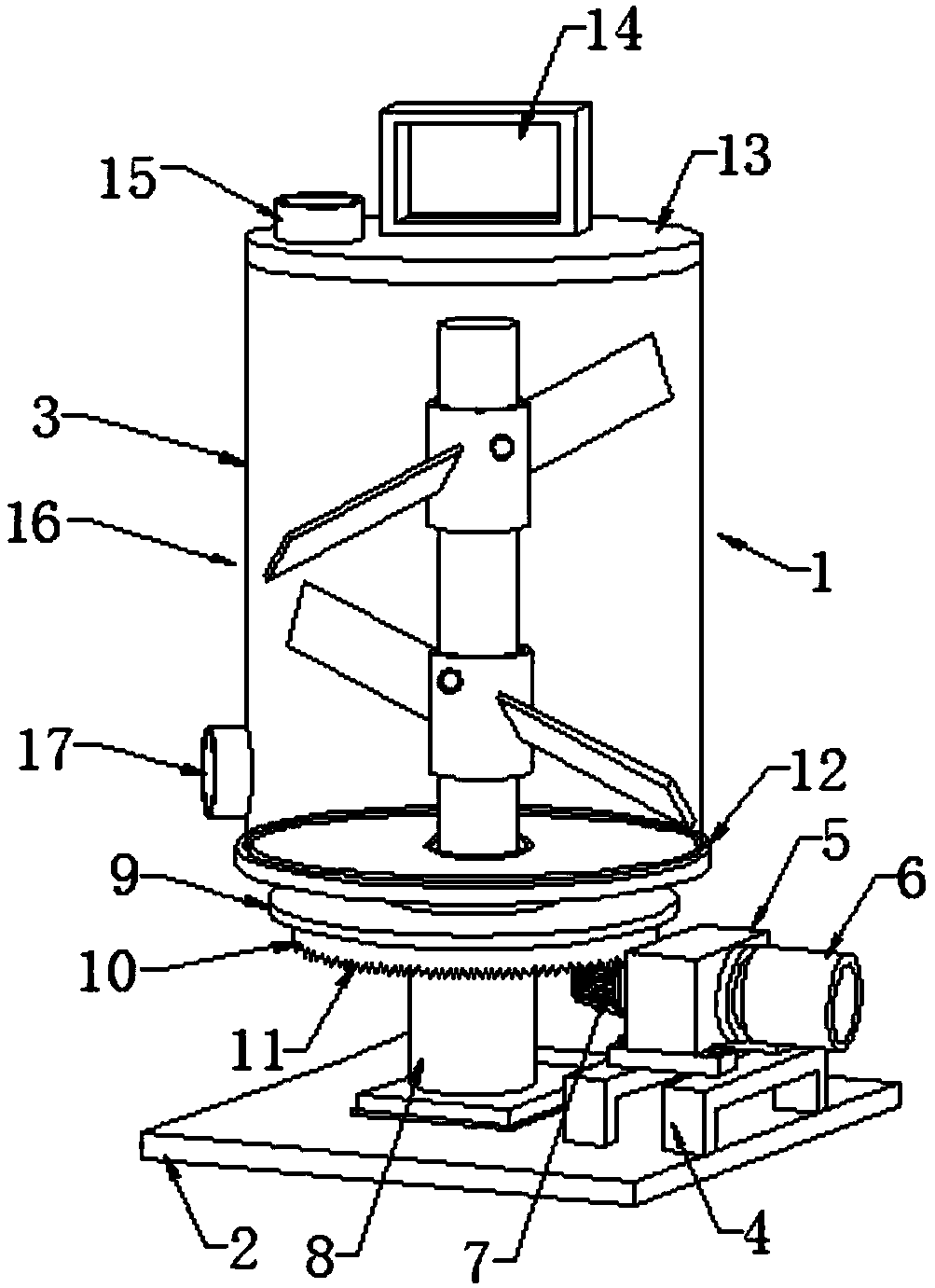

The invention relates to medical medicine processing equipment, in particular to medical medicinal liquid preparing mixing and stirring equipment with an independent stirring container. The inventionsolves the technical problems by providing the medical medicinal liquid preparing mixing and stirring equipment with the independent stirring container, which can mix and stir medicinal liquid in theseparate independent container and can stir the medicinal liquid thoroughly in a turnover way. In order to solve the technical problems, the invention provides the medical medicinal liquid preparing mixing and stirring equipment with the independent stirring container. The medical medicinal liquid preparing mixing and stirring equipment with the independent stirring container comprises a bottom plate, a collecting box, a supporting plate and the like, wherein the collecting box is placed at the upper middle part of the bottom plate. The medical medicinal liquid preparing mixing and stirring equipment with the independent stirring container achieves the effects of capabilities of mixing and stirring the medicinal liquid in the separate independent container and stirring the medicinal liquidthoroughly in a turnover way; by adoption of a way of placing, mixing and stirring the medicinal liquid by rotating a placement box, the medicinal liquid can be overturned during rotation of the placement box, so that the medicinal liquid with different densities can be overturned and mixed.

Owner:王海明

Liquid raw material uniformly mixing device

PendingCN107626232ASimple structureReasonable structureRotary stirring mixersMixing methodsMotor driveEngineering

The invention discloses a liquid raw material uniformly mixing device. The liquid raw material uniformly mixing device comprises a device body, wherein the device body comprises a base and a stirringbarrel; a motor holder and a vertical column are mounted on the top of the base; a connecting base is mounted at the top of the motor holder through fixing bolts; a rotating motor is mounted on one side of the connecting base. Through arrangement of the rotating motor, a transmission wheel, a turnplate, and a transmission disc, the rotating motor drives the transmission wheel to rotate to drive the transmission disc meshed with the transmission wheel to rotate so as to drive the turnplate to rotate, and the turnplate rotates to drive a stirring shaft to rotate, so that material mixing is completed; the liquid raw material uniformly mixing device is simple and reasonable in structure; the stirring barrel is detachably connected with a mounting disc through an insertion slot; after completion of uniform mixing, the stirring barrel can be lifted up through a handle, so that cleaning is convenient; two inclined stirring blades are mounted on each of stirring paddles, and when the liquid raw material uniformly mixing device is in the stirring process, upwardly inclined stirring blades stir an upper area, and downwardly inclined stirring blades stir a lower area, so that the uniformly mixing effect is improved and the uniformly mixing speed is increased.

Owner:徐来

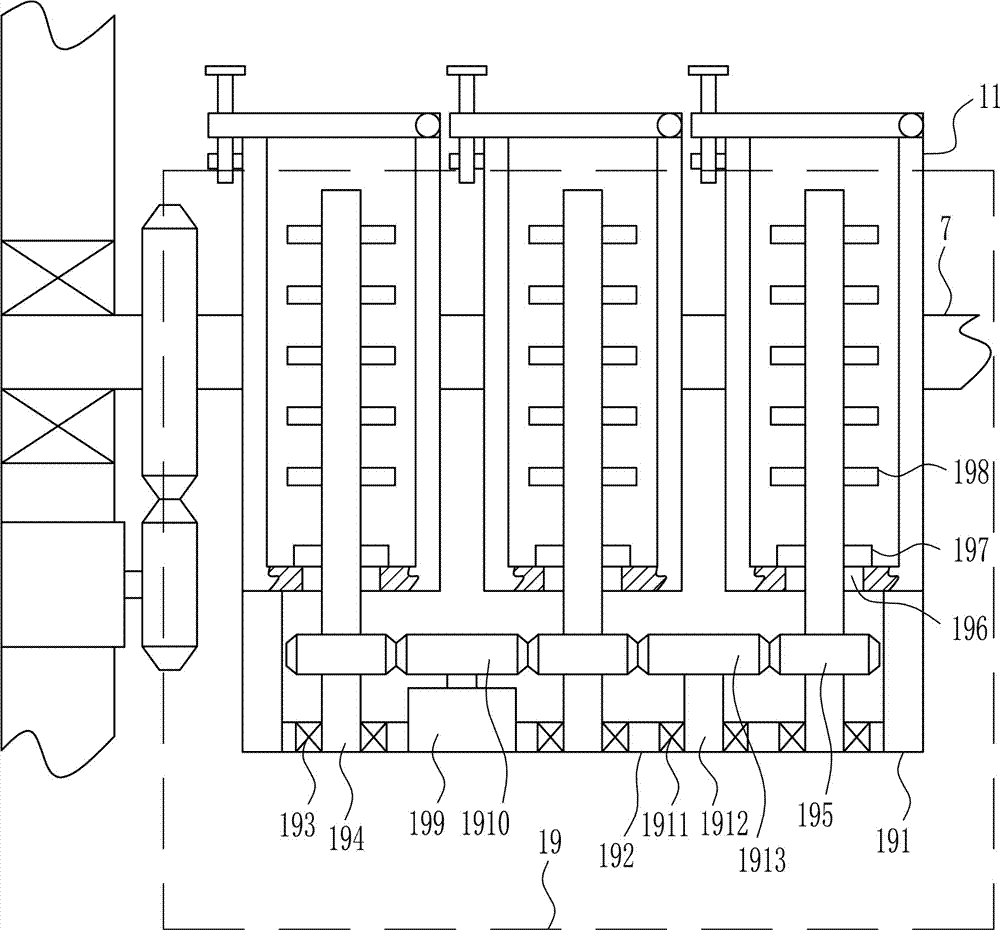

Efficient rare earth stirring, mixing and extracting equipment

ActiveCN107201454AImprove work efficiencyAvoid inaccurate manual blankingProcess efficiency improvementRare earthSediment

The invention relates to rare earth extracting equipment, in particular to efficient rare earth stirring, mixing and extracting equipment. According to the technical aims, the efficient rare earth stirring, mixing and extracting equipment is high in mixing and stirring speed, and mixing of rare earth materials and an extraction agent are relatively complete. In order to achieve the technical aims, the efficient rare earth stirring, mixing and extracting equipment is provided and comprises a base plate, a first sliding rail, a first sliding block, a first sediment box, supporting plates, a first bearing block, a first rotating rod, a first gear, a first motor, a second gear and the like; the first sliding rail is installed in the base plate in a bolt connecting manner, the first sliding block is connected into the first sliding rail in a sliding manner, the first sediment box is installed on the upper side of the first sliding block in a bolt connecting manner, and the supporting plates are installed on the left and right sides of the base plate in a welding manner. By means of the efficient rare earth stirring, mixing and extracting equipment, the effects of being high in mixing and stirring speed, and complete in mixing of rare earth materials and the extraction agent are achieved.

Owner:浙江立盛新型墙体材料有限公司

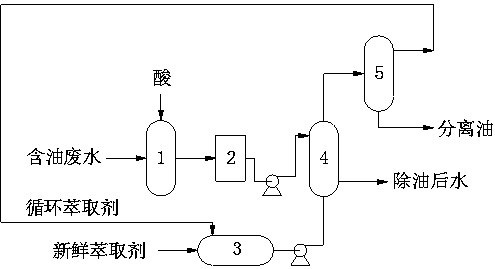

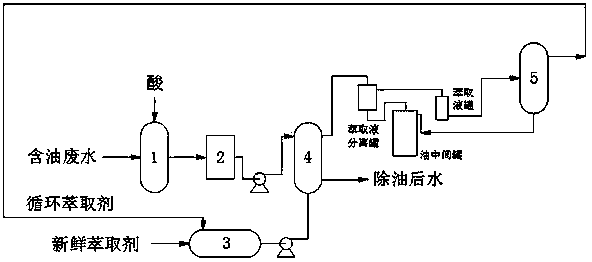

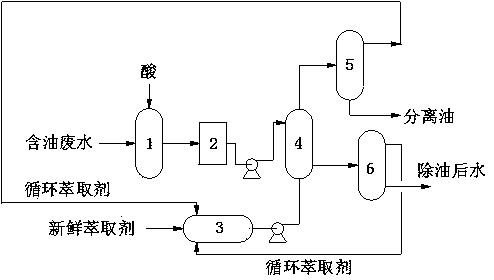

Method for oil removal from wastewater in field of coal chemical industry

InactiveCN103964544ASimplify timeLow costFatty/oily/floating substances removal devicesLiquid separationChemical industryWastewater

The invention discloses a method for oil removal from wastewater in the field of coal chemical industry, which is characterized in that oil contains soluble oil; and the method comprises the following steps: wastewater pretreatment, extraction and oil removal, and extraction agent recovery. Through the method, the oil contained in the wastewater, in particular to the soluble oil can be effectively removed. The invention further provides normal hexane and / or petroleum ether as an extraction agent; and through a practical application experiment, after the method is adopted, the oil contained in the treated wastewater is the soluble oil basically, the removal rate of the oil reaches 95.31-97.91 percent, and the removal rate of the soluble oil reaches 87.08-94.17 percent, so that a good oil removal effect is reached, and particularly, the effect of removing the soluble oil is good.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Raw material mixing plant for fine chemical flavor production

InactiveCN106390810AIncrease mixing speedEasy to operateRotary stirring mixersTransportation and packagingFood flavorMixing effect

The invention relates to a raw material mixing plant, and particularly relates to a raw material mixing plant for fine chemical flavor production. The technical problem to be solved by the invention is to provide a raw material mixing plant for fine chemical flavor production, which achieves the effects of thorough mixing, high mixing speed and convenient operation process. To solve the technical problem, the raw material mixing plant for fine chemical flavor production comprises a bottom plate, a mixing frame, a first sliding block, a first sliding track, a stirring blade, a rotating shaft, a first connecting rod, a first gear, a first bracket, a second sliding track, a second bracket and the like, wherein a left rack is welded at the left end of the top of the bottom plate; the first sliding track is connected to the lower part of the right side of the left rack in a bolt connection manner; and the first sliding block is connected on the first sliding track in a sliding manner. The raw material mixing plant for fine chemical flavor production achieves the effects of thorough mixing, high mixing speed and convenient operation process; and the raw material mixing plant not only plays an important role in achieving the favorable mixing effect, but also improves the work efficiency and ensures high safety.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

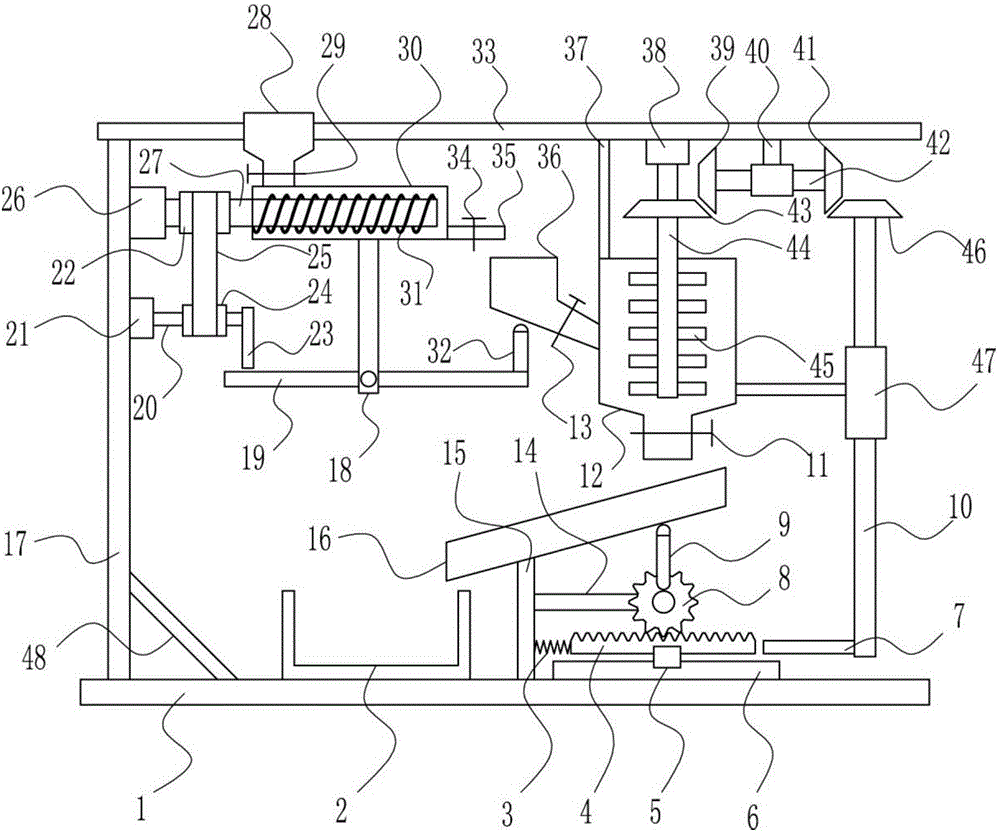

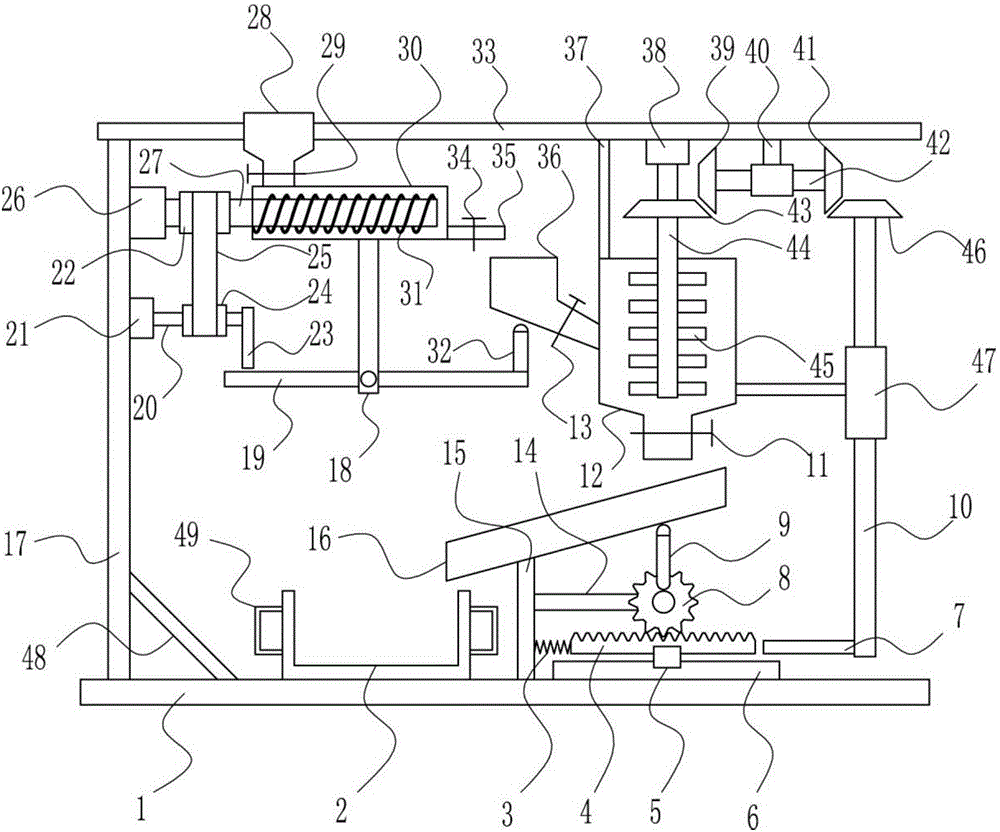

Producing and processing equipment for organic fertilizer

InactiveCN106422933ASimple structureIncrease mixing speedTransportation and packagingMixer accessoriesProcess equipmentOrganic manure

The invention belongs to the technical field of fertilizer production, particularly relates to producing and processing equipment for organic fertilizer and aims to provide the producing and processing equipment which is simple in structure, high in mixing and stirring speed and uniform in mixing and stirring and used for organic fertilizer. The producing and processing equipment for the organic fertilizer comprises a bottom plate, a collecting frame, a first elastic piece, a rack, a slider, a slide rail, a first cam, a first gear, a first rubber hammer, a first rotary shaft, a first electrical valve and the like, wherein a left frame, the collecting frame, a second fixing rod and the slide rail are arranged at the top of the bottom plate from left to right sequentially, the slider is glidingly connected to the slide rail, and the rack is arranged at the upper end of the slider. The producing and processing equipment realizes the effects of simple structure, high mixing and stirring speed and uniform mixing and stirring, and a worker can execute rapid mixing and stirring work during producing and processing of the organic fertilizer by means of the equipment.

Owner:镇沅忠林现代农业科技发展有限公司

Building material processing device

ActiveCN110281387AQuick NestFast pushDischarging apparatusMixing operation control apparatusMaterials processingMechanical engineering

The invention relates to the technical field of building material equipment, in particular to a building material processing device. The building material processing device comprises a supporting frame; the supporting frame is fixedly connected with a stirring cylinder; a material discharging port is formed at the bottom of the stirring cylinder; a rotating shaft is coaxially arranged in the stirring cylinder; a driving unit for driving the rotating shaft to rotate is arranged on the stirring cylinder; the rotating shaft comprises an upper rotating shaft and a lower rotating shaft which are mutually linked; the upper rotating shaft is fixedly connected with an upper spiral sheet; the lower rotating shaft is fixedly connected with a lower spiral sheet; a reversing mechanism for changing the relative rotation direction of the upper rotating shaft and the lower rotating shaft is arranged between the upper rotating shaft and the lower rotating shaft; and the lower rotating shaft is close to the material discharging port. The rotation direction of the lower spiral sheet is changed sequentially through a switching mechanism, and the upper spiral sheet and the lower spiral sheet cooperate with each other to sequentially complete stirring operation and material discharging operation, so that the problems in the prior art that the stirring efficiency is low and the material discharging speed is low are solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

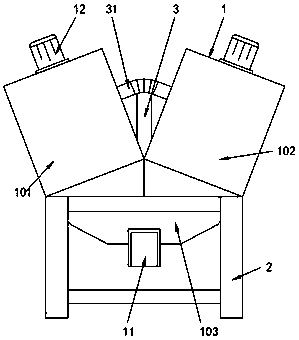

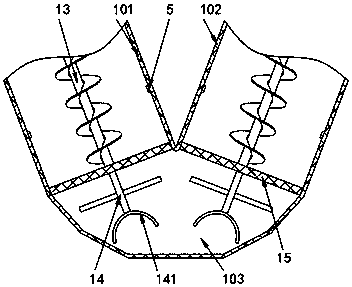

Aquaculture production feed mixing device with automatic filling function

PendingCN109433042ASmall footprintImprove mixing efficiencyFeeding-stuffRotary stirring mixersHollow cylinderGravitational force

The invention discloses an aquaculture production feed mixing device with an automatic filling function and belongs to the technical field of feed mixing equipment. The key point of the technical scheme is that the aquaculture production feed mixing device with the automatic filling function comprises a feed mixing bin and a feed mixing bin bracket fixed at the bottom of the feed mixing bin; the feed mixing bin consists of a first mixing bin, a second mixing bin and a combining bin; and the first mixing bin and the second mixing bin are both hollow cylinders. By designing the feed mixing bin in a V shape formed by two crossed mixing bins and arranging the combining bin which is used for communicating the two mixing bins at the bottom, the advantages of a vertical mode and a horizontal modeare combined, so that the feed mixing bin realizes higher mixing efficiency in the case of small floor area; as materials have certain inclined angles in the mixing bin, the stirring area during mixing is larger, smaller gravity force is borne; and therefore, the load of a motor can be reduced; under coordination of a conical material mixing auger, the stirring speed can be increased, so that thematerial mixing speed is higher and the efficiency is higher.

Owner:HUZHOU JIUZHI AUTOMATION TECH

A method for recovering zinc enrichment and potassium chloride by using rotary hearth furnace dust

ActiveCN106191453BSolve the difficult situation of collecting dust and ashHandle difficult situationsProcess efficiency improvementAlkali metal chloridesProduction linePotassium

The invention discloses a method for recycling zinc-enriched objects and potassium chloride through rotary hearth furnace dust. The method comprises the following steps of pretreatment, slurrying, leaching and extracting, solid-liquid separating, cleaning and drying. By means of the method, the problem that the collected dust of a rotary hearth furnace of an iron and steel enterprise is difficult to treat is effectively solved. According to the method, the process steps are simple, the recycling rate of the zinc-enriched objects is high, resource regeneration is achieved, and the waste is turned into treasure; and a circulation production line can be formed in the iron and steel enterprise, and a large amount of production cost is reduced.

Owner:汉源县伟业环保科技有限公司

Liquid material mixing device

InactiveCN107961725AEasy to cleanEasy to replaceRotating receptacle mixersTransportation and packagingEngineeringReducer

The invention discloses a liquid material mixing device including a device body. The device body comprises a base and a mixing barrel. The middle part of the top of the base is provided with a mounting groove, and both sides of the mounting groove are each provided with a stand column; through arrangement of a first rotation motor, a speed reducer, a first rotation shaft, a second rotation motor and a second rotation shaft, a material barrel and a mixing mechanism in the material barrel rotate at the same time and have opposite rotation directions when the device body is used for mixing, and the mixing speed is improved effectively; through arrangement of an end cover, the end cover is detachably connected with the mixing barrel, and the mixing mechanism and the second rotation shaft are detachably connected through a connecting sleeve, so as to facilitate later cleaning of the interior of the mixing barrel and replacement and maintenance of the mixing mechanism; through arrangement ofa jacking cylinder and a piston rod, a sliding plate can slide up and down along sliding slots on the stand columns, so the height of a stirring barrel is changed, collecting boxes with different heights are conveniently placed at the bottom, and the feeding effect is improved.

Owner:丽水乐发广告有限公司

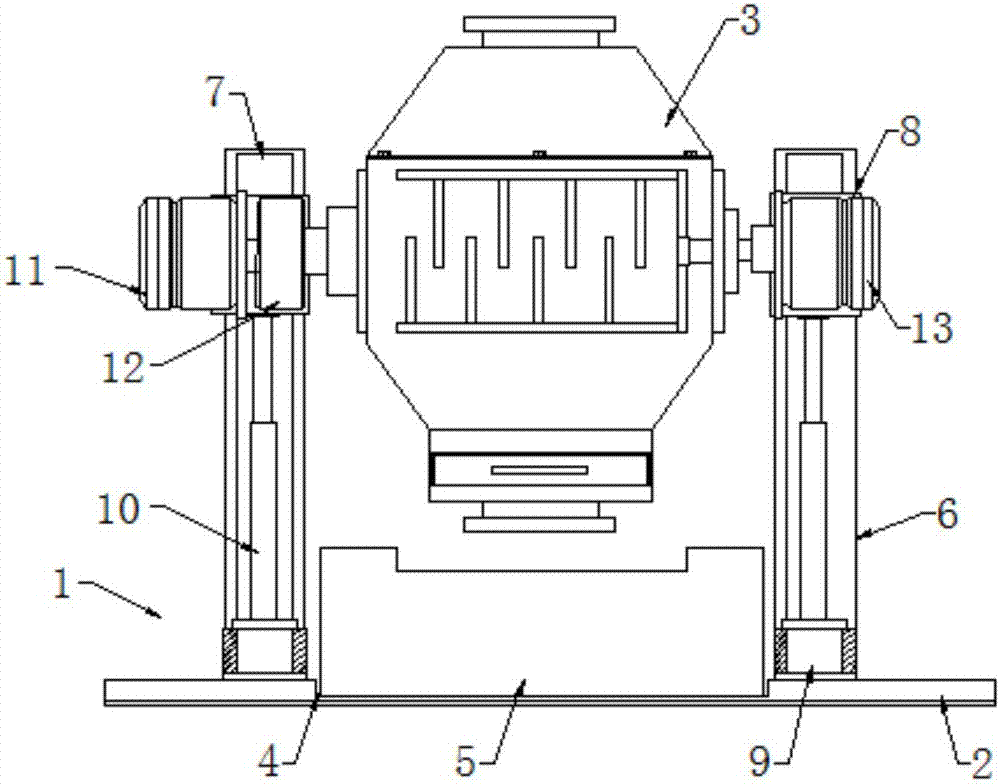

Efficient stirring and mixing device for raw materials of ceramic production process

InactiveCN106621921AWell mixedStir to mix thoroughlyRotary stirring mixersTransportation and packagingMetallurgyMixing effect

The invention belongs to the technical field of ceramic production and especially relates to an efficient stirring and mixing device for raw materials of a ceramic production process. The technical problem to be solved by the invention is to provide the efficient stirring and mixing device for the raw materials of the ceramic production process, with uniform stirring and mixing effect, thorough stirring and mixing effect and high stirring and mixing speed. In order to solve the technical problem, the efficient stirring and mixing device for the raw materials of the ceramic production process provided by the invention comprises a base plate, a left frame, a stirring frame, a right frame, a fixing plate, a mounting base, an electric pushing rod, a first connecting block, a top plate, a fixing base, an arc-shaped connecting rod and a second connecting block, wherein the left frame, the stirring frame and the right frame are successively arranged at the top of the base plate from left to right; the top plate is arranged at the top of the left frame and the right frame; the fixing plate is arranged on the lower part on the right side of the left frame; and the mounting base is arranged at the top of the fixing plate. The efficient stirring and mixing device for the raw materials of the ceramic production process can achieve the effects of uniform stirring and mixing, thorough stirring and mixing and high stirring and mixing speed.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

Foam concrete slab production line

PendingCN107379238AQuality improvementProlonged initial settingCeramic shaping plantsFeeding arrangmentsFoam concreteArchitectural engineering

The invention provides a foam concrete slab production line, and belongs to the technical field of concrete production equipment. The foam concrete slab production line comprises storage equipment, conveying equipment, foaming equipment, stirring equipment, slurry storing, transporting and pouring equipment, foam concrete slab shaping platforms, grid paving equipment and press flattening equipment, the storage equipment is connected with the conveying equipment through the stirring equipment, the foaming equipment is used for making foams and connected with the stirring equipment through pipelines, the slurry storing, transporting and pouring equipment is used for movably pouring foam concrete and is positioned above the foam concrete slab shaping platforms which are used for holding the foam concrete, the grid paving equipment is used for paving grids on the foam concrete, the grid paving equipment and the press flattening equipment are connected above the foam concrete slab shaping platforms, and foam concrete dies are arranged on the foam concrete slab shaping platforms. The foam concrete slab production line has the advantage that through arrangement of working processes and mutual matching of the equipment, continuous production of large-earthwork-volume foam concrete slabs is realized.

Owner:HEBEI SANSHAN BUILDING MATERIALS TECH

Material mixing device used for ceramic production line

InactiveCN109822742ARealize automatic matching workImprove work efficiencyMixing operation control apparatusClay processing apparatusProduction lineEngineering

The invention discloses a material mixing device used for a ceramic production line, and relates to the technical field of ceramic production. The material mixing device comprises a machine frame. A material conveying mechanism is fixedly installed on the top of the machine frame. First supporting legs are fixedly installed on the lower surface of the machine frame. A first feeding mechanism is fixedly installed on the top of the material conveying mechanism. A second feeding mechanism is fixedly installed at the position, located on one side of the first feeding mechanism, on the top of the material conveying mechanism. The material mixing device is scientific and reasonable in structure and convenient to operate; by means of the first feeding mechanism and the second feeding mechanism which are arranged, a regular and quantitative addition working procedure of ceramic production raw materials can be achieved, the automatic matching work of the material mixing device used for ceramicproduction is then achieved, and the work efficiency is effectively improved; by means of the material conveying mechanism which is arranged, the automatic conveying work of the ceramic raw materialsafter matching can be achieved; and by means of a material mixing mechanism which is arranged, the automatic material mixing working procedure of the ceramic production raw materials can be achieved,and the material mixing device is high in material mixing speed, high in material mixing uniformity and high in practicability.

Owner:四川利弘陶瓷有限公司

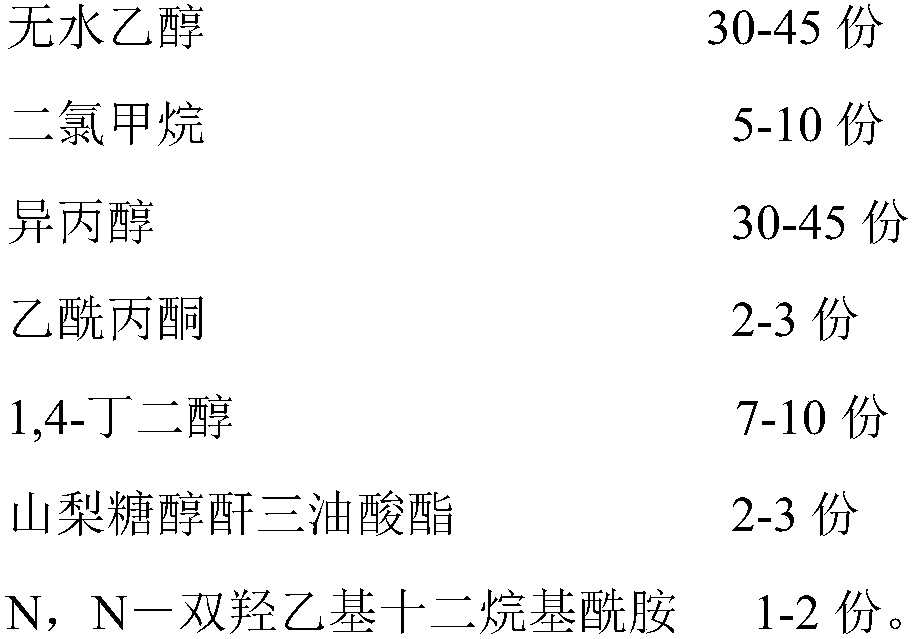

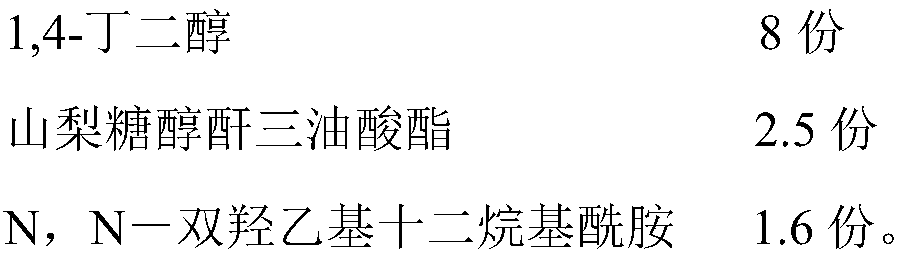

Efficient cleaning fluid for robot PCB circuit boards

InactiveCN108690744AImprove solubilityGood removal effectNon-ionic surface-active compoundsDetergent mixture composition preparationAlcoholEngineering

The invention provides efficient cleaning fluid for robot PCB circuit boards. The efficient cleaning fluid is prepared from, by weight, 30-45 parts of absolute ethyl alcohol, 5-10 parts of absolute ethyl alcohol, 30-45 parts of isopropyl alcohol, 2-3 parts of acetylacetone, 7-10 parts of 1,4-butanediol, 2-3 parts of sorbide trioleate and 1-2 parts of N,N-bis-hydroxyethyl dodecyl amide. Compared with the prior art, the efficient cleaning fluid has advantages of excellent oil stain removal effects and has anti-corrosion and antistatic functions.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

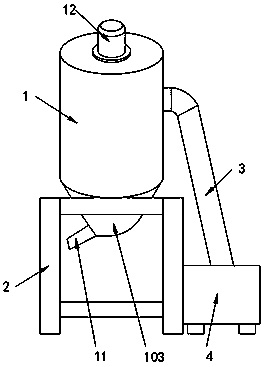

Uniform mixing equipment for biomass processing

InactiveCN111068555AStir wellIncrease mixing speedRotating receptacle mixersTransportation and packagingMechanical engineeringLarge range

The invention discloses uniform mixing equipment for biomass processing. The uniform mixing equipment comprises a bottom plate, a containing frame, a mounting plate and stirring units, the containingframe is mounted above the bottom plate; a mounting plate connected with the bottom plate through a connecting mechanism is mounted above the containing frame; a stirring unit for stirring biomass rawmaterials in the containing frame is mounted on the mounting plate; the stirring unit comprises a plurality of groups of stirring assemblies and a driving assembly for driving the plurality of groupsof stirring assemblies to move; the driving assembly comprises a driving ring, a second connecting rod, a supporting plate, a pin shaft and a power mechanism for driving the driving ring to rotate positively and negatively; and the connecting mechanism comprises a first supporting rod, a second supporting rod and a moving assembly used for driving the mounting plate to move. The stirring unit isarranged, biomass raw materials in the containing frame can be fully and uniformly stirred in a large-range and movable mode, the uniform mixing speed is high, the connecting mechanism is arranged, the stirring angle of the stirring unit can be continuously changed, stirring is more sufficient and uniform, and the uniform mixing efficiency is further improved.

Owner:沈桂香

Double-rotation stirrer

InactiveCN106693801AShorten the timeEasy to transportRotating receptacle mixersTransportation and packagingEngineeringDouble rotation

The invention discloses a double-rotation stirrer which comprises a tank. A tank lid is arranged at the upper end of the tank, an inner tank is arranged inside the tank, the inner bottom of the tank is provided with a rotating motor, the bottom end of the inner tank is connected to a crankshaft of the rotating shaft, the upper end of the inner tank is rotatably connected with the tank lid, a stirrer body is arranged on the tank lid and comprises a motor and a stirring rod, a heater is arranged on the side wall of the tank, a liquid inlet is formed in the lower portion of the side end of the inner tank, and the liquid inlet is closed through a valve. The double-rotation stirrer has the advantages that the inner tank is arranged, materials are put into the inner tank, after processing is completed, the inner tank is taken out, discharging and cleaning are conducted, and a large amount of time is saved. The inner tank of the double-rotation stirrer is driven by the motor to rotate, mixed liquid in the inner tank forms two spirals of two totally opposite directions of rotation at the outer periphery and the inner periphery respectively, and the liquid mixing speed can be increased when the two spirals have a collision.

Owner:重庆禾坛机械有限公司

Efficient raw material mixing device for LOW-E glass production

InactiveCN106975403AAvoid spillingPrevent outflowShaking/oscillating/vibrating mixersTransportation and packagingShake upEngineering

The invention relates to a raw material mixing device for glass production. The raw material mixing device comprises a bottom plate, a left side plate, a left bearing seat, a belt, a small pulley, a motor, a large pulley, a first spring, a rotating shaft, a cam, a right side plate, a right bearing seat and a mixing box. The left side of the top of the bottom plate is provided with the left side plate and the right side of the left side plate is provided with the motor and the left bearing seat. The motor is located above the left bearing seat. In stirring, the cam rotates and drives the mixing box to shake up and down. Stirring and shaking are carried out simultaneously so that a material mixing rate is improved.

Owner:安徽万佳节能科技有限公司

High-efficiency multi-stage mixing device for raw materials for injection molding

InactiveCN108858855AWell mixedIncrease mixing speedNon-rotating vibration suppressionHydraulic cylinderCoupling

The invention discloses a high-efficiency multi-stage mixing device for raw materials for injection molding. The device comprises a base. Hydraulic cylinders are connected to outer walls of four corners of the top of the base through bolts and a same horizontally placed top plate is connected to the outer walls of the tops of the four hydraulic cylinders through bolts; telescopic rods are connected to the outer walls of four corners of the top of the top plate through bolts and a mixing shell is connected to the outer walls of the tops of the four telescopic rods through bolts; a servo motor is connected to the outer wall of the top of the mixing shell through a bolt and the output end of the servo motor is connected to a hollow shaft through a coupling; and the end, far away from the hollow shaft extends to the inner wall of the mixing shell. By arranging a vibrating motor, a shock absorbing spring and the telescopic rods, the mixing shell can be vibrated to achieve multistage mixingfavorably, so that the raw materials in the device are mixed fully. By arranging the hydraulic cylinders, discharge is facilitated; by arranging a sound-isolating shell, noise generated by operation of the servo motor is reduced.

Owner:贵宇金属制品滨海有限公司

Heating and uniform mixing device for production of circulation promotion and hair growth shampoo

InactiveCN111589333AStir wellWell mixedTransportation and packagingRotary stirring mixersHeater RodEngineering

The invention discloses a heating and uniform mixing device for production of circulation promotion and hair growth shampoo. The device comprises an equipment chamber and a mixing chamber, the equipment chamber is positioned at the top of the mixing chamber, stirring paddles are arranged in the mixing chamber, the number of the stirring paddles is two, a transmission mechanism for driving the stirring paddles to rotate is arranged on the stirring paddles, an electric heating wire is embedded in the inner wall of the mixing chamber, a heating rod is embedded in the vertical part of each stirring paddle, the bottom of the mixing chamber communicates with a discharging pipe, an electric telescopic rod is installed at the bottom of the side face of the discharging pipe, and the telescopic endof the electric telescopic rod extends into the discharging pipe and is welded with a push plate. Shampoo can be stirred more sufficiently and mixed more uniformly, the stirring efficiency is high, the contact area of a heat source and the shampoo is increased, the shampoo heating effect is good, the shampoo mixing speed is high, the shampoo can be discharged uniformly, and the discharge amount ofthe shampoo can be controlled.

Owner:上海絮约生物科技有限公司

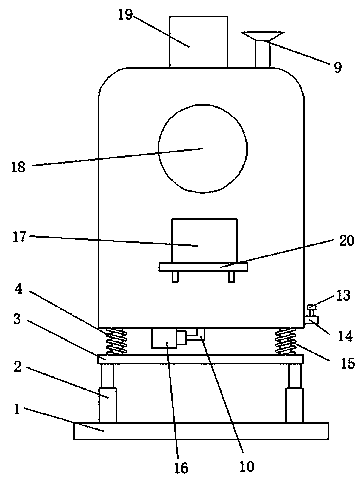

Portable vibration absorption stirrer

InactiveCN106693757AImprove shock resistanceShorten the timeTransportation and packagingRotary stirring mixersEngineeringVibration absorption

The invention discloses a portable vibration absorption stirrer. The portable vibration absorption stirrer comprises a tank body, wherein a tank cover is arranged at the upper end of the tank body and an inner tank is arranged in the tank body; a rotary motor is arranged at the bottom in the tank body; the bottom end of the inner tank is connected onto a motor shaft of the rotary motor; the upper end of the inner tank is rotatably connected with the tank cover; a stirrer is arranged on the tank cover; a detachable vibration absorption device is arranged below the tank body; the vibration absorption device comprises an upper mounting plate and a lower supporting plate; the upper mounting plate is mounted below the tank body through a screw; the lower supporting plate is located at the lower end of the upper mounting plate; a plurality of springs are arranged between the upper mounting plate and the lower supporting plate; at least three universal wheels are uniformly arranged at the edge of the lower side of the tank body; and the universal wheels are mounted on the tank body through an air cylinder. The portable vibration absorption stirrer has the beneficial effects that the universal wheels are arranged at the lower end of the device, so that the device is convenient to transport; and the universal wheels can be retracted so that the universal wheels are landed in a transportation process, and the vibration absorption device is landed in a stirring process.

Owner:重庆禾坛机械有限公司

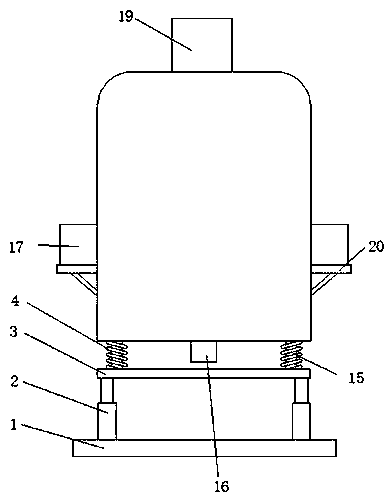

Damping double-rotation stirrer

InactiveCN106693758AShorten the timeImprove shock resistanceRotary stirring mixersTransportation and packagingDouble rotationEngineering

The invention discloses a damping double-rotation stirrer. The damping double-rotation stirrer comprises a tank body, wherein a tank cover is arranged at the upper end of the tank body; an inner tank is arranged in the tank body; a rotary motor is arranged at the bottom part in the tank body; the bottom end of the inner tank is connected with a shaft of the rotary motor; the upper end of the tank cover is rotationally connected with the tank cover; a stirrer is arranged on the tank cover, and comprises a motor and a stirring rod; a heater is arranged at the side wall of the tank body; the lower part of the side end of the inner tank is provided with a liquid inlet, and the liquid inlet is closed by a valve; a detachable damper is arranged under the tank body, and comprises an upper mounting plate and a lower mounting plate; the upper mounting plate is arranged under the tank body through a screw, the lower mounting plate is positioned at the lower end of the upper mounting plate, and a plurality of springs are arranged between the upper mounting plate and the lower mounting plate. The damping double-rotation stirrer has the beneficial effect that by arranging the damping device under the stirrer, the collision between the device and the bottom surface in the working process is avoided, and the collision of parts in the device is reduced, so as to protect the device.

Owner:重庆禾坛机械有限公司

Efficient raw material uniform mixing device for encaustic tile production

InactiveCN106541499AMix thoroughlyIncrease mixing speedCement mixing apparatusEncaustic tileEngineering

The invention relates to a raw material uniform mixing device, in particular to an efficient raw material uniform mixing device for encaustic tile production. The efficient raw material uniform mixing device has the advantages of being thorough in uniform mixing, high in uniform mixing speed and small in workload. The efficient raw material uniform mixing device comprises first springs, a bottom plate, a collecting frame, a discharging pipe, an electronic control valve, a uniform mixing frame, mixing blades, a rotating shaft, a motor, a fixed plate, an electric push rod, a right frame and the like. A left frame is welded at the left end of the top of the bottom plate. The collecting frame is arranged on the left side of the top of the bottom plate. One end of each first spring is connected with the right side of the top of the bottom plate in a hooking manner. The efficient raw material uniform mixing device achieves the effects of thorough uniform mixing, high uniform mixing speed and small workload, is good in uniform mixing effect, is improved in working efficiency, and is high in safety.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

High-precision rapid gas mixing device capable of rotating reversely

ActiveCN109126491AImprove the mixing effectIncrease gas flow and diffusionRotating receptacle mixersTransportation and packagingMode changeEngineering

The invention discloses a high-precision rapid gas mixing device capable of rotating reversely. The high-precision rapid gas mixing device capable of rotating reversely comprises a rotating motor, a rotating shell, an axial rotating embossment device, a rotating type outer side cavity flow channel, a gradually shrunk gas mixing outlet flow channel, a first mixed gas concentration detecting device,a first mixed gas storage bottle, a rotatable inner tube type flow channel, a mixed gas mode change-over switch, a mixed gas / third gas flow channel, a flow detection and flow channel change-over device, an air pump, a second mixed gas concentration monitoring device and a second mixed gas storage bottle; the rotating type outer side cavity flow channel is inserted in the rotating shell, and is fixedly connected with the rotating shell through the axial rotating embossment device; the rotatable inner tube type flow channel is inserted in the inner barrel of the rotating type outer side cavityflow channel; the left end of the rotating shell and the rotatable inner tube type flow channel are driven by the rotating motor; and the right end of the rotating shell is connected with the gradually shrunk gas mixing outlet flow channel through a rotating hinge. The high-precision rapid gas mixing device capable of rotating reversely is exquisite in structure, good in mixing effect and high inpracticality, the gas mixing speed is increased, and two modes can be switched over.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com