Patents

Literature

42 results about "Encaustic tile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encaustic tiles are ceramic tiles in which the pattern or figure on the surface is not a product of the glaze but of different colors of clay. They are usually of two colours but a tile may be composed of as many as six. The pattern appears inlaid into the body of the tile, so that the design remains as the tile is worn down. Encaustic tiles may be glazed or unglazed and the inlay may be as shallow as an eighth of an inch, as is often the case with "printed" encaustic tile from the later medieval period, or as deep as a quarter inch.

Water-based thermal-insulation paint for cement encaustic tiles and roofs and preparation method thereof

ActiveCN102352160AEnhance reflexesImprove thermal insulationAntifouling/underwater paintsPaints with biocidesWater basedThermal insulation

The invention relates to a water-based thermal-insulation paint for cement encaustic tiles and roofs and a preparation method thereof. The water-based thermal-insulation paint for cement encaustic tiles and roofs is prepared by mixing a primer, which has the complex functions of reflecting and radiating solar heat and obstructing heat conduction, and a nano transparent varnish, which has high-light decoration performance and can reflect and transmit infrared rays. Compared with the prior art, under the composite actions of the primer and varnish, the water-based thermal-insulation paint for cement encaustic tiles and roofs has obvious thermal-insulation and cooling effects; and compared with the existing white and light-colored reflection-type thermal-insulation paint for buildings, the water-based thermal-insulation paint for cement encaustic tiles and roofs has the characteristics of multiple color systems, favorable high-light decoration performance, greater temperature difference of thermal insulation, and the like.

Owner:上海材料研究所靖江先进材料技术研究院 +1

Environment-friendly encaustic tile coating and preparation method thereof

InactiveCN101724329AImprove water resistanceGood weather resistanceMulticolor effect coatingsSodium bicarbonateEmulsion

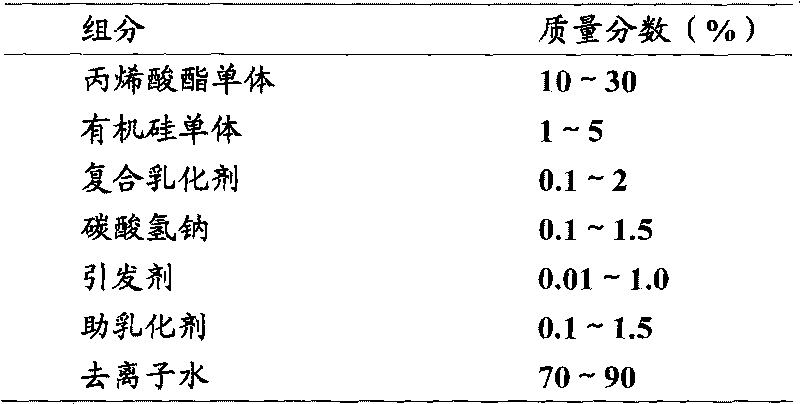

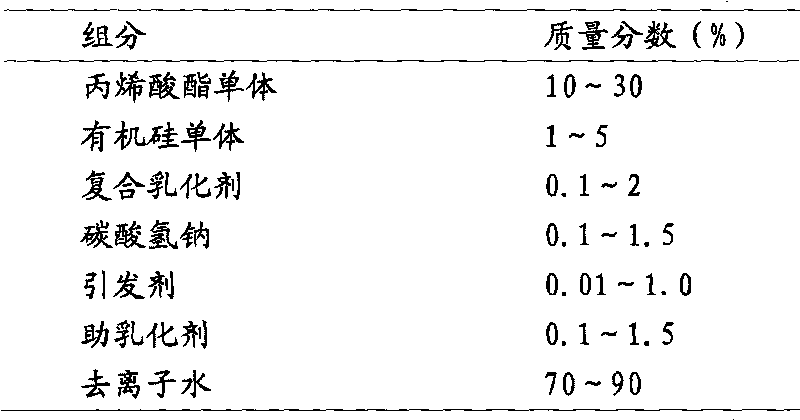

The invention provides environment-friendly encaustic tile coating and preparation method thereof, belonging to the field of coatings for buildings. Organosilicon modified acrylic emulsion obtained by polymerizing miniemulsion is used as a film forming material, and iron series pigment is used as an auxiliary material to prepare the environment-friendly encaustic tile coating, wherein the organosilicon modified acrylic emulsion comprises the following components in percentage by weight: 10-30 percent of acrylate monomer, 1-5 percent of organosilicon monomer, 0.1-2 percent of complex emulsifying agent, 0.1-1.5 percent of sodium bicarbonate, 0.01-1.0 percent of initiator, 0.1-1.5 percent of emulsifying aid and 70-90 percent of deionized water. The water resistance, the weather resistance and the aging resistance of the encaustic tile coating prepared from the emulsion are obviously improved.

Owner:上海漠王复合材料科技有限公司

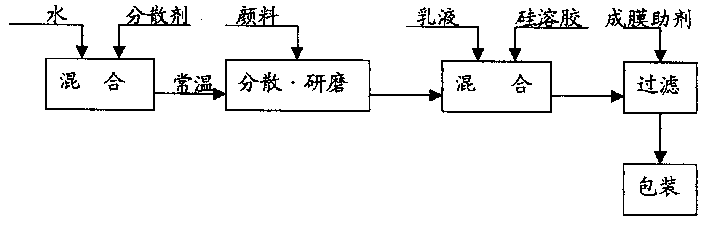

Environmental protection water encaustic tile coating and preparing method thereof

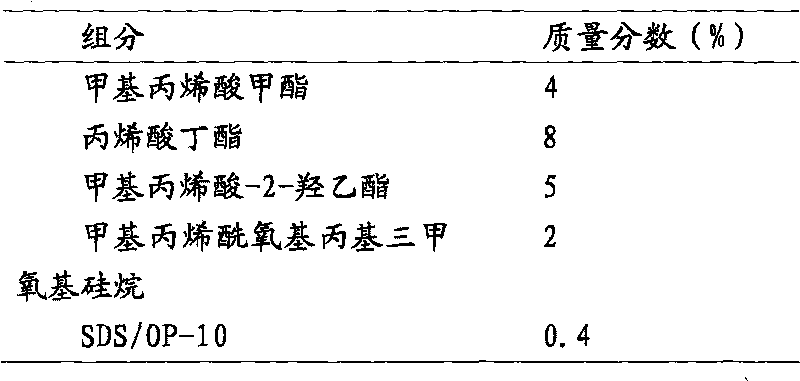

An environment protection type water paint for color tile is prepared from water, disperser, defoaming agent, pigment, emulsion, silicon sol, filming assistant, and bactericiding. Its preparing process is also disclosed. Its advantages are low cost, no poison and ordor, non-explosive and incombustible.

Owner:胡自立

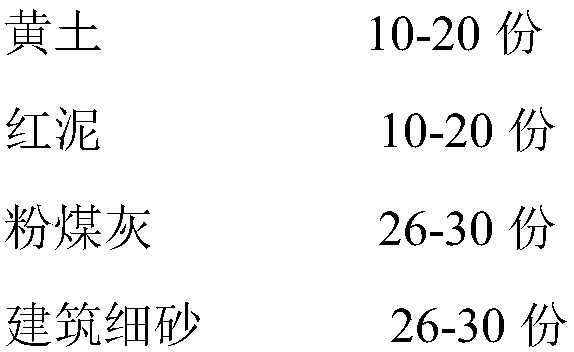

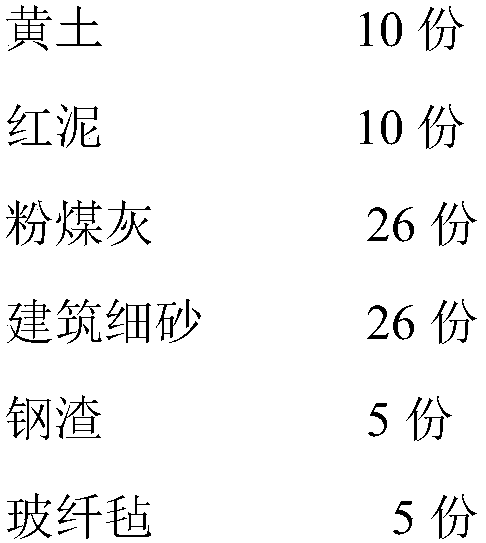

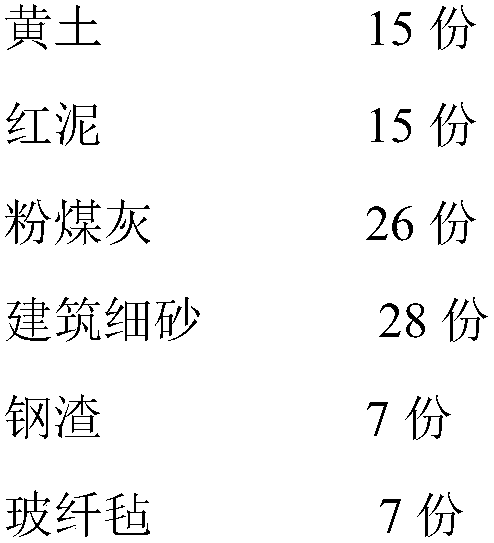

Anti-cracking encaustic tile and production technique thereof

The invention discloses an anti-cracking encaustic tile and a production technique thereof, relating to the field of construction materials. The anti-cracking encaustic tile comprises the following components in parts by weight: 20-30 parts of quicklime, 20-35 parts of clay, 40-50 parts of raw gypsum, 1-2 parts of mixed fiber, 15-20 parts of cement, 25-30 parts of coarse sand, 10-15 parts of fine sand and 9-12 parts of pigment. The production technique disclosed by the technical scheme of the invention has the advantage of high production efficiency. The produced encaustic tile has the advantages of high strength, high safety and reliability, long service life, uniform material distribution and favorable pigment adhesion property, and can prevent cracking.

Owner:肥西县碧涛建材有限公司

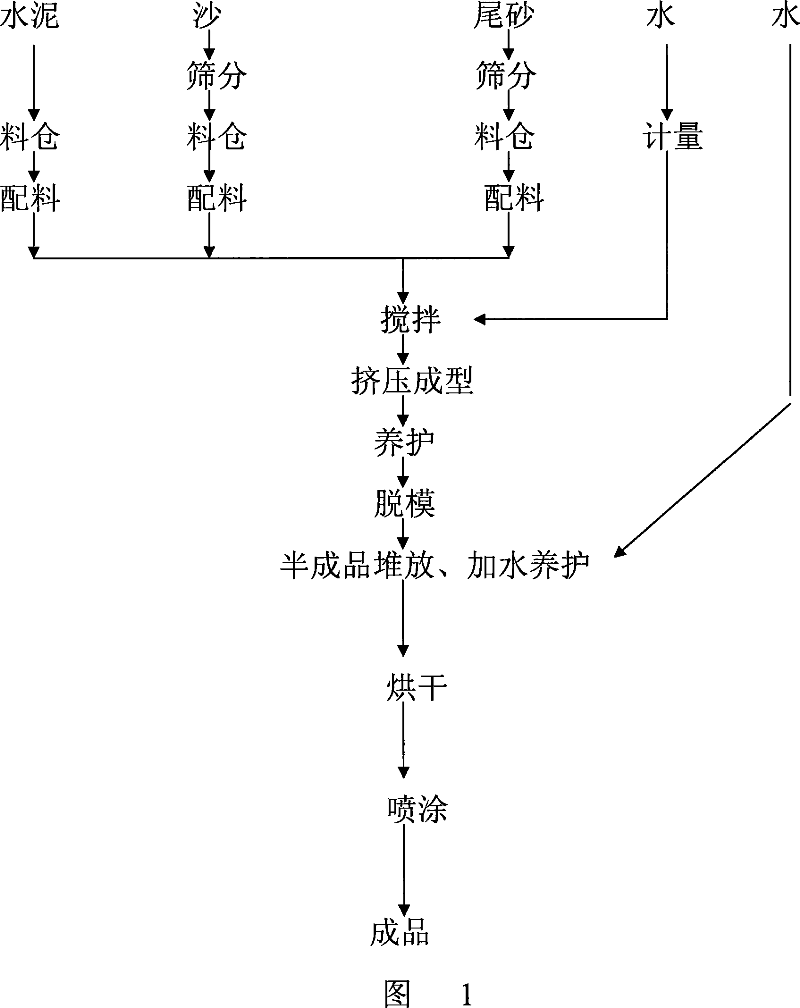

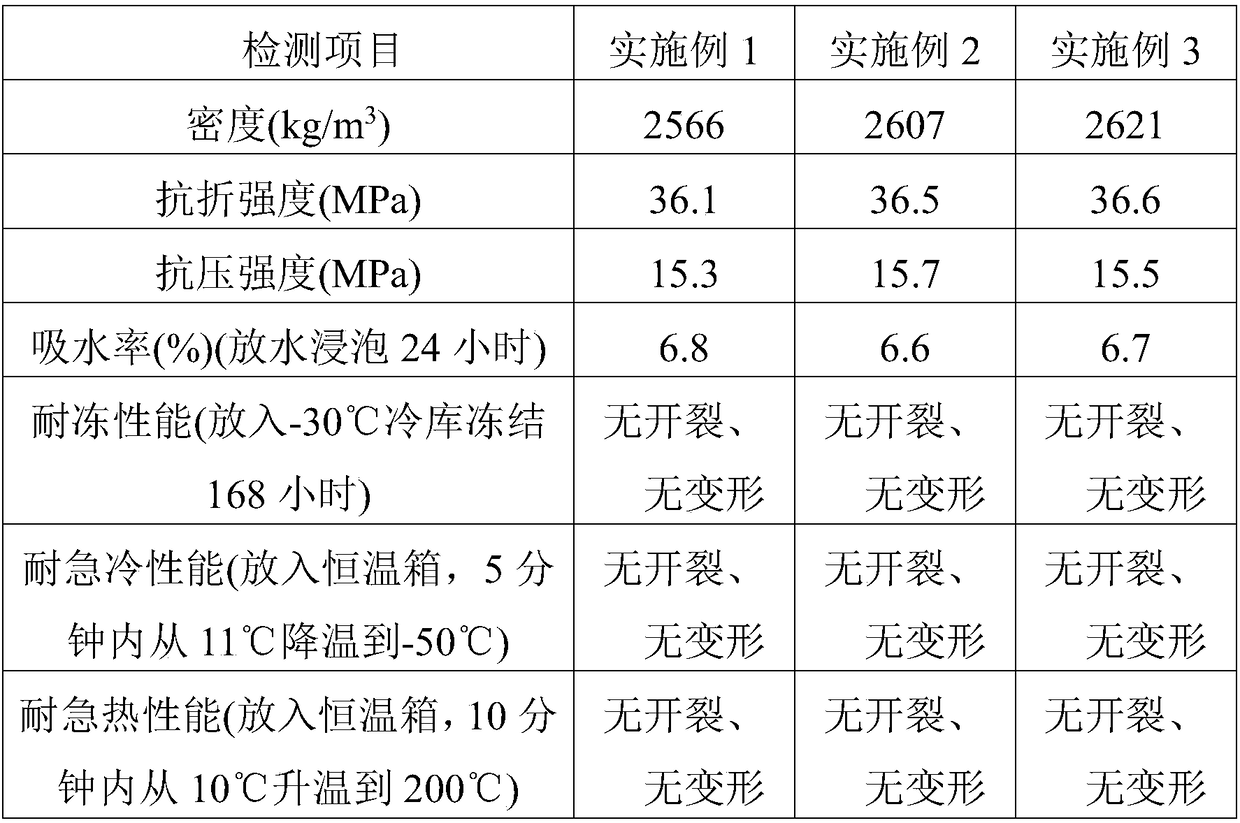

Gold ore tailing sand concrete encaustic tile and manufacturing technique

InactiveCN101041575AChange roughChange the shortcomings such as poor densityRoof covering using tiles/slatesCompression moldingProduction line

The invention discloses a gold ore tail sand concrete coloured tile and preparing craft in architectural materials production technique domain, which comprises the following steps: choosing gold ore tail sand, cement and sand as main material; allocating mass matching at 40%-55%, 30%-40%, 15%-25% separately; 1. stirring the raw material; extrusion forming; 2. curing; demoulding; half-finished product stowing; adding into water; curing; 3. drying; spraying; finishing product. This invention adopts high-pressure compression molding method, which possesses merits of dense tile body and polish surface.

Owner:蓬莱市金正建材有限责任公司

Brownish red gangue encaustic tile and preparation method thereof

InactiveCN108503337ASolve the key technical problems that reduce the service lifeIncrease consumptionCeramic extrusion diesClay mixing apparatusResource utilizationEncaustic tile

The invention belongs to the technical field of building materials, and particularly relates to a brownish red gangue encaustic tile and a preparation method thereof. Preparation materials of the gangue encaustic tile comprise gangue sand, a harmless treating agent, a glaze complexing agent and water; the harmless treating agent is composed of calcium chloride, quick lime and land plaster which are mixed; harmless treatment is carried out on the gangue, and the technical problem is solved that a gangue product separates out crystal substances during the long-term use process in a natural environment so as to reduce the service life; the invention provides a new method of gangue resource utilization, the gangue consumption is increased, the production process is clean and environmentally friendly, and the productivity is high; according to the gangue encaustic tile, the development and utilization of the gangue resources are improved, and the additional valve of products can be effectively improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

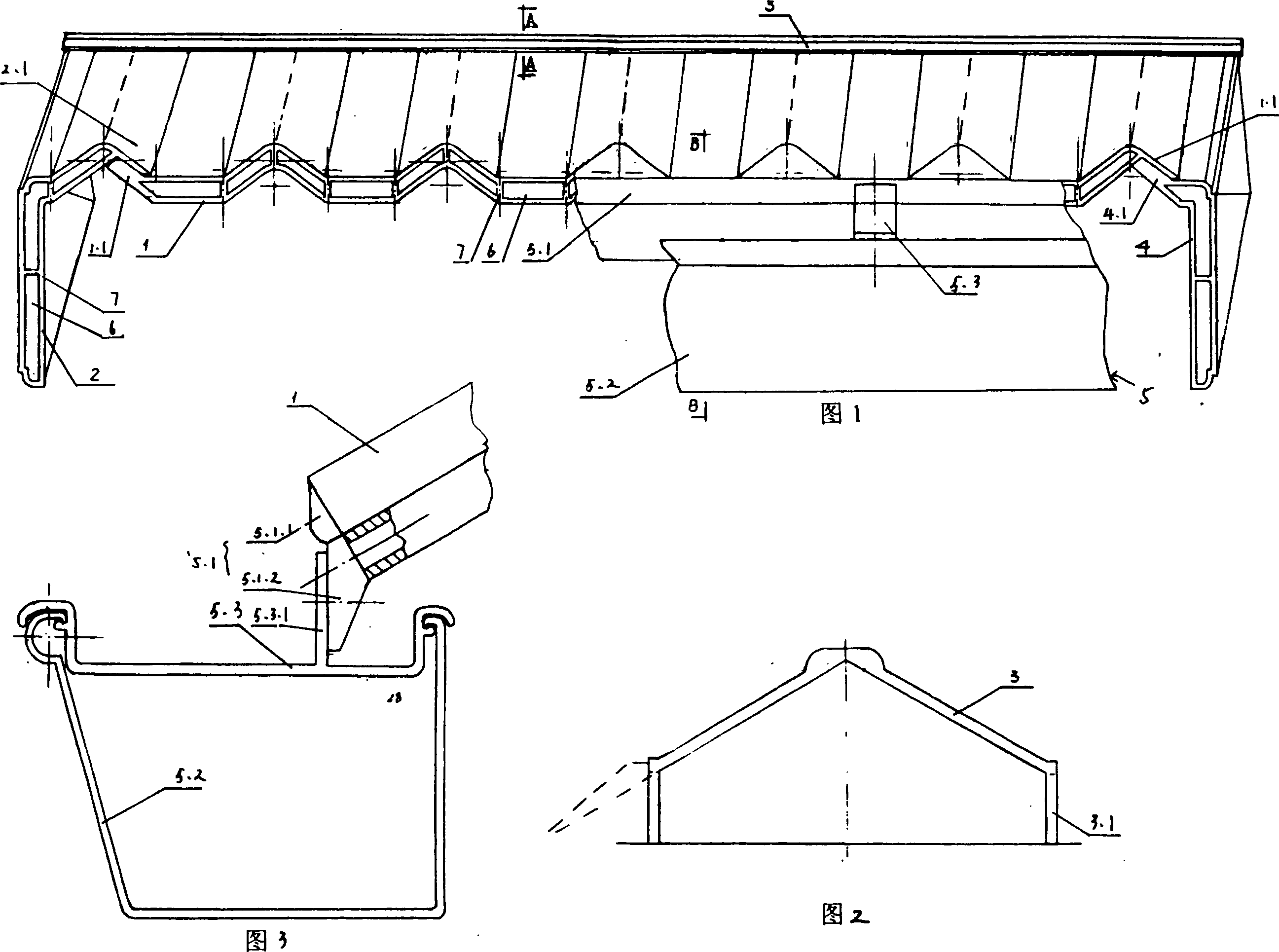

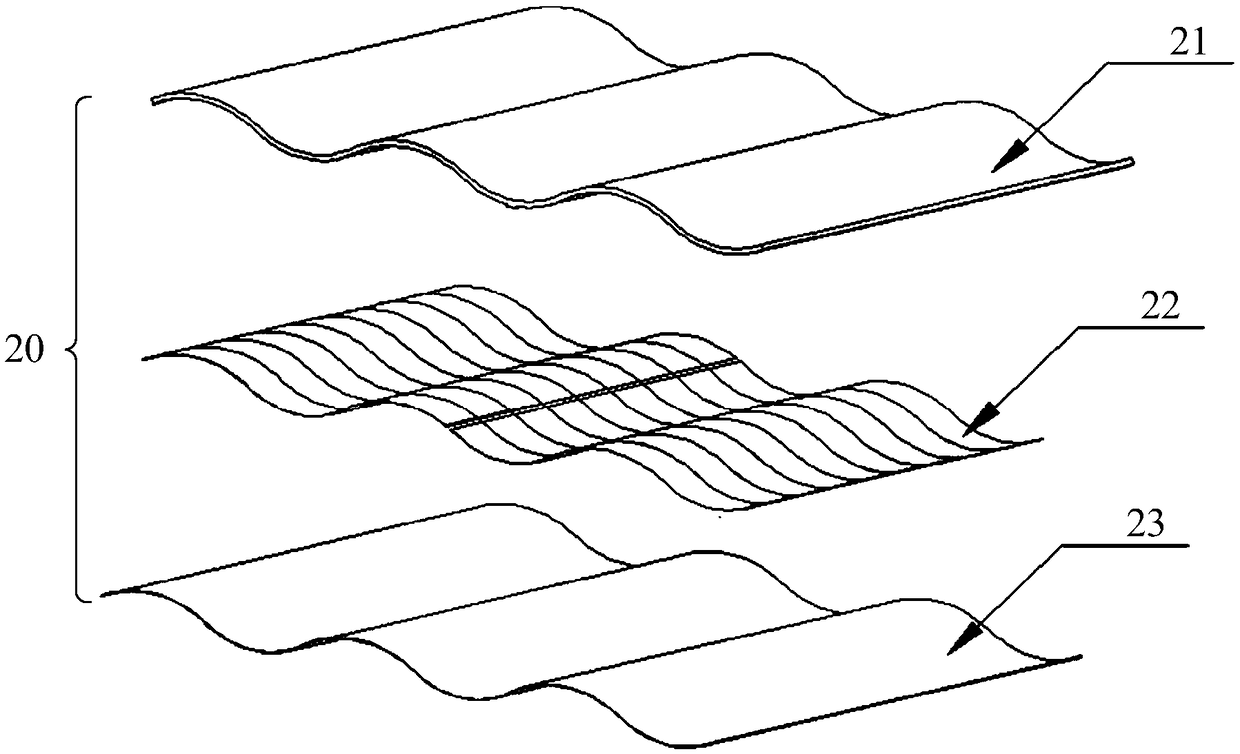

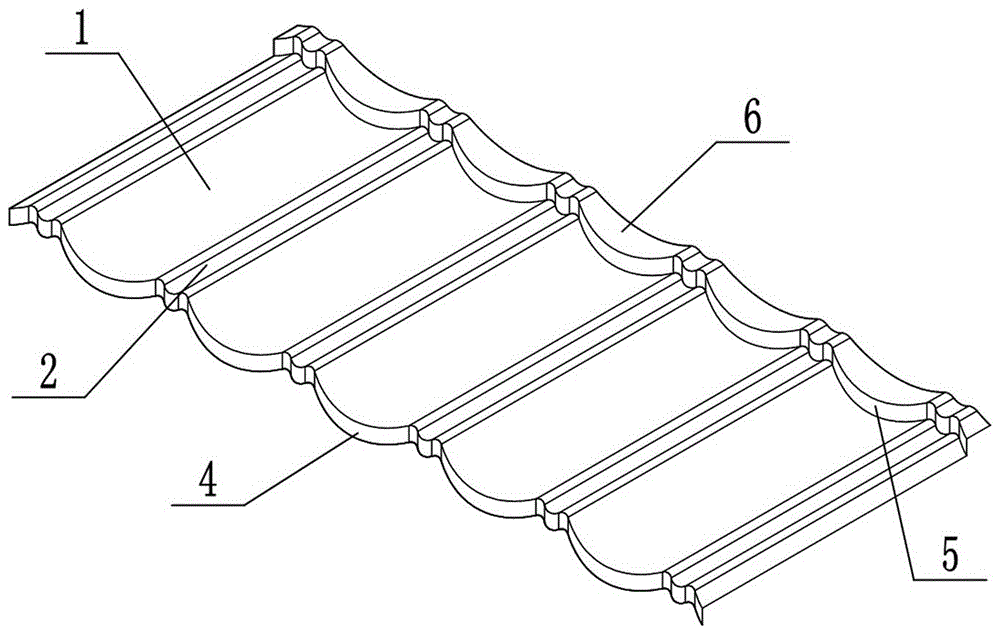

Synthetic hollow encaustic tile assembly

InactiveCN1702262ALow costGood heat insulation and weather resistanceRoof covering using tiles/slatesFiberEaves

This invention relates to a compositing hollow encaustic tile assembly, which comprises tiles used in dome, plain tile (1) for short; tiles used in eaves, verge tile (2, 4, 5) for short and tiles used in ridge, ridge tile (3) for short; wherein the verge tile (2,4,5) including the left verge tile (2), the right verge tile (4) and the front and rear verge tile (5), characterized in that said plain tile (1), verge tile (2, 4, 5) and ridge tile (3) are all hollow structures (6) compounded by the waste plastics, chips or plants pole fabric, and inside the hollow structures (6) set several dabber boards broadways. The invention is light, high-intensity, aid-resistant, alkaliresistant and water resistant, in addition it is heat-proof and thermal insulation.

Owner:孙锡高

Raw materials formulation and method for preparing concrete encaustic tile by using gallet

The invention provides the formulation and method for preparing encaustic concrete tile by using attle, wherein the formula of the raw material include (by weight parts): attle 53-58, cement (P.O 42.5#) 29-33, additive (TW-3 high efficiency water reducing agent) 0.5-1, and balancing water.

Owner:QUNFENG INTELLIGENT MACHINERY

Fiber cement wave-mode encaustic tile and preparation technique thereof

The invention relates to a manufacture process of fiber cement wave-typed color tiles, including the following steps: picking up; spraying film and color recovering; pressurizing and draining the recovered color; integrating tile billet and resin paints; color pastes sprayed on the cloth pad being naturally absorbed to the tile billet surface after pressurization and obtaining the product by curing after removing film, trimming and sucking and removing bottom lines. The invention uses the tiles in color of traditional cements to produce the color tiles, elegant and popular, which meets the requirements of modern architecture and beautifies the environment. The invention can also reduce water vapor transmission rate and is environment-friendly and energy saving.

Owner:尹明和

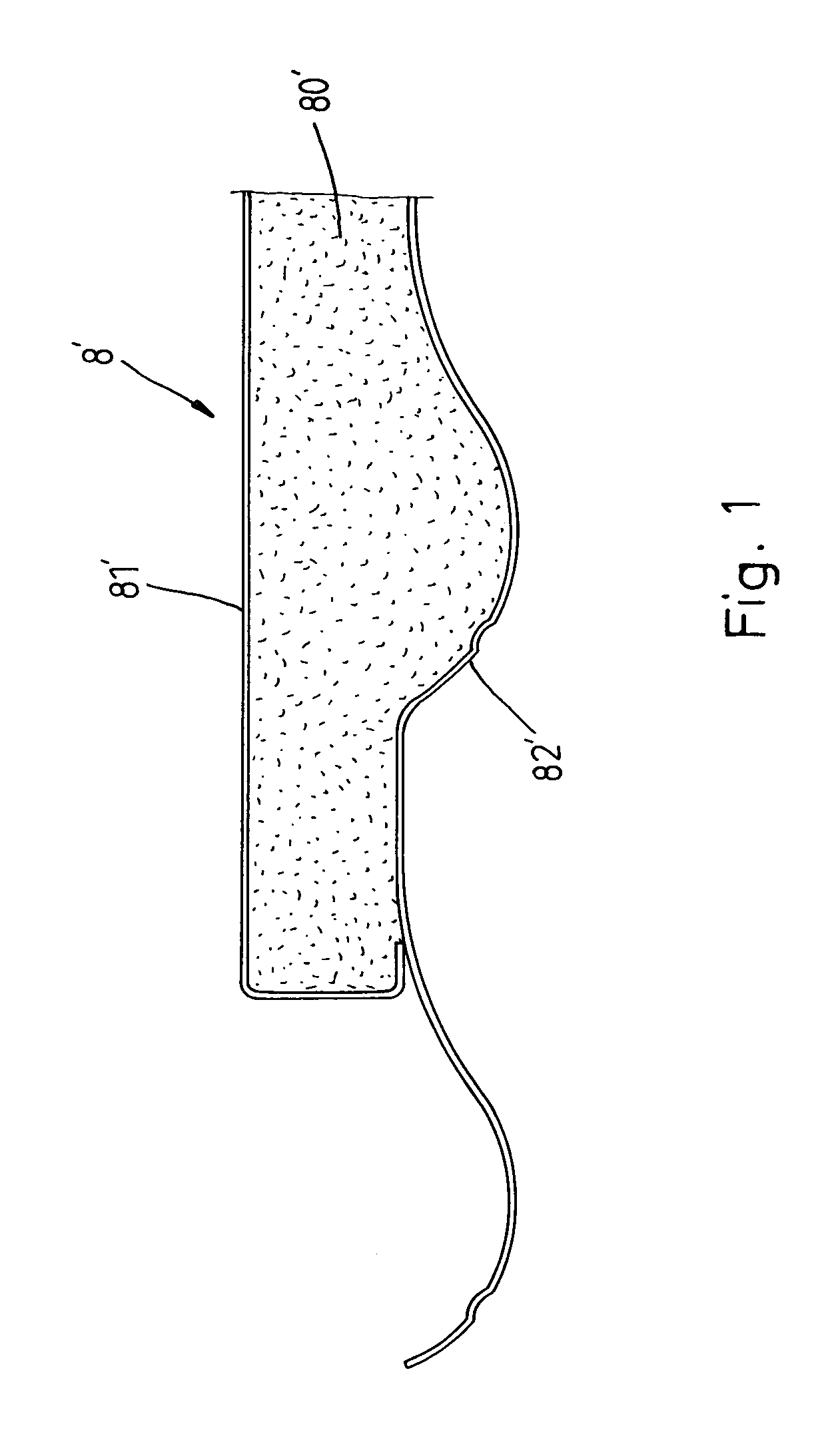

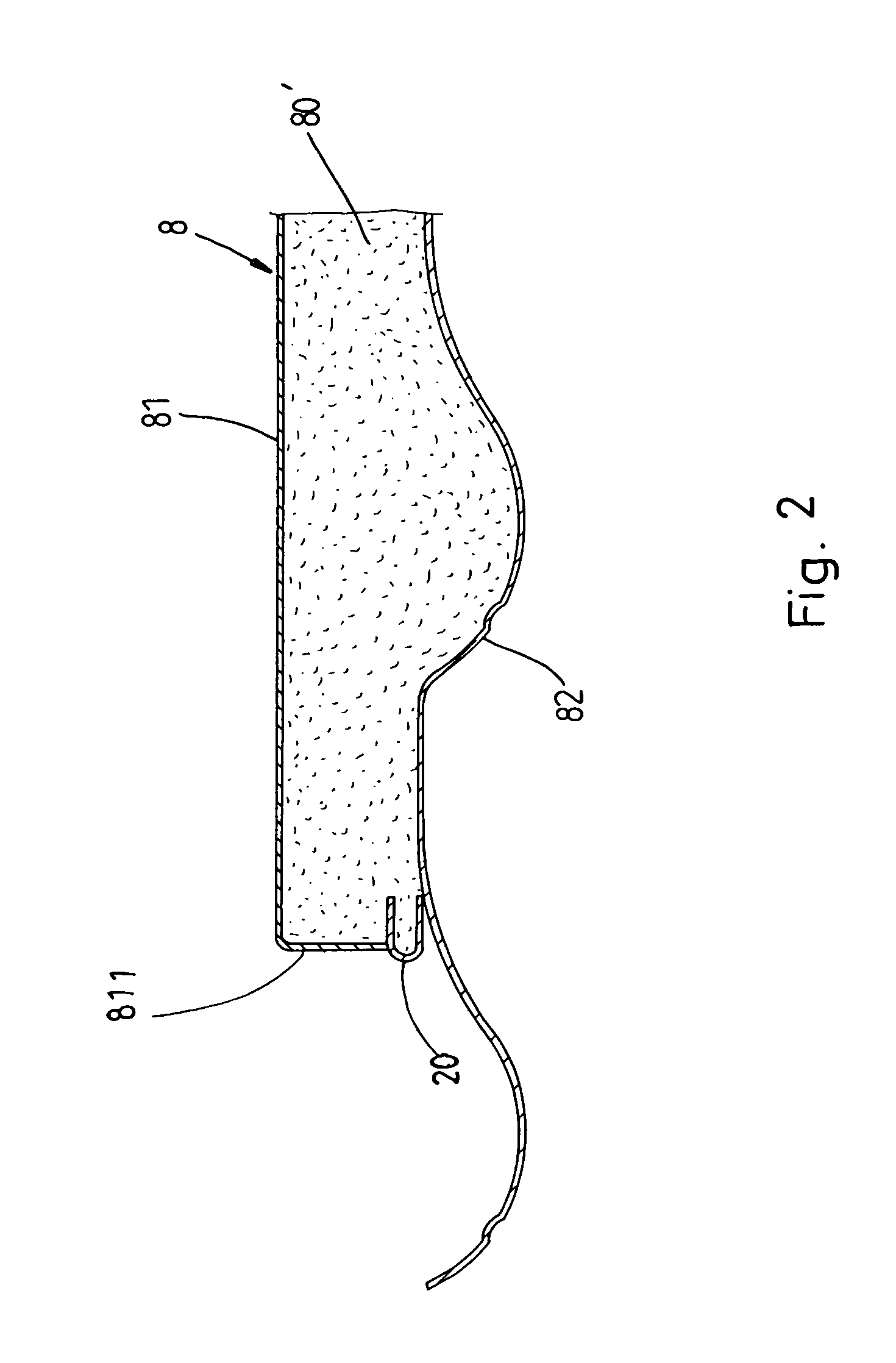

Thermoinsulation metal encaustic tile making machine

InactiveUS7302983B1Made practicalAvoid wrinklesMechanical working/deformationEncaustic tileThin layer

Owner:CHUANG SEN JUNG

Encaustic tile

PendingCN109301013AUniform colorThere will be no color differencePhotovoltaic supportsRoof covering using slabs/sheetsEncaustic tileEngineering

The present invention provides an encaustic tile. The encaustic tile comprises: a light transmission hook face front panel; and a flexible colorful composite layer laminated with the light transmission hook face front panel. The flexible colorful composite layer is introduced into a tire to ensure that the flexible colorful composite layer is uniform in color and cannot have large chromatic aberration, and the flexible colorful composite layer can be laminated with the light transmission hook face front panel to allow the surface of the encaustic tile to have uniform and consistent colors.

Owner:汉瓦技术有限公司

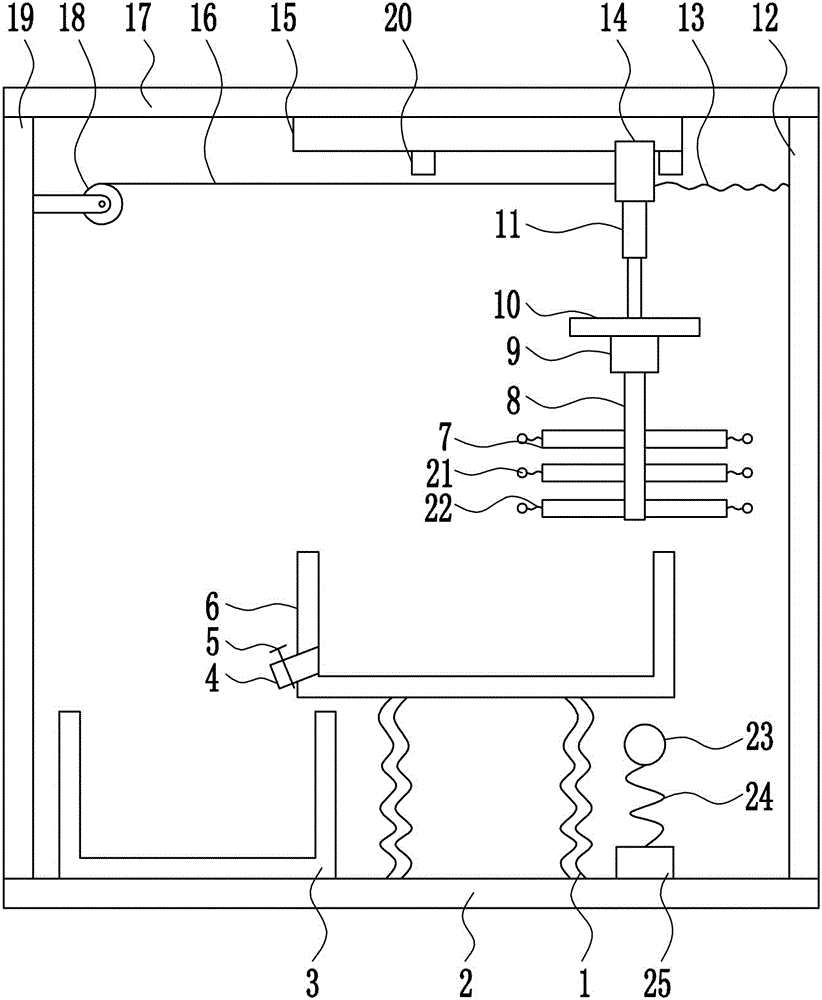

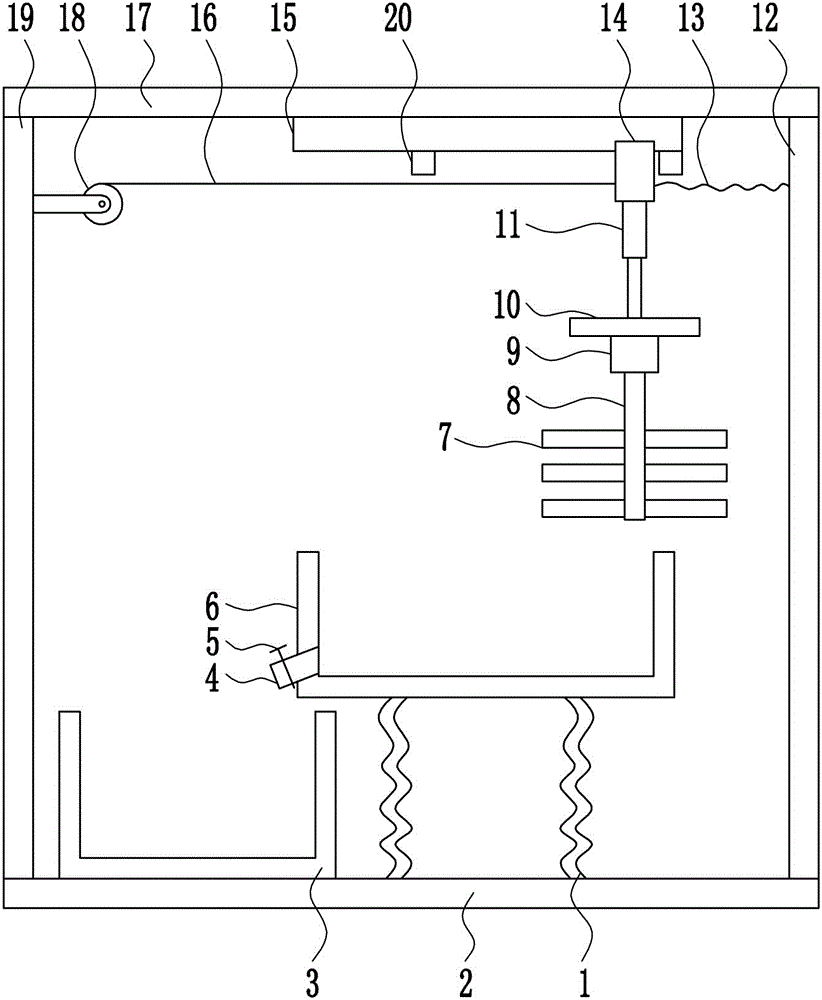

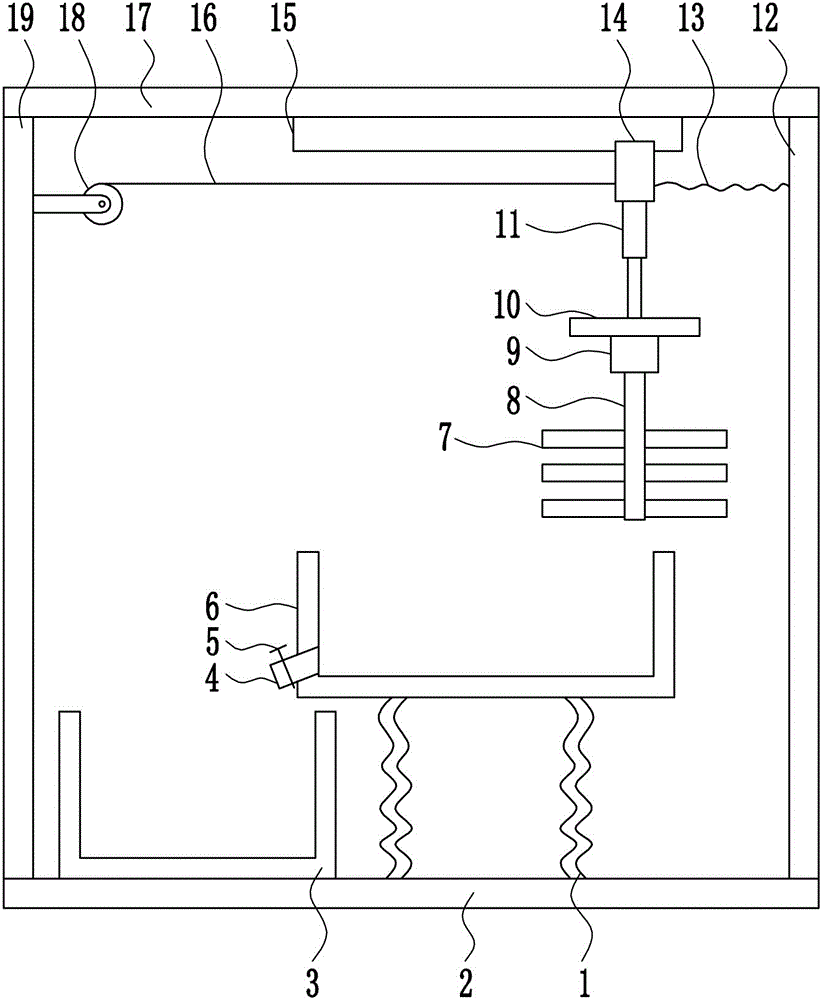

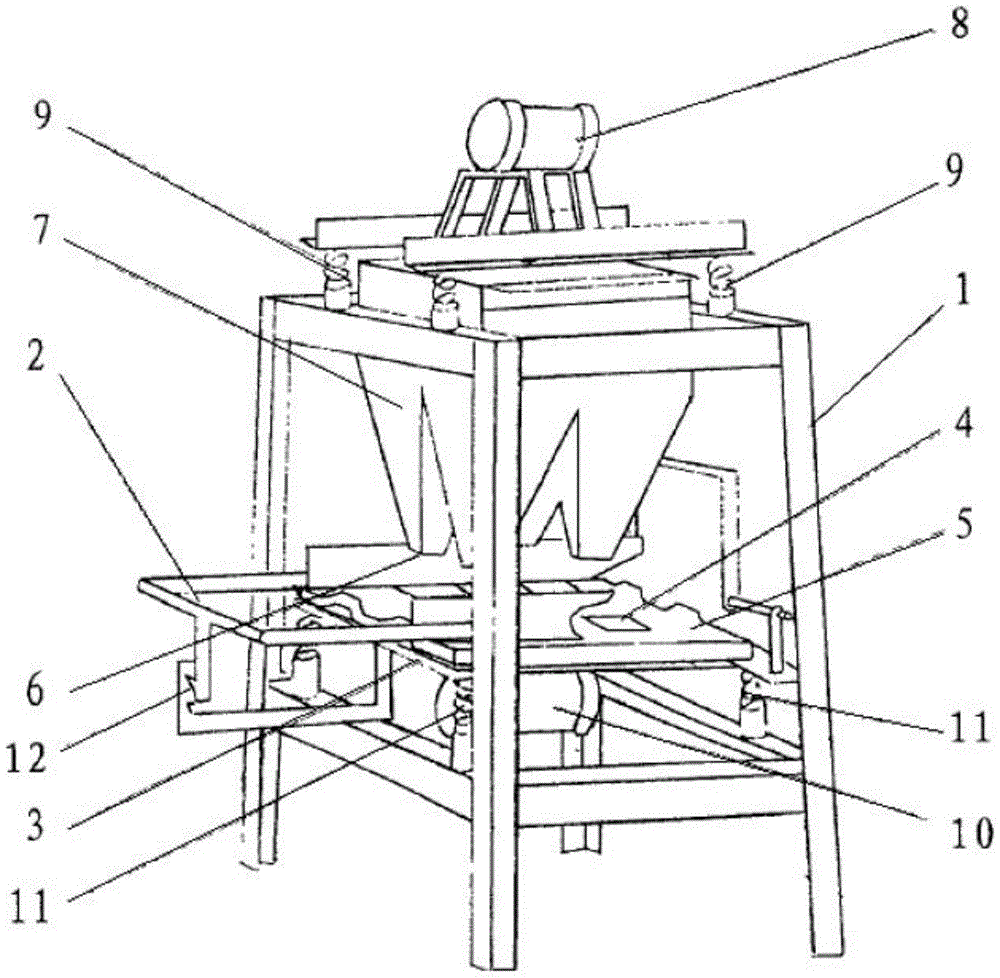

Efficient raw material uniform mixing device for encaustic tile production

InactiveCN106541499AMix thoroughlyIncrease mixing speedCement mixing apparatusEncaustic tileEngineering

The invention relates to a raw material uniform mixing device, in particular to an efficient raw material uniform mixing device for encaustic tile production. The efficient raw material uniform mixing device has the advantages of being thorough in uniform mixing, high in uniform mixing speed and small in workload. The efficient raw material uniform mixing device comprises first springs, a bottom plate, a collecting frame, a discharging pipe, an electronic control valve, a uniform mixing frame, mixing blades, a rotating shaft, a motor, a fixed plate, an electric push rod, a right frame and the like. A left frame is welded at the left end of the top of the bottom plate. The collecting frame is arranged on the left side of the top of the bottom plate. One end of each first spring is connected with the right side of the top of the bottom plate in a hooking manner. The efficient raw material uniform mixing device achieves the effects of thorough uniform mixing, high uniform mixing speed and small workload, is good in uniform mixing effect, is improved in working efficiency, and is high in safety.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Acrylic emulsion for encaustic tile paint

The invention discloses an acrylic emulsion for encaustic tile paint, which is mainly prepared from alkene monomers, an emulsifier, a co-emulsifier, an initiator, a buffering agent and water. The improvement of the invention is as follows: alkene hydrophobic function monomer acrylamide and alkene organosilane coupling agent are utilized to modify acrylic polymers, thereby enhancing the adhesion of the polymers to cement tiles and the rainfall erosion resistance of the polymers; and especially, polyester polyol with proper molecular weight is introduced into the emulsion polymerization to obviously enhance the luster, fullness and leveling property of the polymer film, thereby enhancing the color vividness and brightness of encaustic tiles. The emulsion is mainly used for manufacturing roof encaustic tile paint, thereby beautifying the roofs of the city buildings.

Owner:江苏日出化工有限公司

Novel environment-friendly encaustic tile and preparation thereof

InactiveCN104193278AReduce pollutionSave resourcesSolid waste managementMoisture resistanceFatty alcohol

The invention discloses a novel environment-friendly encaustic tile which is prepared from the following raw materials in parts by weight: 20-40 parts of modified desulfurization gypsum, 15-25 parts of corncob, 10-20 parts of barite powder, 20-40 parts of quartz sand, 1-3 parts of Arabic gum, 4-8 parts of cement, 0-20 parts of pigment, 1-2 parts of dimethicone, 1-3 parts of white mineral oil, 0.5-1 part of fatty alcohol-polyoxyethylene ether, 1-3 parts of sugar calcium and 20-40 parts of water. The encaustic tile disclosed by the invention is high in bearing capacity and good in water resistance and moisture resistance, and has the effects of reducing the environmental pollution, saving the resources and according with the energy-saving and environment-friendly industrial policies by effectively utilizing the waste materials.

Owner:安徽维东建材股份有限公司

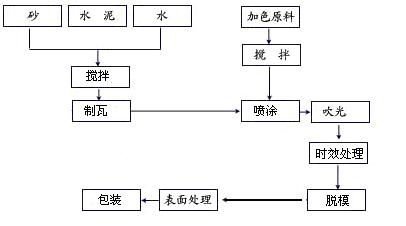

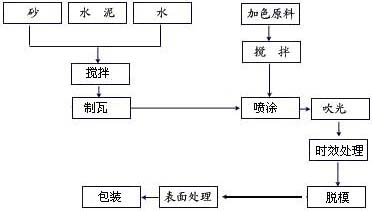

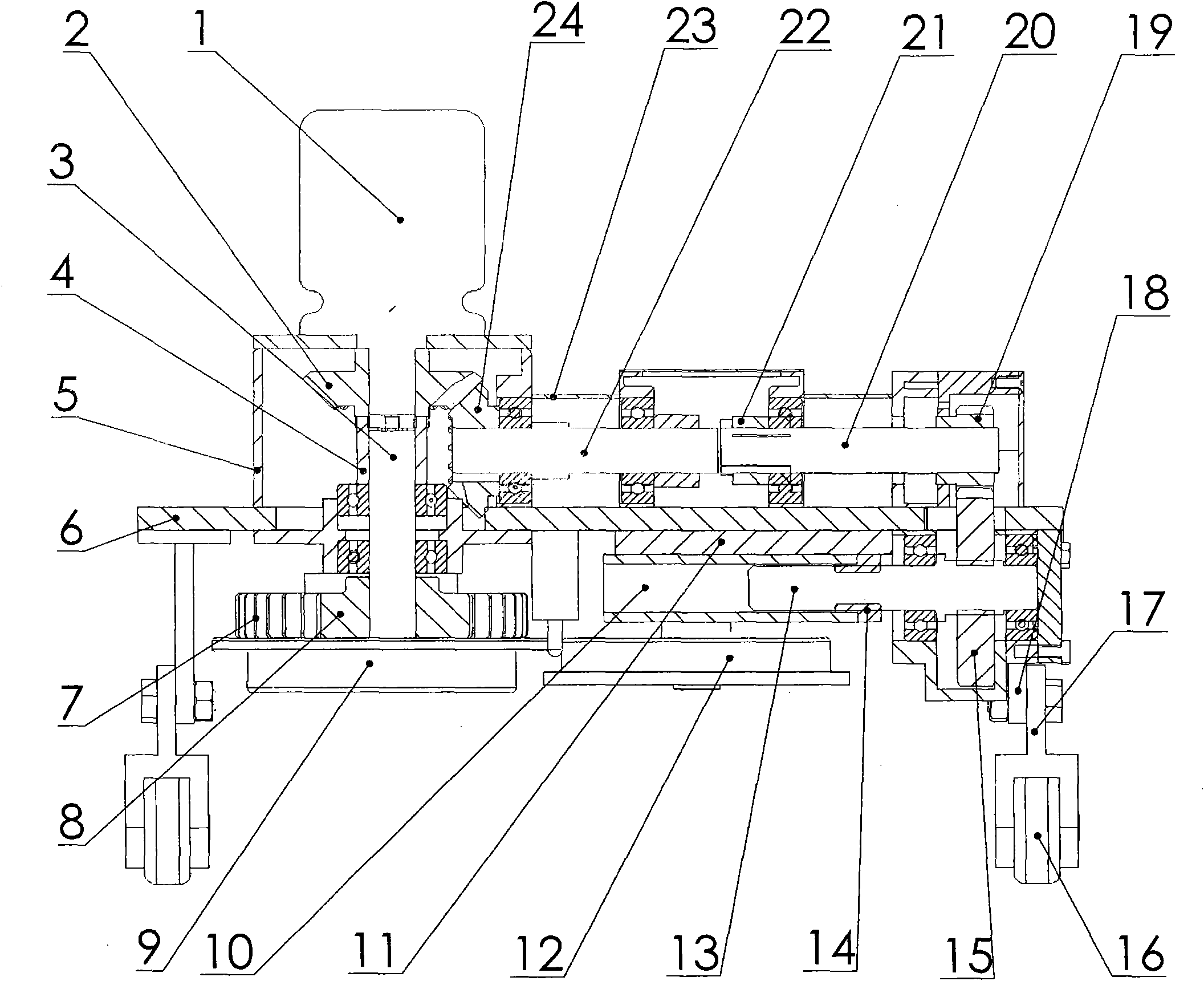

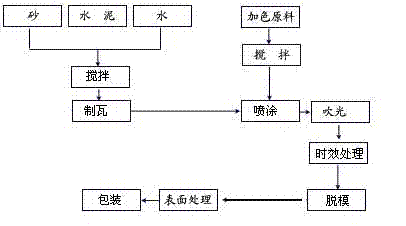

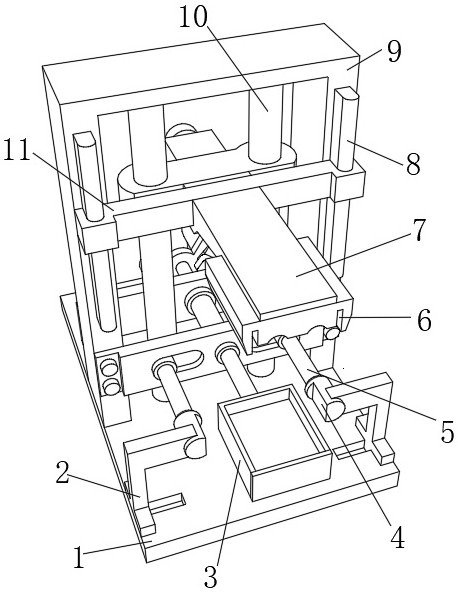

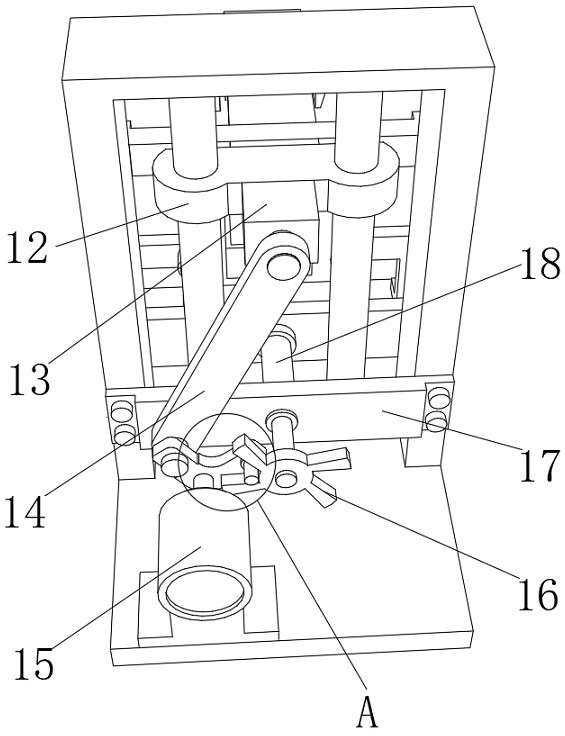

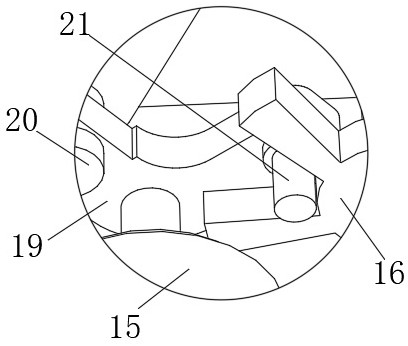

Technique for manufacturing high-strength encaustic tiles and extruding device thereof

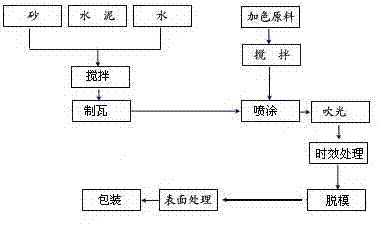

The invention relates to a technique for manufacturing high-strength encaustic tiles, comprising the steps of mixing sand, cement and water according to the proportion of 1.12-1.5:1:0.38-0.50, stirring the sand, the cement and the water by a stirrer, injecting the mixture into a charging barrel of a tile making machine, extruding raw materials which are 55-125mum in particle size and are mixed uniformly by an extruding device of the tile making machine, and extruding the raw materials onto a tile mold paved with glass fiber; coloring propylene material, stirring the material by a small stirrer, spraying the material on the tile surface on the mold, and polishing the surface of the mold in a blowing manner; and then putting the tile mold on a tile frame, carrying out aging treatment, then carrying out mechanical demolding and surface treatment, removing burrs at the corners and finally packaging. The screw extruding device adopted in the technique for manufacturing the high-strength encaustic tiles comprises a motor, a transmission device, a main shaft, a blanking hopper, a screw, an outer pipe, a discharging port and a frame. The invention has the advantages that the process is simple, and the control is easy, so that the requirements for an operator are reduced; and simultaneously, the strength of products is high, the color is rich, the rejection rate is low, the cost is low and the application range is wide.

Owner:东北金城建设股份有限公司

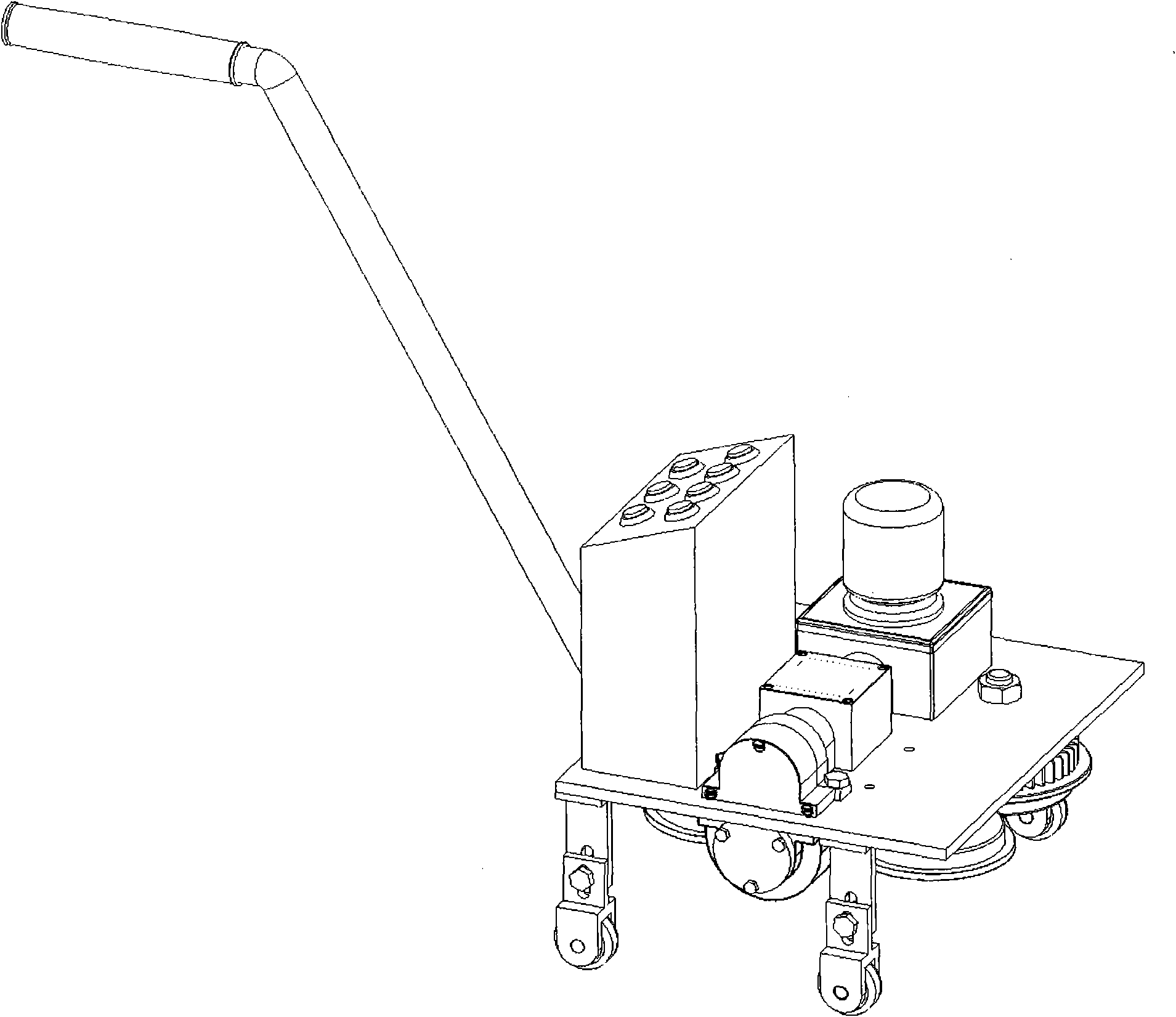

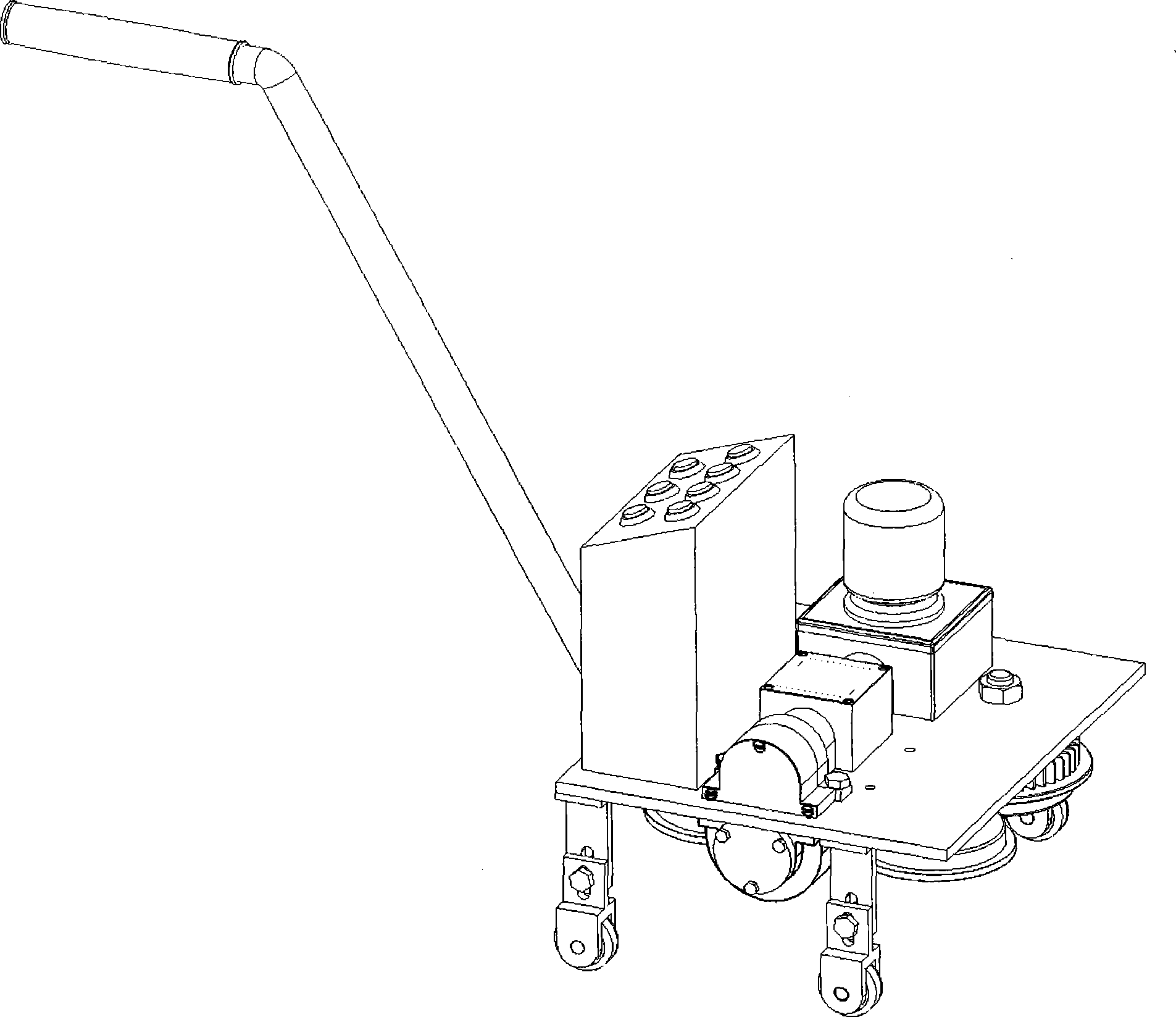

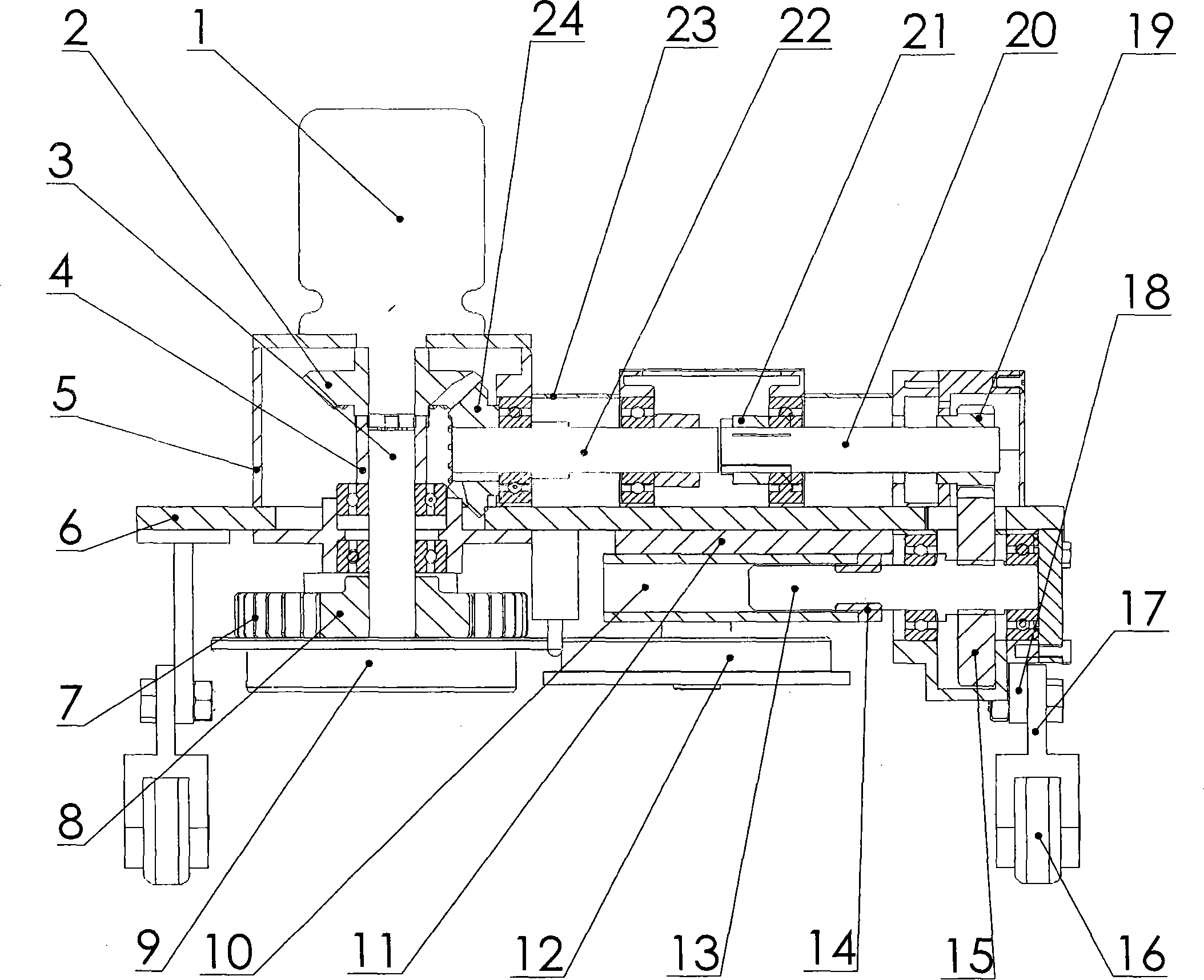

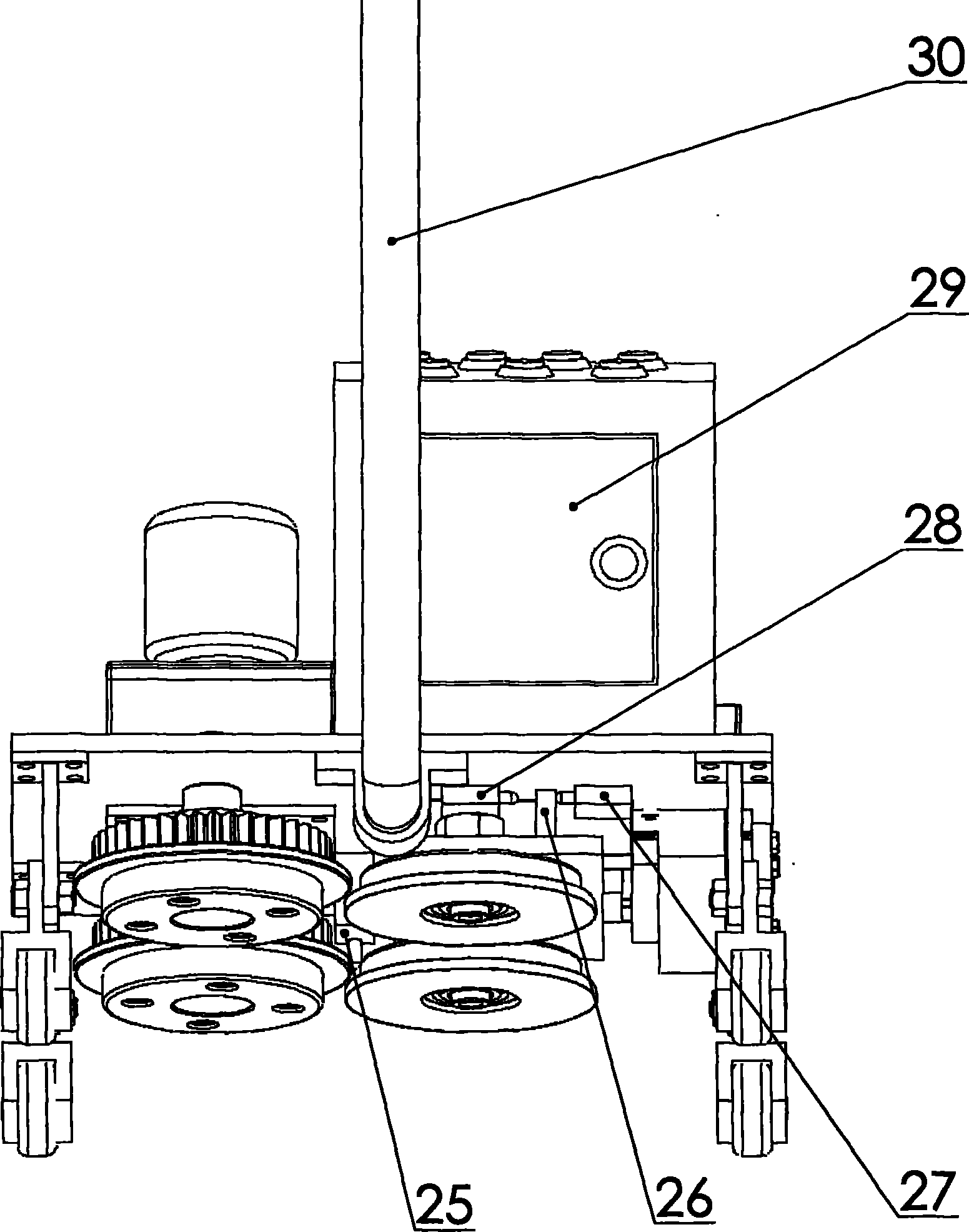

Full-automatic edge locking machine for 760-type encaustic tiles

InactiveCN102808485AImprove work efficiencyEasy to operateRoof toolsElectromagnetic clutchEncaustic tile

The invention relates to a full-automatic edge locking machine for 760-type encaustic tiles. The machine comprises a main body plate, a differential case, a motor, gears, shafts, edge locking forming wheels, electromagnetic clutches, travel switches and the like. Through the technical scheme, a transmission device and an automatic device are arranged, so that the edge locking forming wheels are automatically extruded, and then edges are automatically locked; and the machine can be automatically retreated and stopped after one edge seam is locked, the edge locking forming wheels can be automatically loosened and restored to the initial state, and the machine is ready to lock the next edge seam. The defects of the conventional edge locking machine for the 760-type encaustic tiles are overcome, the edge seams of the 760-type encaustic tiles are fully automatically extruded and locked, and the machine has the advantages that manual extrusion is not needed, the machine is low in labor intensity, convenient to operate, high in working efficiency, standard, accurate and high in edge locking quality, and the like.

Owner:刘全涛

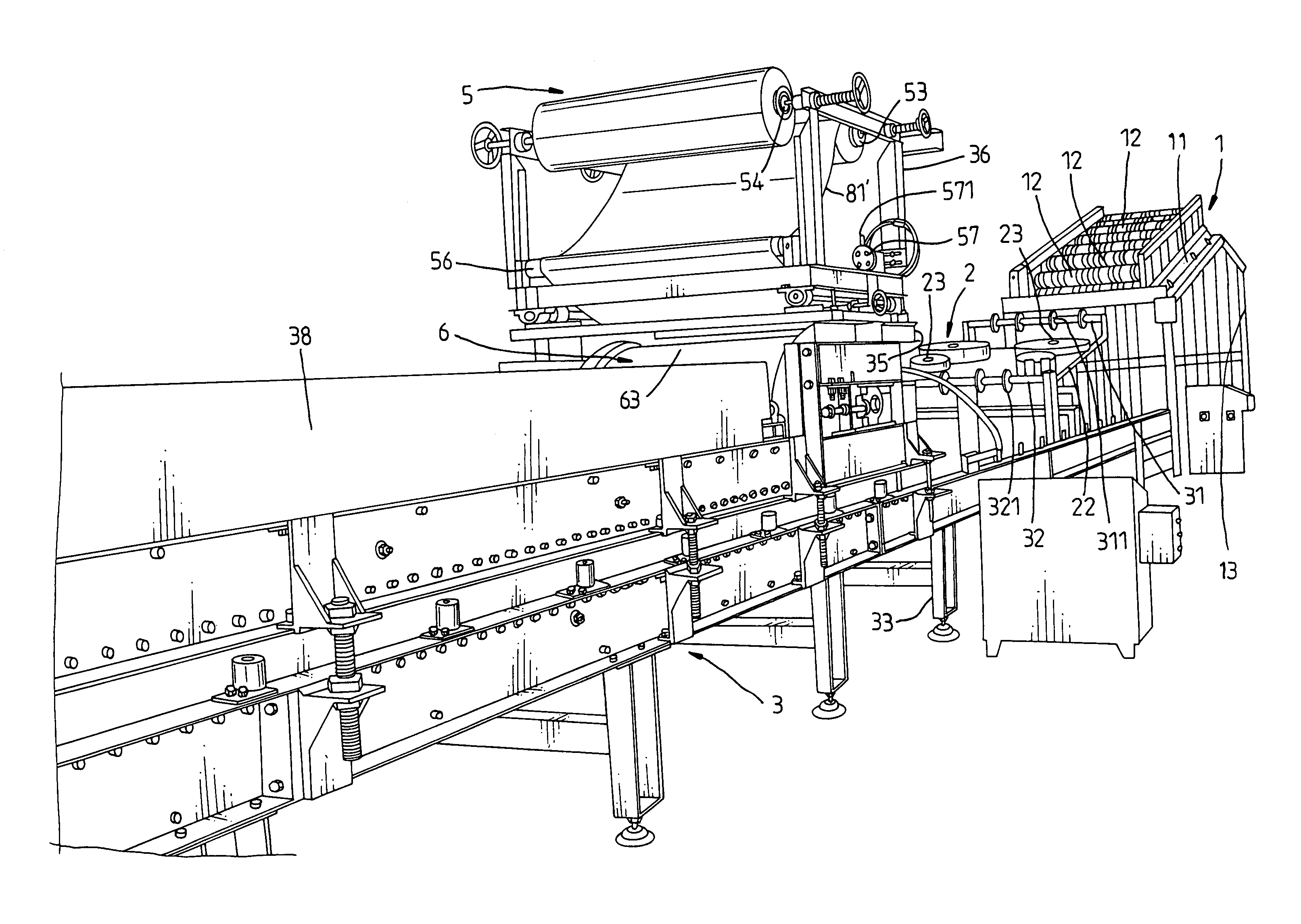

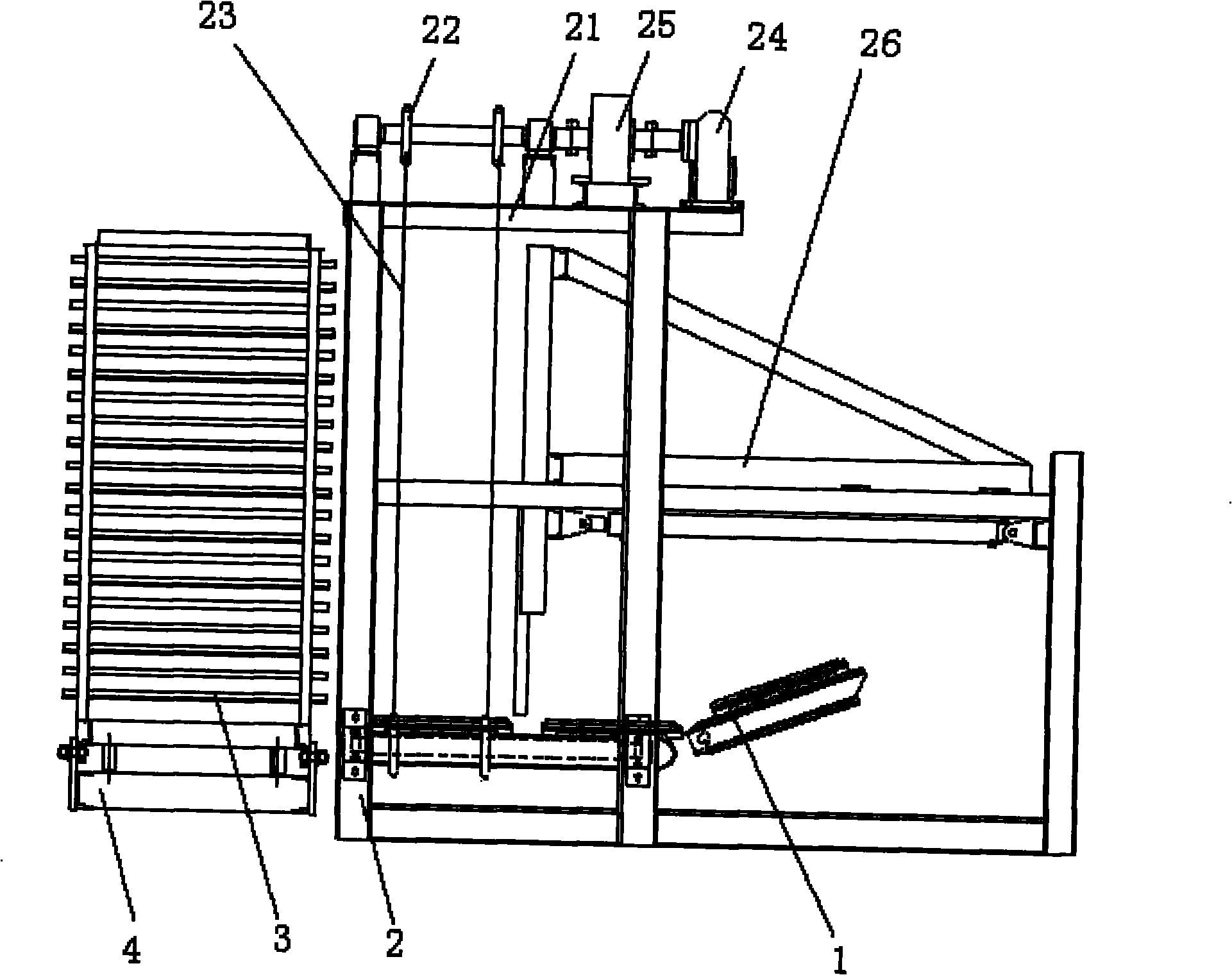

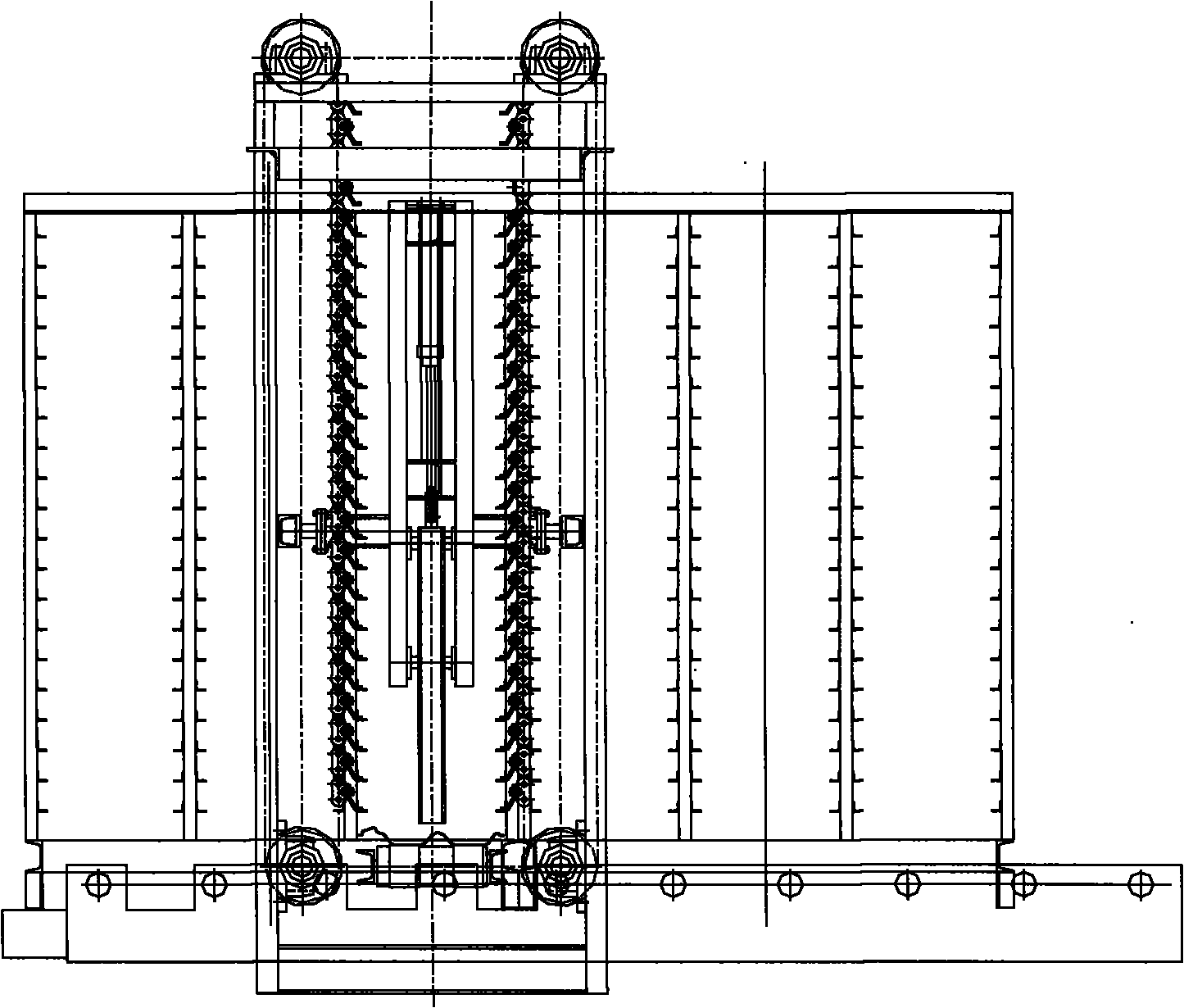

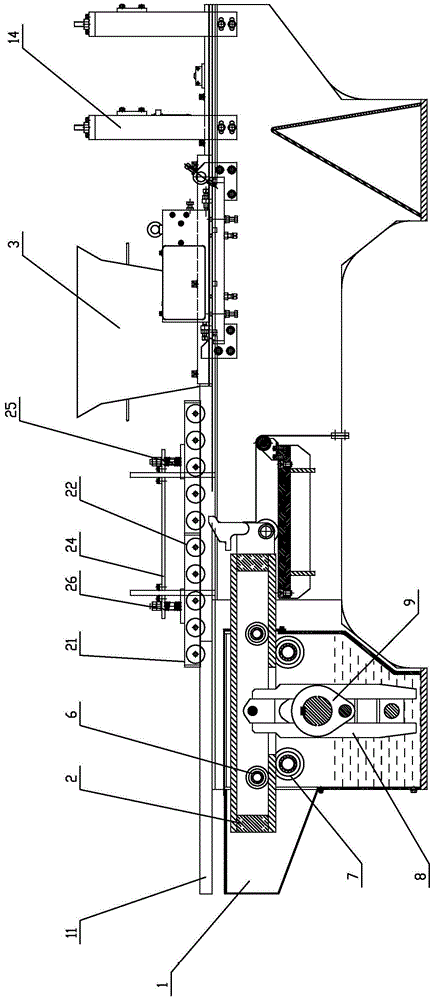

Automatic rack-mounting system of numerical control mould pressing encaustic tile production equipment

InactiveCN101804904AWork reliablyExtended service lifeConveyor partsMechanical conveyorsNumerical controlEncaustic tile

The invention discloses an automatic rack-mounting system of numerical control mould pressing encaustic tile production equipment. The automatic rack-mounting system comprises a transportation line, a rack-mounting machine, a tile rack and a tile rack transversely moving mechanism, wherein the rack-mounting machine pushes the tile to be mounted on the transportation line to the tile rack; the tile rack is arranged on the tile rack transversely moving mechanism; the tile rack transversely moving mechanism realizes the transverse movement of the tile rack; the rack-mounting machine comprises a frame, and a sprocket wheel, a chain, a motor, a driving mechanism and a tile line pushing mechanism which are arranged on the frame; the sprocket wheel is connected with the motor through the driving mechanism; a clamping hook for clamping and conveying the tile is arranged on the chain and is matched with the tile rack; and the tile line pushing mechanism pushes the tile on the clamping hook to the tile rack. The automatic rack-mounting system can automatically convey the finished product tile (containing a tile supporting plate) to the tile rack continuously, so the system has the advantages of improvement on labor condition, low labor intensity, little personnel allocation, safety and reliability, convenient operation and long service life.

Owner:句容金猴机械研究所有限公司

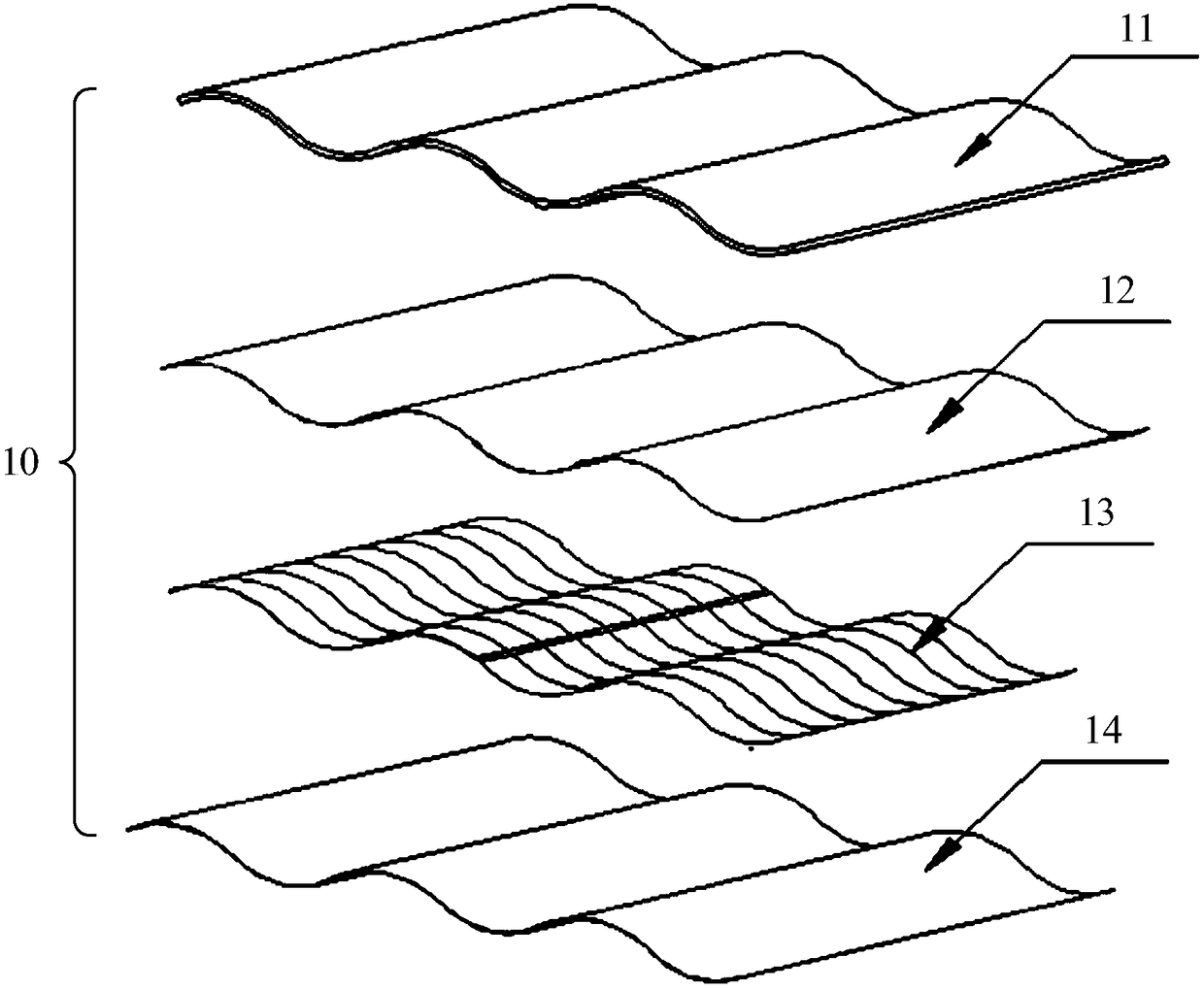

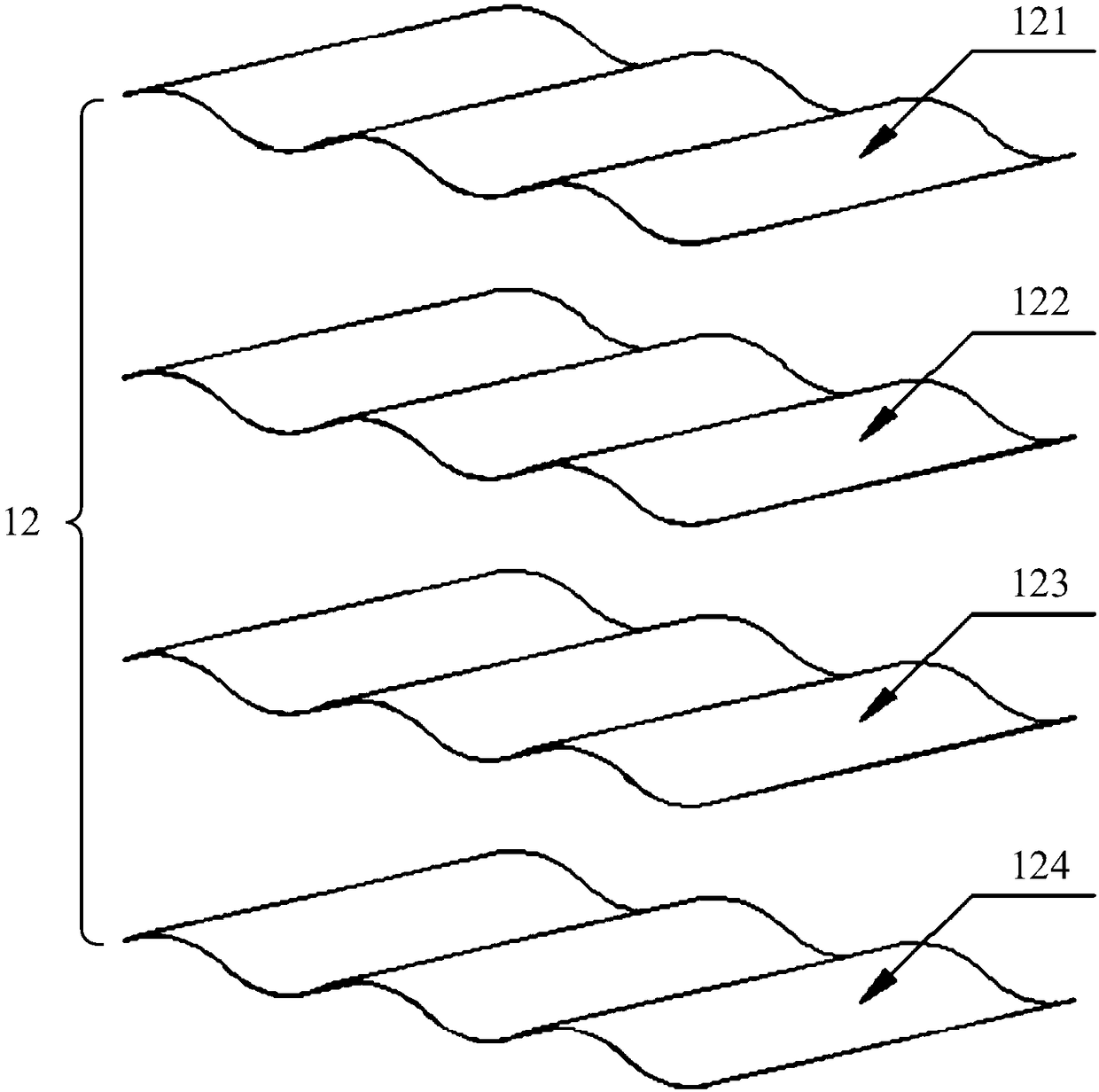

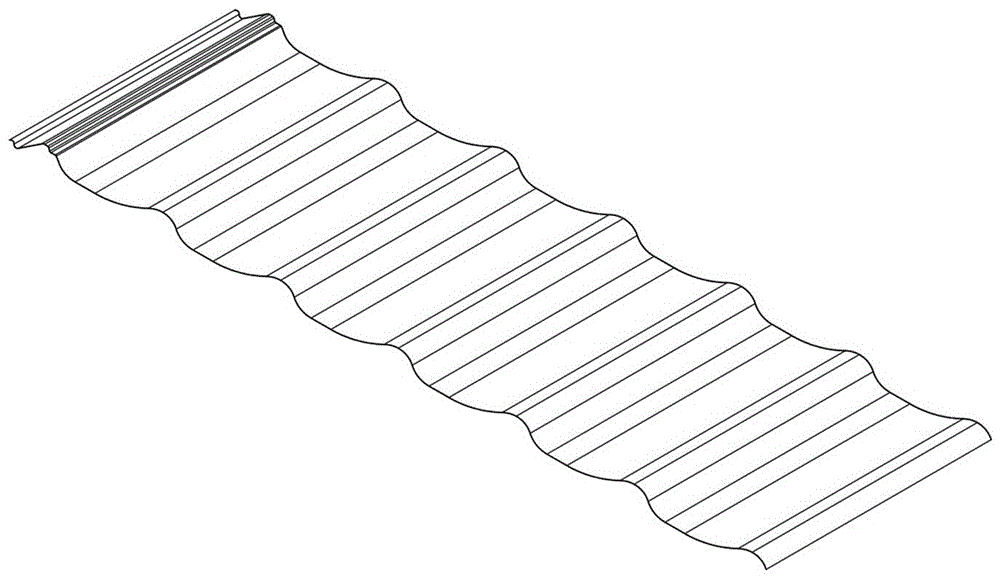

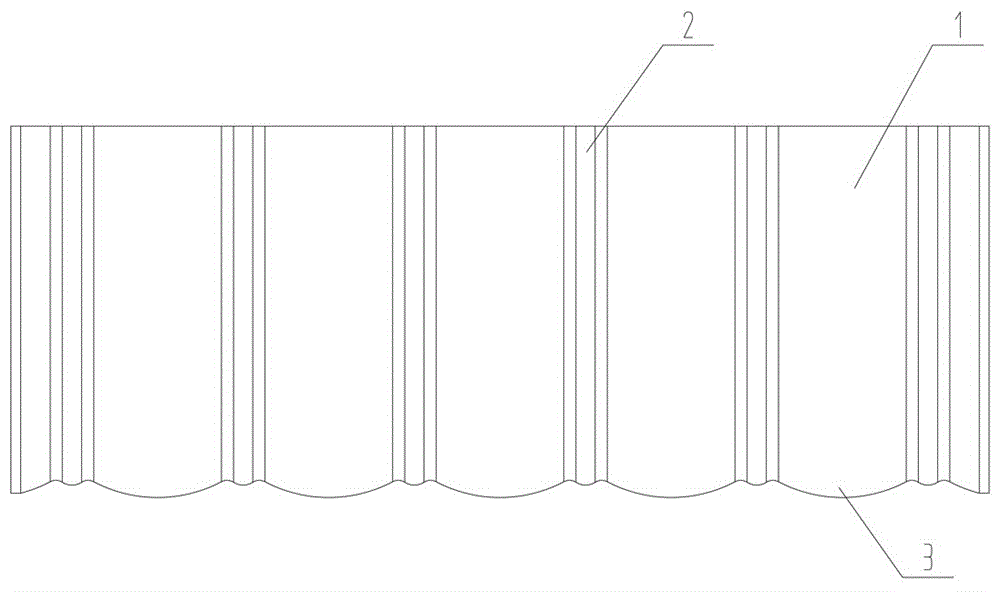

Colored steel encaustic tile and production equipment thereof

PendingCN107520330ASimple structureFlexible collocationShaping toolsRoof covering using slabs/sheetsEncaustic tileEngineering

The invention discloses a colored steel encaustic tile and production equipment thereof. A plurality of tile ridges are arranged along the length direction of an encaustic tile body of the colored steel encaustic tile, a wavy notch end is arranged at the front end of the encaustic tile body, the notch end is turned over to a lower downward inclined edgefold relative to the encaustic tile body, the cross section of the lower edgefold is wavy, an upward inclined upper edgefold relative to the encaustic tile body is arranged at the tail end of the encaustic tile body, the cross section of the upper edgefold is wavy, and an overlapping tile body parallel to the encaustic tile body is arranged at the other end of the upper edgefold. The colored steel encaustic tile is simple in structure, flexible to match and convenient to mount. During mounting, the upper edgefold of one plate is overlapped to the lower edgefold of the other one. By overlapping the colored steel encaustic tiles, a roof of a plant is mounted. The production equipment of the colored steel encaustic tile can produce the colored steel encaustic tiles precisely and quickly by means of actions of a profiling hydraulic cylinder, a shearing hydraulic cylinder and a shearing integrated mold.

Owner:XINXIANG TIANFENG MACHINERY MFG

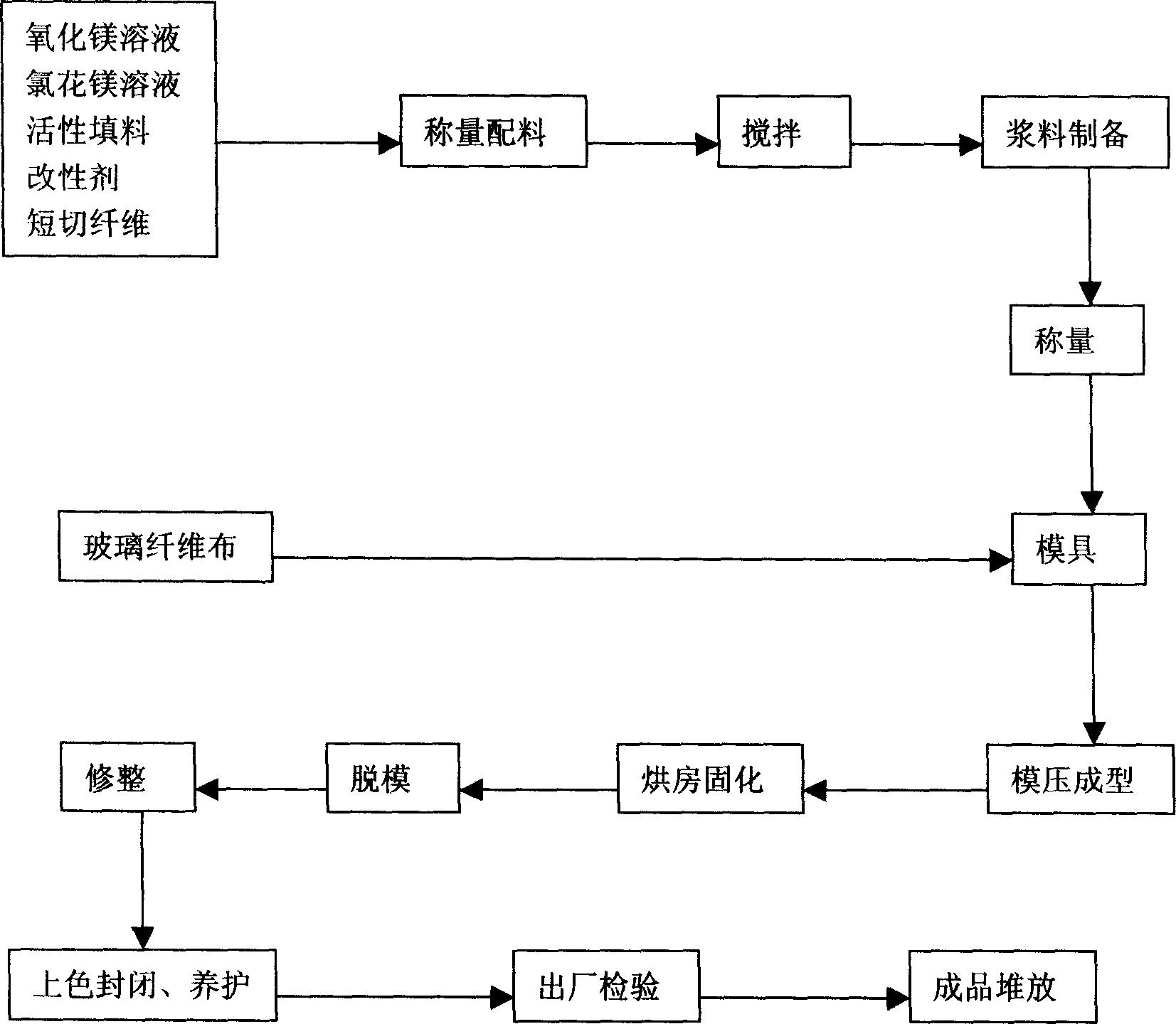

Lightweight encaustic tiles in high strength

InactiveCN1727601AImprove water resistanceReduce manufacturing costRoof covering using tiles/slatesCeramic shaping apparatusFiberEncaustic tile

A high-strength light-weight color tile is prepared from the Cl-O-Mg cement (inorganic glass) containing reduced MgO, MgCl2 and H2O, powdered coal ash, diatomite, quartz powder, PVA modified urea-aldehyde resin, polyacrylic acid solution and alkali-resistant short fibers through proportional mixing, spreading a layer of lattice fiber cloth, moulding while pressing, baking while solidifying, demoulding and coloring.

Owner:德清县方舟新型建材有限公司

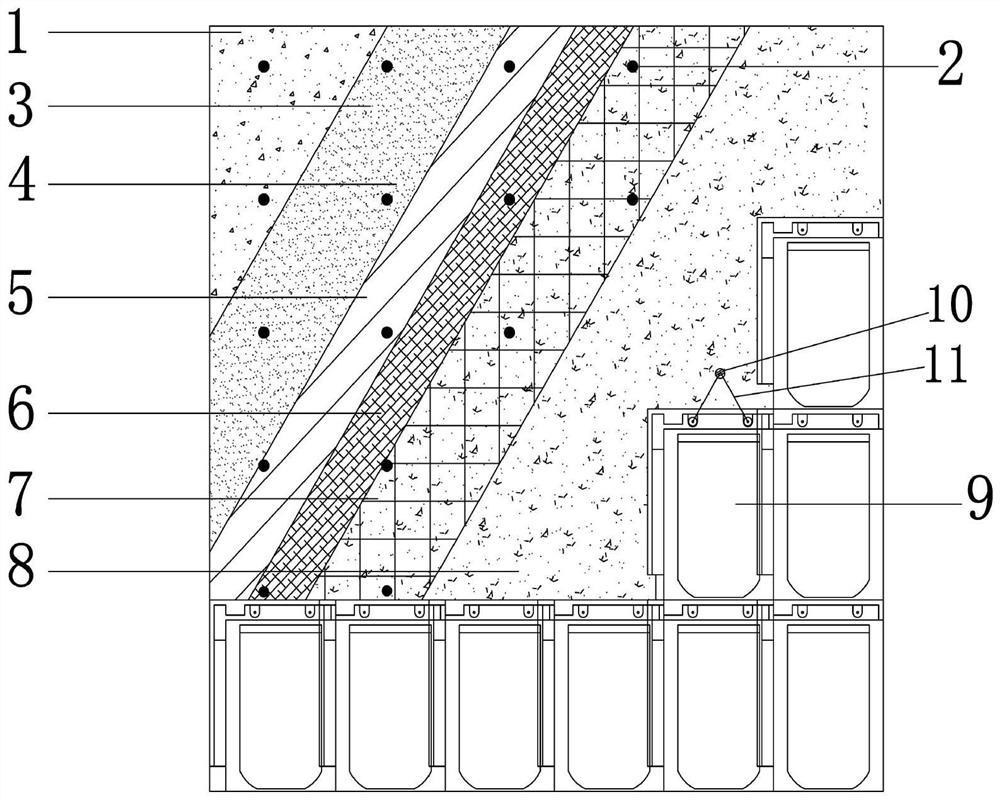

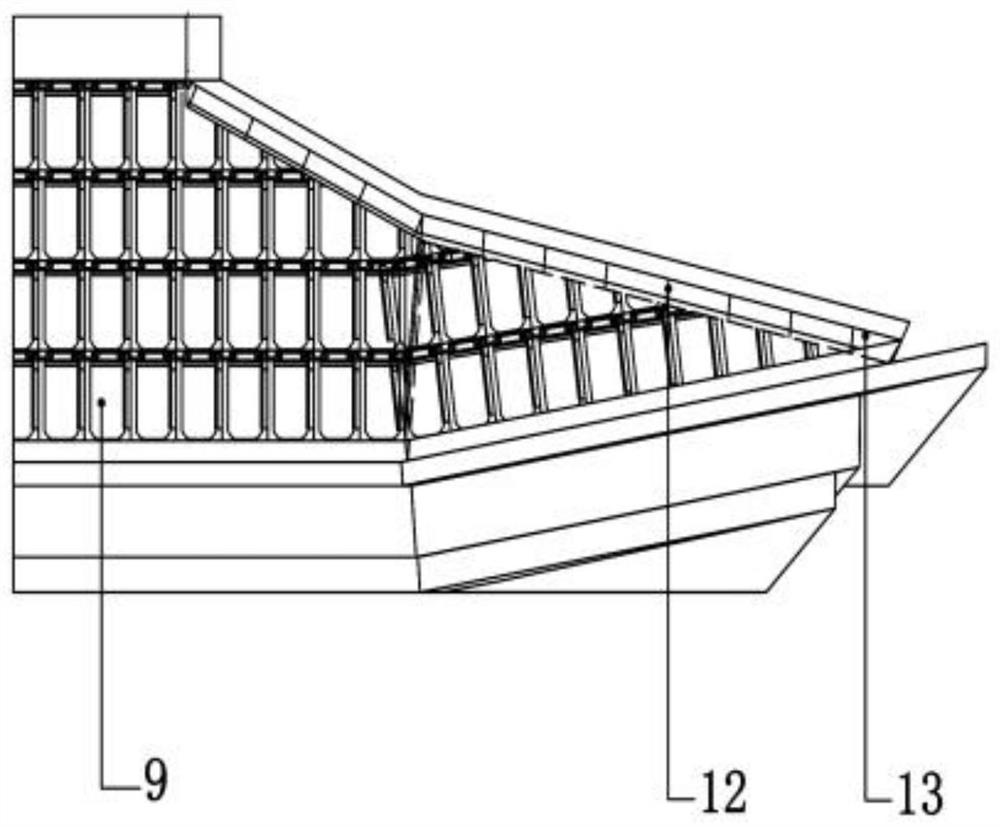

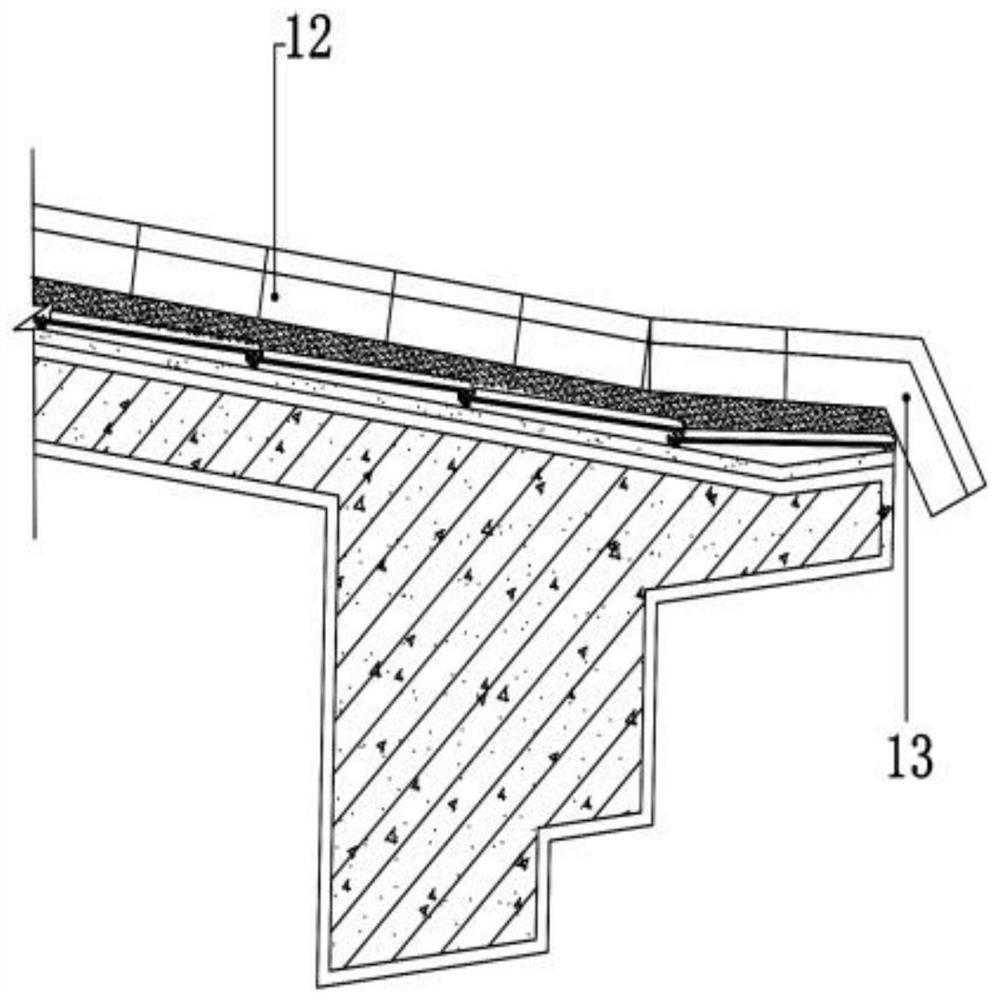

Large dip angle sloping roof encaustic tile paving structure and construction method

PendingCN112376807AImprove waterproof performanceGuaranteed service lifeRoof covering using tiles/slatesBuild-up roofsWire gauzeEncaustic tile

The invention discloses a large dip angle sloping roof encaustic tile paving structure and a construction method. The structure comprises a group of anchor bars pre-buried on a concrete slope roof andarranged in a matrix, wherein a cement mortar leveling layer, a waterproof coil layer, a non-fabric isolating layer, a fine stone concrete protecting layer and a cement mortar tile paving layer are paved successively on the concrete slope roof. A steel wire gauze is embedded into the fine stone concrete protecting layer and is fixedly connected to the anchor bars, and the encaustic tiles are paved on the cement mortar tile paving layer. The structure is simple in structure. Rectangular plain tiles are used in a large area, local ridge and side ridge are formed by combining ridge tiles and ridge tile sealing heads, so that the roof is good in waterproofness, the insulating and heat-isolating demand is met, the structure is conveniently maintained, and the maintenance cost is saved greatly,and therefore, the service life of the encaustic tile roof is ensured. Meanwhile, each rectangular plain tile is fixed with a steel screw and a copper wire, so that the stability of the encaustic tile is enhanced structurally and slip is avoided.

Owner:CHINA CONSTR FOURTH ENG DIV

Encaustic tile paint and preparation method thereof

The invention discloses an encaustic tile paint which comprises 20-30 parts of acrylic resin, 40-50 parts of a mixture of methylbenzene and butyl ester, 25-30 parts of texanol ester alcohol, 1-2 parts of a preservative, 1-2 parts of a wetting agent, 2-4 parts of a thickener, 1-3 parts of methylcellulose, 3-5 parts of a dispersing agent, and 25-30 parts of talcum powder. The invention also discloses a preparation method of the encaustic tile paint. By reasonably selecting the components of the encaustic tile paint and excellently proportioning the components, the prepared encaustic tile paint has an excellent adhesive force with a tile, is evenly distributed on the tile, and is also quite prominent in coloring, waterproof and wear-resisting capabilities.

Owner:句容金猴机械研究所有限公司

Dry method production process for ancient building encaustic tile

InactiveCN108689603AEliminate drying processReduce processing timeCeramic materials productionClaywaresMaterials preparationEncaustic tile

The invention relates to an encaustic tile preparation technology, and discloses a dry method production process for an ancient building encaustic tile. The process comprises the following steps of material preparation: preparing blank body raw materials, glaze material raw materials and setting accelerators; blank body shaping: conveying the mixed blank body raw materials to a blank material hopper of a tile shaping machine; meanwhile, adding the setting accelerators in the blank material hopper to realize uniform mixing with the blank body raw materials; shaping the mixed blank body raw materials and the setting accelerators into a tile blank through a tile shaping machine; glazing: conveying the tile blank onto a glazing machine; conveying the glaze material raw materials to a glaze hopper of the glazing machine; meanwhile, adding the setting accelerators into the glaze material hopper to realize the uniform mixing with the glaze material raw materials; coating the mixed glaze material raw materials and the setting accelerators onto the surface of the tile blank through the glazing machine; firing: conveying the tile blank with the glaze layer into a kiln for firing. The dry method production process for the ancient building encaustic tile provided by the invention has the advantages that through the step of drying the shaped tile blank, the fast setting of the tile blank isrealized; the processing time is shortened; the work efficiency is improved.

Owner:桐乡市乌镇内利仿古园林建设有限公司

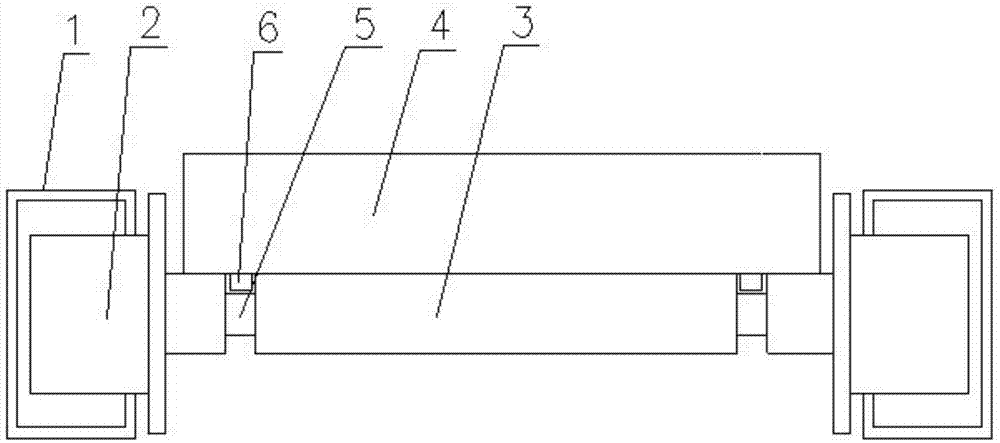

Encaustic tile conveying device

InactiveCN104495255ASimple structureReasonable designMechanical conveyorsEncaustic tileMechanical engineering

The invention discloses an encaustic tile conveying device, and relates to a conveying device. The encaustic tile conveying device comprises C-shaped steels laterally placed at two sides, wherein rollers are clamped in the C-shaped steels; rolling shafts are connected between the rollers at the two sides; and conveying platforms spanned on the rolling shafts, are contacted end-to-end, and are arranged in sequence. The encaustic tile conveying device is simple in structure and reasonable in design; the conveying platforms are directly arranged on the rolling shafts; and the later conveying platforms are used for pushing the previous conveying platforms to move, so that the conveying is smooth, and the effects of convenience, practicability and convenience for disassembly and maintenance are achieved.

Owner:熊世武

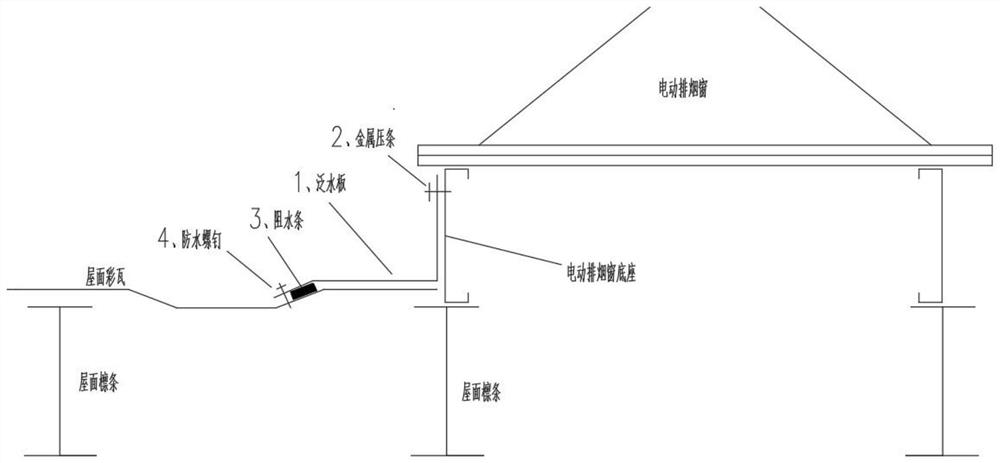

Waterproof construction method for electric smoke exhaust window of color steel tile roof

InactiveCN113279522AReduce leakageReduce post-maintenance costsRoof covering using slabs/sheetsRoof drainageEncaustic tileWater block

The invention discloses a waterproof construction method for an electric smoke exhaust window of a color steel tile roof, and belongs to the technical field of waterproof of color steel tile roofs. The waterproof construction method comprises the following steps that step 1, a flashing plate is manufactured, an encaustic tile with the width of 500 mm and the length equal to that of the electric smoke exhaust window is blanked according to the specified requirement, the thickness is 0.6 mm, and the encaustic tile is folded into the shape of the flashing plate according to the roof panel type and the skylight height; step 2, a metal pressing strip is manufactured, the metal pressing strip is made of galvanized flat iron with the thickness being 2 mm, and the upper end of the flashing plate and a base of the electric smoke exhaust window are fixed through screws after blanking is completed; step 3, a water blocking strip is pasted between the lower end of the flashing plate and the roof encaustic tile, and the water blocking strip is made of double faced adhesive tape; and step 4, the flashing plate and the roof plate are fixed through waterproof screws, the waterproof screws need to be provided with waterproof caps, waterproof work at the joints of the electric smoke exhaust window can be completed, and the step is repeated in remaining projects. The waterproof construction method for the electric smoke exhaust window of the color steel tile roof is simple in structure, easy to manufacture, high in efficiency and high in quality reliability, and the roof leakage condition is greatly reduced.

Owner:CHINA MCC17 GRP

Technique for manufacturing high-strength encaustic tiles and extruding device thereof

Owner:东北金城建设股份有限公司

Colored tile compression molding device

ActiveCN114131736AImprove efficiencyQuality improvementAuxillary shaping apparatusShaping press ramCompression moldingEncaustic tile

The invention discloses an encaustic tile compression molding device, and relates to the technical field of encaustic tile production. The limitation problem of single pressing forming is solved. Comprising a base, a support is arranged on the outer wall of the middle of the top of the base, two sliding columns are arranged on the outer wall of the top of the support, sliding blocks are slidably connected to the circumferential outer walls of the two sliding columns, mounting plates are arranged on the outer walls of the bottoms of the front face and the back face of the support correspondingly, and an intermittent rotating lifting mechanism is arranged on the outer wall of one side of each sliding block; a rotating rod is arranged at one end of the intermittent rotating lifting mechanism and penetrates through the two mounting plates, a forming base is arranged at the end of the rotating rod, a partition plate is arranged in the forming base, a fixing plate is arranged on the outer wall of the other side of the sliding block, and a pressing plate is arranged on the outer wall of the bottom of the fixing plate. According to the tile blank secondary pressing device, secondary pressing can be conducted on a single tile blank, burrs and burrs are not prone to occurring in the tile blank pressing process, and the pressing effect is stable.

Owner:衡阳阳光陶瓷有限公司

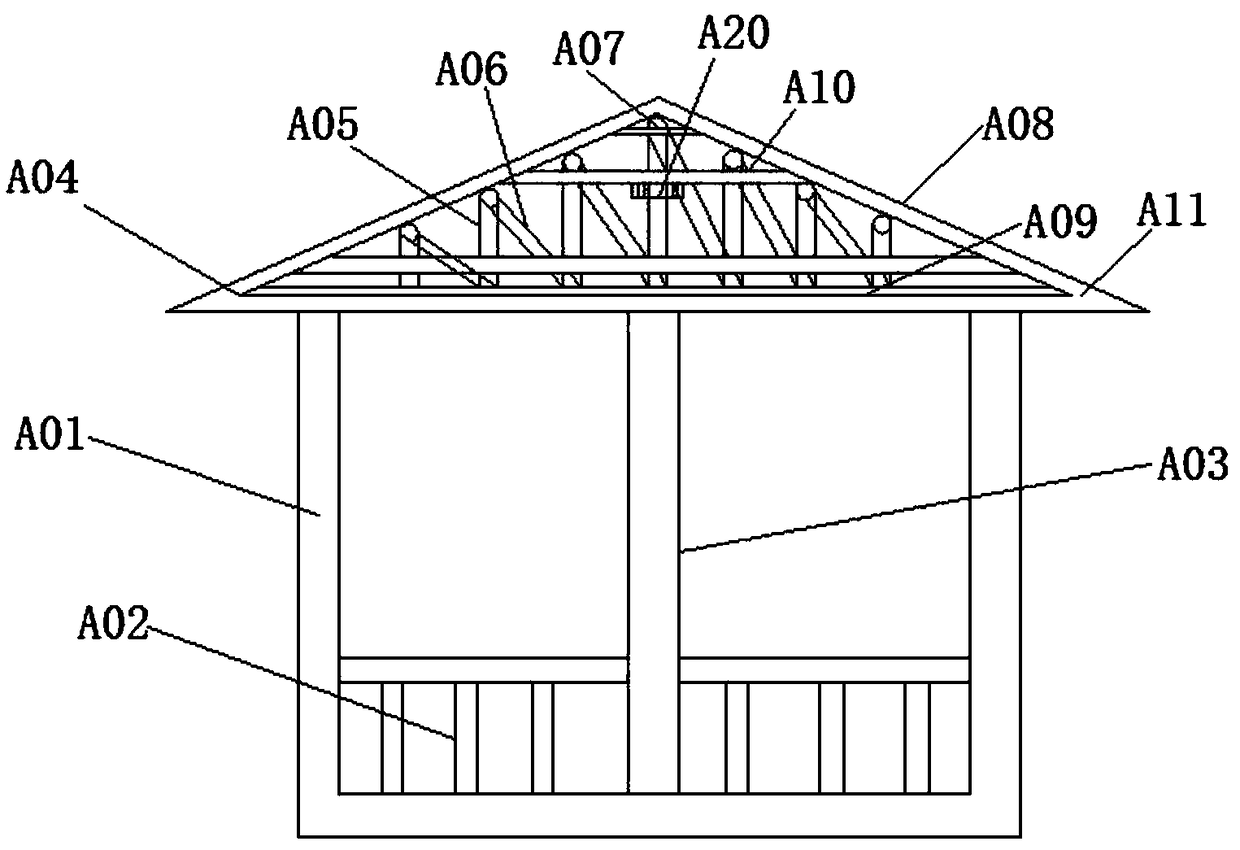

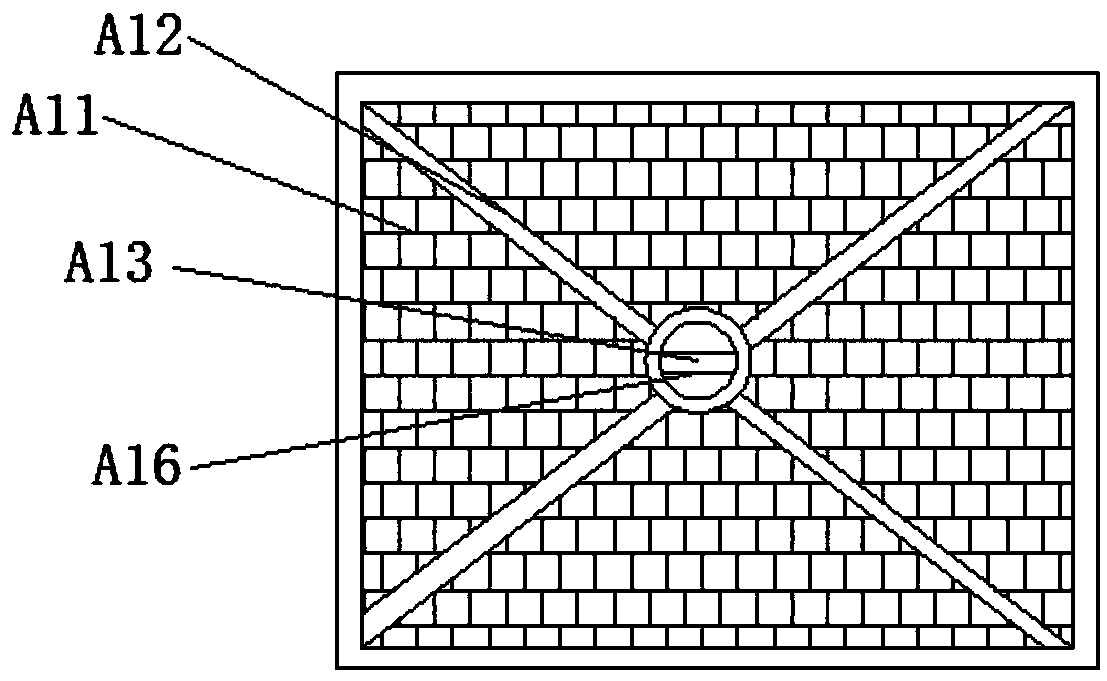

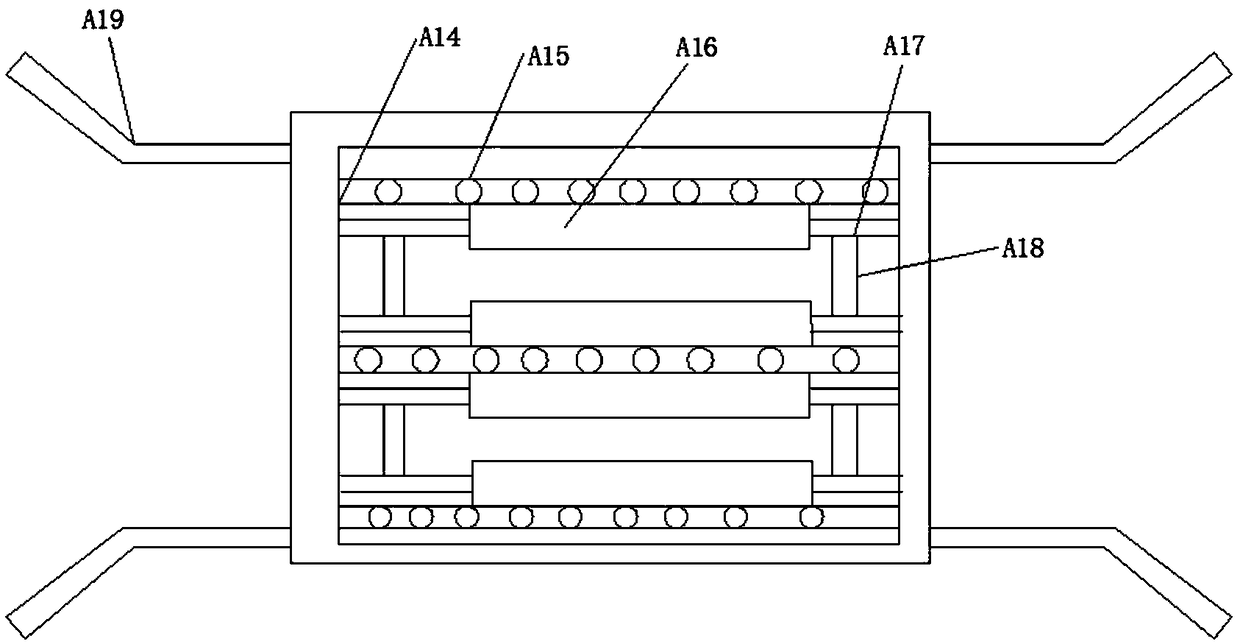

Light material shading kiosk with decorative sheet for garden

InactiveCN109057414AEasy to assemble and disassembleEasy to useSpecial buildingSmall buildingsEavesKeel

The invention discloses a light material shading kiosk with a decorative sheet for a garden. The light material shading kiosk comprises a kiosk body, a kiosk eave, a keel, eave square columns and a fixed blocks. Fences are arranged on the two sides of the kiosk body, encaustic tiles are mounted outside the kiosk eave, a vertical ridge is mounted above the encaustic tiles, a pavilion roof is mounted above a main ridge, and a straight beam rod is mounted on the left side in the kiosk eave. A clamping plate is mounted above the fixed block, a cross beam is mounted above the straight beam rod, anupper chord is mounted above a lower chord, straw frame columns are embedded into the keel, the keel is located on the upper left portion of the main ridge, head holding beams are mounted below the eave square columns, and a corner beam is mounted on the right side of the keel. After the light material shading kiosk with the decorative sheet for the garden is used, a supporting and protecting function can be achieved, the fences are mounted on the two sides of the kiosk body and achieve a protection function, the fences are convenient to demount and mount, and the repeated usability is good.

Owner:龚昌昌

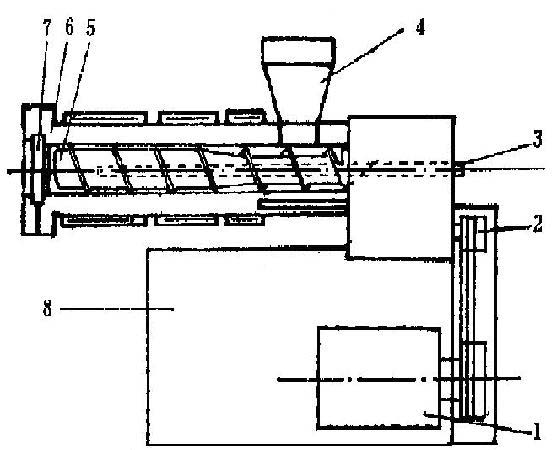

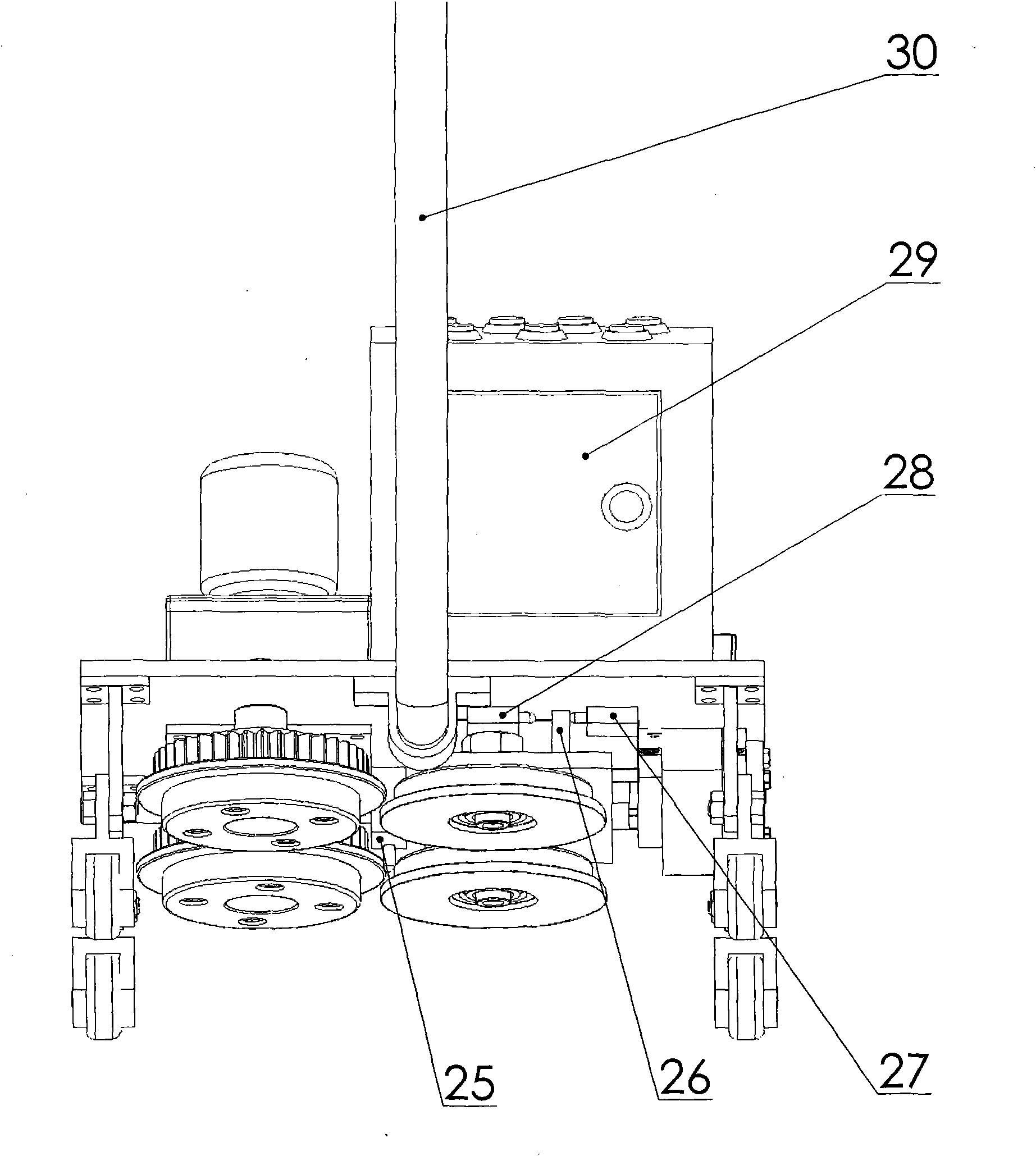

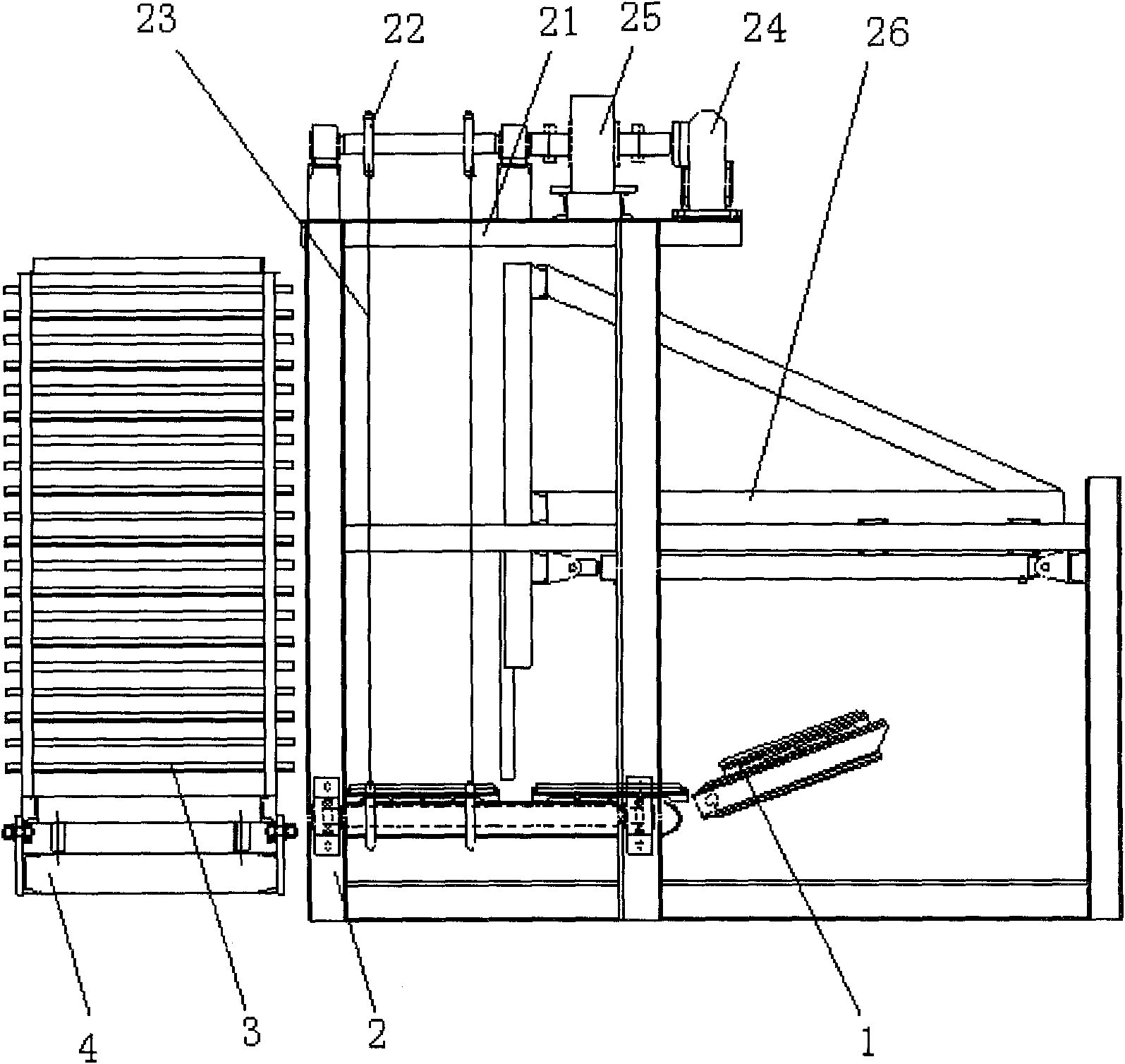

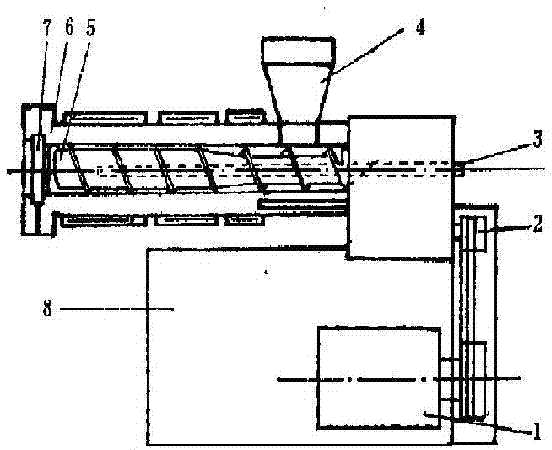

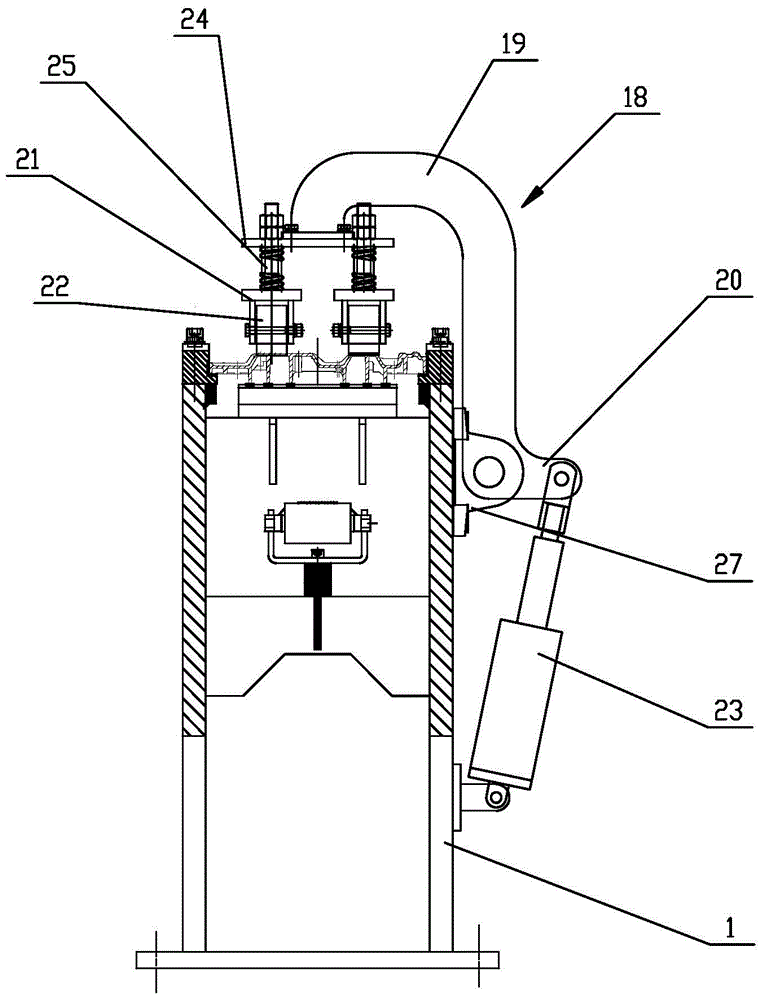

A roll-pressed colored tile forming equipment

ActiveCN104626338BEfficient productionPress rollersFeeding arrangmentsEncaustic tileReciprocating motion

The invention discloses a roll-in encaustic tile forming device and relates to an encaustic tile preparation device. The roll-in encaustic tile forming device comprises two parallel machine frames. A sliding ram capable of driving tile dies placed on the machine frames to move forwards is arranged between the machine frames, a feed hopper is arranged at the front end in the tile die heading direction, a rotary forming roll is arranged on one side of the feed hopper far away from the ram so as to perform roll-in forming on concrete on the tile dies, and a dividing cutter performing reciprocating motion up and down is arranged on one side of the forming roll far away from one side of the feed hopper, so as to cut formed encaustic tiles. The roll-in encaustic tile forming device can continuously produce the encaustic tiles and is high in efficiency.

Owner:HAIAN TIANPENG MACHINERY MFG

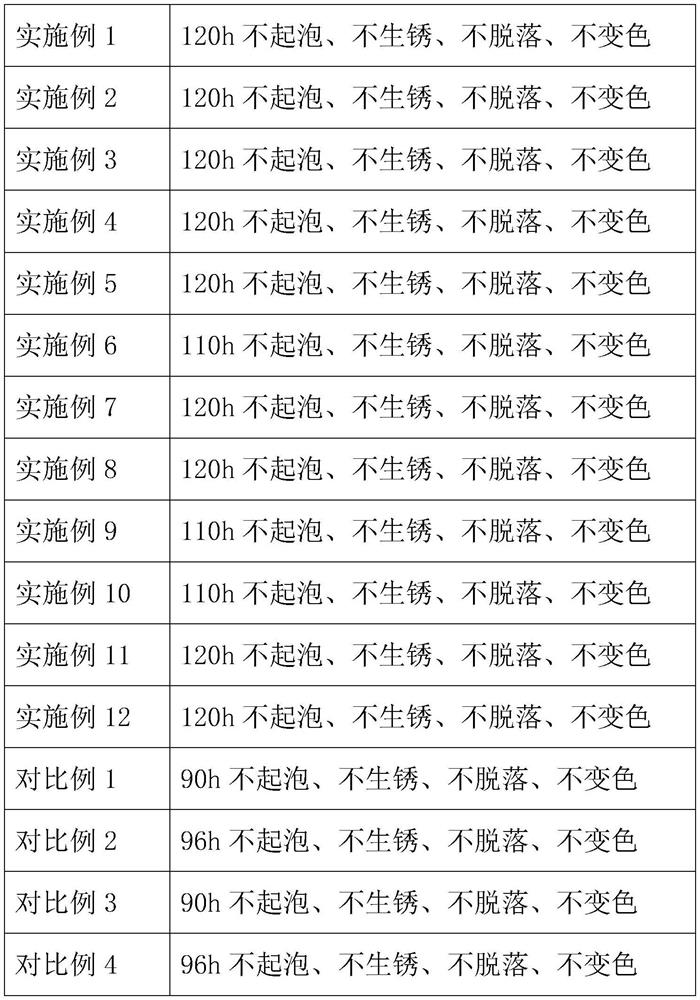

Colored tile paint and construction method

PendingCN114410163AImprove hydrolytic stabilityEffective coalescingAnti-corrosive paintsPyrophylliteStone dust

The invention relates to the field of encaustic tile paint, and particularly discloses encaustic tile paint which is prepared from the following raw materials: titanium dioxide, sodium dioctyl sulfosuccinate, precipitated barium sulfate, a wetting agent, a silane coupling agent, a multifunctional additive, a defoaming agent, fumed silica, a thickening agent, butyl ether, a flatting agent and a performance regulator. The performance regulator comprises texanol, acrylic emulsion, polytetrafluoroethylene micro powder and zinc phosphate, and the thickening agent comprises pyrophyllite powder, calcium chloride and sodium silicate. The construction method of the encaustic tile paint comprises the following steps: step 1, cleaning impurities such as floating rust, foreign matters, oil stains and dust on the surface of a base material, and preheating the base material to 45-55 DEG C for later use; and step 2, diluting the prepared encaustic tile paint with water, adjusting the viscosity to 20-30s, filtering with 80-150-mesh filter gauze, and then carrying out construction. The encaustic tile paint prepared by the invention has excellent heat and humidity resistance and good product quality.

Owner:蔚湃建筑科技(上海)有限公司

Full-automatic edge locking machine for encaustic tiles

InactiveCN102808485BImprove work efficiencyEasy to operateRoof toolsElectromagnetic clutchEncaustic tile

The invention relates to the construction capping field, especially to a full-automatic edge locking machine for encaustic tiles. The machine comprises a main body plate, a differential case, a motor, gears, shafts, edge locking forming wheels, electromagnetic clutches, travel switches and the like. Through the technical scheme, a transmission device and an automatic device are arranged, so that the edge locking forming wheels are automatically extruded, and then edges are automatically locked; and the machine can be automatically retreated and stopped after one edge seam is locked, the edge locking forming wheels can be automatically loosened and restored to the initial state, and the machine is ready to lock the next edge seam. The defects of the conventional edge locking machine for the encaustic tiles are overcome, the edge seams of the encaustic tiles are fully automatically extruded and locked, and the machine has the advantages that manual extrusion is not needed, the machine is low in labor intensity, convenient to operate, high in working efficiency, standard, accurate and high in edge locking quality, and the like.

Owner:刘全涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com