Insulator for the spark plug and the manufacturing approach thereof, together with the spark plug

A manufacturing method and a technology for an insulator, applied in the field of spark plugs, can solve the problems of difficulty in completely removing the inspection liquid, deterioration of the appearance quality of the insulator, impermeability of the inspection liquid, etc., and achieve the effects of improving the appearance quality, suppressing the mechanical strength, and shortening the drying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

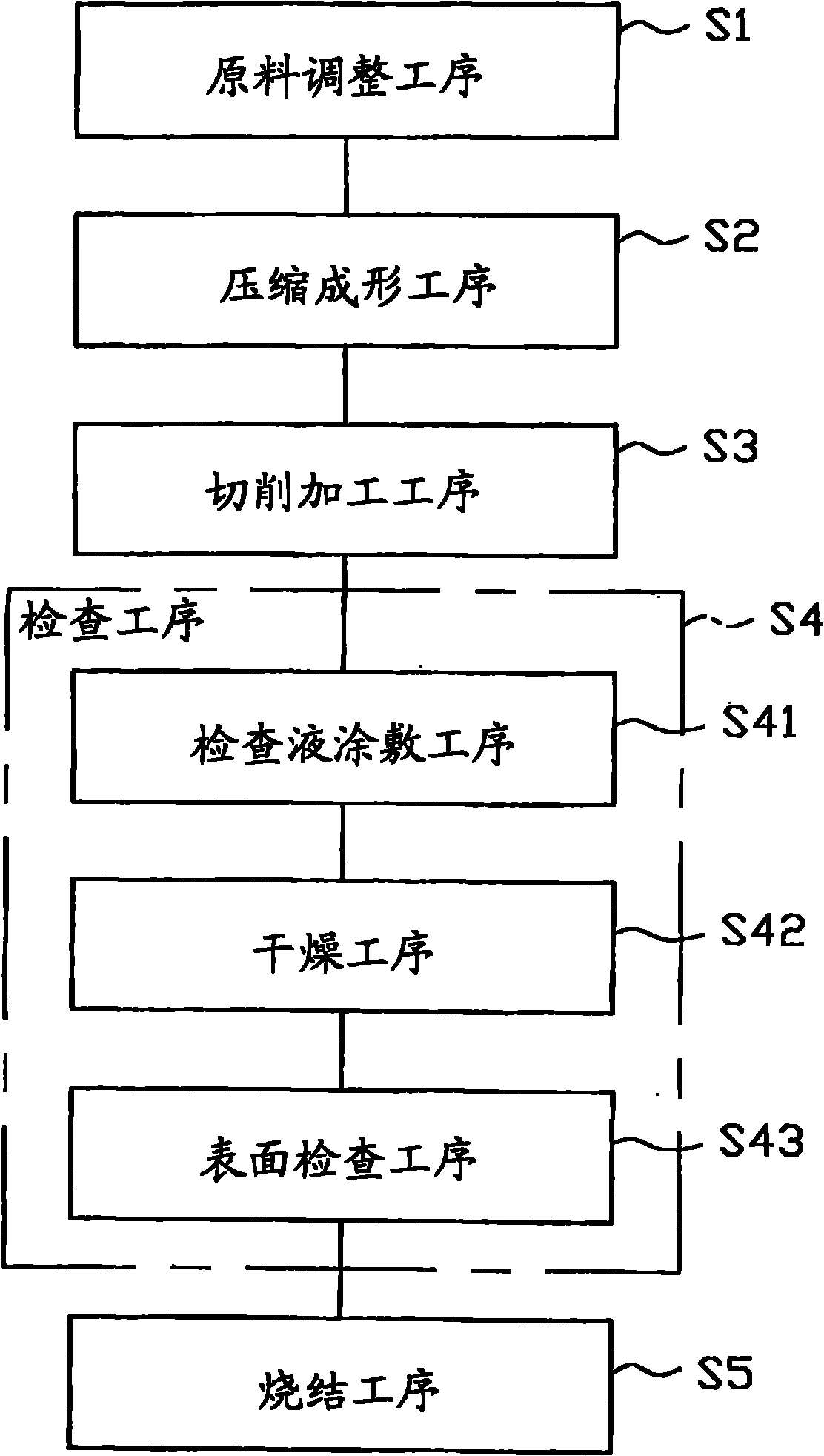

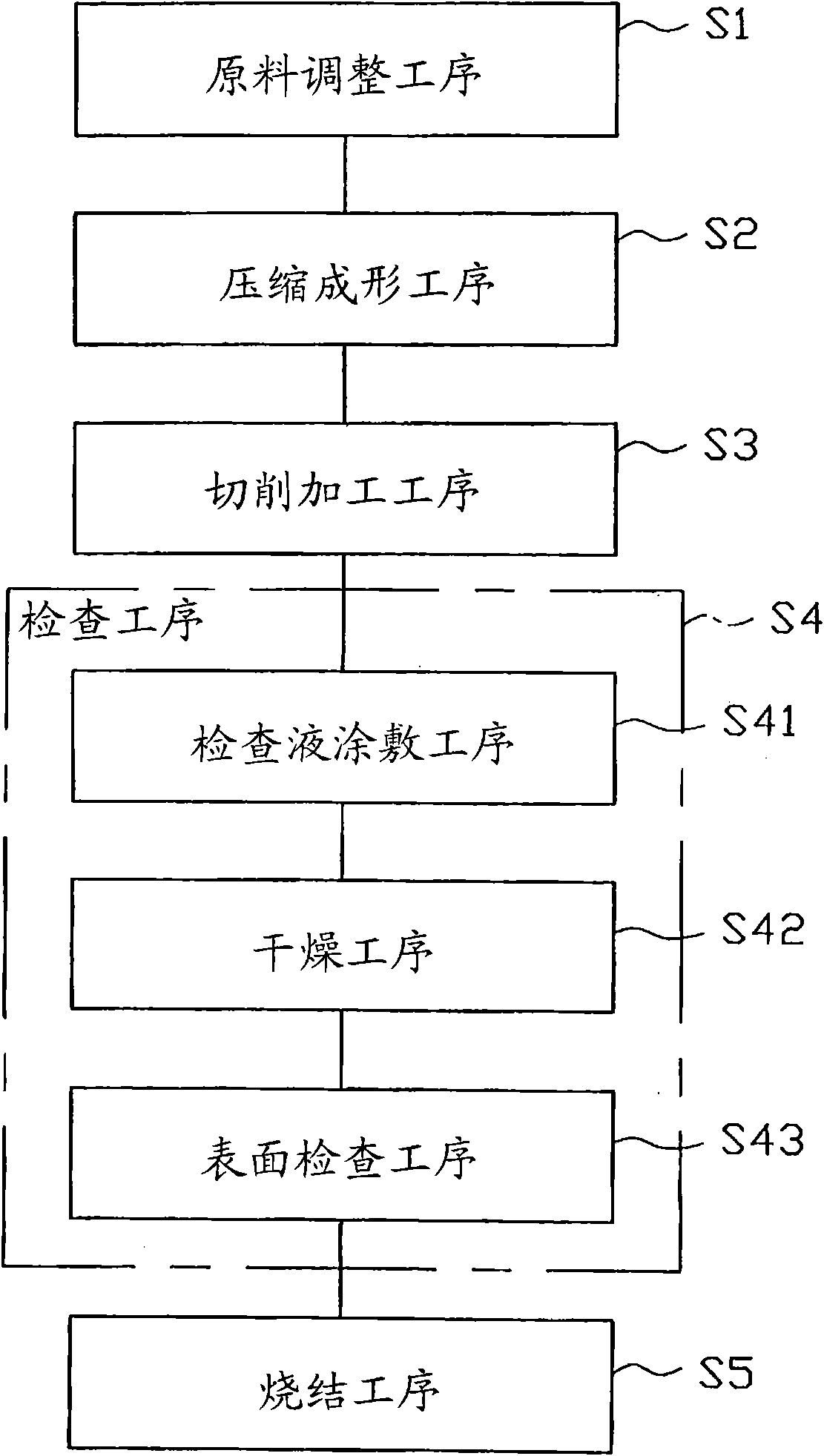

Method used

Image

Examples

Embodiment Construction

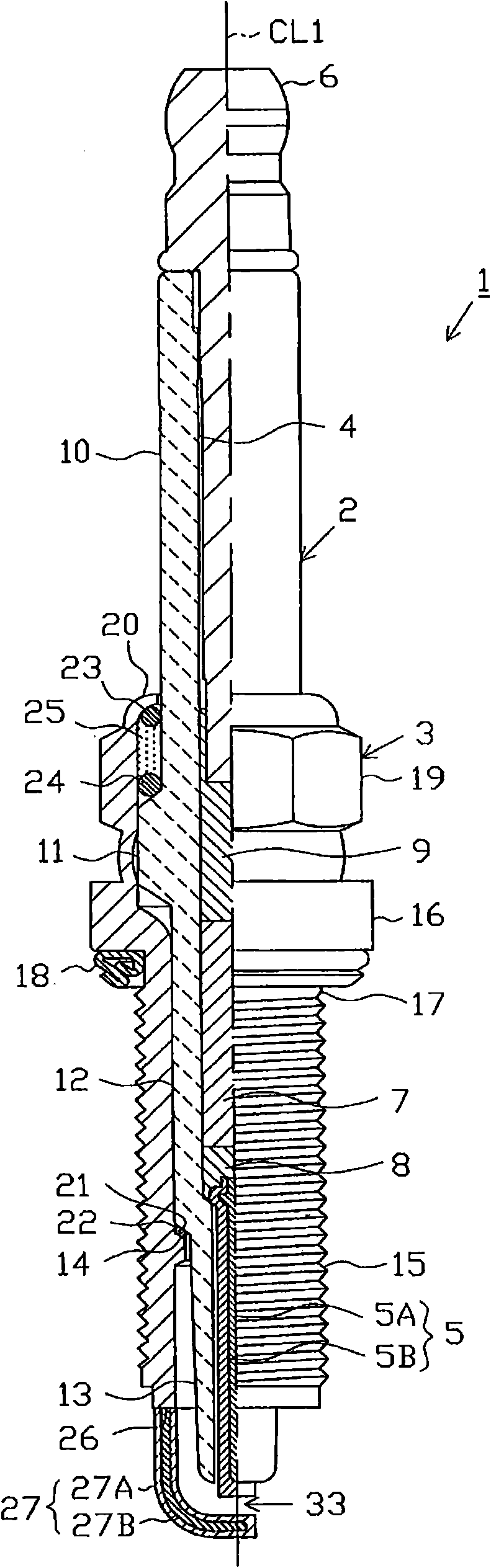

[0039] Hereinafter, an embodiment will be described with reference to the drawings. FIG. 1 is a partially cutaway front view showing a spark plug 1 . In addition, in FIG. 1 , the axis CL1 direction of the spark plug 1 is described as the vertical direction in the figure, the lower side is the front end side of the spark plug 1 , and the upper side is the rear end side of the spark plug 1 .

[0040] The spark plug 1 is composed of an insulator 2 which is a cylindrical insulator for a spark plug, a cylindrical main body case 3 holding the insulator 2 , and the like.

[0041] The insulator 2 is formed by sintering alumina or the like as known, and its outer shape includes: a rear-end side trunk portion 10 formed on the rear end side; The large-diameter part 11 that is protrudingly formed; the middle trunk part 12 that is closer to the front end side than the large-diameter part 11 and is formed to be smaller than the diameter of the large-diameter part 11; the middle trunk part 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com