Environment-friendly encaustic tile coating and preparation method thereof

A color tile coating, an environmentally friendly technology, applied in the field of architectural coatings, can solve the problems of poor long-term stability of the emulsion, and achieve the effect of improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of silicone acrylic emulsion by miniemulsion polymerization

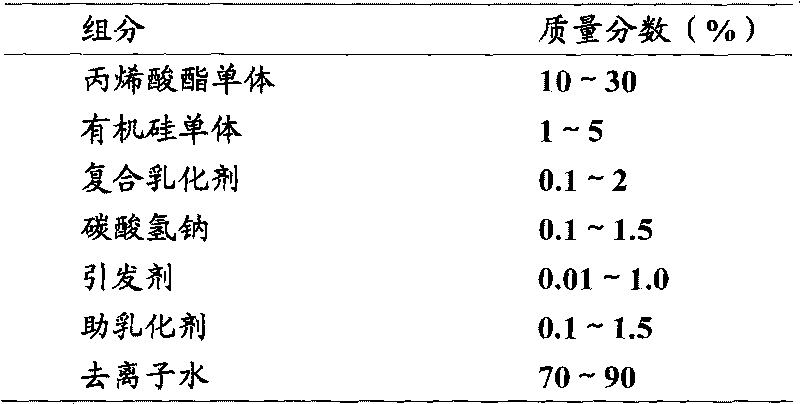

[0041] The following table is a formula for miniemulsion polymerization:

[0042]

[0043]

[0044] Silicone acrylic emulsion is prepared through the following steps according to the formula:

[0045] Step 1, prepare water phase and oil phase solution respectively

[0046] Stir the compound emulsifier, deionized water, and sodium bicarbonate in the reaction kettle for 10-20 minutes according to the formula to prepare an aqueous solution; mix hexadecane, acrylate monomer, and methacryloxypropyl trimethoxy The base silane is mixed evenly under stirring to obtain an oil phase solution;

[0047] Step 2, prepare the miniemulsion

[0048] Stir and mix the aqueous phase solution and the oil phase solution prepared in step 1 in a reactor for 20 minutes, then place them in a powerful ultrasonic pulverizer, and ultrasonically emulsify for 20 minutes at a certain power to obtain a fine emulsion;

...

example 2

[0061] 1. Preparation of silicone acrylic emulsion by miniemulsion polymerization

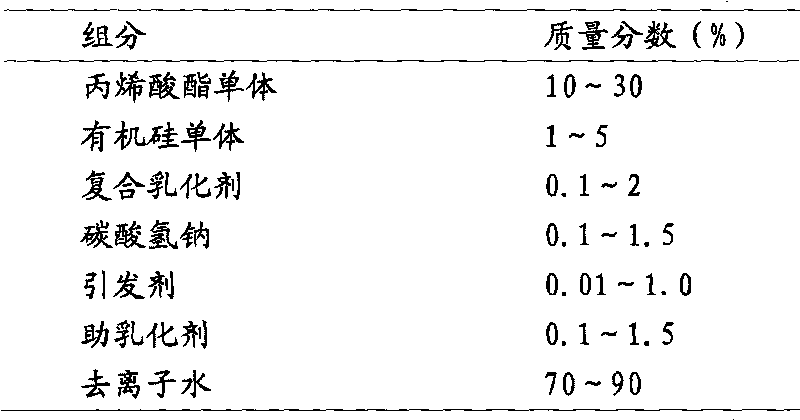

[0062] The following table is a formula for miniemulsion polymerization:

[0063]

[0064] Silicone acrylic emulsion is prepared through the following steps according to the formula:

[0065] Step 1, prepare water phase and oil phase solution respectively

[0066] Stir the compound emulsifier, deionized water, and sodium bicarbonate in the reaction kettle for 10-20 minutes according to the formula to prepare an aqueous phase solution; mix octadecane, acrylate monomer, and methacryloxypropyl triiso Propoxysilane is mixed evenly under stirring to obtain an oil phase solution;

[0067] Step 2, prepare the miniemulsion

[0068] Stir and mix the aqueous phase solution and the oil phase solution prepared in step 1 in a reactor for 20 minutes, then place them in a powerful ultrasonic pulverizer, and ultrasonically emulsify for 20 minutes at a certain power to obtain a fine emulsion;

[0069] St...

example 3

[0080] 1. Preparation of silicone acrylic emulsion by miniemulsion polymerization

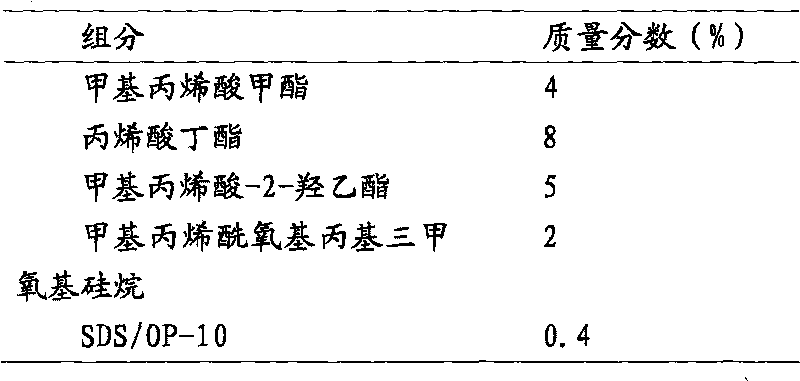

[0081] The following table is a formula for miniemulsion polymerization:

[0082]

[0083] Silicone acrylic emulsion is prepared through the following steps according to the formula:

[0084] Step 1, prepare water phase and oil phase solution respectively

[0085] Stir the compound emulsifier, deionized water, and sodium bicarbonate in the reaction kettle for 10 to 20 minutes according to the formula to prepare an aqueous phase solution; mix hexadecane, acrylate monomer, and methacryloxypropyl triethyl The oxysilane is uniformly mixed under stirring to obtain an oil phase solution;

[0086] Step 2, prepare the miniemulsion

[0087] Stir and mix the aqueous phase solution and the oil phase solution prepared in step 1 in a reactor for 20 minutes, then place them in a powerful ultrasonic pulverizer, and ultrasonically emulsify for 20 minutes at a certain power to obtain a fine emulsion;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com