Synthetic hollow encaustic tile assembly

A hollow and colored technology, applied to tile/slate tile roofs, roofs, buildings, etc., can solve the problems of poor anti-aging performance, short service life, water resistance, etc., achieve good heat insulation and weather resistance, and save energy , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

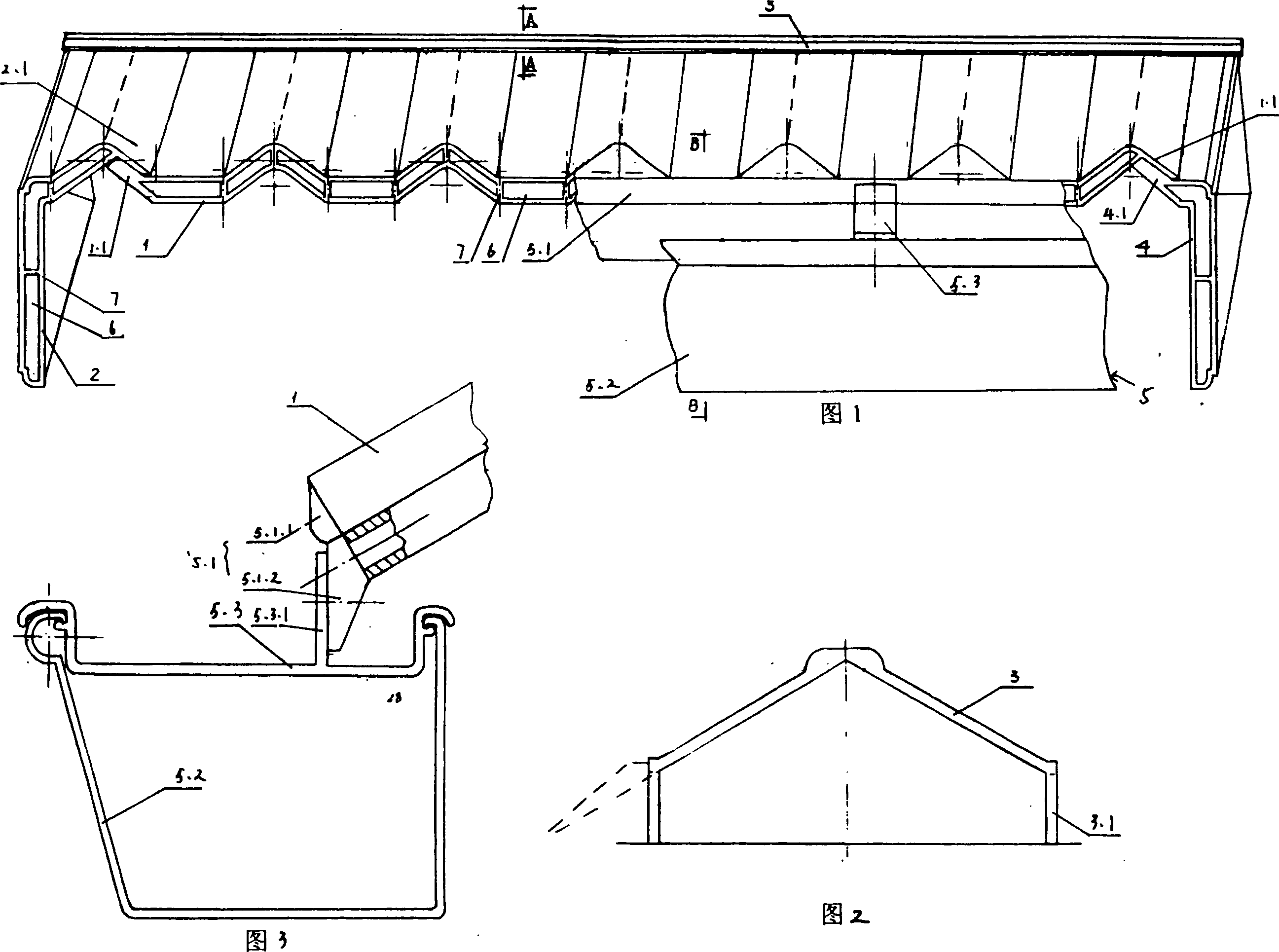

[0015] Referring to Fig. 1, the present invention is a synthetic hollow color tile assembly. Including tiles for slopes, referred to as flat tiles 1; tiles for eaves, referred to as eaves tiles 2, 4, 5 and ridge tiles, referred to as ridge tiles 3; 4 and front and rear eaves tiles 5. The flat tiles 1, eaves tiles 2, 4, 5 and ridge tiles 3 are all colored by waste plastics, wood chips or / and plant orange stalk fibers according to the required colors, and then mixed and extruded to form a closed hollow structure 6, A number of stiffeners 7 are arranged in the hollow structure 6 along the width direction. The flat tile 1 has a corrugated shape along the length direction, and the top surface of the flat tile 1 extends to the left and right sides along the length direction and is provided with hypotenuses 1.1 for overlapping. Corresponding to the hypotenuse 1.1, the right side of the top surface of the left eaves tile 2 and the left side of the top surface of the right eaves tile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com