Liquid raw material uniformly mixing device

A liquid raw material and mixing technology, which is applied to mixers with rotating stirring devices, mixers, mixing methods, etc., can solve the problems of inconvenient cleaning, slow stirring speed, and general mixing effect, and achieve simple structure, convenient cleaning, Effects that improve mixing performance and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

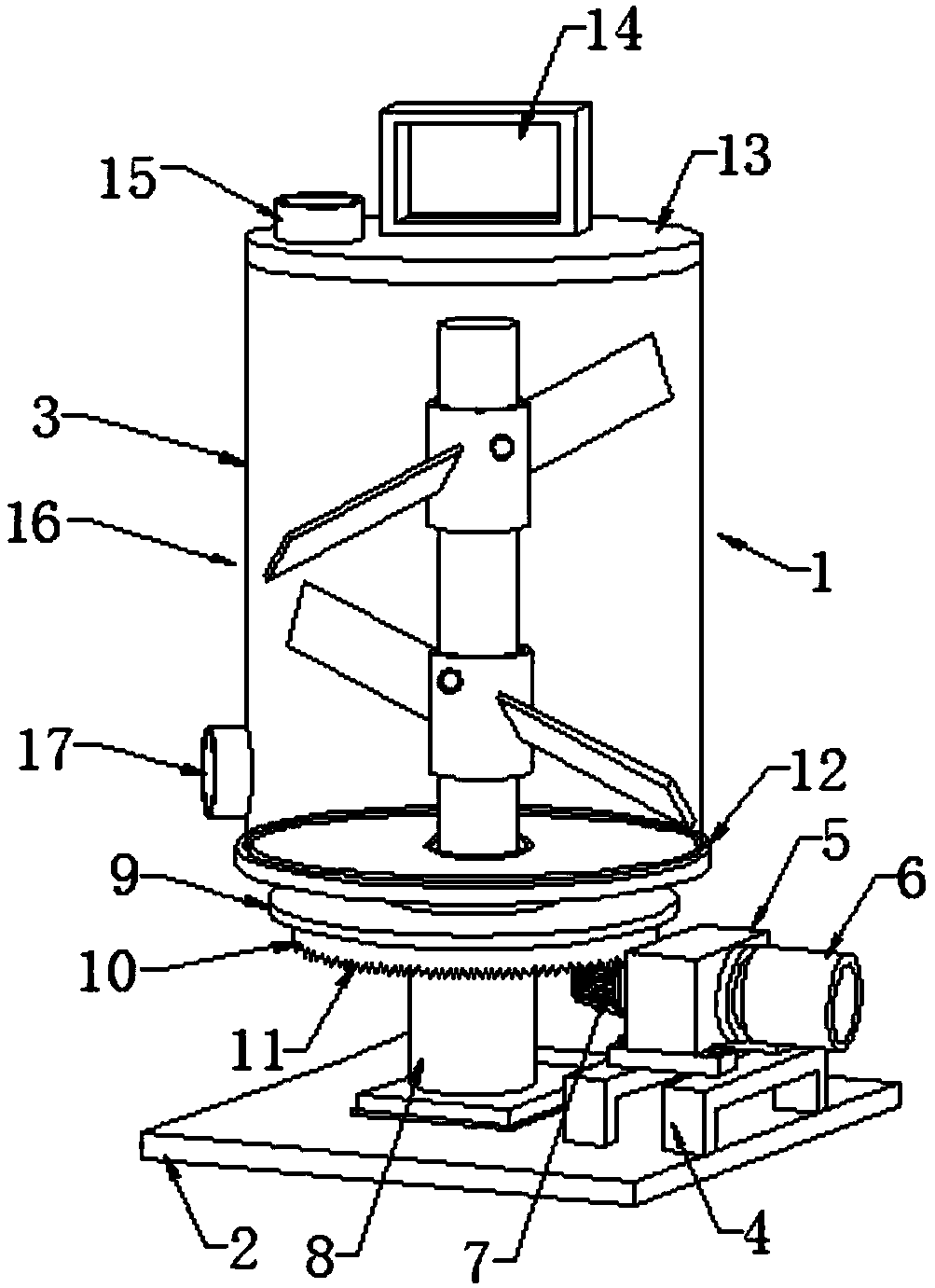

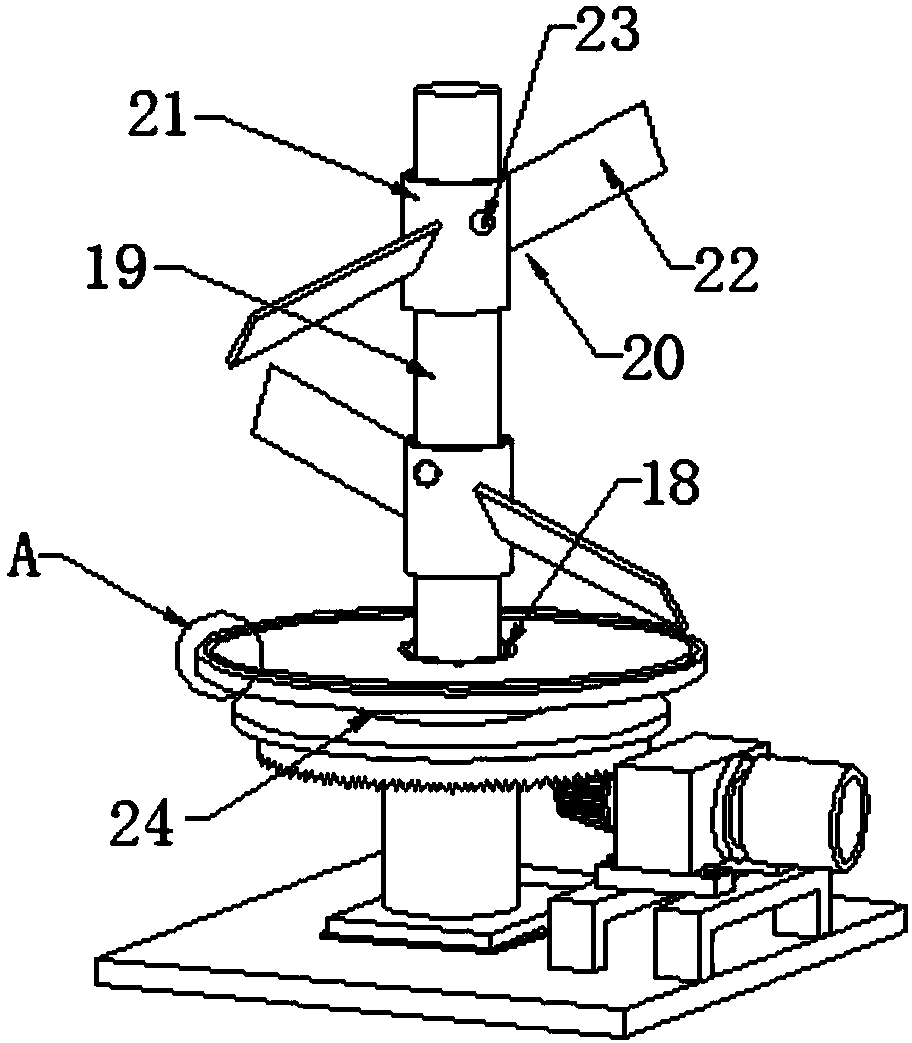

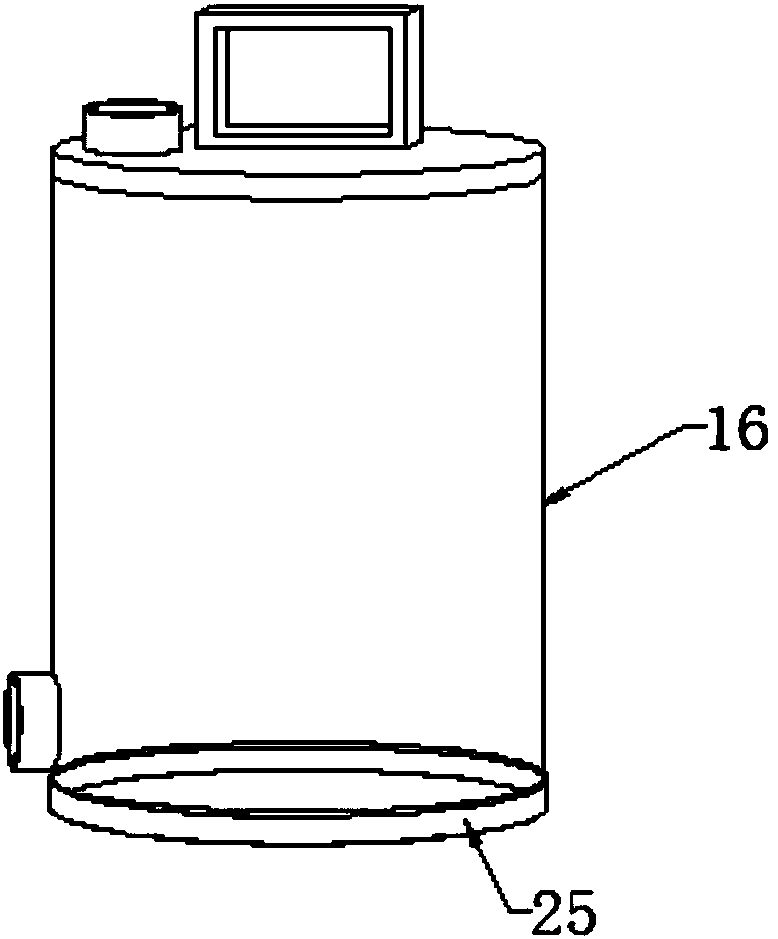

[0023] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a liquid raw material mixing device, including a device body 1, the device body 1 includes a base 2 and a mixing bucket 3, and a motor frame 4 and a column are installed on the top of the base 2 8. A connection seat 5 is installed on the top of the motor frame 4 through fixing bolts, a rotating motor 6 is installed on one side of the connection seat 5, and a transmission wheel 7 is installed on the other side of the connection seat 5, and one end of the transmission wheel 7 Connected to the output end of the rotating motor 6, a turntable 9 is movably connected to the top of the column 8, and a transmission disc 10 is installed at the bottom of the turntable 9, and the gear teeth 11 on the transmission disc 10 mesh with the transmission wheel 7 connection, the top of the turntable 9 is fixedly installed with a mounting plate 12 through a connecting shaft 24, the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com