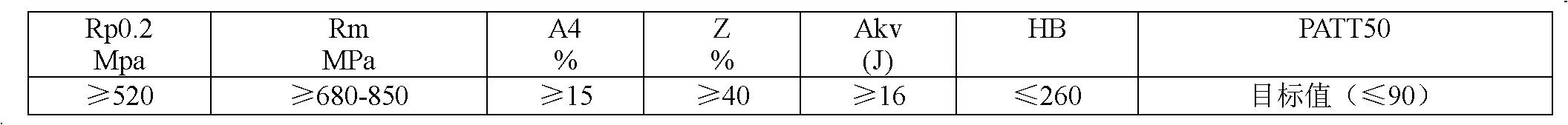

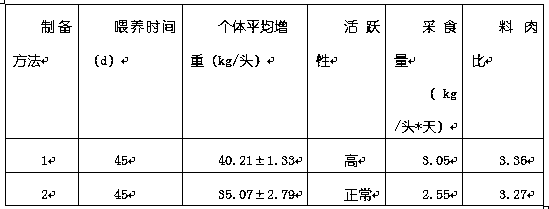

Patents

Literature

54results about How to "Eliminate drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

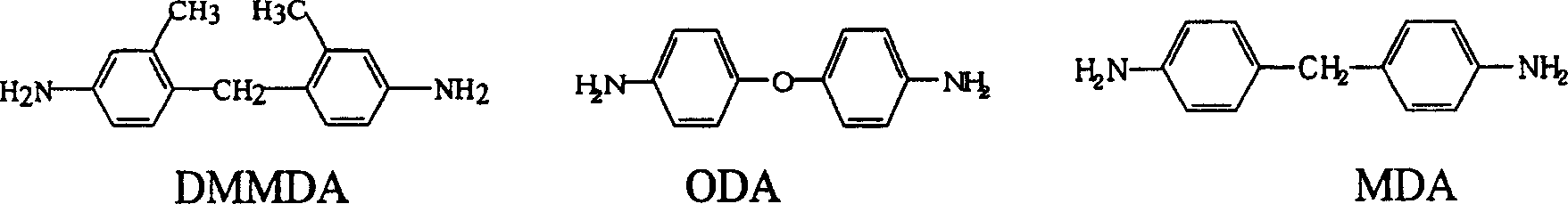

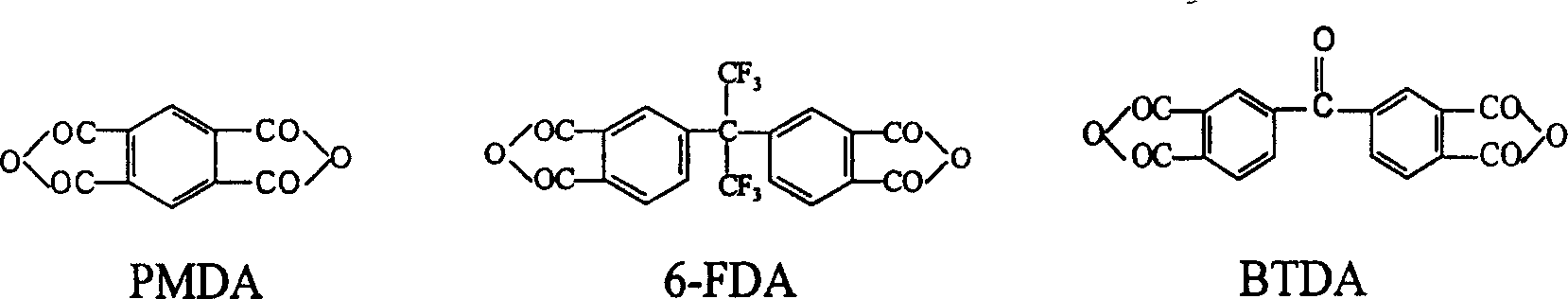

Preparation method of polyimide nanometer filtering membrane

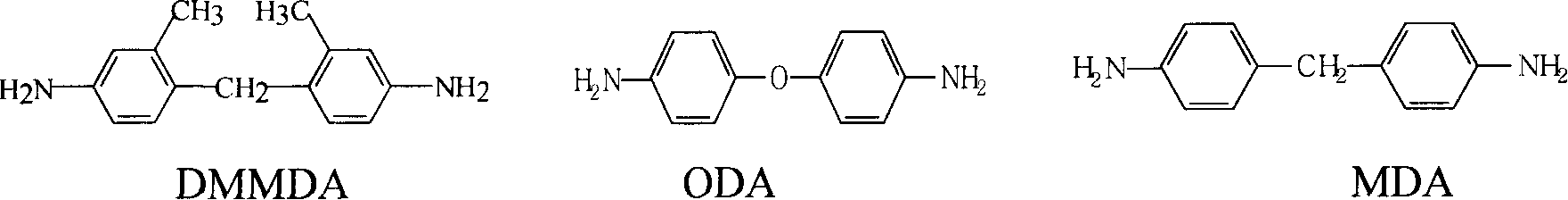

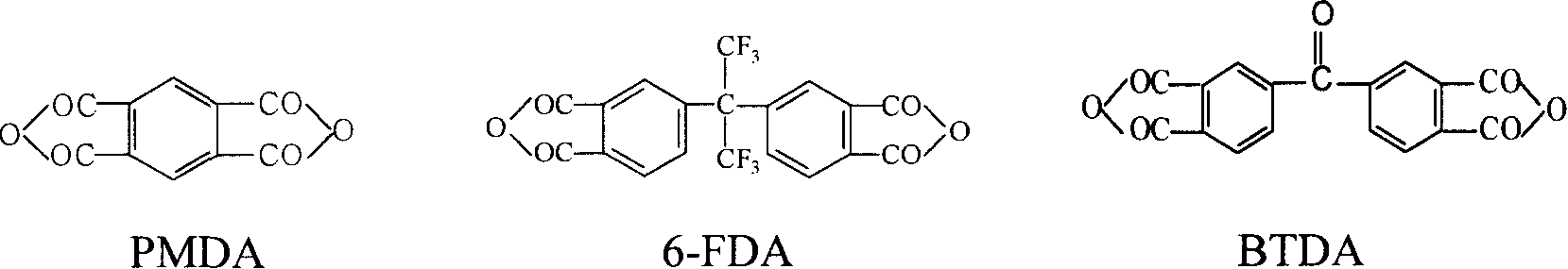

ActiveCN1911494AIncrease varietyReduce the amount of solvent usedSemi-permeable membranesPolyimide membraneBenzene

The present invention relates to a preparation process of nanofiltering polyimide membrane for recovering lubricant oil acetone-benzene dewaxing solvent. The preparation process includes the following steps: preparing polyamic acid solution, adding additive for phase transfer to prepare nanofiltering polyamic acid membrane, imidating the membrane chemically, solvent exchanging and heat treatment. Or, the preparation process may include the following steps: the first preparing partially imidated polyimide capable of being dissolved in some solvents, preparing film casting solution, filming in a phase transfer process, solvent exchanging and heat treatment. The present invention has low preparation cost, and the prepared nanofiltering polyimide membrane has lubricant oil intercepting rate greater than 90 % and mixed acetone-benzene solvent flux greater than 12 L / sq m .hr at the conditions of -18 deg.c and 3 MPa.

Owner:PETROCHINA CO LTD +1

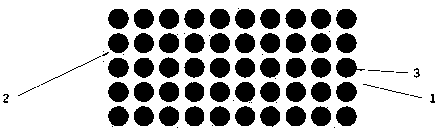

Polymer slurry, composite diaphragm and preparation method thereof

ActiveCN109994695AUniform sizeAvoid easy cloggingSecondary cellsCell component detailsPolymer scienceCeramic coating

The invention relates to the technical field of lithium ion battery diaphragm preparation and discloses polymer slurry, a composite diaphragm and a preparation method thereof. The polymer slurry includes, by weight, 10-30 parts of the polymer, 0.05-1.0 parts of the thickener, 5.1-26.5 parts of the wetting agent, 1.0-5.0 parts of the binder, 0.1-1.0 parts of the dispersant and 80-120 parts of the water. The composite diaphragm includes a base film, and a ceramic coating and a polymer dot coating coated on both sides of the base film, wherein the polymer dot coating is obtained by coating the above polymer slurry in a high pressure jet mode. The composite diaphragm has good thermal stability, strong adhesion stress and good permeability, when the composite diaphragm is applied to a lithium ion battery, performance of the lithium ion battery is improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

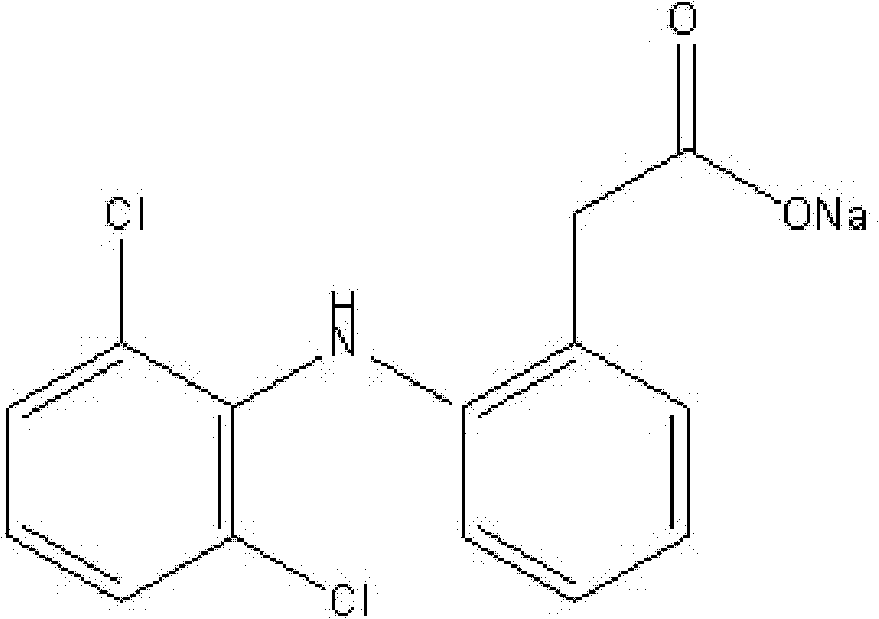

Diclofenac sodium sustained-release tablet and its preparation process

ActiveCN102274200AAvoid condensationReduce usageOrganic active ingredientsAntipyreticDiclofenacAdhesive

The invention relates to the technical field of medicine, in particular to diclofenac sodium sustained release tablets and a preparation process thereof. The diclofenac sodium sustained release tablets provided by the invention comprise the following components in percentage by mass: 16.5 to 39.0 percent of diclofenac sodium, 10.0 to 35.5 percent of sustained release agent, 33.5 to 65.0 percent of filling agent, 2.01 to 8.0 percent of glidant, 0 to 2.5 percent of lubricating agent, and 0 to 8.0 percent of adhesive. According to the diclofenac sodium sustained release tablets and a whole-powder direct tabletting method thereof provided by the invention, by changing the components and the preparation method, the production process is simplified, the production cost is reduced, the production efficiency is improved, the yield is improved to 98.0 to 100 percent, granule condensation is avoided, the surface of the tablets is smooth, meanwhile, consumption of high-concentration alcohol is avoided, and the potential safety hazard in the production process is reduced.

Owner:SINOPHARM GRP ZHIJUN SHENZHEN PINGSHAN PHARMA CO LTD

Process for primary refining coarse p-phthalic acid by solvent washing process

InactiveCN1510023AReduce consumptionReduce productionCarboxylic compound separation/purificationAcetic acidSlurry

A process for primarily refining coarse terephthalic acid (CTA) by solvent washing method includes such steps as using the mixture of p-xylene (PX), water and acetic acid to wash the acetic acid contained terephthalic acid slurry generated by the oxidizing reactor for preparing terephthalic acid by oxidizing PX, solid-liquid separating to obtain CTA crystal containing acetic acid and catalyst, washing with water, mixing with water, and hydrorefining.

Owner:中国石化集团天津石油化工公司

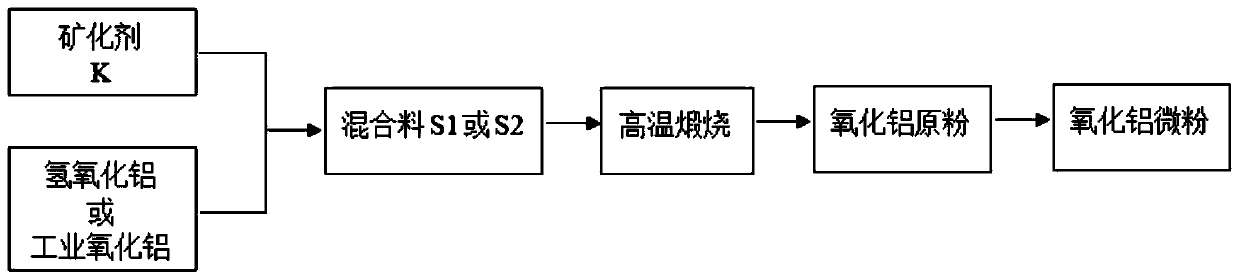

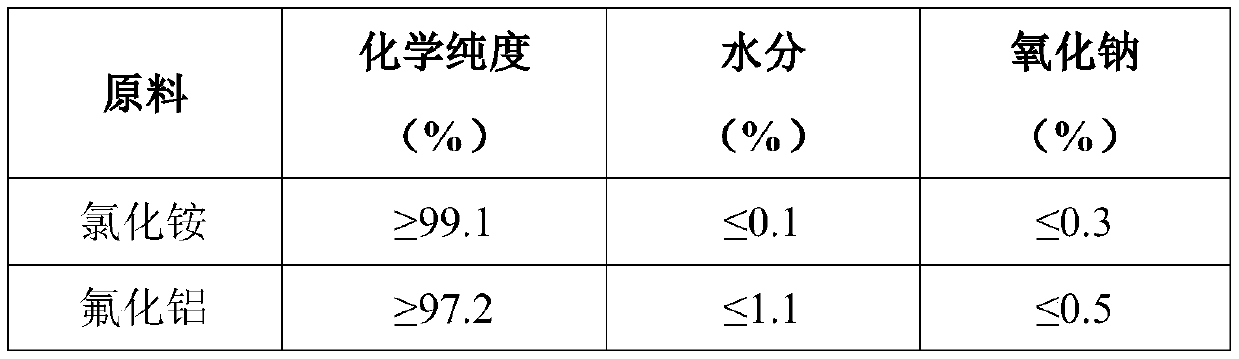

Preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder

InactiveCN110342556AWide variety of sourcesHigh chemical purityAluminium compoundsAluminium hydroxideHigh activity

The invention discloses a preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder. The preparation method comprises the steps that aluminum hydroxide or industrial aluminaserves as main raw materials, and ammonium chloride and aluminum fluoride serve as a mineralizer; the aluminum hydroxide or the industrial alumina and the mineralizer are mixed, a mixture is subjectedto high-temperature calcination to prepare low-sodium and high-specific-surface-area alpha-Al2O3 raw powder, the alpha-Al2O3 raw powder is placed into a ball mill for grinding, and the alpha-Al2O3 micro powder is prepared. According to the preparation method, the raw materials are wide in source, sodium removal is conducted through the ammonium chloride and aluminum fluoride composite mineralizer, the whole technology is completed through one step, neither a drying technology after acid pickling and nor silicon sand screening with silicon sodium removal is not needed, the overall cost is low,boric oxide and silicon dioxide do not remain in a final product, the alpha-Al2O3 micro powder is high in chemical purity, low in sodium oxide content, high in specific surface area and high in activity, the alpha-aluminum oxide conversion rate is greater than or equal to 96.0%, and grain size distribution is reasonable.

Owner:苏州盛曼特新材料有限公司

Synthetic method of 2-cyanogroup-4-nitro-6-bromaniline diazosalt

ActiveCN101671272AReduce production processThree wastes are produced lessCarboxylic acid nitrile preparationOrganic compound preparationBromineChemistry

The invention relates to a synthetic method of 2-cyanogroup-4-nitro-6-bromaniline diazosalt, solving the technical problems of simple technique and operation, low requirement for production field andequipment, and low energy consumption and low 'three wastes'. The invention comprises the following steps: using o-cyanogroup paranitroaniline as a raw material, pulping in the sulphuric acid at the mass percent of 10% to 98%, adding brominated compound and oxidant for bromination, and directly diazotizing the mixture with the diazotized agent after bromination to obtain the product, wherein the molar ratio of o-cyano paranitroaniline sulphuric acid, brominated compound, oxidant and diazotized agent is 1:3.0 to 20.0:0.5 to 1.5:0.4 to 1.5:1.0 to 2.0.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

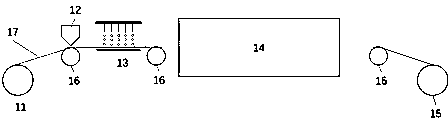

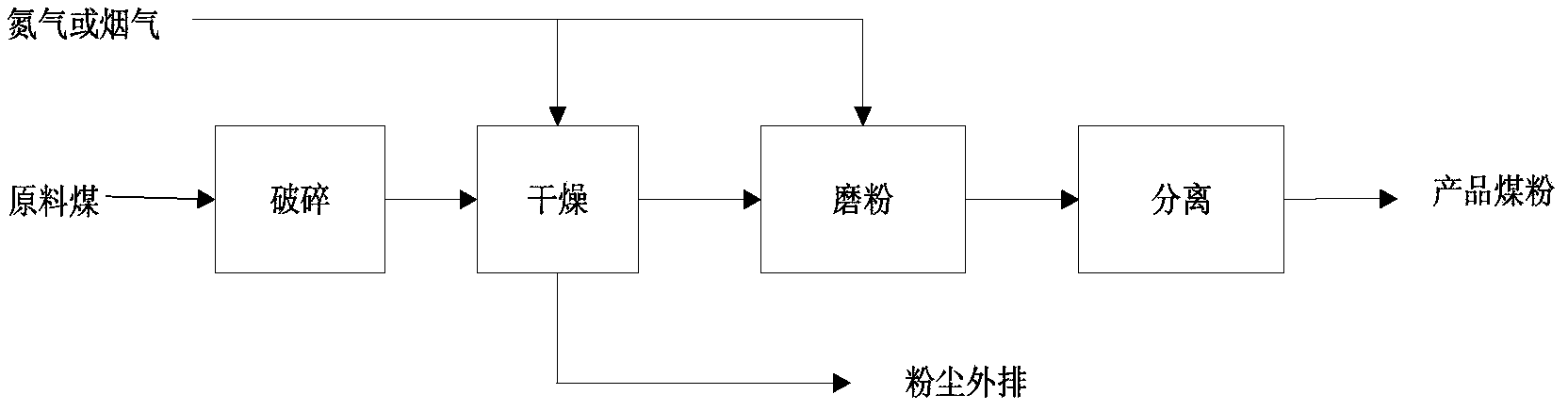

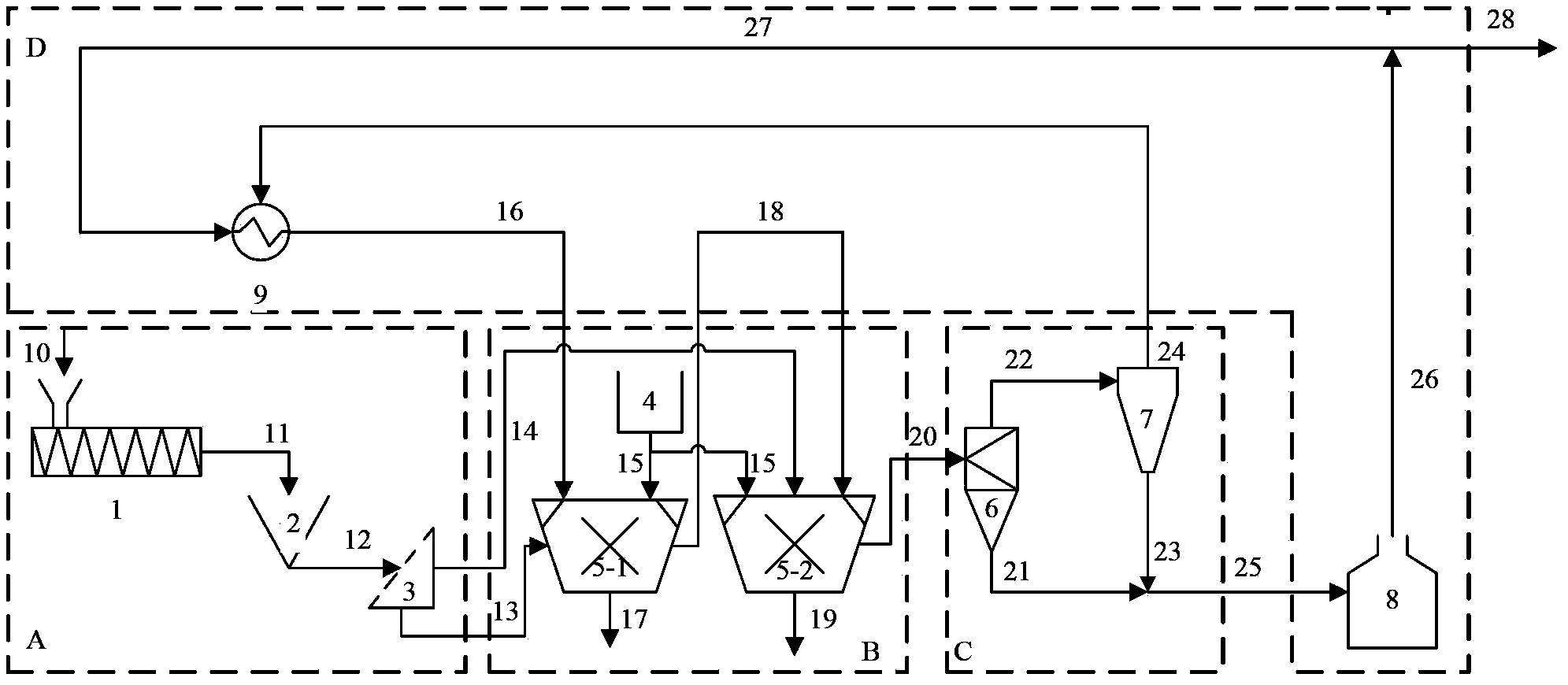

Safe and efficient system and safe and efficient method for preparing powdered coal

ActiveCN103447137AReduce processing costsAvoid security issuesGrain treatmentsShielding gasPollutant emissions

The invention provides a safe and efficient system and a safe and efficient method for preparing powdered coal. The system comprises a coal preparation system, a coal grinding system, a separating system and a superheated steam generating system, wherein the coal grinding system is provided with a material inlet, a superheated steam inlet, a powered coal outlet and a hot dust steam outlet; an outlet of the coal preparation system is communicated with the material inlet of the coal grinding system; an outlet of the superheated steam generating system is communicated with the superheated steam inlet of the coal grinding system; a hot dust steam outlet of the coal grinding system is communicated with an inlet of the separating system; the separating system is provided with a powered coal outlet and a hot steam outlet; the hot steam outlet of the separating system is communicated with a circulating steam inlet of the superheated steam generating system. Superheated steam is taken as protective gas, and thus the safety problem during the preparation of powered coal is solved; the protective medium of superheated steam can be basically subjected to full cyclic utilization, and thus the problems of pollutant discharge and heat waste are solved; the powered coal is dried by the superheated steam in a coal grinding machine, and thus the drying process is eliminated, the technical process is simplified, and the material processing cost is reduced.

Owner:SHAANXI COAL & CHEM TECH INST

Fiber reinforced resin-based wet friction material and preparation method

ActiveCN108559446AImprove performanceStable coefficient of frictionOther chemical processesFibre typesAdhesiveStability coefficient

The invention relates to a fiber reinforced resin-based wet friction material and a preparation method. A mature non-woven technology is combined with a preparation process of a paper-base friction material to open up the prospect of a new paper-base friction material preparation technology, the problems existing in existing traditional preparation technologies can be solved, and then paper-base friction discs which are high in performance are obtained. The preparation method comprises the steps that firstly, fibers are carded and laid up through the non-woven technology to obtain porous fibercloth; secondly, mixed filler paste is uniformly added into the fiber cloth, phenolic resin serves as an adhesive, and finally the paper-base friction material is prepared through gum dipping and hotpressing. The friction coefficient of the paper-base friction material is 0.1-0.13, the static friction coefficient is 0.148-0.160, the stability coefficient is up to 90% or above, the friction coefficient is stable even at high pressure and high speed, and the friction coefficient little fluctuates.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

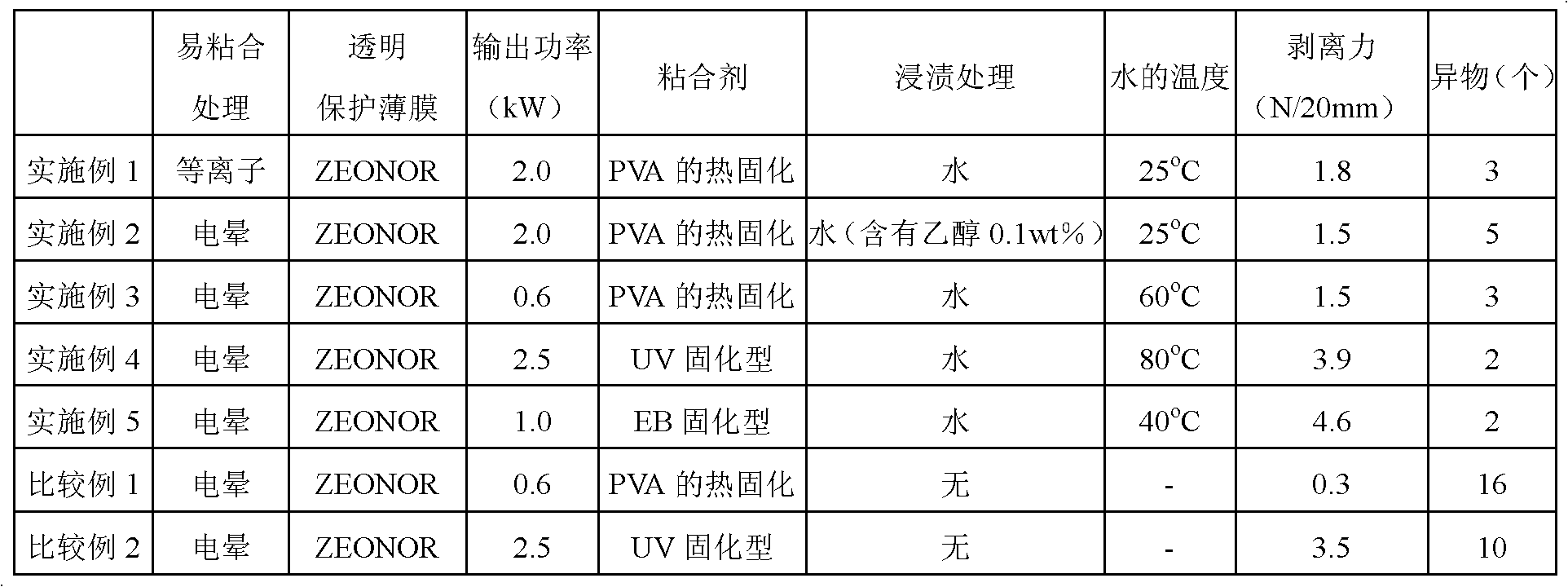

Polarizing plate manufacturing method

InactiveCN102439495AImprove adhesionPrevent floatingPolarising elementsNon-linear opticsPolarizerComposite material

Provided are: a polarizing plate manufacturing method which makes it possible to increase the throughput by preventing adhesion failure between a polarizing film and a transparent protective film even immediately after the transparent protective film is laminated on and adhered to the polarizing film; and a polarizing plate obtained by the method. On the transparent protective film, at least a surface thereof to be attached to the polarizing film is subjected to adhesion improving treatment. Then, water and at least the surface having been subjected to the adhesion improving treatment are brought into contact with each other. Then, the transparent protective film is laminated on the polarizing film in such a manner that a surface on one side of the transparent protective film is attached to the polarizing film, the one side having the surface that has been brought into contact with water and has been subjected to the adhesion improving treatment.

Owner:NITTO DENKO CORP

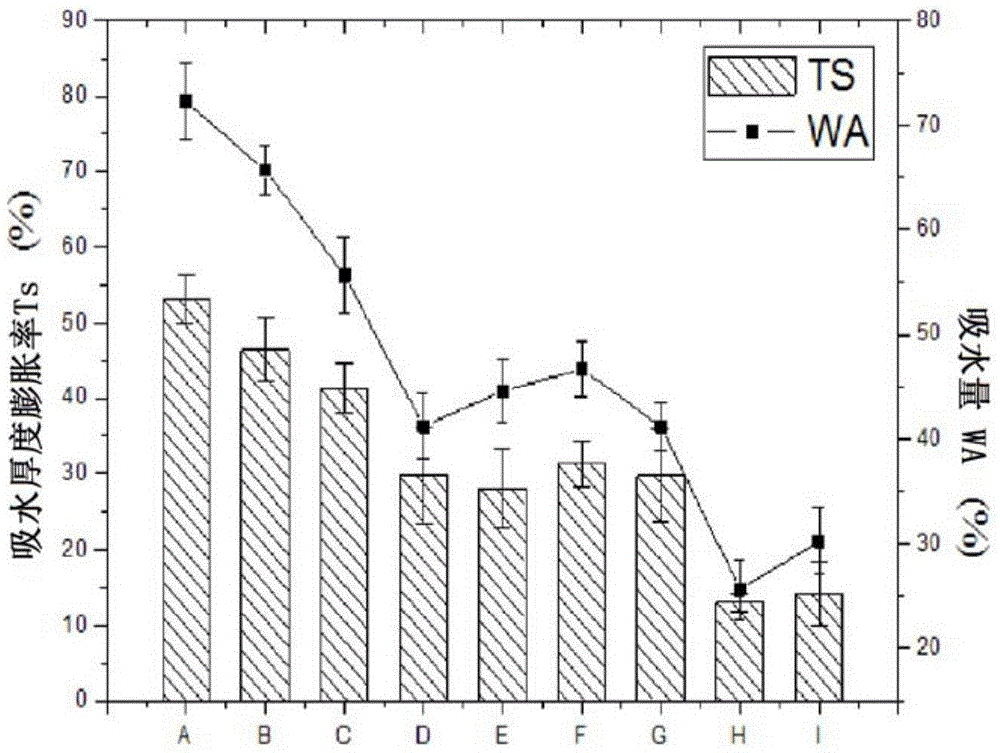

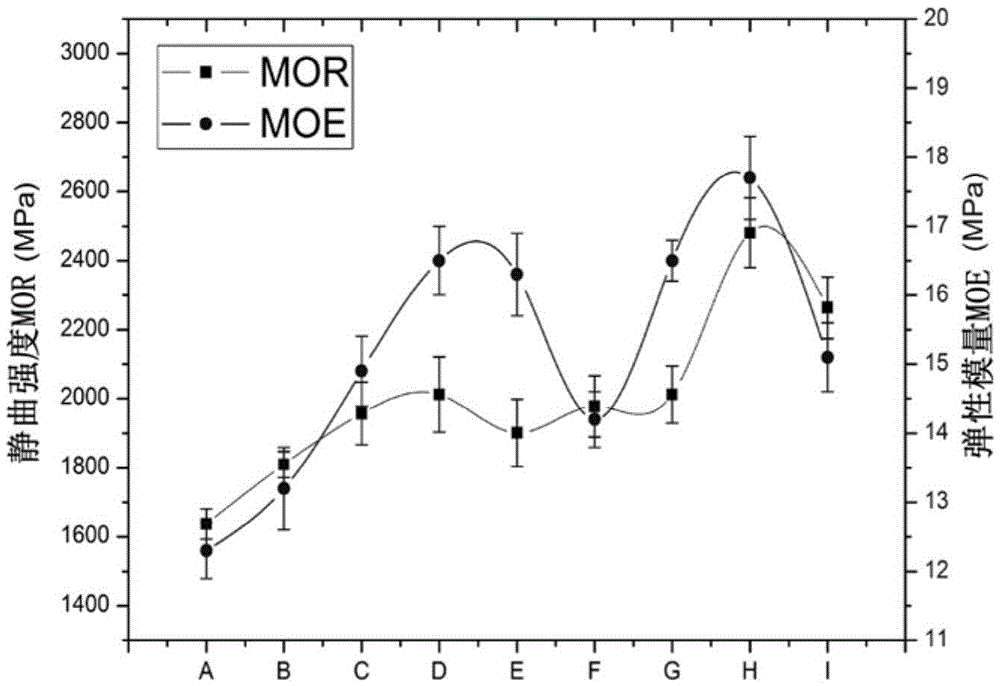

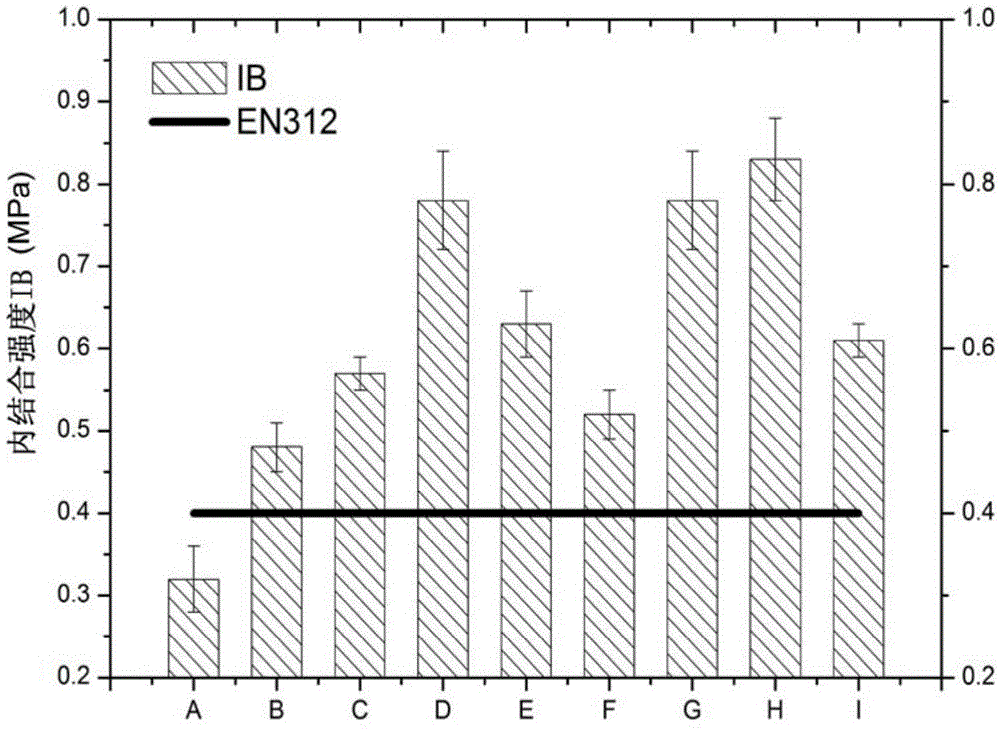

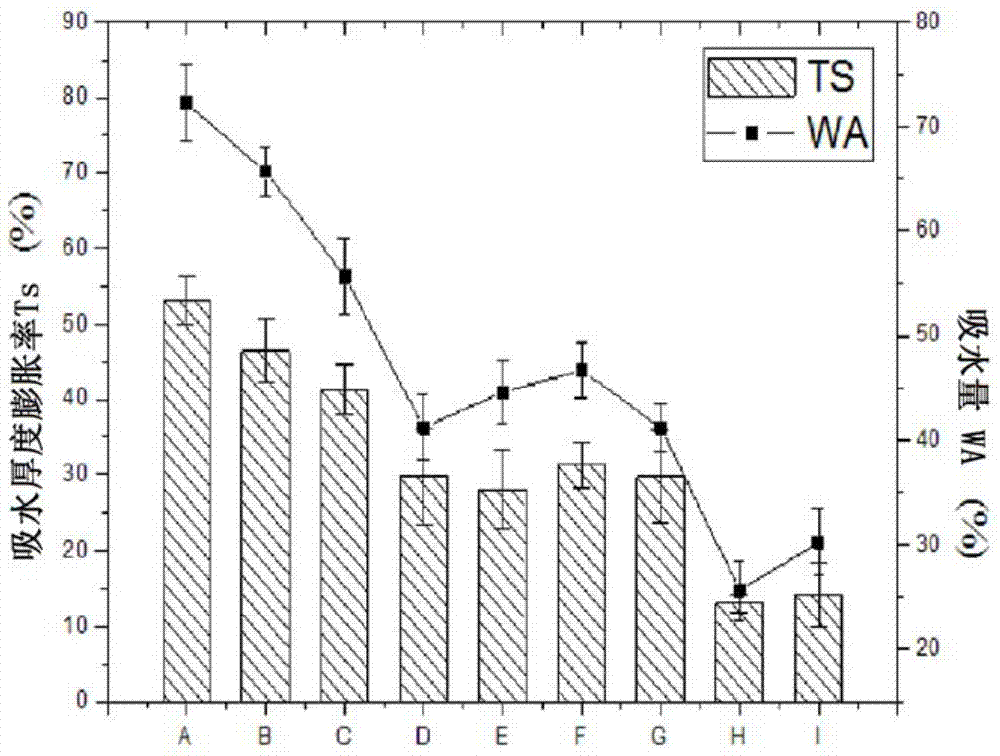

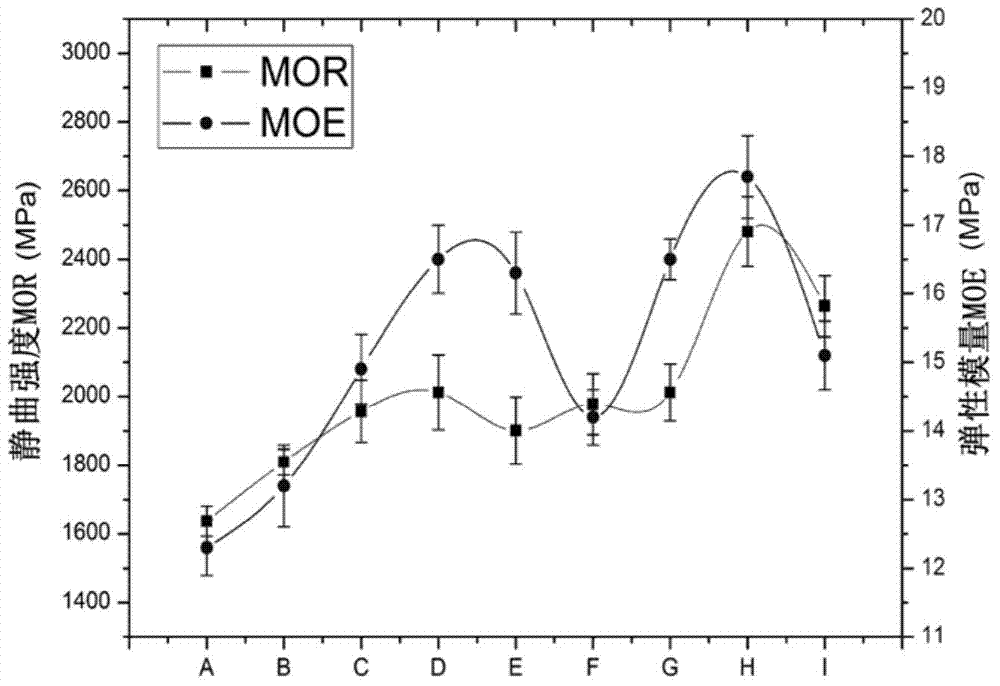

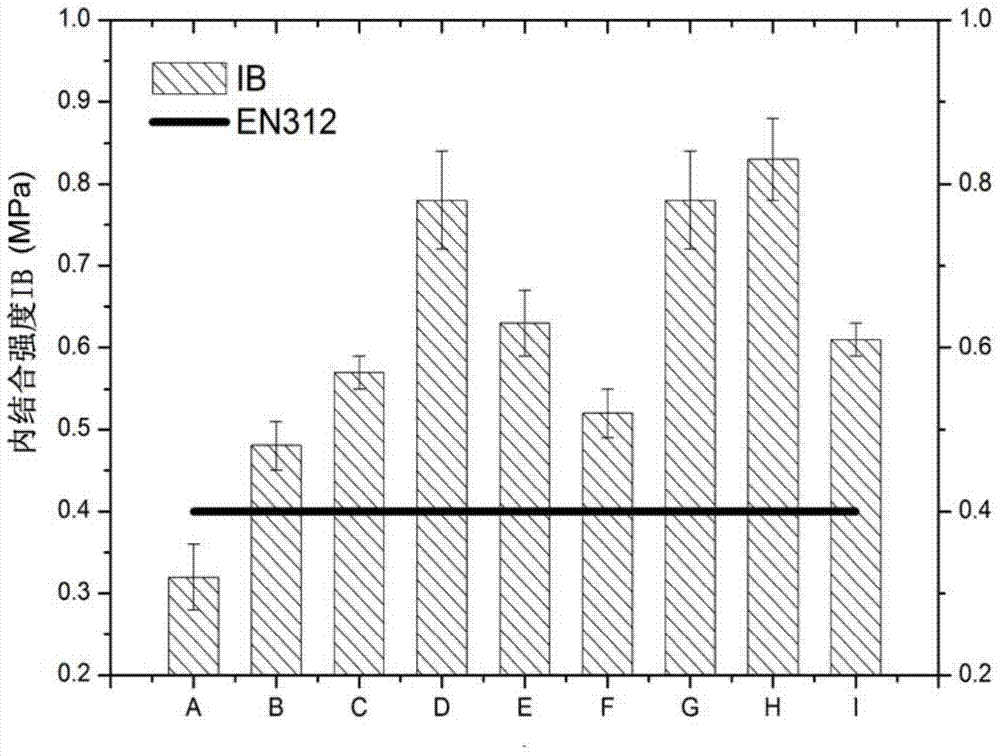

A kind of preparation method of high moisture content particleboard

ActiveCN104493948BReduced activityGood storage stabilityMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhysical healthPolymer science

The invention discloses a preparation method for a shaving board with high moisture content. The preparation method comprises the following specific steps: carrying out shaving screening on raw materials of different specifications and drying qualified shavings; weighing the shavings according to the density and the size of the to-be-manufactured shaving board and regulating the moisture content of each shaving to be 20-40 percent; enabling the sizing amount to be 5-8 percent by weight; uniformly laying the sized shavings in a mould, and hot-pressing for 8-10 minutes under the density of 700-800 g / cm<3> at the temperature of 130-140 DEG C so as to obtain the shaving board with high moisture content. The shaving board with high moisture content prepared by the method has high mechanical property and excellent size stability, such as lower water absorption and thickness swelling rate, reduces formaldehyde release quantity, and is beneficial to physical health.

Owner:NANJING FORESTRY UNIV

Method for synthesizing rubber vulcanization accelerator NS (N-tertiary butyl-2-benzothiazole sulfenamide) through two-step method by taking hydrogen peroxide as oxidant

InactiveCN102838562ASimple processReduce recycling processOrganic chemistrySulfuric acidHydrogen peroxide

The invention discloses a method for synthesizing rubber vulcanization accelerator NS (N-tertiary butyl-2-benzothiazole sulfenamide) through a two-step method by taking hydrogen peroxide as an oxidant. The method comprises the following steps of: (1) weighing 80 g of 98 percent sulfuric acid, preparing 20 percent of sulfuric acid, adding in a reaction kettle with 60 g of tert-butylamine, fully reacting the sulfuric acid with the tert-butylamine under the conditions of 40 DEG C and rotation speed of 600 rpm and dropwise adding 105 ml of M-Na salt with density of 1.5 g / ml to produce M-tert-butylamine salt; and (2) adding 360 ml of oxidant hydrogen peroxide with mass content of 12.0-18.0 percent according to a flow speed of 3 ml / min, wherein the dropwise adding time is 2.0 hours, and performing suction filtration, washing, filtration and drying after reaction to obtain the rubber vulcanization accelerator NS product. The method has the advantages of simple process, use of the environment-friendly hydrogen peroxide as the oxidant, easiness in industrialization, proper amount of the used tert-butylamine, capability of saving acidification, spin-drying and drying steps of an M workshop, high yield of synthesized NS and high quality.

Owner:KEMAI CHEM

Non-drying preparation method of ethylene glycol antimony

ActiveCN102060666AAvoid destructionEliminate drying processPreparation of metal alcoholatesHydroxy compound separation/purificationPolyesterActivated carbon

The invention provides a non-drying preparation method of ethylene glycol antimony, and relates to a preparation method of antimony-containing compound catalyst which is used in polyester polycondensation reaction. The preparation method is characterized by comprising the following steps: adding antimony trioxide and ethylene glycol in a reaction tank to be subjected to esterification dehydrationreaction, wherein the weight ratio of the antimony trioxide to ethylene glycol is 1:(6-7), the temperature in the reaction tank is 135-150 DEG C and the pressure ranges from minus 0.10MPa to minus 0.08MPa; after the reaction, adding a single activated carbon decolouring impurity-removing reagent in the reaction tank for decolouring and impurity removal, then performing circulating filtration, andthen filtering again; and then conveying filtrate to a crystallizing tank, crystallizing the filtrate, performing centrifuge dripping, and then directly performing inspection and packaging. In the method provided by the invention, washing and drying are not required, and the chelate structure of the product is not damaged; and the single activated carbon decolouring impurity-removing reagent is used, thus the effects of decolouring and impurity removal are good, the hue value of the product is high, the loss of ethylene glycol is less, the stability of the product quality is good, the operation is simple, and the production cost is low.

Owner:益阳市华昌锑业催化剂有限公司

Dust-removal carbon drying device

PendingCN109373742ALight in massUniform and smooth feedingGas current separationDrying gas arrangementsEngineeringCarbon black

The invention relates to the field of carbon black producing processing equipment, and discloses a dust-removal carbon drying device. The dust-removal carbon drying device comprises a vertical barrelbody, wherein the top of the barrel body is sealed; the upper part of the barrel body is connected with a charge hole; the free end of the charge hole is connected with an air exhaust hole; the upperpart of the charge hole is connected with a charge assembly; a rotary shaft is coaxially arranged in the barrel body in a penetrating mode; the upper end of the rotary shaft extends to the outside ofthe barrel body, and is equipped with drive equipment for driving the rotary shaft to rotate; a spiral plate is fixedly arranged at the periphery of the rotary shaft; the outer edge of the spiral plate is adaptive to the inner wall of the barrel body; a plurality of vent holes are uniformly formed in the plate surface of the spiral plate; a lifting-pulling rotary shaft and a lifting assembly of the drive equipment are arranged above the barrel body; the lower section of the barrel body is provided with a discharge hole; and the bottom of the barrel body is equipped with a hot air feeding-in hole. According to the dust-removal carbon drying device disclosed by the invention, carbon can be dried by many times, so that the carbon drying effect is especially obvious, the drying rate is also greatly increased, and the carbon drying process is shortened.

Owner:攀枝花宝恒新材料科技有限公司

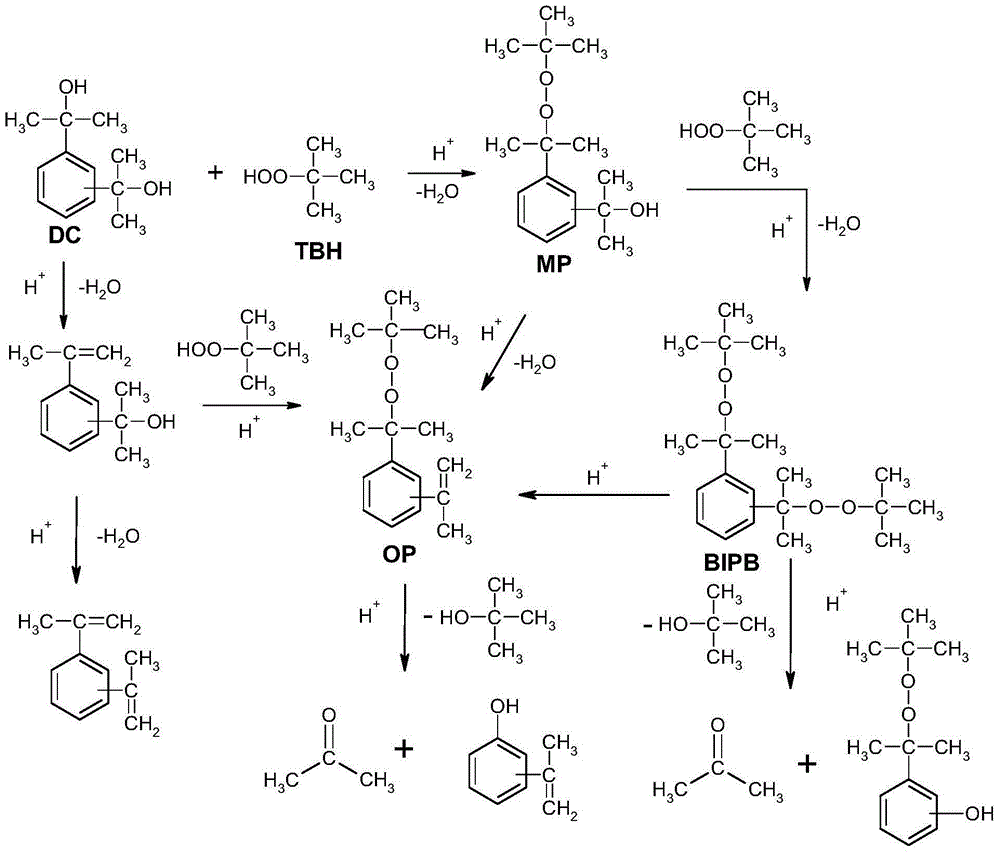

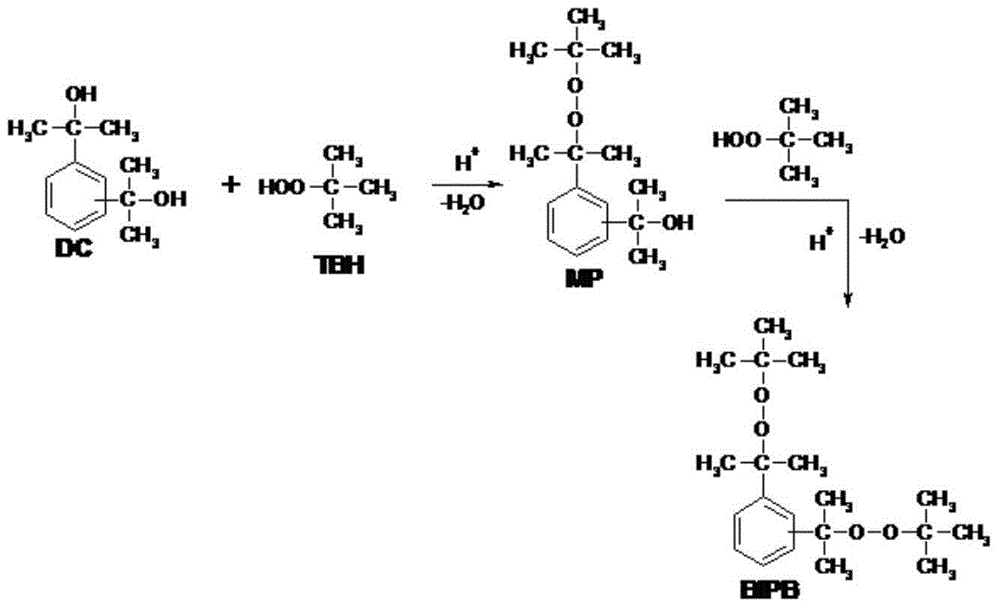

Bis(t-butylperoxyisopropyl)benzene production method

ActiveCN106588735AReduce unit consumptionHigh content/purityOrganic compound preparationPeroxy compound preparationBenzeneChloric acid

The present invention provides a bis(t-butylperoxyisopropyl)benzene (abbreviated as BIPB) production method, wherein a condensation dehydration reaction is performed under a negative pressure condition by adopting di-(2-hydroxyisopropyl)benzene and a t-butyl hydrogen peroxide aqueous solution as raw materials, adopting a perchloric acid aqueous solution as a catalyst, and by adopting toluene as a solvent, such that the loss of t-butyl hydrogen peroxide is reduced, the side effect is less, the conversion rate of the raw materials is improved, the BIPB product having high yield and high purity is obtained, and the production cost is reduced.

Owner:CHINA PETROCHEMICAL CORP

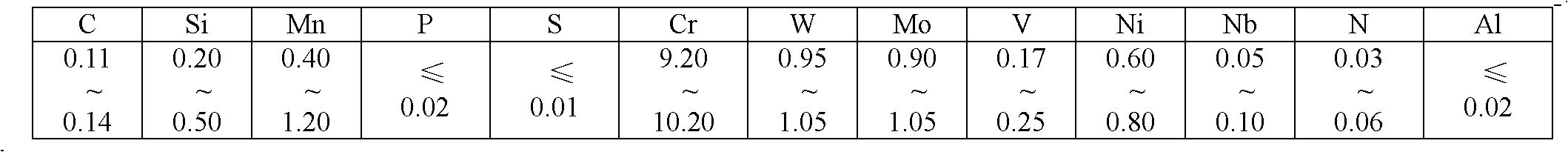

Molding sand proportioning technology for producing large supercritical casting steel

InactiveCN102861865AImprove liquidityHigh hardening strengthFoundry mouldsFoundry coresUltimate tensile strengthMolding sand

The invention relates to a molding sand proportioning technology for producing large supercritical casting steel. The back sand in the technology adopts alkaline phenolic resin sand, and the weight ratio of alkaline phenolic resin to quartz sand is (1.5-2):100, and the weight ratio of the alkaline phenolic resin to a hardener is 100: (20-30). The face sand adopts alkaline phenolic resin chrome ores, and the weight proportion of the alkaline phenolic resin to chrome ores is (1.5-2):100, and the weight ratio of the alkaline phenolic resin to the hardener is 100: (15-25). The invention provides the sand technology for producing the large supercritical casting steel which has high proportioning and casting strength, hot deformability and good collapsibility.

Owner:SANXIN HEAVY IND MACHINERY

Preparing method of magnetic powder for dry pressing anisotropic permanent-magnetic ferrite

The invention discloses a preparing method of magnetic powder for a dry pressing anisotropic permanent-magnetic ferrite. The method comprises the steps of adopting small-particle-size ferric oxide andstrontium carbonate, conducting low temperature pre-sintering after ferric oxide and strontium carbonate are mixed to obtain ferrite pre-sintering materials of which the average crystal particle sizeis smaller than 1.2 micron, adding calcium carbonate and silicon dioxide into the ferrite pre-sintering materials, then preparing fine powder of which the average particle size is 1.0-1.7 micron after dry grinding conducted by a dry grinding mill, and preparing the magnetic powder for the dry pressing anisotropic permanent magnet through dispersion conducted by a powder machine after camphor powder and calcium stearate are added to the fine powder. According to the preparing method of magnetic powder for the dry pressing anisotropic permanent-magnetic ferrite, currently common methods are changed, that is to say, regarding the fine grinding method, common wet fine grinding is replaced by dry fine grinding, wet material grinding , dewatering and drying steps are omitted, the technical procedures are reduced, water and energy consumption during production is reduced, and the preparing method is more environmentally friendly and low carbon.

Owner:安徽盛美格新材料有限公司

Environment-friendly salted egg wrapping material capable of replacing yellow mud and pickling method thereof

PendingCN112656016AImprove shelf lifeStay granularFood coatingEggs preservationCitrate sodiumAstaxanthin

The invention relates to the technical field of poultry egg processing, in particular to an environment-friendly salted egg wrapping material capable of replacing yellow mud and a pickling method thereof, the wrapping material comprises the following components: modified starch, eggshell powder, a cactus alcohol extract, edible salt, a sodium citrate phosphate buffer solution, tea polyphenol, astaxanthin and selenium yeast; the method for pickling the salted eggs by using the wrapping material comprises the following steps: cleaning duck eggs, smearing the wrapping material on the duck eggs, pickling the duck eggs, taking out of a jar, cleaning, packaging and cooking. Along with the requirements of modern food processing on hygienic standards and environmental protection, the traditional technology for pickling salted eggs with yellow mud has the problems of large microbial pollution, heavy metal migration and residual hidden dangers and difficult discharge of high-salt yellow mud water, and the novel wrapping material for pickling salted eggs has the advantages of safety, environmental protection, large amount of oil sand, good quality and long shelf life.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

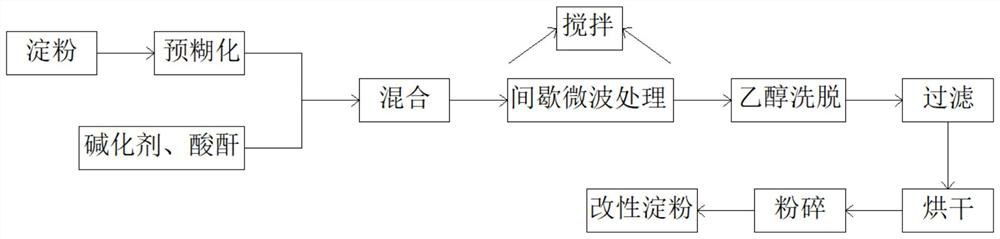

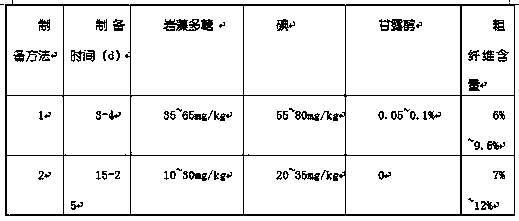

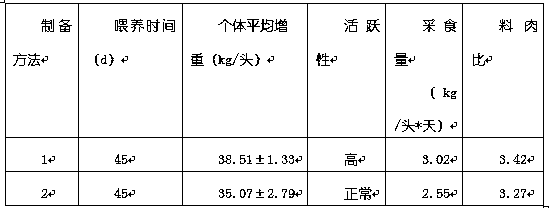

Kelp probiotic fermented feed and preparation method thereof

The invention belongs to the field of feeds, and aims at providing a kelp probiotic fermented feed and a preparation method thereof. According to the kelp probiotic fermented feed, kelp is subjected to pre-enzymolysis by using sodium alginate lyase, so that sodium alginate in the kelp becomes alginate oligosaccharide through enzymolysis, the viscosity of fermentation raw materials is reduced, thepermeability is improved, and the fermentation conditions are improved; after auxiliary materials are added in an obtained kelp enzymolysis solution, probiotics are inoculated, and solid-state fermentation is carried out for 3-4 days to prepare the kelp fermented feed rich in alginate monosaccharide and probiotics. The kelp probiotic fermented feed and the preparation method thereof have the advantages that the loss of nutrients such as minerals and mannitol in the drying and powdering process of the kelp can be avoided; before the kelp is fermented, pre-enzymolysis is carried out, hard-to-consume substances such as sodium alginate and crude fibers in the kelp are converted into small molecular sugar through enzymolysis, and the digestibility of animals is increased. Meanwhile, the viscosity of the fermentation raw materials is reduced, the gas permeability of the fermentation raw materials is improved, common local overheating in solid-state fermentation is prevented, and the preparation method is more suitable for the growth of thalli.

Owner:威海长青海洋科技股份有限公司 +1

Non-drying preparation technology of ethylene glycol antimony

InactiveCN102225884AAvoid destructionGood colorPreparation of metal alcoholatesPolyesterPolymer science

The invention which provides a non-drying preparation technology of ethylene glycol antimony relates to a preparation method of an antimony-containing compound catalyst for a polyester polycondensation reaction. The preparation method, which comprises the following steps: treating excessive ethylene glycol and diantimony trioxide as raw materials, carrying out esterification and dehydration under heating and negative pressure conditions, and filtering and cooling to crystallize, is characterized in that: cooled and crystallized crystals are directly subjected to quality inspection and packing after being dried by a centrifugation drier. In the invention, procedures of drying and washing are omitted, so the damage to ethylene glycol antimony chelates Sb2(OCH2CH2O)3 caused by drying is avoided, and usage of high toxic, flammable and explosive methanol and ethanol is avoided, thereby the production environment is improved, unsafe factors are eliminated, the technology is simplified and the safety cost is reduced; and simultaneously products of the technology of the present invention have 54% to 55% of antimony, the content of antimony is controlled below a theoretical value, and diantimony trioxide is eliminated in the products, so the catalytic performance of the products is improved, the dissolving temperature is reduced, a b value and an L value are improved, and raw material consumption is reduced.

Owner:安化县文威化工有限公司

Preparation method of polyimide nanometer filtering membrane

ActiveCN100363094CSimple manufacturing methodReduce manufacturing costSemi-permeable membranesBenzenePolyamic acid

The present invention relates to a preparation process of nanofiltering polyimide membrane for recovering lubricant oil acetone-benzene dewaxing solvent. The preparation process includes the following steps: preparing polyamic acid solution, adding additive for phase transfer to prepare nanofiltering polyamic acid membrane, imidating the membrane chemically, solvent exchanging and heat treatment. Or, the preparation process may include the following steps: the first preparing partially imidated polyimide capable of being dissolved in some solvents, preparing film casting solution, filming in a phase transfer process, solvent exchanging and heat treatment. The present invention has low preparation cost, and the prepared nanofiltering polyimide membrane has lubricant oil intercepting rate greater than 90 % and mixed acetone-benzene solvent flux greater than 12 L / sq m .hr at the conditions of -18 deg.c and 3 MPa.

Owner:PETROCHINA CO LTD +1

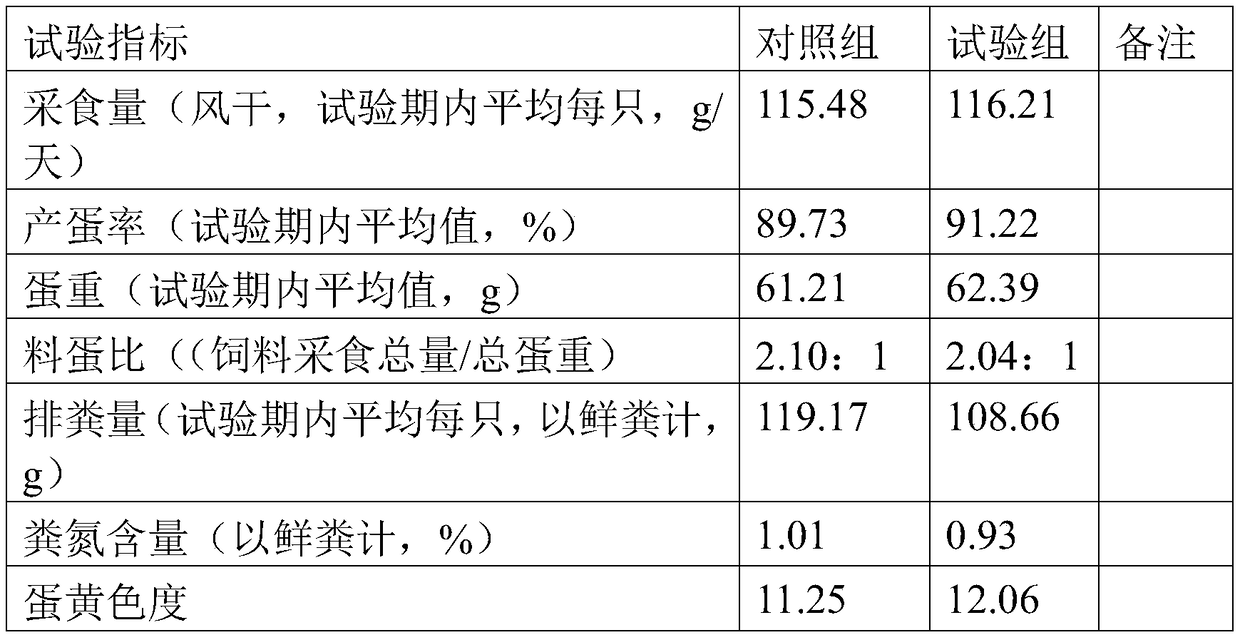

Wet fermentation feed for laying hens and production process of wet fermentation feed

InactiveCN109497336AEliminate drying processLow costFood processingAnimal feeding stuffSoybean productRapeseed

The invention provides wet fermentation feed for laying hens and a production process of the wet fermentation feed. The wet fermentation feed comprises the following ingredients in percentage by weight: 20-50% of seaweeds (wet), 0-30% of distillers' grains (wet), 5-15% of sesame seed meal, 3-10% of rapeseed meal, 5-15% of cottonseed meal, 10-40% of corn germ meal, 5-15% of corn DDGS, 3-10% of ricehull powder, 5-10% of molasses, 1-5% of calcium hydrophosphate, 3-10% of mountain flour, 3-10% of zeolite powder, 0.5-1.5% of 98% betaine hydrochloride, 0.5-1.5% of multi-mineral premix, 0.2-0.8% ofa complex enzyme and 0.5-1.5% of microecological bacteria. According to the wet fermentation feed disclosed by the invention, the problems that daily ration digestion utilization rate of the laying hens is low, people and livestock fight over grains during breeding of the laying hens, the laying hens does not subject to health protection, the breeding of the laying hens is not energy-saving or environmentally friendly, and seaweed wastes cannot be reutilized can be comprehensively relieved; the dosage of soybean products is reduced; the soybean import dependence is reduced. In addition, the ingredient cost in the breeding process is reduced, the feed-gain ratio is improved, the egg products and flavor are improved, and the effect of achieving many things at one stroke is achieved.

Owner:QINGDAO PUXING BIO TECH CO LTD

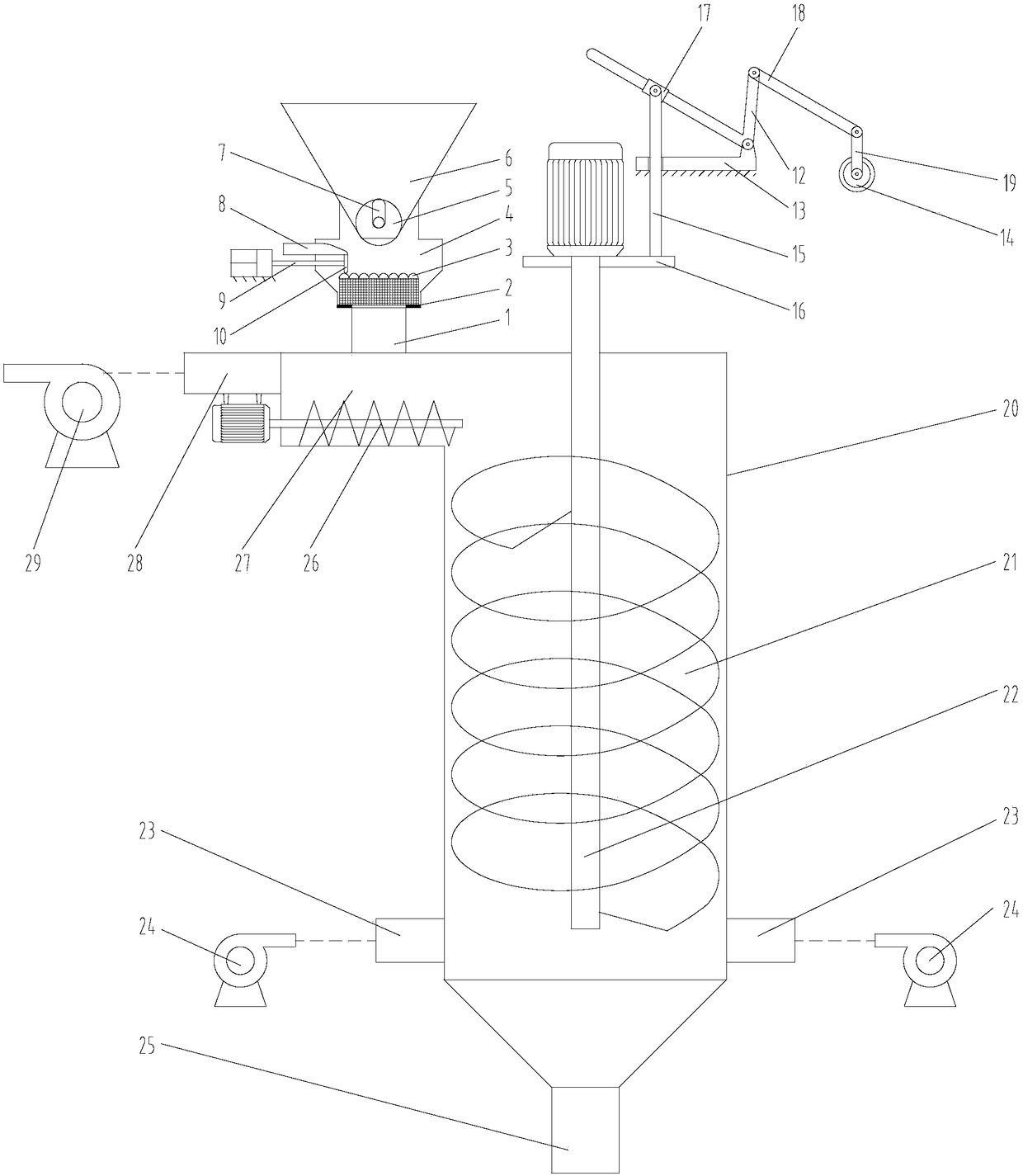

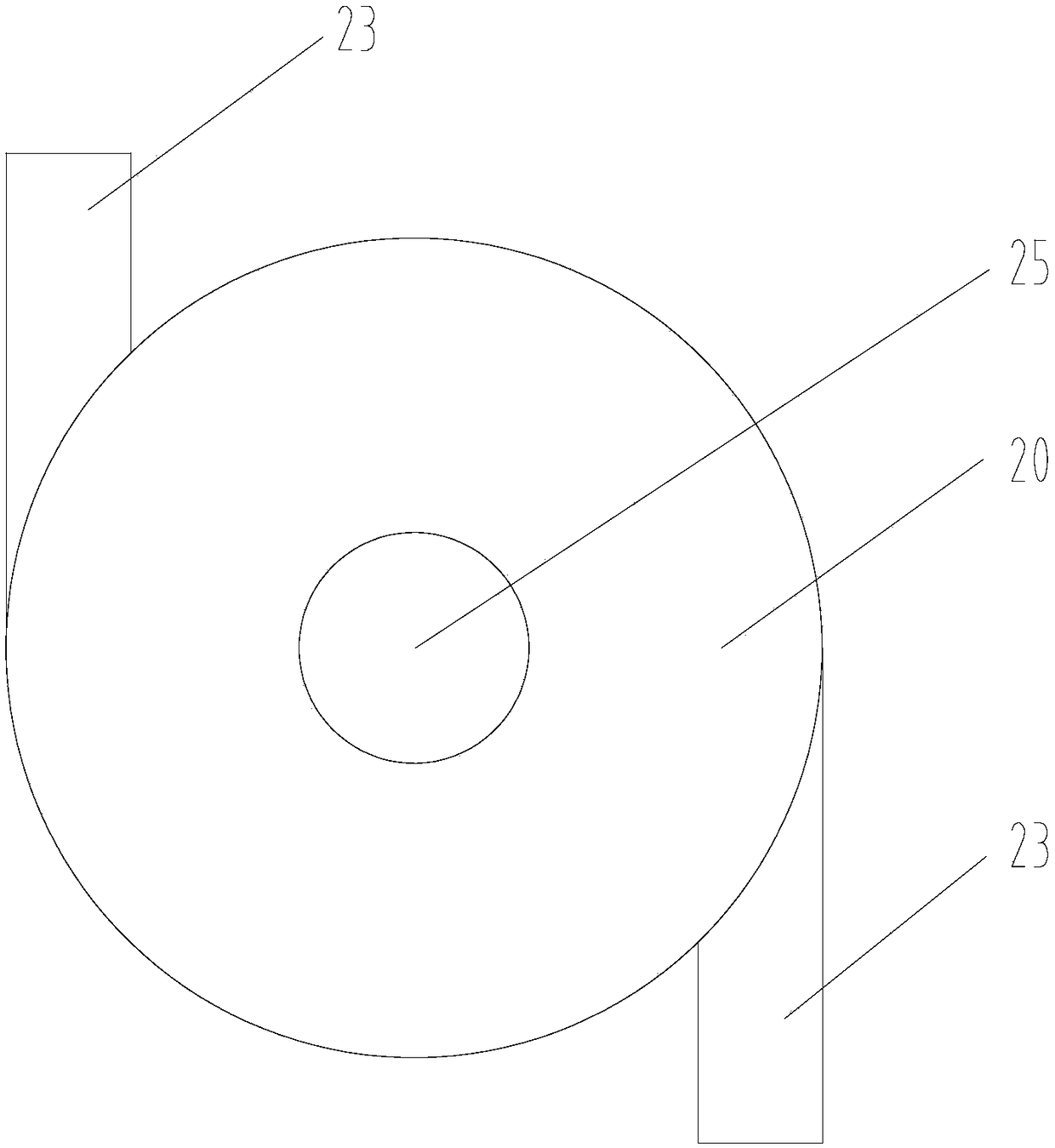

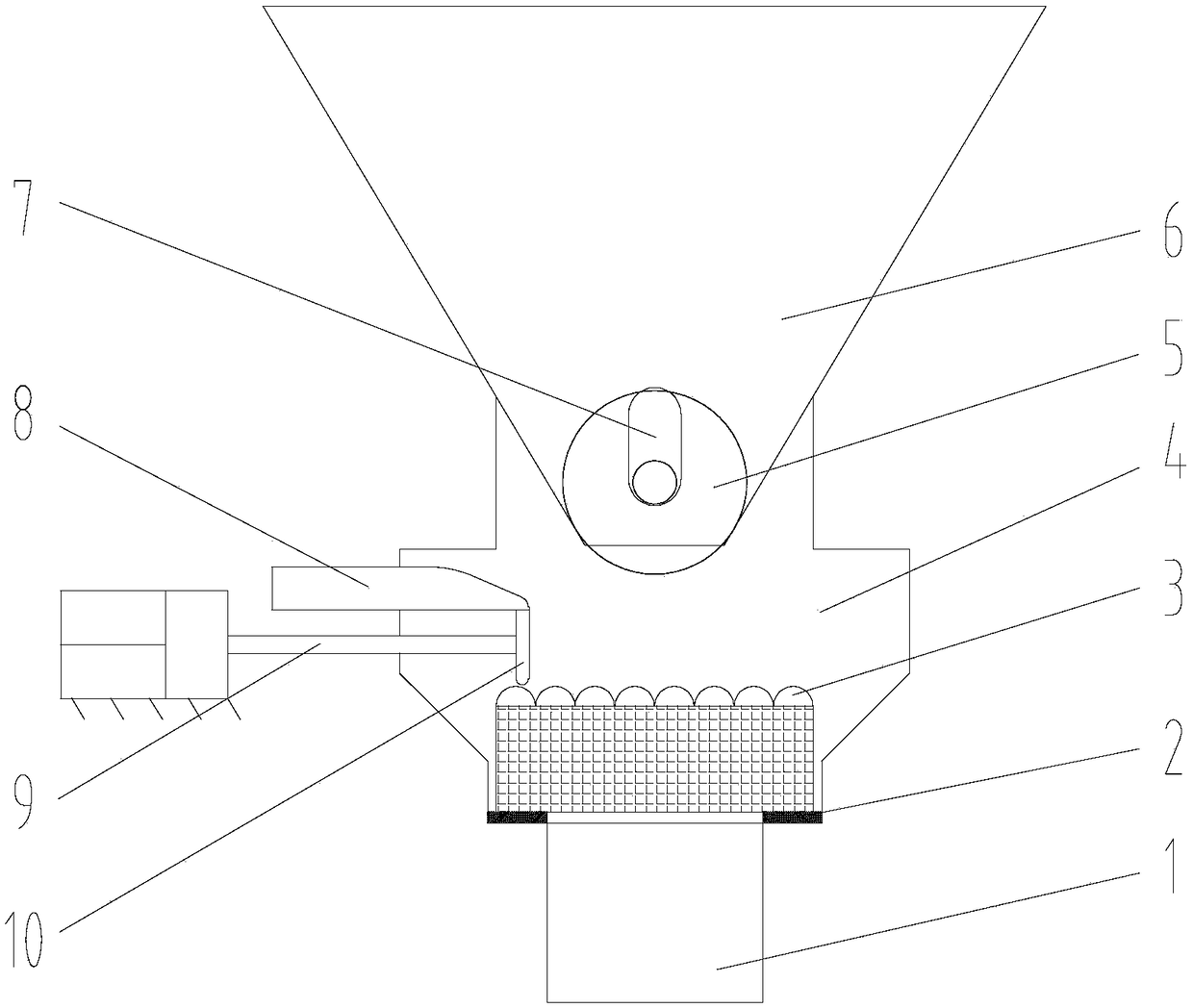

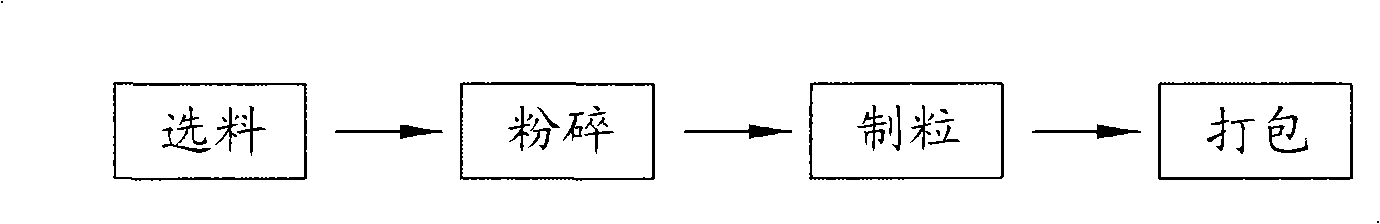

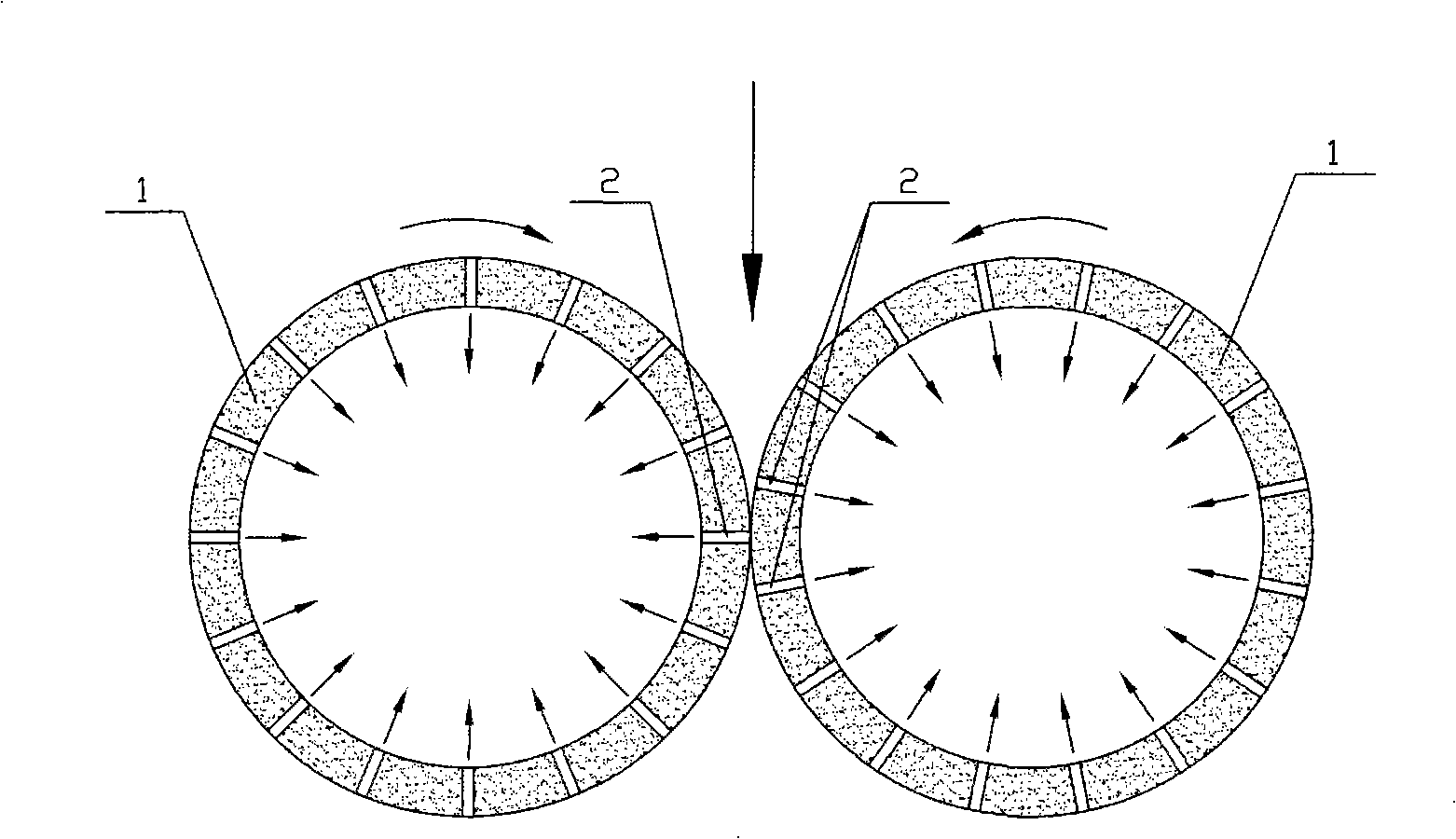

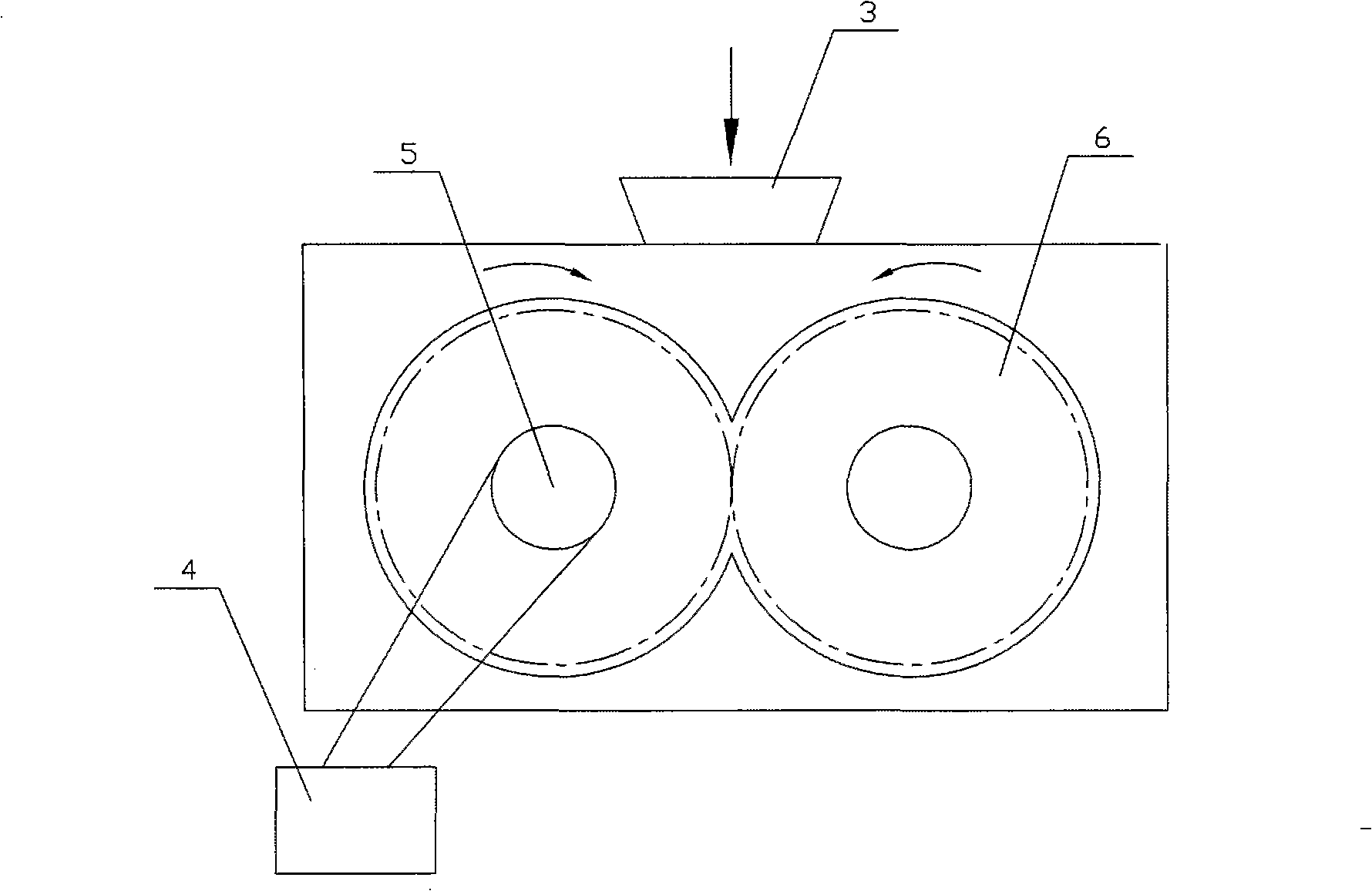

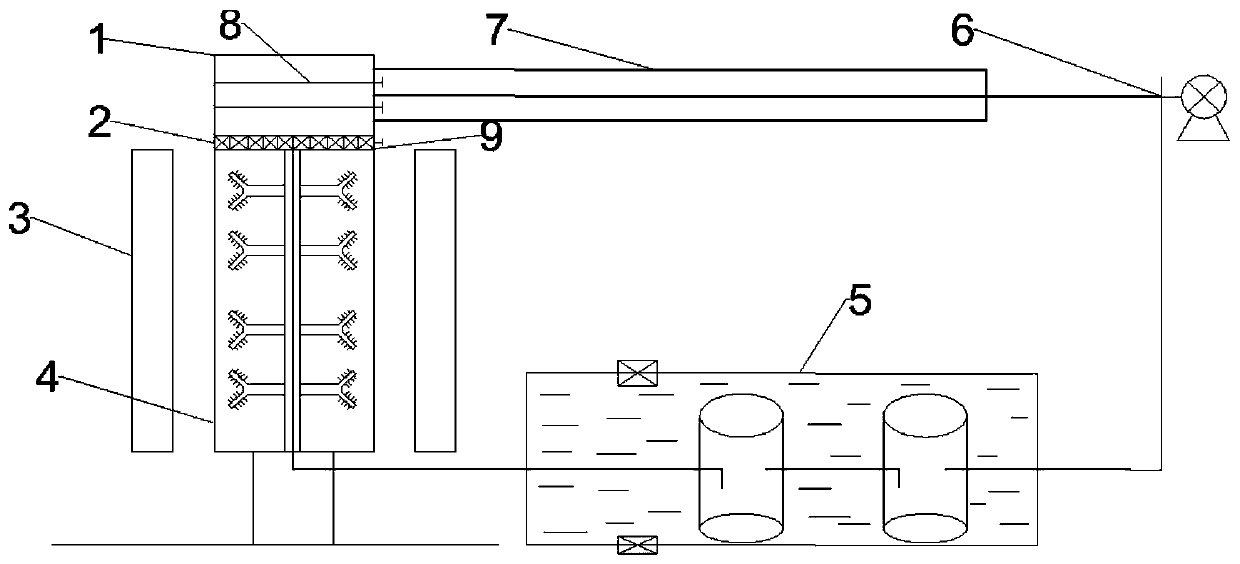

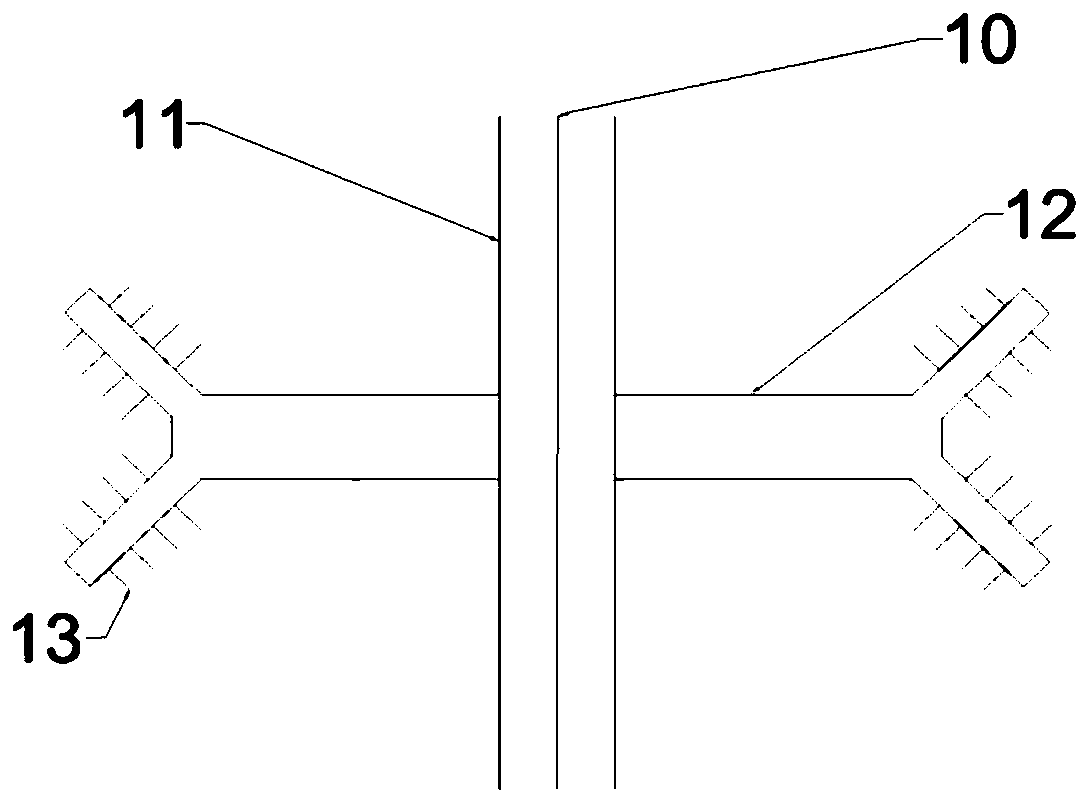

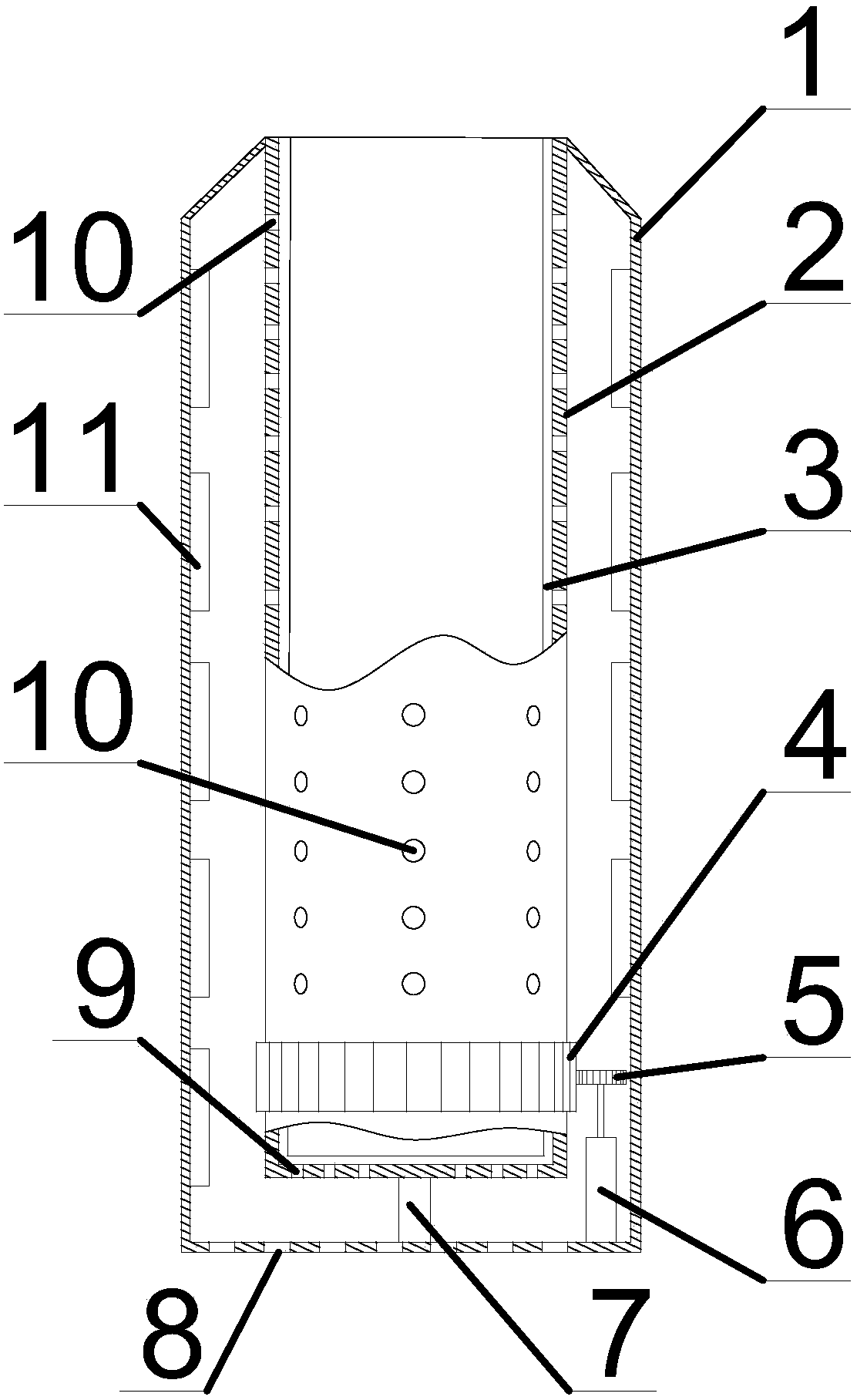

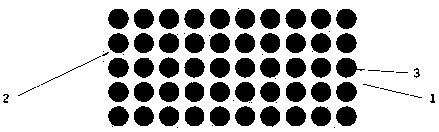

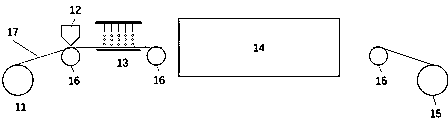

Process for preparing biomass granular fuel and granulating machine used in the process

InactiveCN101338233AReduce energy consumptionEliminate drying processBiofuelsSolid fuelsEngineeringEnergy consumption

The invention discloses a preparation process for producing biomass pellet fuel which has four steps of choosing materials, crushing, granulating and packing, and at the same time discloses a biomass pellet fuel granulating machine used in the process, comprising two circular moulds. The two circular moulds are presented in circumscribed cylinder and are oppositely rotated. A plurality of pressing through holes is uniformly distributed on each of the circular mould. The pressing through holes on the same vertical section are all direct towards the circular mould center of the section. The pressing through holes are alternatively distributed on the tangency place of the two circular moulds. The preparation process effectively reduces the energy consumption. The unit energy consumption in the entire pellet production process is 25-60kWh / t, and compared with the traditional processing the energy consumption is reduced more than 70 percent. At the same time, the pellet can be made once when the humidity is 10-35 percent, which the drying procedure is saved. After the pellet is made, the temperature is just risen 10-15 centigrade. The temperature of the pressed pellet is generally 55-60 centigrade. The pellet can be directly packaged without cooling. The cooling procedure is saved and the working efficiency is improved.

Owner:施迎春

Preparation method for shaving board with high moisture content

ActiveCN104493948AImprove wettabilityHigh bonding strengthMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhysical health

The invention discloses a preparation method for a shaving board with high moisture content. The preparation method comprises the following specific steps: carrying out shaving screening on raw materials of different specifications and drying qualified shavings; weighing the shavings according to the density and the size of the to-be-manufactured shaving board and regulating the moisture content of each shaving to be 20-40 percent; enabling the sizing amount to be 5-8 percent by weight; uniformly laying the sized shavings in a mould, and hot-pressing for 8-10 minutes under the density of 700-800 g / cm<3> at the temperature of 130-140 DEG C so as to obtain the shaving board with high moisture content. The shaving board with high moisture content prepared by the method has high mechanical property and excellent size stability, such as lower water absorption and thickness swelling rate, reduces formaldehyde release quantity, and is beneficial to physical health.

Owner:NANJING FORESTRY UNIV

An oil producing device integrating biomass drying, crushing and pyrolysis

InactiveCN109777464AFull residence timeExtended stayLiquid hydrocarbon mixture productionGrain treatmentsResidual carbonProcess engineering

An oil producing device integrating biomass drying, crushing and pyrolysis is provided. The device includes a fed material storage device, a furnace chamber, a pyrolysis chamber, a crusher, a condenser and a ventilation pipeline. The pyrolysis chamber is disposed in the furnace chamber. A feeding device is disposed on the pyrolysis chamber. The crusher is disposed in the pyrolysis chamber. The inlet of the condenser is connected to the outlet of the pyrolysis chamber, and the outlet of the condenser is connected to the ventilation pipeline. After a raw material is fed into the pyrolysis chamber, the raw material is crushed and stirred by the crusher in the pyrolysis chamber, and a thermocouple in the pyrolysis chamber adjusts the temperature in the pyrolysis chamber through a temperature controller. A pyrolysis product is fed into the condenser from the outlet of the pyrolysis chamber through a pipeline, biological oil after condensation is collected and residual carbon is collected atthe bottom of the pyrolysis chamber. Gas that cannot be condensed is conveyed to the fed material storage device through the ventilation pipeline, and waste heat of the gas is utilized to dry the biomass in the fed material storage device. The oil producing device is beneficial to sufficient biomass pyrolysis, and increases the yield of the biological oil by about 15%, heat can be recycled and air pollution is reduced.

Owner:JIANGSU UNIV

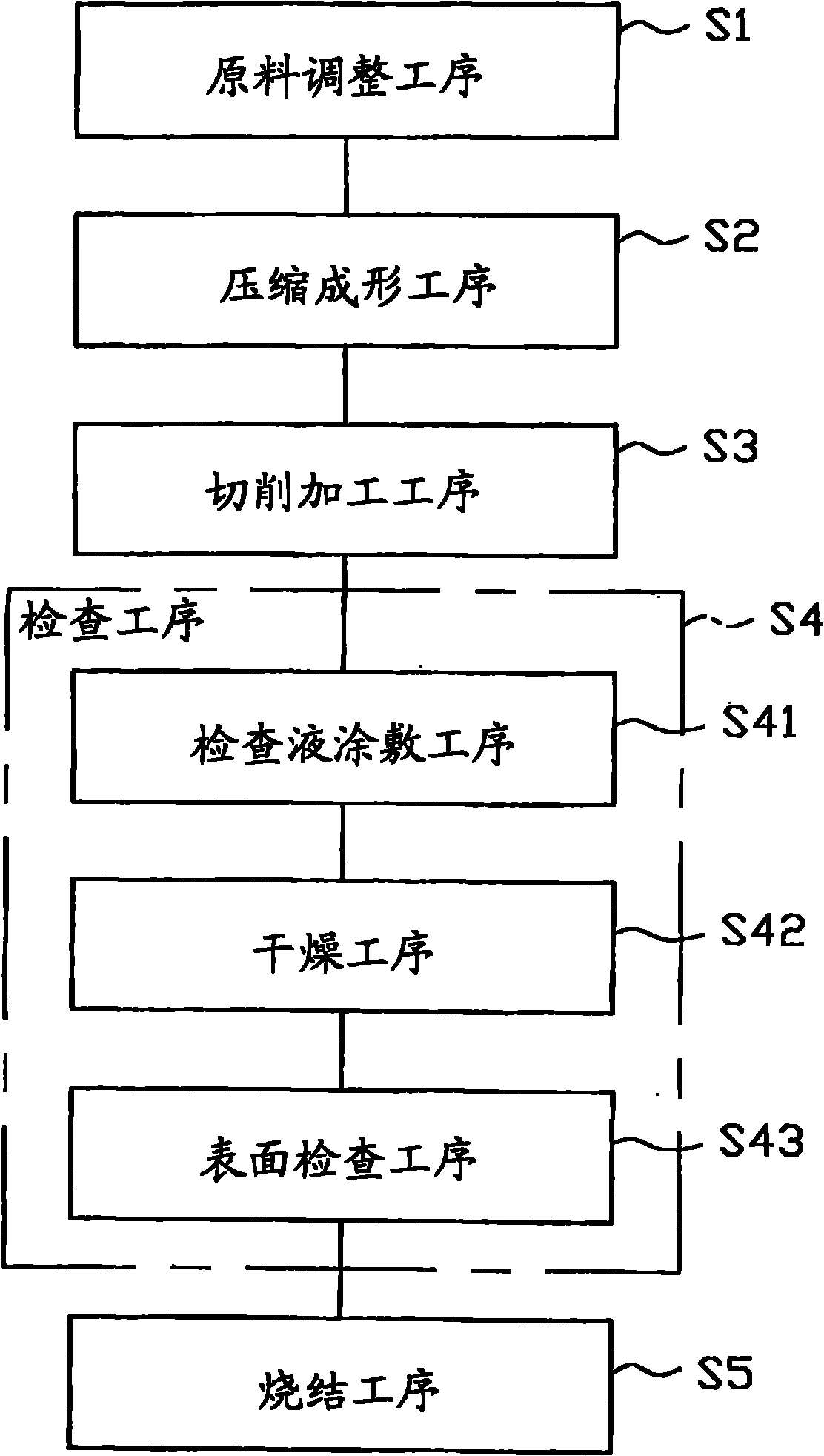

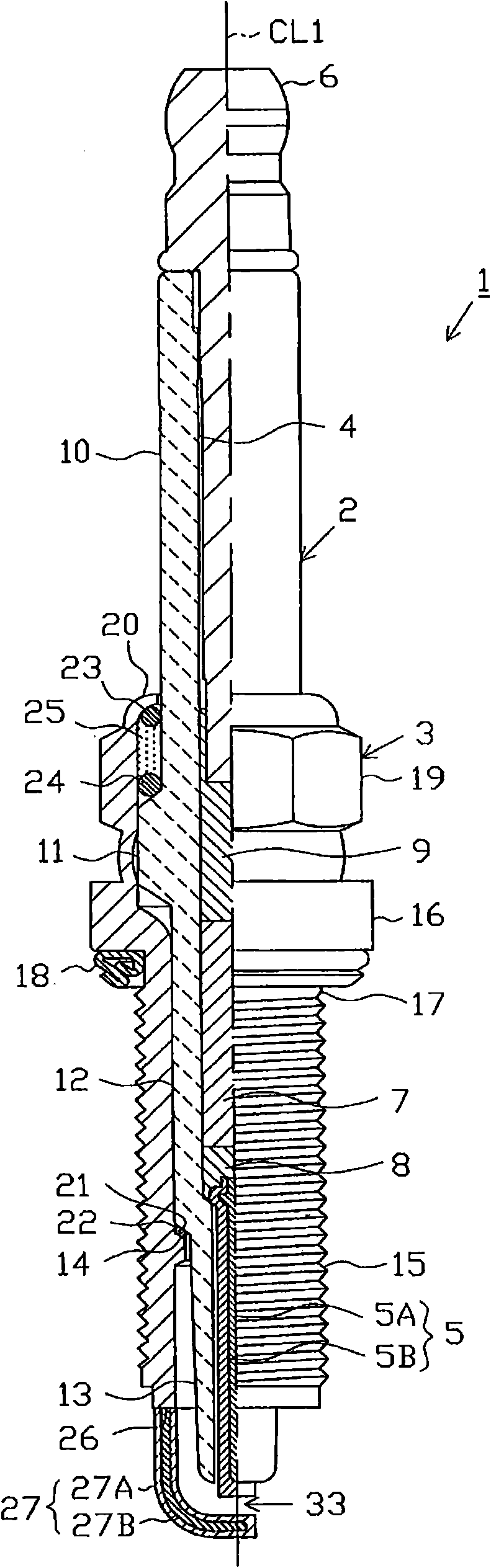

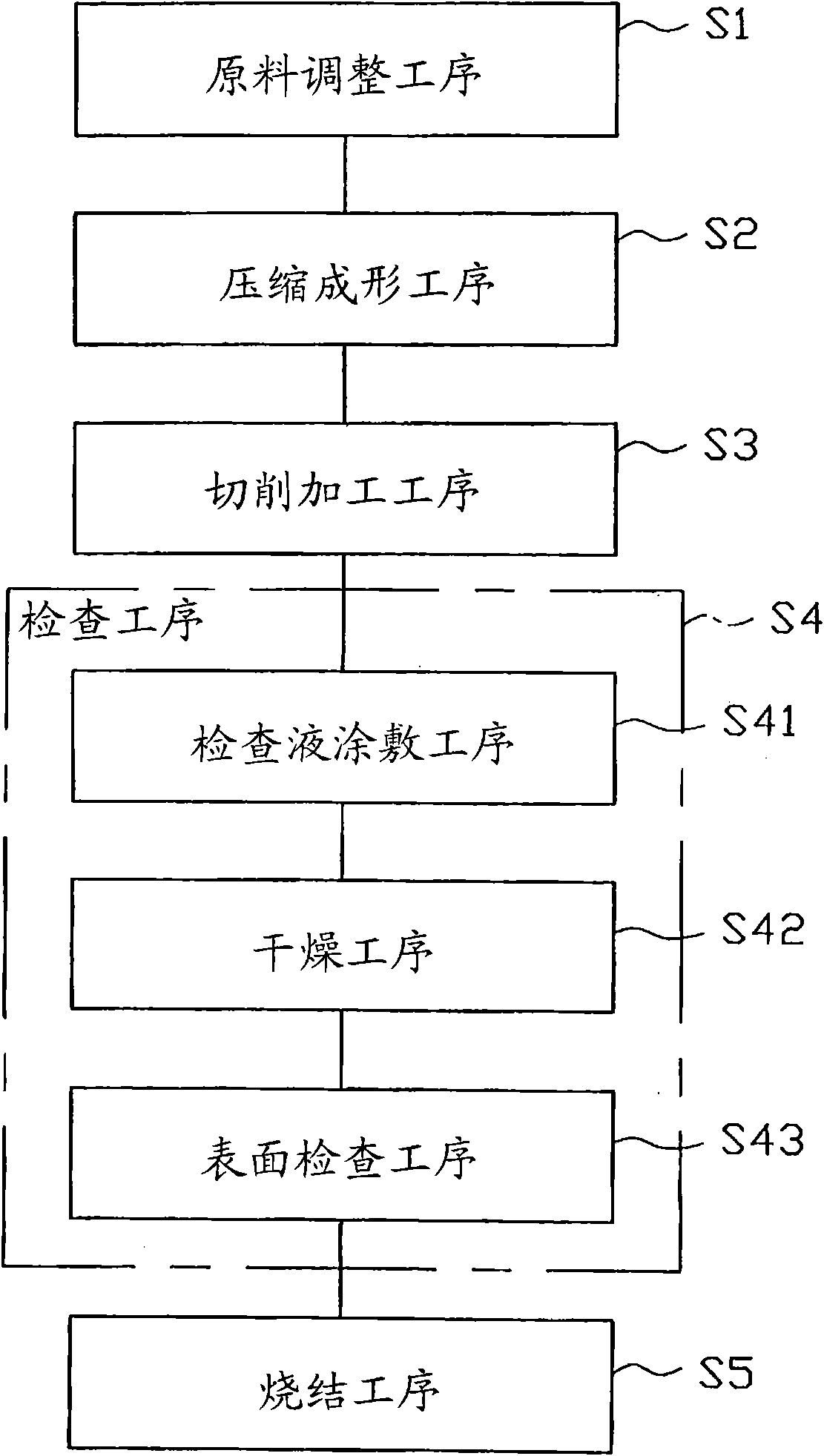

Insulator for the spark plug and the manufacturing approach thereof, together with the spark plug

ActiveCN101814702AImprove permeabilityAvoid quality lossSparking plugs manufactureEngineeringForming processes

This invention provides a type of insulator for the spark plug and the manufacturing approach, together with spark plug, by which the product quality can be improved through an accuracy test on the products that determining whether a crack is happened during the manufacturing process. The insulator is manufactured by followed steps: I) Forming process. Shape the unsintered insulator that is in a set shape (compression and shape process, cutting process); II) Sintering process. Sinter the unsintered insulator. In addition, a crack detecting process is arranged between above two process. And the detecting process includes: 1) Examination liquid coating process, which is by means of coating penetrant examination liquid on the surface of the unsintered insulator; 2) Drying process, which is by means of drying the penetrant examination liquid on the surface of the unsintered insulator ; 3) Surface examineing process, which is by means of examining the surface of the unsintered insulator tofind out if any crack is occurred .

Owner:NGK SPARK PLUG CO LTD

Fresh honey-fried rhizoma gastrodiae slice and preparation method thereof

InactiveCN110013029AAvoid multi-level loss and destructionAvoid the problem of medicinal material contaminationFood ingredient as antioxidantNervous disorderNutrientChemistry

The present invention discloses a fresh honey-fried rhizoma gastrodiae slice and a preparation method thereof. The processing technology of the finished product comprises the following steps: fresh rhizoma gastrodiae is selected and processes of washing, slicing, color protecting, hardening, pre-cooking, three sugar boiling, drying, etc. The preparation method the following advantages: 1, the technology uses the fresh rhizoma gastrodiae as a raw material to process the fresh honey-fried rhizoma gastrodiae slice, maintains nutrients and medicinal effect components in the rhizoma gastrodiae to the maximum extent without losing, and can avoid a problem of contamination of the medicinal material caused by multi-procedure processing; 2, the technology uses the steps of vitamin C color protecting, calcium chloride hardening, honey stir-frying, etc. to treat the fresh rhizoma gastrodiae to play anti-oxidation effects and pharmacodynamic effect-stabilizing effects; 3, the technology directly uses the fresh rhizoma gastrodiae for processing, shortens production cycle, reduces production costs, saves a drying treatment process of the fresh rhizoma gastrodiae, can conduct the processing on the spot, and saves storage and transportation costs of the processed dry rhizoma gastrodiae product; 4, the fresh honey-fried rhizoma gastrodiae slice is long in shelf life and has the shelf life up to12 months when preserved at room temperature in the dark; and 5, the method is suitable for large-scale processing and production of the fresh rhizoma gastrodiae, greatly alleviates dilemma of difficult production, storage and transportation of the rhizoma gastrodiae, and the technology is stable in processes, simple and convenient in production operation and easy for pilot production and industrial production.

Owner:CHENGDU UNIV +1

Method for preparing alpha semi-hydrated gypsum pulp and plaster products by desulphurizing gypsum

Disclosed is a method which uses desulfurization dihydrate gypsum to prepare alpha-type semi-hydrated gypsum slurry, comprising the following steps: getting the power plant desulfurization dihydrate gypsum; mixing the power plant desulfurization dihydrate gypsum with water to form slurry with concentration between 10% and 50%; adding a crystal modifier into the slurry, wherein, the crystal modifier can be succinate, sodium succinate or succinate magnesium, and the dosage of the crystal modifier takes up 0.5 to 8 per mille of the mass of the desulfurization dihydrate gypsum; heating the slurring with crystal modifier to 120-160 DEG C and preserving the slurry for 1 to 4 hours so as to get the alpha-type semi-hydrated gypsum slurry. An alpha-type semi-hydrated gypsum product preparation method comprises the following steps: taking the alpha-type semi-hydrated gypsum slurry as the raw material, and then directly pouring the slurry into a mold through centrifugal or vacuum dehydration without drying, so as to obtain gypsum blocks or other alpha-type semi-hydrated gypsum products.

Owner:SOUTHEAST UNIV

Dust capturing device

InactiveCN107817138AAvoid easy cloggingSampling results are objective and accurateWithdrawing sample devicesDispersed particle separationWater vaporEngineering

The invention discloses a dust capturing device, relating to air detection equipment. The dust capturing device comprises a shell, a cylinder and a motor, wherein a cavity and only one upper opening are formed in the shell, a plurality of wind holes are formed in the bottom of the shell, a plurality of side holes are formed in the side wall of the shell, and a plurality of heating plates are further arranged in the shell; a plurality of small holes are formed in the bottom of the cylinder, and a filter net is distributed on the inner wall of the cylinder; and the motor is fixed in the cavity in the shell, a main gear is connected to an output end of the motor, the cylinder is sleeved with an auxiliary gear, the cylinder is mounted on the inner wall of the shell through a rotating shaft, and the main gear and the auxiliary gear are mutually meshed. The motor is started to drive the cylinder to rotate around the rotating shaft, and then the dust falling to the bottom of the cylinder is thrown to the side wall of the cylinder through a centrifugal force, so that the filter net at the bottom of the cylinder is unlikely to be blocked; and meanwhile, the heating plate is started to heata space in the shell, air and dust which enter the cylinder are heated during the rotation of the cylinder, moisture in the air and the dust are evaporated into water vapor, and the water vapor is thrown out of the cylinder through the side holes.

Owner:重庆美高科技有限公司

Polymer slurry, composite diaphragm and preparation method thereof

ActiveCN109994695BUniform sizeAvoid easy cloggingSecondary cellsCell component detailsCeramic coatingPhysical chemistry

The invention relates to the technical field of lithium-ion battery diaphragm preparation, and discloses a polymer slurry, a composite diaphragm and a preparation method thereof. The polymeric slurry includes 10-30 parts by weight of a polymer, 0.05-1.0 parts by weight of a thickener, 5.1-26.5 parts by weight of a wetting agent, 1.0-5.0 parts by weight of a binder, 0.1-1.0 parts by weight of dispersant and 80-120 parts by weight of water. The composite diaphragm provided by the invention includes a base film, a ceramic coating and a polymer dot coating respectively coated on both sides of the base film, wherein the polymer dot coating is obtained by coating the above polymer slurry through high-pressure jet flow. The composite diaphragm has good thermal stability, strong cohesive force and good air permeability, and when it is applied to a lithium-ion battery, it is beneficial to improve the performance of the battery.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

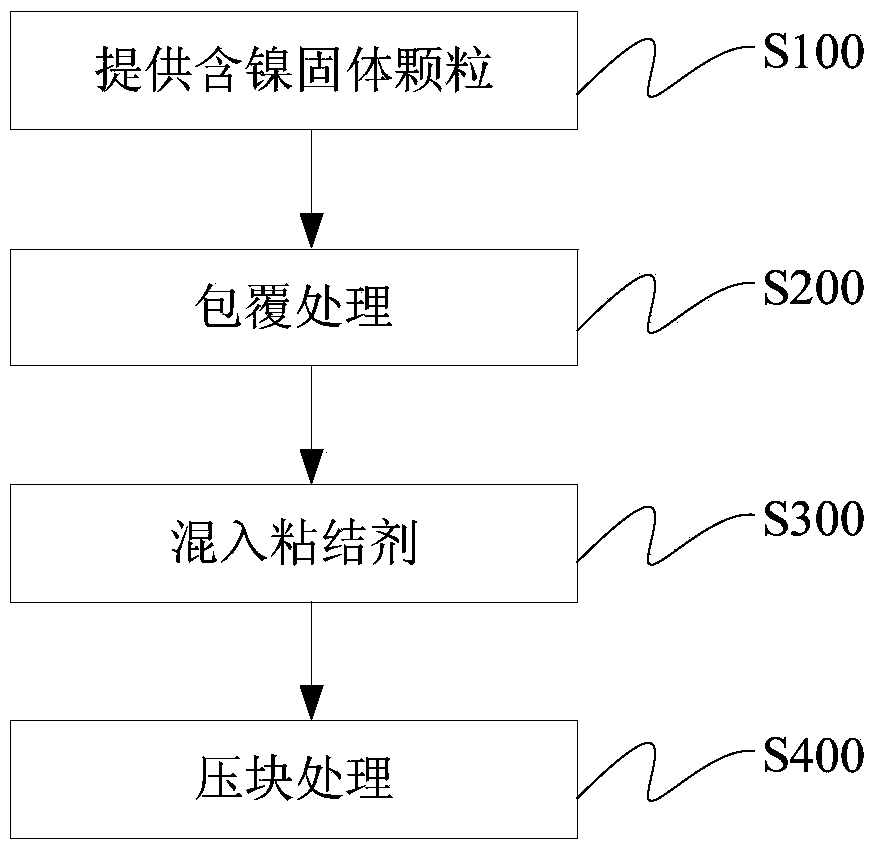

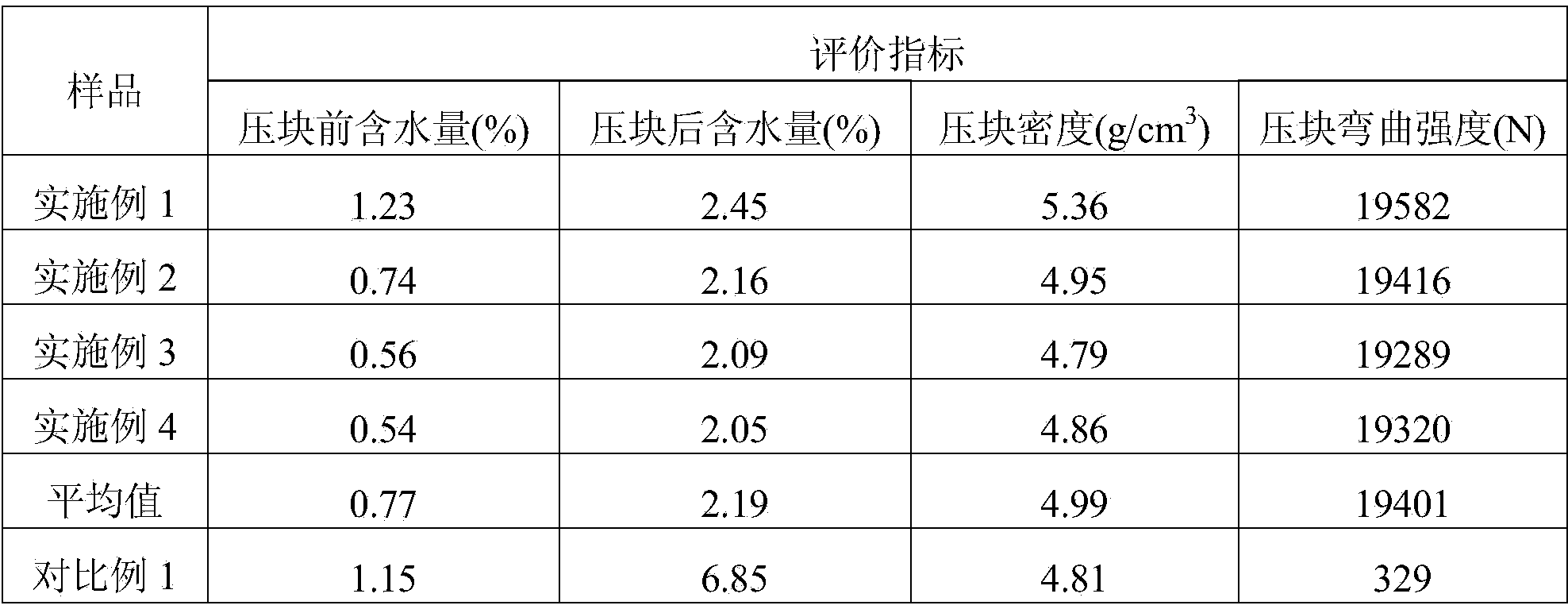

Method for preparing nickel-containing solid particle briquette

The invention discloses a method for preparing a nickel-containing solid particle briquette. The method comprises steps of (1) providing nickel-containing solid particles with average particle size below 75 micron; (2) wrapping the nickel-containing solid particles with organic coating agent; (3) mixing the wrapped nickel-containing solid particles obtained in step (2) with adhesive, wherein the adhesive contains syrup and at least one of hydrated lime and quick lime; (4) briquetting the mixture obtained in step (3), so as to obtain the nickel-containing solid particle briquette. The method can remarkably lower the cost for preparing the nickel-containing solid particle briquette, the prepared nickel-containing solid particle briquette can be used for smelting without drying, so that the industrial production technology for producing ferro-nickel alloy saves one step, and the production cost is remarkably lowered.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com