Patents

Literature

1025results about "Sparking plugs manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spark plug heating for a spark ignited engine

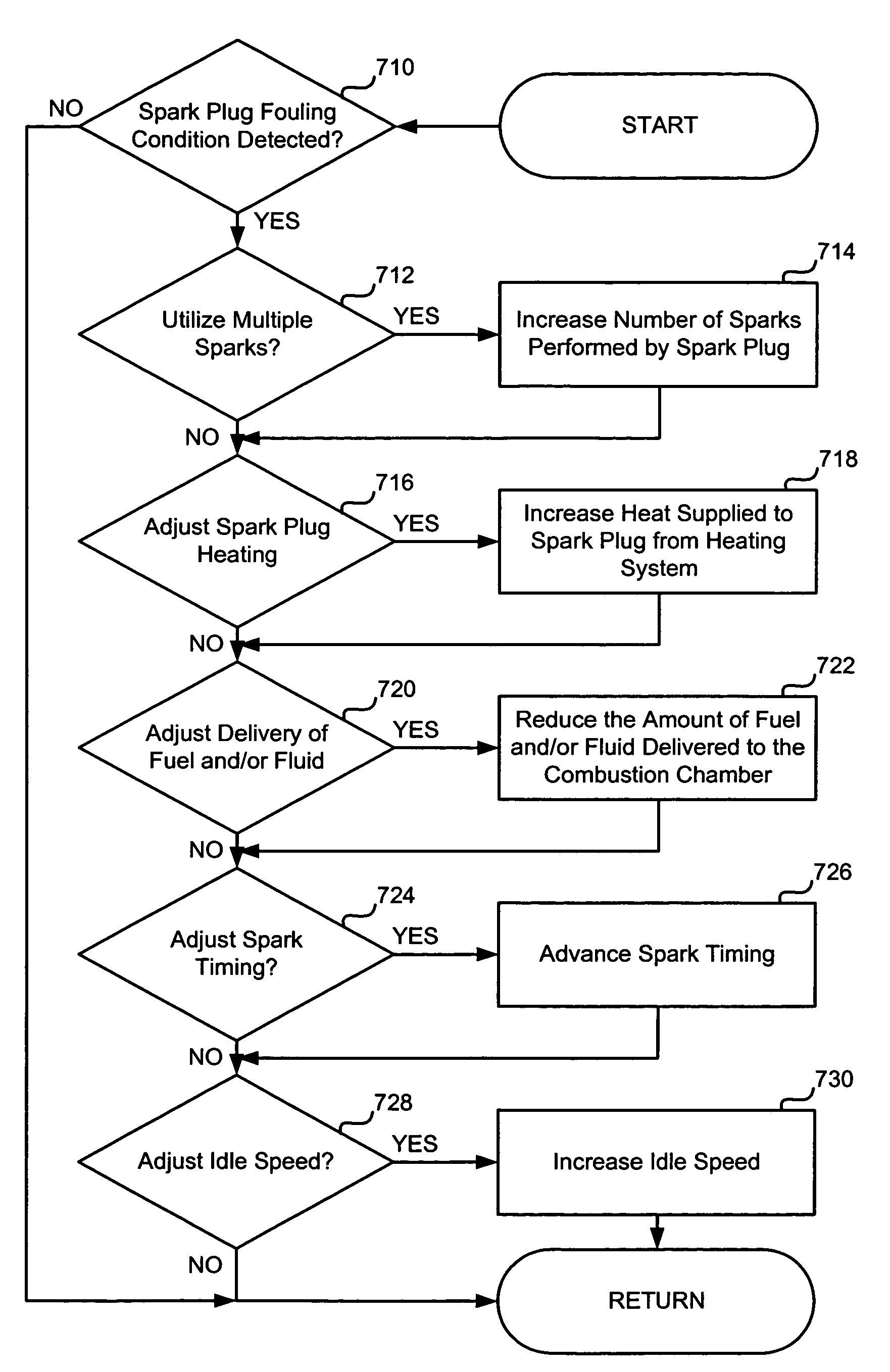

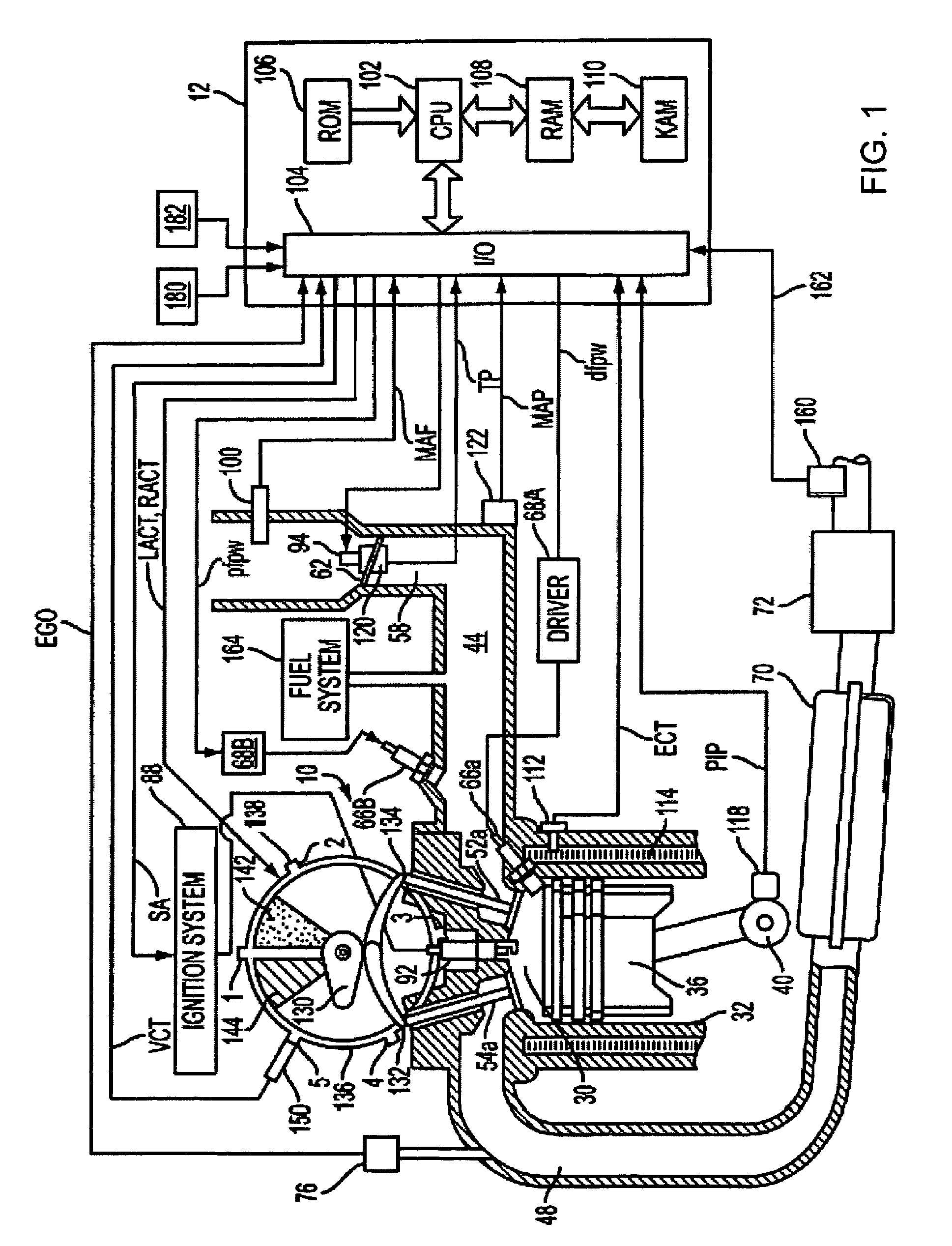

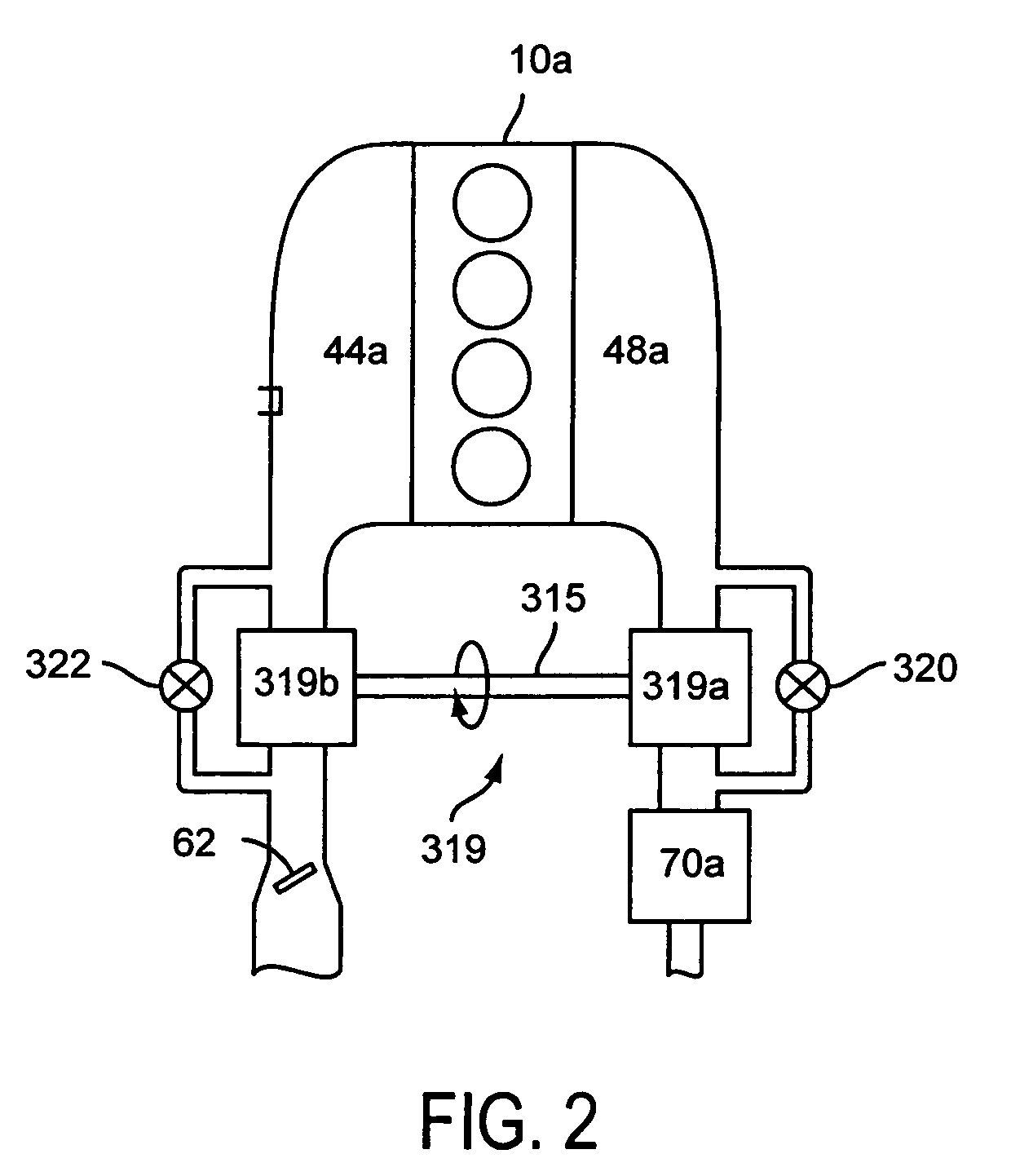

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, a spark plug heating system configured to supply heat to the spark plug, and a control system configured to vary an amount of heat supplied to the spark plug by the spark plug heating system responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

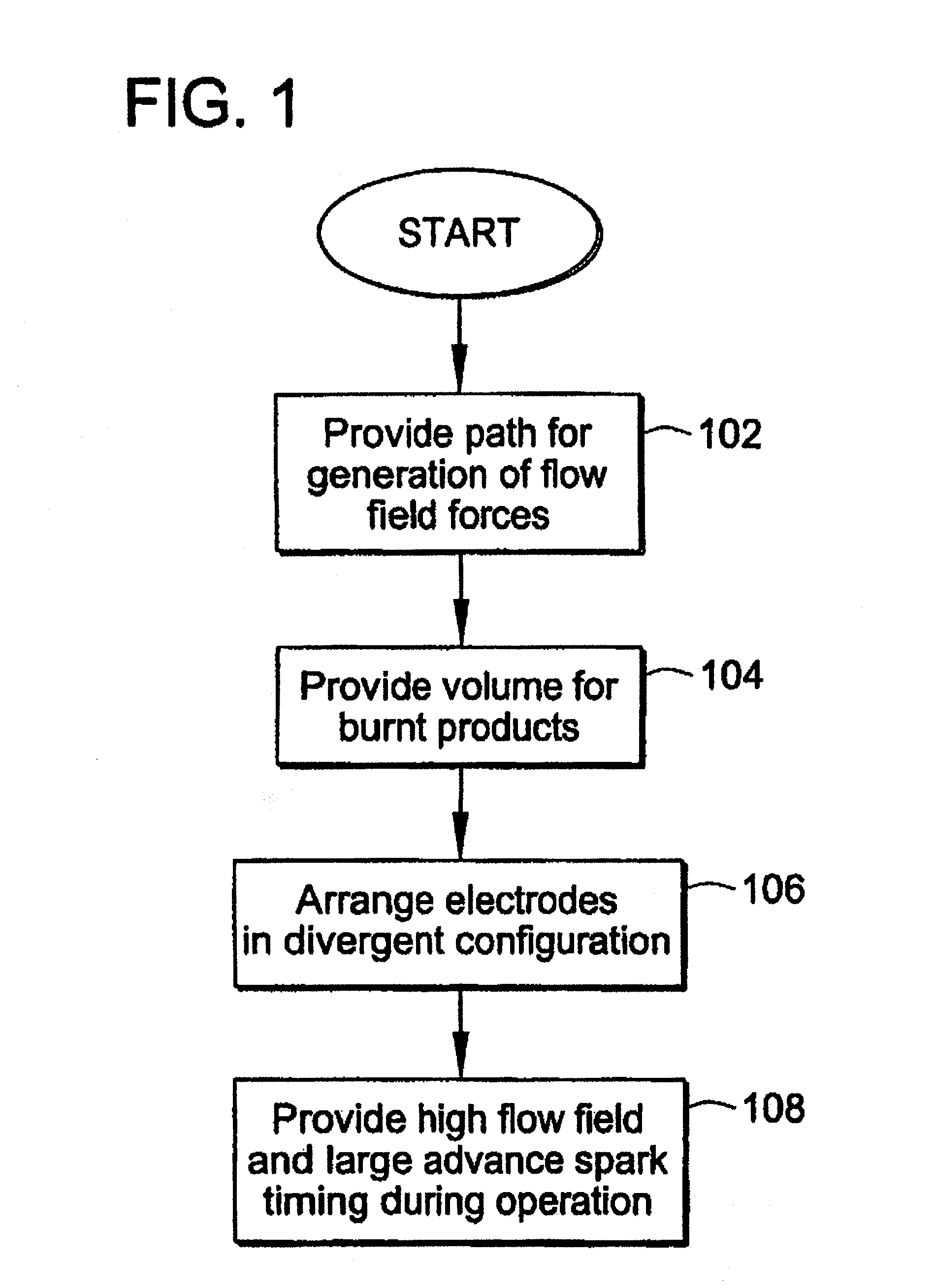

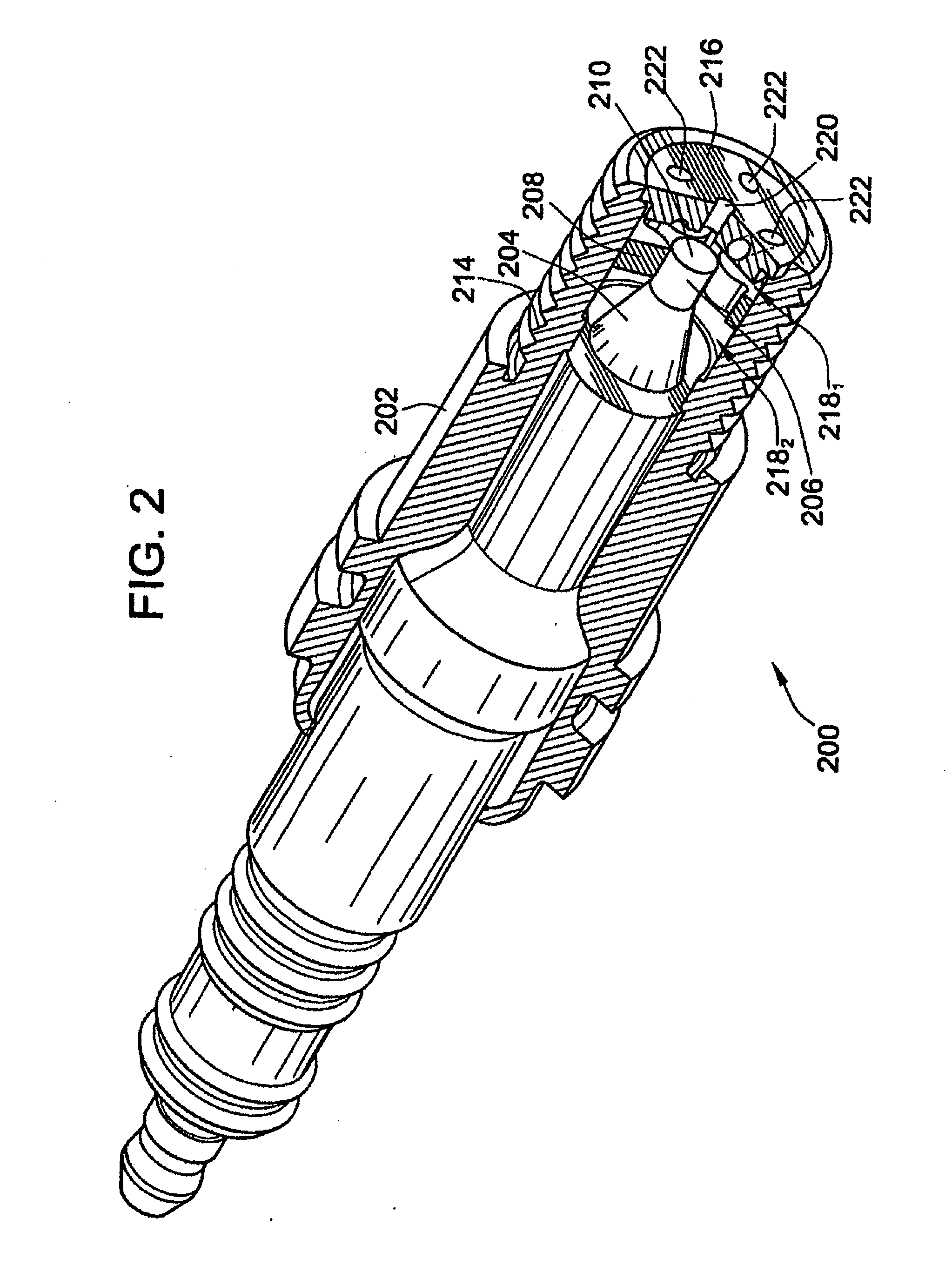

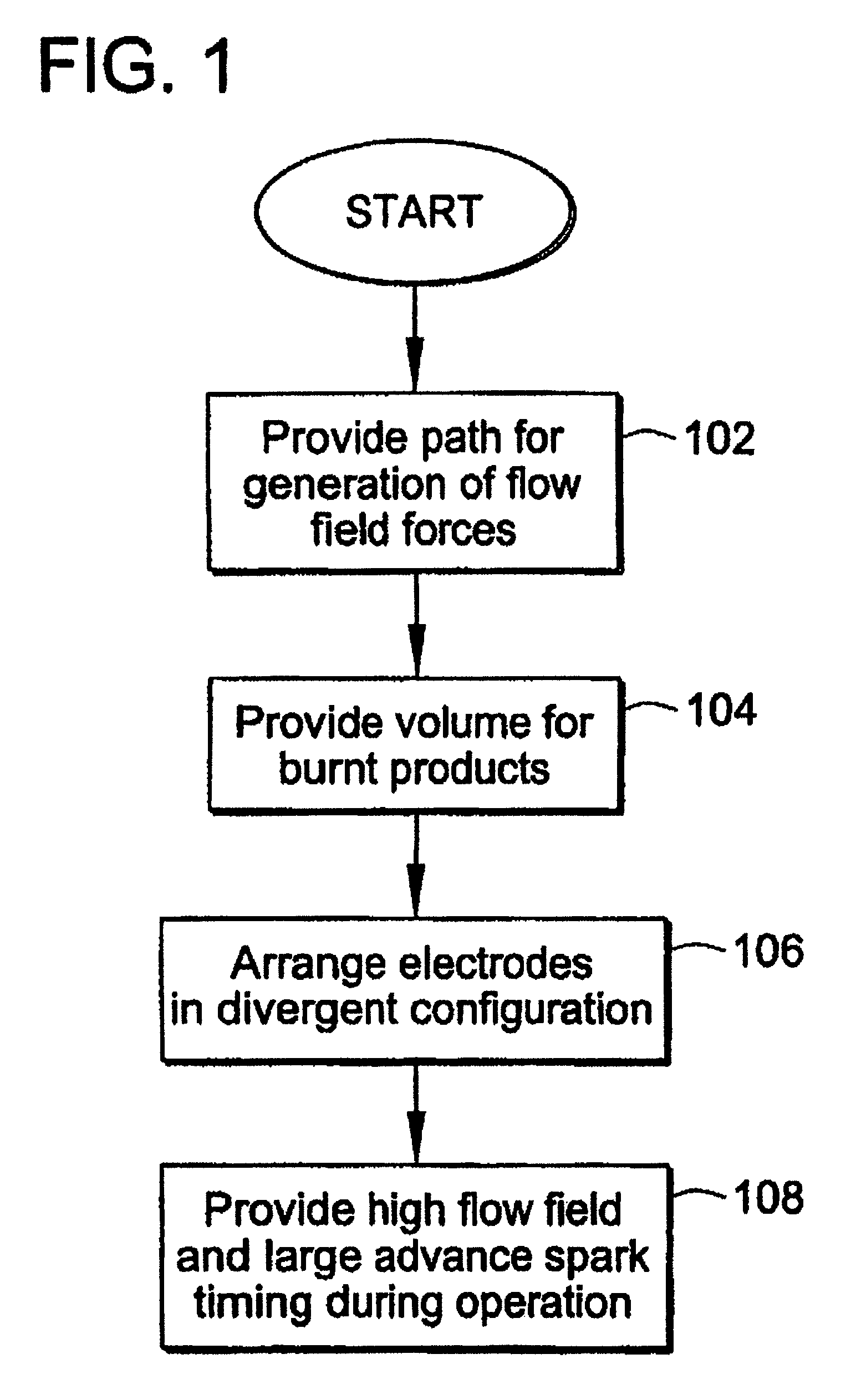

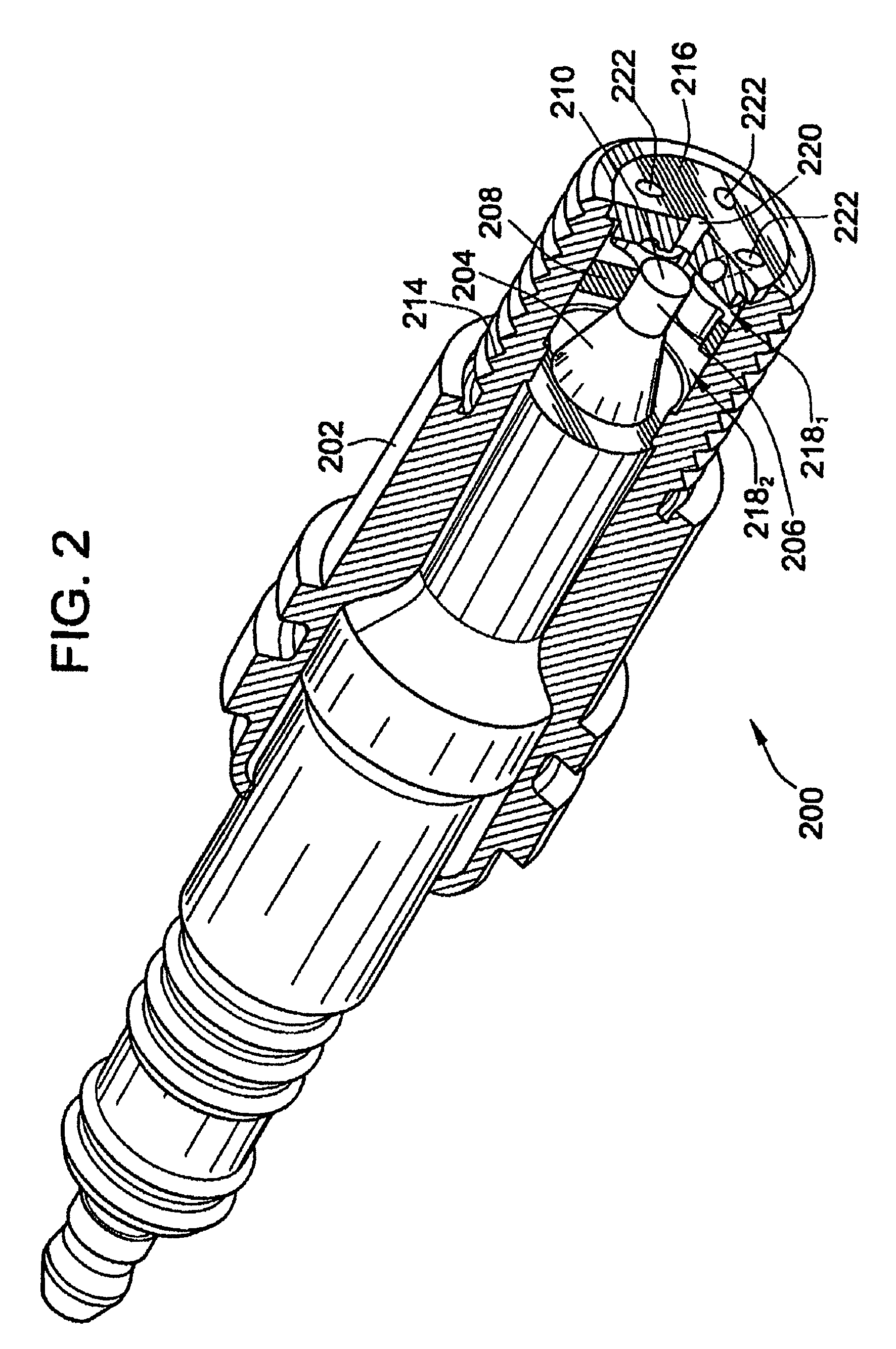

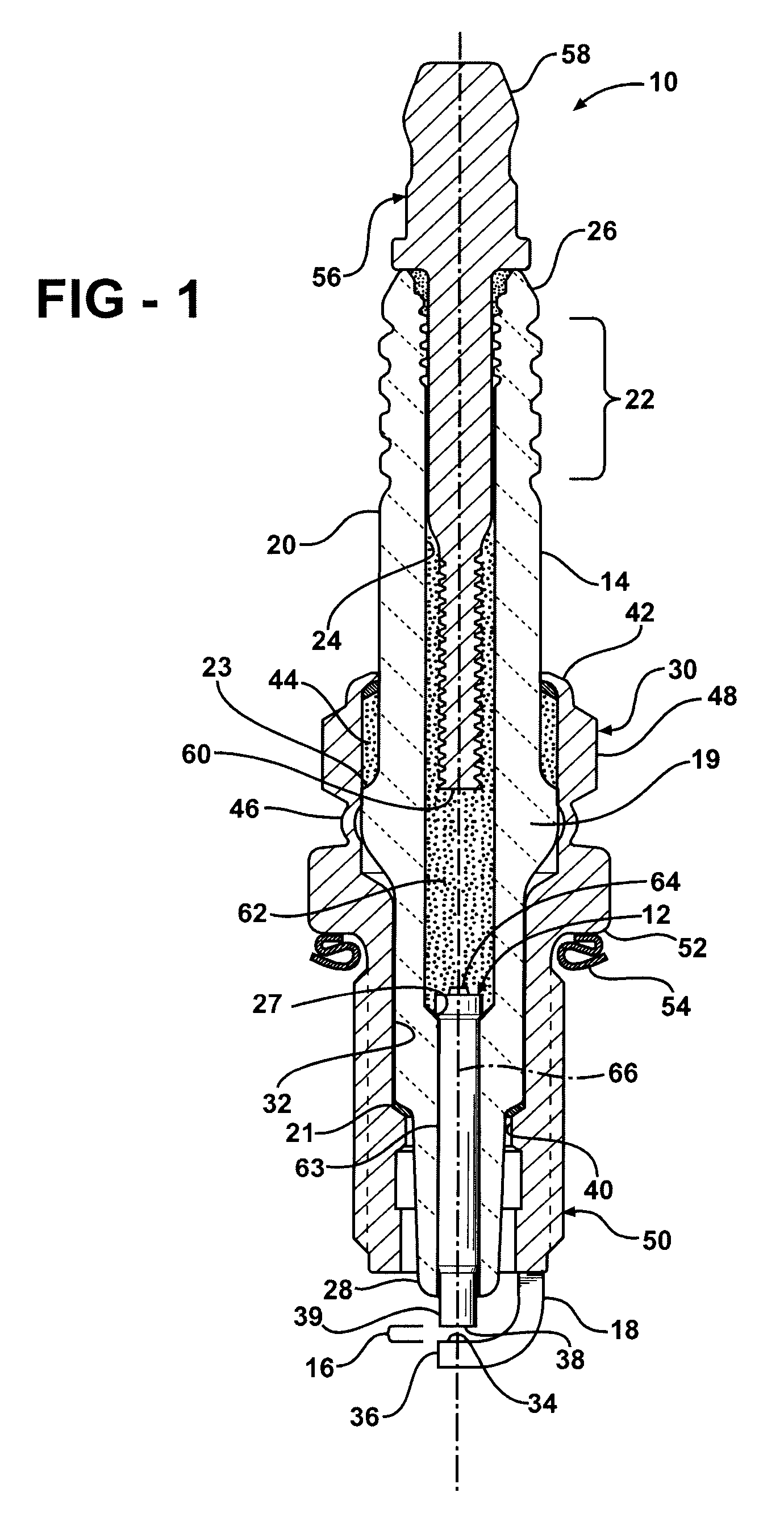

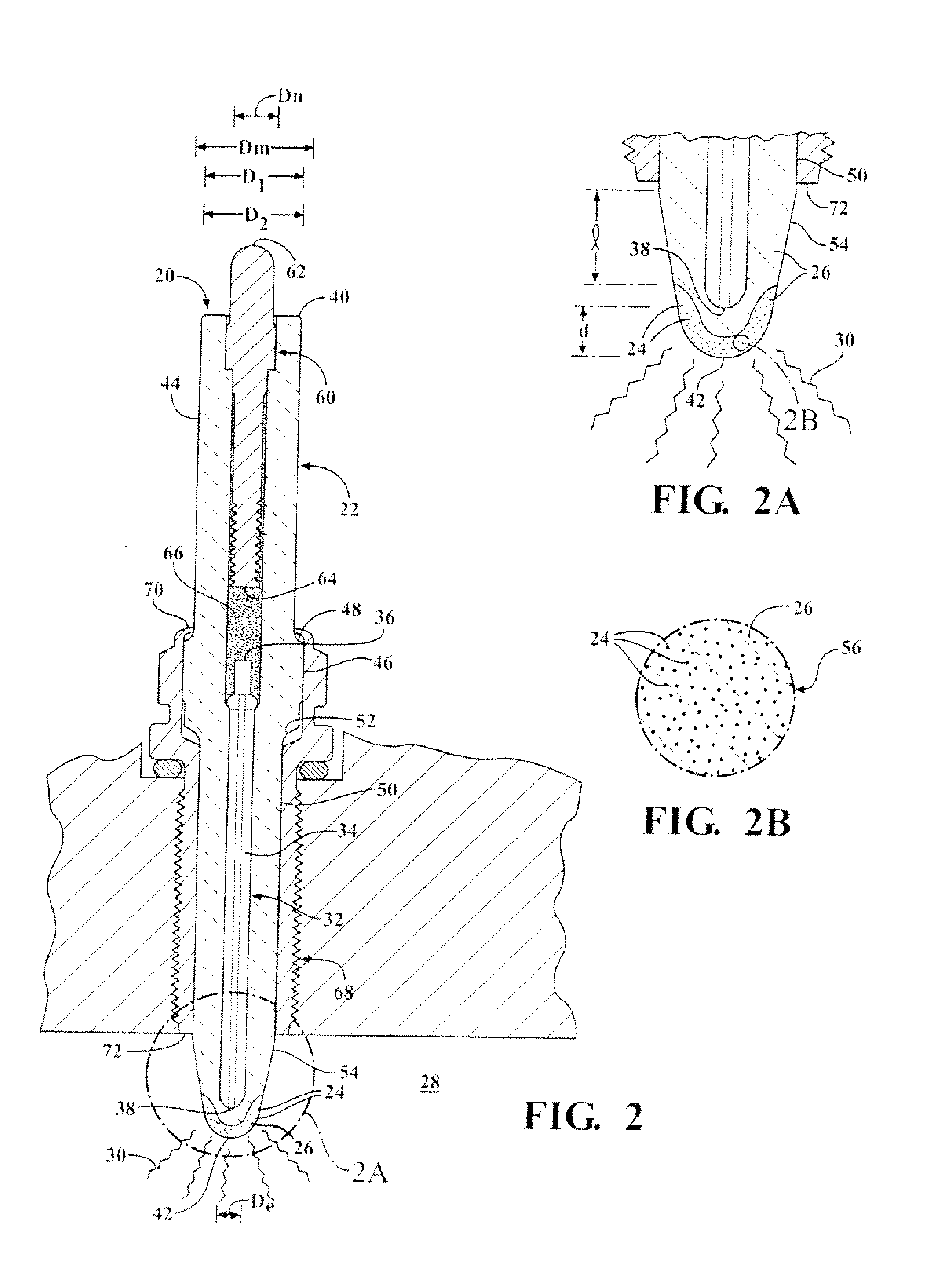

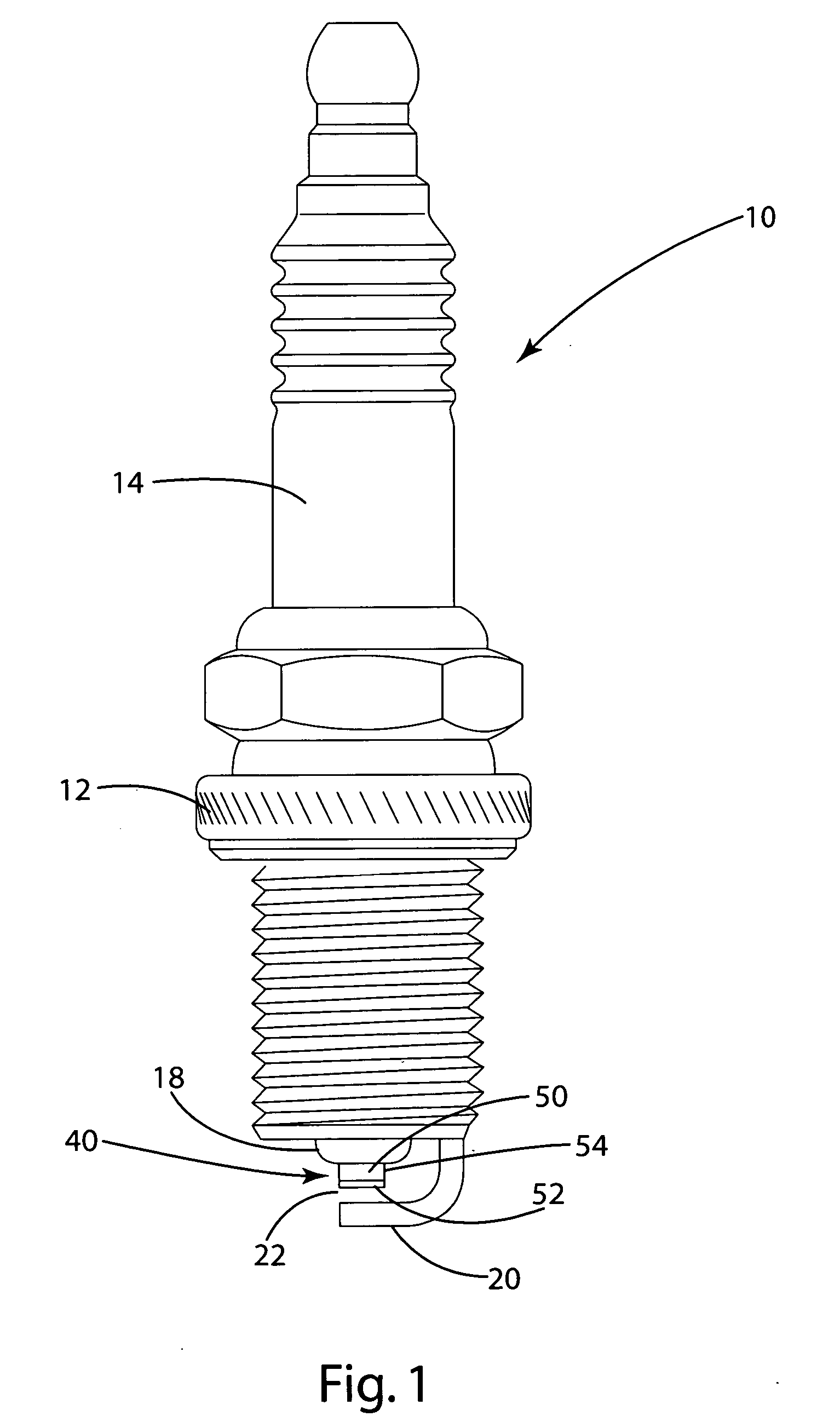

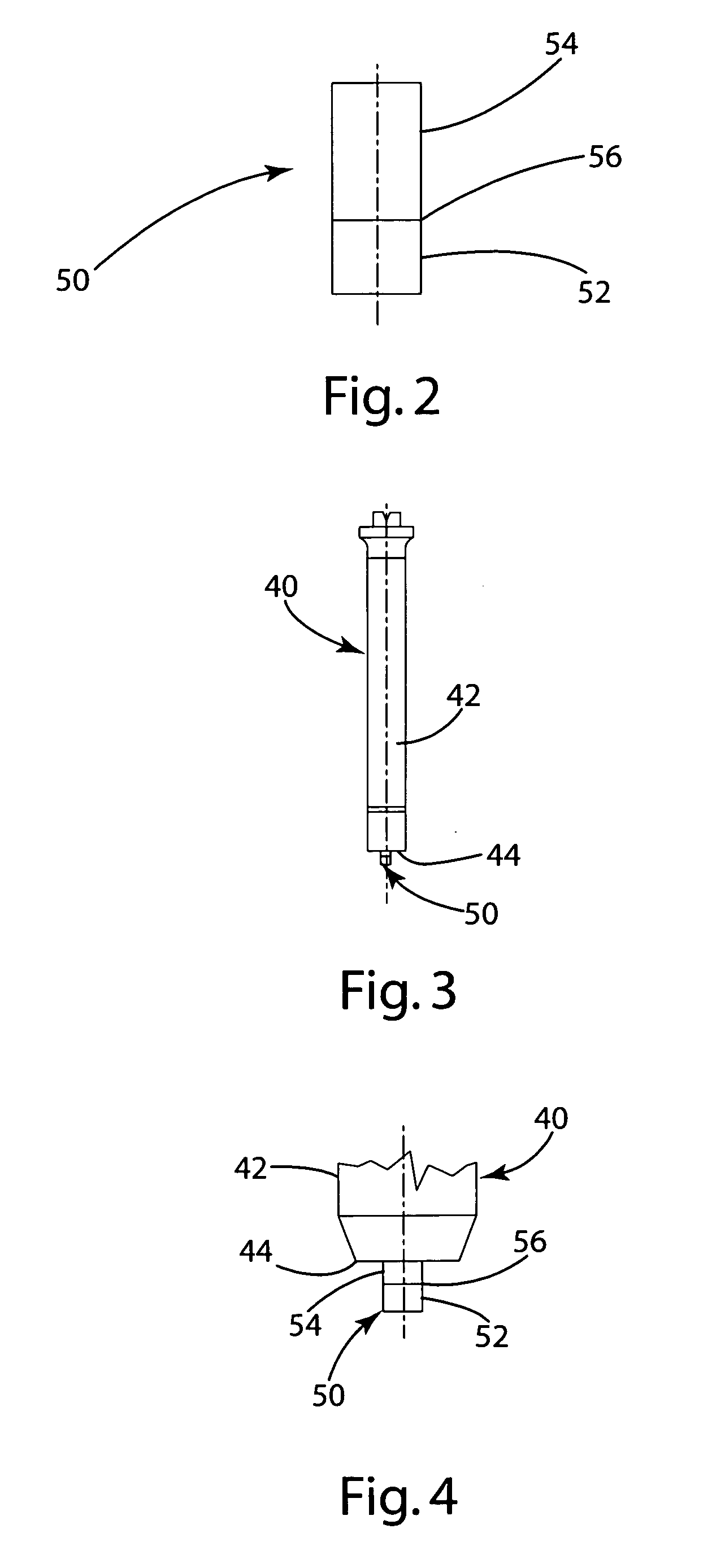

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

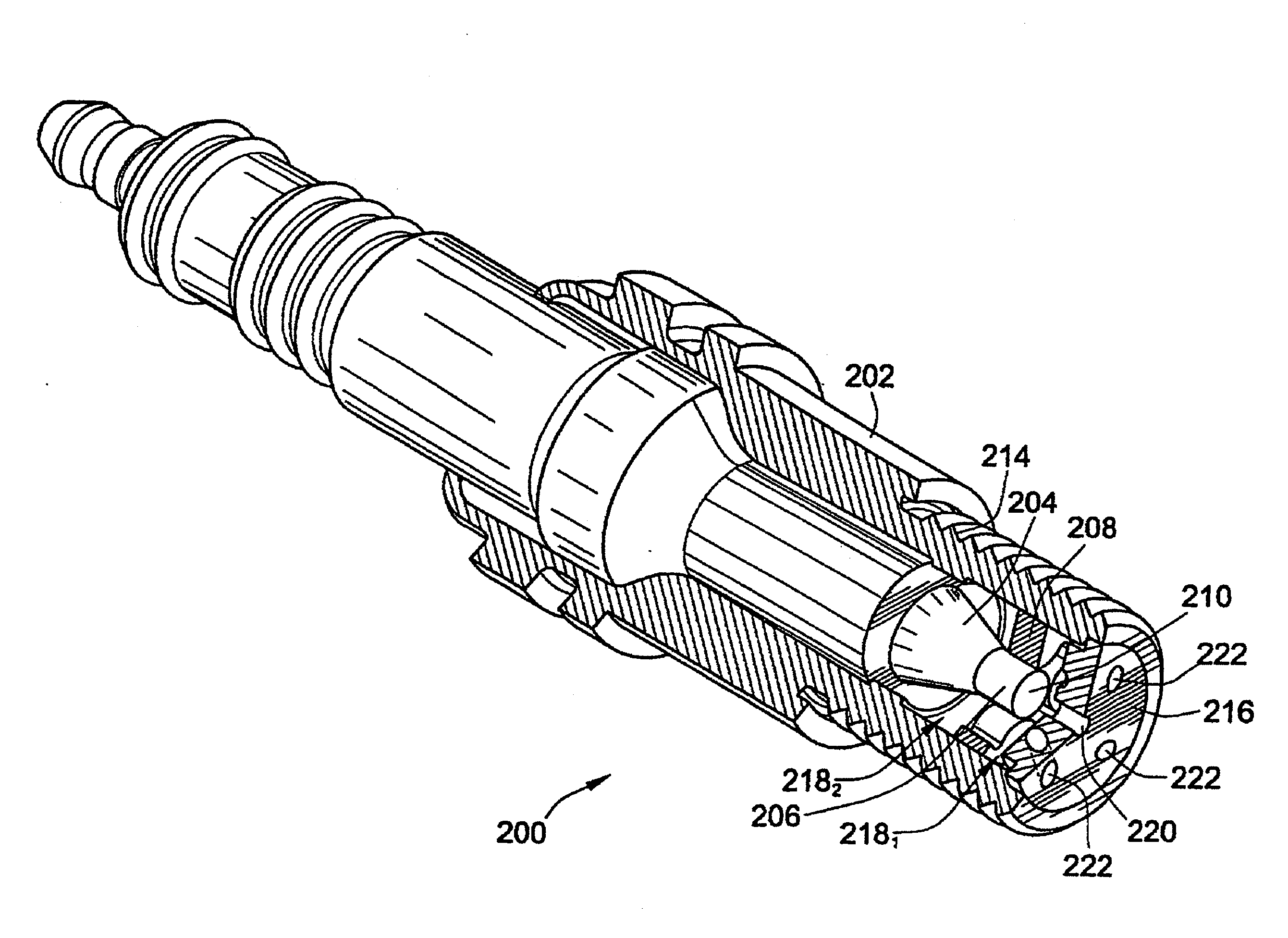

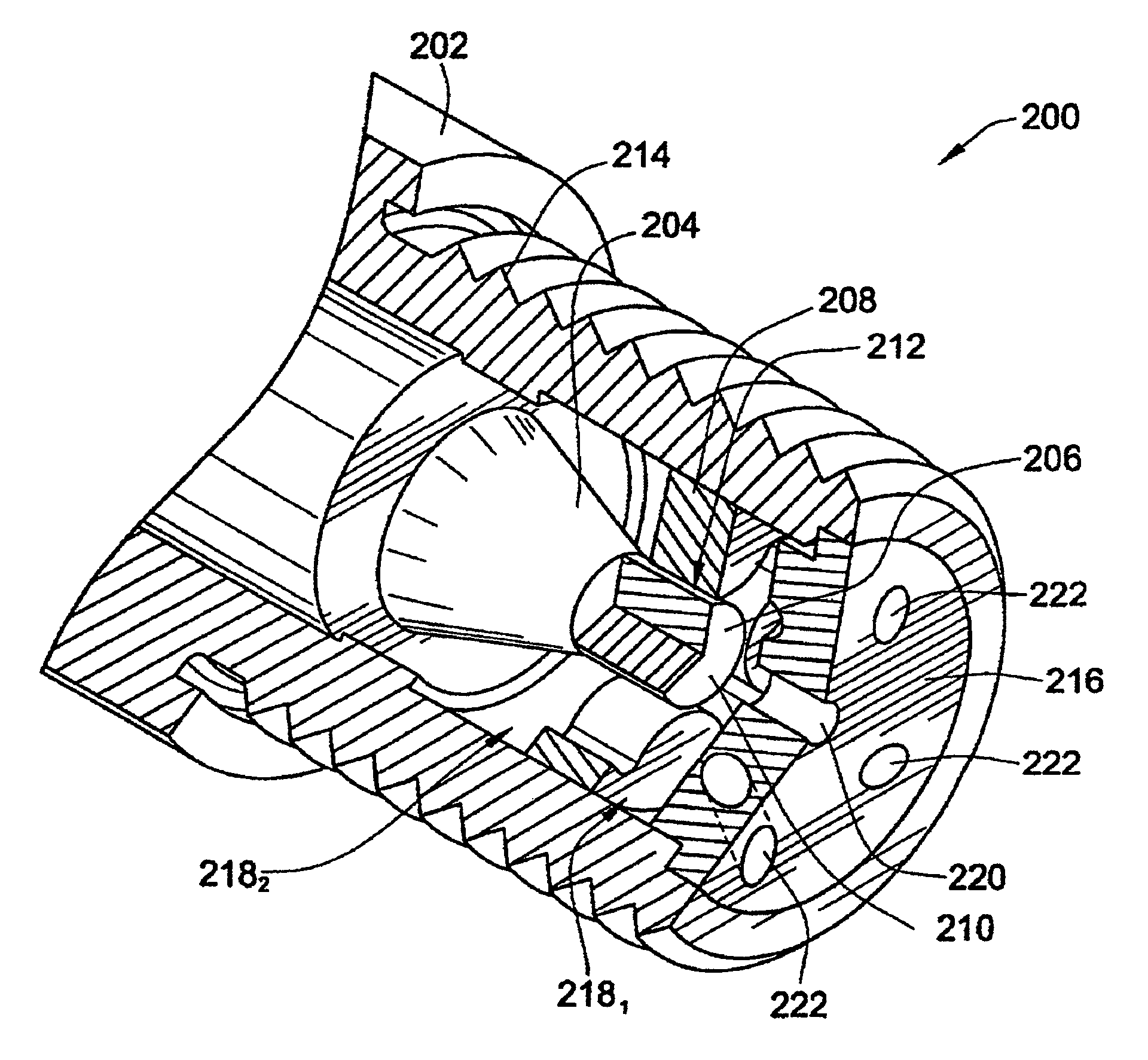

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

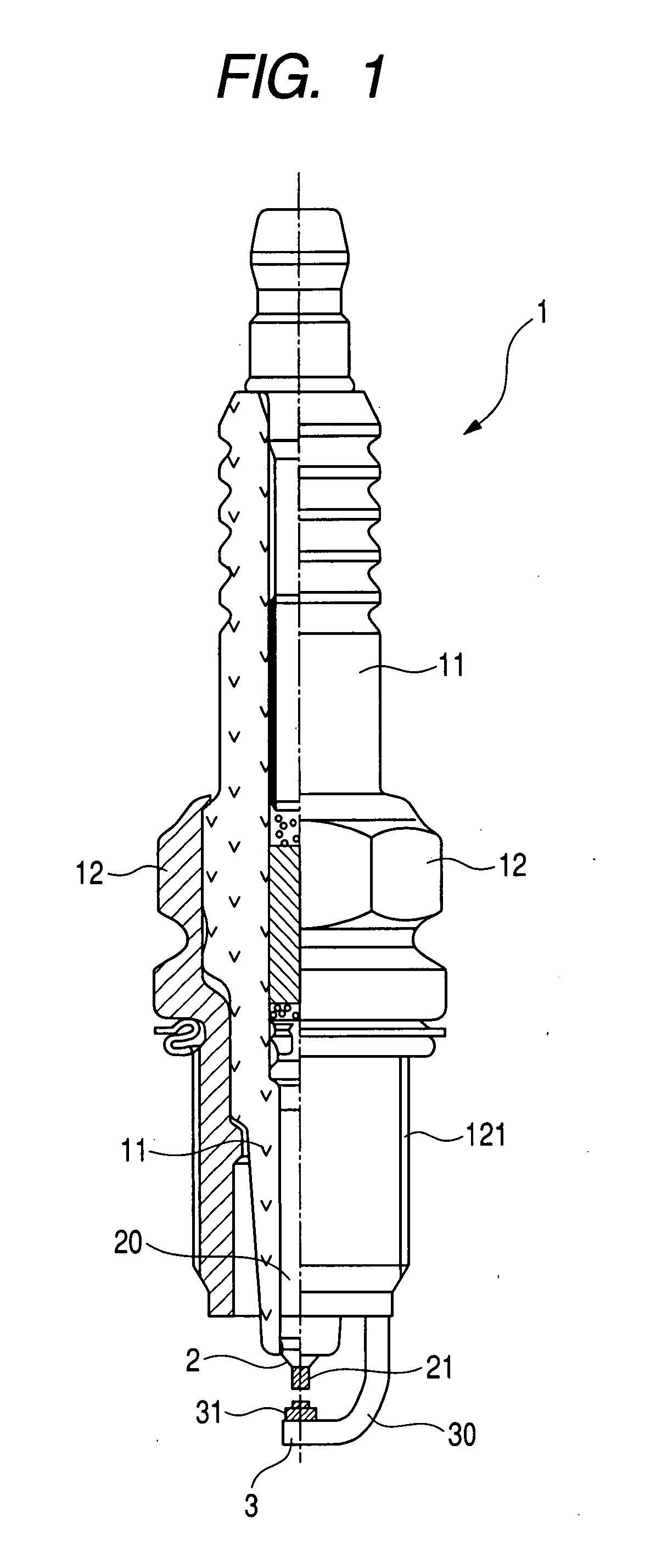

Spark plug and its manufacturing method

InactiveUS20020130602A1Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

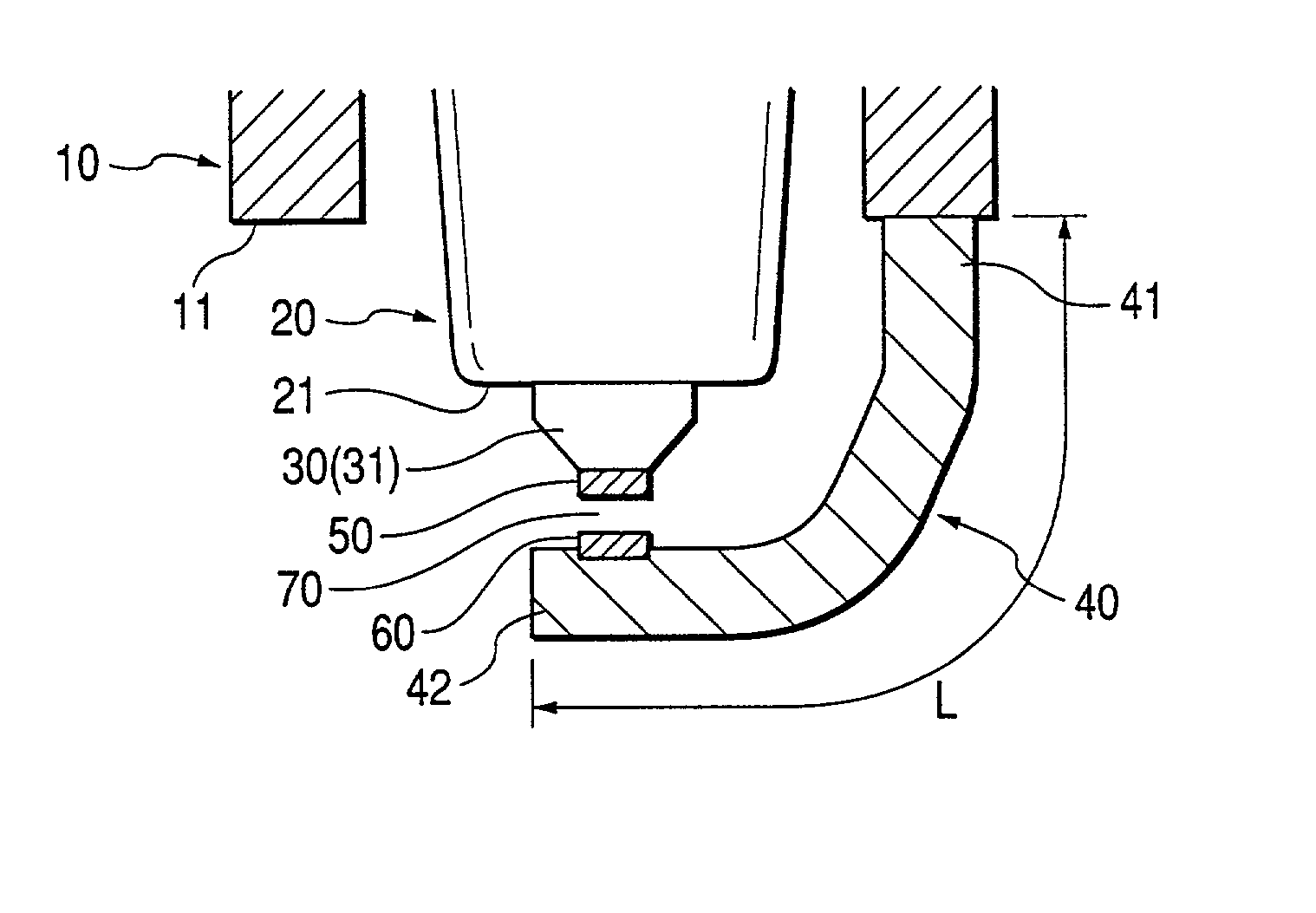

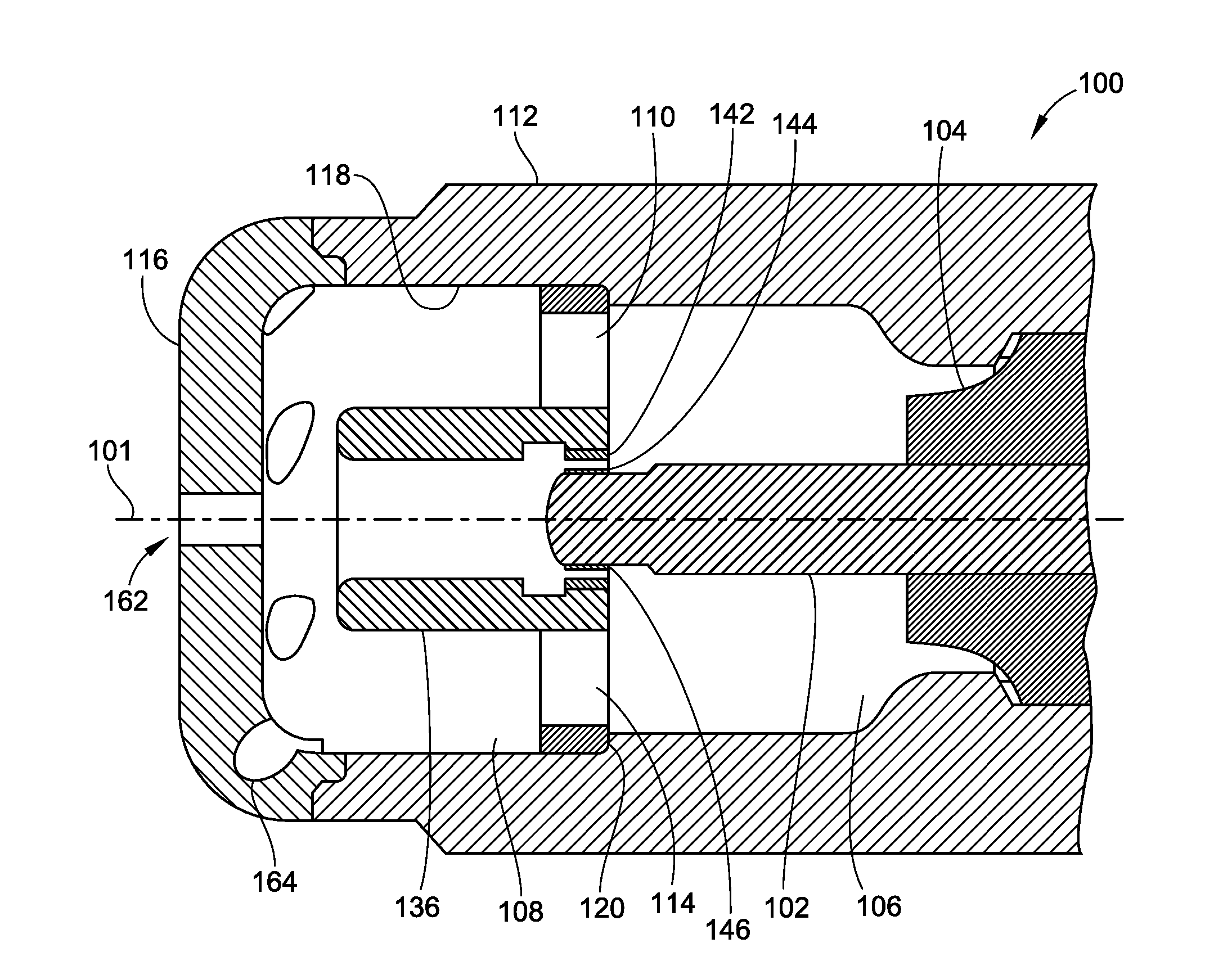

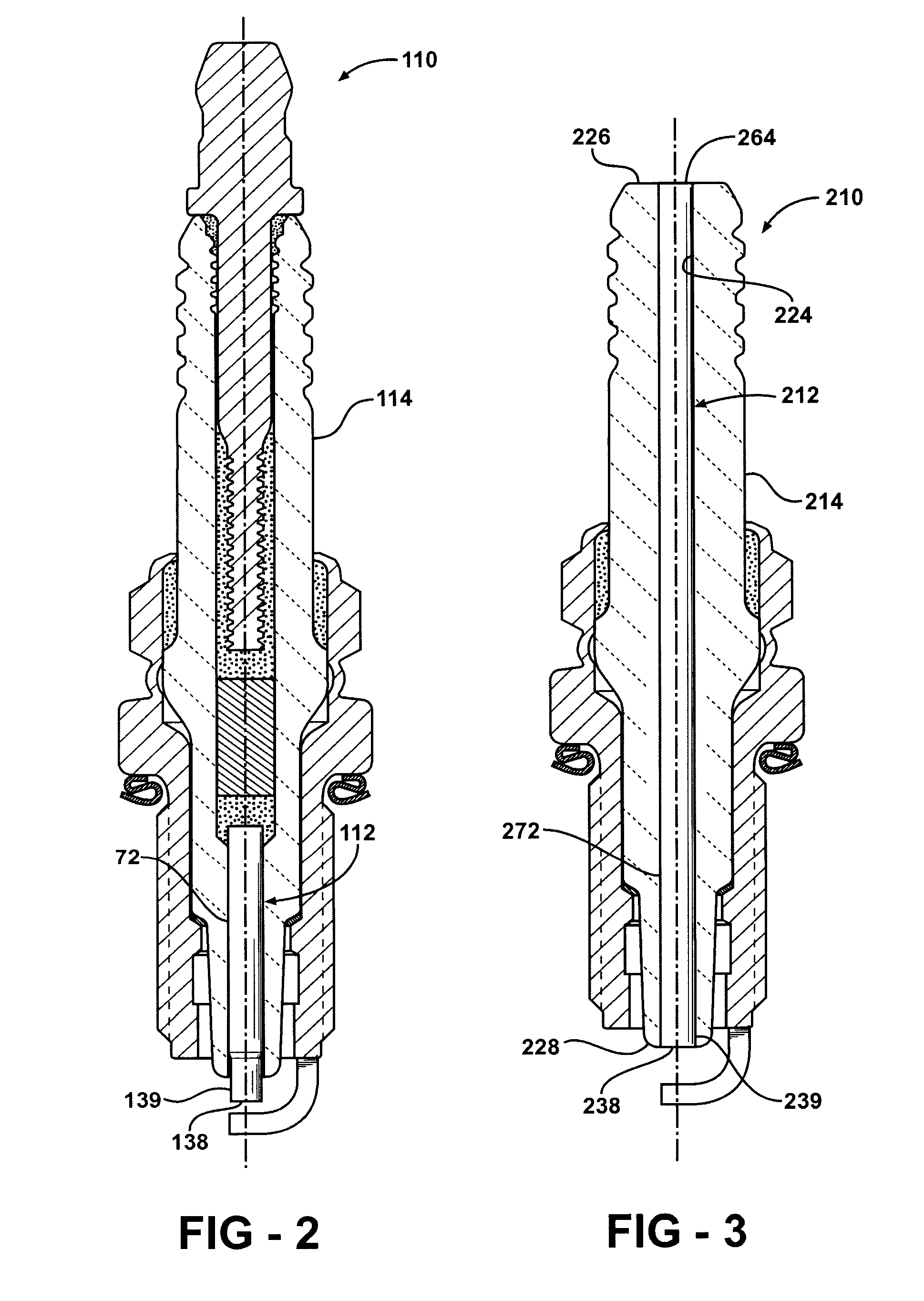

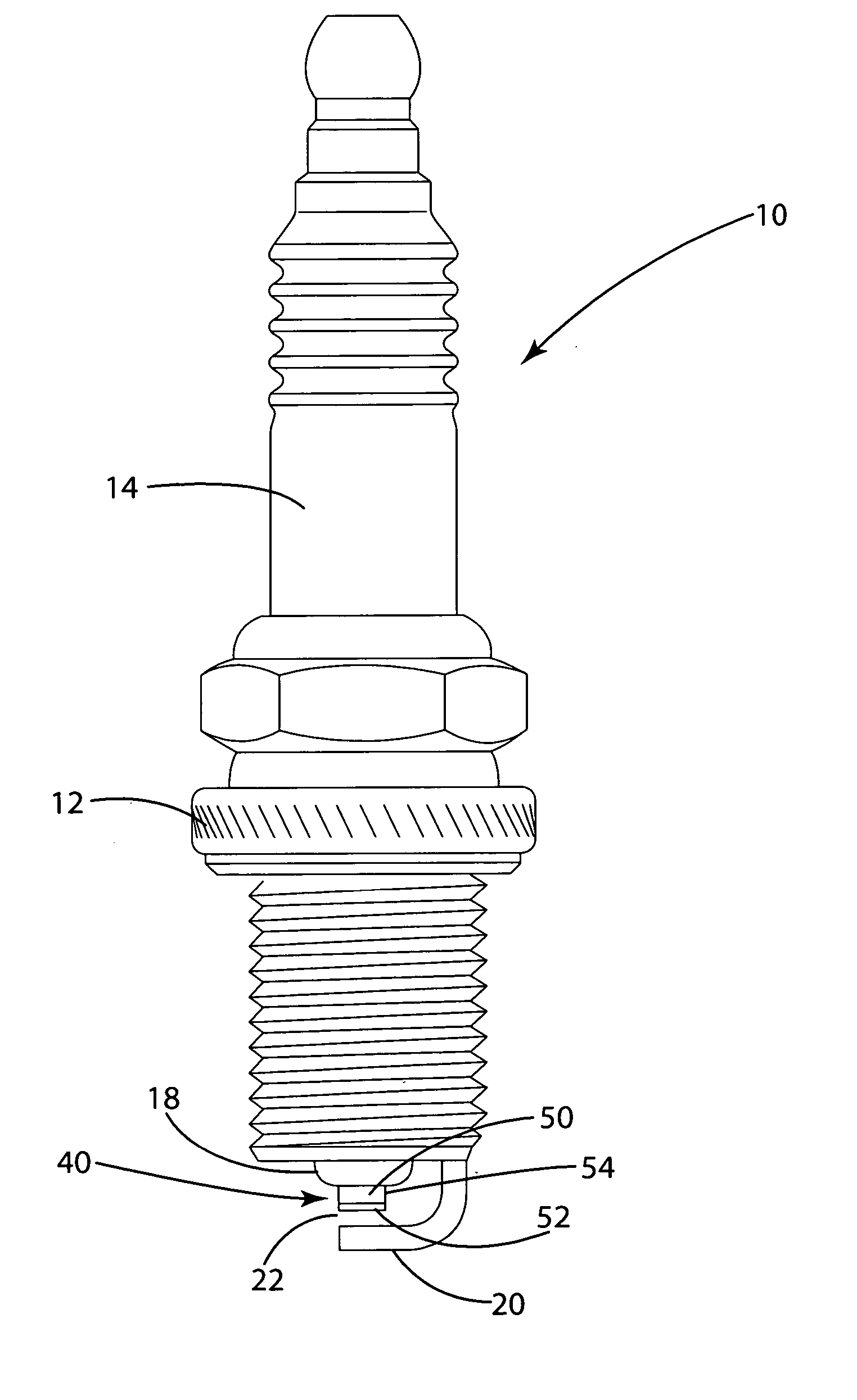

Pre-chamber spark plug with tubular electrode and method of manufacturing same

ActiveUS20120125279A1Improve flowHigh trafficSpark gapsInternal combustion piston enginesEngineeringAlloy

A pre-chamber spark plug that includes a shell, and an end cap attached to the shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell and end cap. In a further embodiment, a ground electrode is attached to the shell. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life.

Owner:WOODWARD GOVERNOR CO

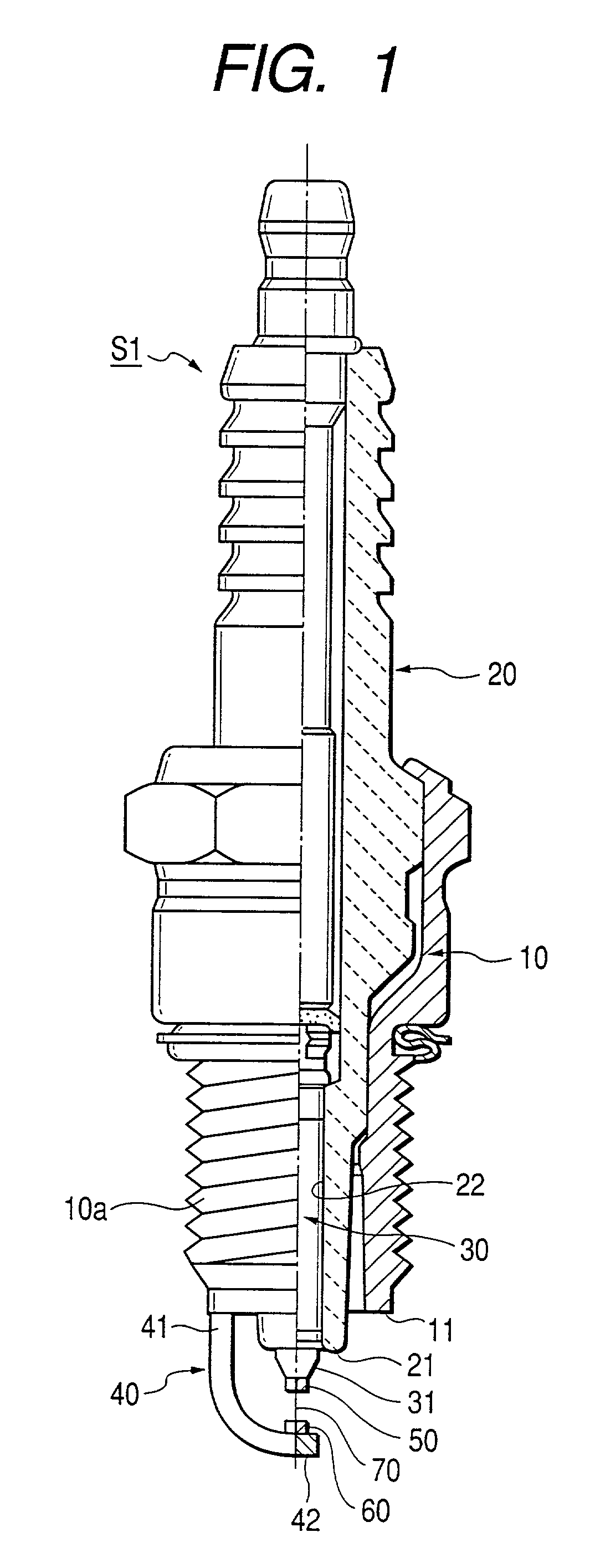

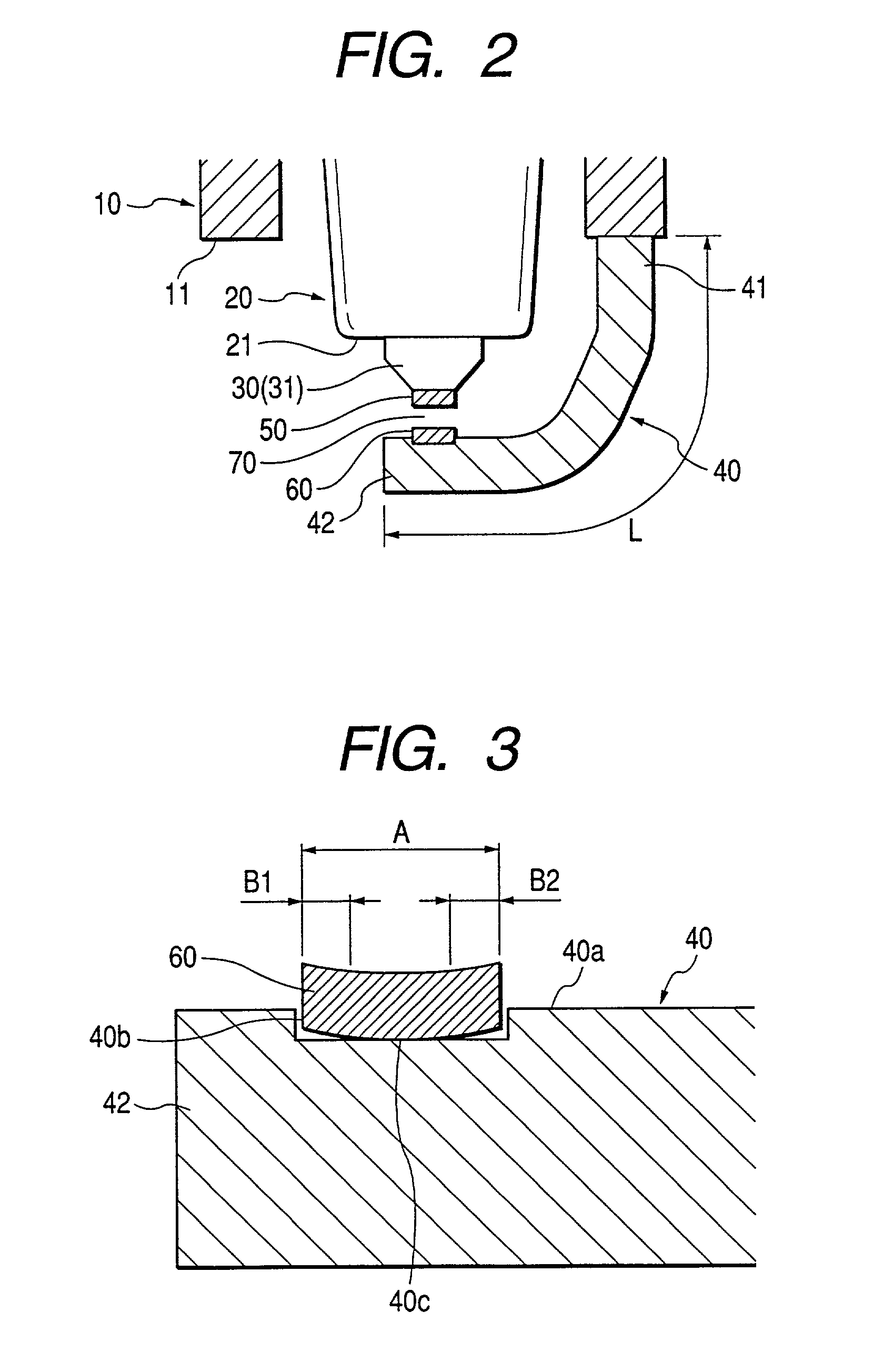

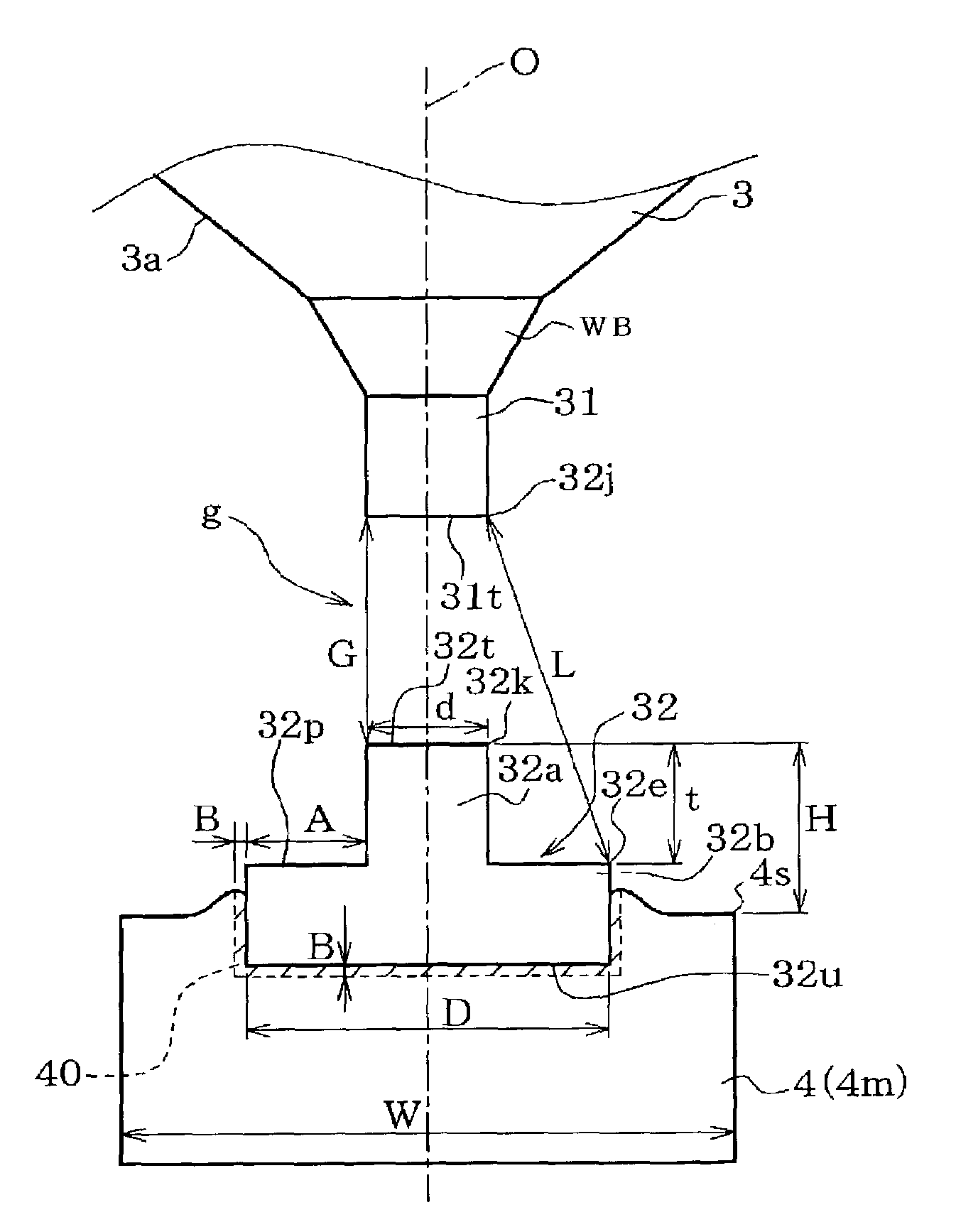

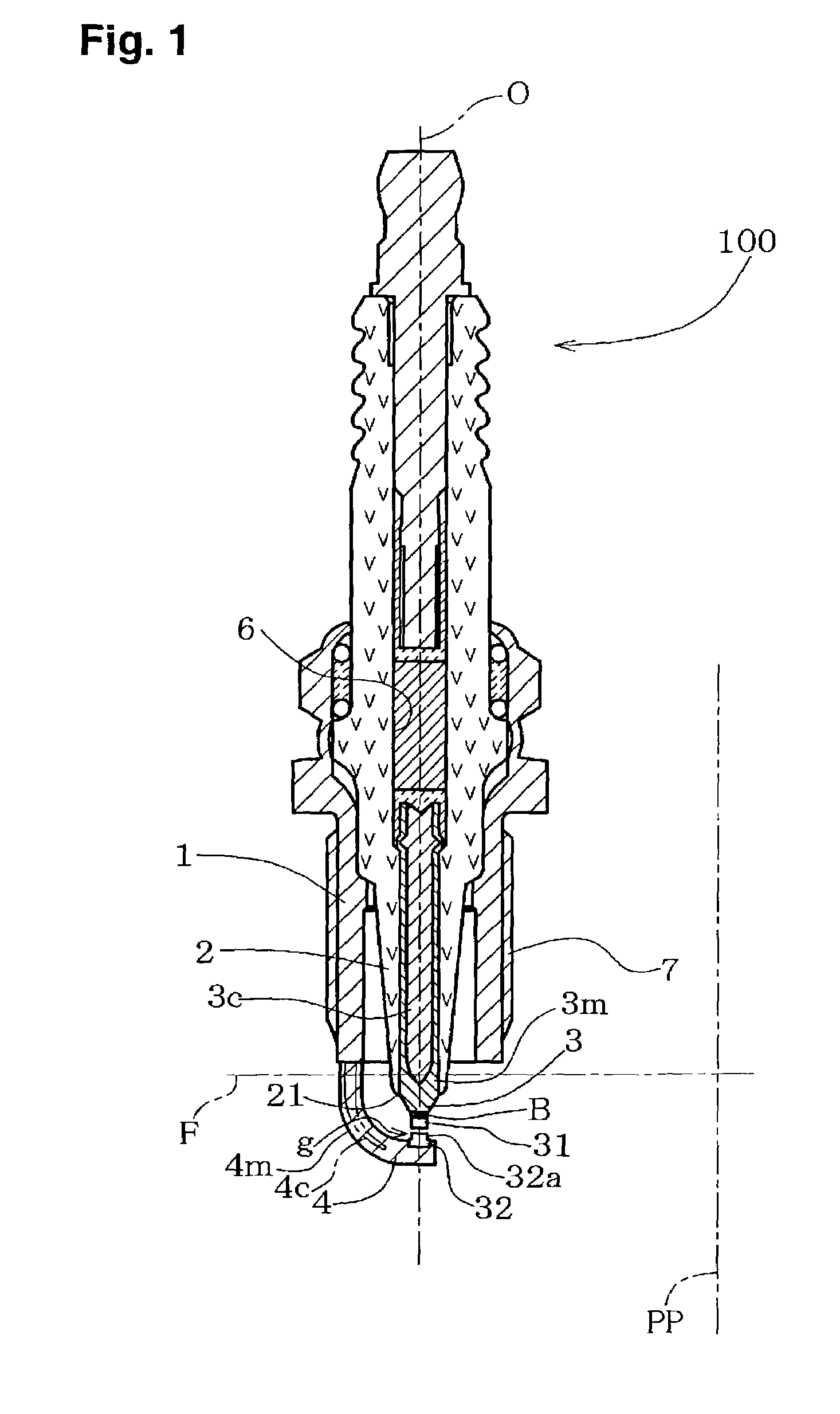

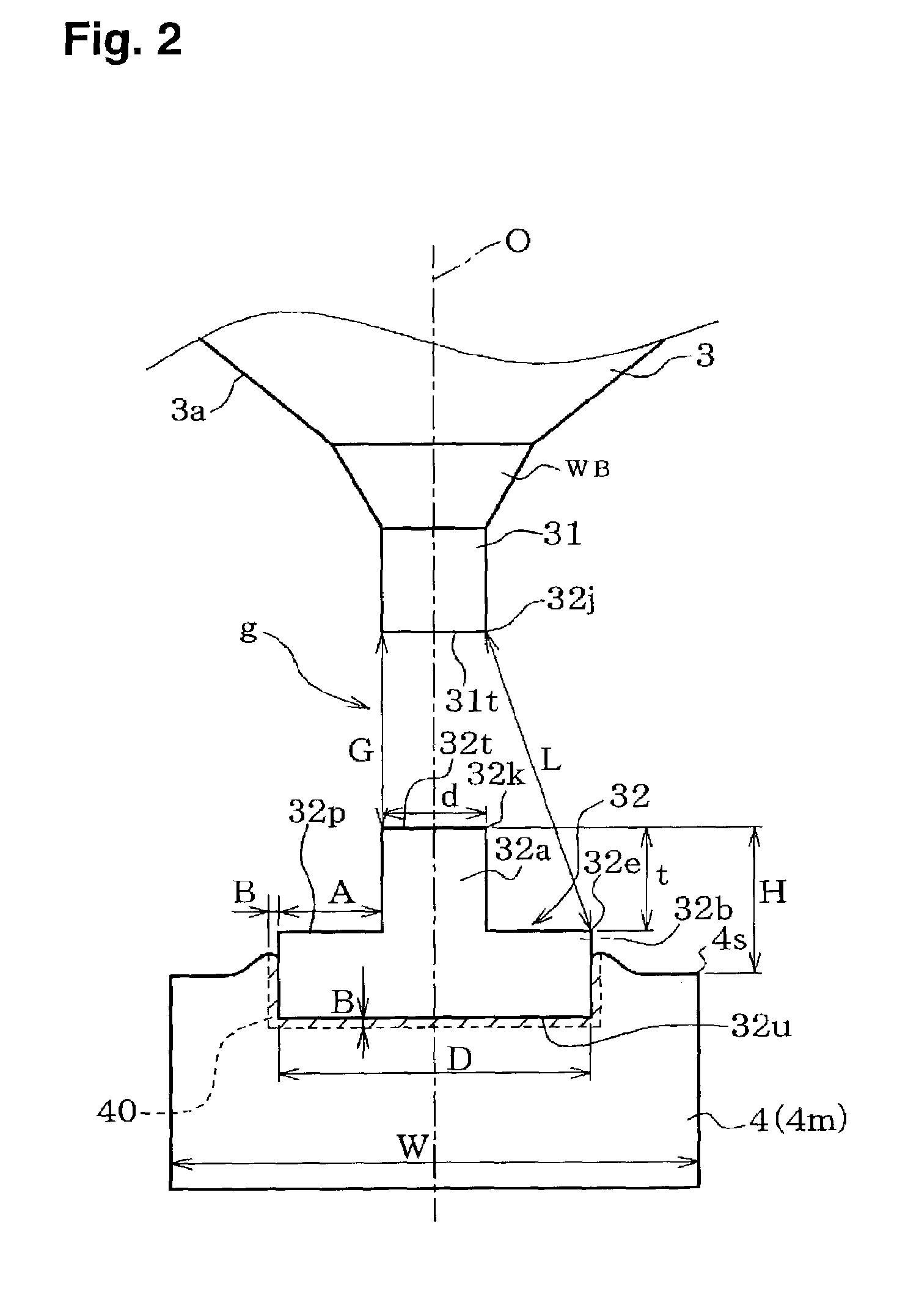

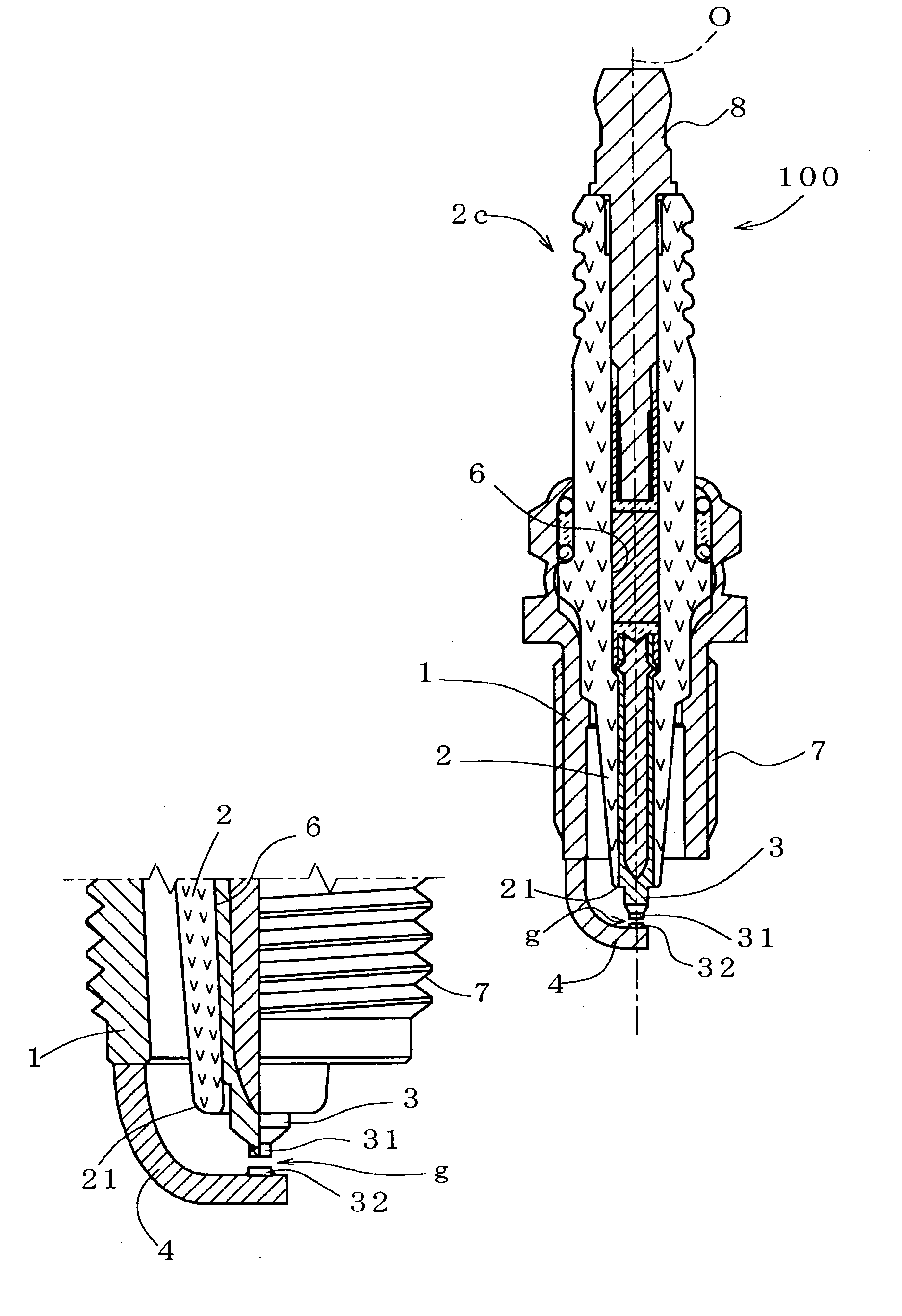

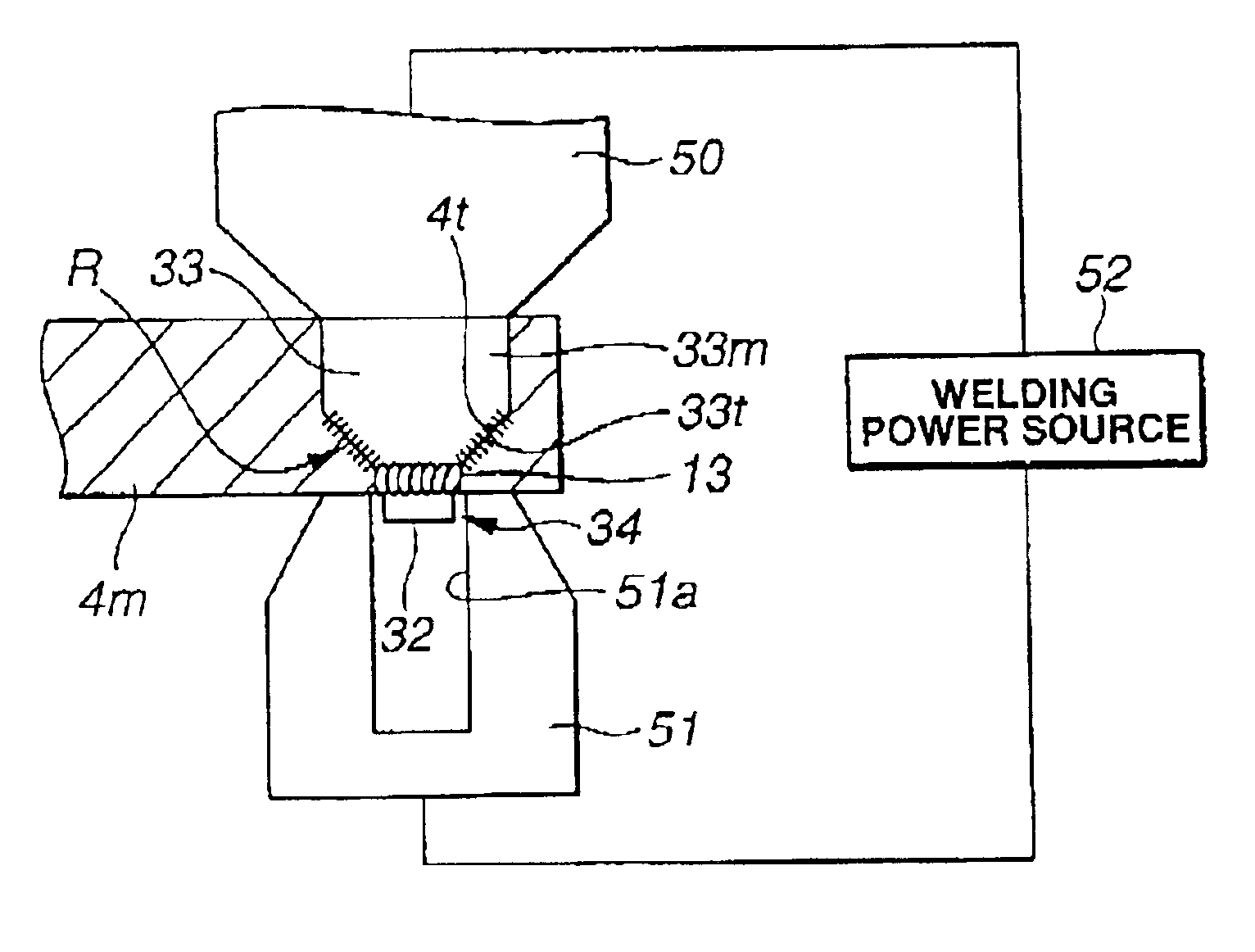

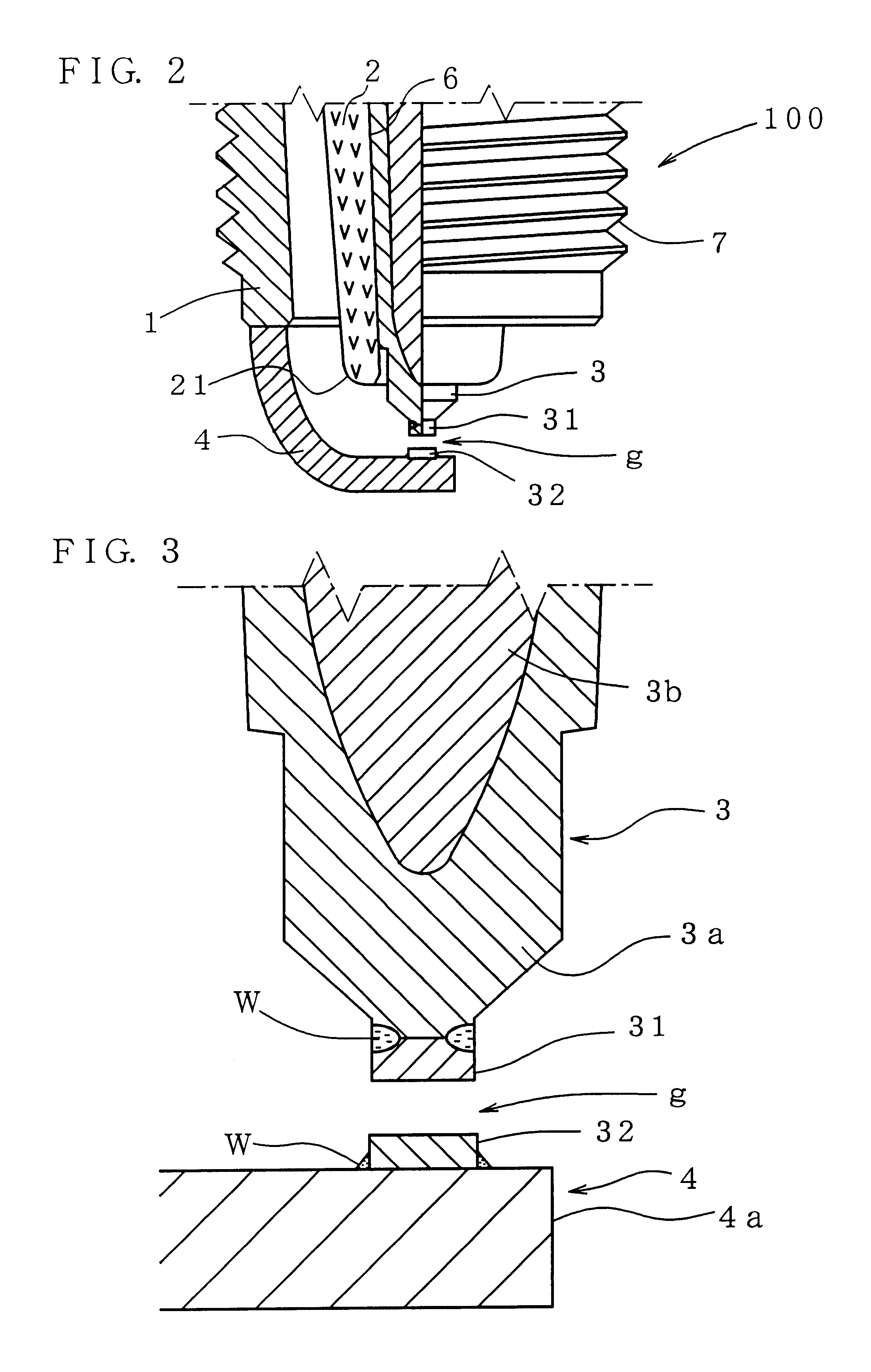

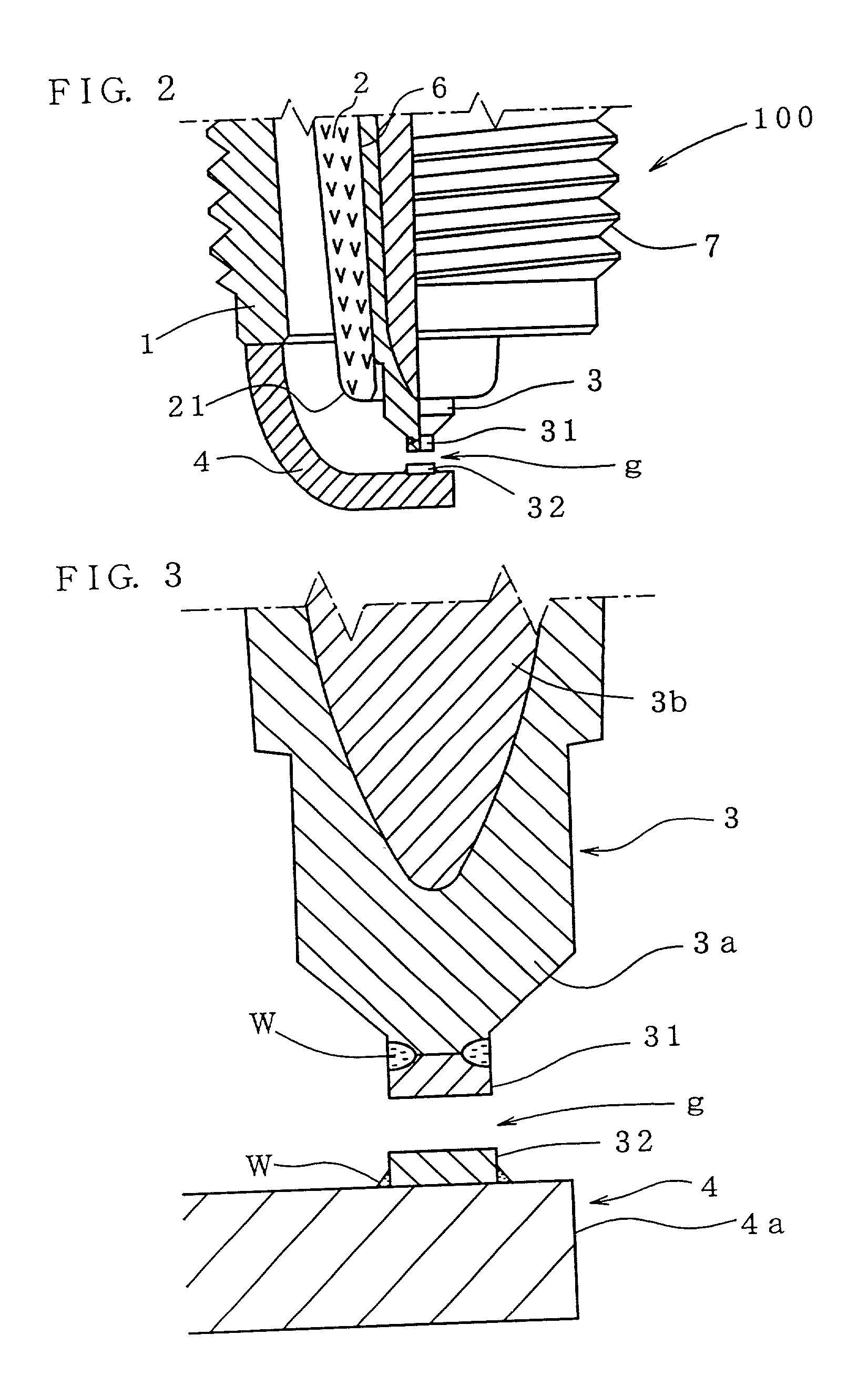

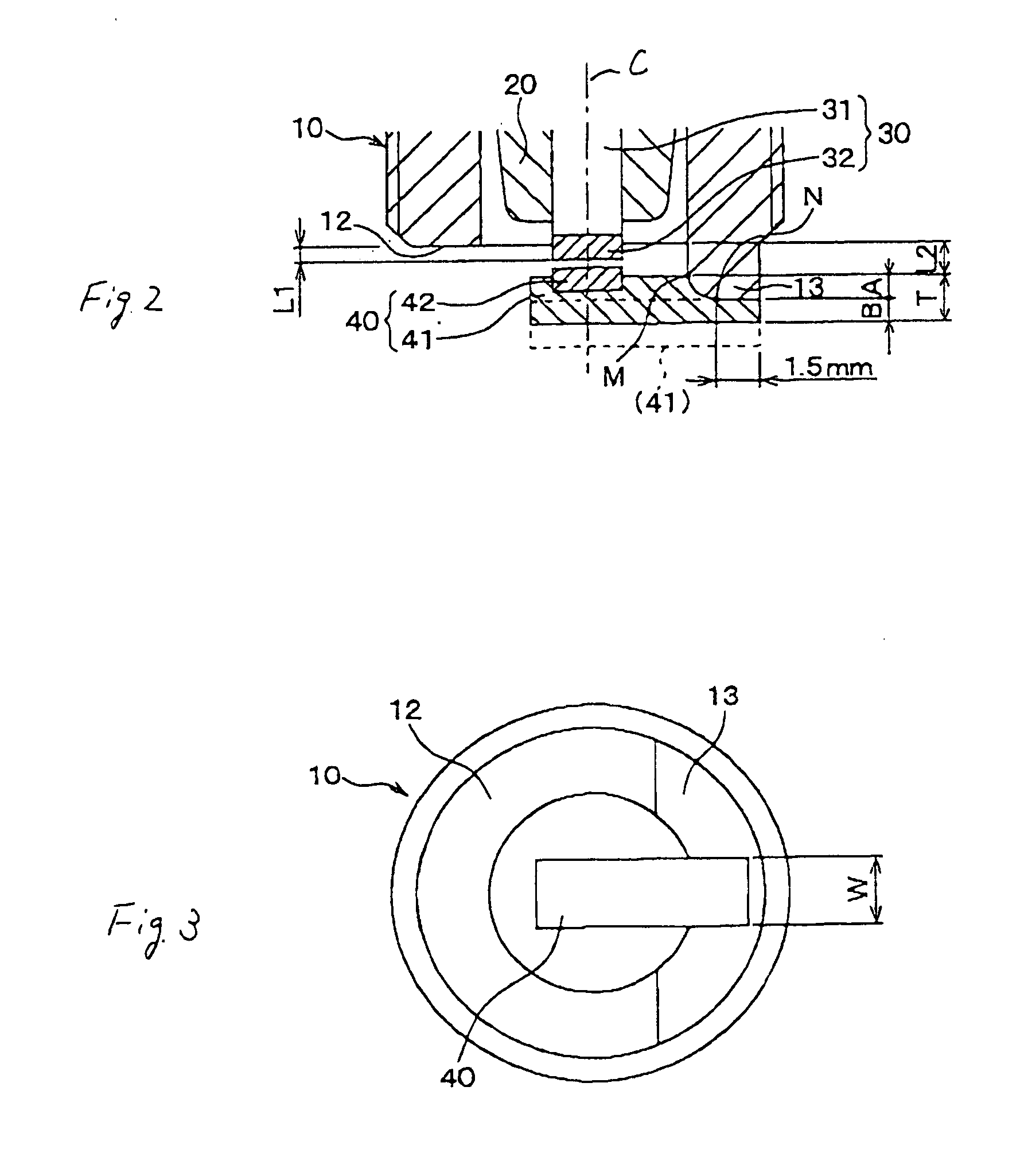

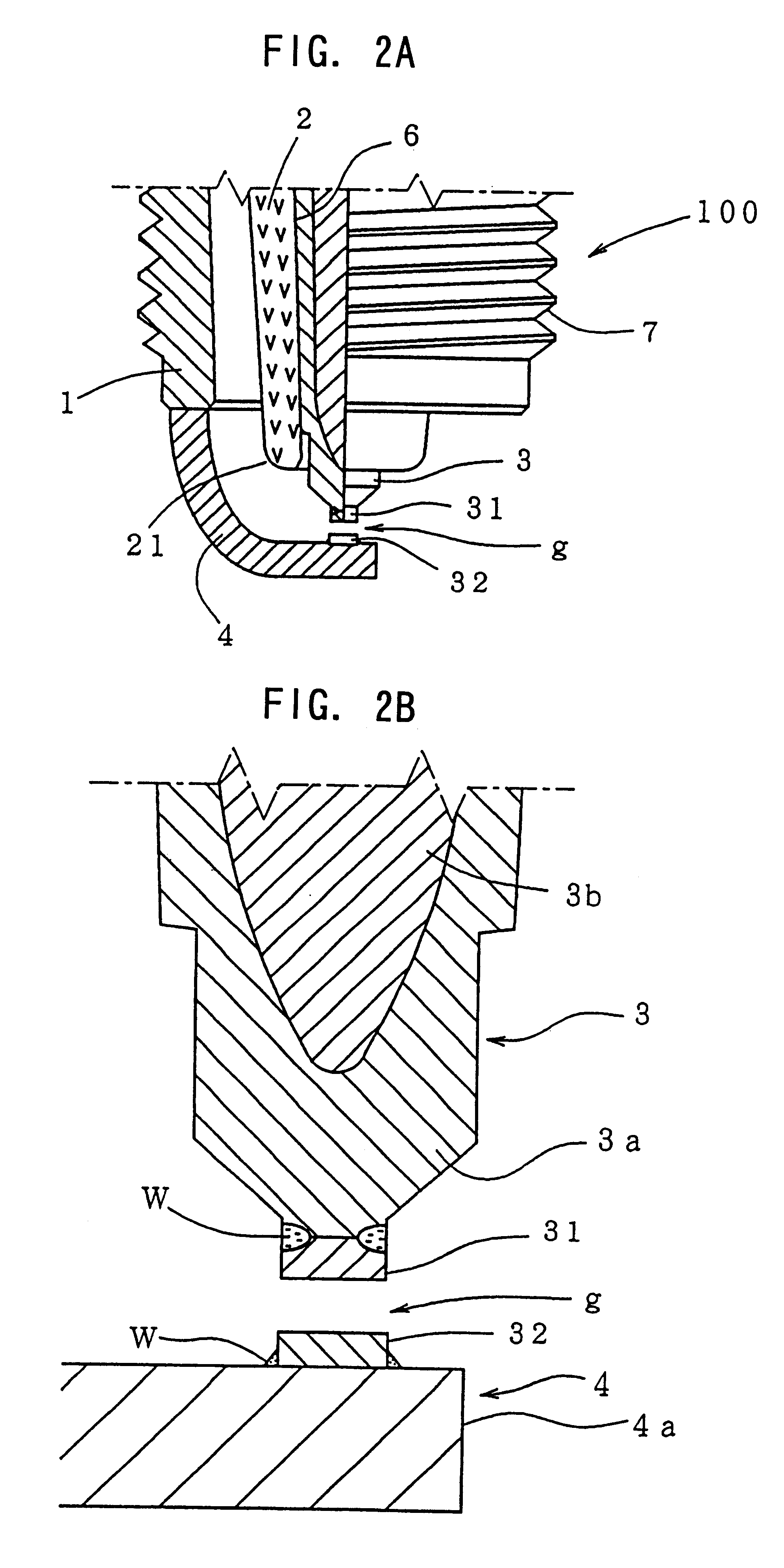

Spark plug and method for manufacturing the spark plug

InactiveUS7084558B2OptimizationJoining process can be facilitatedSpark gapsSparking plugs manufactureIn planeAlloy

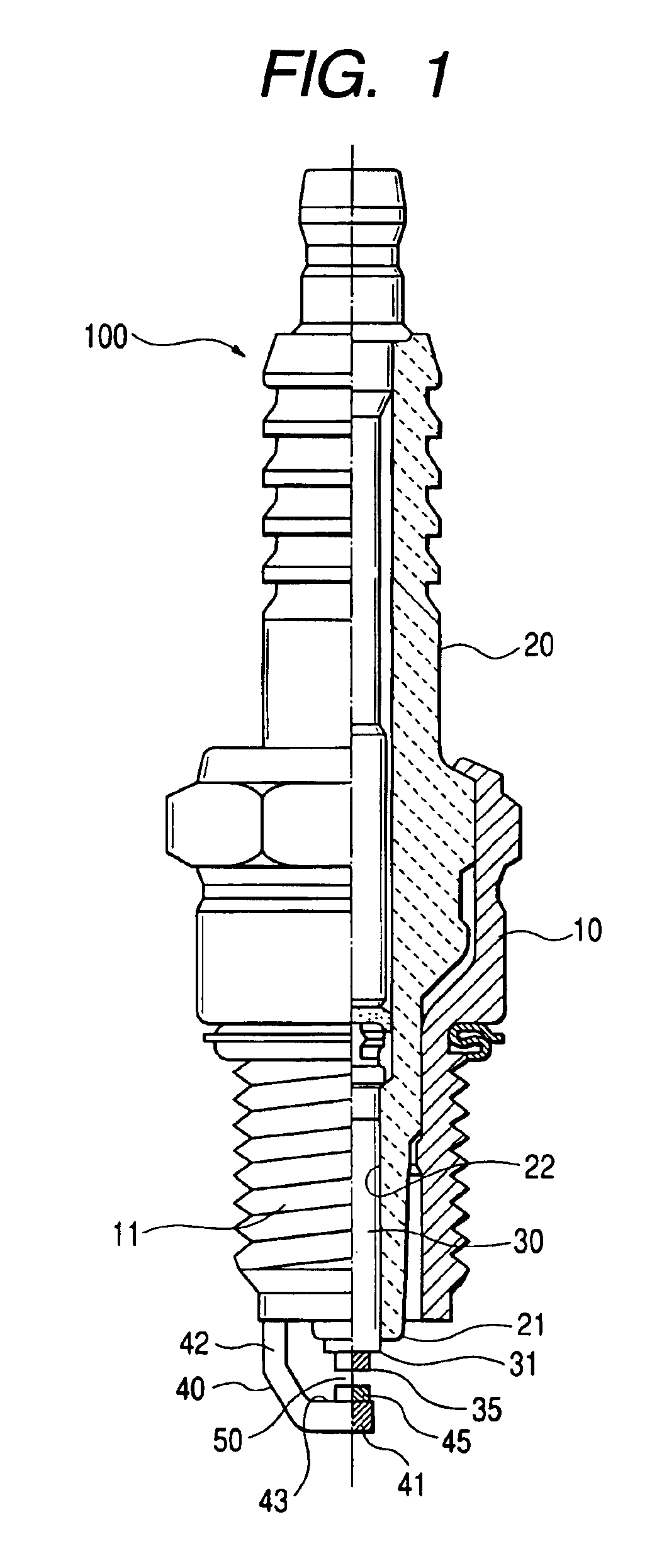

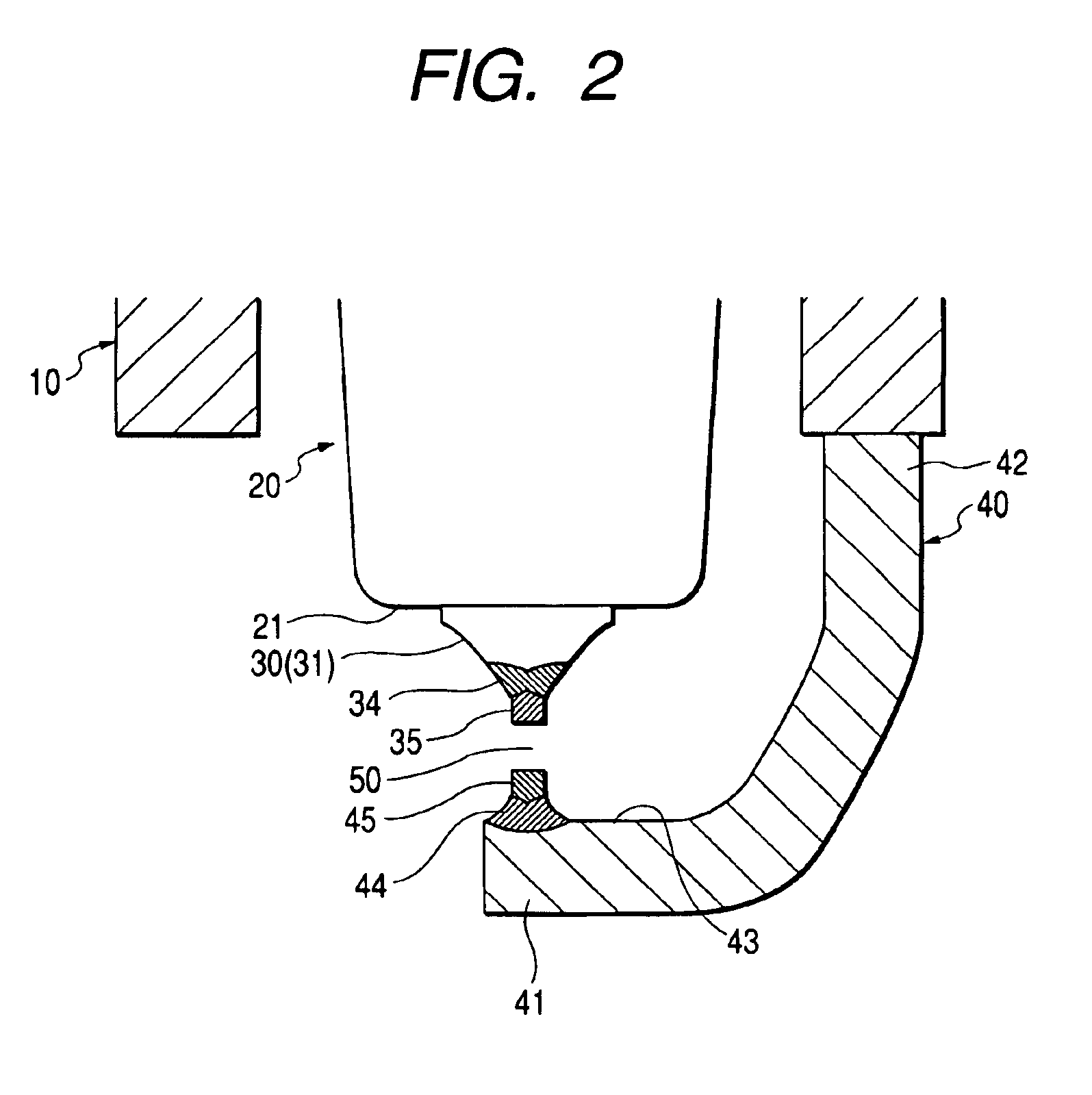

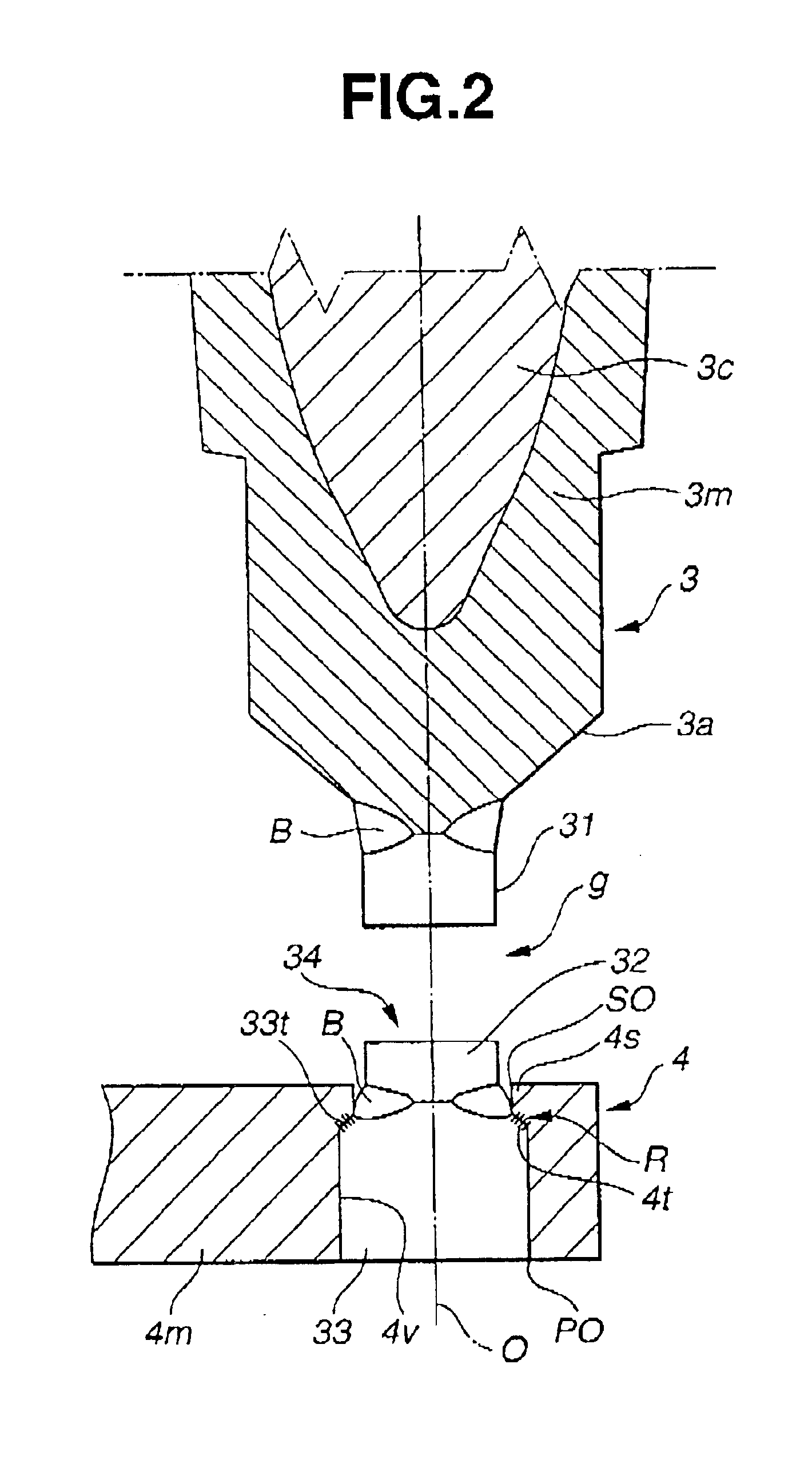

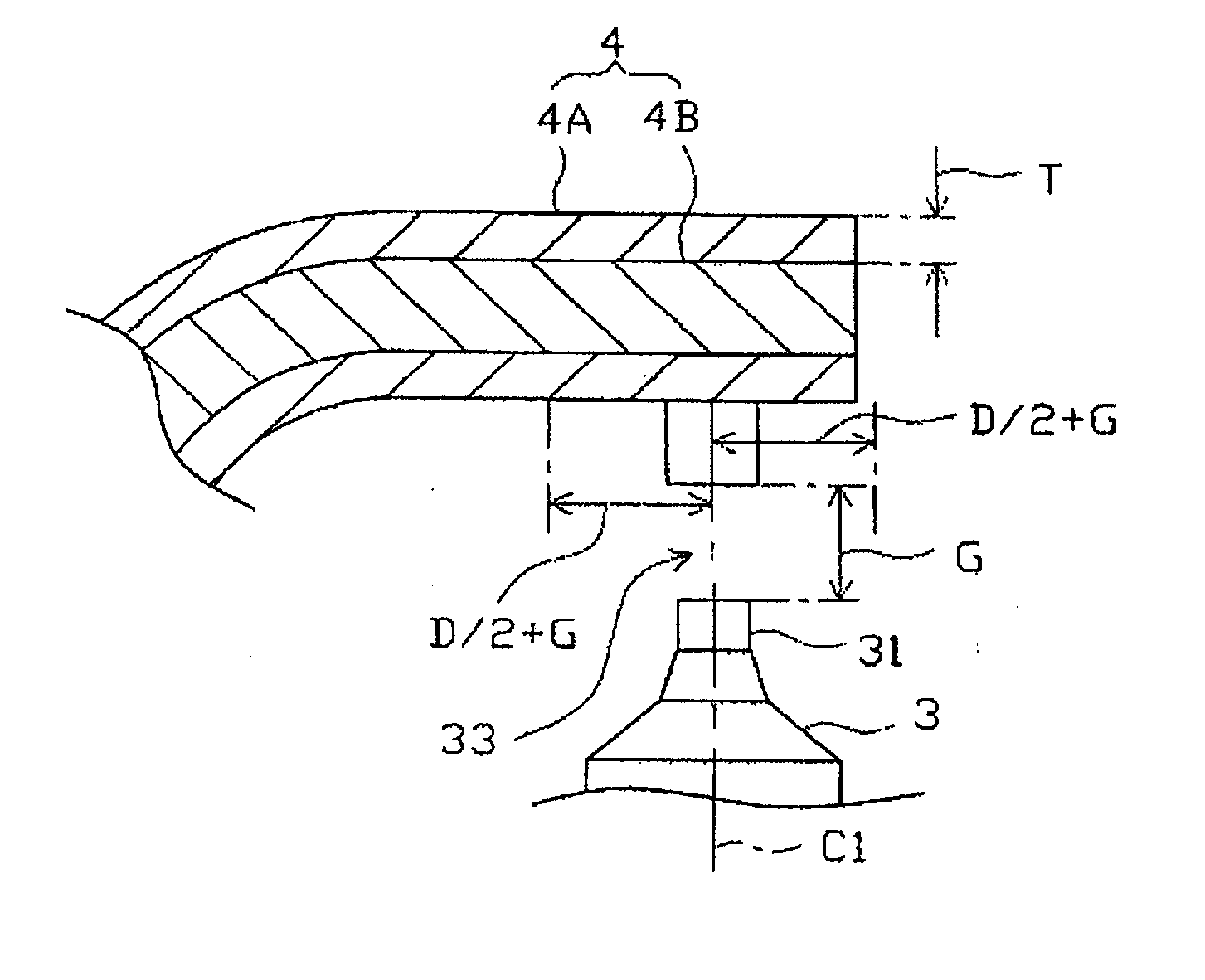

A ground-electrode spark portion 32 is formed from a noble metal which contains Pt as a main component, and is joined to a main metal portion of the ground electrode 4 via an alloy layer which has a thickness ranging from 0.5 μm to 100 μm and in which the noble metal that constitutes the ground-electrode spark portion 32 and the metal that constitutes the main metal portion of the ground electrode 4 are alloyed with each other. The ground-electrode spark portion 32 is configured such that a distal end surface 32t facing a spark discharge gap g is smaller in diameter than a bottom surface 32u joined to the ground electrode 4; and the distal end surface 32t is protrusively located beyond the side surface 4s of the ground electrode 4. When the ground-electrode spark portion 32 is viewed in plane from the distal end surface 32t, a portion of the surface of the ground-electrode spark portion 32 is viewed as a peripheral exposed-region surface 32p which is exposed on the side surface 4s of the ground electrode 4 so as to surround the distal end surface 32t.

Owner:NGK SPARK PLUG CO LTD

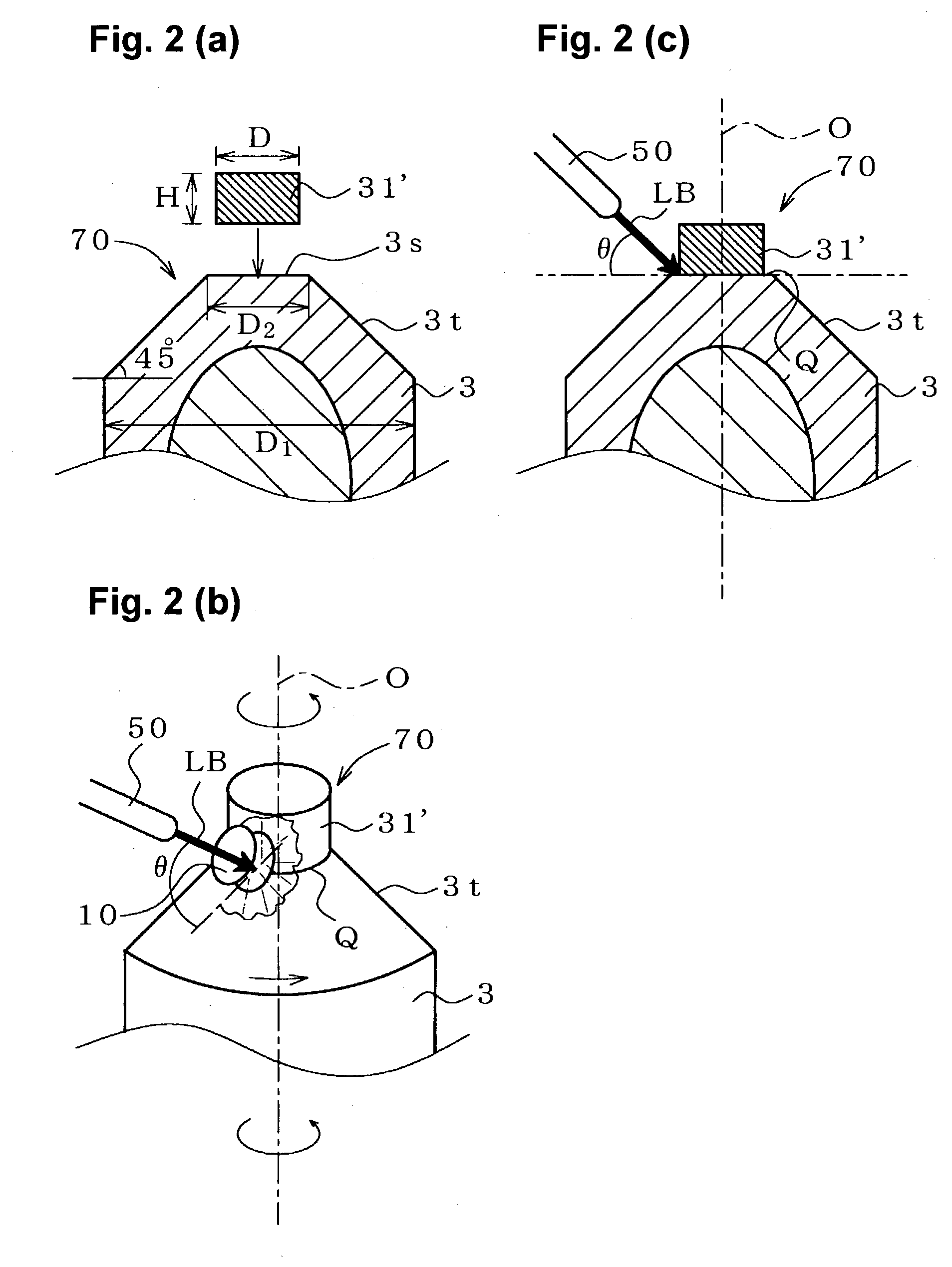

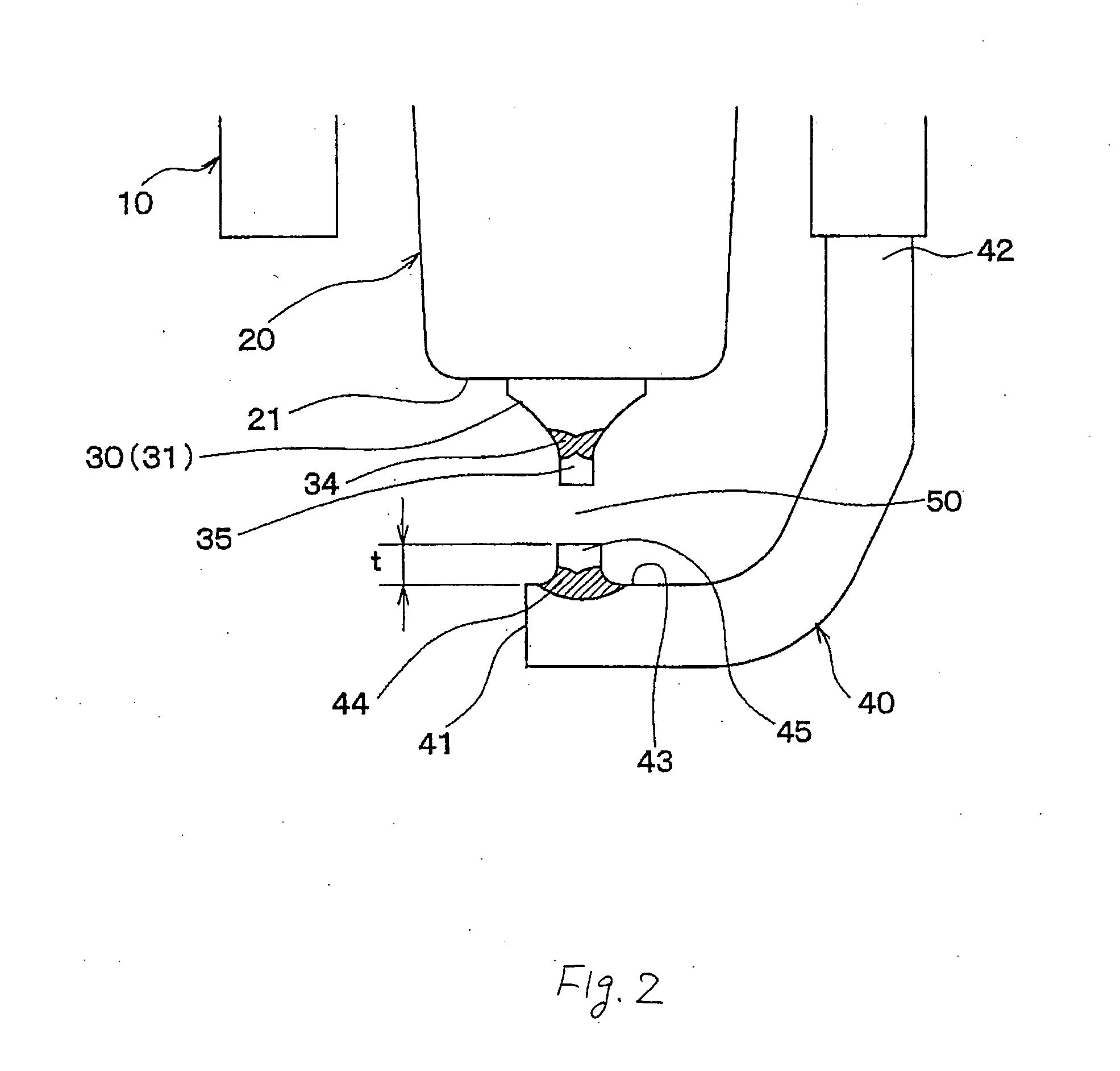

Method for manufacturing a spark plug, and spark plug

A method for manufacturing a spark plug which reduces the generation of spatters and the possibility of insufficient weld strength resulting from penetration depth insufficiency of a weld metal portion is disclosed. In accordance with the method, a chip joint face formation portion of a center electrode is formed from a heat-resistant alloy predominantly containing Fe or Ni. A noble metal chip is attached to a chip joint face of the chip joint face formation portion to thereby form a chip-attached assembly. A full-circled laser-beam weld metal portion is formed on the chip-attached assembly in such a manner as to intrude into the noble metal chip and into the chip joint face formation portion. A graded-index-type fiber optic cable is used as an optical transmission path extending between a laser beam generator and an optical emission section. A laser beam which is transmitted from the laser beam generator through the cable irradiates the chip-attached assembly while being condensed.

Owner:NGK SPARK PLUG CO LTD

Spark plug and its manufacturing method

InactiveUS6885135B2Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

Method of producing a spark plug

In producing a spark plug including a central electrode having a first chip including noble metal and an earth electrode having a second chip including the noble metal, a spark gap being disposed between the first and second chips, a chip including the noble metal. The chip is welded to an end of the central electrode and to an end of the earth electrode. The welded chip is cut to form the first and second chips and the spark gap.

Owner:DENSO CORP

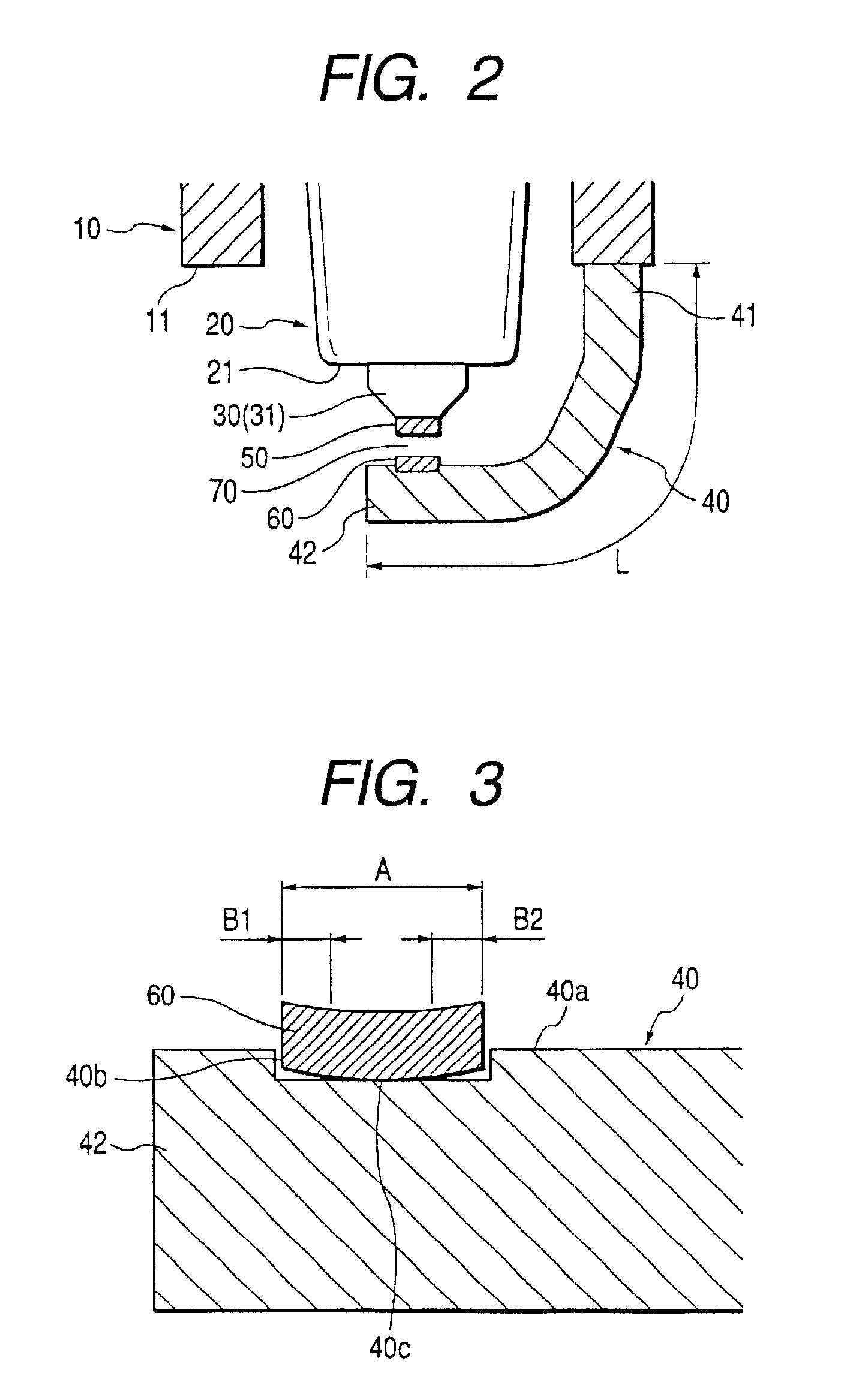

Structure of spark plug designed to provide higher durability and ignitability of fuel

InactiveUS6853116B2Improve welding reliabilityImprove flammabilitySpark gapsFuel injection apparatusMaximum depthEngineering

An improved structure of a spark plug which provides higher durability and ignitability of a gaseous fuel. The spark plug consists of a center electrode, a ground electrode, a noble metal chip joined to a center electrode-opposed surface of the ground electrode by laser welding, and a fused portion that forms a weld of the noble metal chip and the ground electrode formed by materials of the ground electrode and the noble metal chip melted together. A sectional area of the noble metal chip traversing a length thereof is between 0.1 mm2 and 0.6 mm2. An unfused sectional area percentage that is a percentage of a sectional area of an unfused portion of a joined end of the noble metal chip within a range of a sectional area of the noble metal chip closest to the fused portion traversing the length of the noble metal chip is less than or equal to 50%. A melt angle that is an angle which a line extending through the fused portion along a maximum depth of the fused portion makes with the center electrode-opposed surface of the ground electrode is less than or equal to 60°.

Owner:DENSO CORP

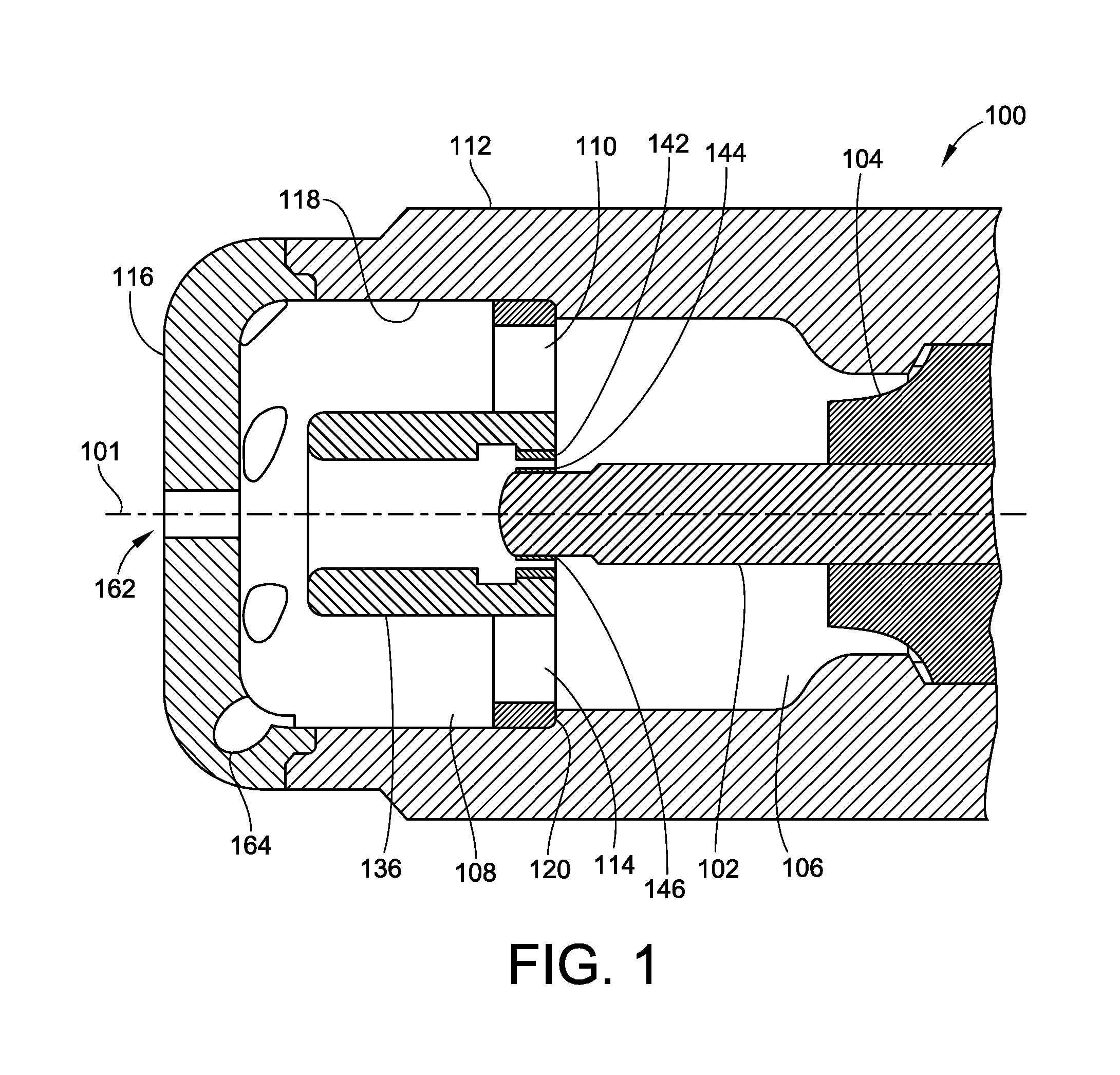

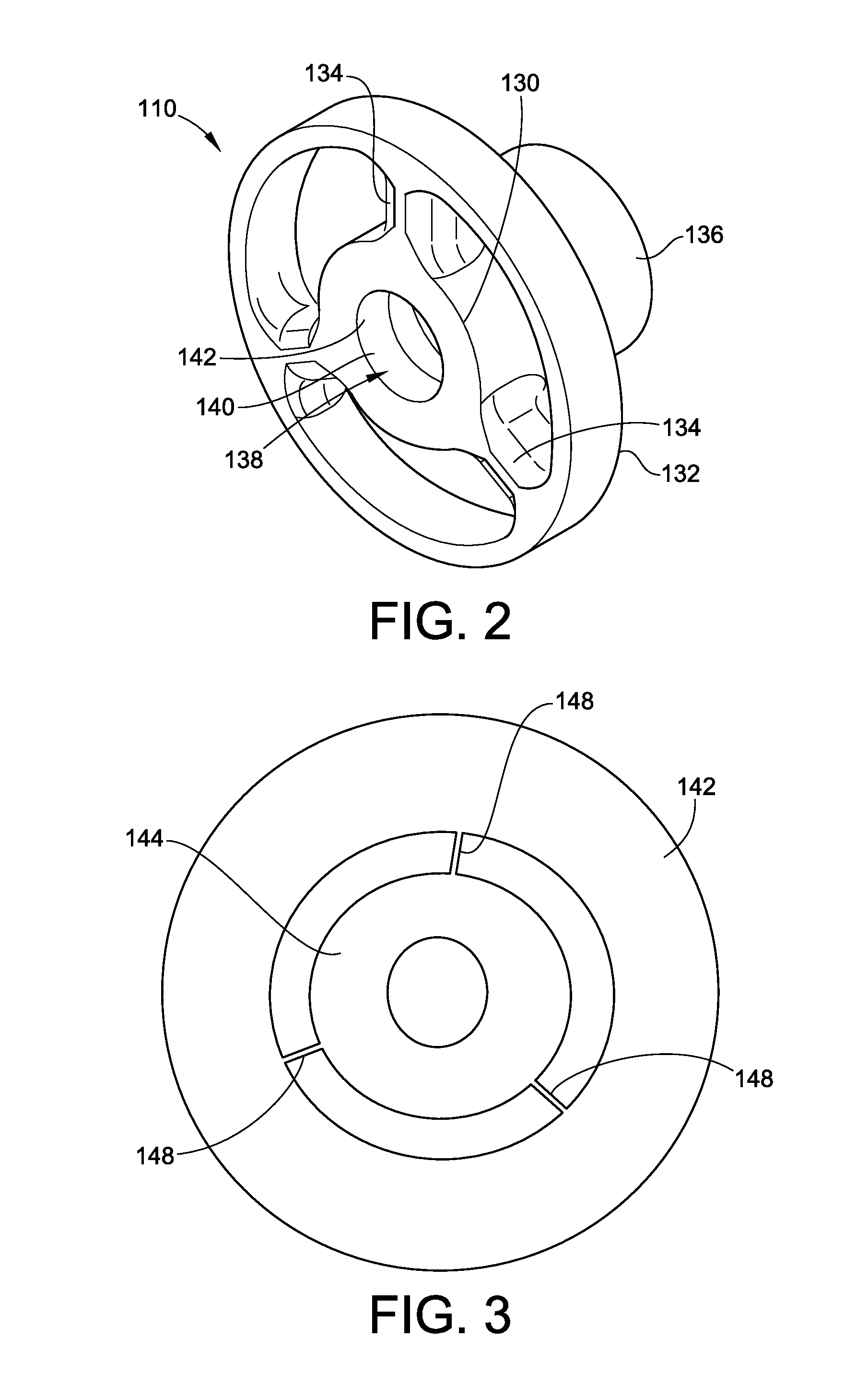

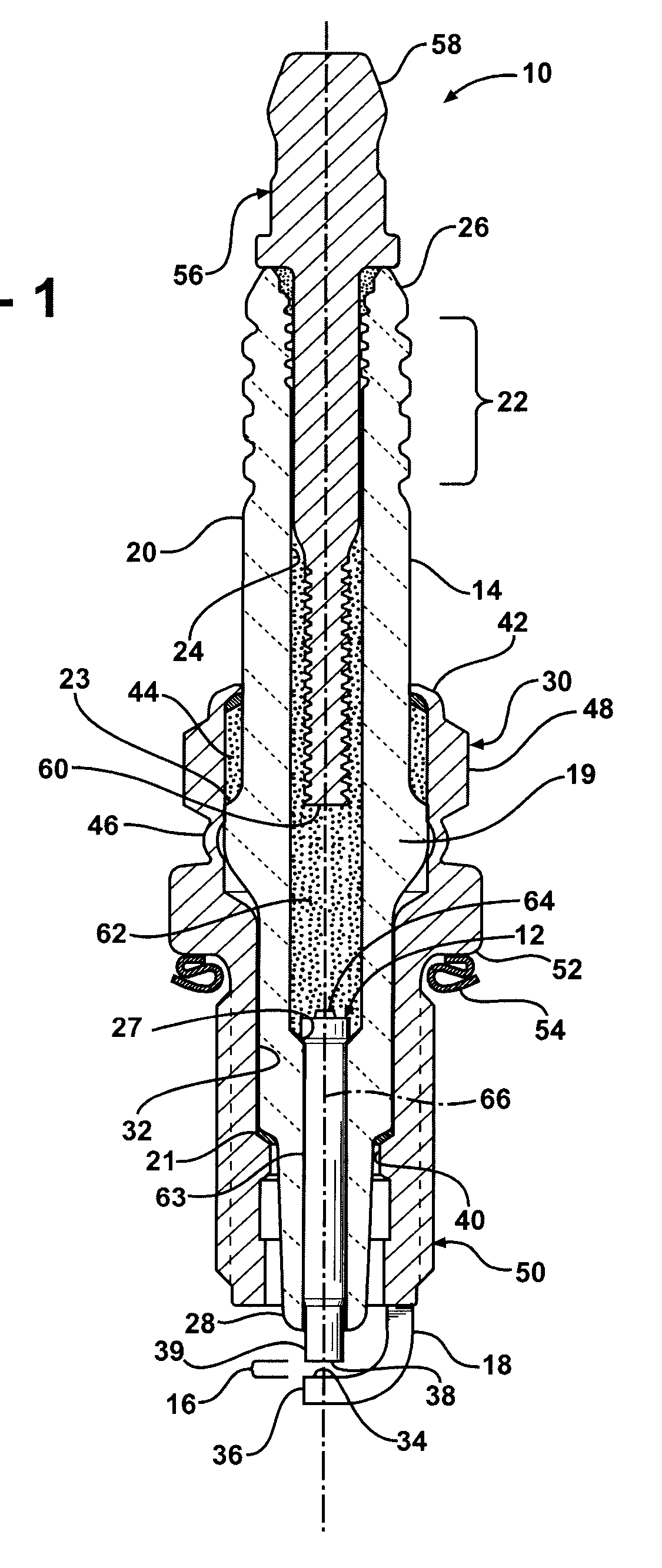

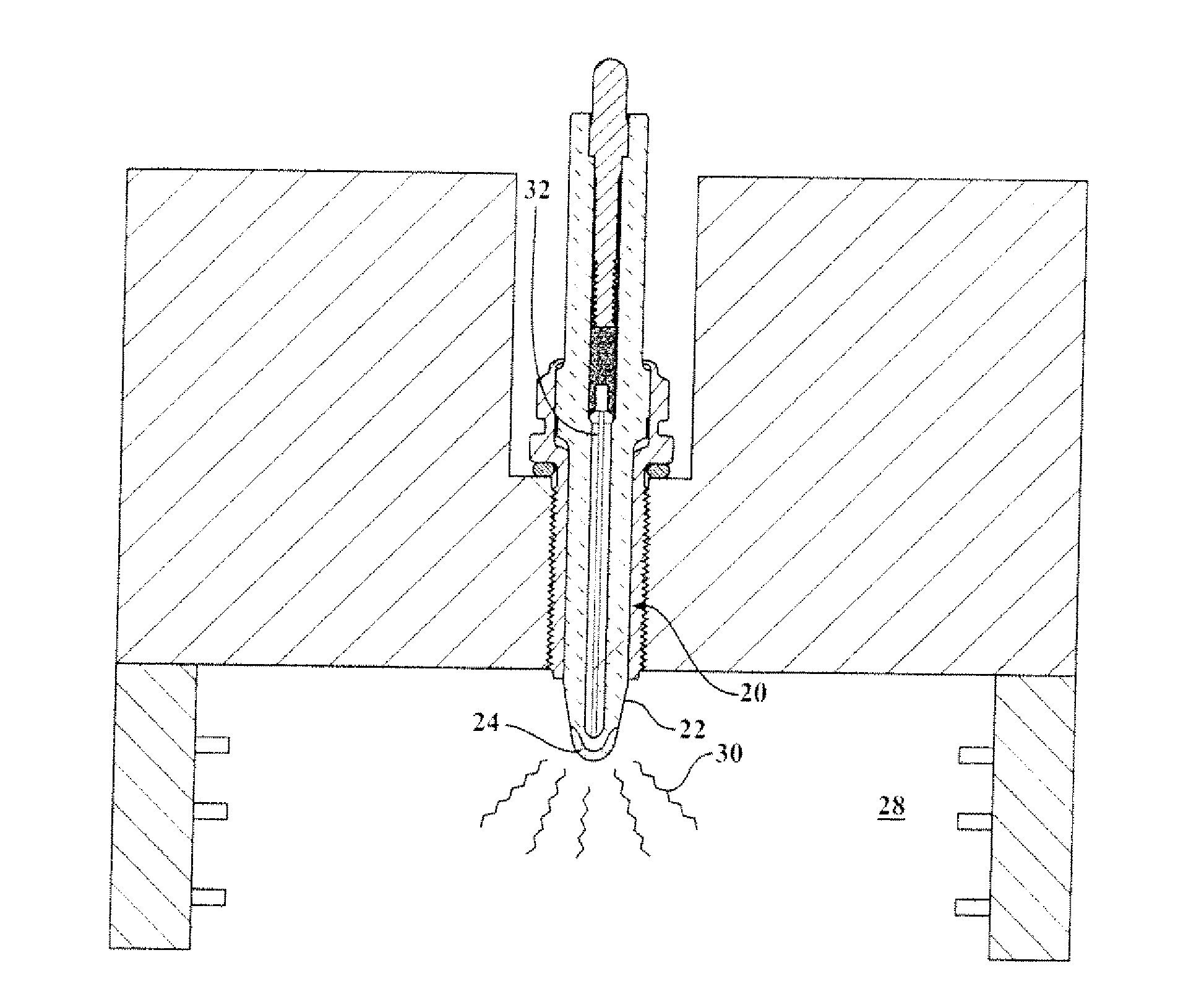

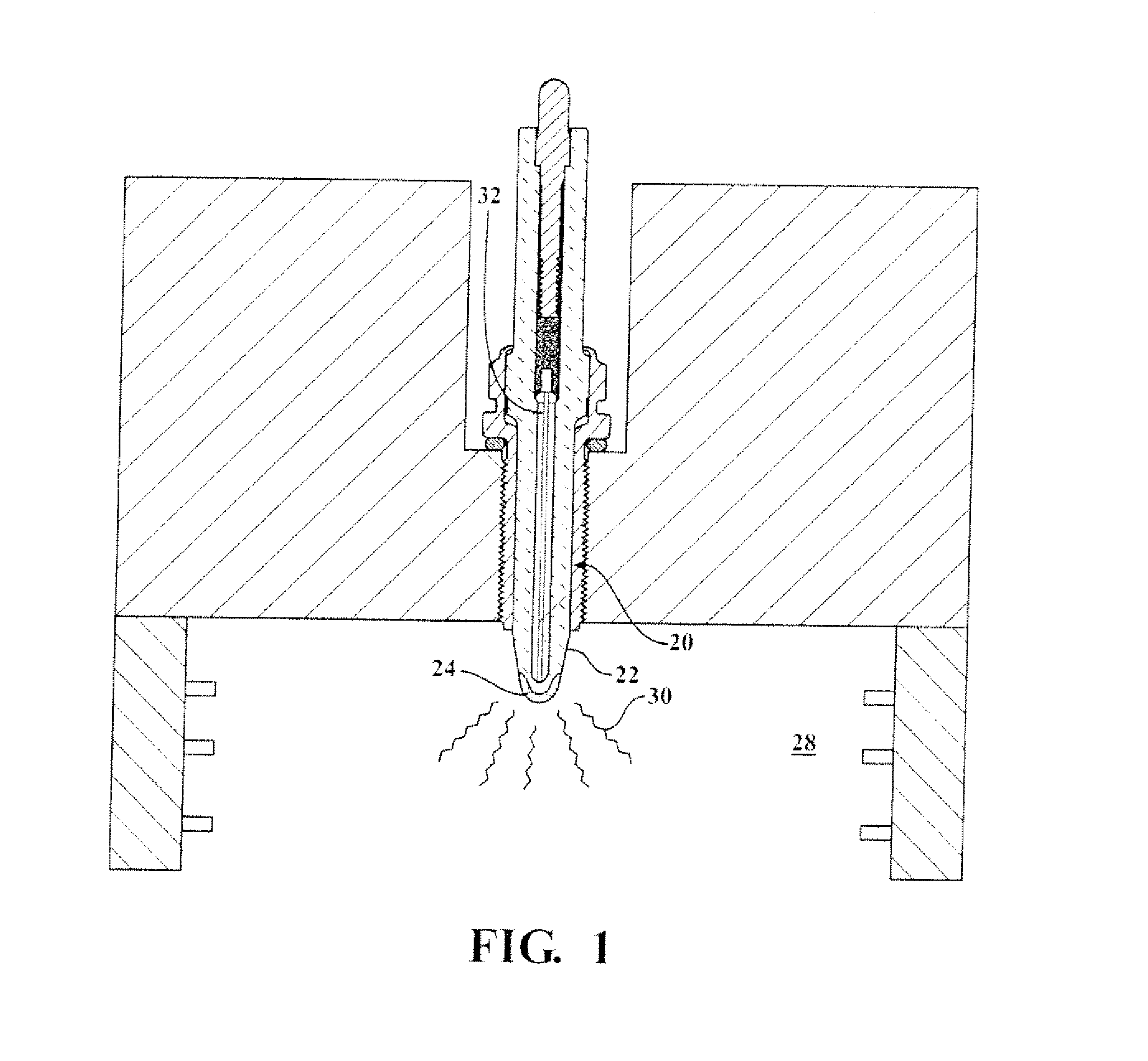

Pre-chamber spark plug

ActiveUS7922551B2Life maximizationReduce erosionSpark gap detailsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

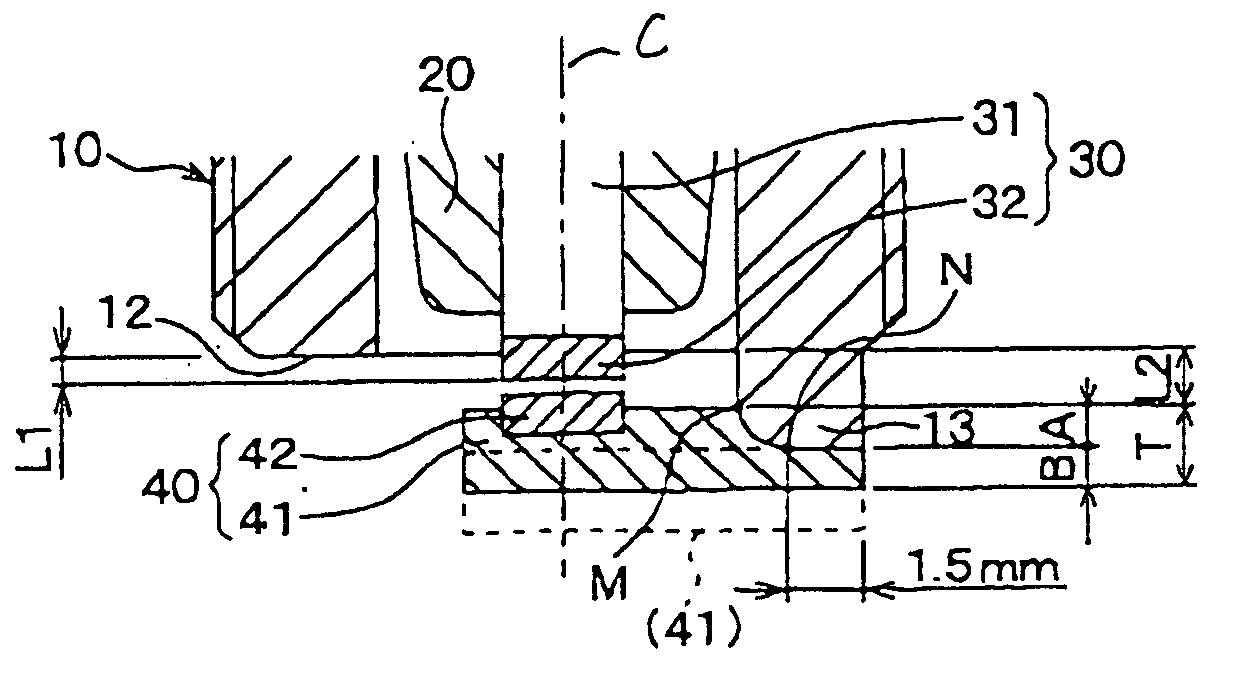

Method of making a spark plug

InactiveUS6923699B2Restrict movementHigh melting pointLine/current collector detailsSpark gapsBiomedical engineeringGrounding electrodes

A method of making a spark plug having a noble metal chip joined to an electrode main body of a ground electrode by interposing therebetween an intermediate member. The method comprises the steps of prior to joining the noble metal chip to the electrode main body, joining the intermediate member and the noble metal chip together, placing a noble metal chip and intermediate member assembly on the electrode main body in a way as to allow the intermediate member to contact the electrode main body, and welding the electrode main body and the intermediate member together while restricting relative movement of the electrode main body and the intermediate member without applying an urging force to a joint between the intermediate member and the noble metal chip.

Owner:NGK SPARK PLUG CO LTD

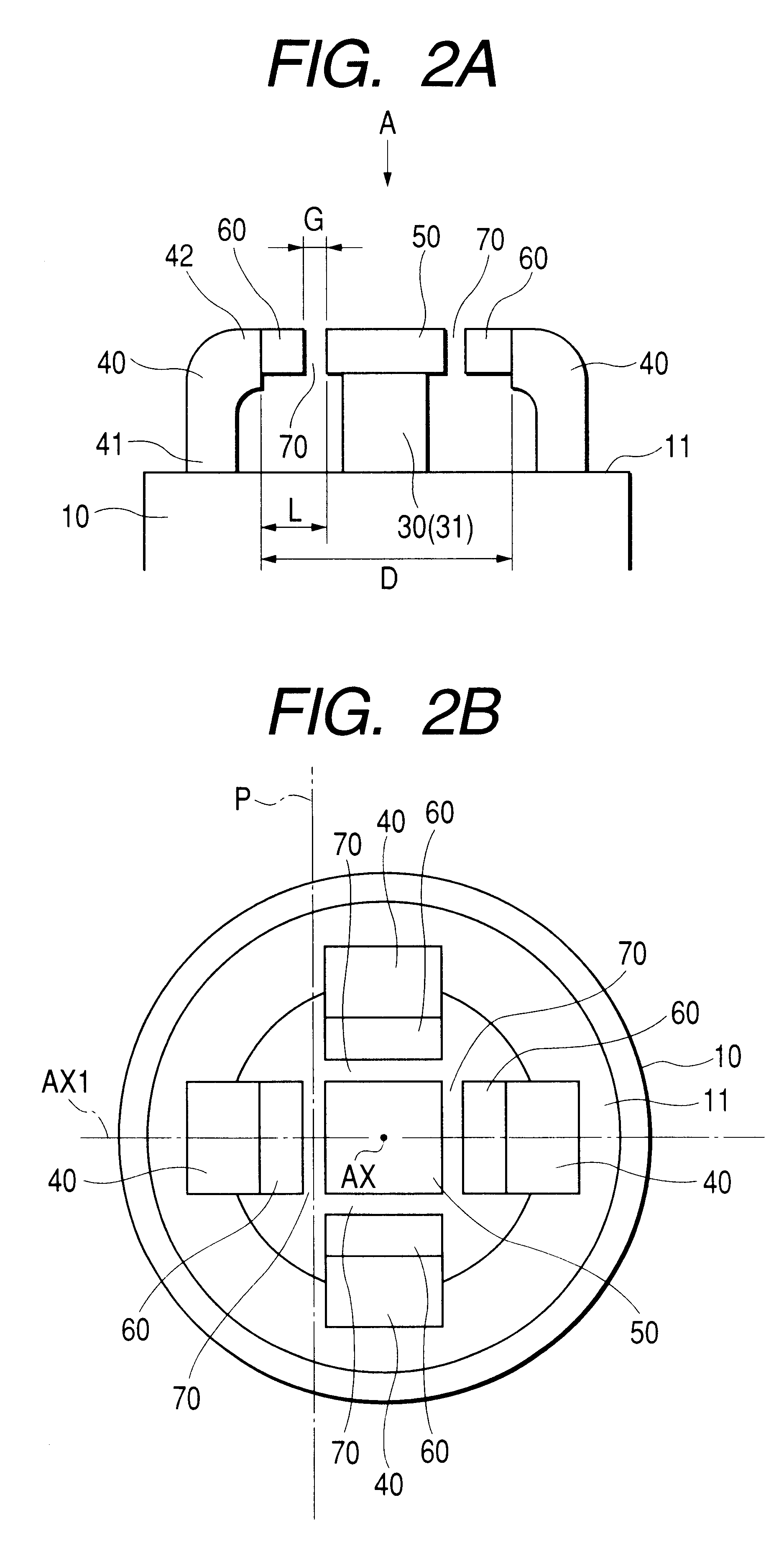

Spark plug and method of manufacturing spark plug

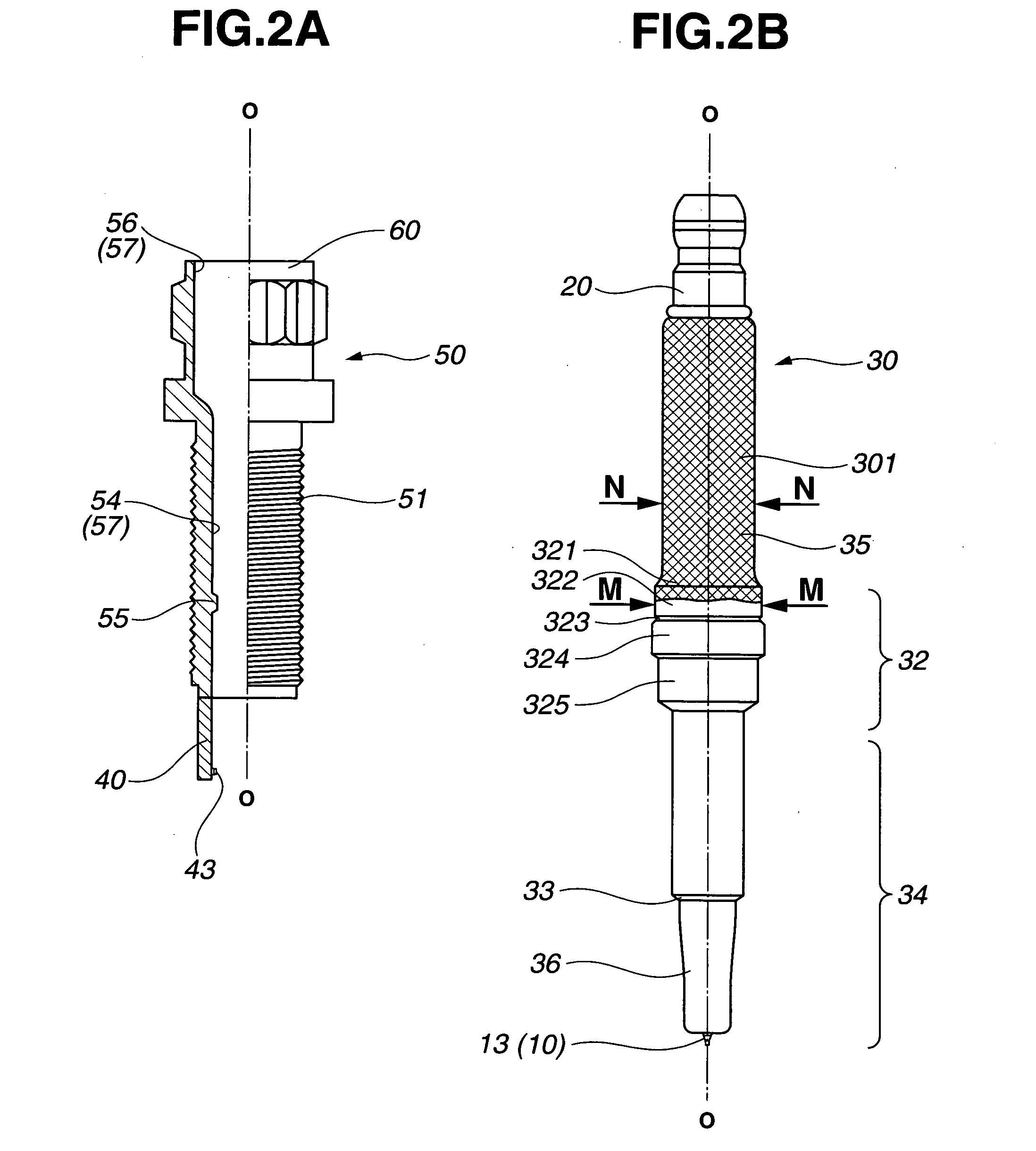

ActiveUS20120299459A1Easy to adjustReliable preventionSpark gaps adjustmentSparking plugs manufactureEngineeringGrounding electrodes

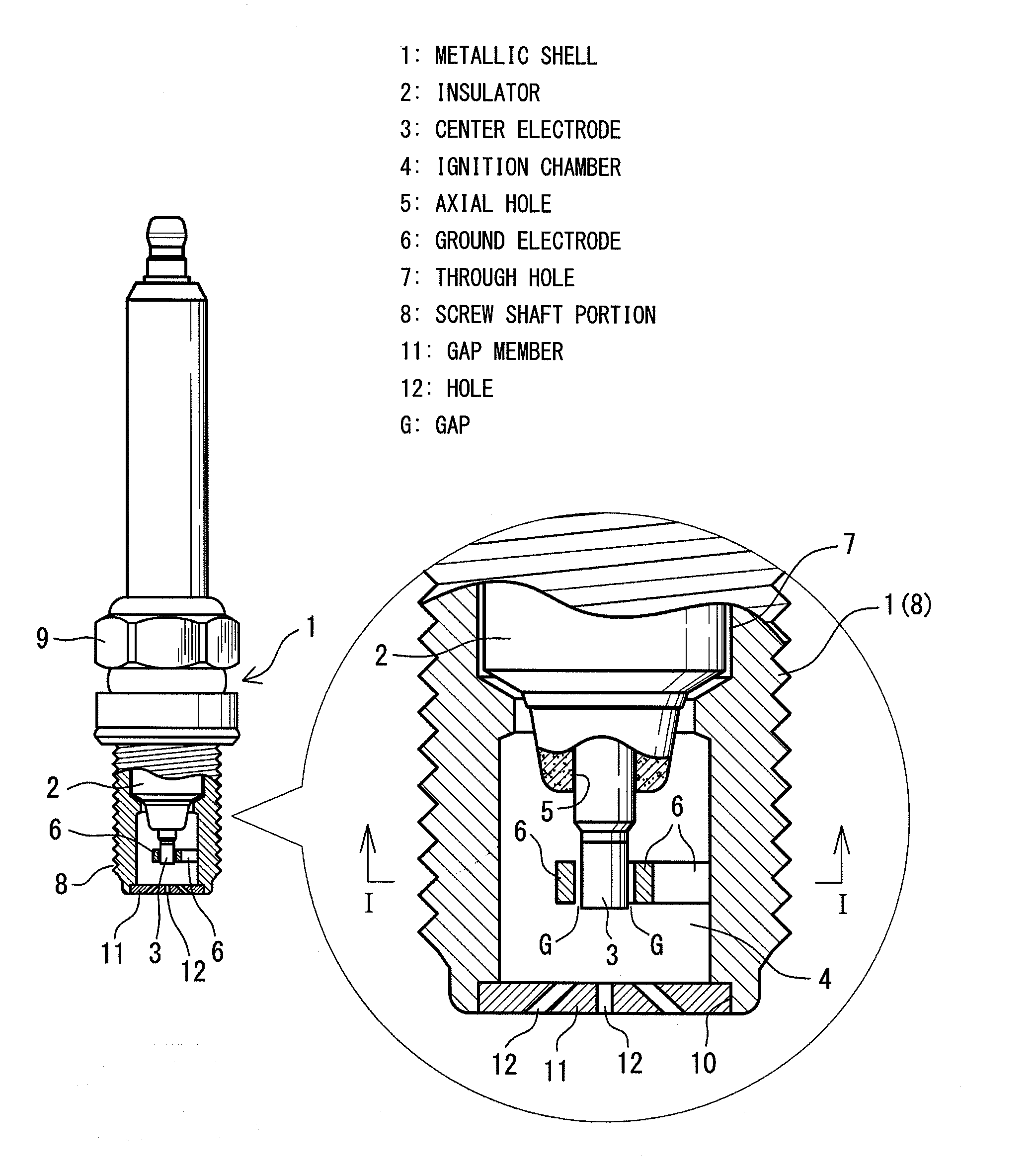

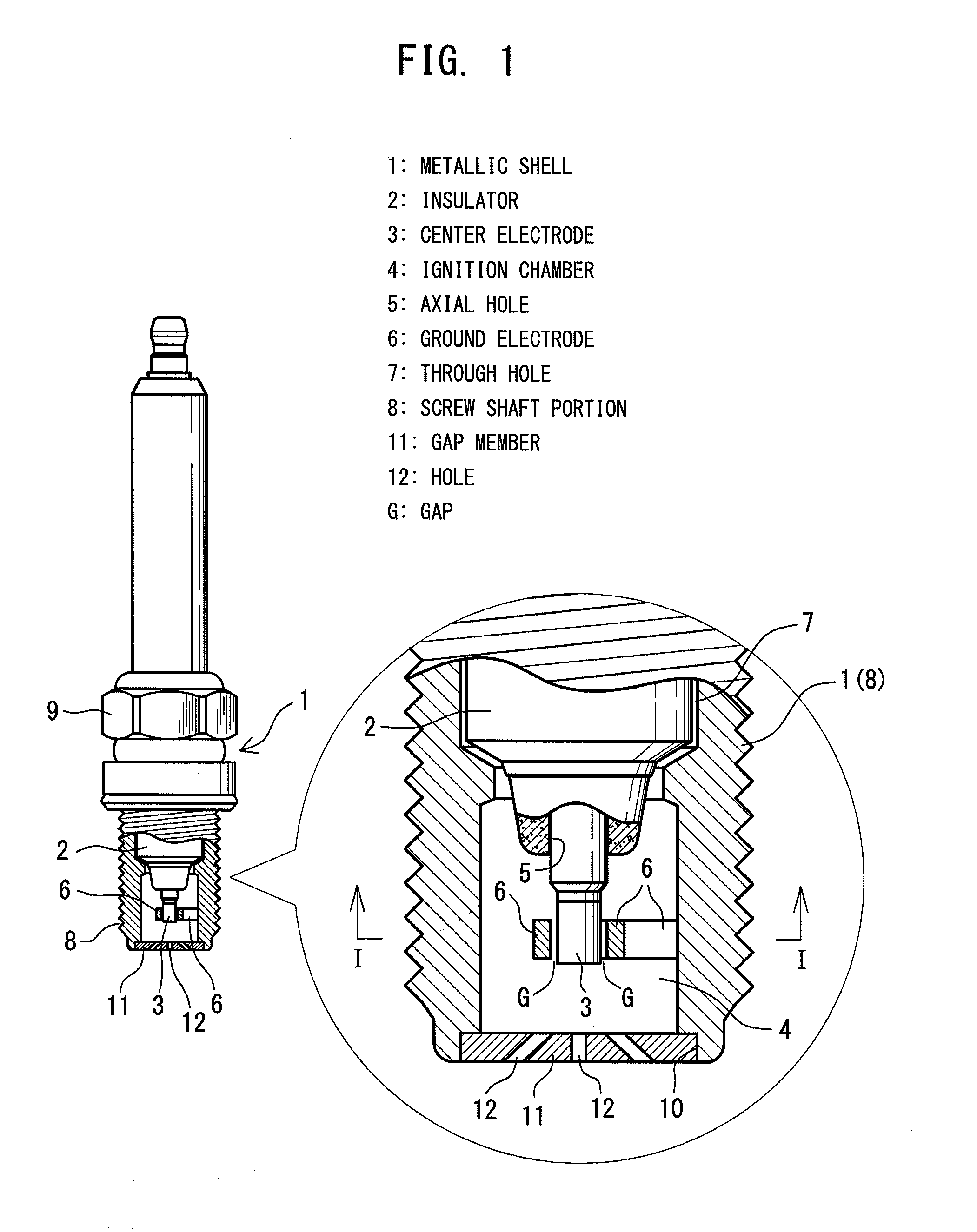

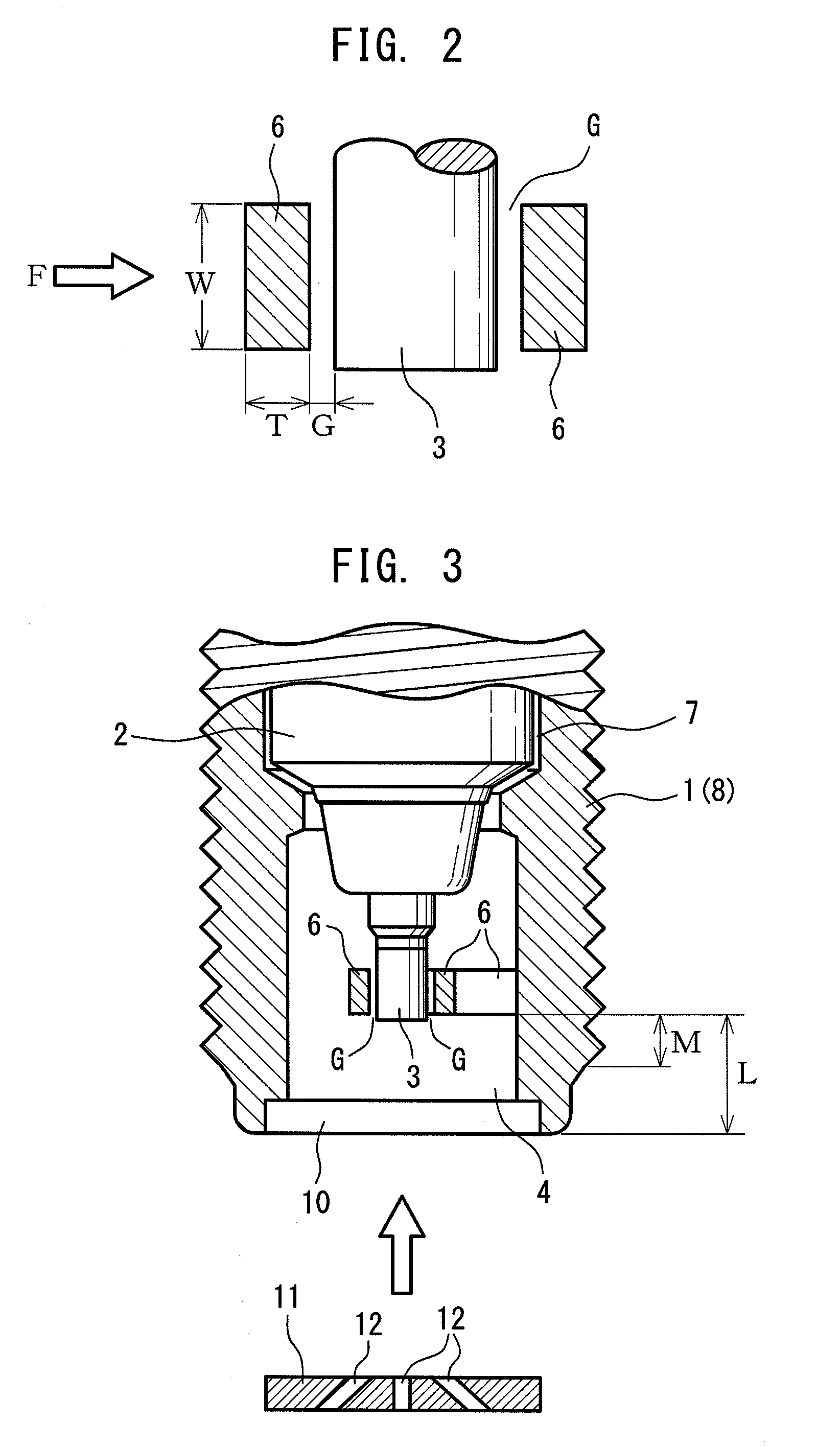

An ignition plug having a metallic shell with a through hole extending therethrough in an axial direction, an insulator fitted into the through hole of the metallic shell and having an axial hole extending in the axial direction, and a center electrode fitted into the axial hole of the insulator. The ignition plug further includes a cap member which covers a front end opening of the metallic shell, provided on a front end side thereof where the center electrode is disposed, to thereby form an ignition chamber at the front end portion of the metallic shell, and a ground electrode disposed within the ignition chamber and facing a circumferential surface of the center electrode directly or indirectly.

Owner:NGK SPARK PLUG CO LTD

Ceramic electrode, ignition device therewith and methods of construction thereof

A spark plug, a center electrode therefore and method of construction is provided. The spark plug has a generally annular ceramic insulator extending between a terminal end and a nose end. A conductive shell surrounds at least a portion of the ceramic insulator and a ground electrode having a ground electrode sparking surface is operatively attached to the shell. An elongate center electrode has a body extending between opposite ends, wherein the body is compacted and sintered of a conductive or semi-conductive ceramic material. One of the electrode ends provides a center electrode sparking surface to provide a spark gap between the center electrode sparking surface and the ground electrode sparking surface.

Owner:FEDERAL MOGUL IGNITION

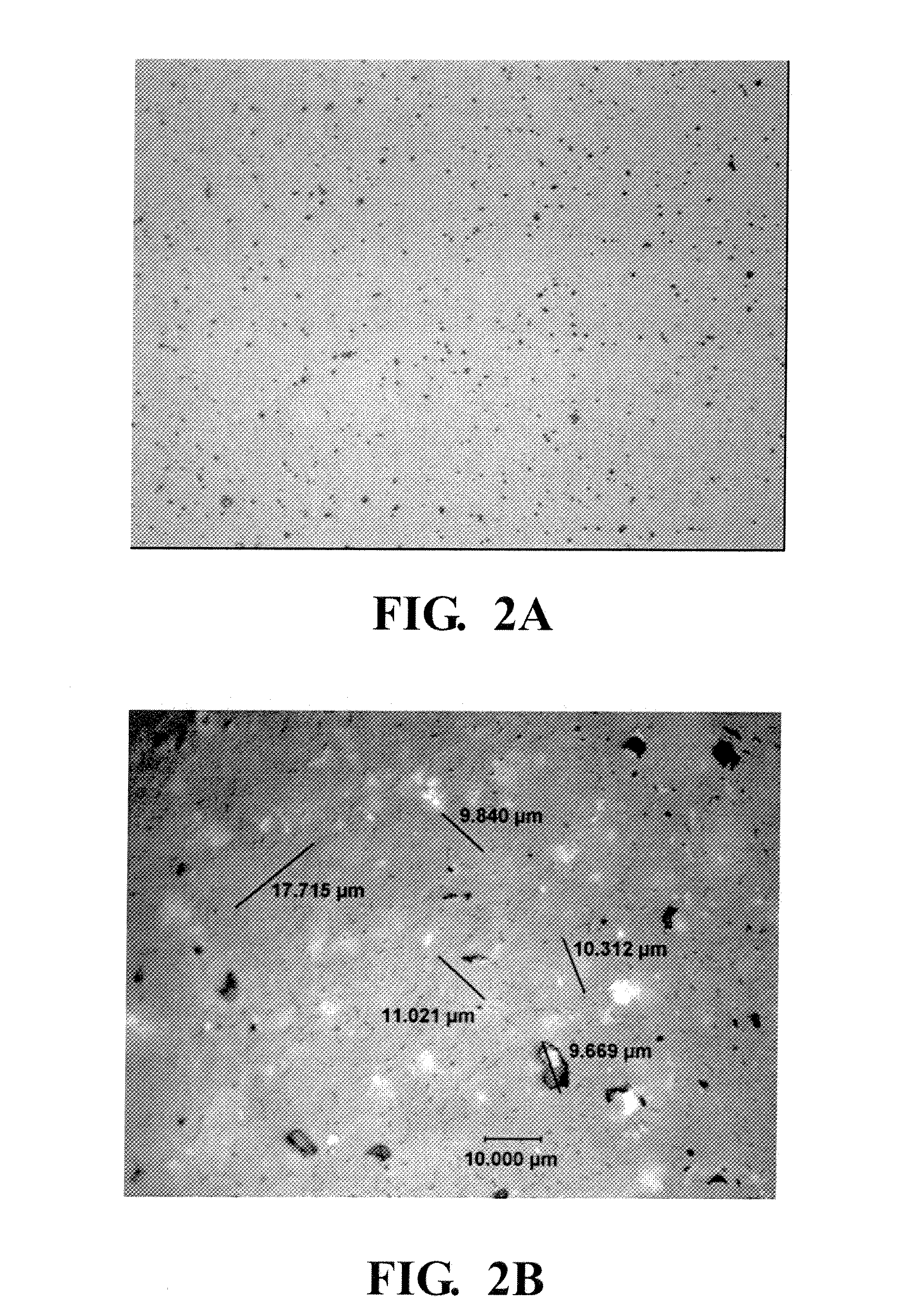

Alumina ceramic for spark plug insulator

ActiveUS20110077141A1Improve conductivityHigh strengthElectric discharge tubesDischarge tube main electrodesAluminateMullite

A spark plug includes an insulator formed of a ceramic material. The ceramic material comprises Al2O3 in an amount of 98.00 wt % to 99.50 wt %; Group 2 oxides in an amount of 0.16 wt % to 0.70 wt %; SiO2 in an amount of 0.25 wt % to 0.75 wt %, Group 4 oxides in an amount of 0.01 wt % to 0.16 wt %, Group 1 oxides in an amount less than 0.0060 wt %, and P2O5 in an amount of less than 0.0040 wt %. The Al2O3 is formed of particles having a D50 median particle size by volume of 1.2 μm to 1.8 μm. The ceramic material is pressed, sintered, and formed to a predetermined shape. The sintered ceramic material includes a glass phase comprising the Al2O3, Group 2 oxides, and SiO2. The sintered ceramic material also includes secondary crystals of calcium hexa-aluminate (CaAl12O19) spinel (MgAl2O4), anorthite (CaAl2Si2O8), and mullite (Al6Si2O13).

Owner:FEDERAL MOGUL IGNITION

Spark plug with noble metal chip joined by unique laser welding and fabrication method thereof

ActiveUS20050023949A1Improve welding reliabilitySacrifice productivityFuel injection apparatusMachines/enginesMaterials scienceLaser soldering

A spark plug is provided which ensures the reliability of a weld between a noble metal chip and a ground electrode as well as higher durability and ignitability of fuel. The ground electrode is joined to a metal shell, after which the noble metal chip is laser-welded to the ground electrode. The laser welding is achieved by emitting laser beams around an interface between the noble metal chip and the ground electrode outside a given angular range within which the metal shell will be an obstruction to the traveling of the laser beams. Specifically, the laser beams are emitted without any optical interference with the metal shell. This permits the angle between the orientation of each of the laser beams and the surface of the ground electrode to be minimized regardless of the metal shell, thus ensuring a desired depth of the fused portions in the noble metal chip.

Owner:DENSO CORP

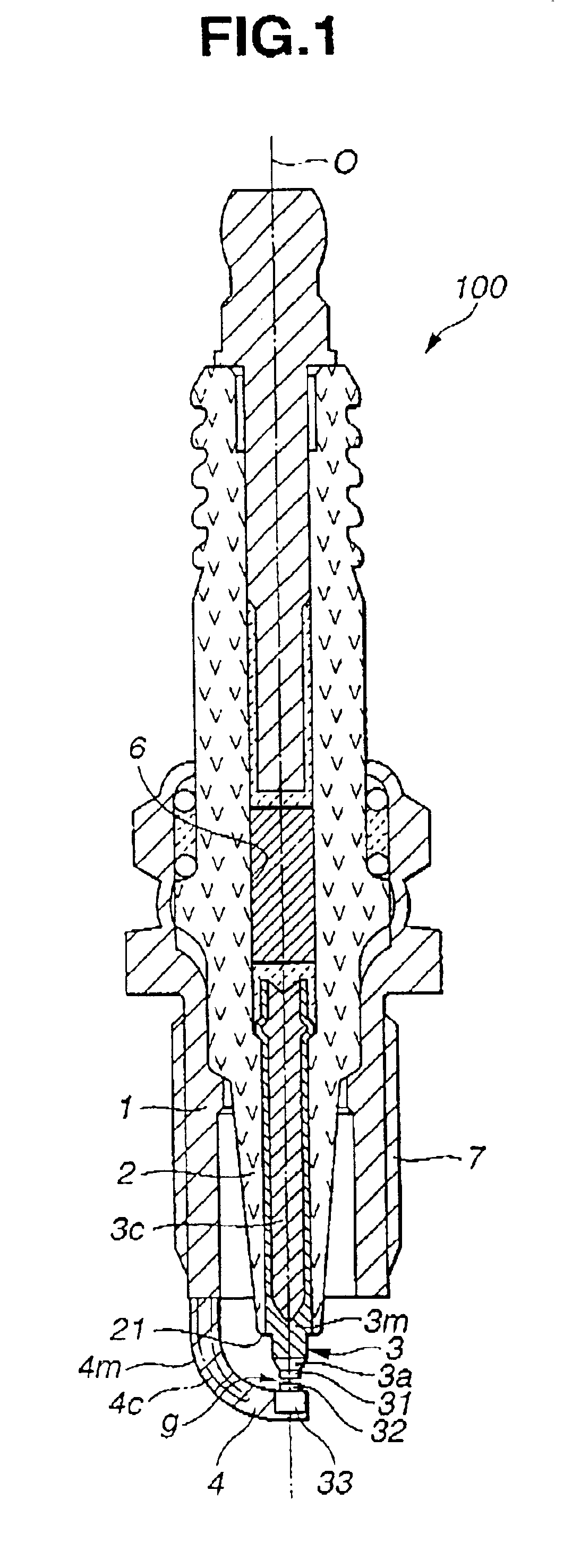

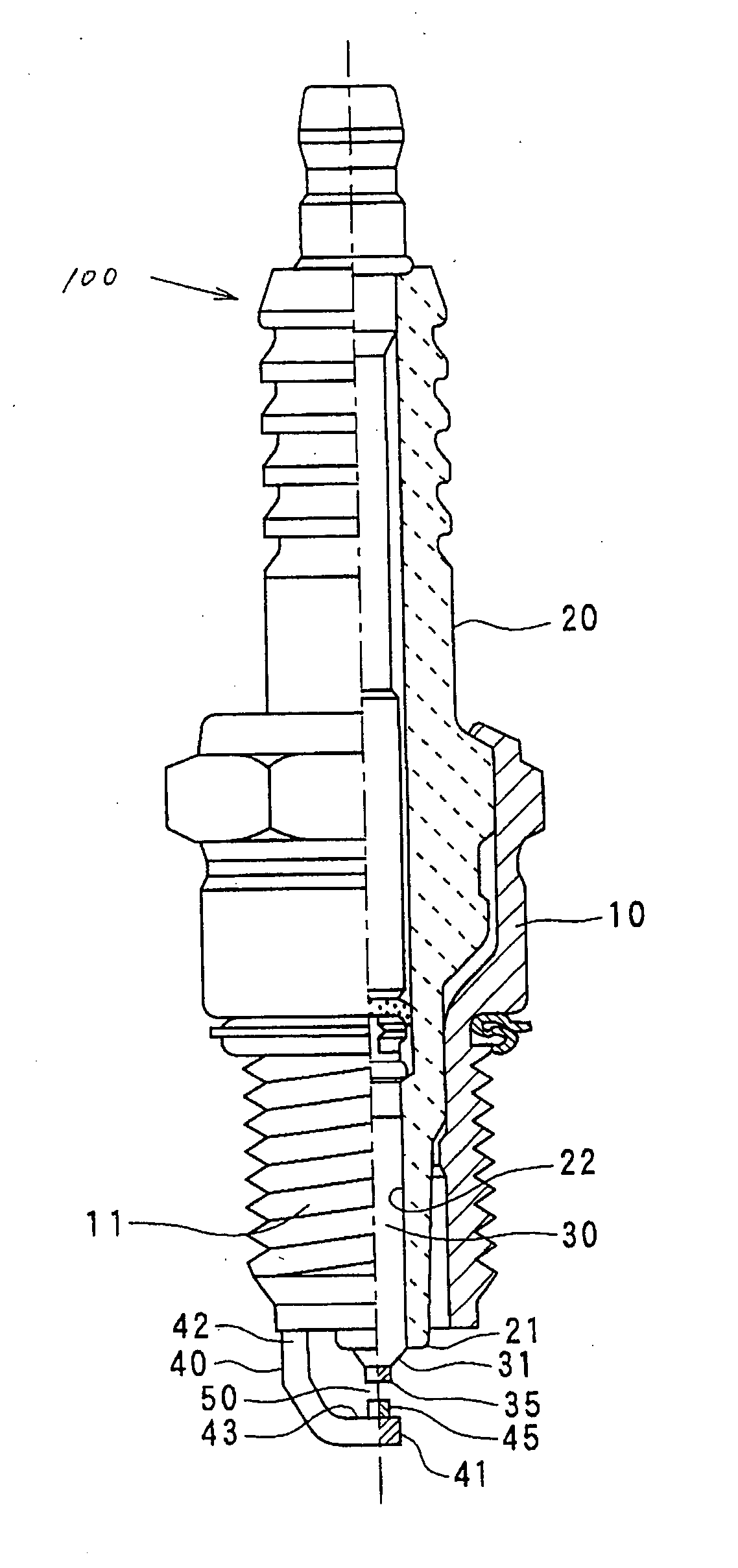

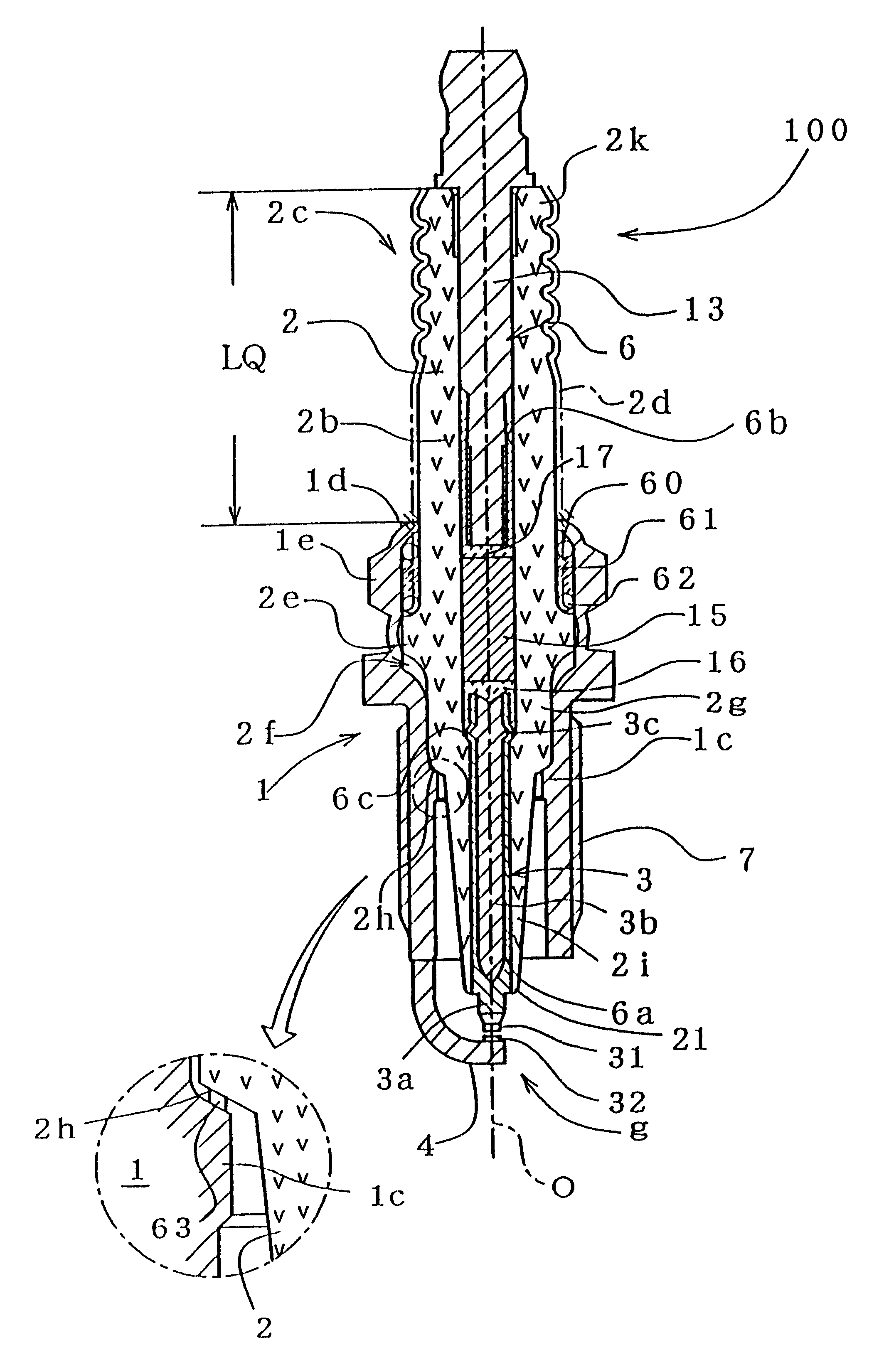

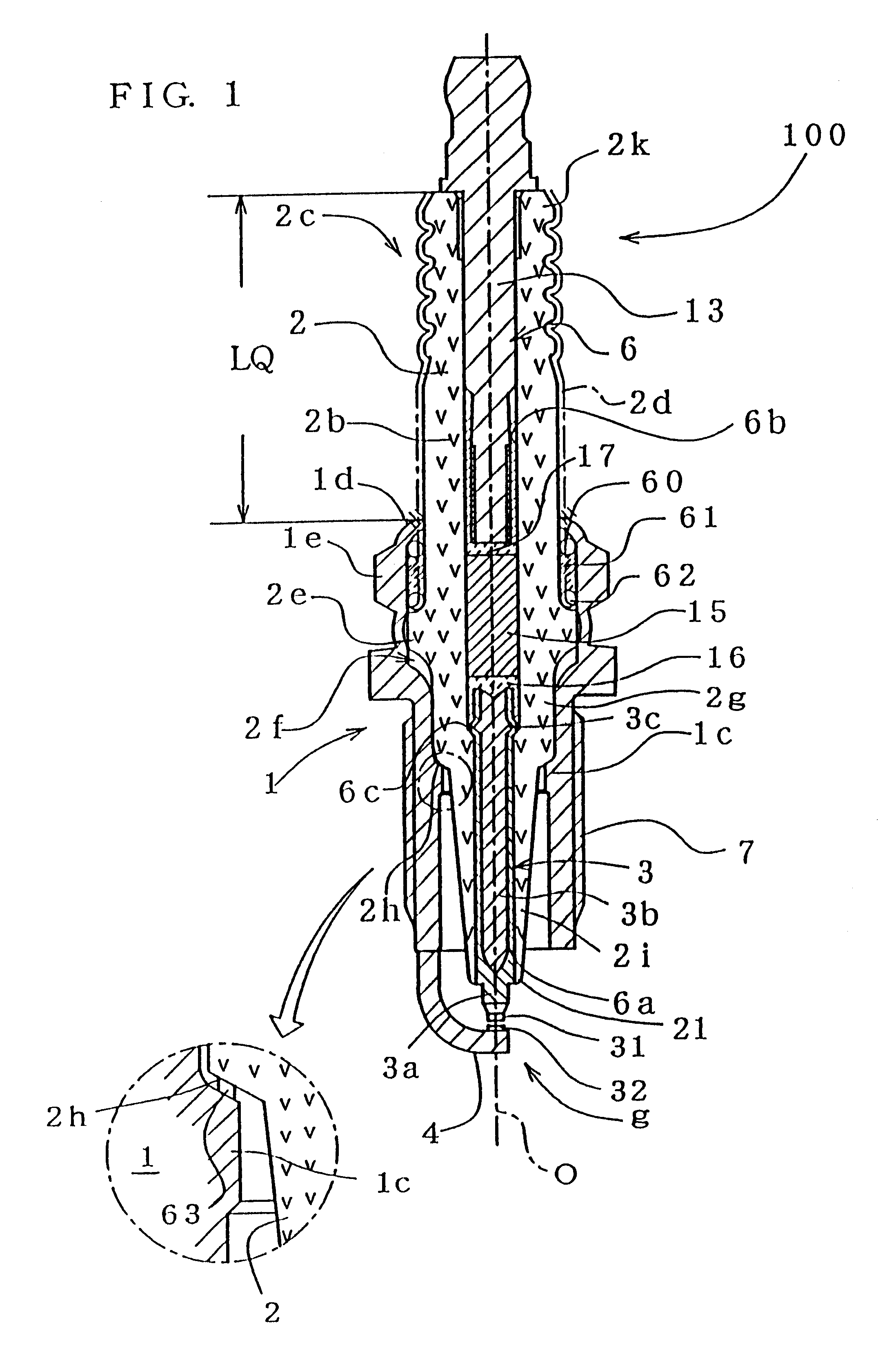

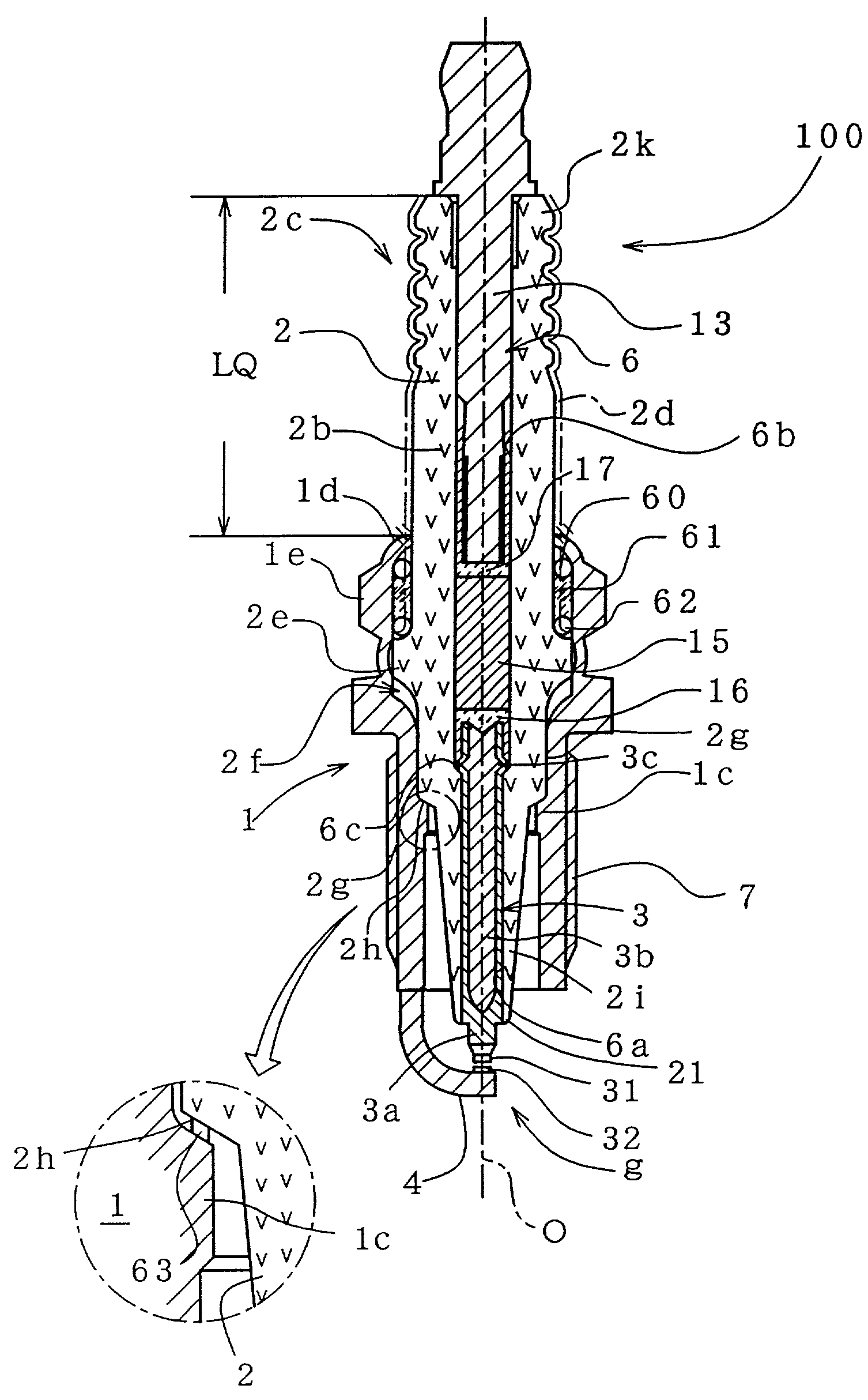

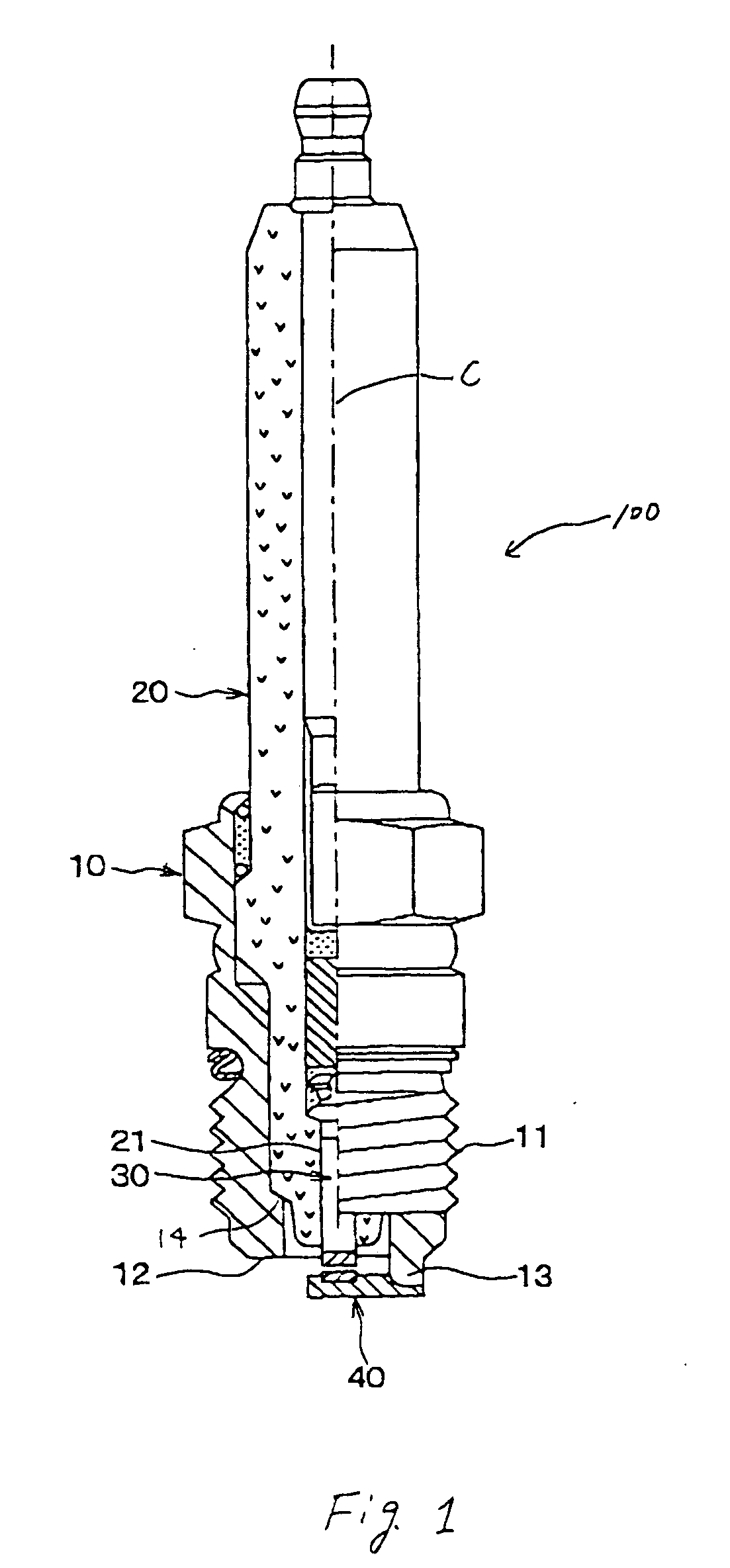

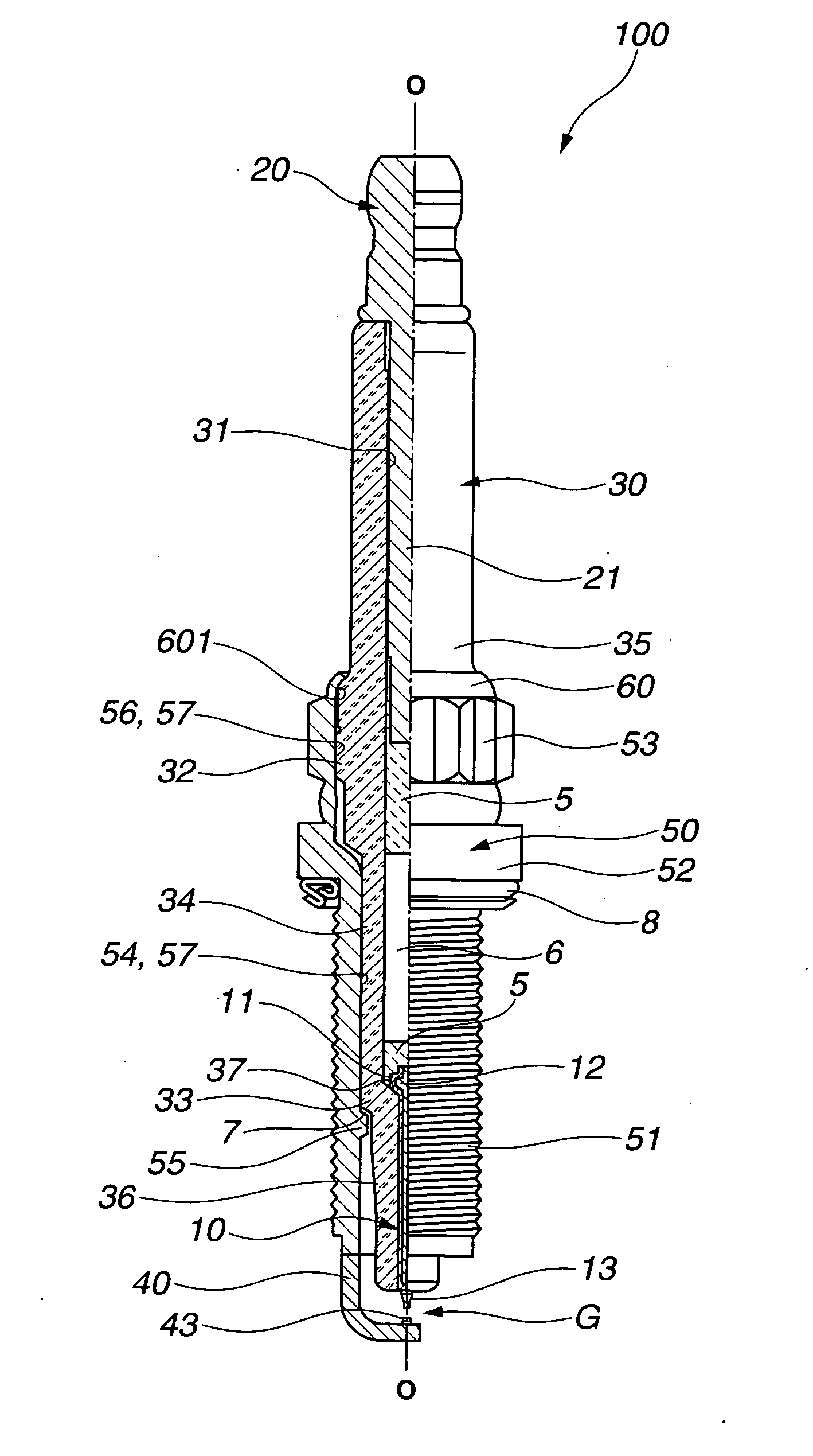

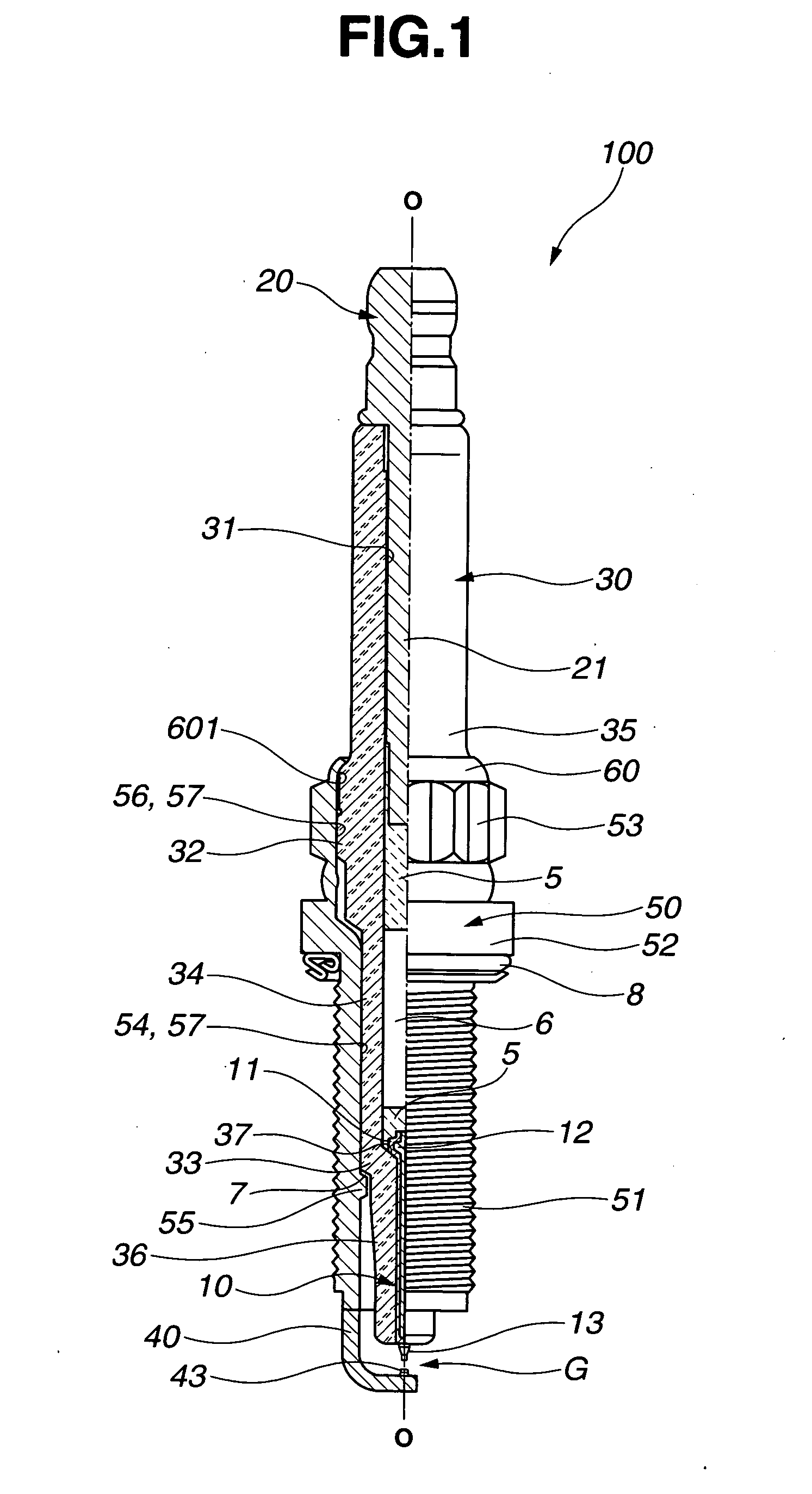

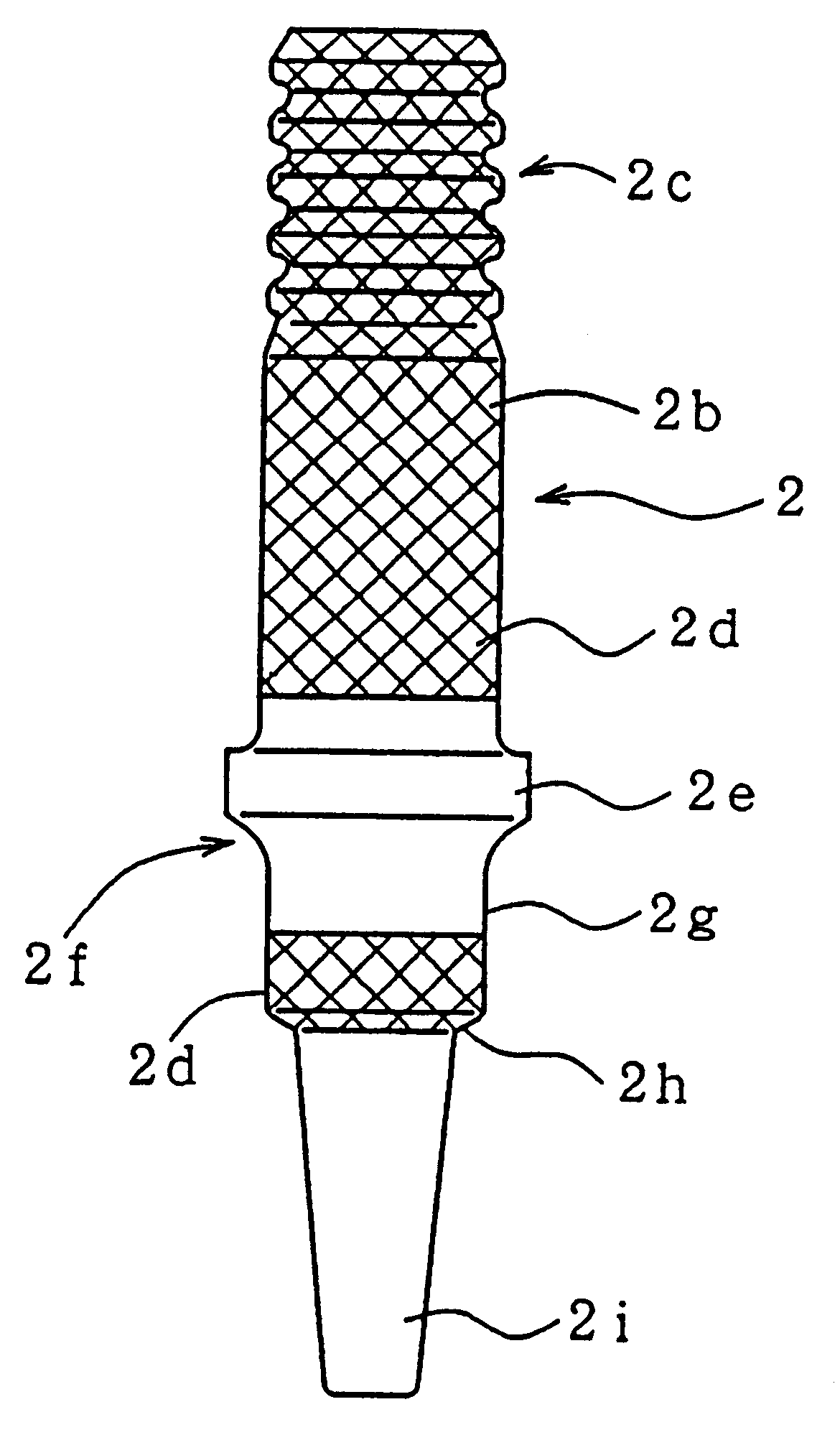

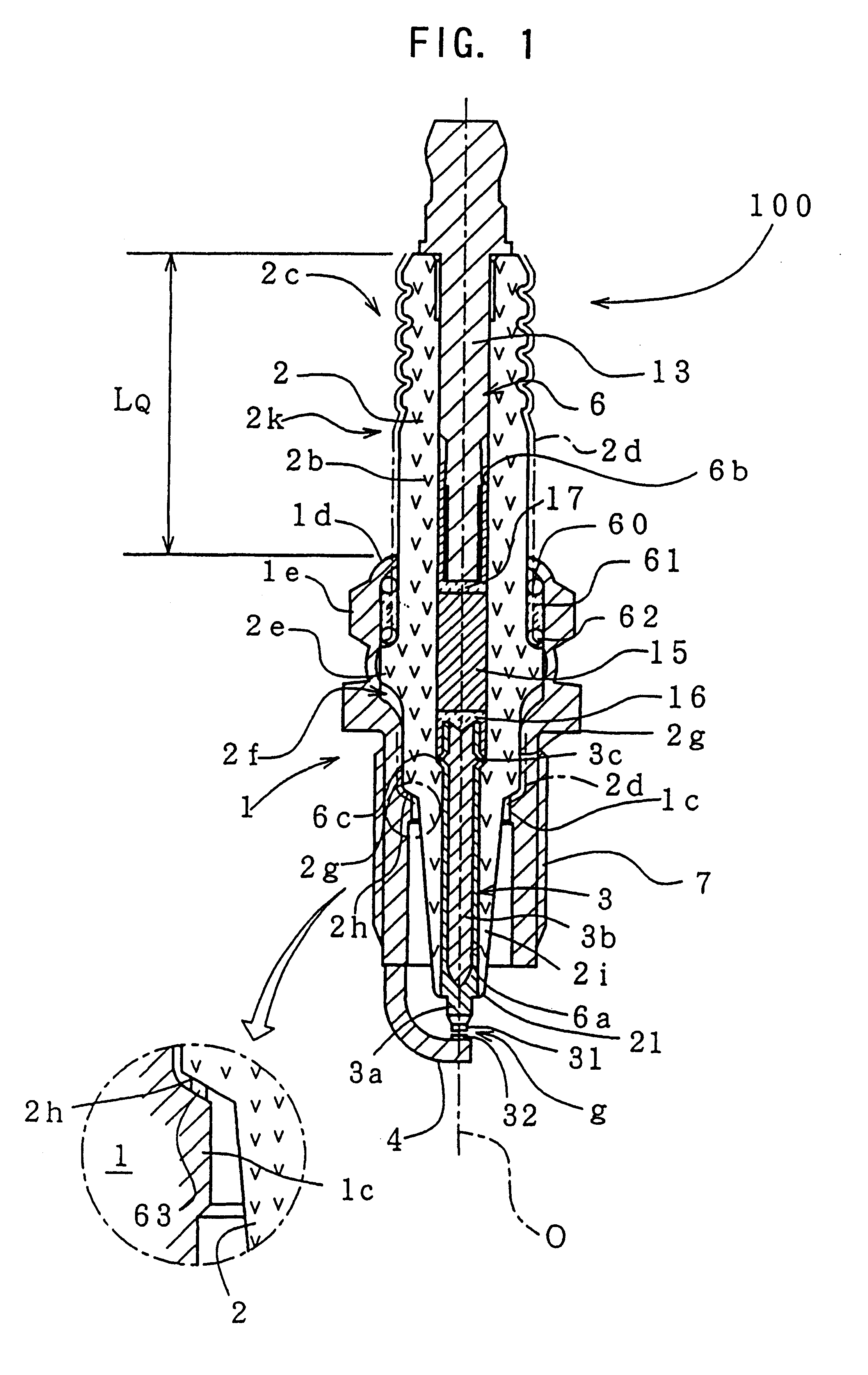

Spark plug, alumina insulator for spark plug, and method of manufacturing the same

InactiveUS6407487B1Low costLow production costSpark gapsCeramic shaping apparatusElectrical resistance and conductanceUltimate tensile strength

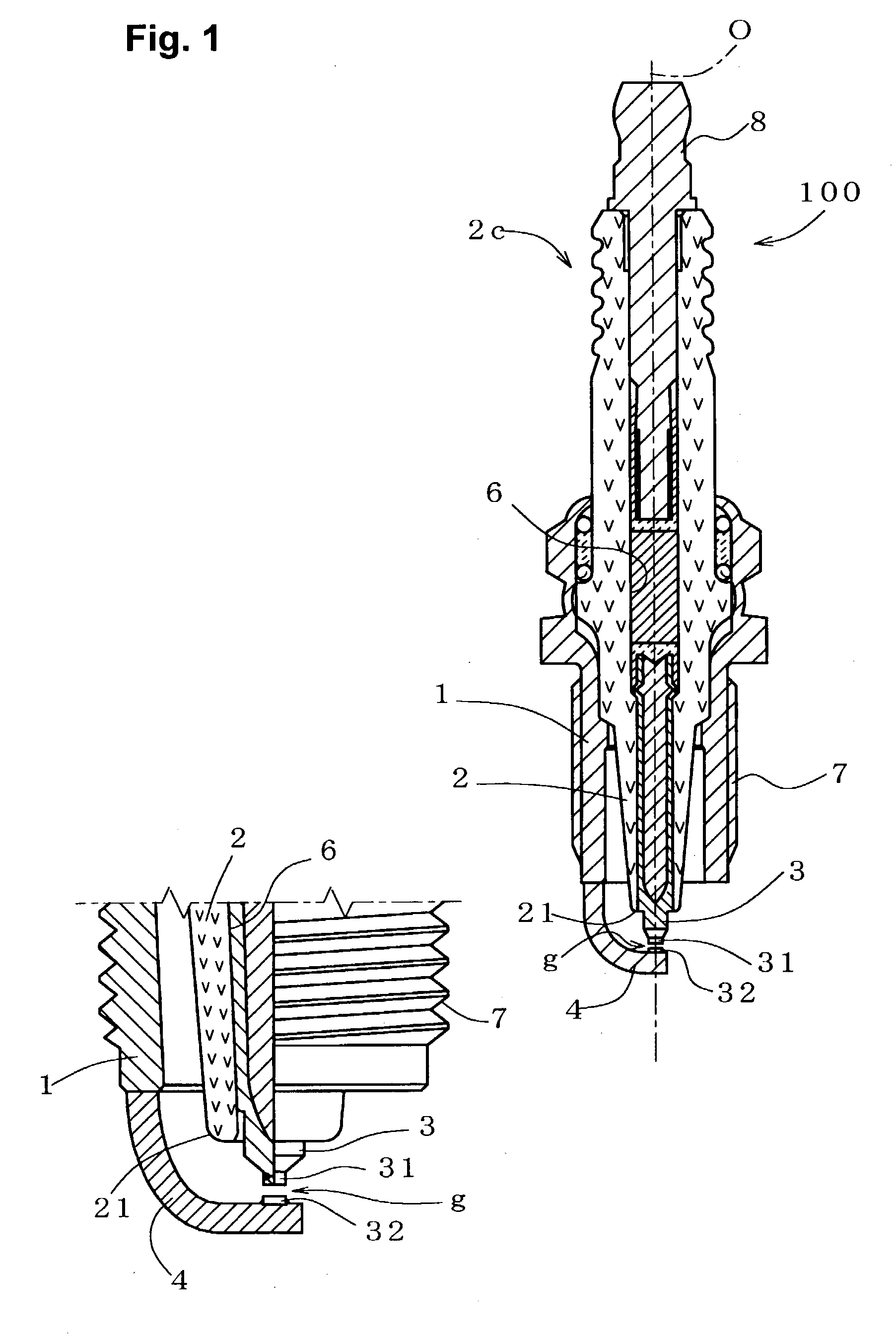

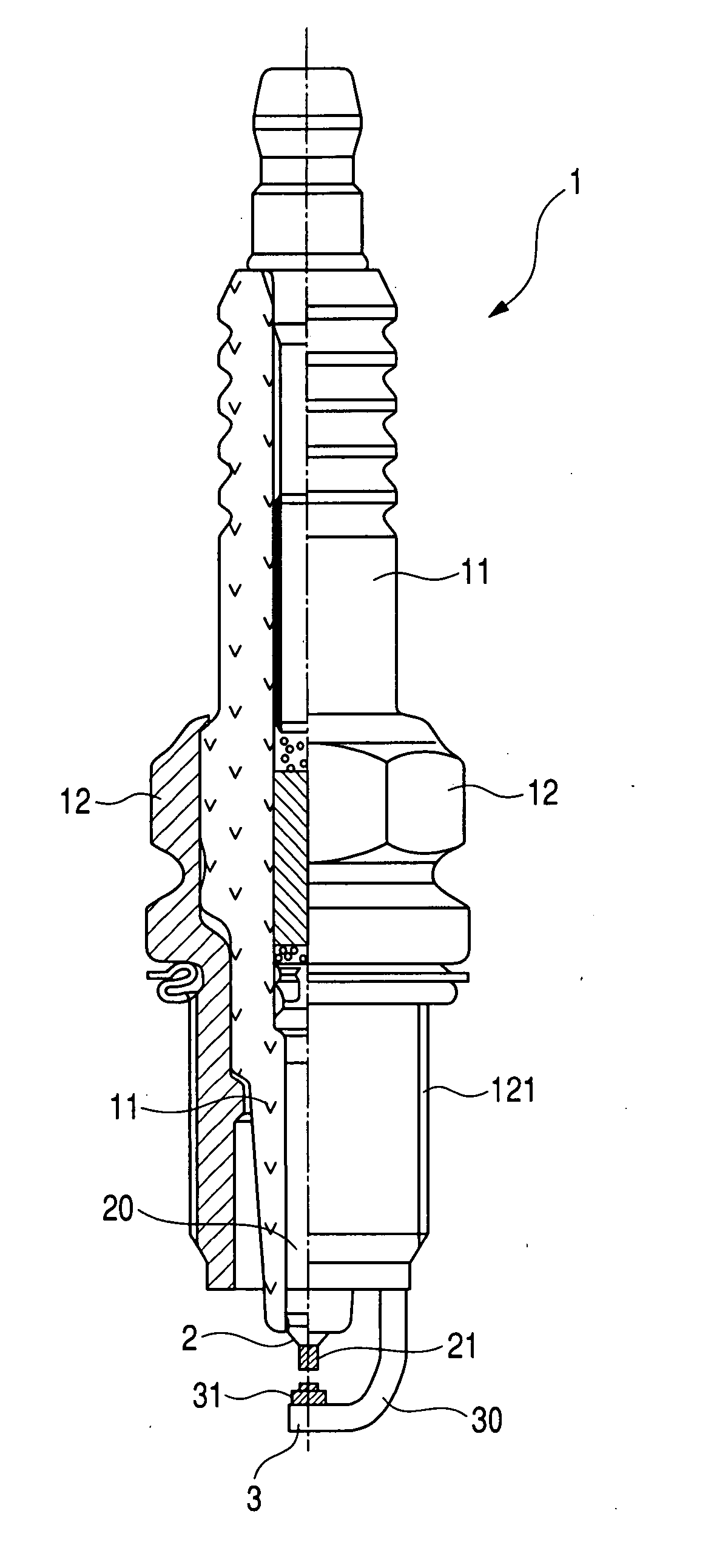

In insulator including alumina as a main component, a Na component in the insulator is set in the range of 0.07 to 0.5 wt % as Na2O. While the Na component content is as high as to have conventionally been regarded to be beyond the common sense, with this range of the Na component content, insulation resistance, mechanical strength and the like at high temperature are unexpectedly not reduced and an insulator with performances comparable to those of an insulator from conventional low soda alumina lower in Na component content than the above described range can be obtained. As a result, medium soda alumina and regular soda alumina that are much lower in cost than conventionally used low soda alumina can be used instead of the low soda alumina, so that dramatic reduction in production costs of insulator 2 for a spark plug 100 and in addition, of the spark plug 100 using the insulator 2 are realized.

Owner:NGK SPARK PLUG CO LTD

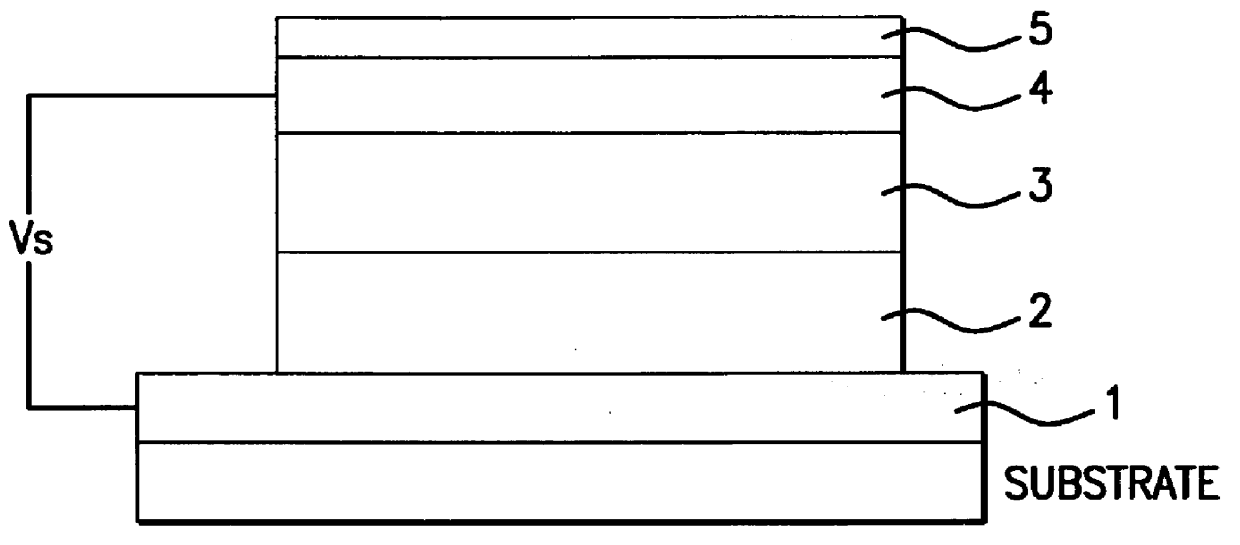

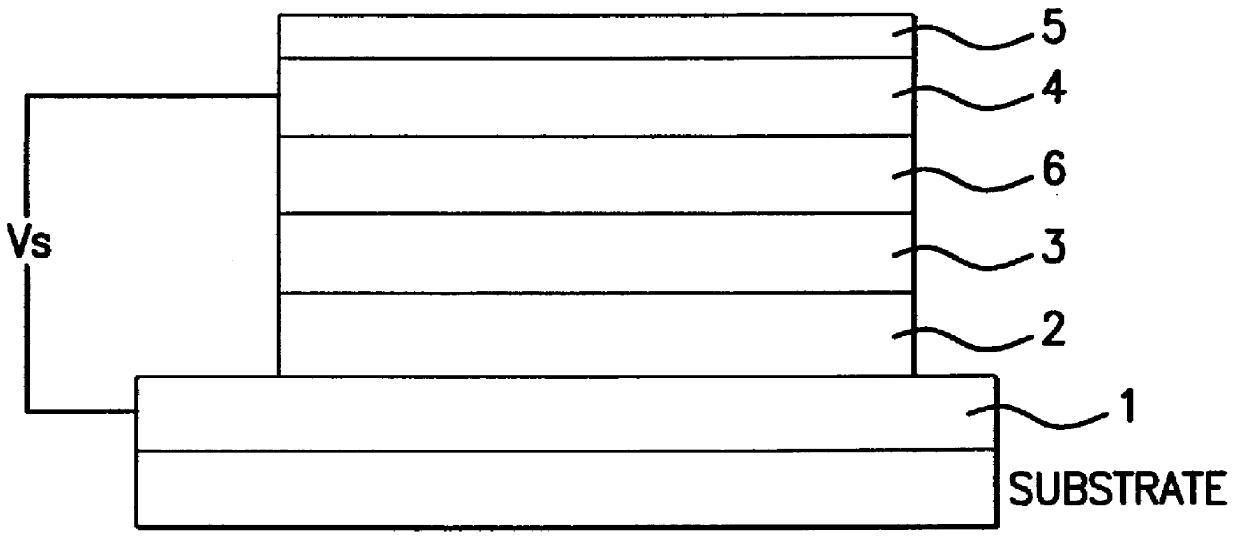

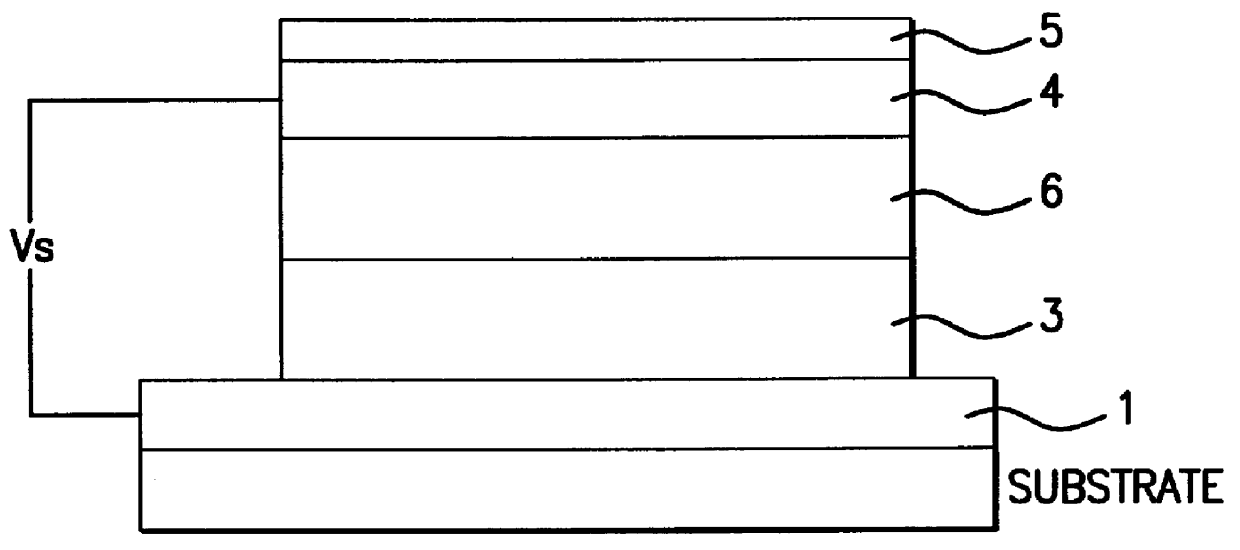

Organic electroluminescent element having an excimer light irradiated positive electrode and method of manufacturing the same

InactiveUS6060826ALow luminescence starting potentialLuminous properties are stableSpark gapsDischarge tube luminescnet screensOrganic layerOrganic electroluminescence

The purpose of the present invention is to provide an organic electroluminescent element having uniform surface luminescence, large luminescence intensity, and excellent stability over repeated use. The present invention provides a method of manufacturing an organic electroluminescent element using a positive electrode irradiated by excimer light when manufacturing an organic electroluminescent element comprising at least a substrate on which is sequentially formed a positive electrode, organic layer including an organic luminescent layer, and negative electrode, and an organic electroluminescent element manufactured by said method.

Owner:KONICA MINOLTA INC

Spark plug, alumina based insulator for spark plug and production process for same insulator

InactiveUS20020024160A1Facilitate spark consumptionIncrease contentCeramic shaping apparatusSparking plugs manufactureElectrical resistance and conductanceUltimate tensile strength

In insulator including alumina as a main component, a Na component in the insulator is set in the range of 0.07 to 0.5 wt % as Na2O. While the Na component content is as high as to have conventionally been regarded to be beyond the common sense, with this range of the Na component content, insulation resistance, mechanical strength and the like at high temperature are unexpectedly not reduced and an insulator with performances comparable to those of an insulator from conventional low soda alumina lower in Na component content than the above described range can be obtained. As a result, medium soda alumina and regular soda alumina that are much lower in cost than conventionally used low soda alumina can be used instead of the low soda alumina, so that dramatic reduction in production costs of insulator 2 for a spark plug 100 and in addition, of the spark plug 100 using the insulator 2 are realized.

Owner:NGK SPARK PLUG CO LTD

Spark plug designed to ensure high strength of electrode joint and production method thereof

ActiveUS20050174025A1Improve joint strengthEliminate needSpark gapsSparking plugs manufactureHigh intensityIncreased sizes

An improved structure of a spark plug is provided to ensure a high strength of joint between a ground electrode and a metal shell. The ground electrode is resistance-welded to the metal shell so that it is embedded partially in an end surface of the metal shell to create a weld interface extending from the end surface to an inner periphery of the metal shell, thus resulting in an increased size of the weld interface to increase the joint strength. The resistance welding keeps the temperature of a weld between the ground electrode and the metal shell at a lower level during welding as compared with laser welding, thus minimizing solidification cracking in the weld.

Owner:DENSO CORP

Corona tip insulator

This invention relates to a corona discharge ignitor used to ignite air / fuel mixtures in automotive applications and the like. To suppress an arc from forming when a voltage is applied to the ignitor, the corona discharge ignitor has various shapes and configurations, such as angular depressions or grooves, at the tip of the insulator. The shape and configuration of the tip provides a smaller radius which creates a more intensified electric field and provides better combustion.

Owner:TENNECO INC

Corona igniter with improved corona control

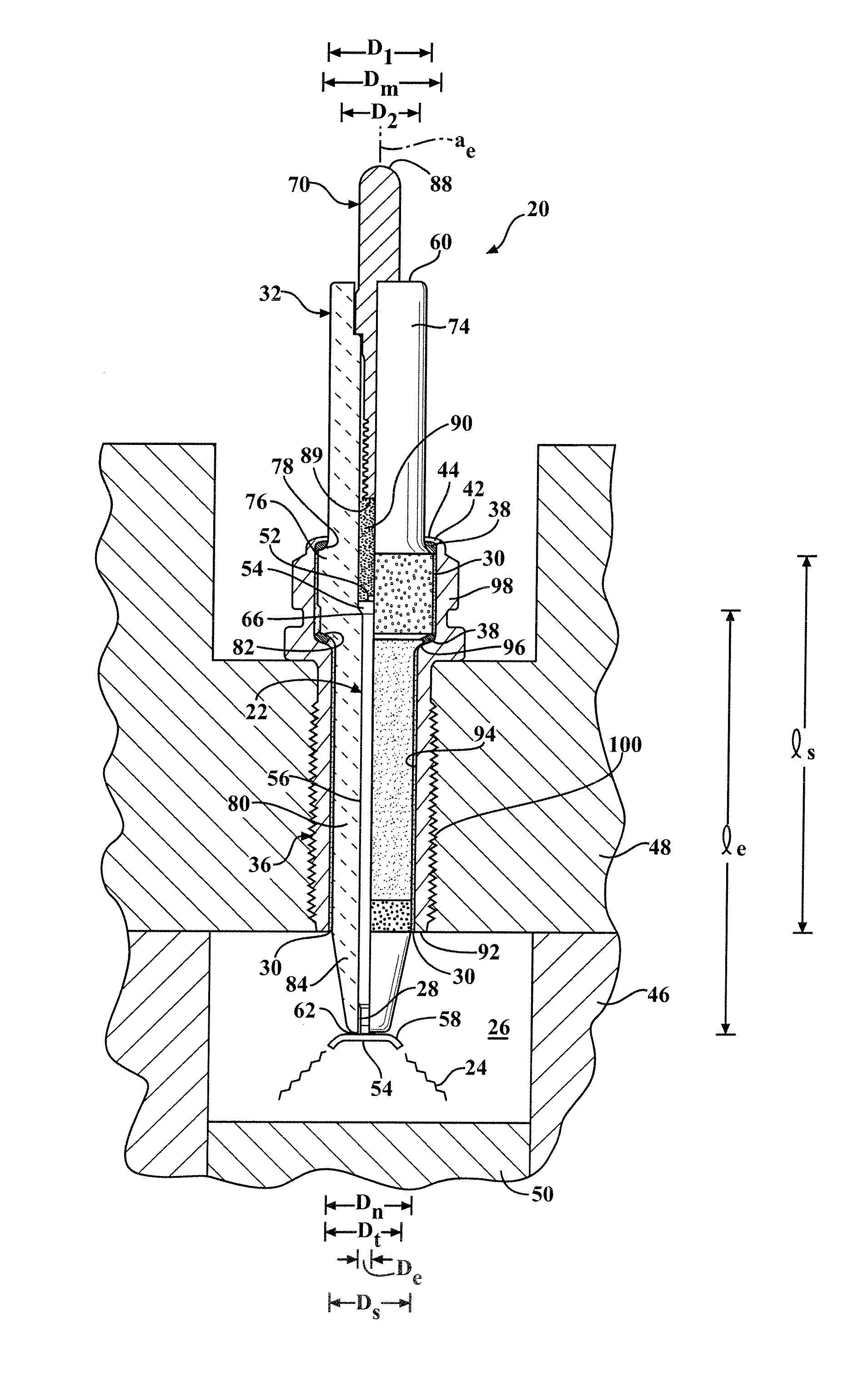

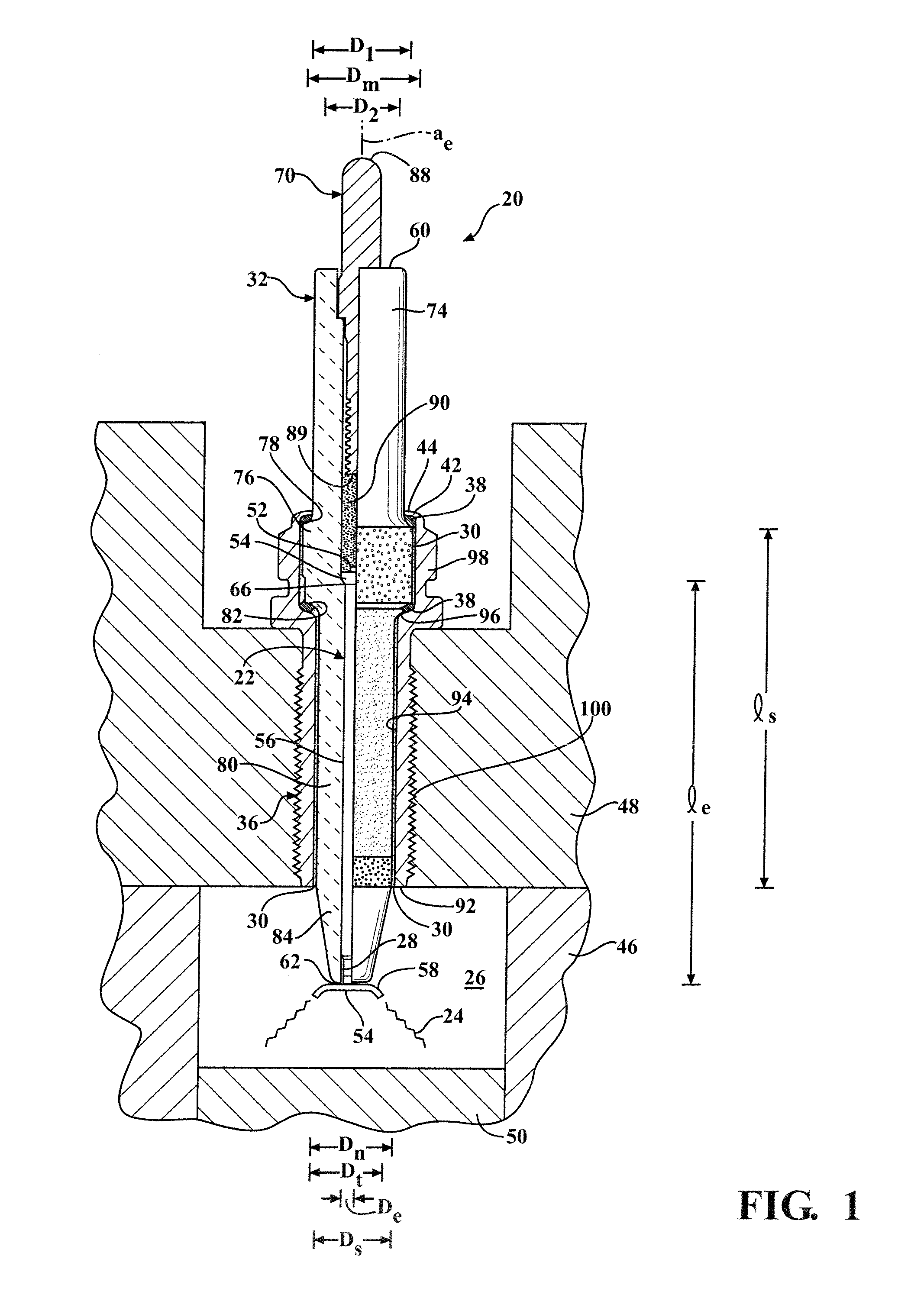

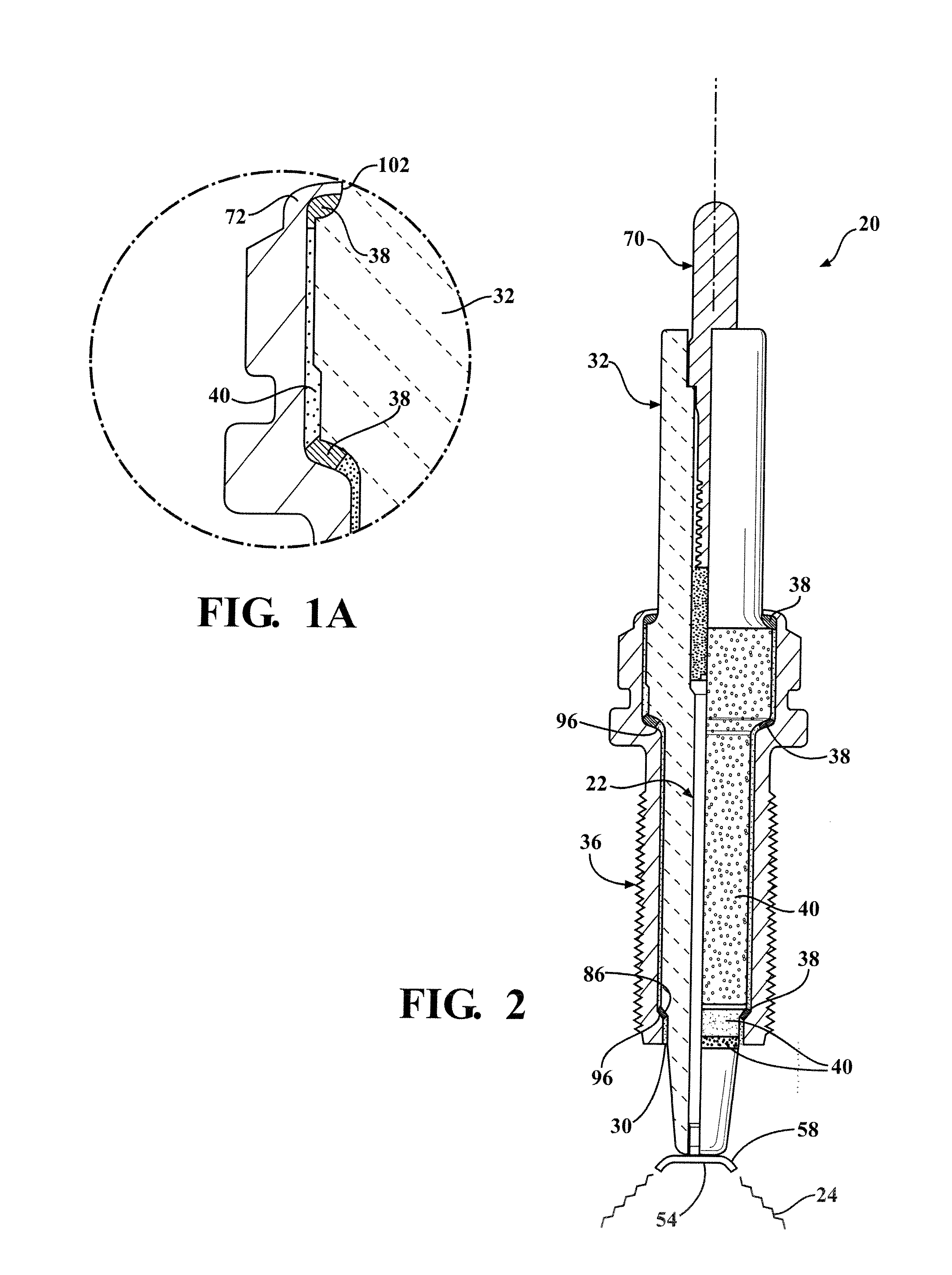

InactiveUS20120210968A1Prevent ionizationReduce gapCombustion enginesEngine ignitionCorona dischargeVoltage drop

A corona igniter 20 includes an electrode gap 28 between the central electrode 22 and the insulator 32 and a shell gap 30 between the insulator 32 and the shell 36. The gaps 28, 30 are filled with a filler material 40 to prevent corona discharge 24 in the gaps 28, 30 and to concentrate the energy at a firing tip 58 of the central electrode 22. The filler material 40 may be electrically insulating or conductive. The shell gap width ws may be greatest at a shell lower end 92. The shell gap 30 may also be in a turnover region between a shell upper end 44 and the insulator 32, in which case the filler material 40 is injection molded around the turnover region. During operation of the igniter 20, the filler material 40 provides a reduced voltage drop across the gap 28, 30.

Owner:FEDERAL MOGUL IGNITION

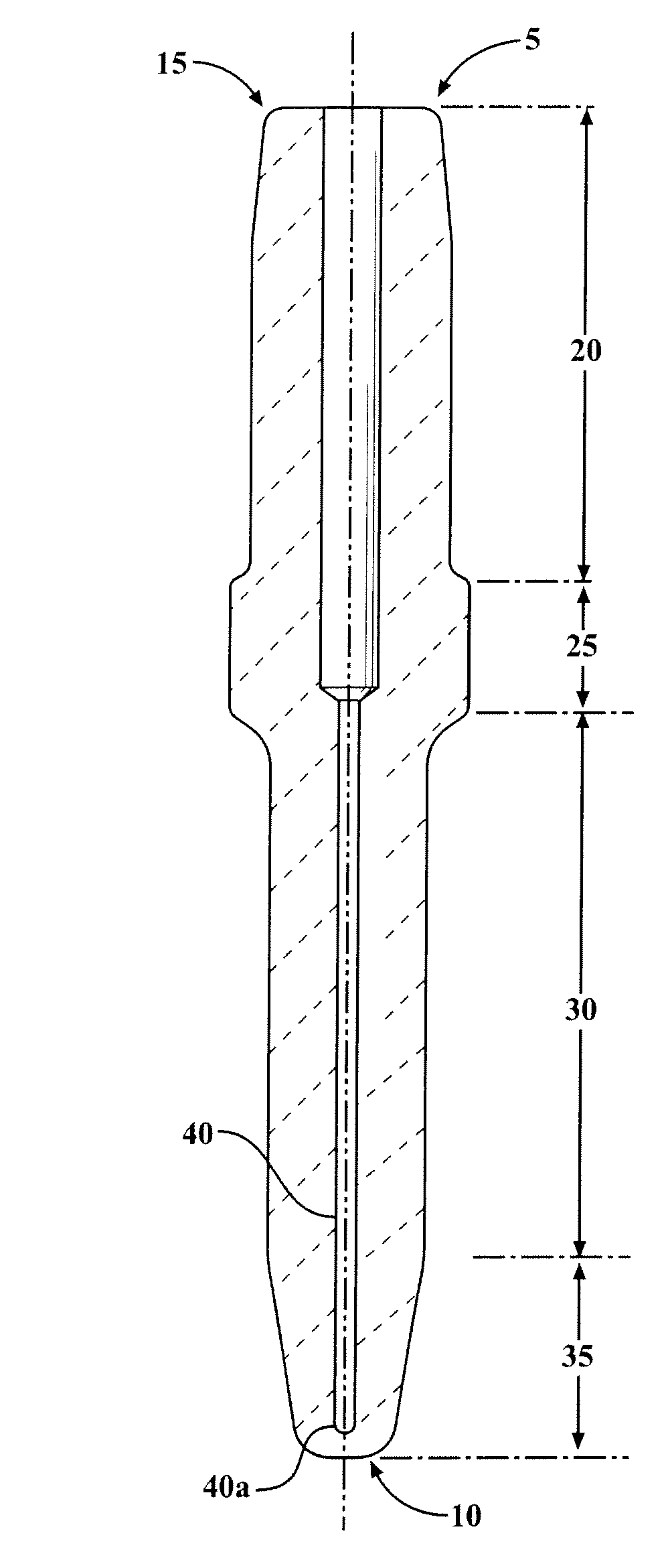

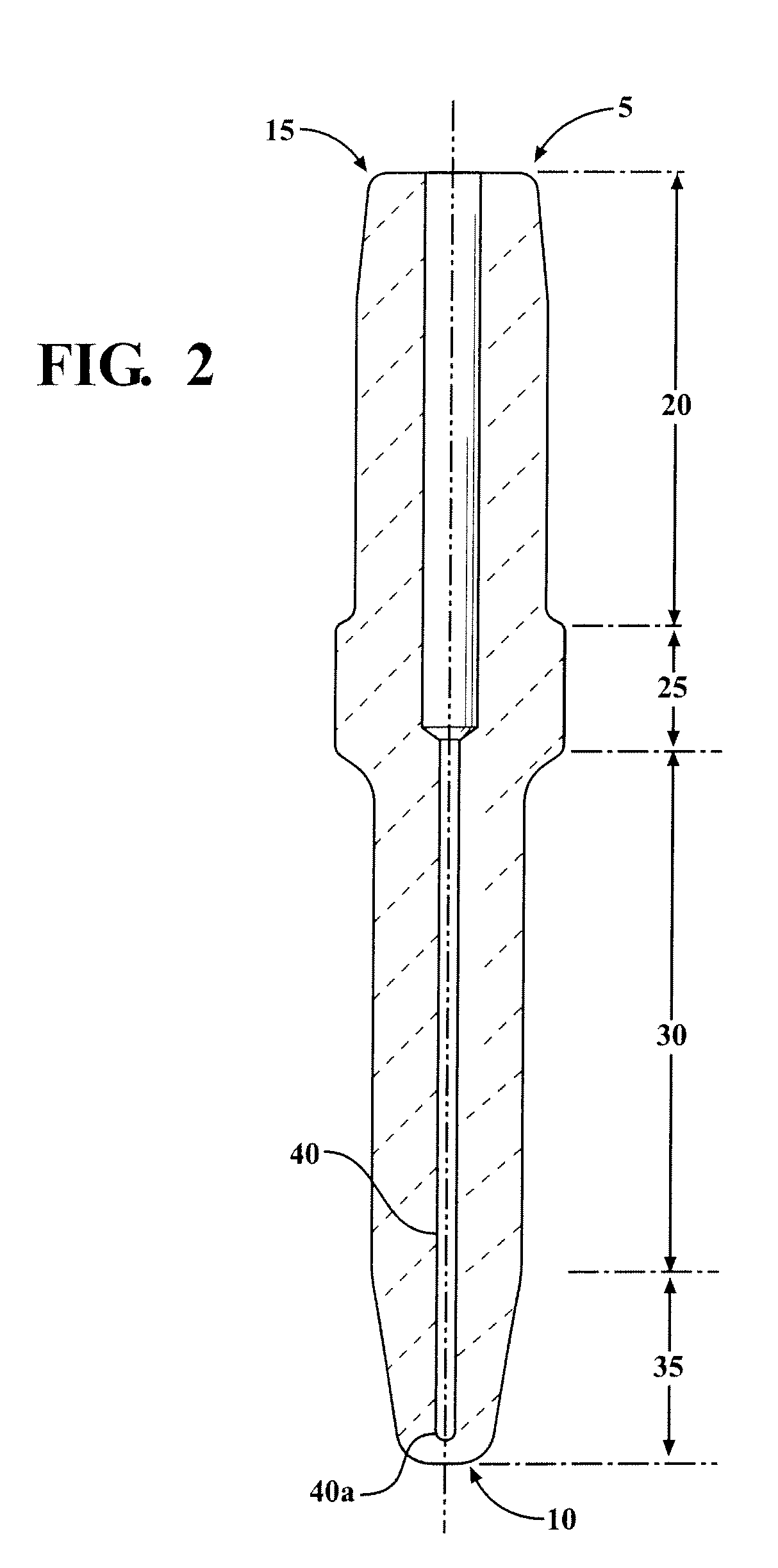

Heater equipped spark plug

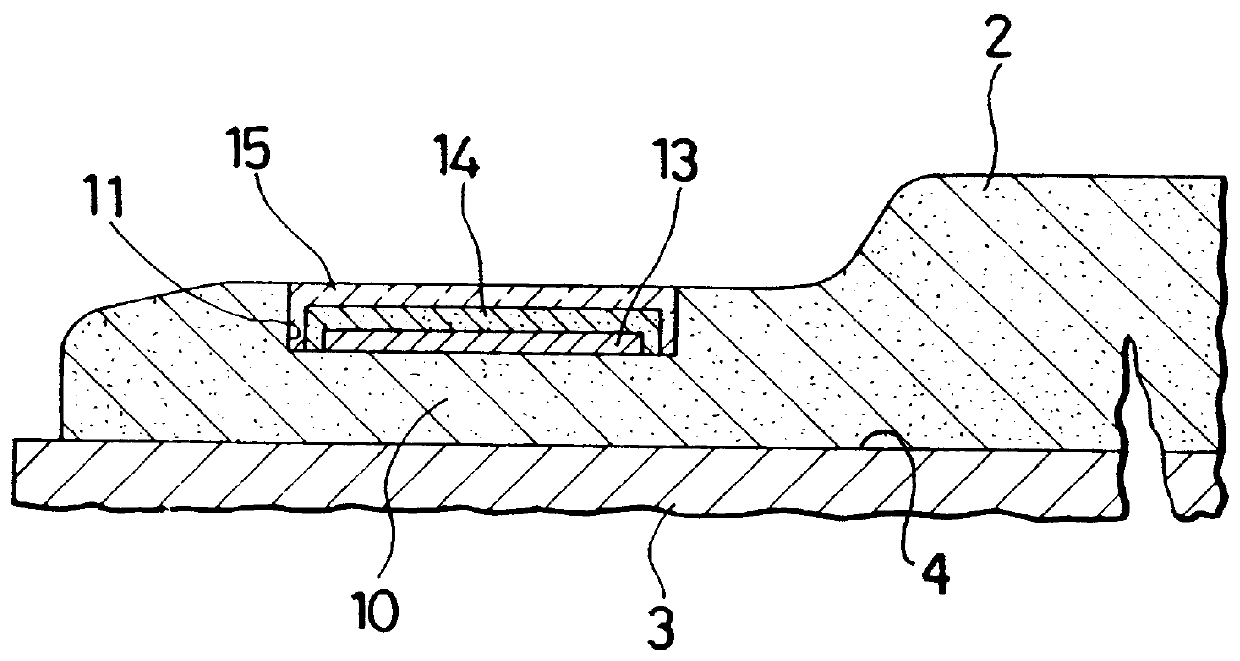

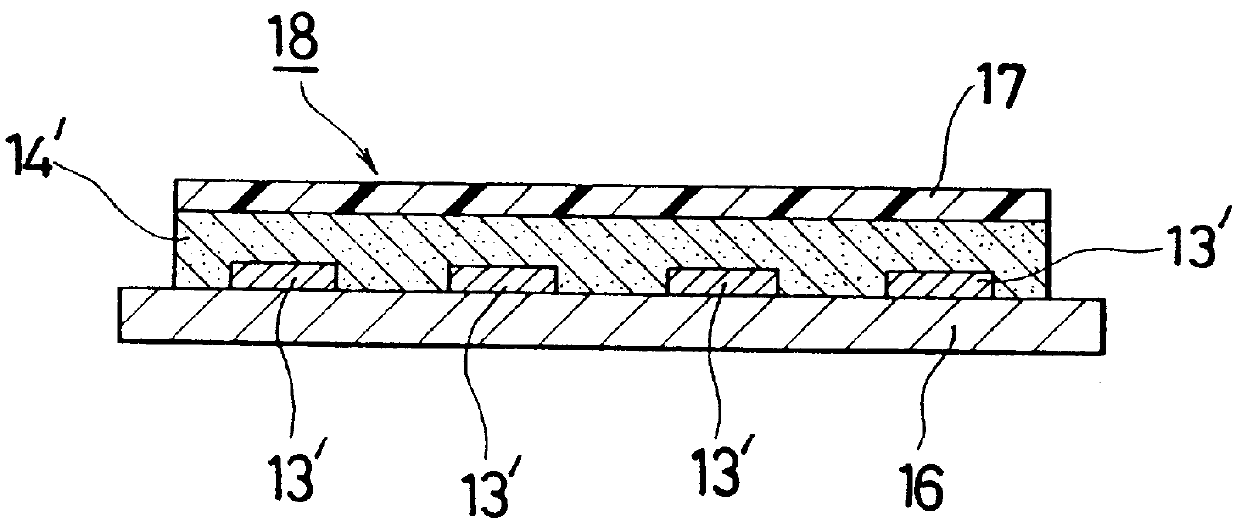

InactiveUS6060821ASufficient voltage withstand performanceImprove insulation performanceSpark gapsGenerator generated ignition energyEngineeringMetal

A heater-equipped spark plug comprises an insulator having an insulator nose which holds thereon a center electrode in the vicinity of a free end of an axial bore, a lead wire arranged along a surface of the insulator, a heater formed on the insulator nose by baking a metal paste and connected to the lead wire; and a high softening-point glass layer covering and holding the heater in place with an alumina layer interposed between the high softening-point glass and the heater. Preferably, the alumina layer can have a thickness of 20-200 mu m and the high softening-point glass layer can have a thickness of 30-500 mu m.

Owner:NGK SPARK PLUG CO LTD

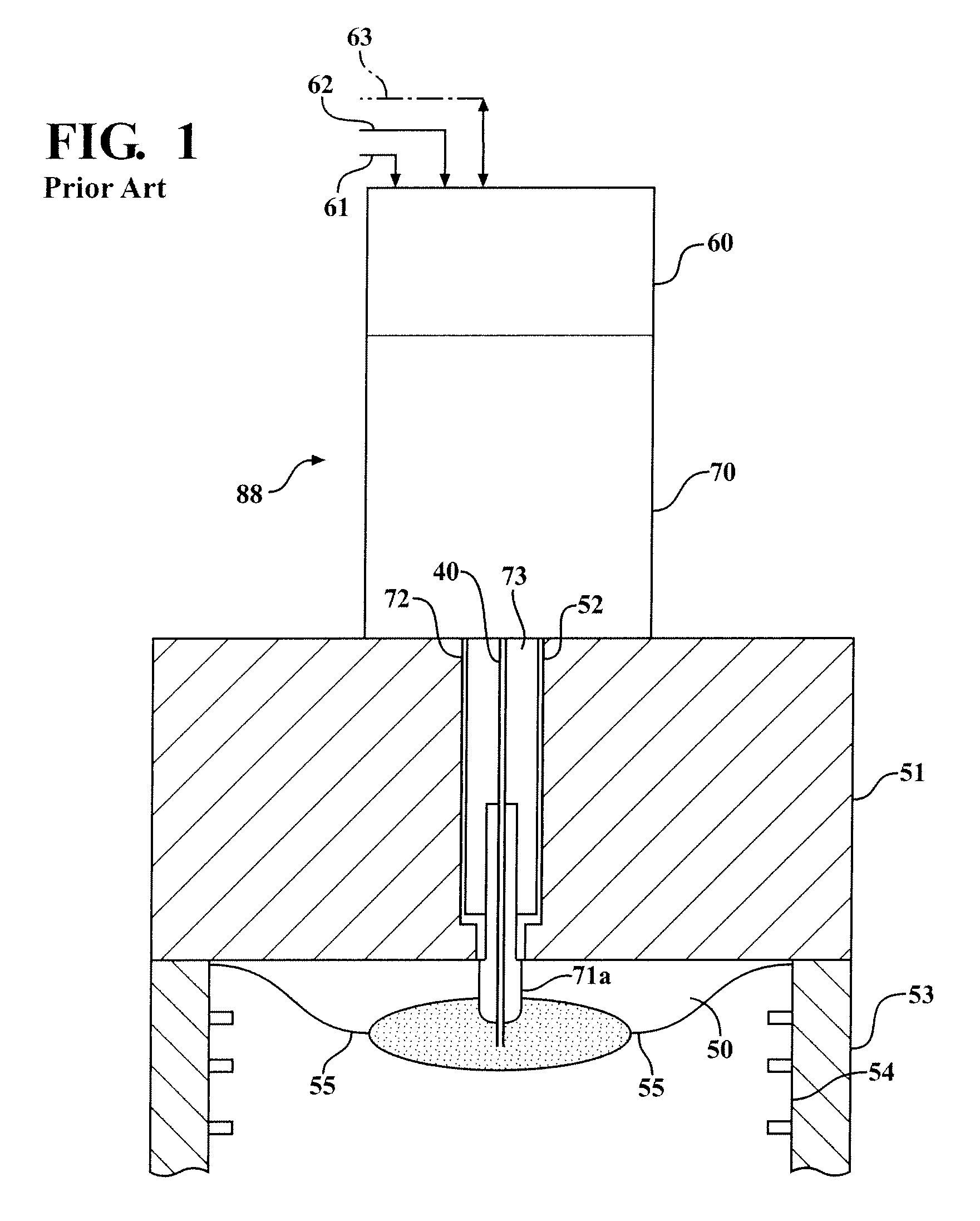

High power discharge fuel ignitor

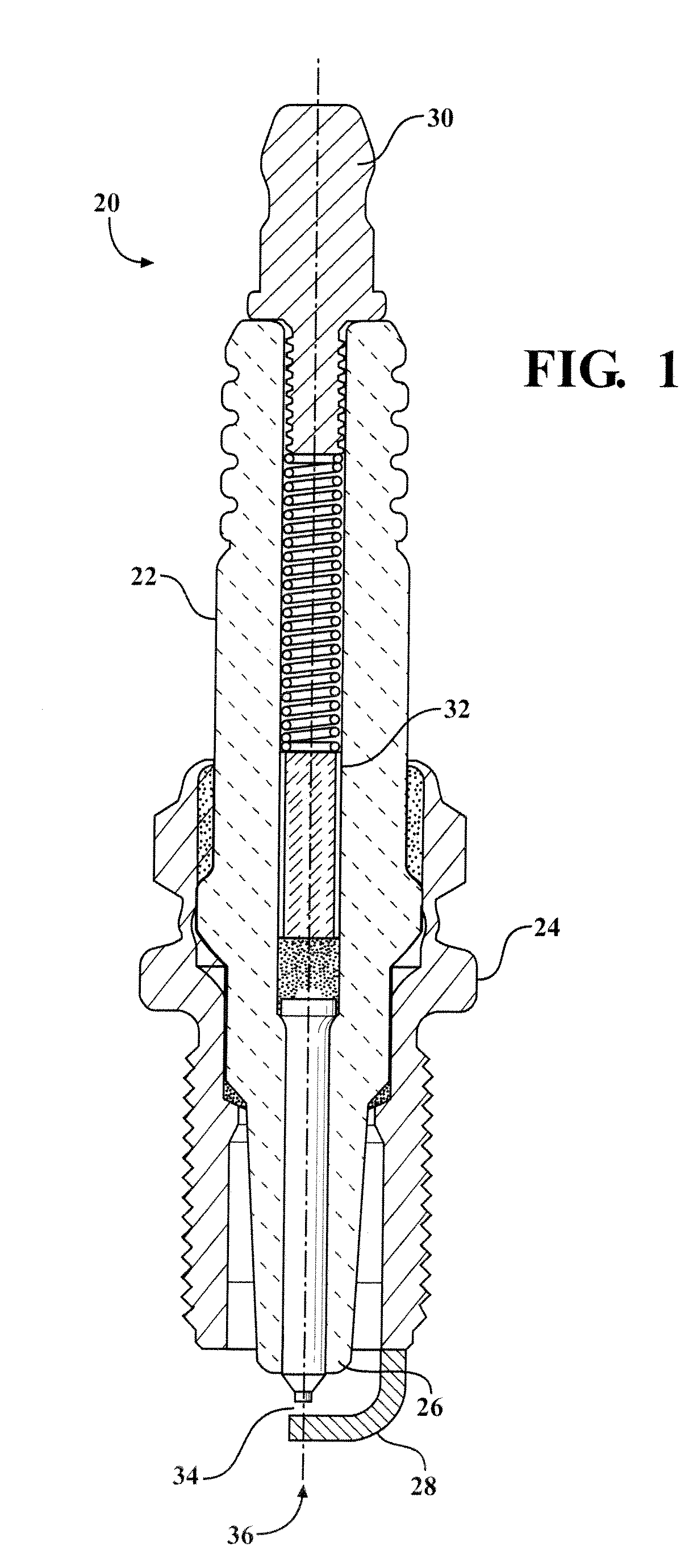

ActiveUS20080018216A1Reduce erosionGreat cross sectionSpark gapsMachines/enginesElectricityCombustion

A spark-ignited, internal combustion engine ignition device to increase electrical transfer efficiency of the ignition by peaking the electrical power of the spark during the streamer phase of spark creation and improving combustion quality, incorporating an electrode design and materials to reduce electrode erosion due to high power discharge, an insulator provided with capacitive plates to peak the electrical current of the spark discharge, and concomitant methods.

Owner:PASSAIC RIVER CO INC

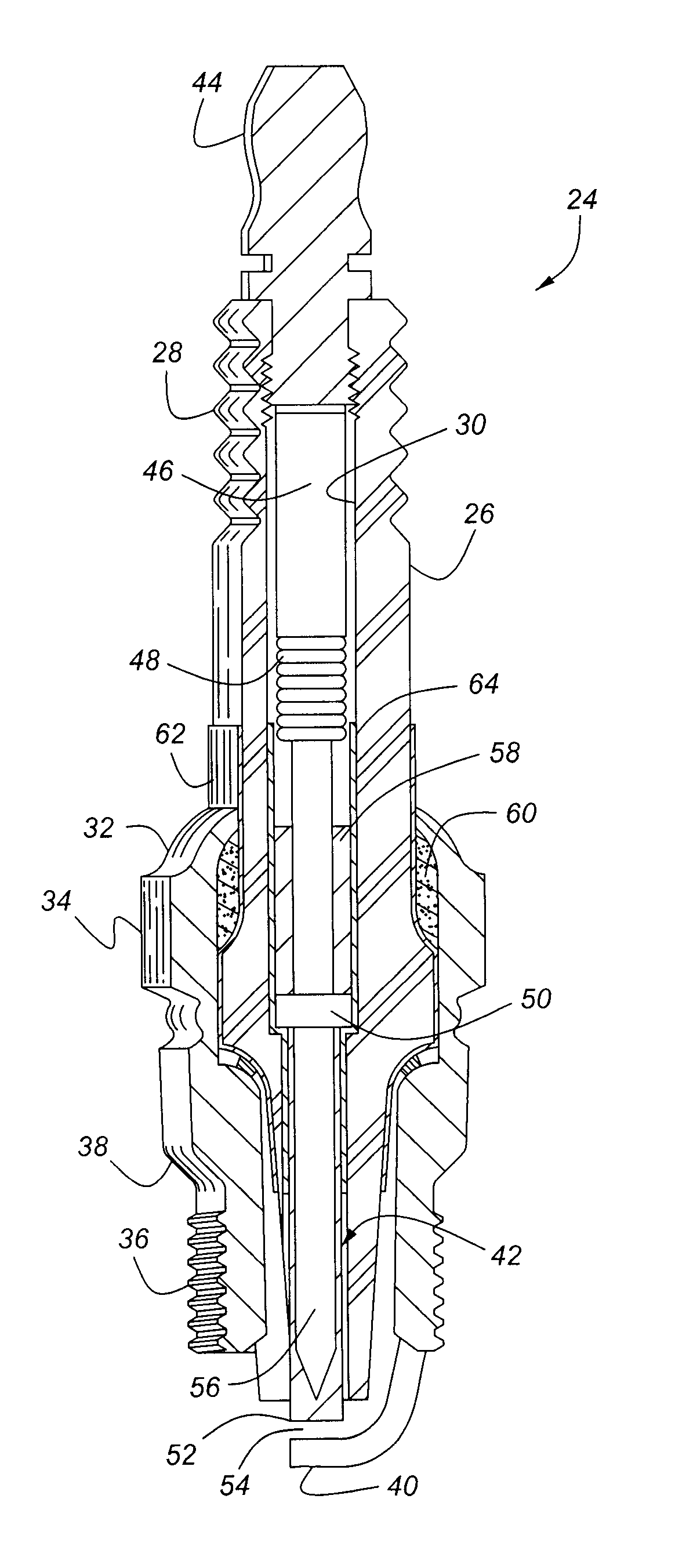

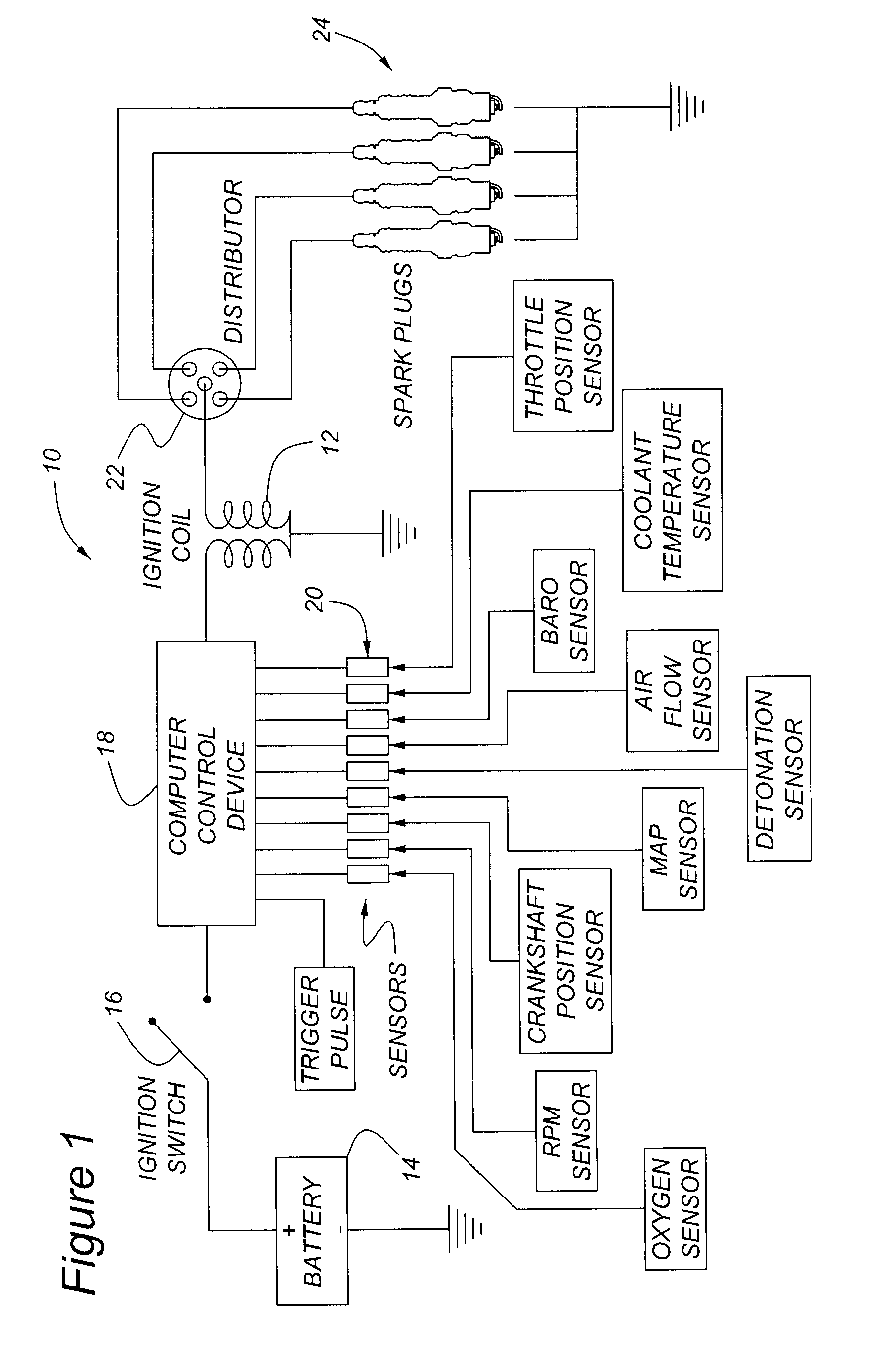

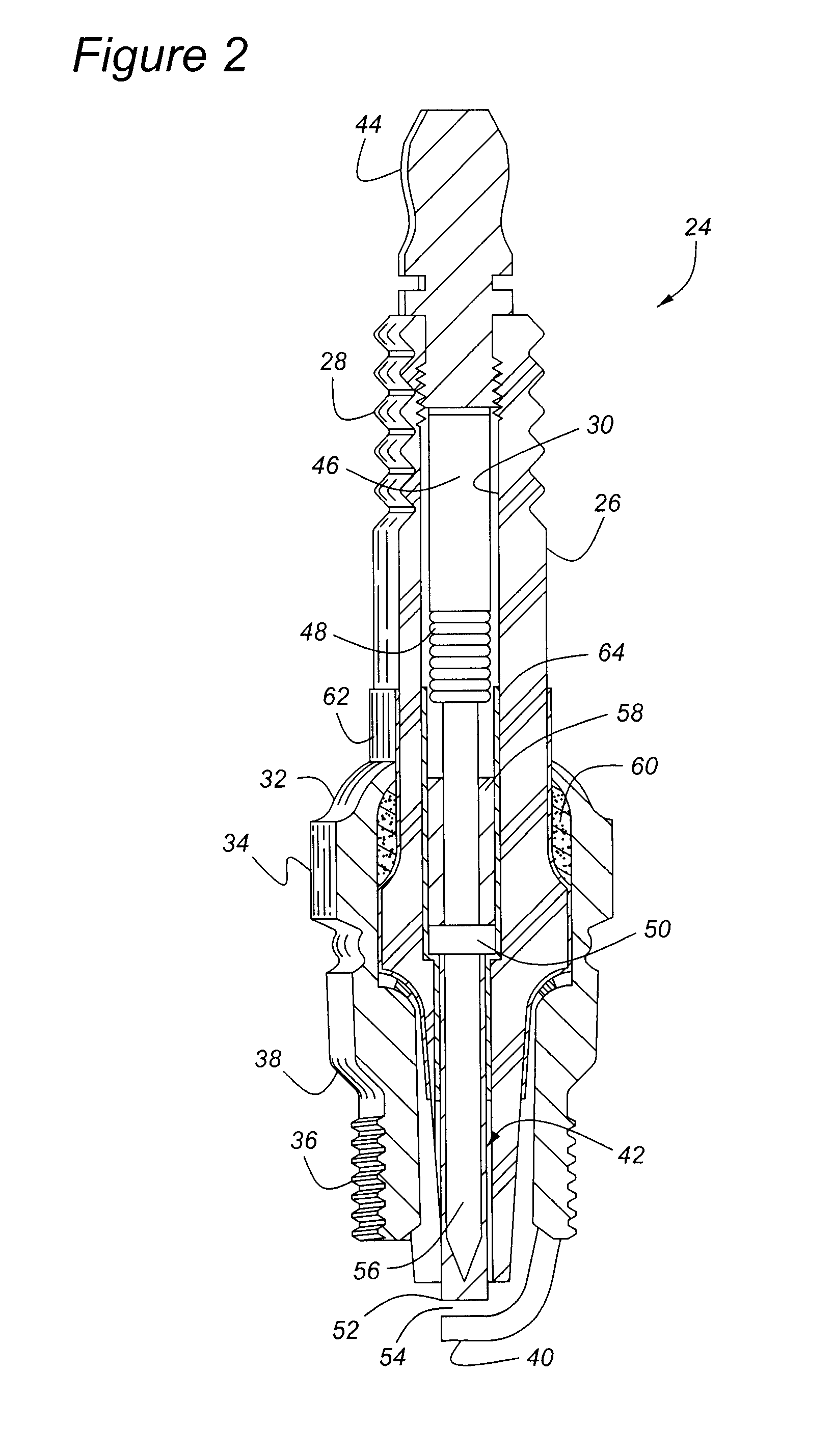

Metallic insulator coating for high capacity spark plug

A spark plug (24) is used in an ignition system (10) of the type for creating a precisely timed spark to ignite an air / fuel mixture in an internal combustion engine. The spark plug (24) is provided with an integrated capacitor feature to increase the intensity of its spark. The capacitor feature is formed by applying metallic film (62, 64) to the inner (30) and outer surfaces of a tubular insulator (26). The insulator (26), made from an alumina ceramic material, forms a dielectric and sustains an electrical charge when an electrical differential is established between the inner (64) and outer (62) metallic films. The stored electrical charge is discharged with the firing of a spark in the spark gap (54). The inner (64) and outer (62) metallic films can be applied as a paint or ink directly to the surfaces of the insulator (26), or can be mixed with a glazing compound to form conductive coatings simultaneous with the glazing operation. Ganged (62′) or serpentine (62″) micro-plates can be formed within either or both of the inner and outer metallic films to increase the charge-carrying surface area. The metallic film (62, 64) is specially selected from materials that will not migrate into the porous matrix of the ceramic insulator (26). The metallic film (62, 64) is preferably gold, platinum, copper, or a platinum group metal.

Owner:PASSAIC RIVER CO INC

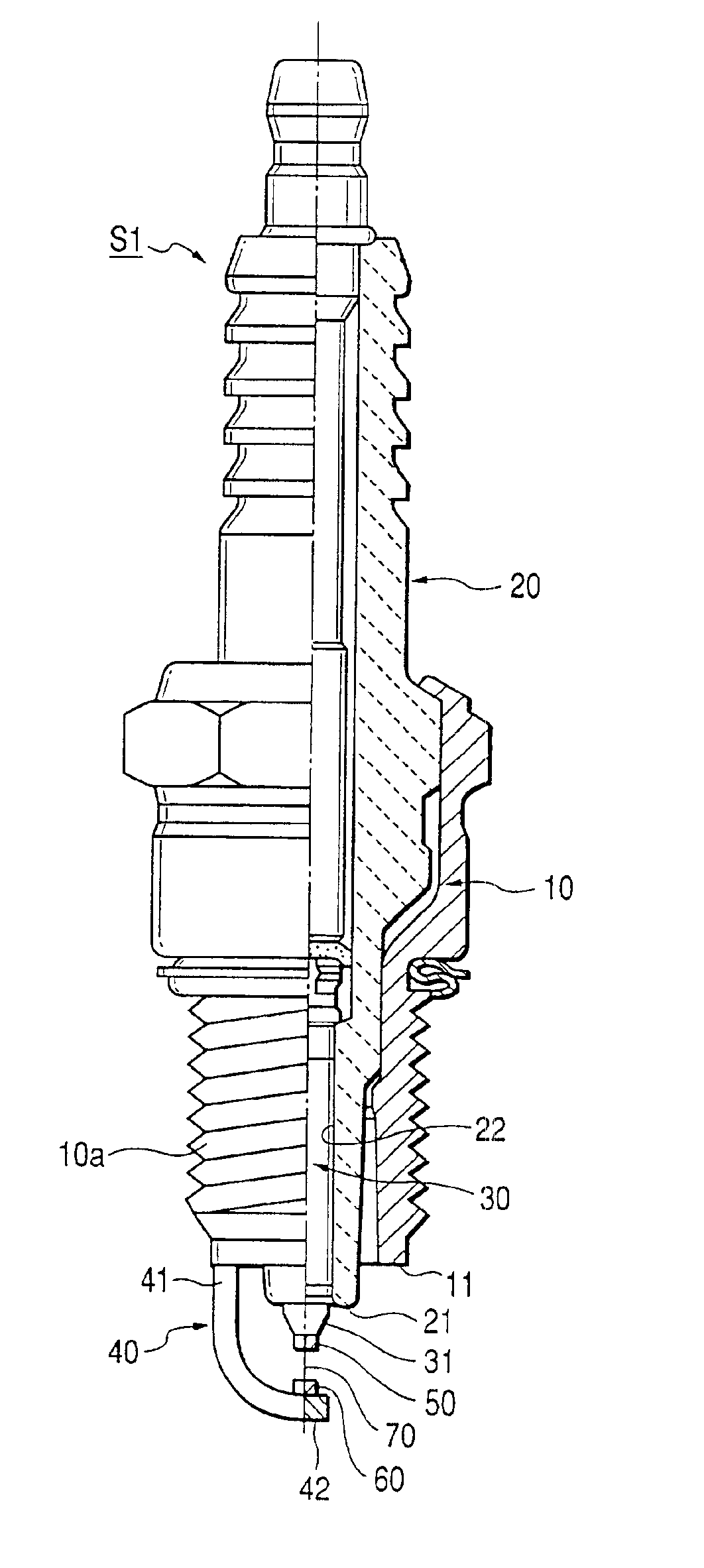

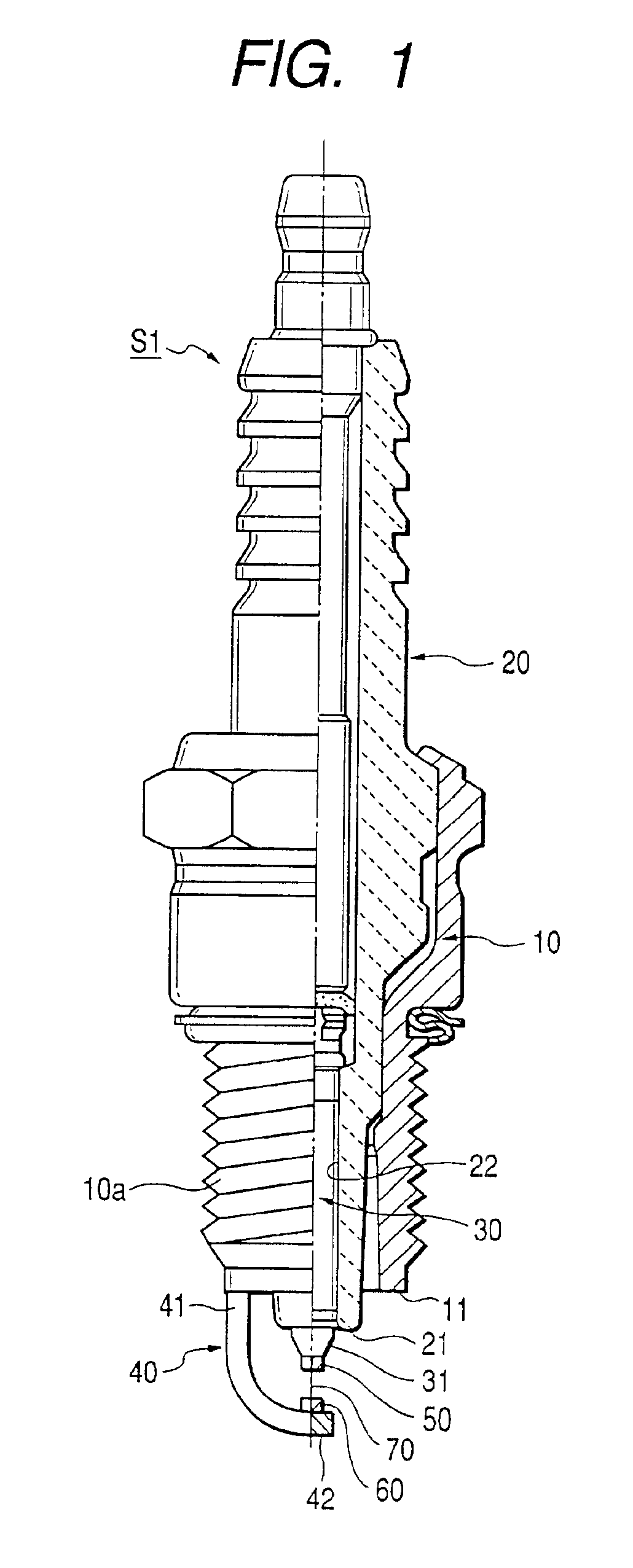

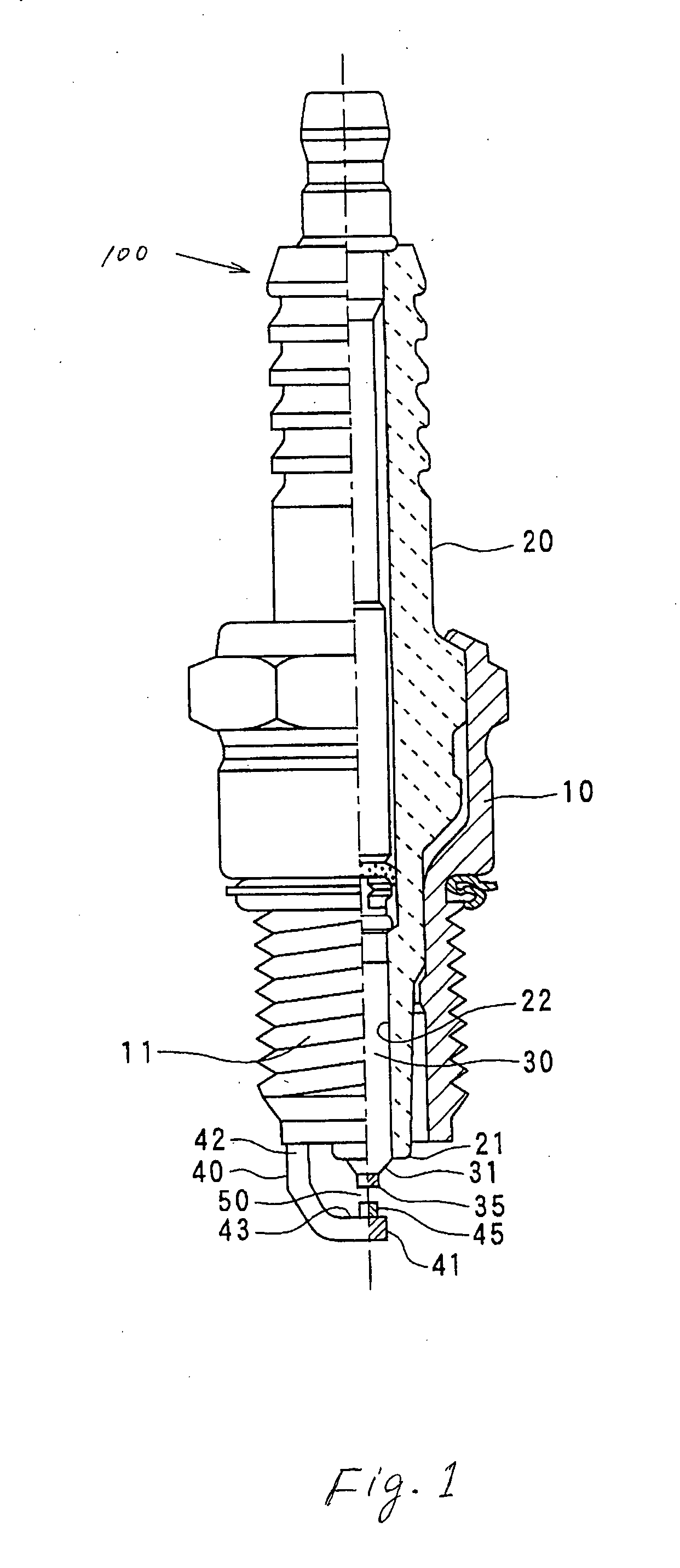

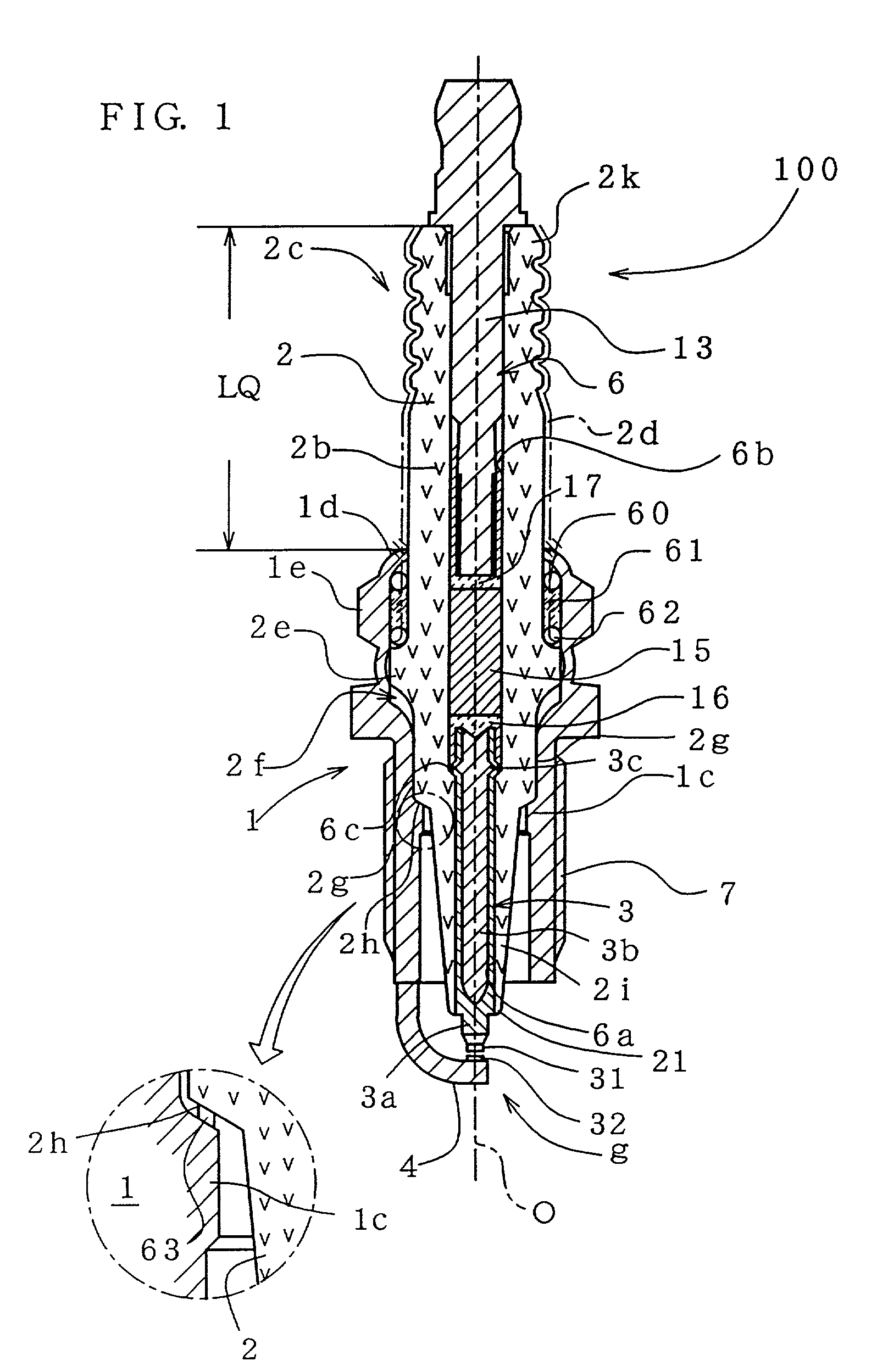

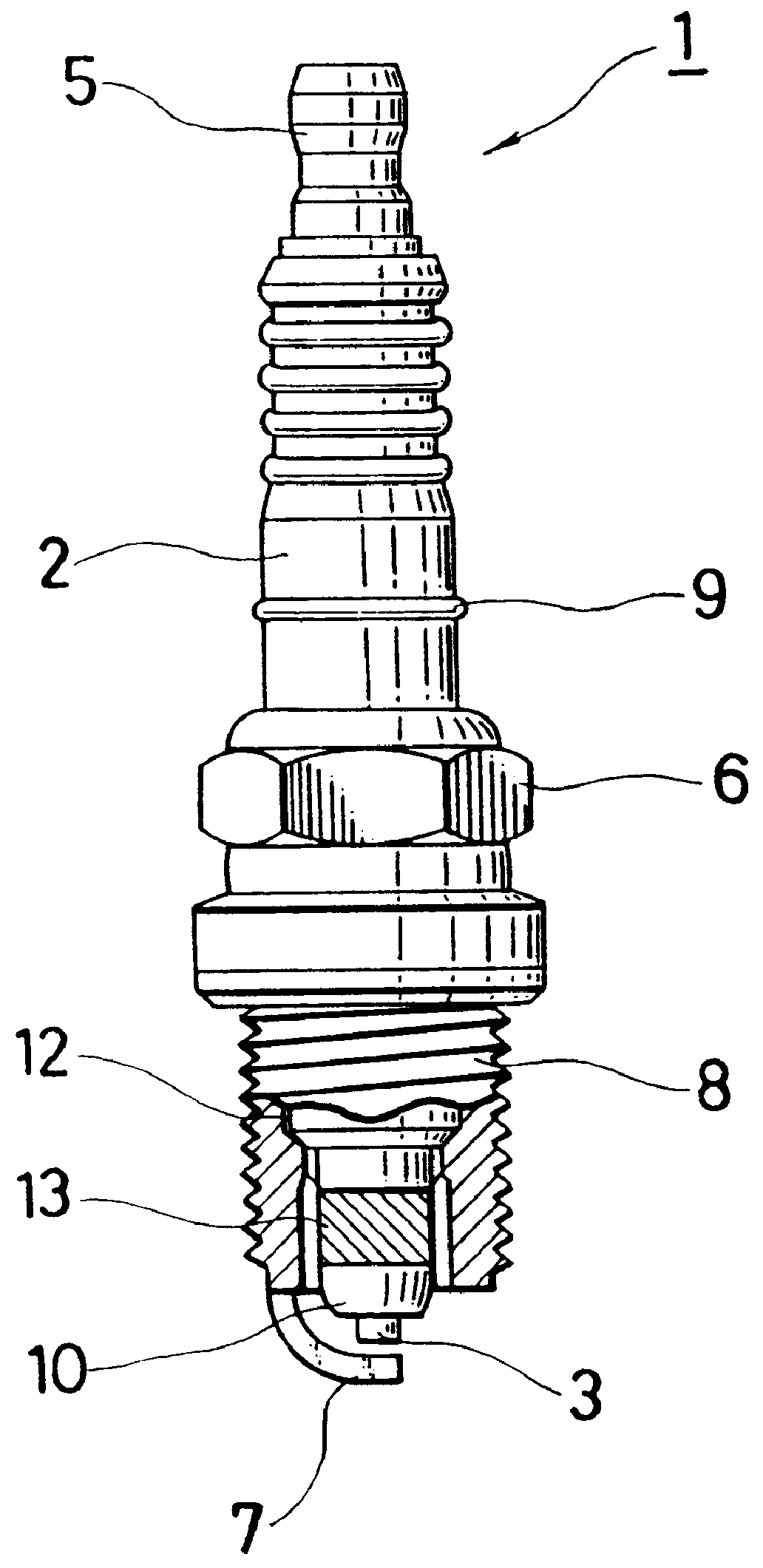

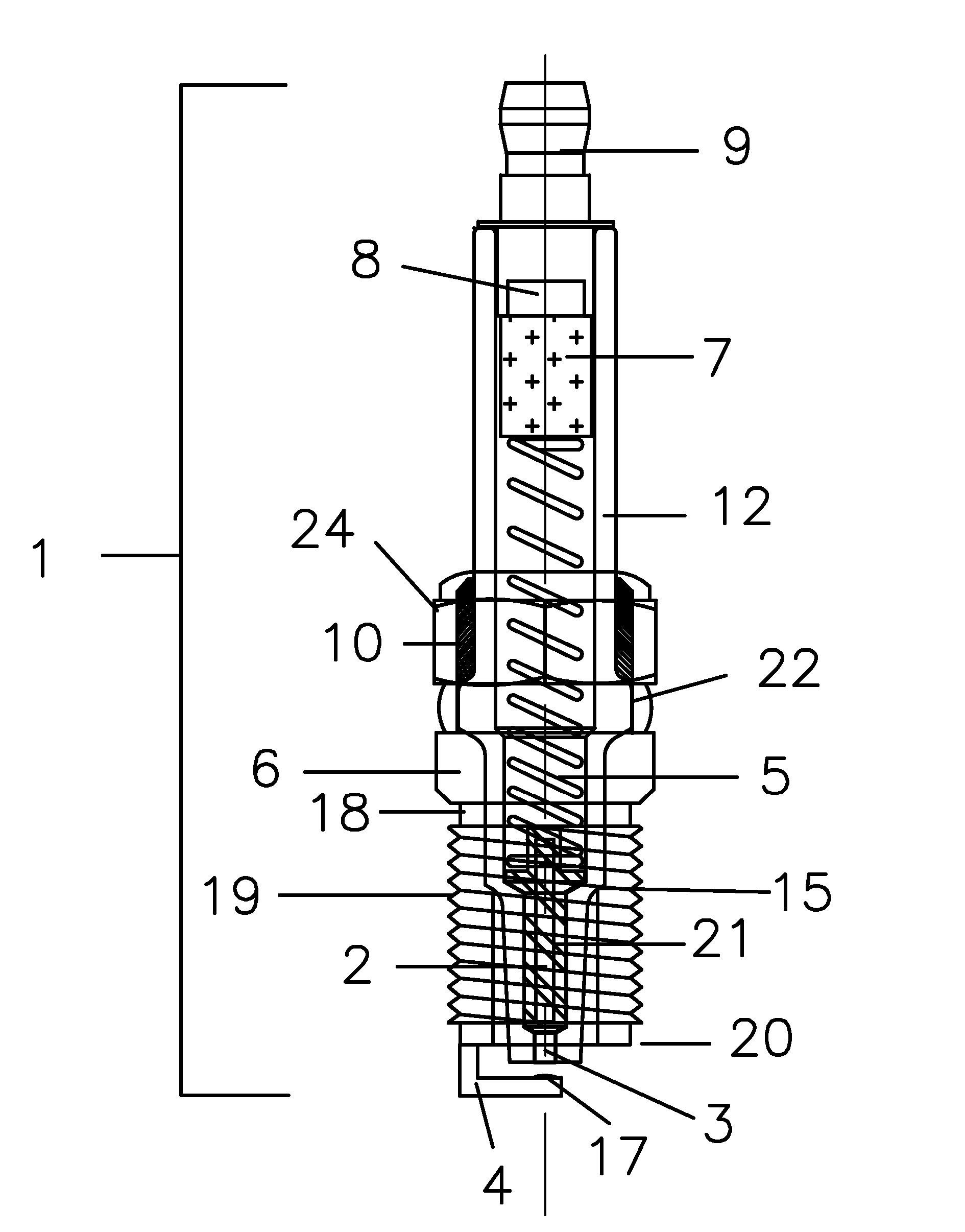

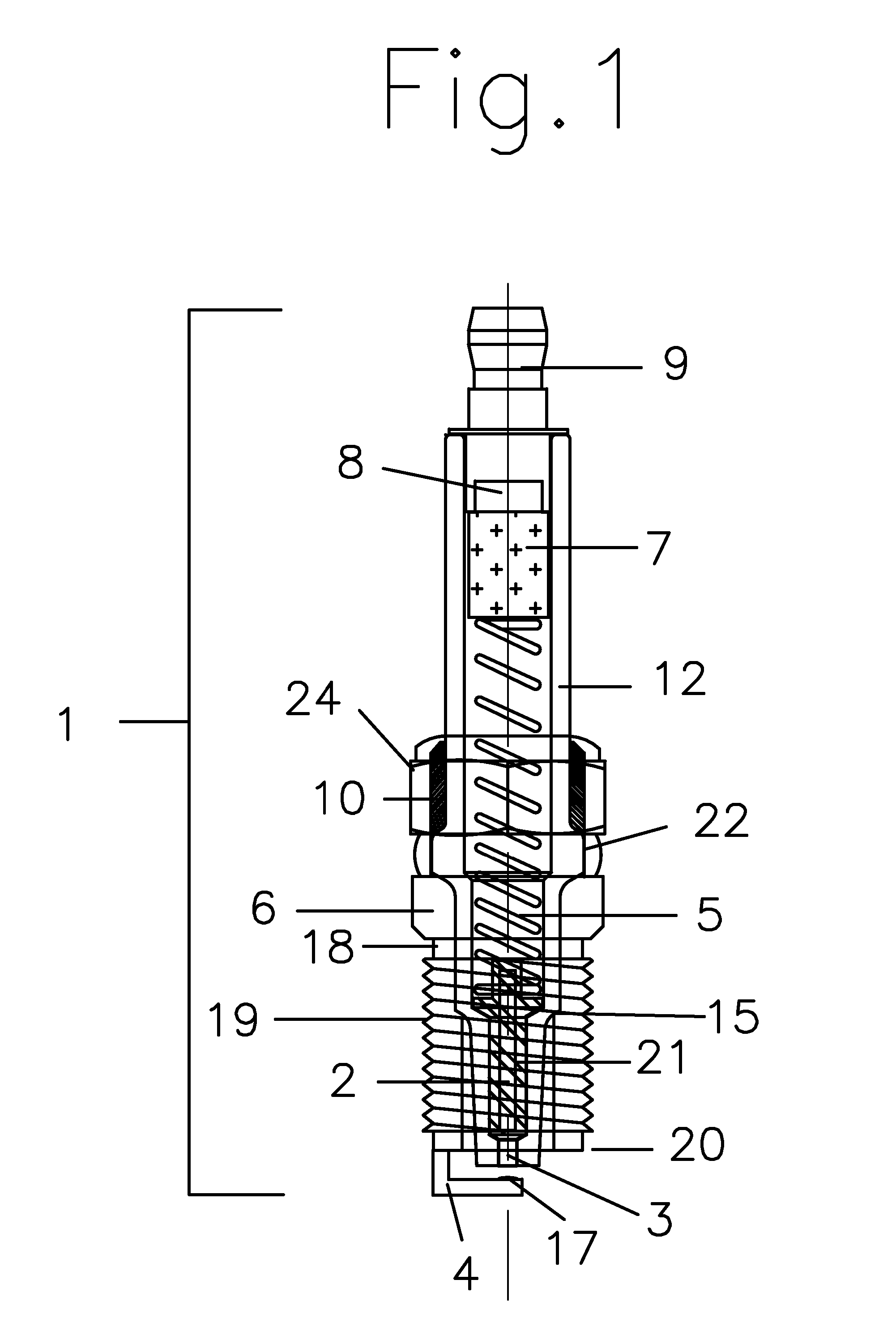

Spark plug for use in an internal-combustion engine

ActiveUS20070216275A1Reduce widthImprove thermal conductivityThermionic cathodesDischarge tube/lamp detailsThermal expansionEngineering

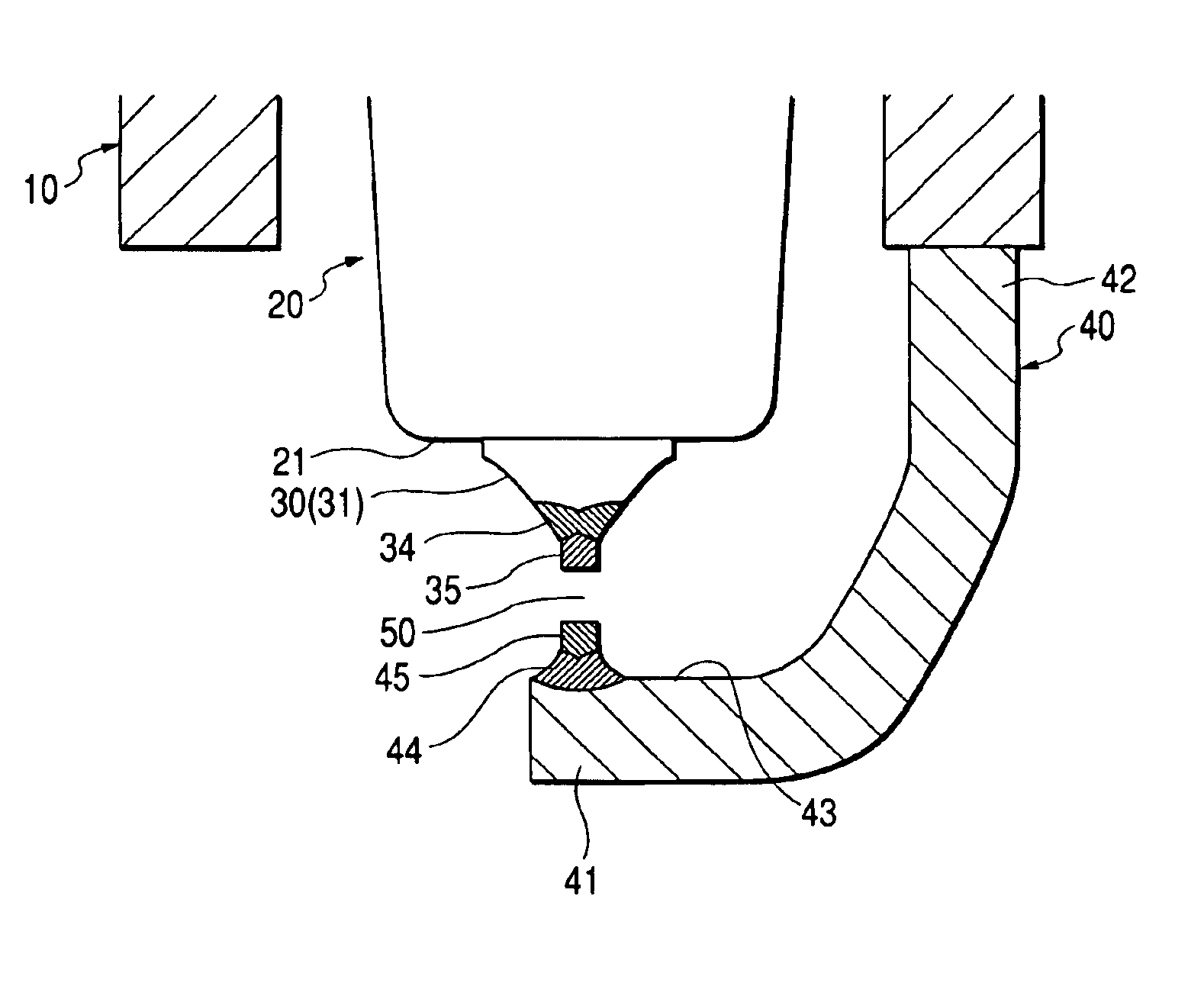

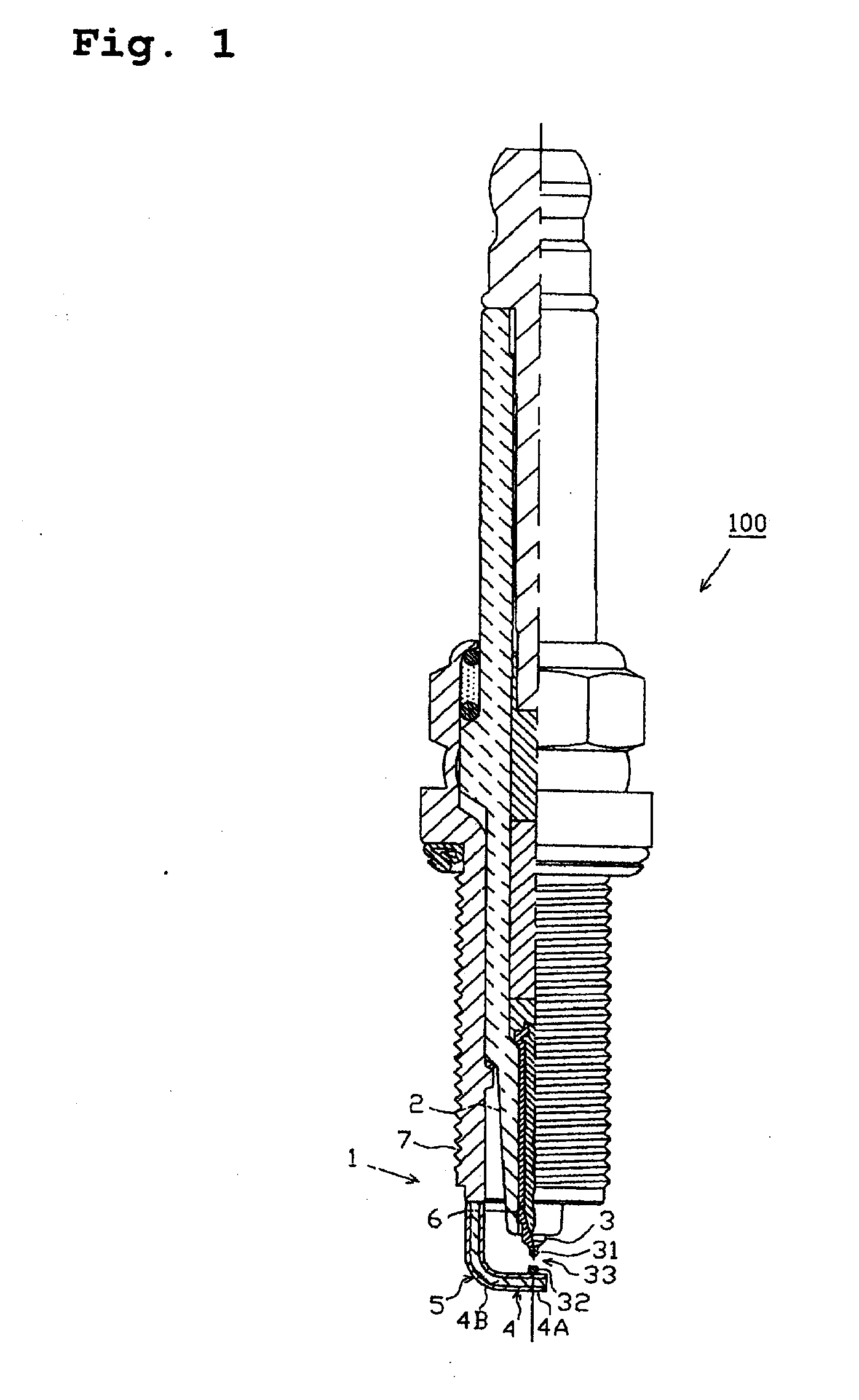

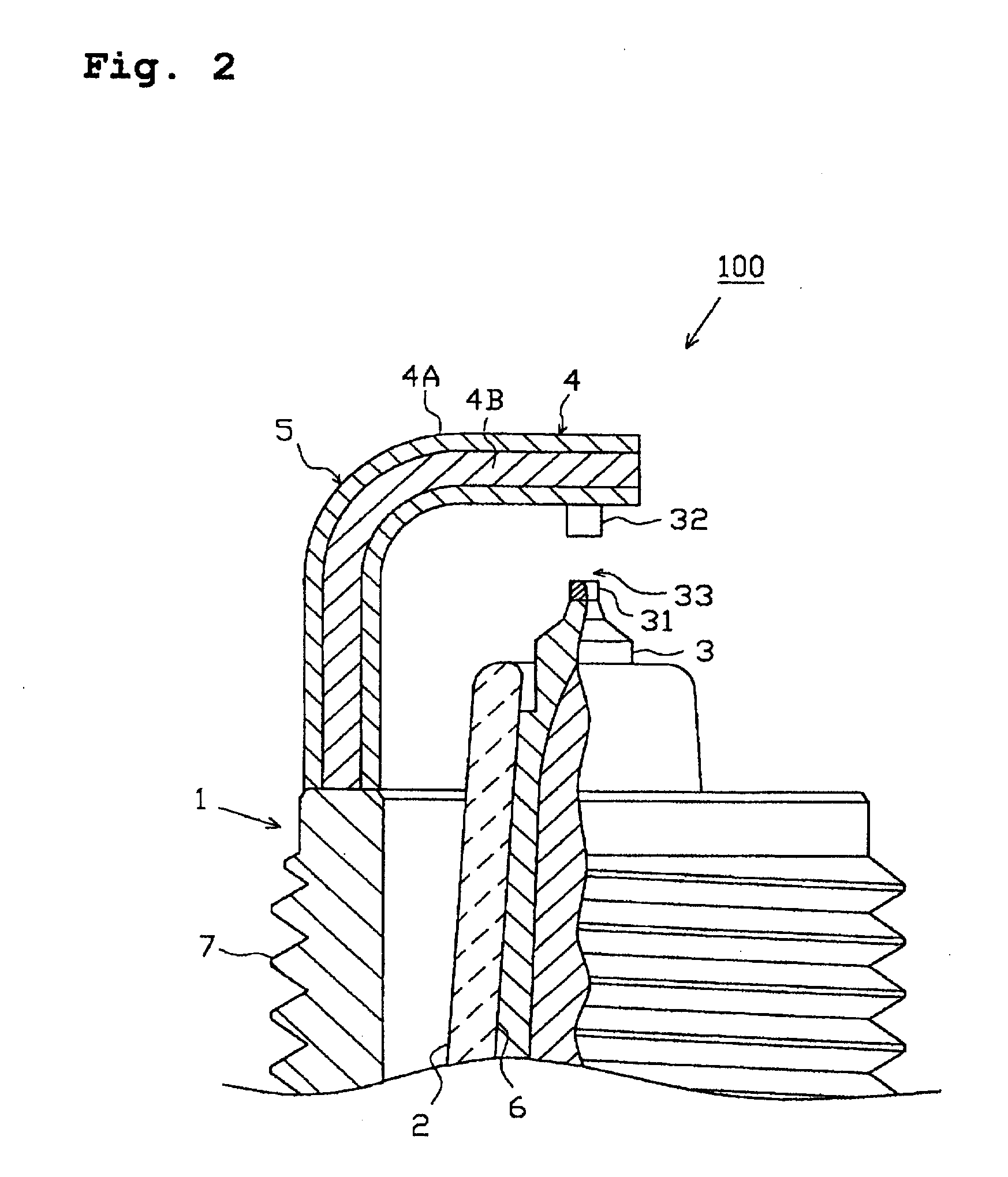

A spark plug 100 comprised of a metal shell 1, an insulator 2, a center electrode 3 and a ground electrode 4. A rear-end face of the ground electrode 4 is welded to a front-end face of the metal shell 1, and a bent portion 5 located at the intermediated position in the longitudinal direction is bent toward the center of the spark plug 100. The ground electrode 4 assumes a circular-shape with a diameter of 2 mm or less whereby an inflow of an air-fuel mixture is not disturbed even when the air-fuel mixture directly flows into a back face of the ground electrode 4. The ground electrode 4 is comprised of an outer layer 4A made of a nickel alloy and an inner layer 4B made of pure copper with an excellent thermal conductivity, in which a ratio of a cross-sectional area of the inner layer 4B to the entire cross-sectional area of the ground electrode 4 is 10% or more to 35% or less. Thus, the spark plug 100 which is excellent in heat sinking ability and can prevent a spring back phenomenon due to a difference in a coefficient of thermal expansion.

Owner:NGK SPARK PLUG CO LTD

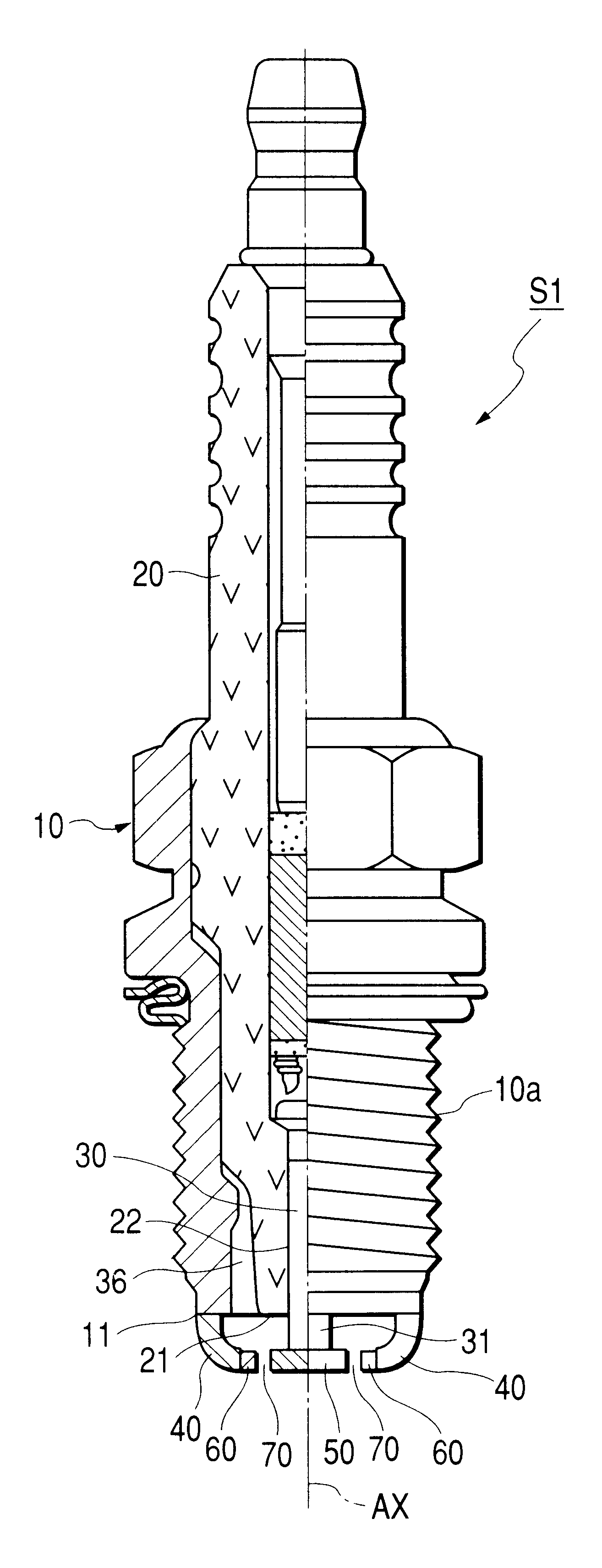

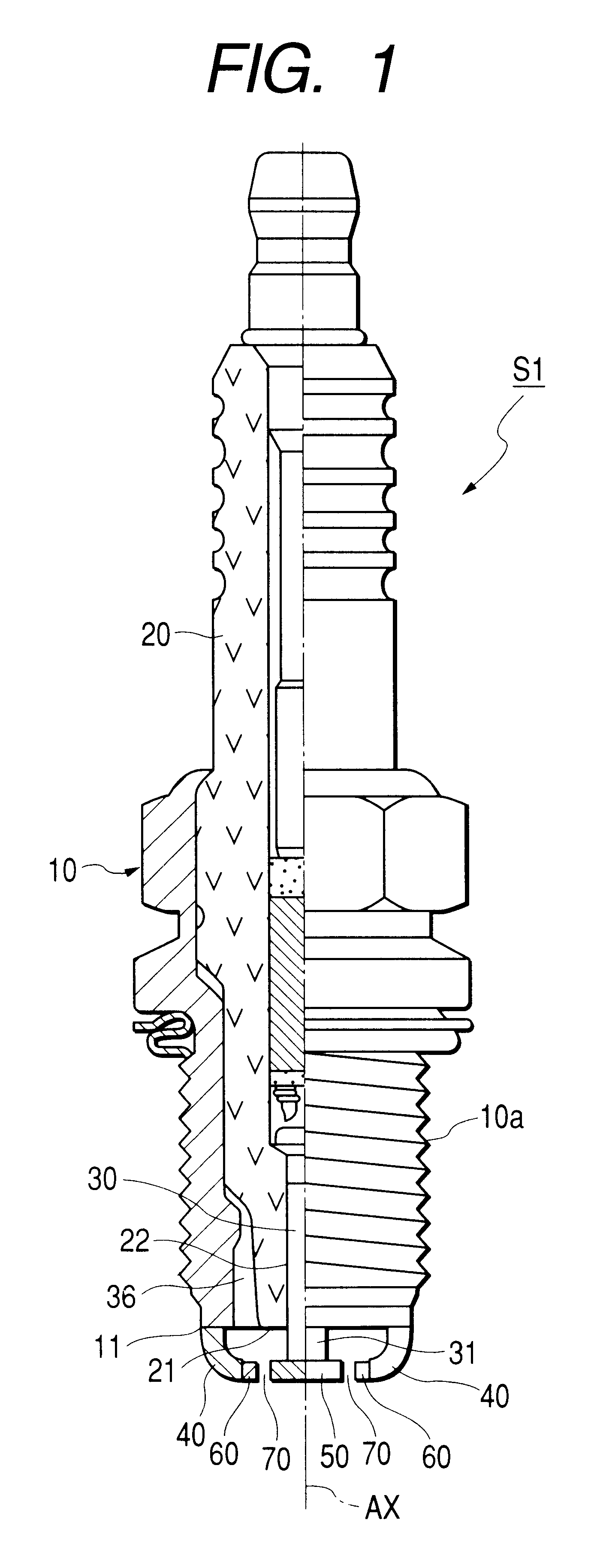

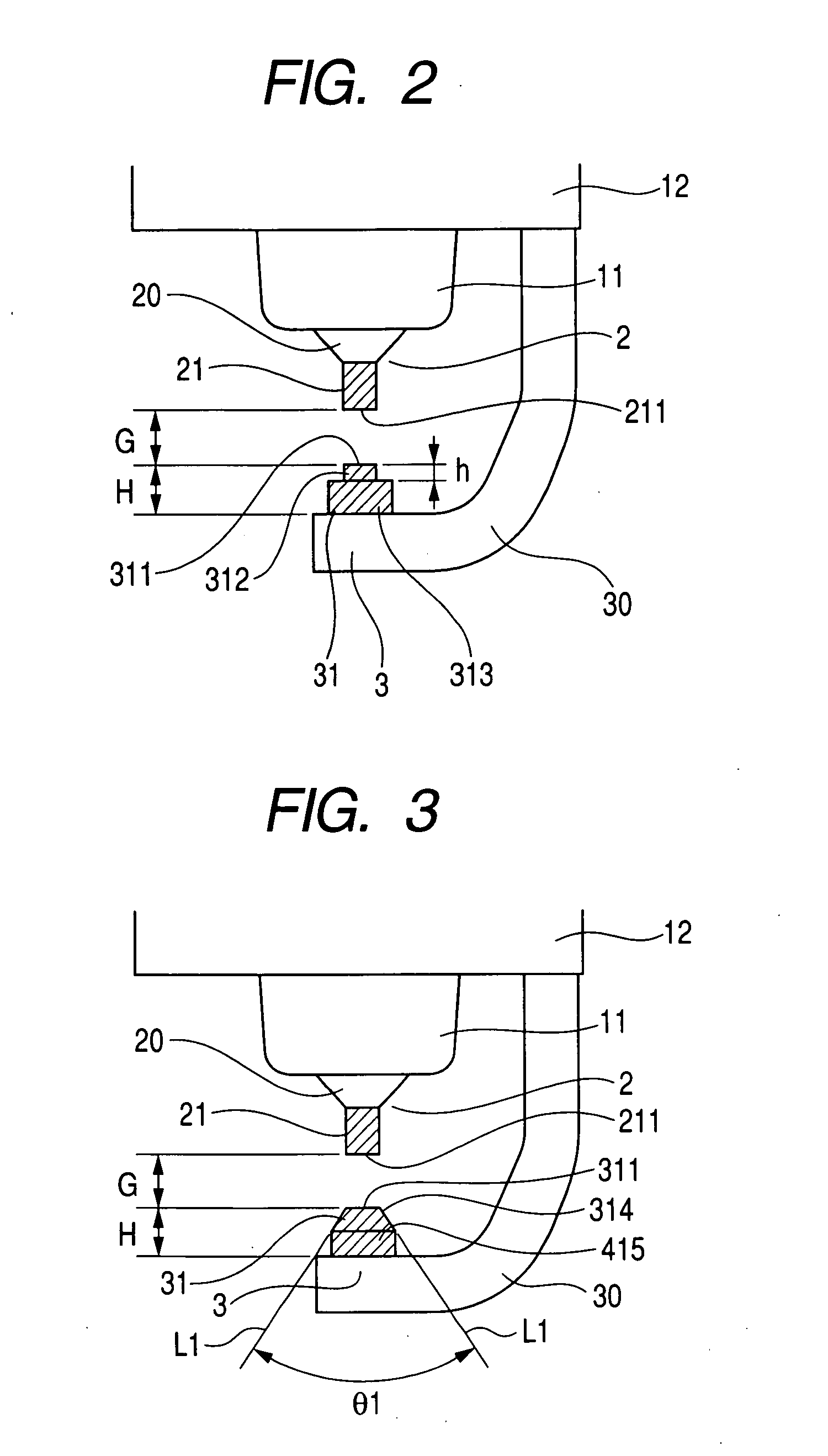

Spark plug for internal combustion engine designed to keep ignitability of fuel high

InactiveUS20080074025A1Improve flammabilityReduce voltageSpark gapsSparking plugs manufactureEngineeringInternal combustion engine

A spark plug having a length for an internal combustion engine is provided which is designed to keep the ignitability of a gaseous fuel high to decrease a rise in voltage required by the spark plug to discharge, thereby prolonging the service life of the spark plug. The spark plug includes noble metal chips joined to a ground electrode and a center electrode to define a spark gap therebetween. At least one of the noble metal chips has a length of 0.3 mm or more and includes a portion whose sectional area traversing a lengthwise direction of the spark plug is greater than an area of a top end surface, thereby ensuring a higher degree of ignitability of the fuel and minimizing the rate of the rise in the required voltage.

Owner:DENSO CORP

Spark plug

A spark plug is provided with a metal shell and a ceramic insulator to support therein a center electrode. The ceramic insulator includes a front portion with a stepped outer surface, a middle portion, a rear portion and a shoulder portion defined between the middle and rear portions. A difference between the outer diameters of the middle and rear portions of the ceramic insulator is 1.8 mm or smaller. The metal shell includes a radially inward protrusion to retain thereon the stepped outer surface of the ceramic insulator and a rear end portion crimped onto the shoulder portion of the ceramic insulator. An inner circumferential surface of the crimped shell portion has a region held in contact with the insulator shoulder portion with a radially innermost point of the crimped shell portion being spaced radially apart from the ceramic insulator and axially apart from the insulator shoulder portion.

Owner:NGK SPARK PLUG CO LTD

Spark plug and method of manufacturing the same

A glaze layer formed on the surface an alumina-based insulator of a resistor spark plug contains SiO2 (18 to 35% by weight), B2O3 (25 to 40% by weight), ZnO (10 to 25% by weight), BaO (7 to 20% by weight), Na2O (3 to 9% by weight), and K2O (3 to 9% by weight). Since the difference between the coefficients of linear expansion of the glaze and that of the alumina-based insulating material is relatively small, the glaze layer is less susceptible to cracks and the like. Also, since the glaze has a softening point lower than that of conventional lead-silicate-glass-based glaze, the glost-firing temperature can be as low as 800° to 950° C. Therefore, even in the case where glost firing is performed concurrently with a glass sealing step, a center electrode and a terminal metal piece are less susceptible to oxidation. Further, even though the content of the alkali metal component is high, a good insulating performance is obtained so that excellent flashover resistance is attained.

Owner:NGK SPARK PLUG CO LTD

Non-thermal plasma ignition arc suppression

ActiveUS20120112620A1Eliminates arcingReduces arcingSpark gapsEngine ignitionCombustion chamberEngineering

An igniter (20) of a corona ignition system emits a non-thermal plasma in the form of a corona (30) to ionize and ignite a fuel mixture. The igniter (20) includes an electrode (32) and a ceramic insulator (22) surrounding the electrode (32). The insulator (22) surrounds a firing end (38) of the electrode (32) and blocks the electrode (32) from exposure to the combustion chamber (28). The insulator (22) presents a firing surface (56) exposed to the combustion chamber (28) and emitting the non-thermal plasma. A plurality of electrically conducting elements (24) are disposed in a matrix (26) of the ceramic material and along the firing surface (56) of the insulator (22), such as metal particles embedded in the ceramic material or holes in the ceramic material. The electrically conducting elements (24) reduce arc discharge during operation of the igniter (20) and thus improve the quality of ignition.

Owner:FEDERAL MOGUL IGNITION

Spark plug with multi-layer firing tip

ActiveUS20070114900A1Quantity minimizationSolve the lack of resistanceCoupling contact membersSparking plugs manufactureEngineeringThermal expansion

A spark plug having a multilayer firing tip that minimizes the amount of precious metal used and a method of assembling a spark plug with a multilayer firing tip. The firing tip includes a discharge end and a weld end, with the weld end being connected to a center electrode, and more specifically to a base electrode on the center electrode. The weld end has a coefficient of thermal expansion, which is not between the values for the coefficients of thermal expansion for the discharge end and the base electrode. More specifically, the weld end has a coefficient of thermal expansion which is greater than the coefficients of thermal expansion for the discharge end and base electrode. The weld end is formed from Nickel and Chromium with a limited amount of additional elements. The spark plug is assembled by providing a first elongated material formed from the material used for the discharge end and a second elongated material formed from a material used for the weld end. The two materials are then joined to form a single joined material and are severed to create a firing tip. The firing tip is welded to the center electrode of the spark plug and more specifically, the base electrode.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com