Patents

Literature

186results about How to "Satisfactory property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

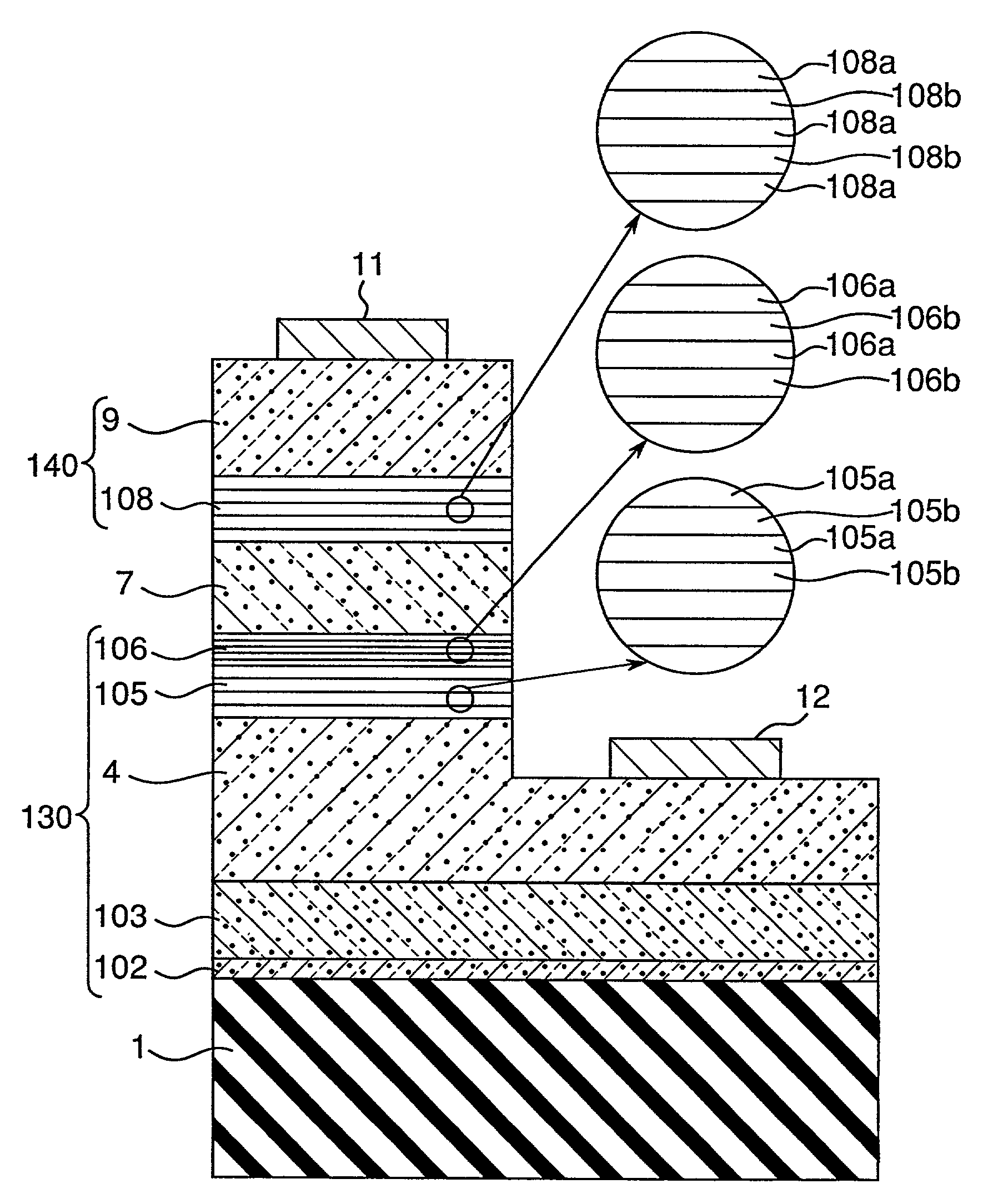

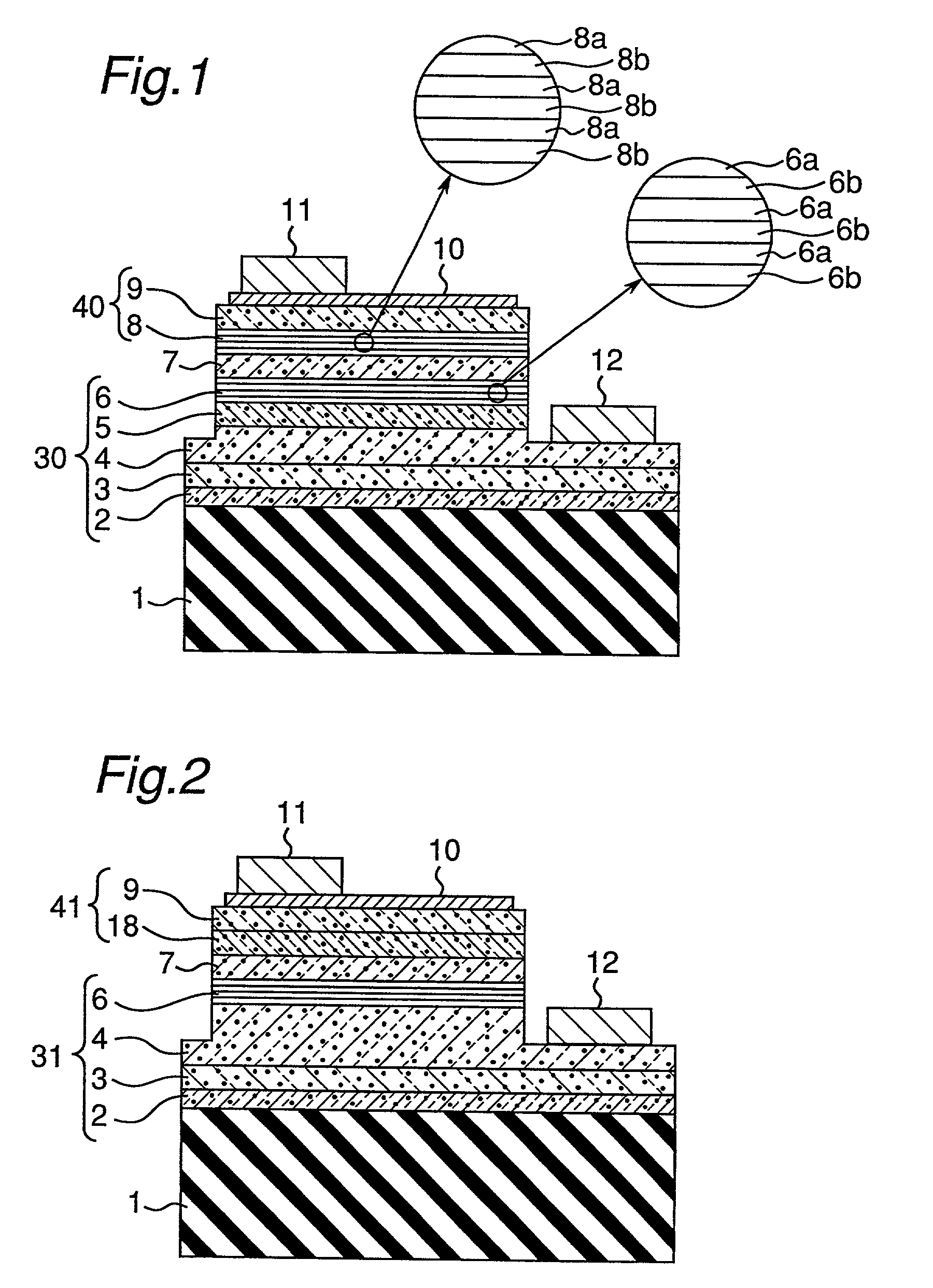

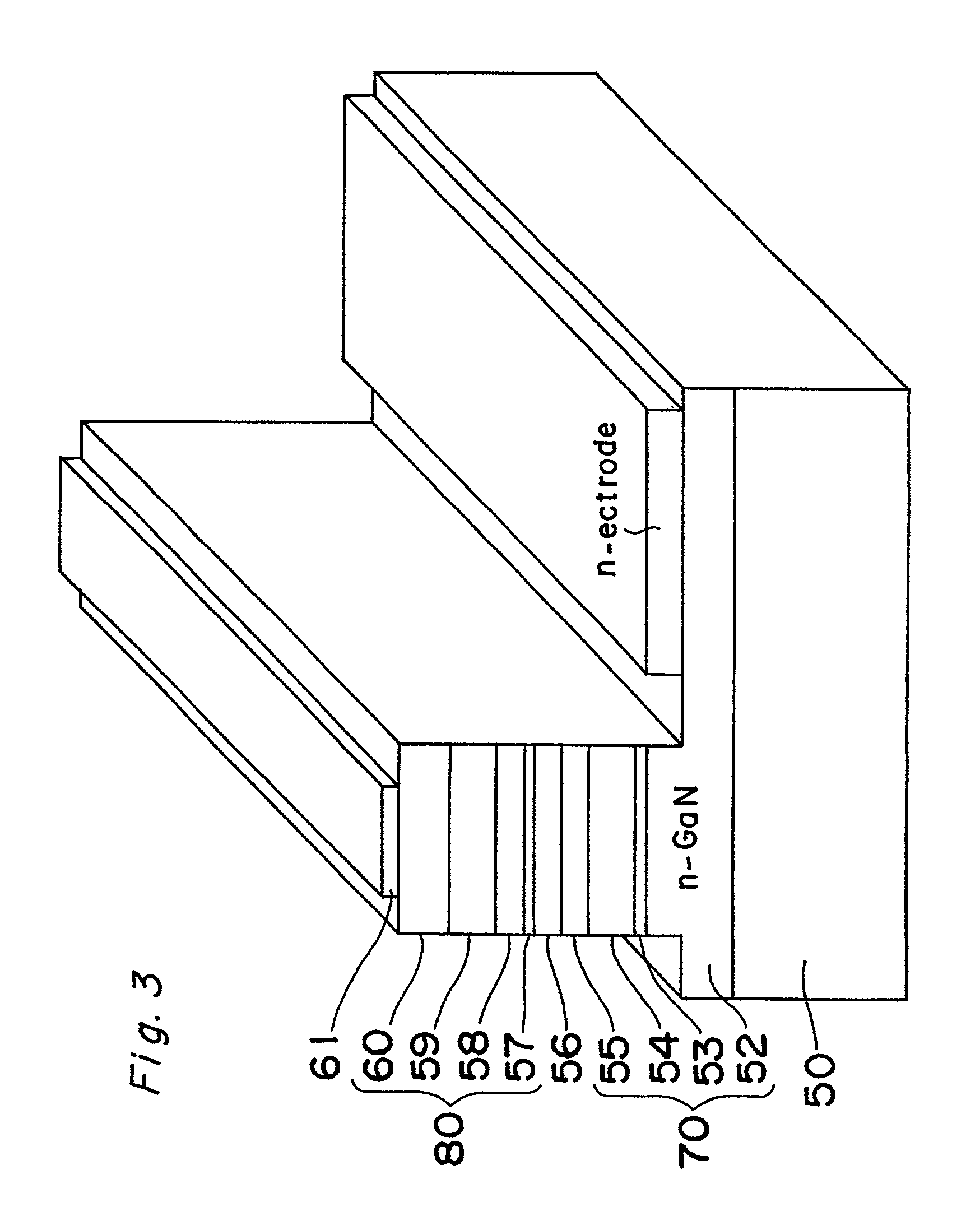

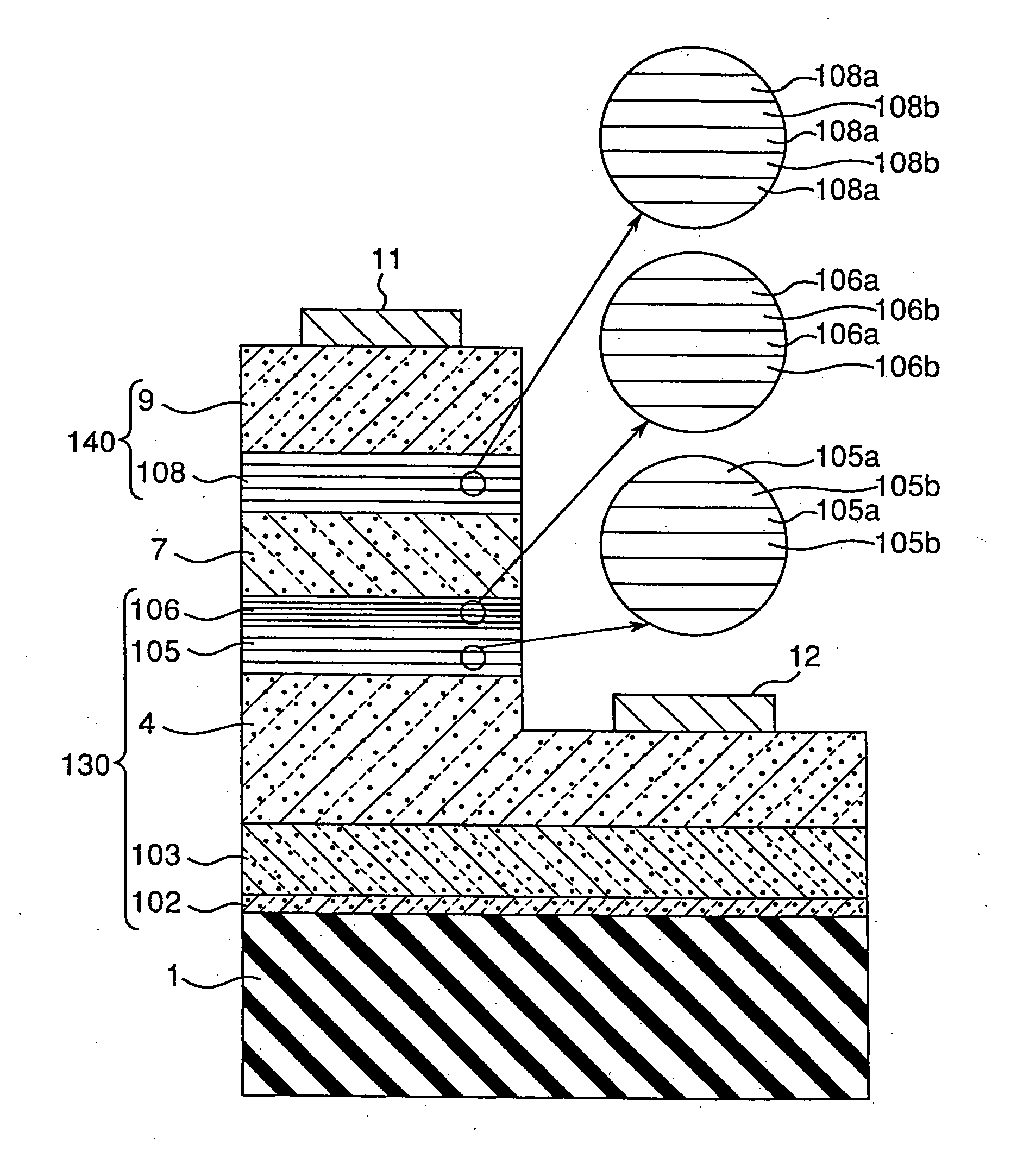

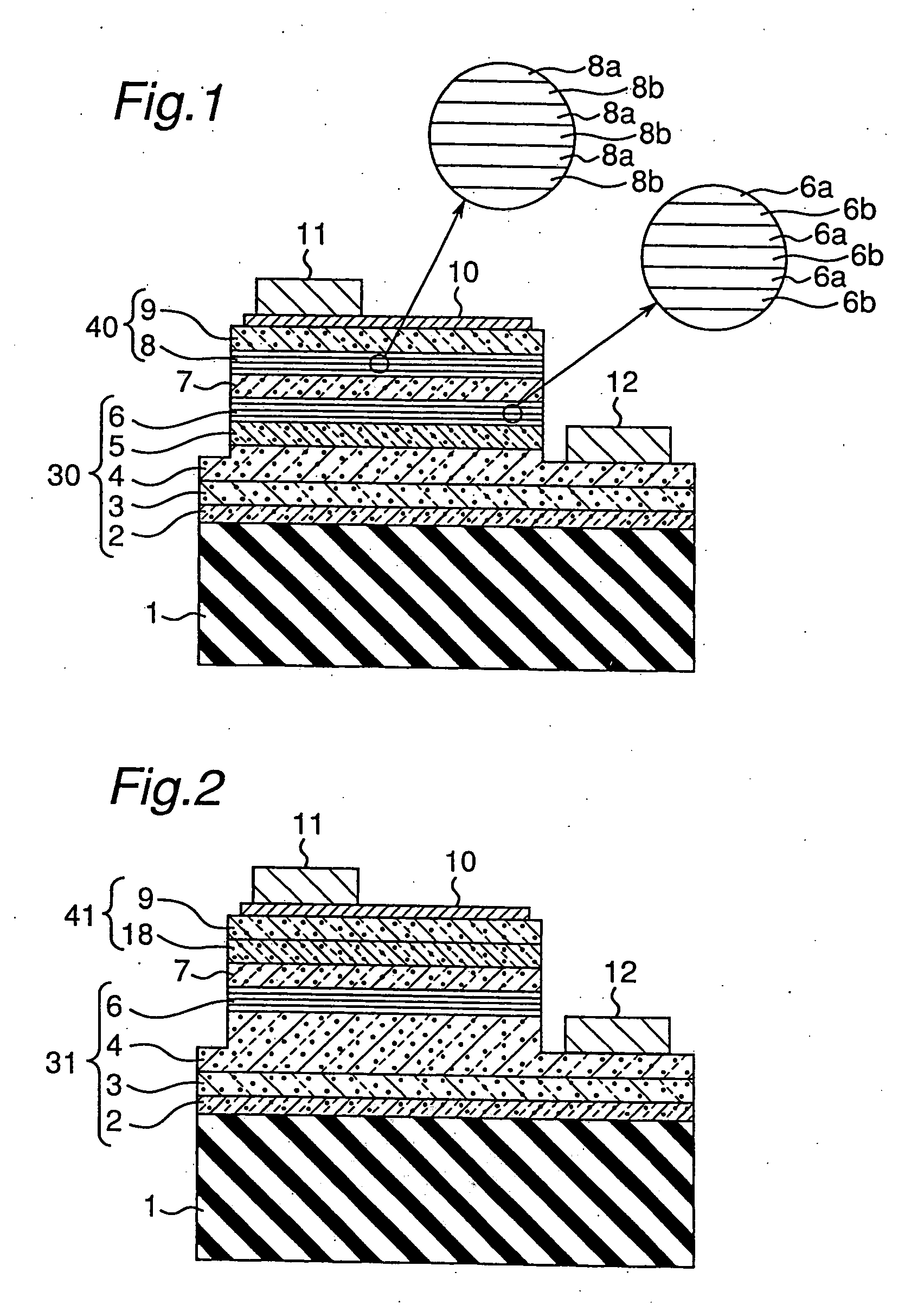

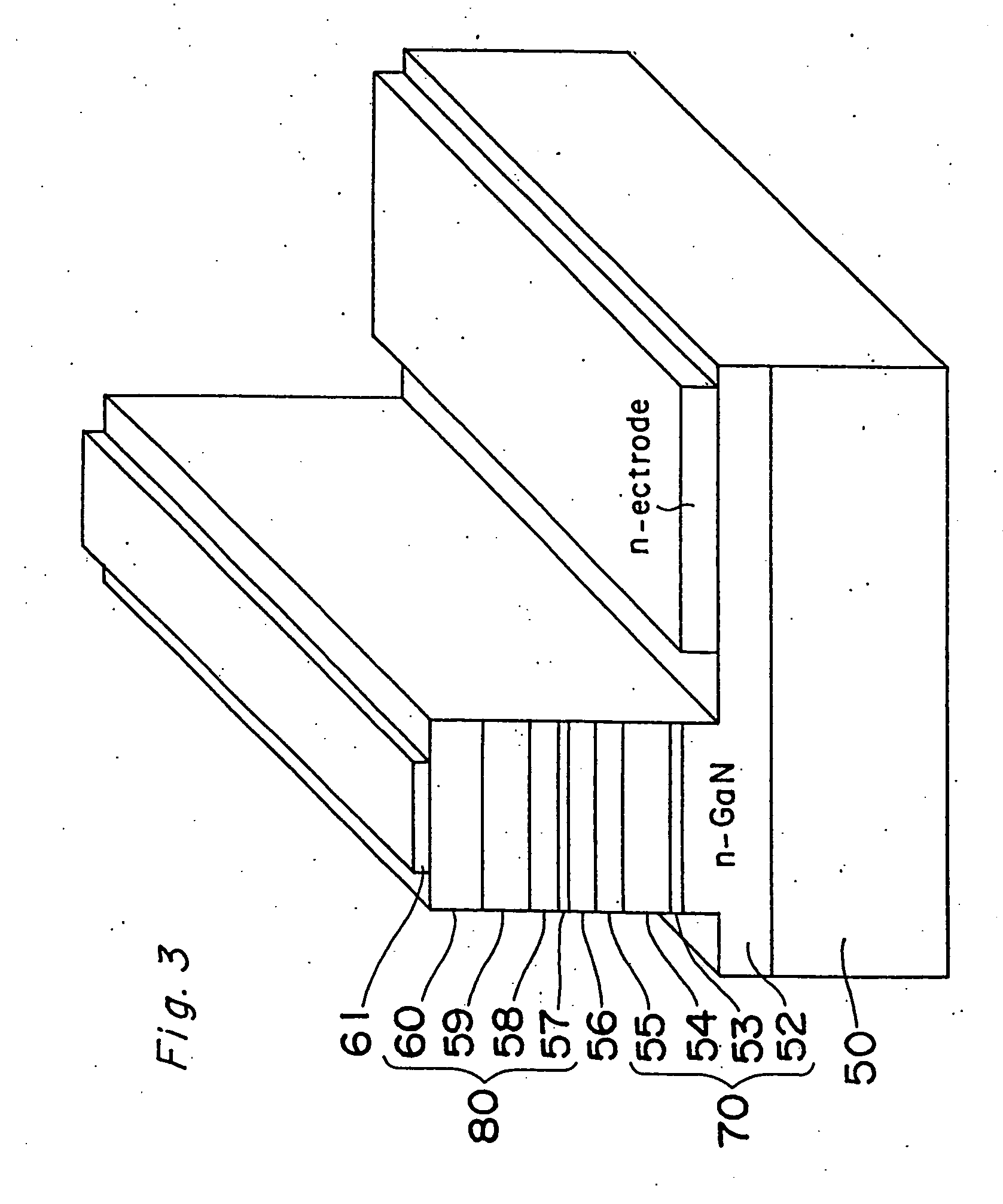

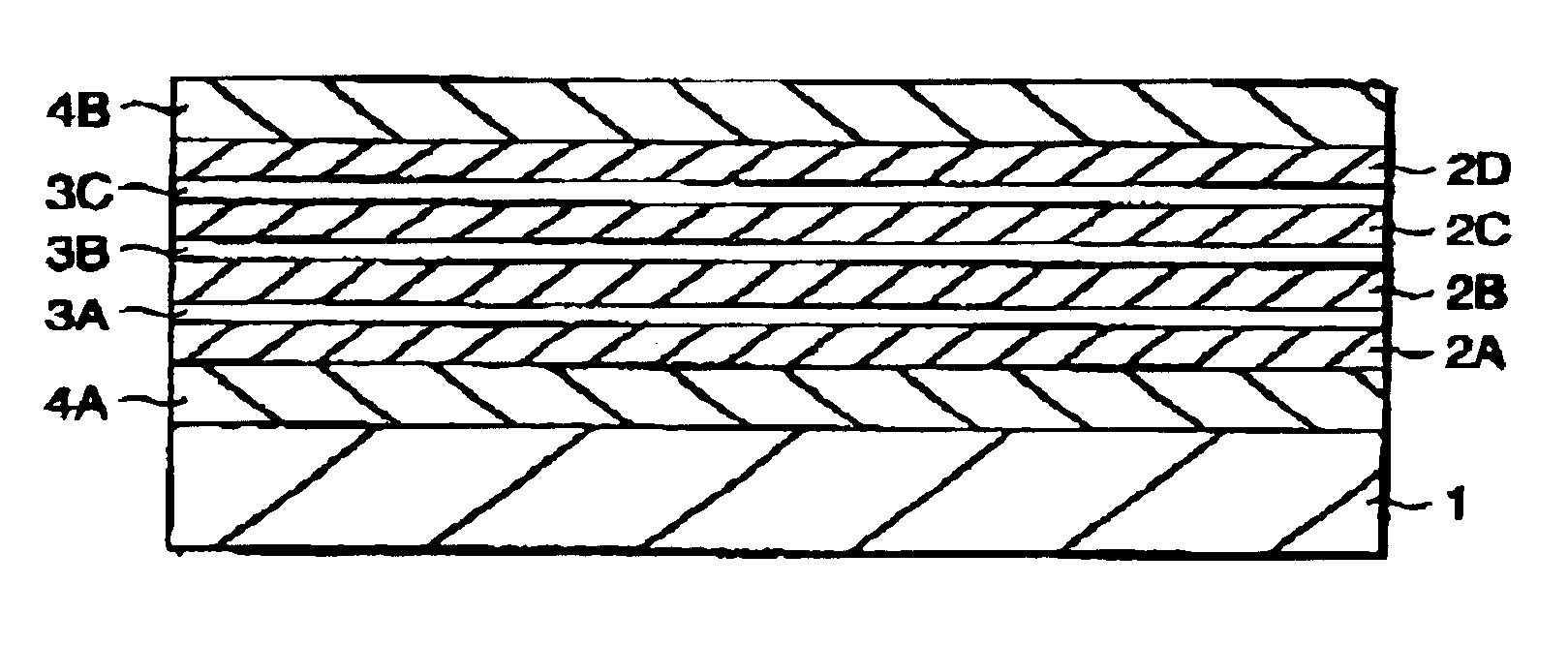

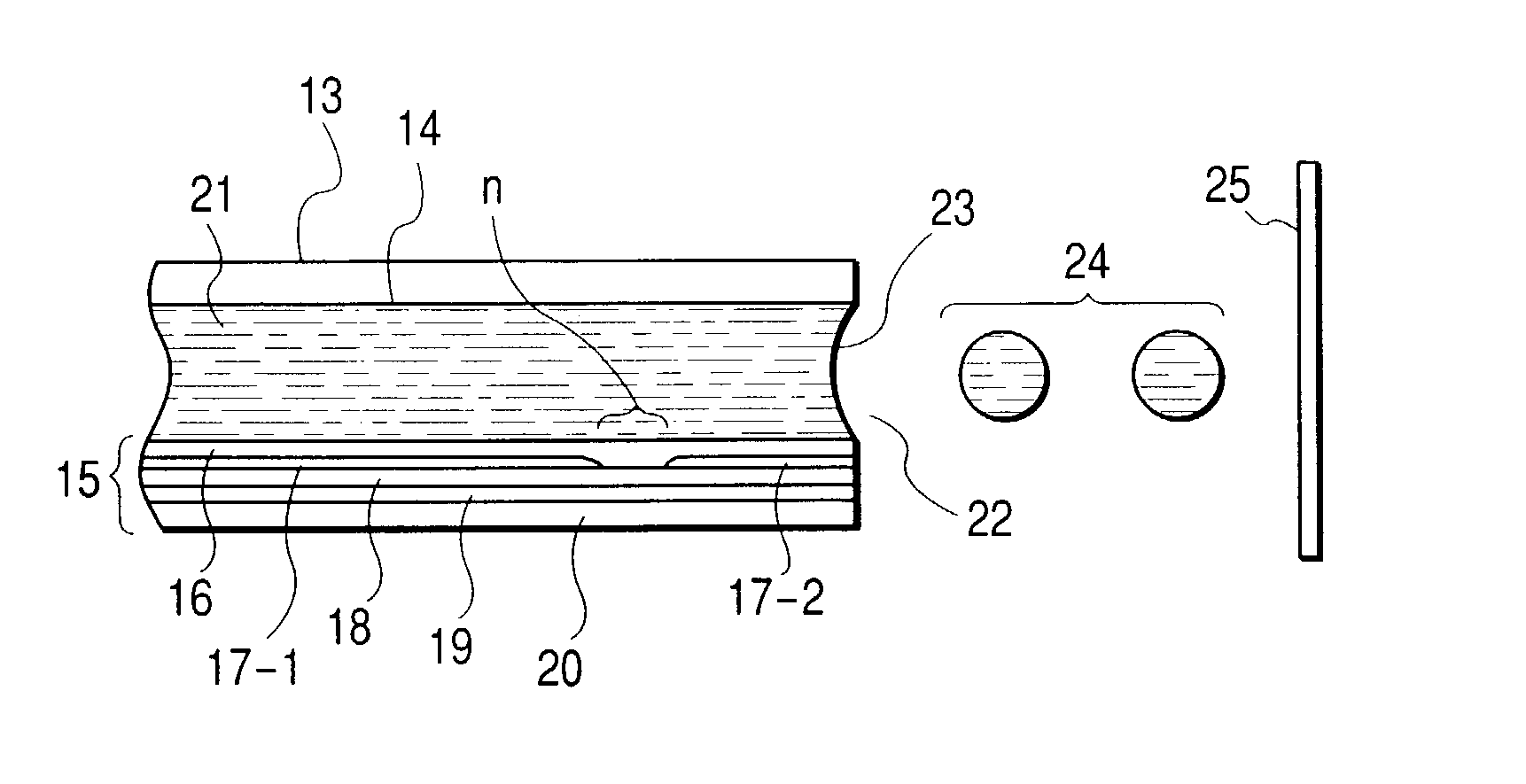

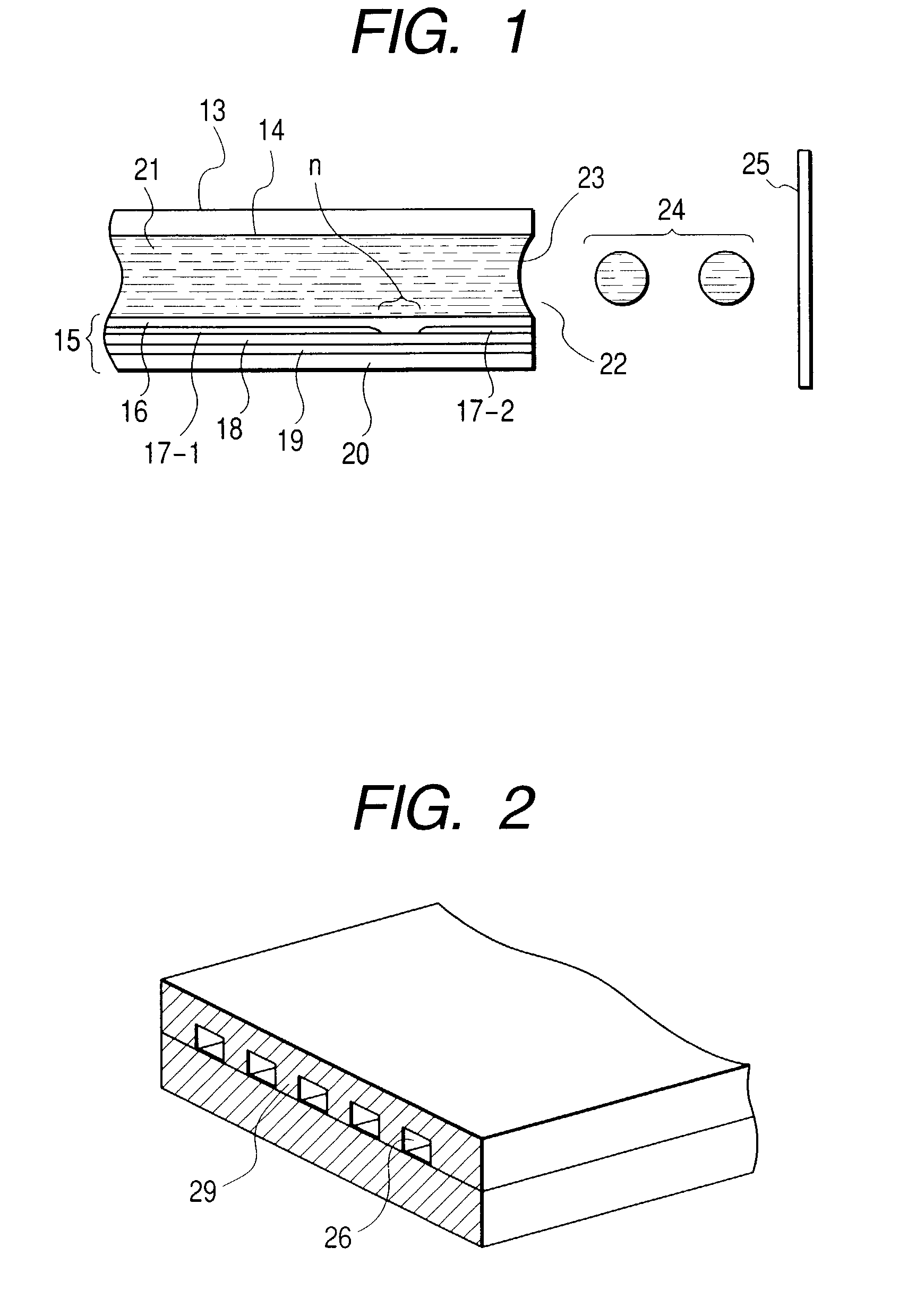

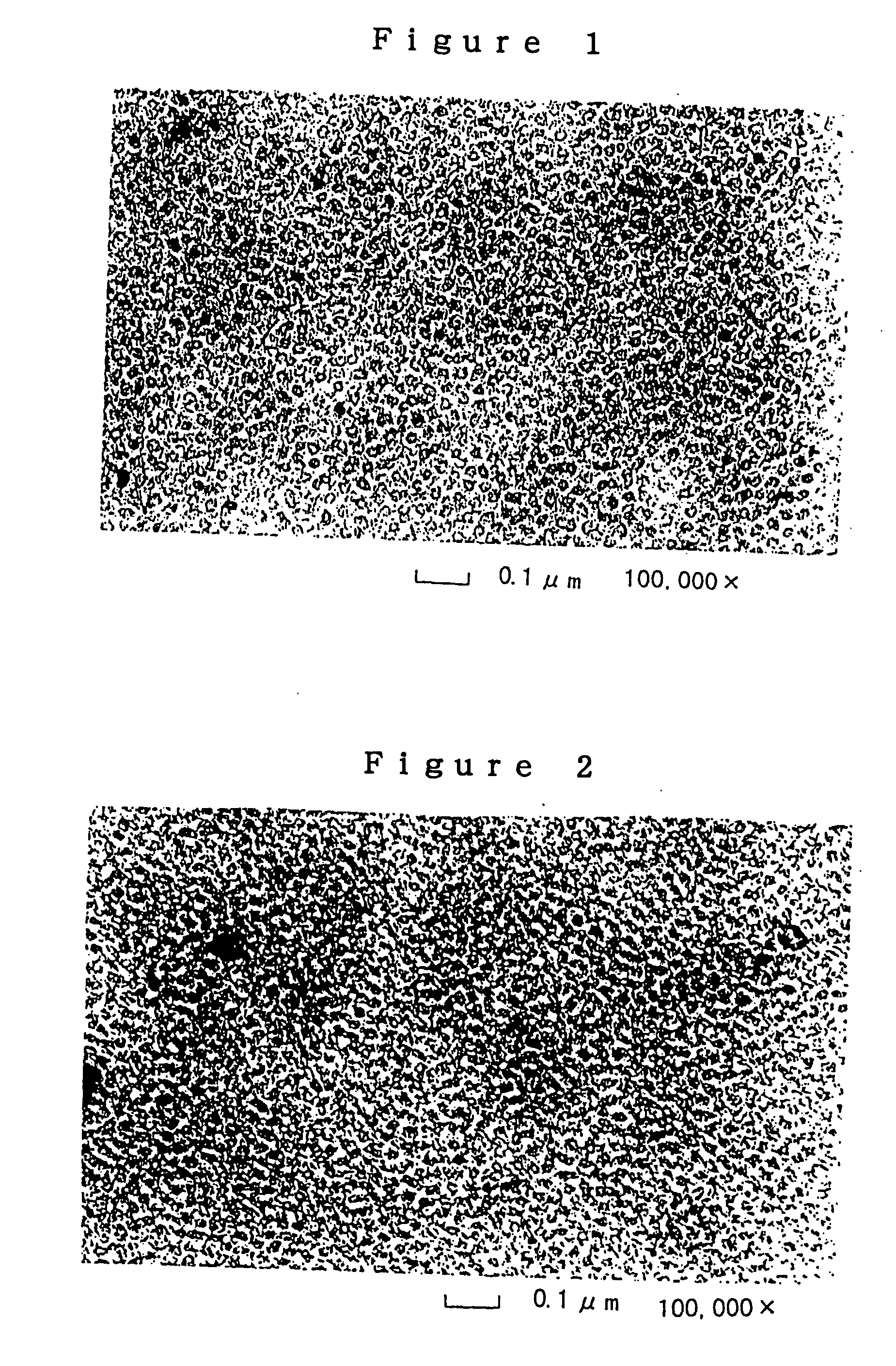

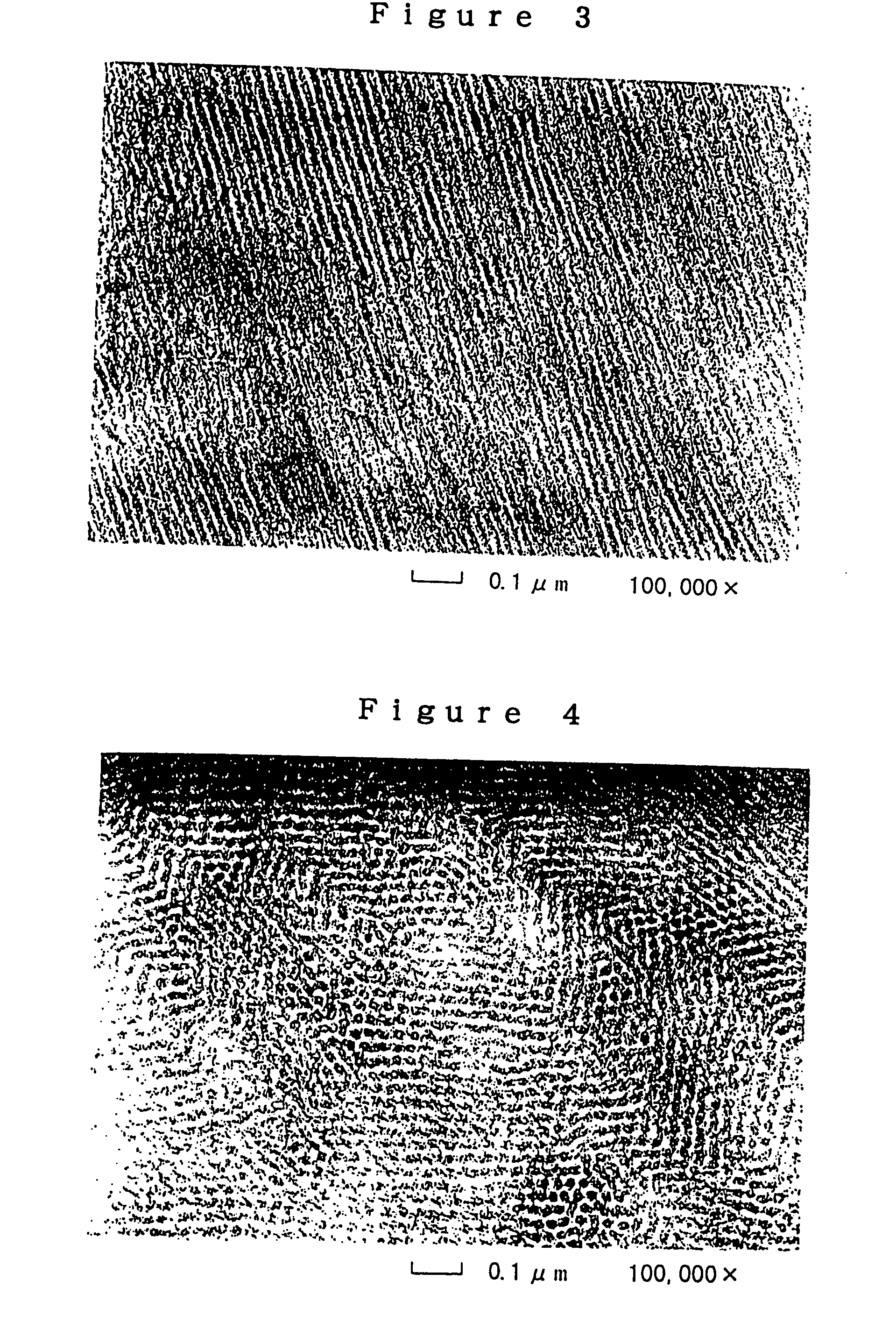

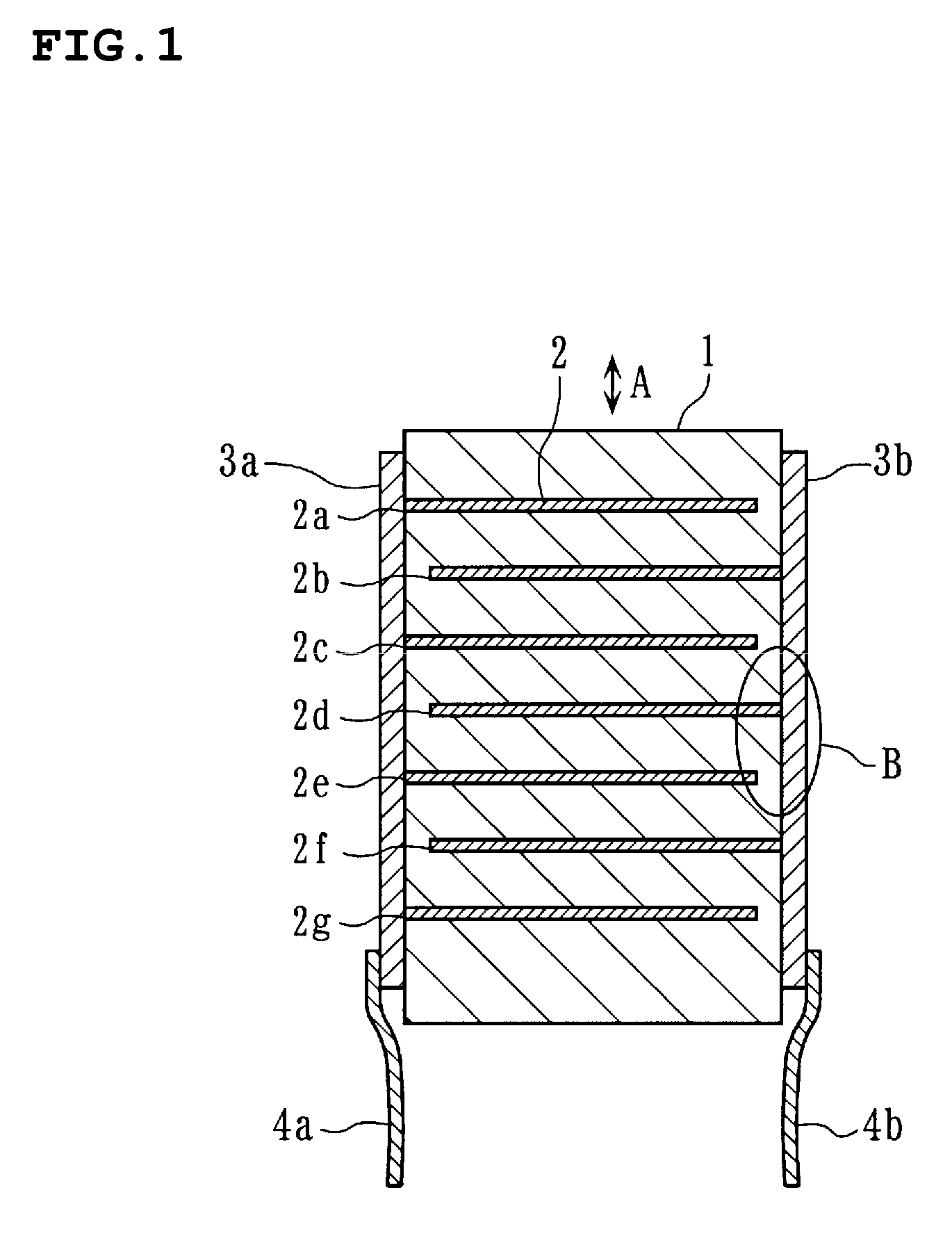

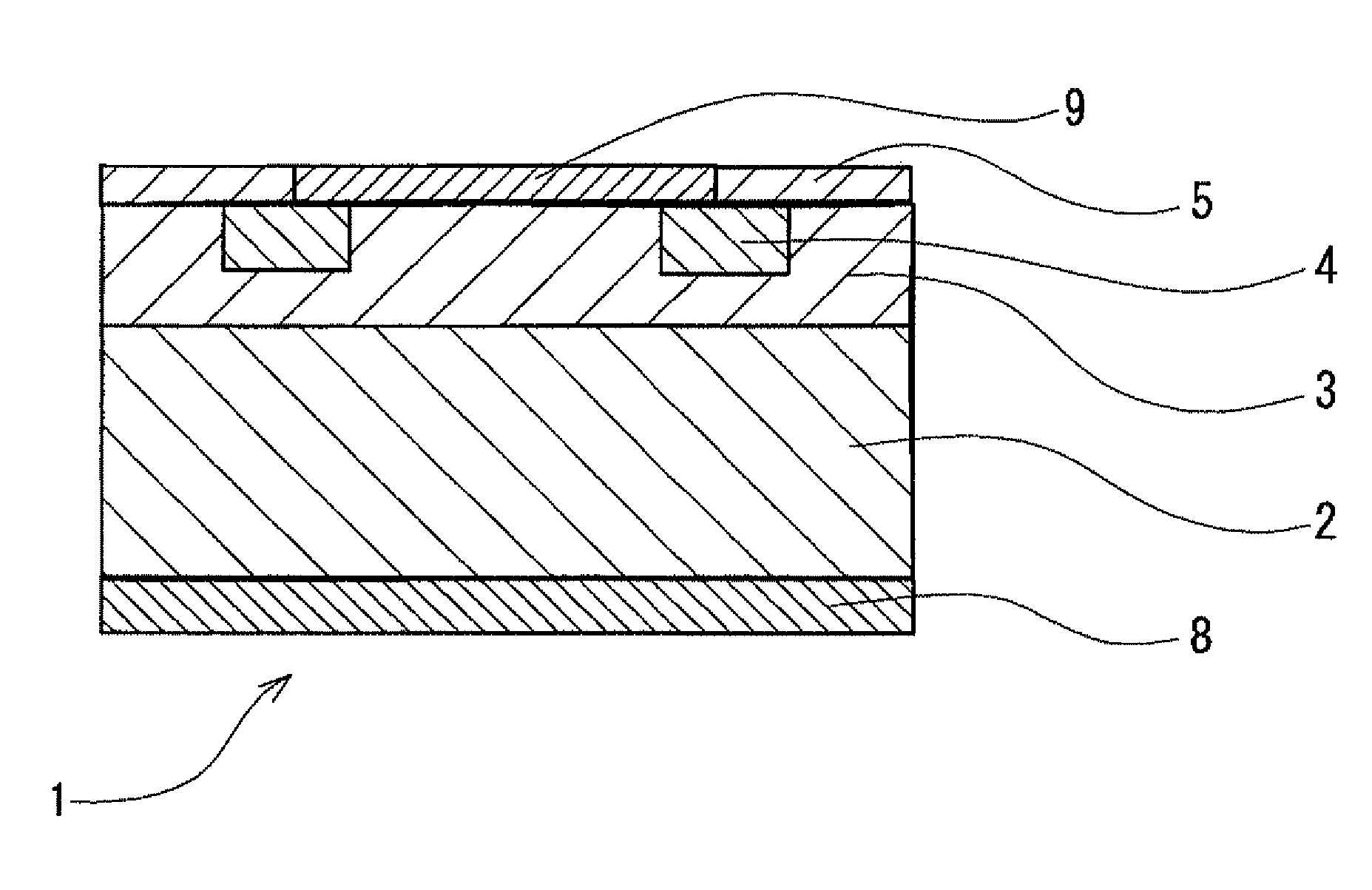

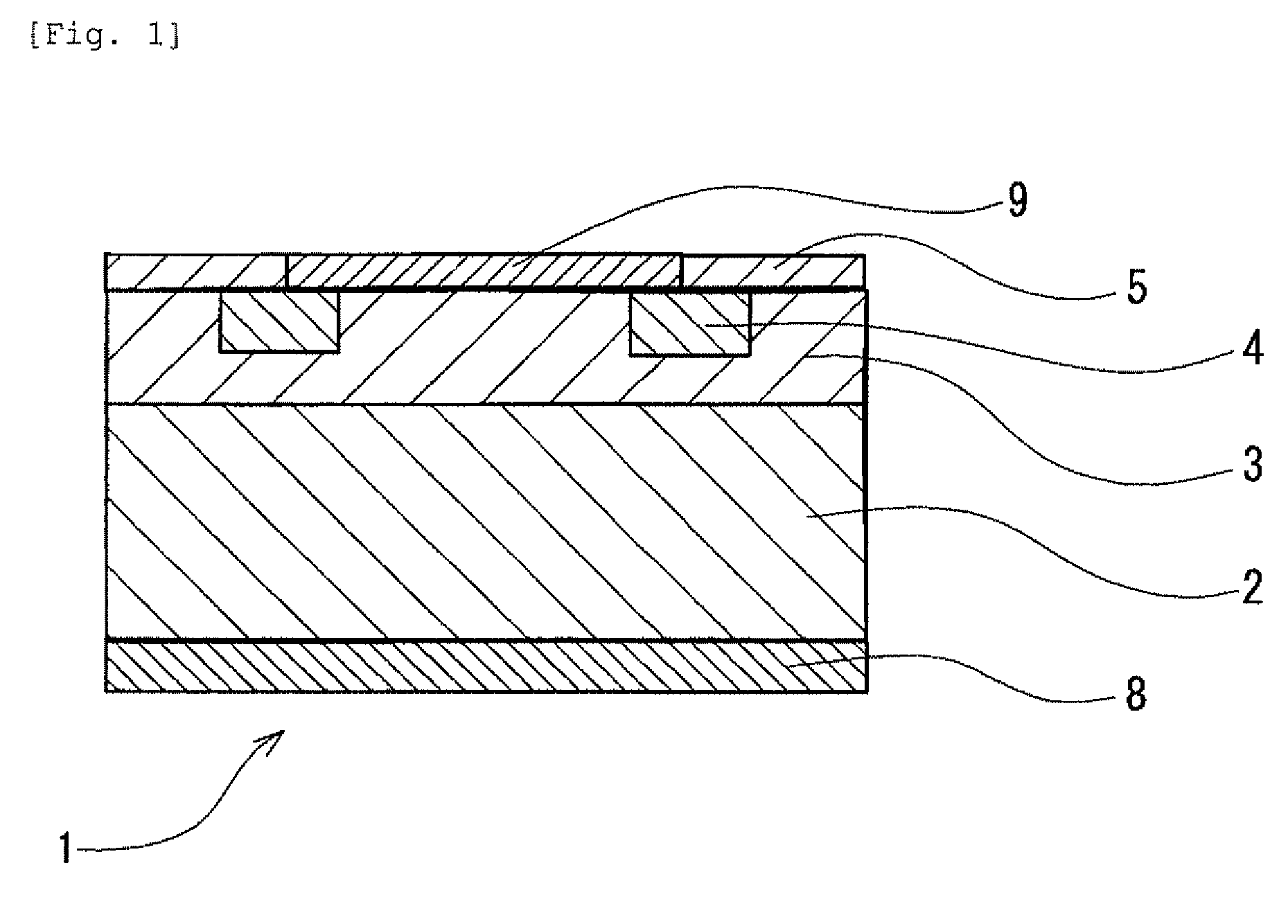

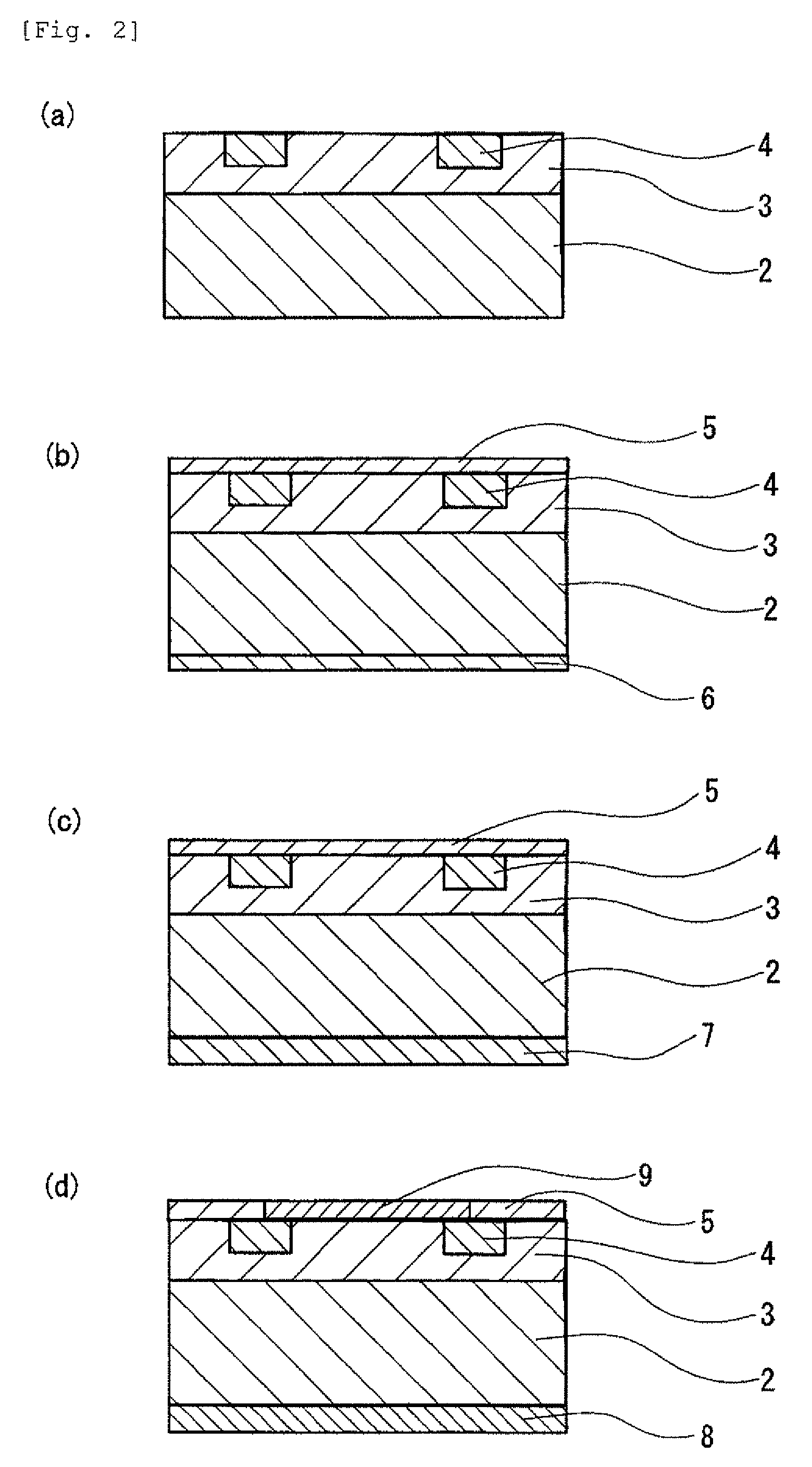

Nitride semiconductor device

InactiveUS7193246B1Light emission efficiencyHigh luminous outputOptical wave guidanceLaser detailsMultiple quantumNitride semiconductors

According to the nitride semiconductor device with the active layer made of the multiple quantum well structure of the present invention, the performance of the multiple quantum well structure can be brought out to intensify the luminous output thereof thereby contributing an expanded application of the nitride semiconductor device. In the nitride semiconductor device comprises an n-region having a plurality of nitride semiconductor films, a p-region having a plurality of nitride semiconductor films, and an active layer interposed therebetween, a multi-film layer with two kinds of the nitride semiconductor films is formed in at least one of the n-region or the p-region.

Owner:NICHIA CORP

Nitride semiconductor device

InactiveUS20070063207A1Light emission efficiencyHigh luminous outputOptical wave guidanceLaser detailsActive layerNitride semiconductors

According to the nitride semiconductor device with the active layer made of the multiple quantum well structure of the present invention, the performance of the multiple quantum well structure can be brought out to intensify the luminous output thereof thereby contributing an expanded application of the nitride semiconductor device. In the nitride semiconductor device comprises an n-region having a plurality of nitride semiconductor films, a p-region having a plurality of nitride semiconductor films, and an active layer interposed therebetween, a multi-film layer with two kinds of the nitride semiconductor films is formed in at least one of the n-region or the p-region,

Owner:NICHIA CORP

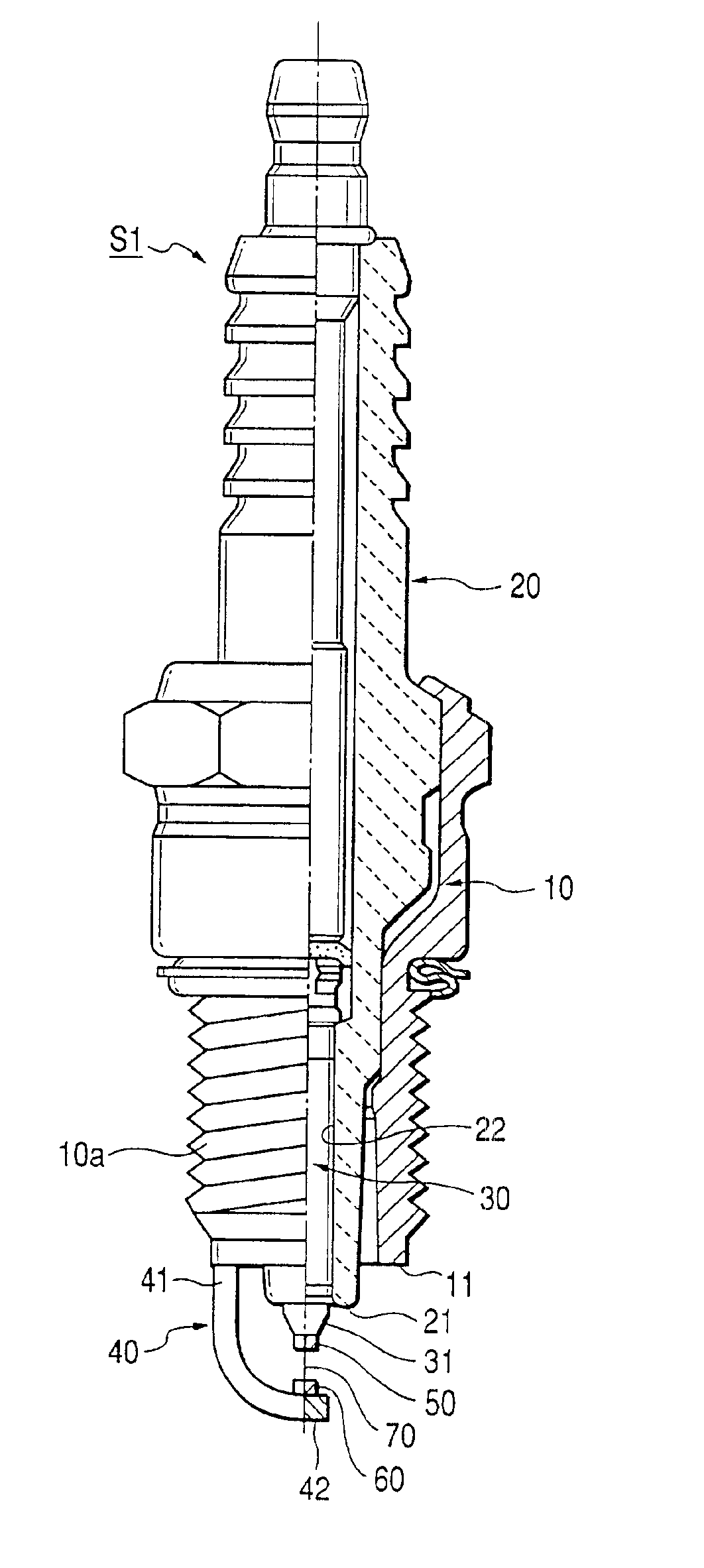

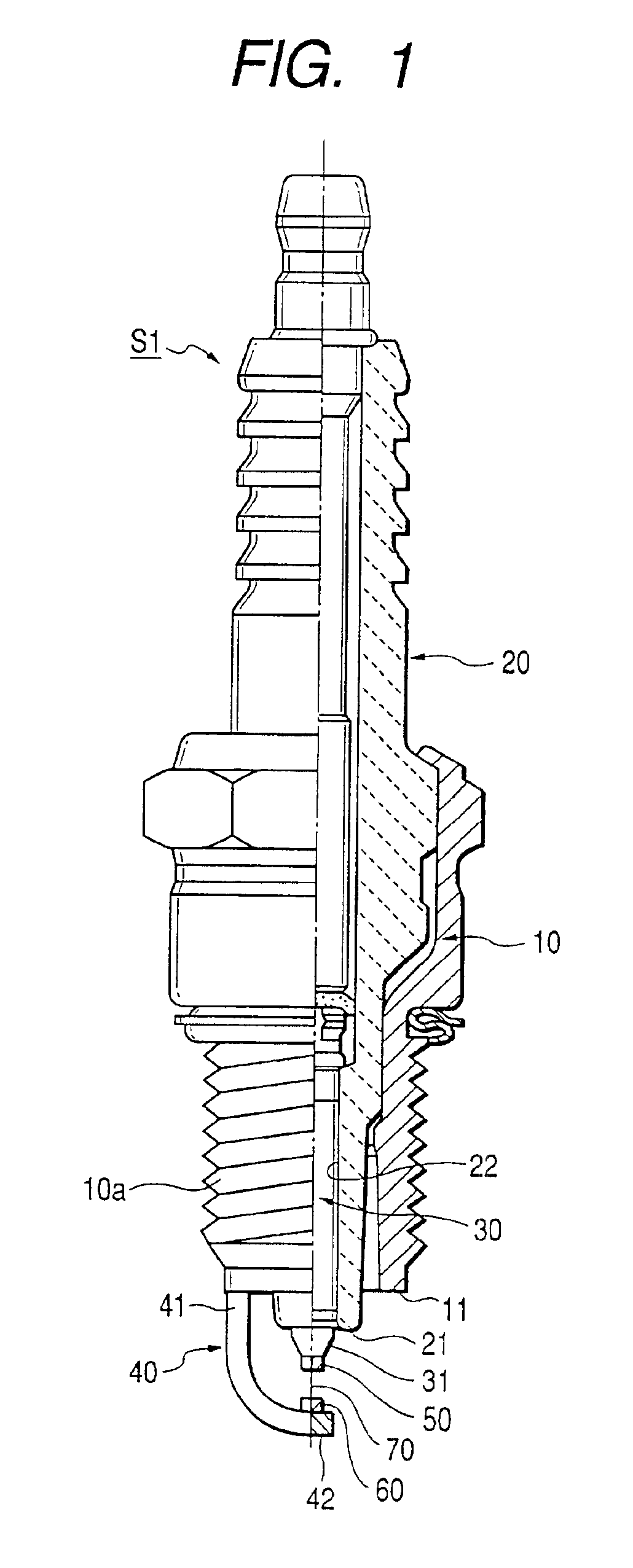

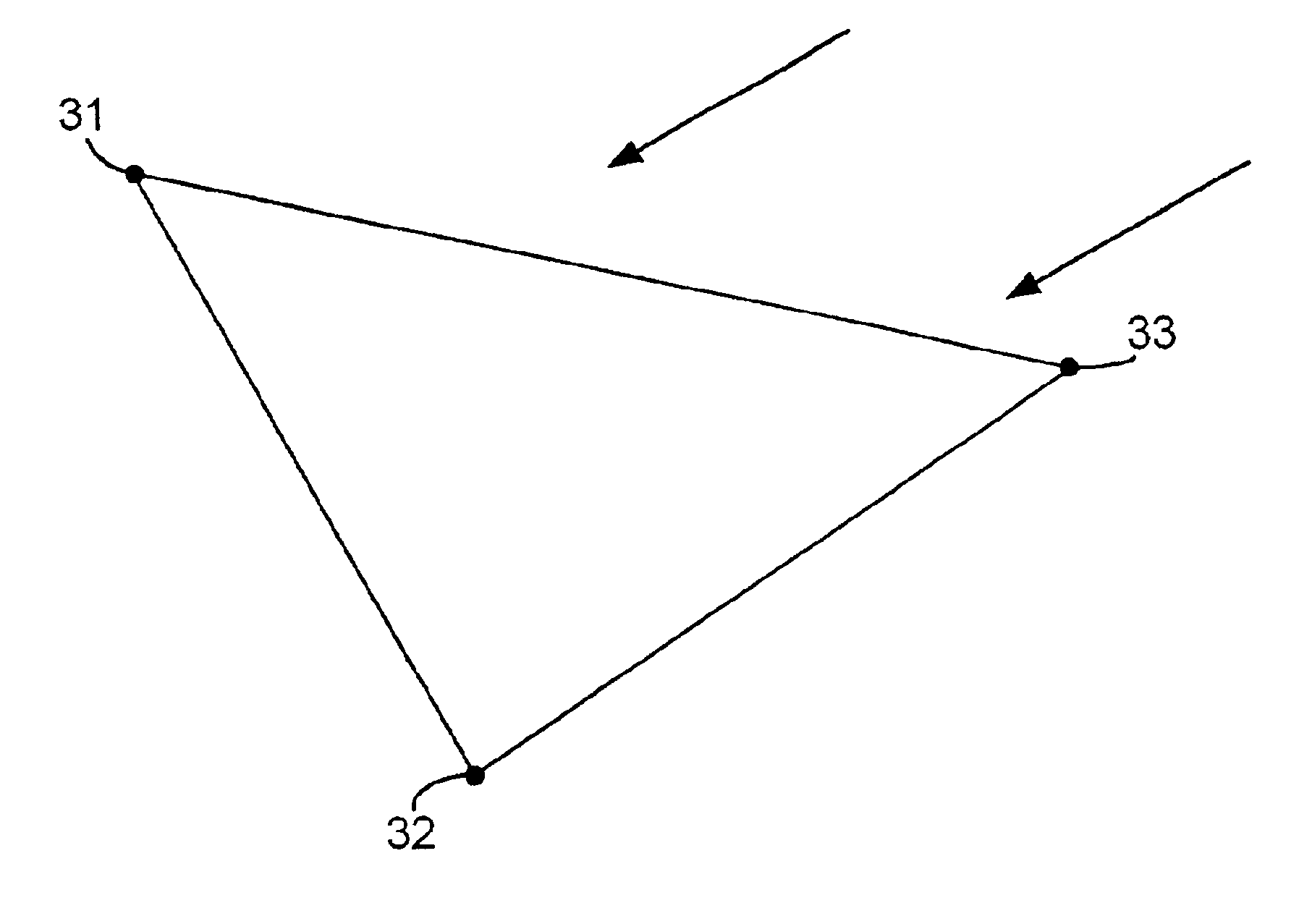

Spark plug and its manufacturing method

InactiveUS6885135B2Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

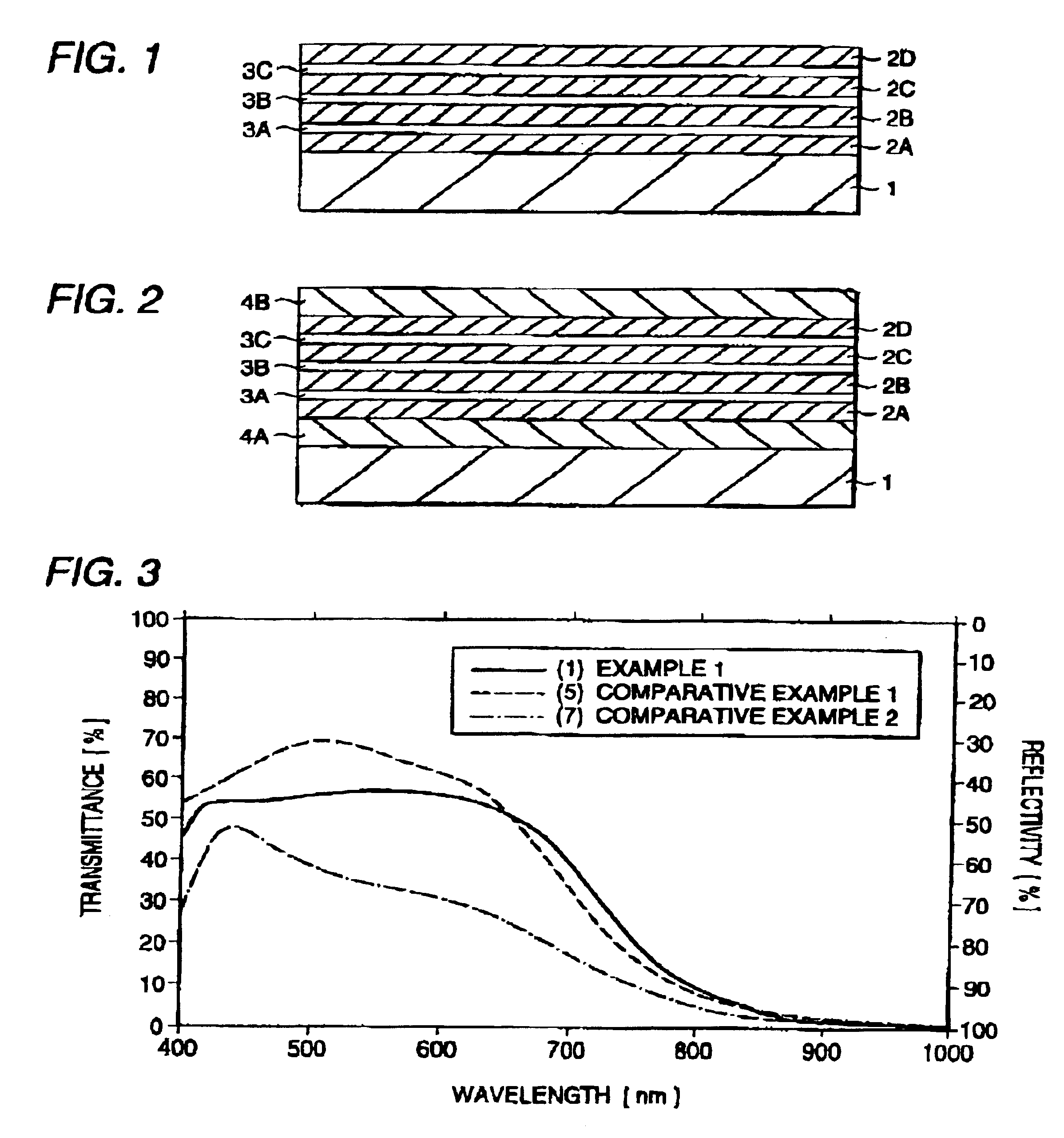

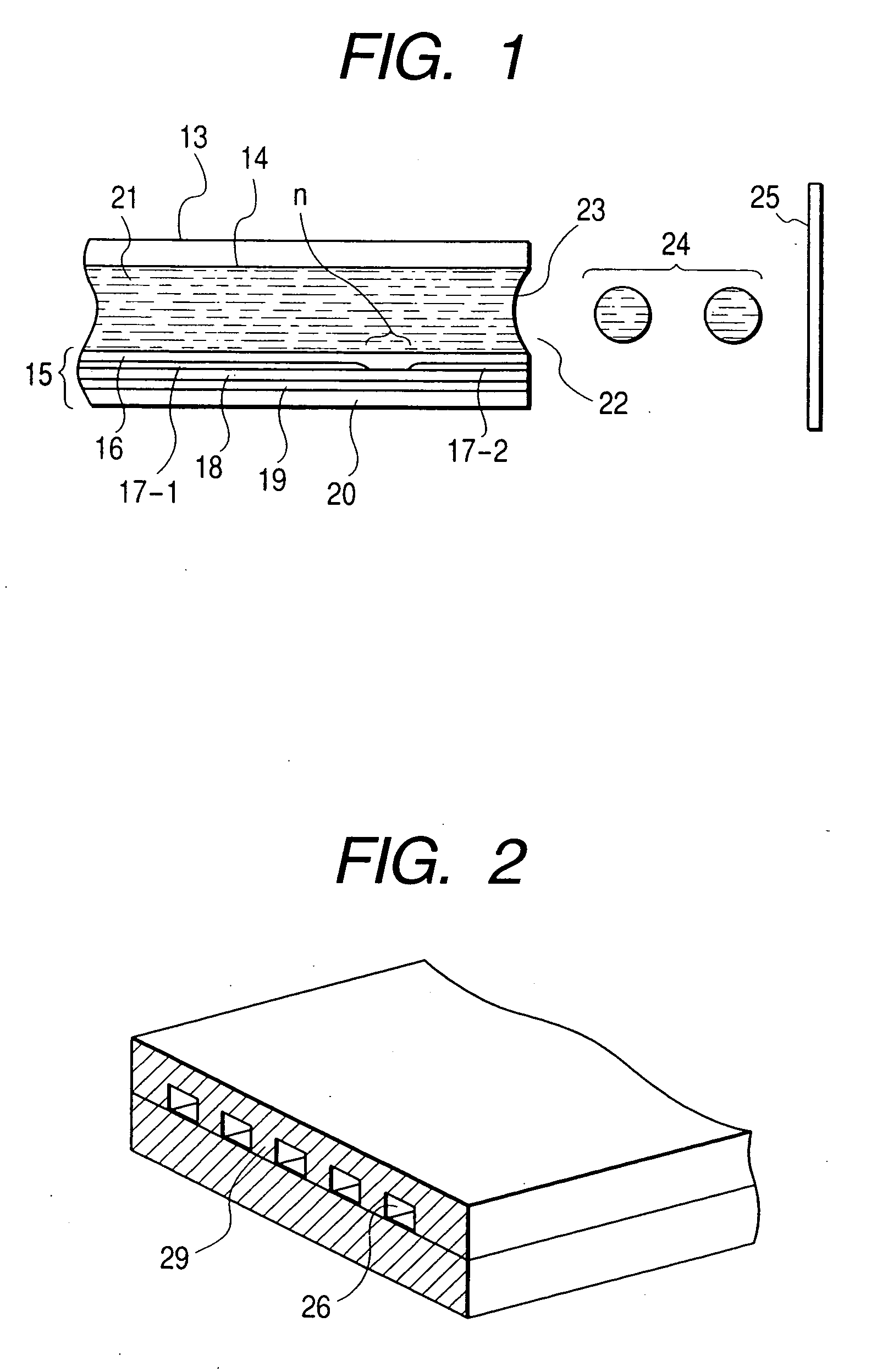

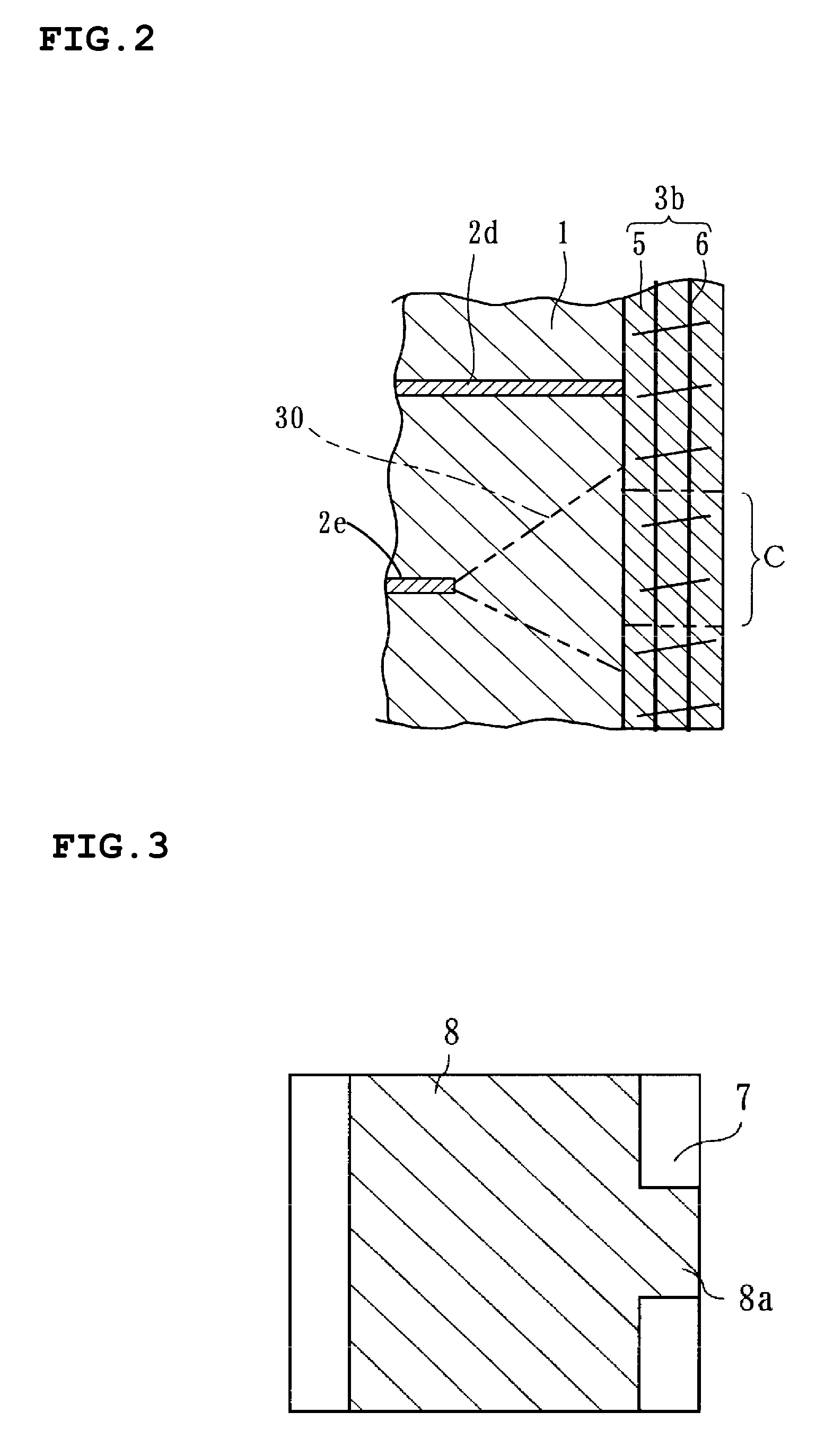

Transparent laminate, method for producing the same, and plasma display panel

InactiveUS6855369B2Little dependenceImprove visibilityMirrorsOptical filtersTransmittanceRefractive index

In a transparent laminate, n thin-film units (n=3 or 4) are laminated unit by unit successively on a surface of a substrate, and a high-refractive-index transparent thin film is deposited on a surface of the laminate of the n thin-film units, each of the n thin-film units consisting of a high-refractive-index thin film and a silver transparent conductive thin film. When the silver transparent conductive thin films are deposited by a vacuum dry process, the temperature T(K) of the transparent substrate at the time of film deposition is set to be in a range 340≦T≦410, whereby the transparent laminate having a standard deviation of visible light transmittance which is not larger than 5% in a wave range of from 450 to 650 nm can be produced.

Owner:NITTO DENKO CORP

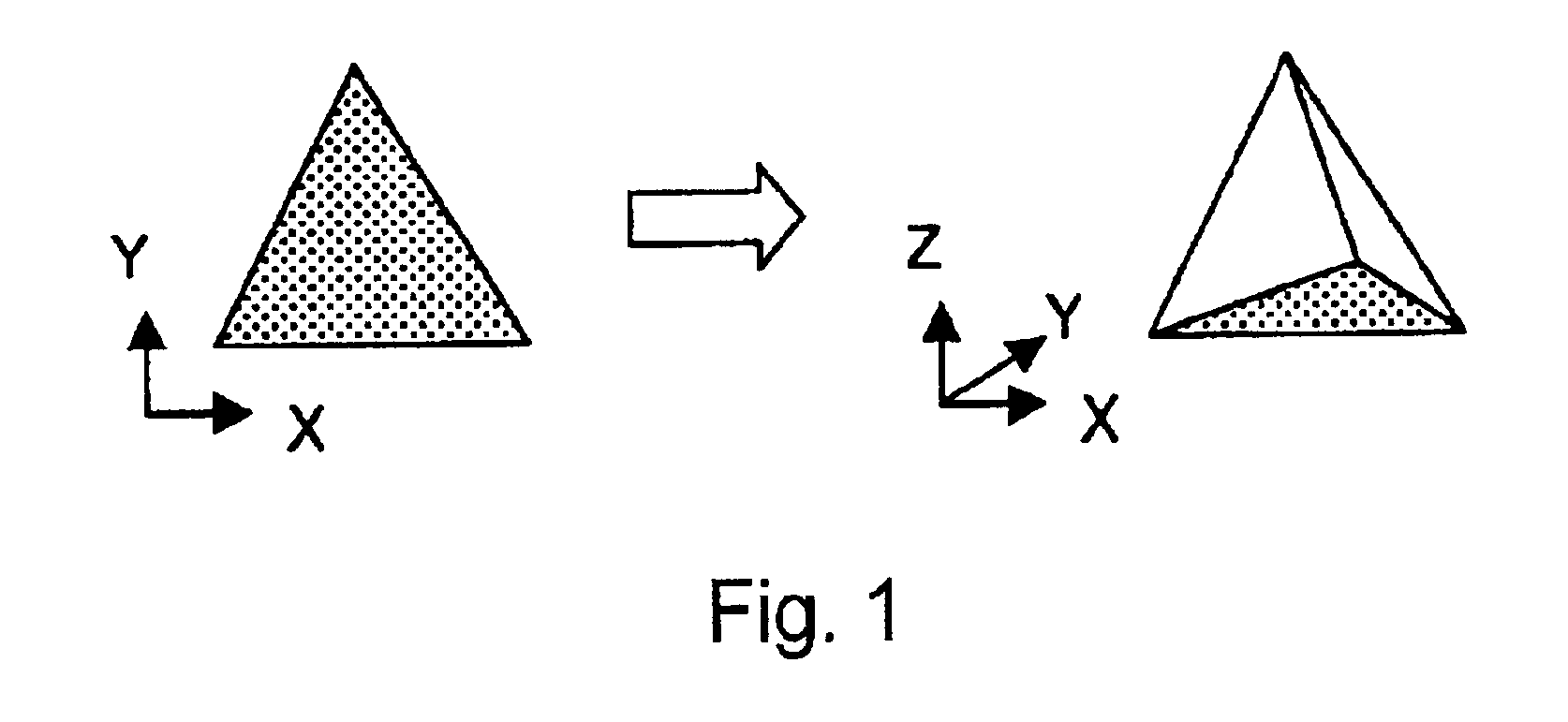

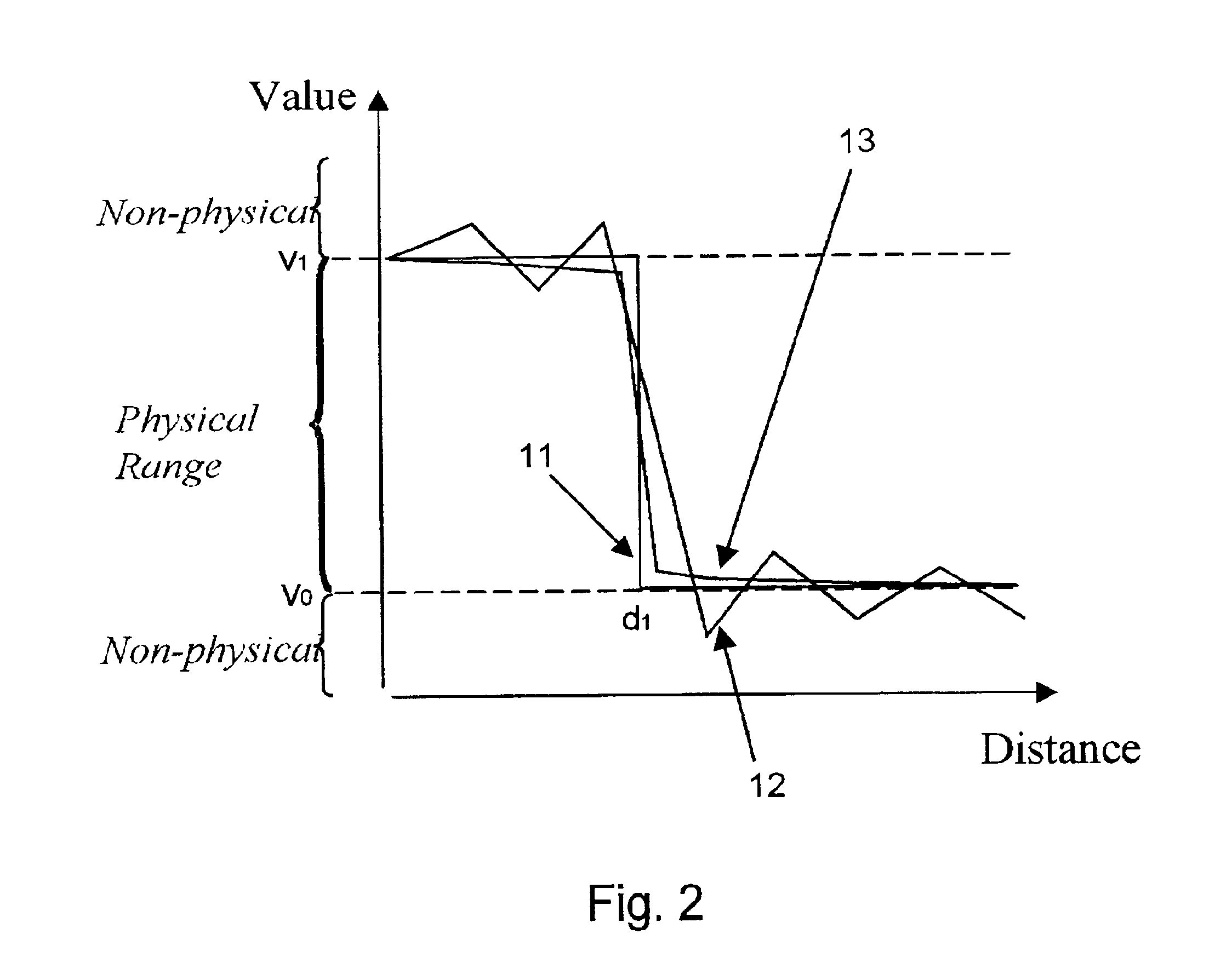

Method and system for solving finite element models using multi-phase physics

InactiveUS7027964B2Satisfactory propertyGeometric CADComputation using non-denominational number representationElement modelWeight coefficient

Systems and methods for solving finite element models, wherein the matrix that governs the solution is modified by adjusting the weighting coefficients of the matrix so that the elements which lie on the diagonal of the matrix are non-negative and the elements which are off the diagonal are non-positive. In one embodiment, a system is discretized on a finite element mesh with the contribution of each node to the discretization being weighted based upon the direction of fluid flow across each element. The nodes which are upstream from the other nodes of the respective elements are weighted more heavily to cause the resulting matrix to be substantially diagonal. This matrix is solved using traditional techniques.

Owner:LANDMARK GRAPHICS CORP

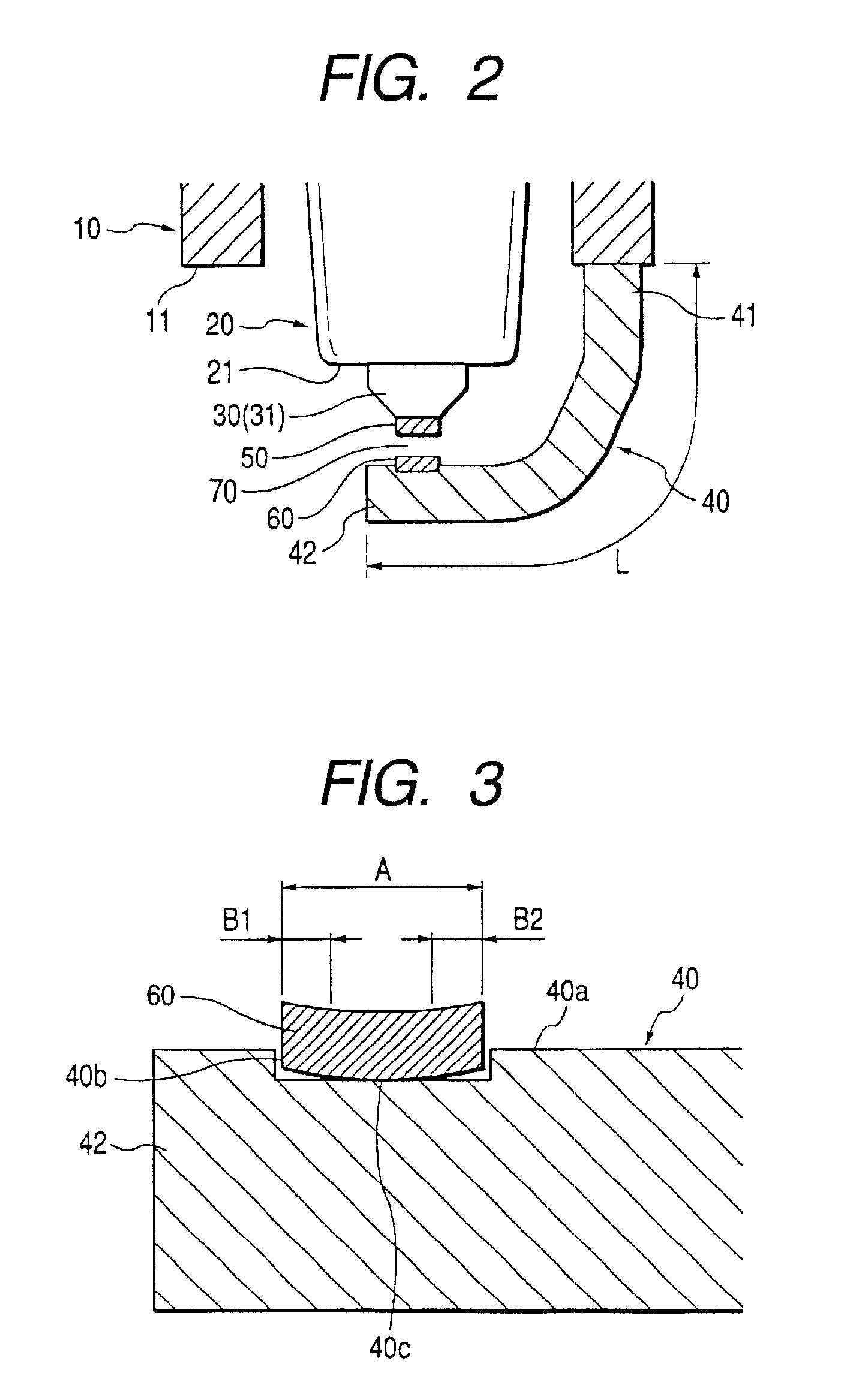

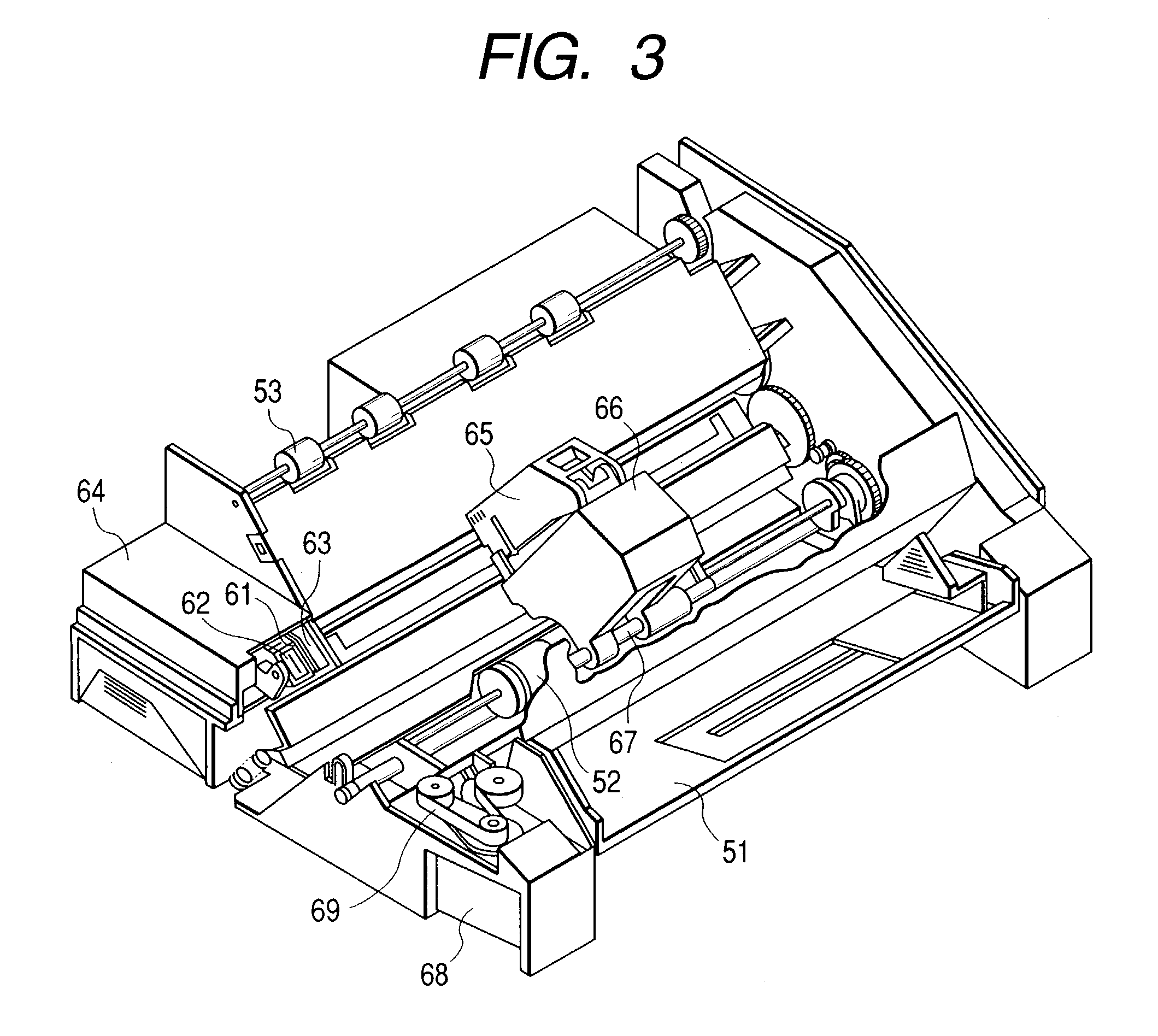

Epoxy resin composition, surface treatment method, liquid ejection recording head, and liquid ejection recording apparatus

InactiveUS7074273B2Improve impact performanceImprove printing qualityRecording apparatusLiquid surface applicatorsEpoxyCationic polymerization

An embodiment of the invention relates to a novel epoxy resin composition. The epoxy resin composition comprises (i) a first epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, and having a number average molecular weight ranging from 8,000 to 22,000 and a polydispersity ranging from 3.5 to 5.0, (ii) a second epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, having a number average molecular weight ranging from 2,500 to 8,000 and a polydispersity ranging from 1.5 to 3.0, and (iii) a cationic polymerization catalyst.

Owner:CANON KK

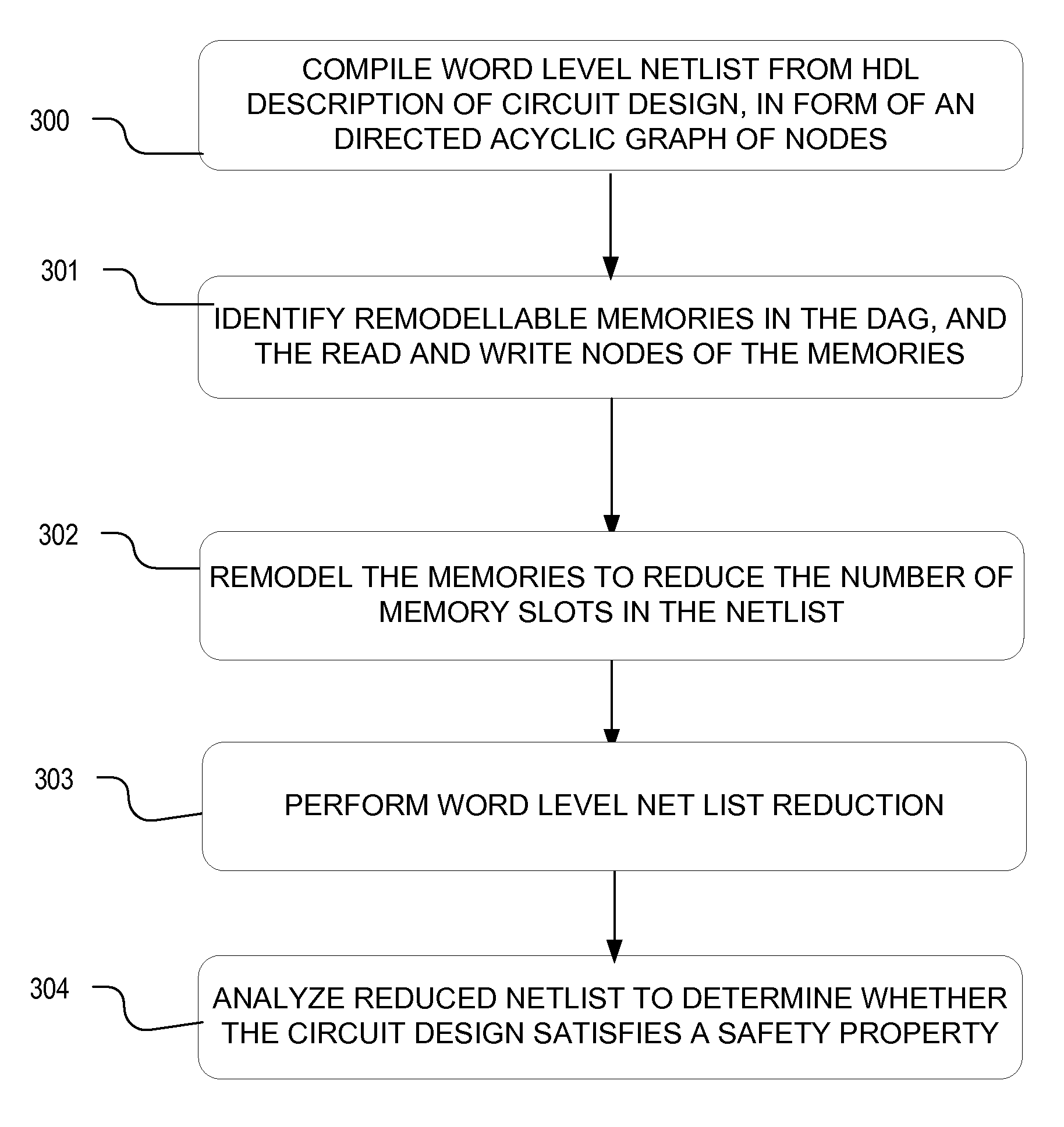

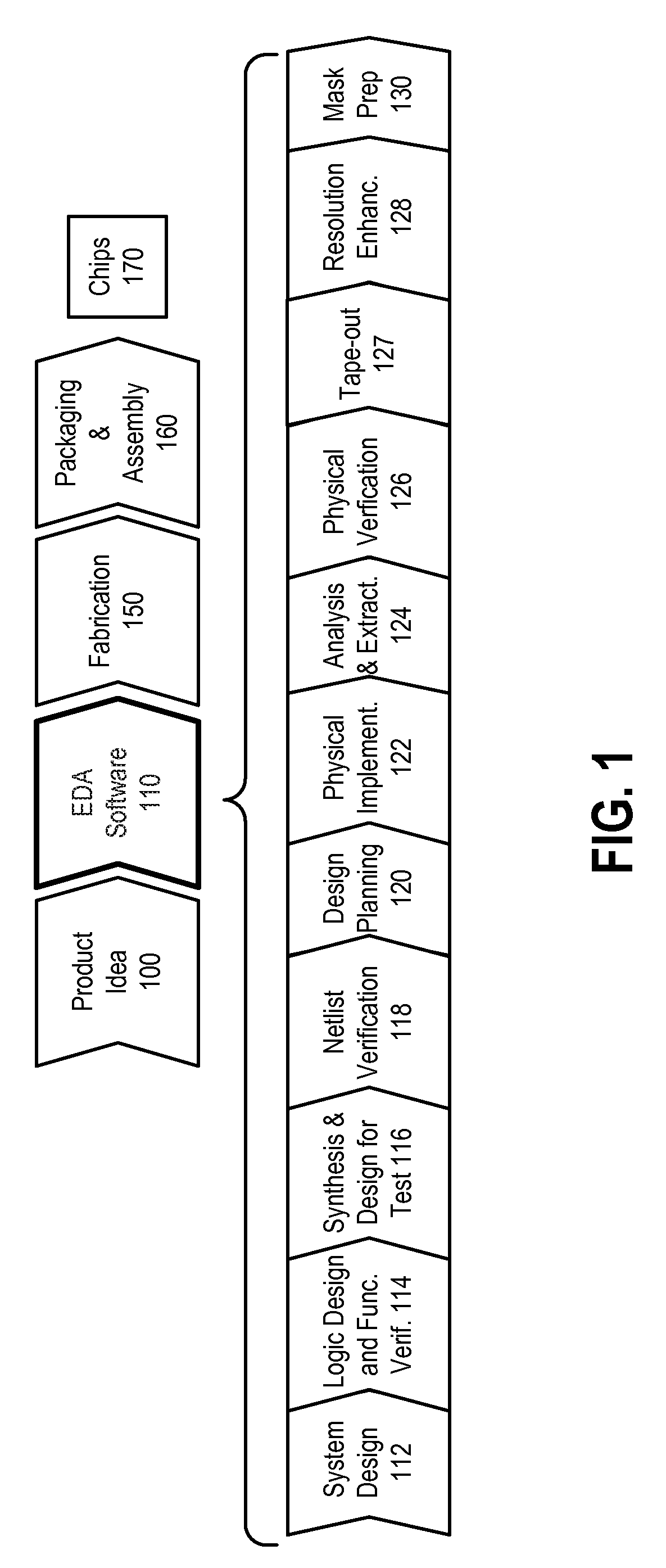

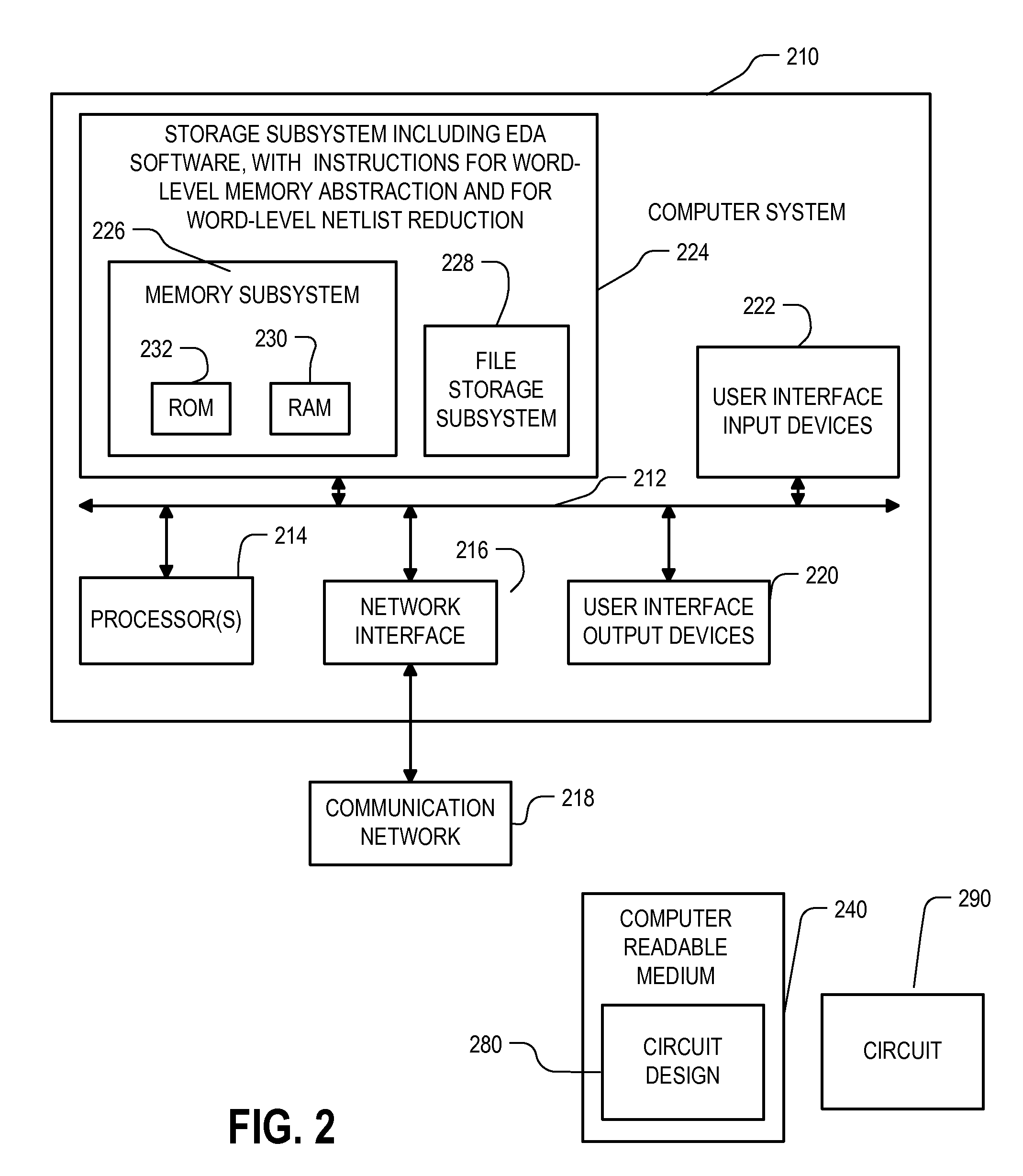

Method and apparatus for memory abstraction and for word level net list reduction and verification using same

ActiveUS20100107132A1Reduce decreaseReduced netlistComputer aided designSoftware simulation/interpretation/emulationNetlistCircuit design

A computer implemented representation of a circuit design including memory is abstracted to a smaller netlist by replacing memory with substitute nodes representing selected slots in the memory, segmenting word level nodes, including one or more of the substitute nodes, in the netlist into segmented nodes, finding reduced safe sizes for the segmented nodes and generating an updated data structure representing the circuit design using the reduced safe sizes of the segmented nodes. The correctness of such systems can require reasoning about a much smaller number of memory entries and using nodes having smaller bit widths than exist in the circuit design. As a result, the computational complexity of the verification problem is substantially reduced.

Owner:SYNOPSYS INC

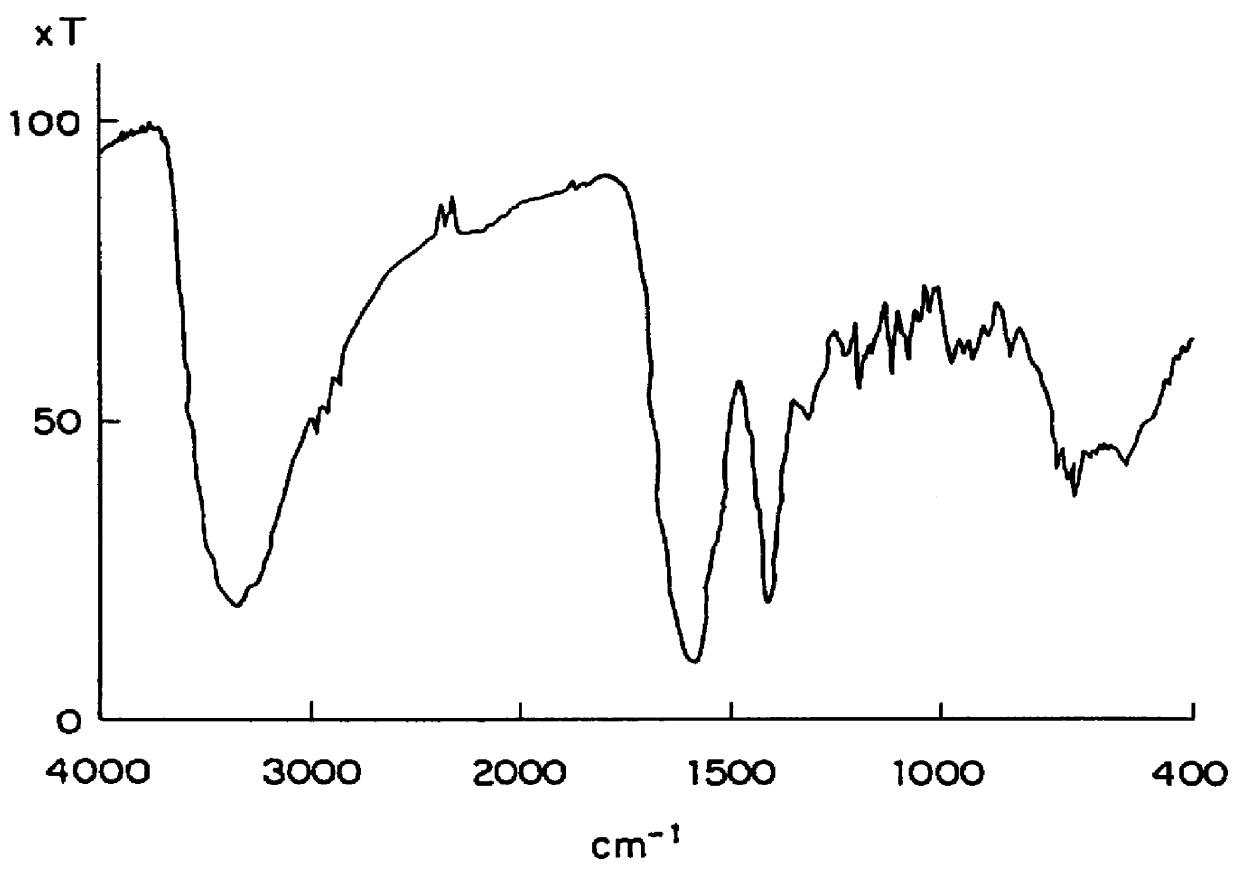

Aromatic vinyl/isoprene block copolymer, process for the production thereof, and hardenable pressure-sensitive adhesive composition containing the same

An aromatic vinyl compound-isoprene block copolymer composition comprising (i) 5-50 wt. % a branched copolymer of the formula: (A-B)nX wherein A is a polymer block of an aromatic vinyl monomer, B is a polymer block of isoprene, and X is a residue of a polyfunctional coupling agent, and (ii) 50-95 wt. % of a diblock copolymer of the formula: A-B wherein A and B are as defined above. This copolymer composition is produced by allowing an aromatic vinyl monomer to contact with an organic lithium initiator to prepare a polymer block A; incorporating isoprene thereto to prepare a diblock copolymer A-B; and then, adding a polyfunctional coupling agent to convert a part of the diblock copolymer A-B to the branched copolymer (A-B)nX. This block copolymer composition is useful for an adhesive or pressure sensitive adhesive composition.

Owner:ZEON CORP

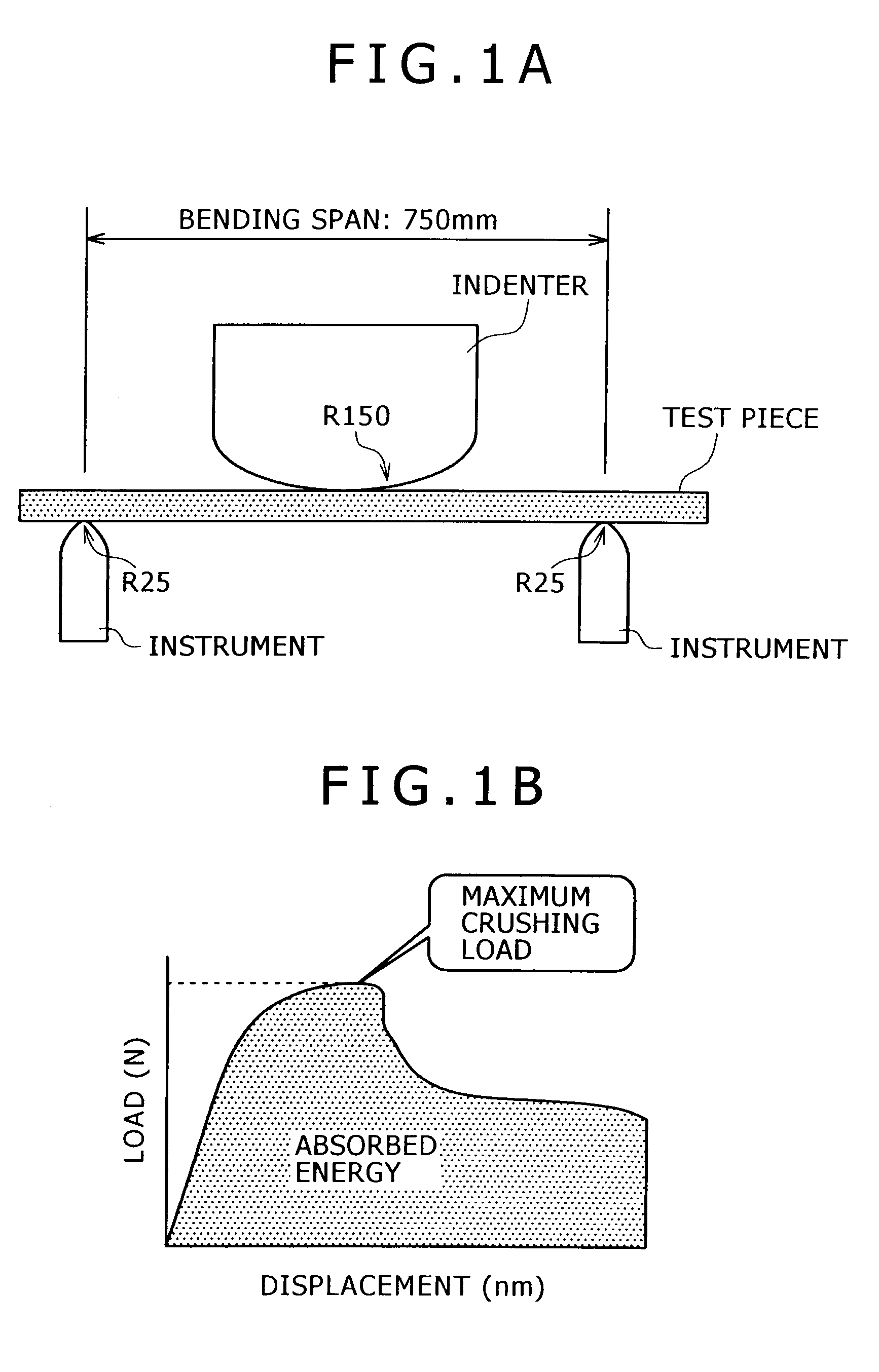

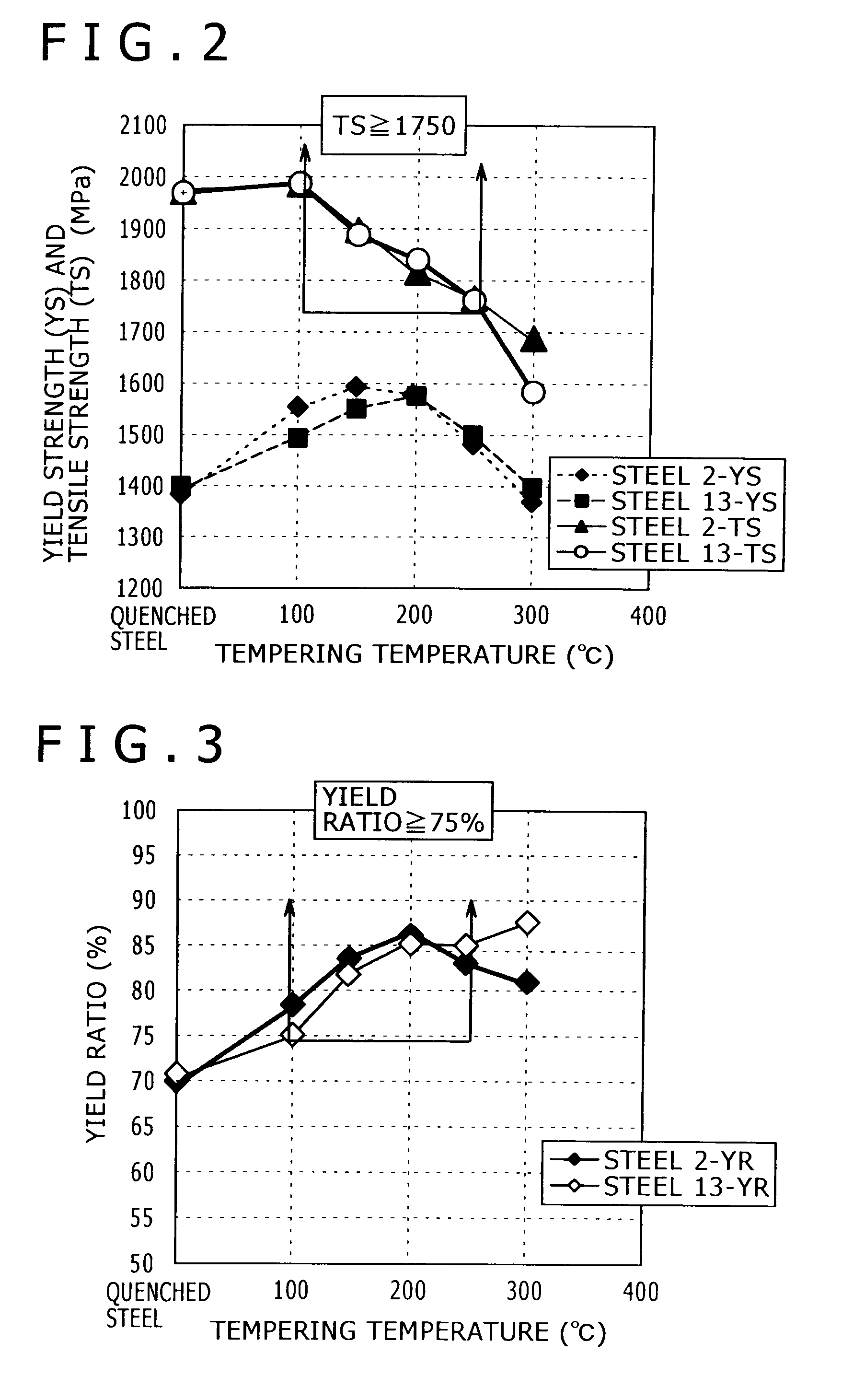

Automobile high-strength electric resistance welded steel pipe with excellent low-temperature impact properties and method of manufacturing the same

InactiveUS20080226491A1High yield strengthExcels in shock absorptivityFurnace typesVehicle componentsSheet steelHigh intensity

Disclosed is a high-strength electric resistance welded steel pipe which is manufacture from a steel sheet containing, on mass basis, 0.2% to 0.4% C, 0.05% to 0.5% Si, 0.5% to 2.5% Mn, 0.025% or less P, 0.01% or less S, 0.01% to 0.15% or Al, 0.01% to 2% Cu, 0.05% to 2% Cr, 0.005% to 0.2% Ti, and 0.0002% to 0.005% B, with the remainder being iron and inevitable impurities. The steel pipe has a tensile strength of 1750 N / mm2 or more, a 0.1%-proof stress of 1320 N / mm2 or more, and a Charpy impact value at a testing temperature of minus 40° C. of 50 J / cm2 or more.

Owner:KOBE STEEL LTD

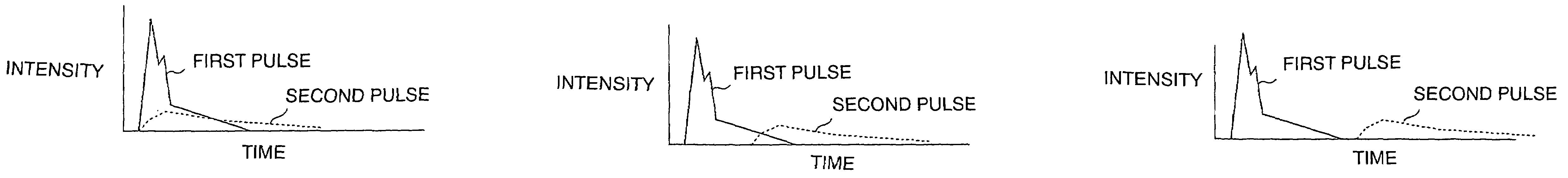

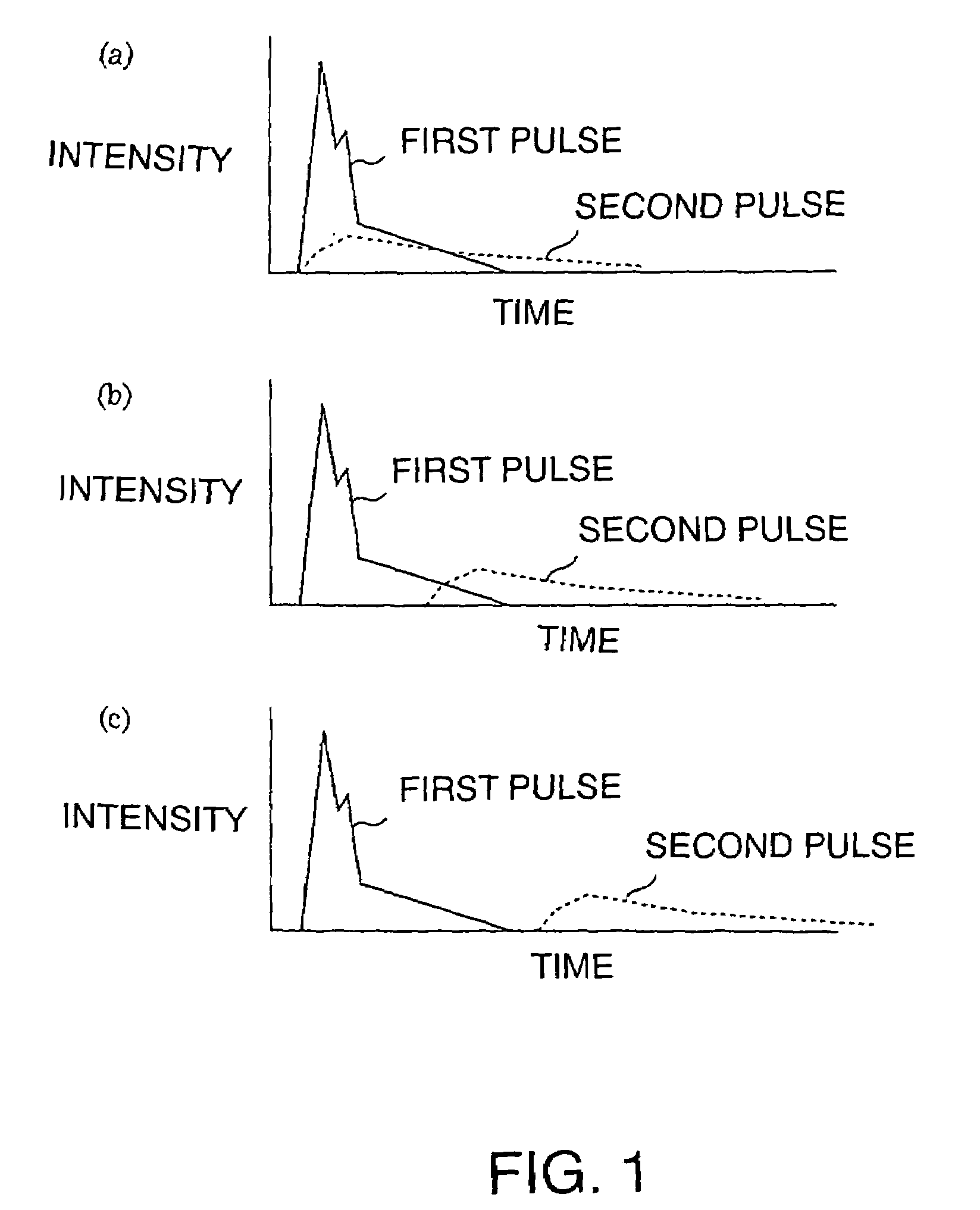

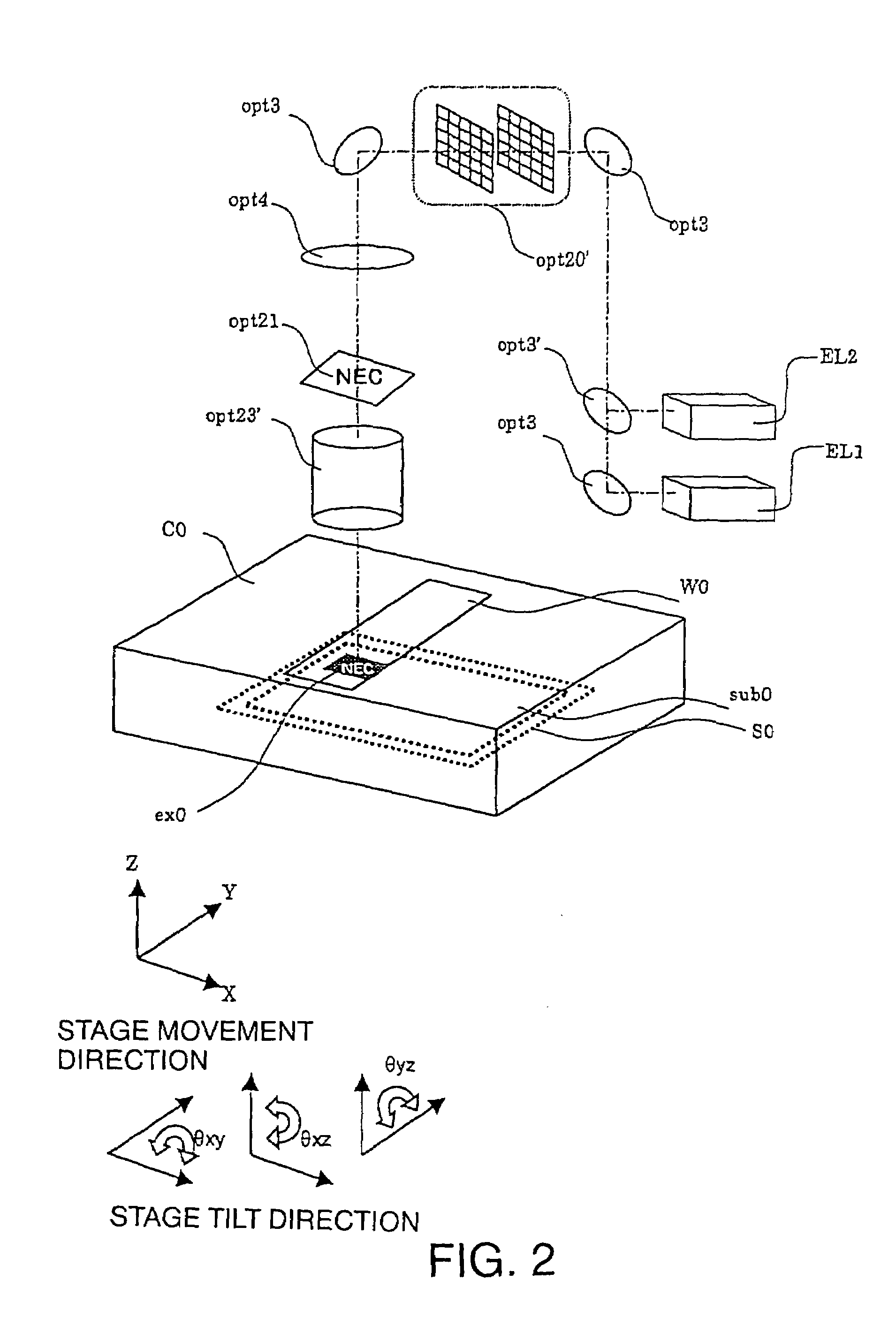

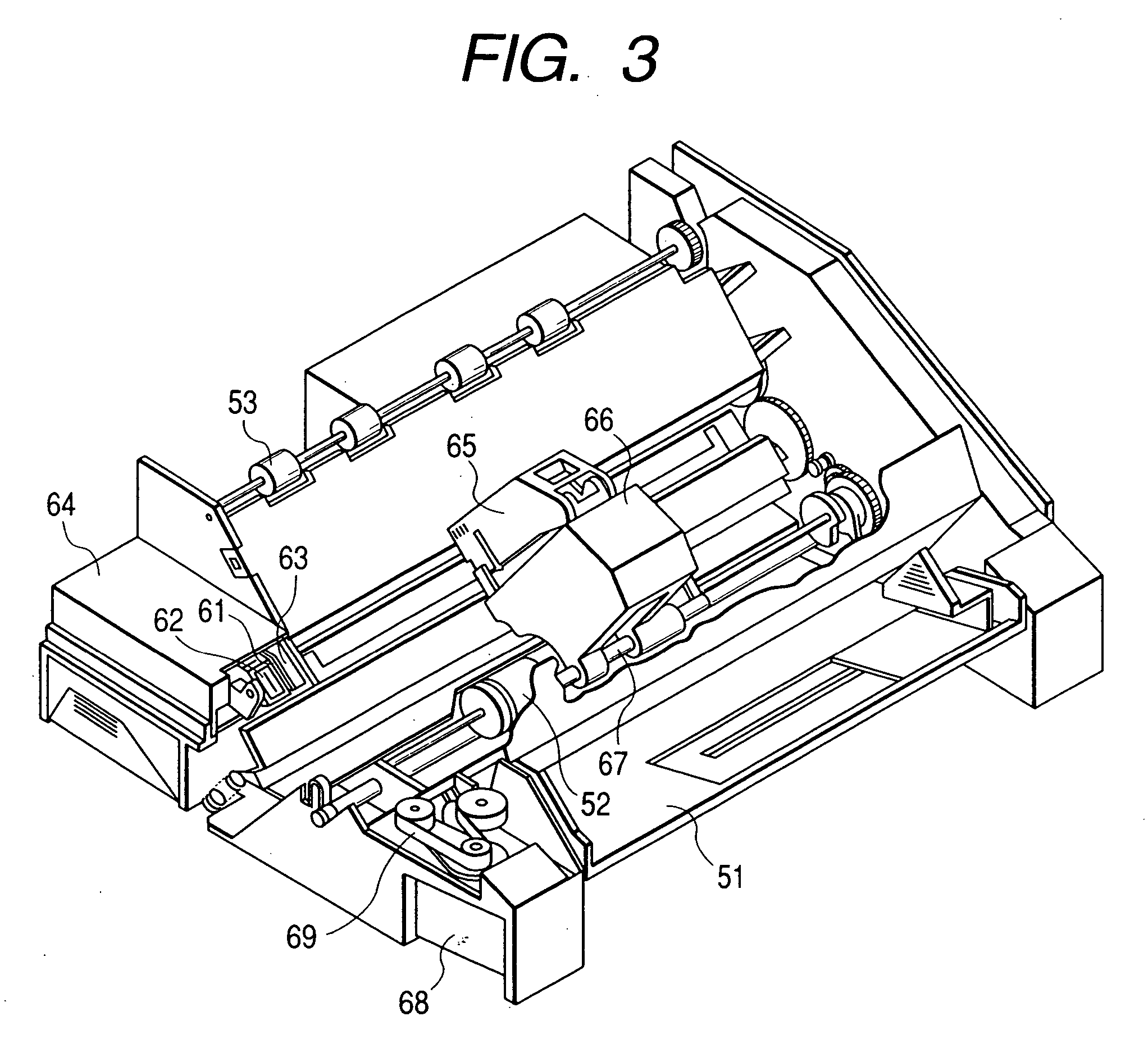

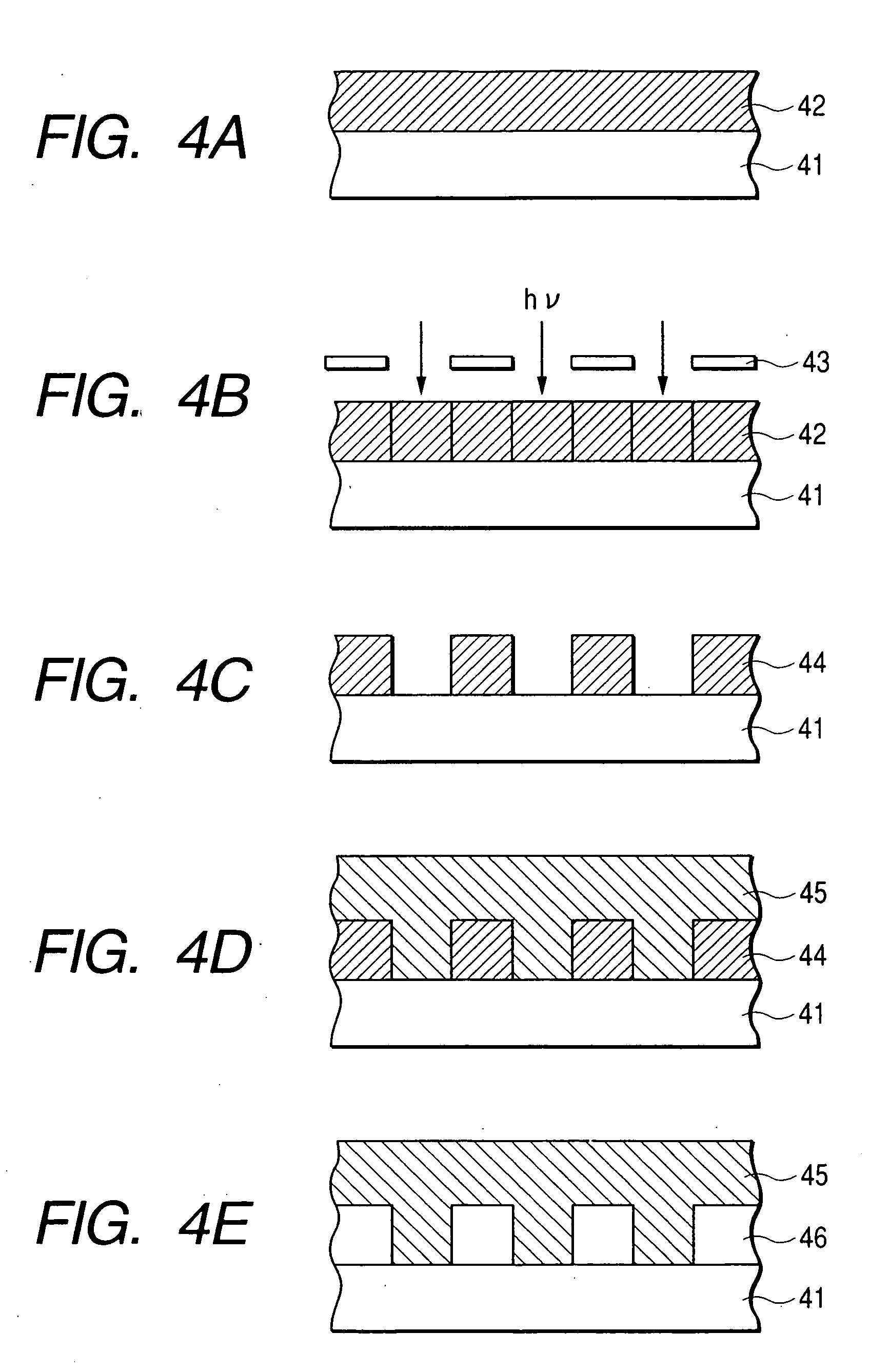

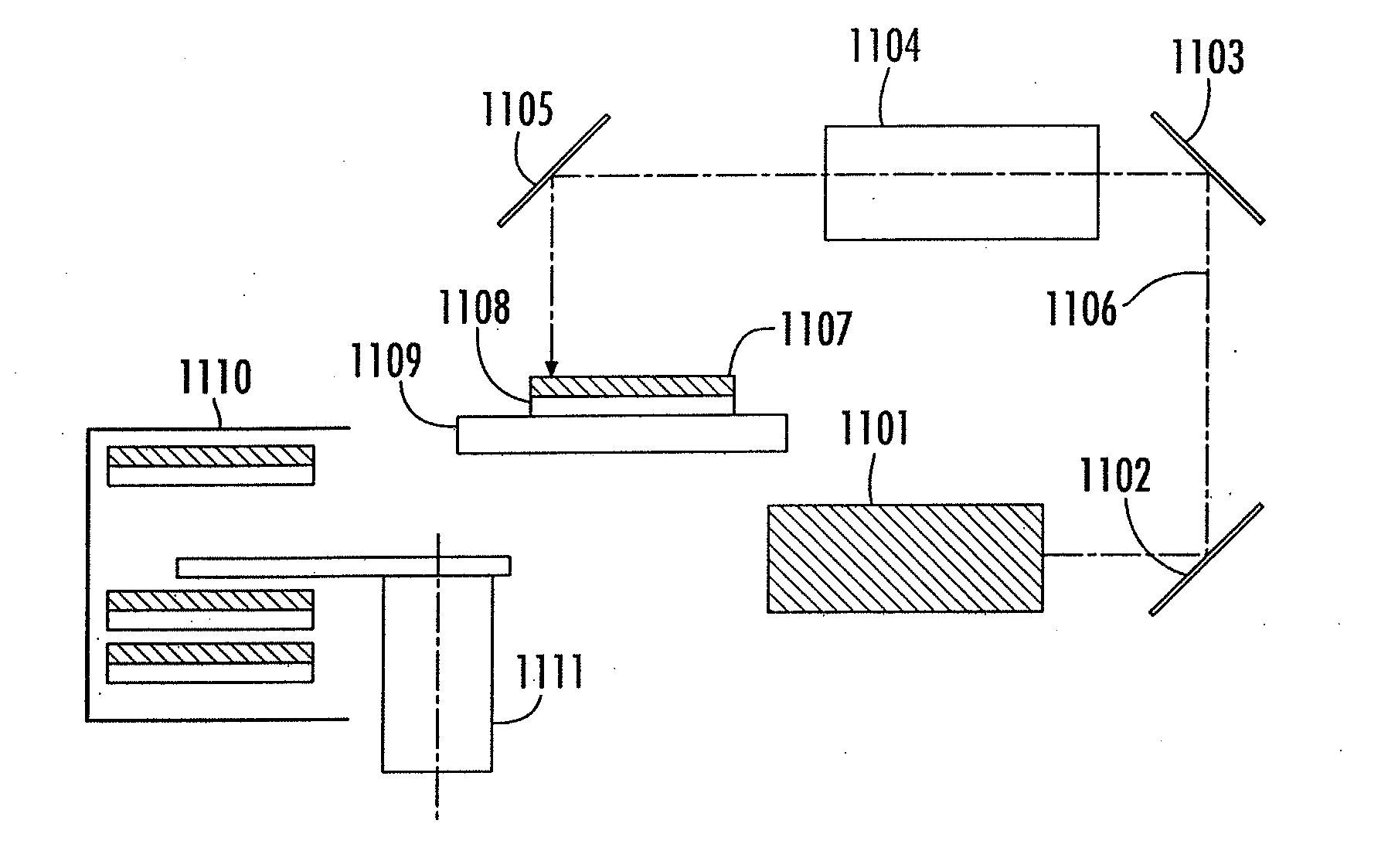

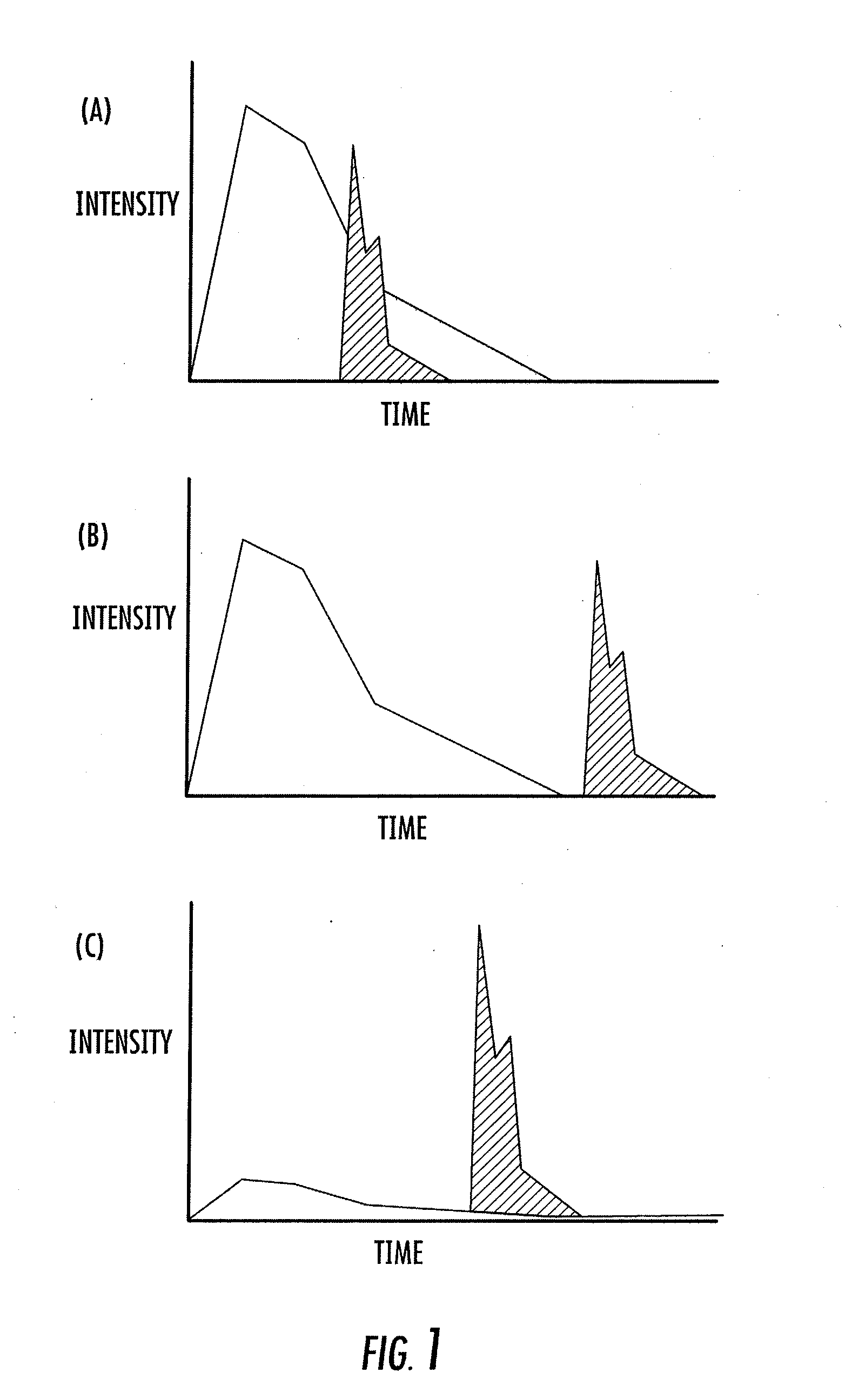

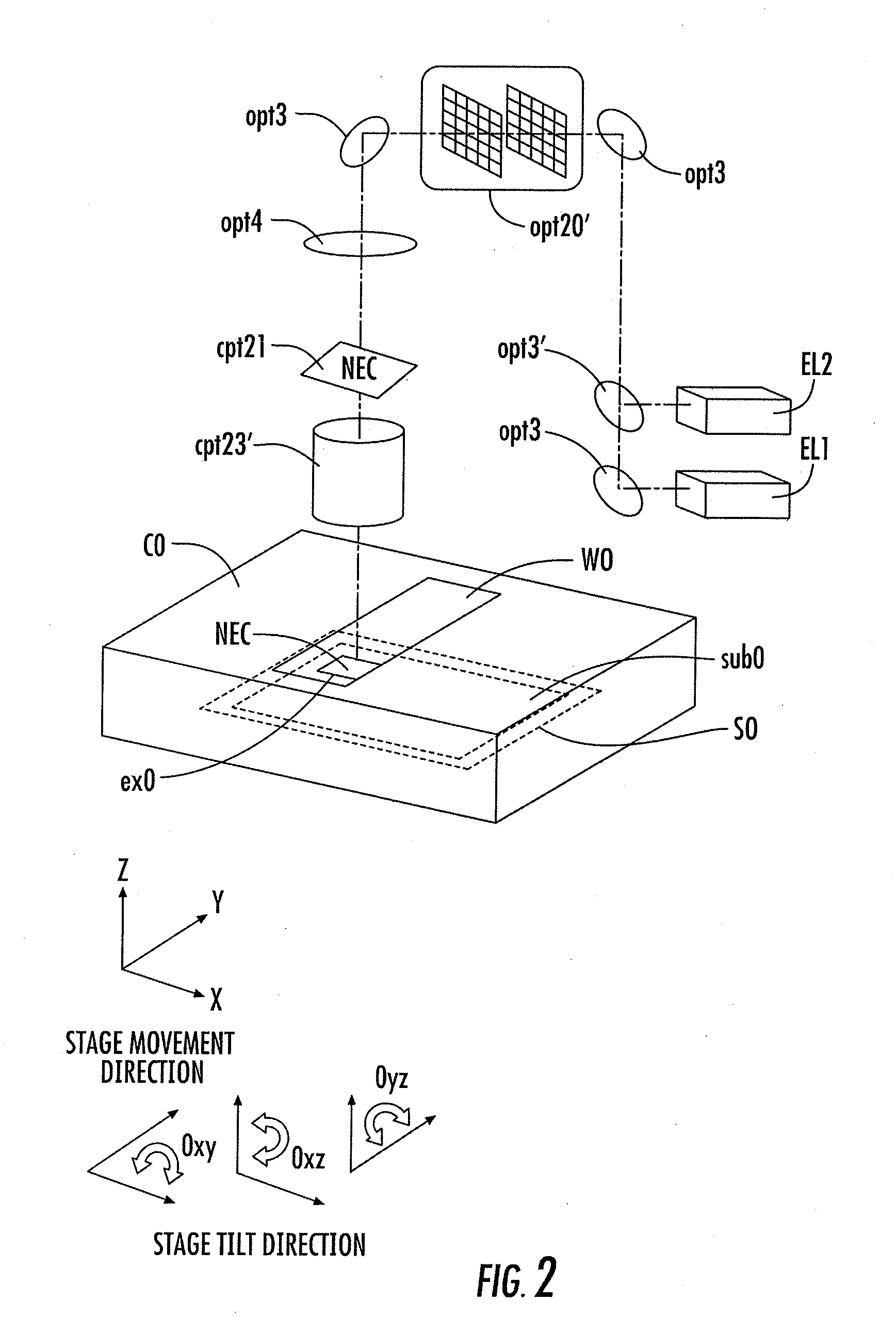

Thin film processing method and thin film processing apparatus including controlling the cooling rate to control the crystal sizes

InactiveUS7063999B2Quality improvementSatisfactory propertyTransistorSemiconductor/solid-state device manufacturingPhysicsPhoto irradiation

A thin film processing method for processing the thin film by irradiating an optical beam to the thin film. A unit of the irradiation of the optical beam includes a first and a second optical pulse irradiation to the thin film, and the unit of the irradiation is carried out repeatedly to process the thin film. The first and the second optical pulse have pulse waveforms different from each other. Preferably, a unit of the irradiation of the optical beam includes the a first optical pulse irradiated to the thin film and a second optical pulse irradiated to the thin film starting substantially simultaneous with the first optical pulse irradiation. In this case, the relationship between the first and the second optical pulse satisfies (the pulse width of the first optical pulse)<(the optical pulse of the second optical pulse) and (the irradiation intensity of the first optical pulse)≧(the irradiation intensity of the second optical pulse). A silicon thin film with a small trap state density can be formed by the optical irradiation.

Owner:NEC CORP +1

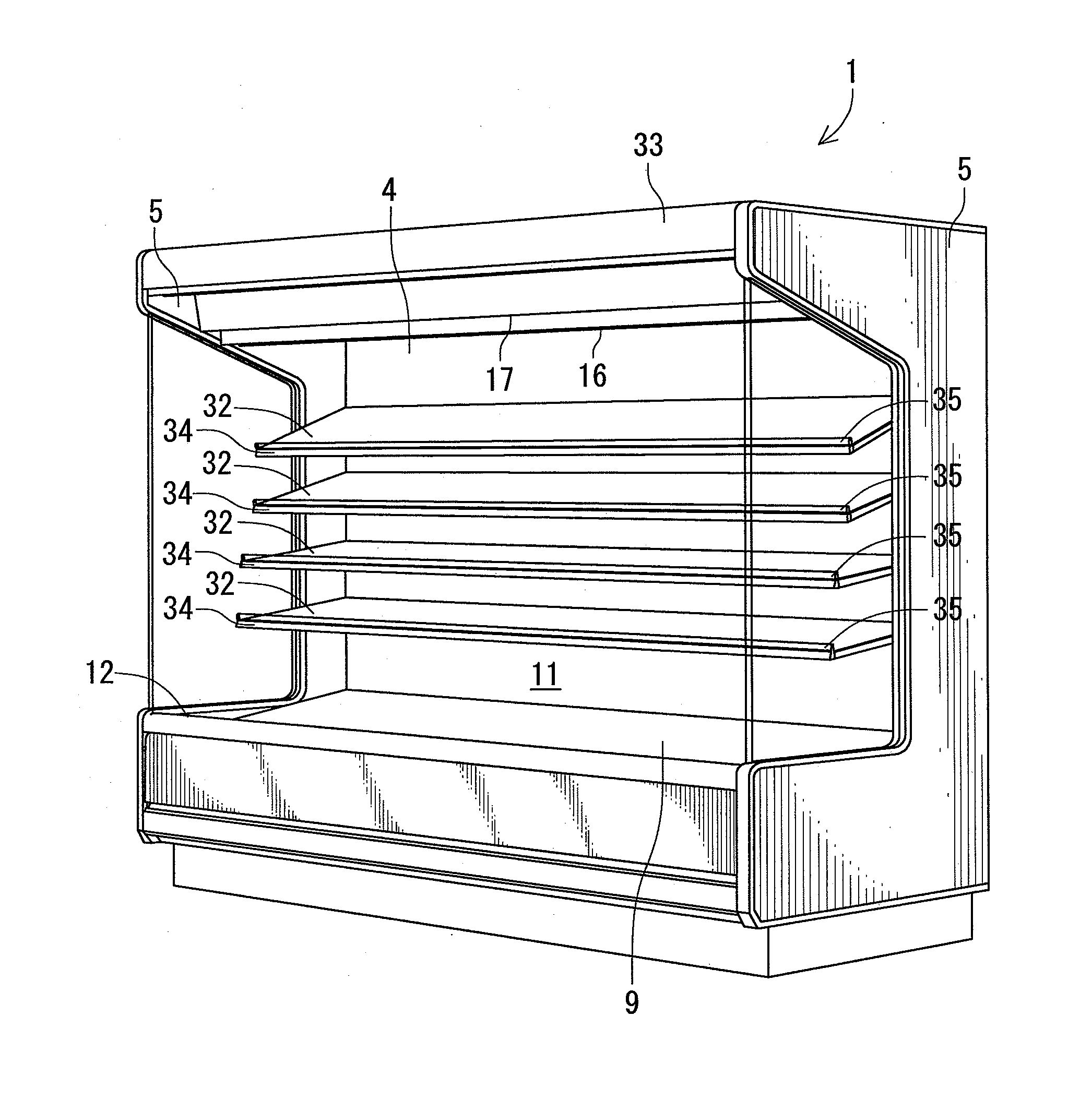

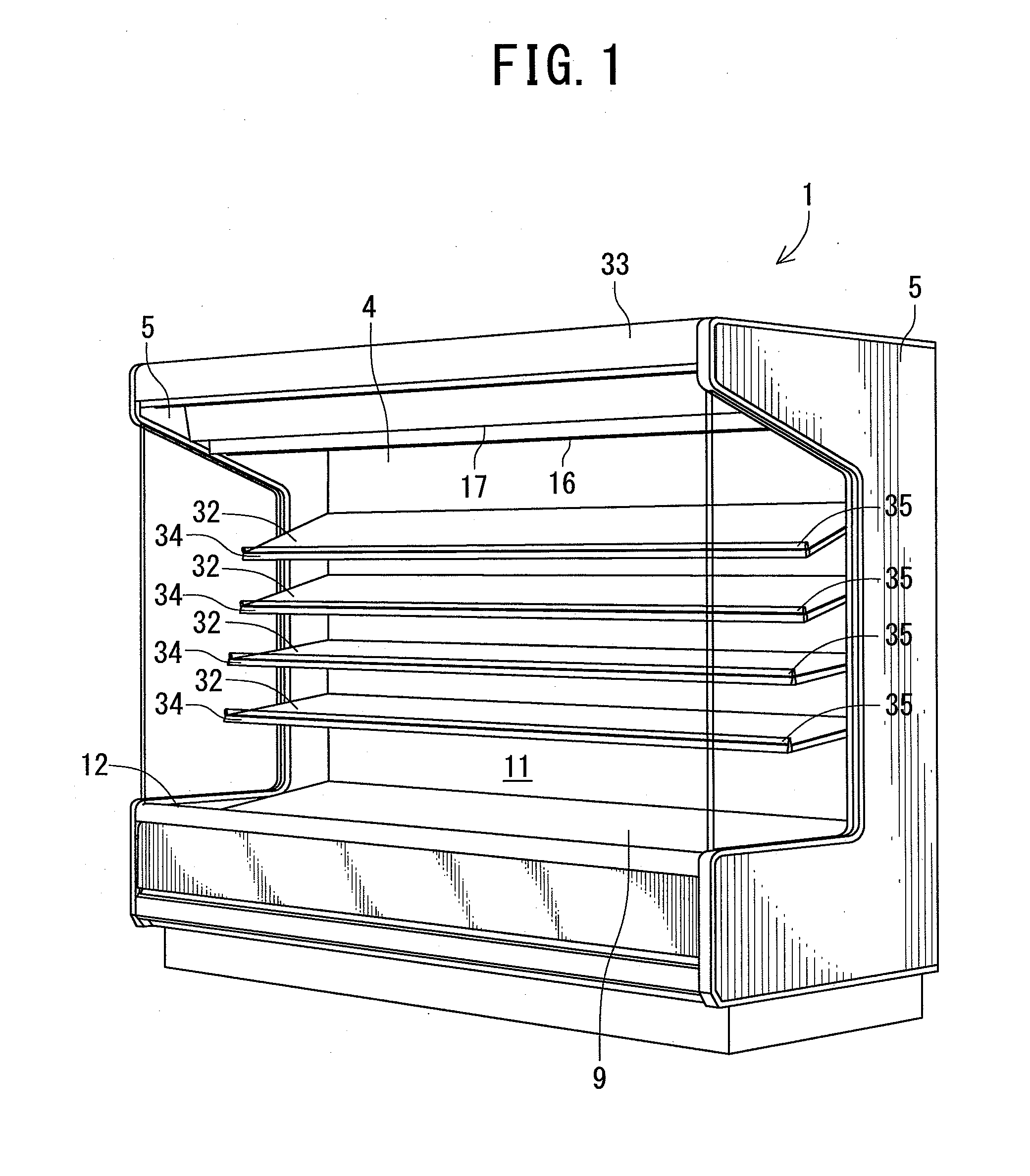

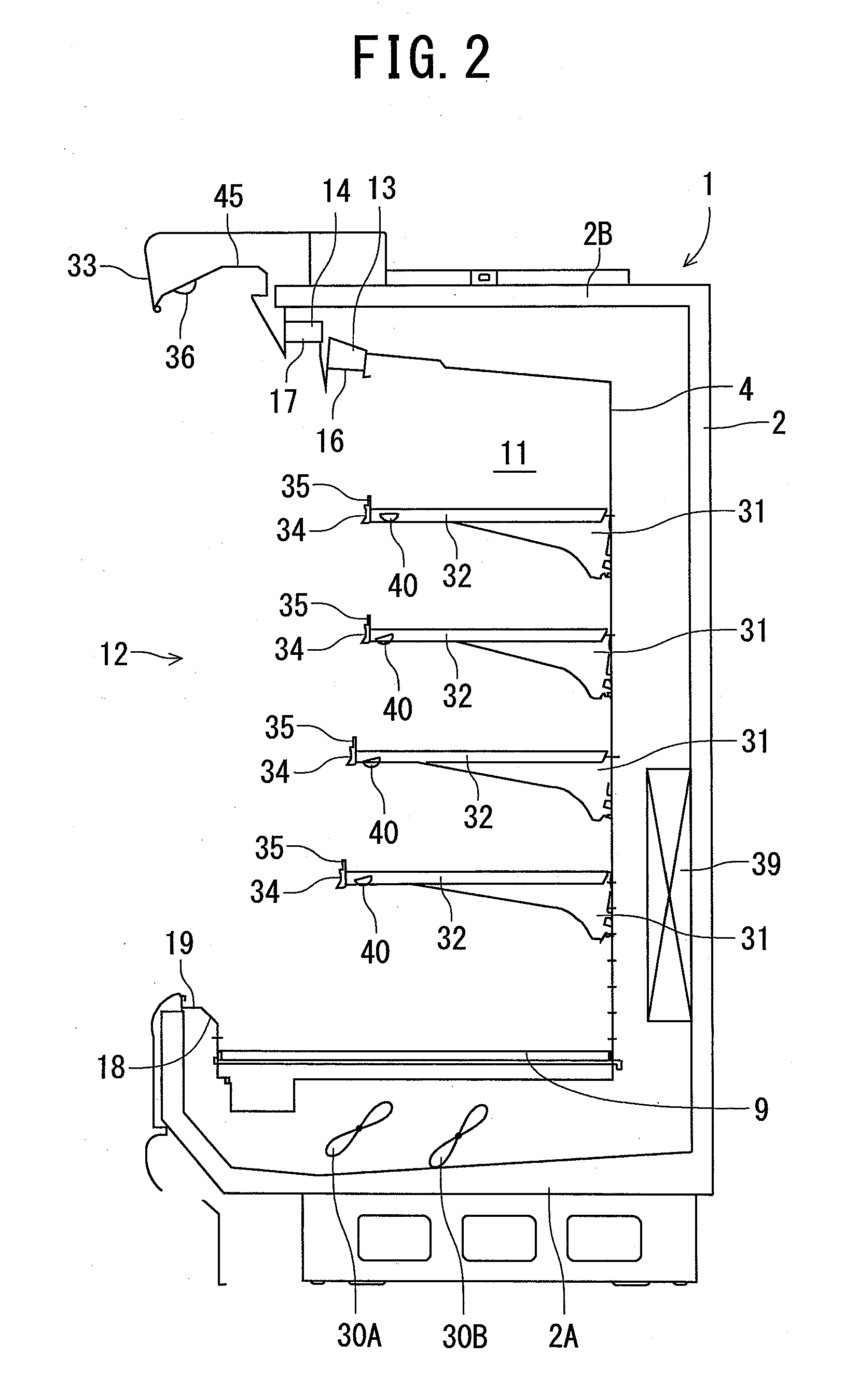

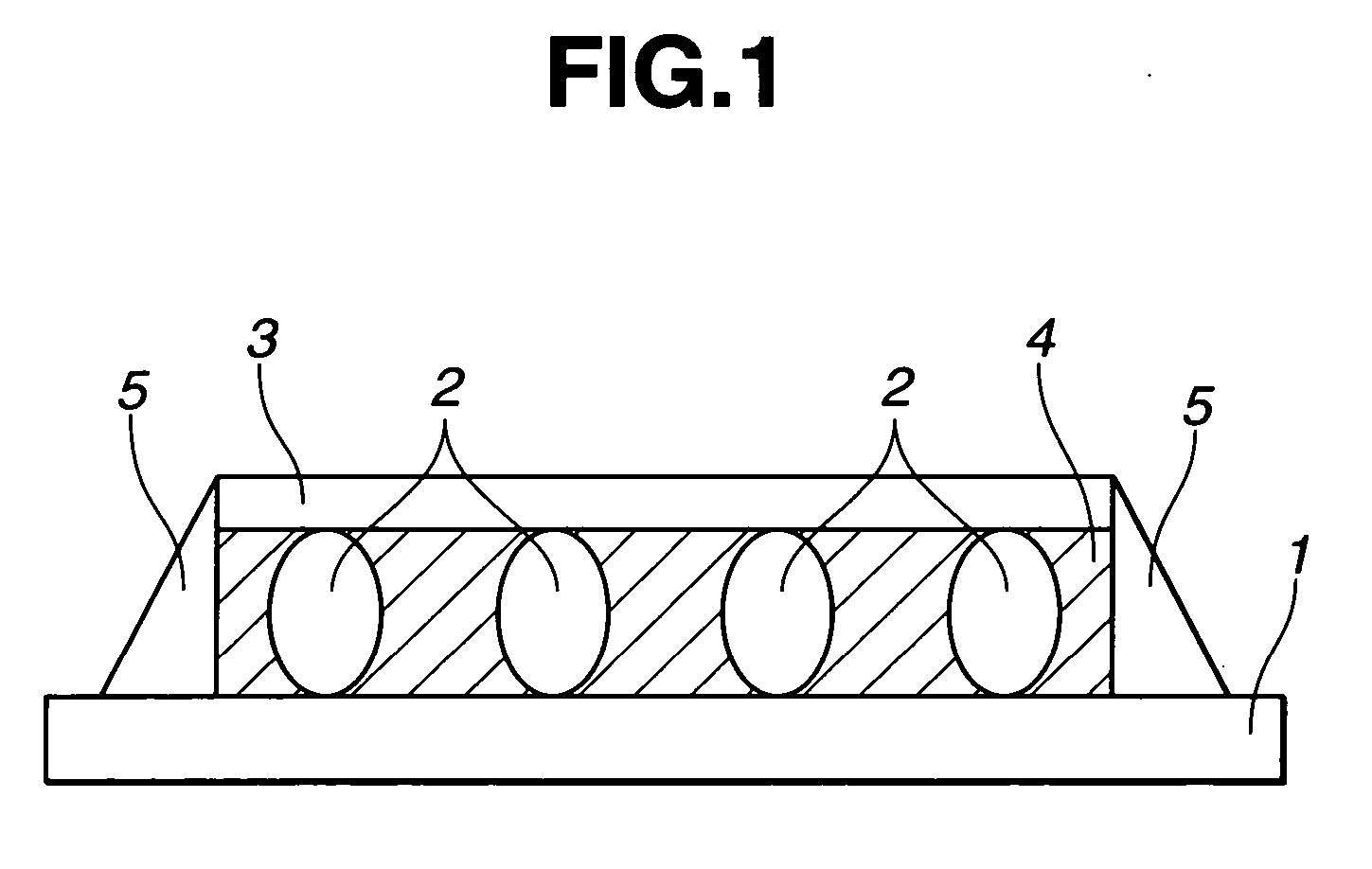

Showcase

InactiveUS20100195317A1Present inventionSatisfactory propertyMechanical apparatusLighting support devicesAcute angleEngineering

There is disclosed a showcase comprising an illumination apparatus which can stably be held by a simple structure and which can illuminate the inside of a display chamber effectively without any unevenness. The illumination apparatus provided in the showcase comprises a shade member constituted of a light-transmitting front wall positioned on the side of the light emitting surfaces of LED elements, and a back wall positioned on the side of a substrate provided with the LED elements, the front wall comprising a curved portion having an arc-like section and a pair of flat portions extended continuously from both ends of the curved portion to intersect with the back wall at an acute angle, corner portions where the flat portions intersect with the back wall being a pair of engaging portions; and a holder provided with a plurality of engagement portions and the like with which the engaging portions are disengageably engaged.

Owner:SANYO ELECTRIC CO LTD

Two-layer fabric and heat-resistant protective clothing containing the same

InactiveUS20090137176A1Improved satisfactory propertyGood lookingLayered productsMulti-ply fabricsFiberThermal insulation

A two-layer fabric according to the present invention has an integral structure containing a base cloth on the upper side and a reinforcing cloth for reinforcing the entire fabric on the under side, wherein (a) the base cloth of the two-layer fabric is flame-retardant and contains a warp yarn and a weft yarn containing 30% by weight or more of a flame-retardant fiber having a limiting oxygen index (LOI) of 26 or more and a tensile strength of 8 cN / dtex or less, (b) the reinforcing cloth of the two-layer fabric contains a warp yarn and a weft yarn containing a heat-resistant high-strength fiber having a tensile strength of 15 cN / dtex or more as a main component, and (c) the base cloth and the reinforcing cloth are connected by the warp yarn and / or the weft yarn of the base cloth, to form the integral structure.Further, a heat-resistant protective clothing contains an outer fabric layer of the two-layer fabric, stacked and sutured by sewing. The heat-resistant protective clothing has improved properties such as a thermal insulation property and abrasion resistance, in addition to excellent appearance.

Owner:TEIJIN LTD

Hair cosmetic

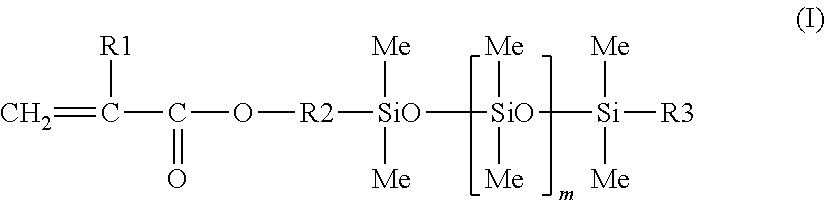

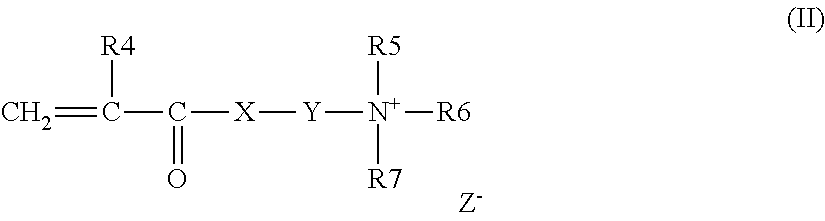

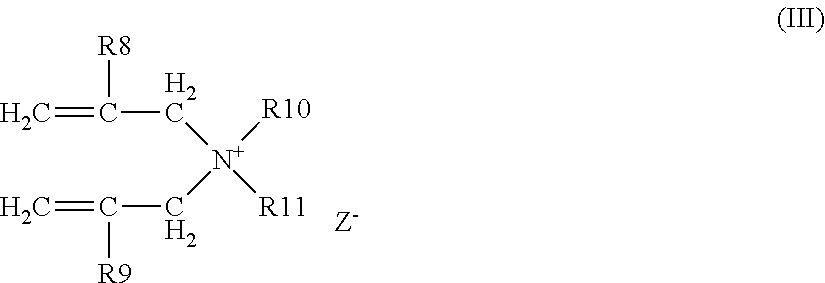

ActiveUS20150050231A1Satisfactory hair-setting propertyHigh hair-rearranging propertyCosmetic preparationsHair cosmeticsAlcoholMass ratio

It is an object of the present invention to provide a hair cosmetic achieving a hair-setting property without causing flaking and further having an excellent hair-rearranging property and non-stickiness. The hair cosmetic of the present invention includes the following components (A) to (D):(A) a (meth)acrylic silicone-based graft copolymer;(B) at least one film-forming polymer selected from nonionic, amphoteric, and cationic polymers;(C) a monohydric lower alcohol; and(D) at least one selected from polyalkylene glycols and sugar alcohols, whereinthe component (A) and the component (B) preferably have a content ratio (A):(B) within a mass ratio range of 1:10 to 2:1; and the hair cosmetic preferably has a viscosity at 25° C. of 1000 mPa·s or less.

Owner:KOBAYASHI KOSE CO LTD

Epoxy resin composition

InactiveUS20060089466A1Improve accuracyEnhance friction strengthLiquid surface applicatorsPlastic/resin/waxes insulatorsEpoxyCationic polymerization

An embodiment of the invention relates to a novel epoxy resin composition. The epoxy resin composition comprises (i) a first epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, and having a number average molecular weight ranging from 8,000 to 22,000 and a polydispersity ranging from 3.5 to 5.0, (ii) a second epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, having a number average molecular weight ranging from 2,500 to 8,000 and a polydispersity ranging from 1.5 to 3.0, and (iii) a cationic polymerization catalyst.

Owner:CANON KK

Block copolymer

A block copolymer is obtained by anionic polymerization, includes two or more polymer blocks A miscible with each other, and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A, has a ratio [Mn(Amax) / Mn(Amin)] of 2 or more, wherein the ratio [Mn(Amax) / Mn(Amin)] is the ratio of the largest number average molecular weight [Mn(Amax)] to the smallest number average molecular weight [Mn(Amin)] among the polymer blocks A, has at least one block bonding including polymer block Amax-polymer block B-polymer block Amin, and has a total content of the polymer blocks A ranging from 20 wt % to 45 wt % based on the total mass of the block copolymer. This invention provides block copolymers having two or more polymer blocks A miscible with each other and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A and exhibiting satisfactory flexibility, melt fluidity, moldability, coatability, mechanical properties, and other properties. The block copolymers of the present invention can yield molded articles having reduced anisotropy and surface stickiness and excellent mechanical properties and pressure-sensitive adhesive compositions having excellent adhesive properties.

Owner:KURARAY CO LTD

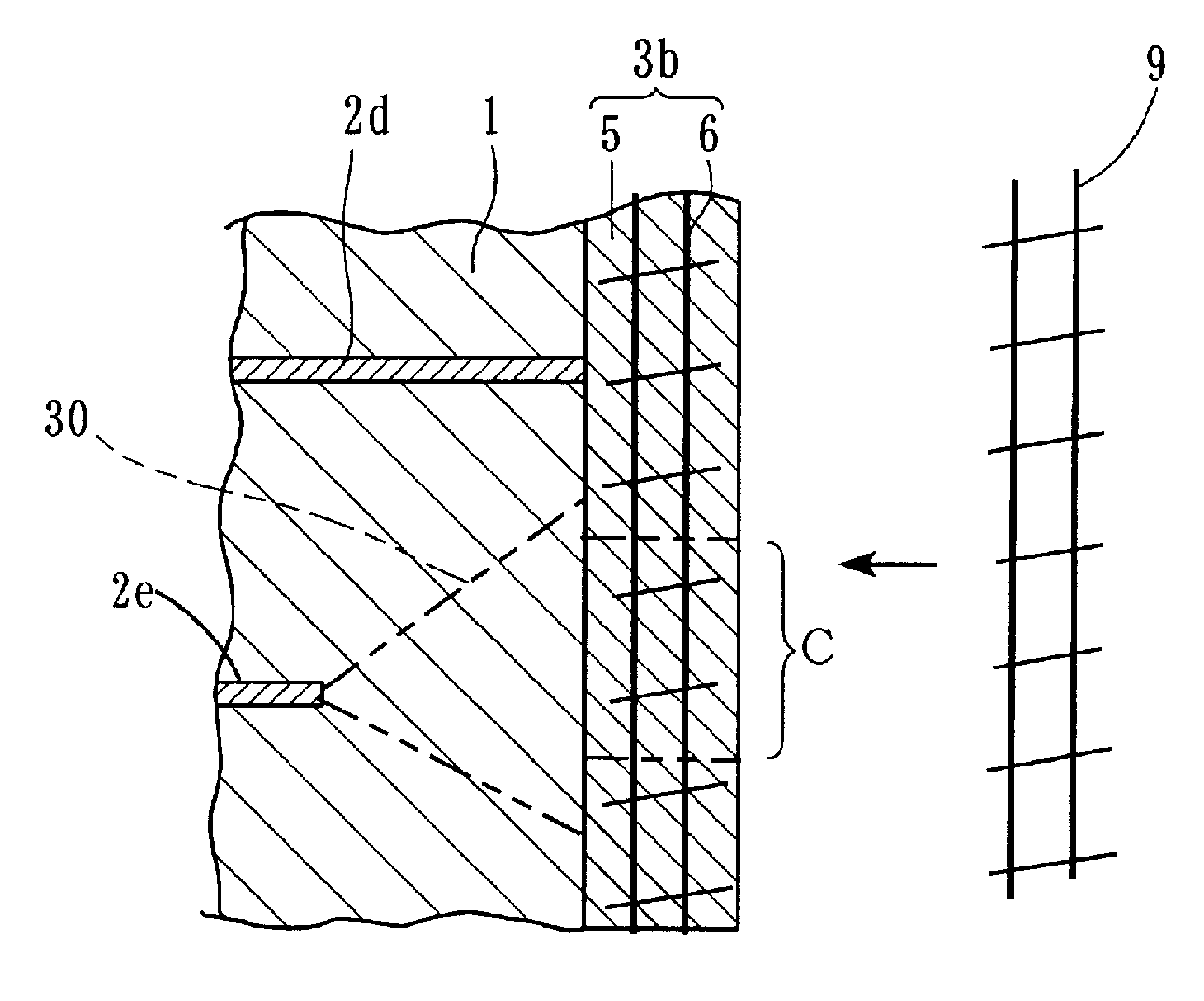

Thick film electrode and multilayer ceramic electronic device

ActiveUS7276841B2Satisfactory propertyReduce conductivityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMoisture resistanceContinuous operation

A multilayer ceramic device includes an external electrode disposed on a piezoelectric ceramic body including internal electrodes. The external electrode is a sintered body in which an Ag grid is integrally embedded in a coating film primarily composed of Ag. Therefore, it is possible to obtain a multilayer ceramic device having outstanding properties, such as durability and moisture resistance, without leading to poor electrical continuity and a decrease in conductivity even when a continuous operation is performed for a prolonged period of time.

Owner:MURATA MFG CO LTD

Liquid epoxy resin composition and semiconductor device

ActiveUS20060217499A1Shorten the curing timeMaintaining shelf stabilitySemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyBenzoic acid

Better semiconductor encapsulation is achieved with a liquid epoxy resin composition comprising (A) a liquid epoxy resin, (B) a curing agent containing at least 5 wt % of an aromatic amine compound, (C) a microencapsulated catalyst containing a phenolic hydroxy-bearing benzoic acid derivative, and optionally, (D) an inorganic filler.

Owner:SHIN ETSU CHEM IND CO LTD

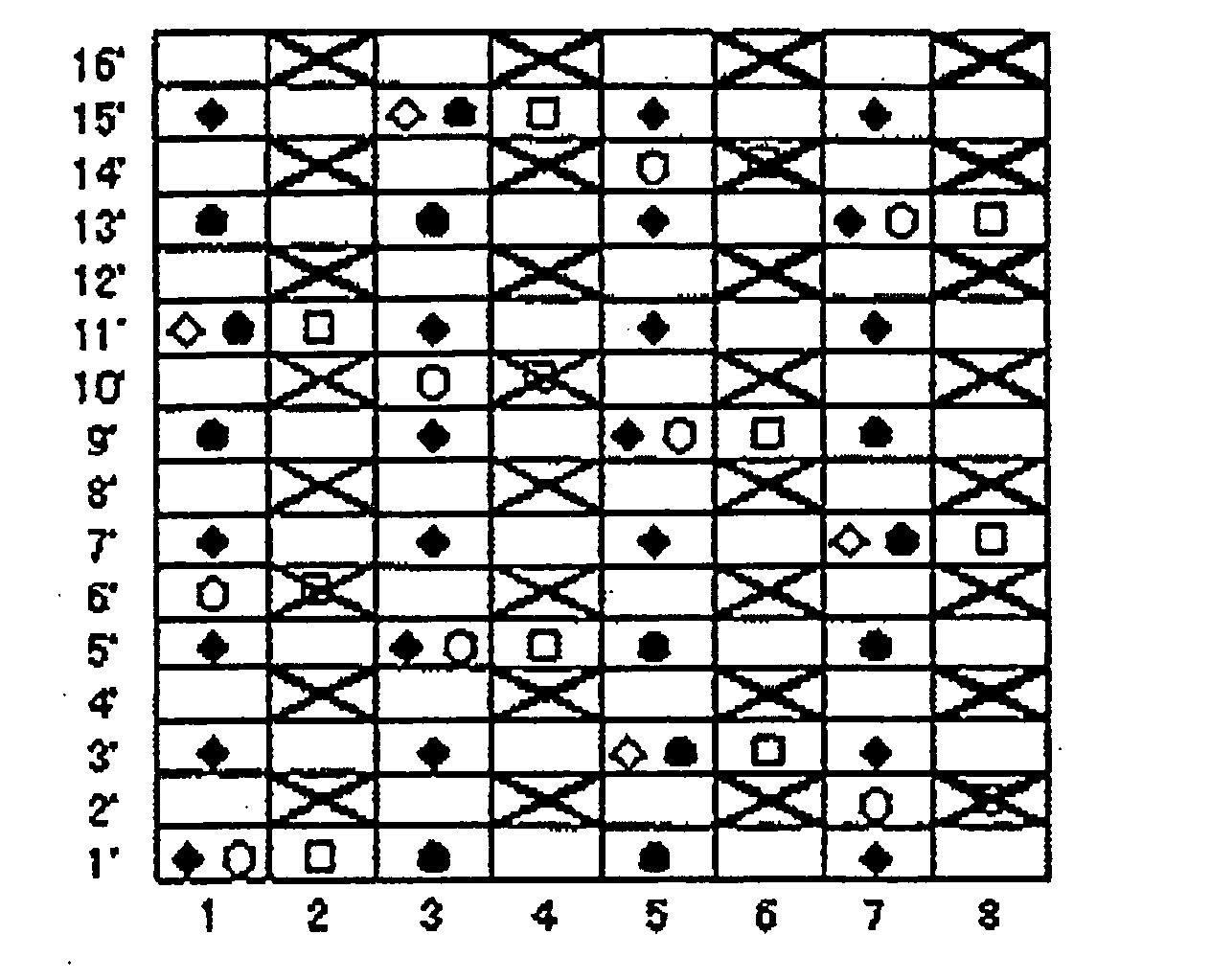

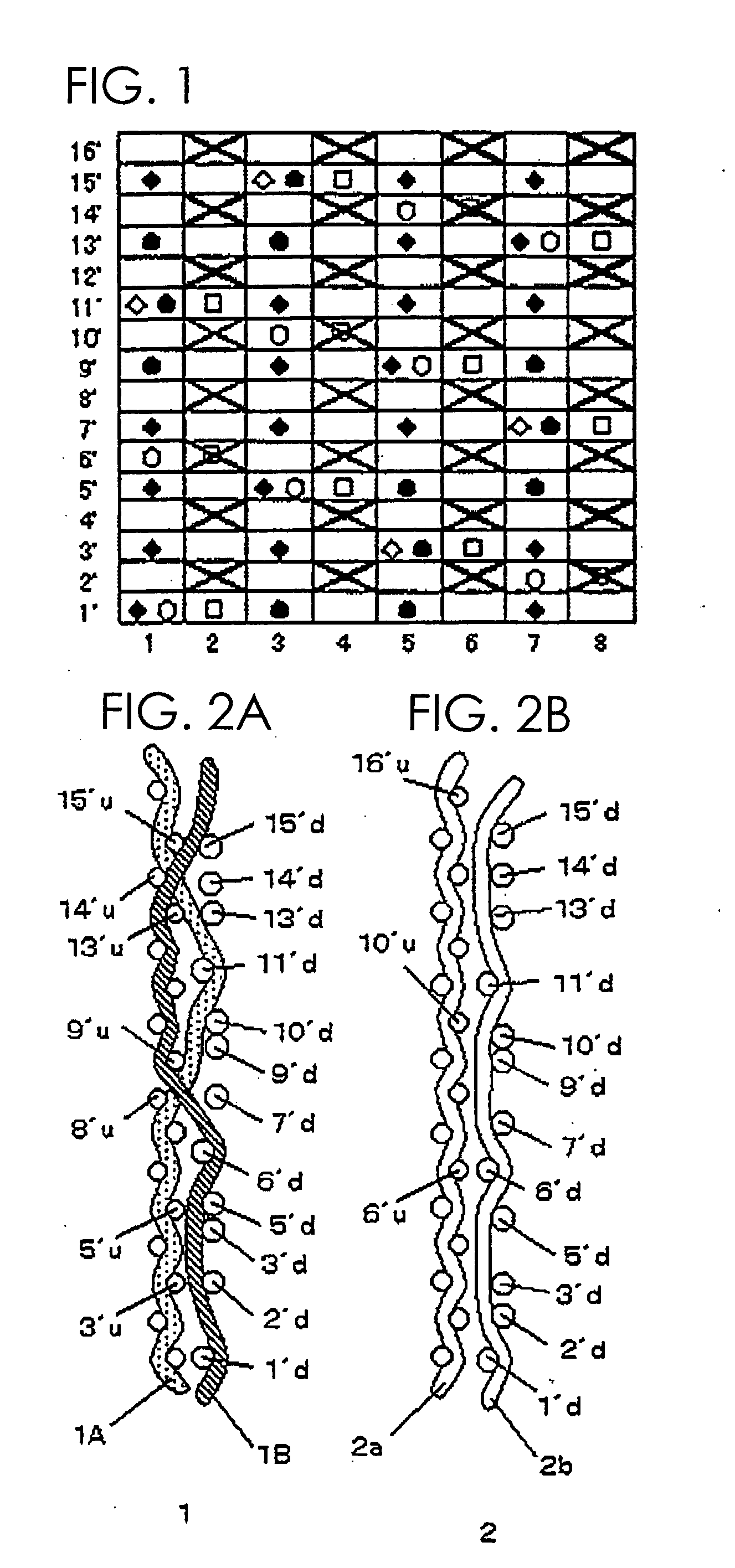

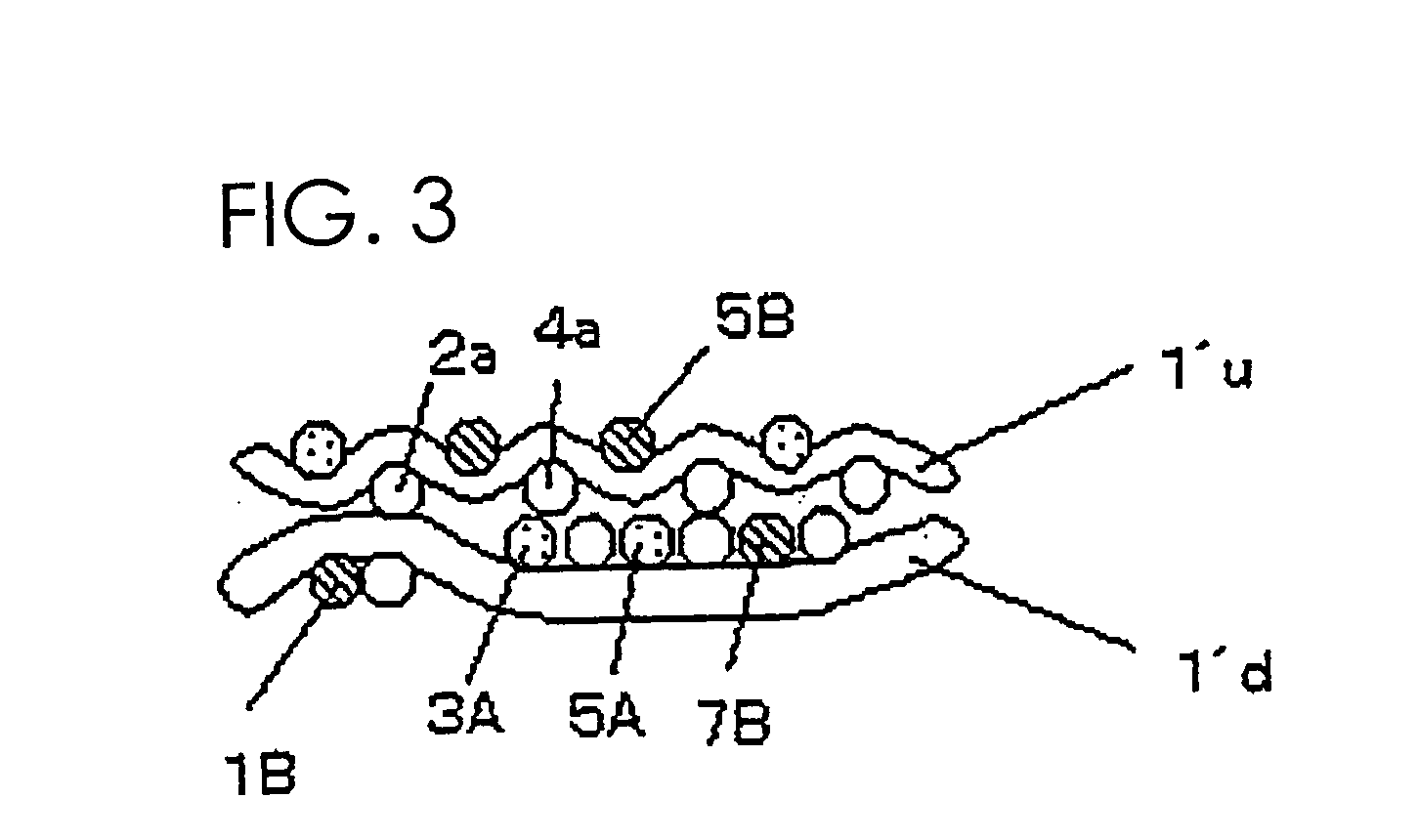

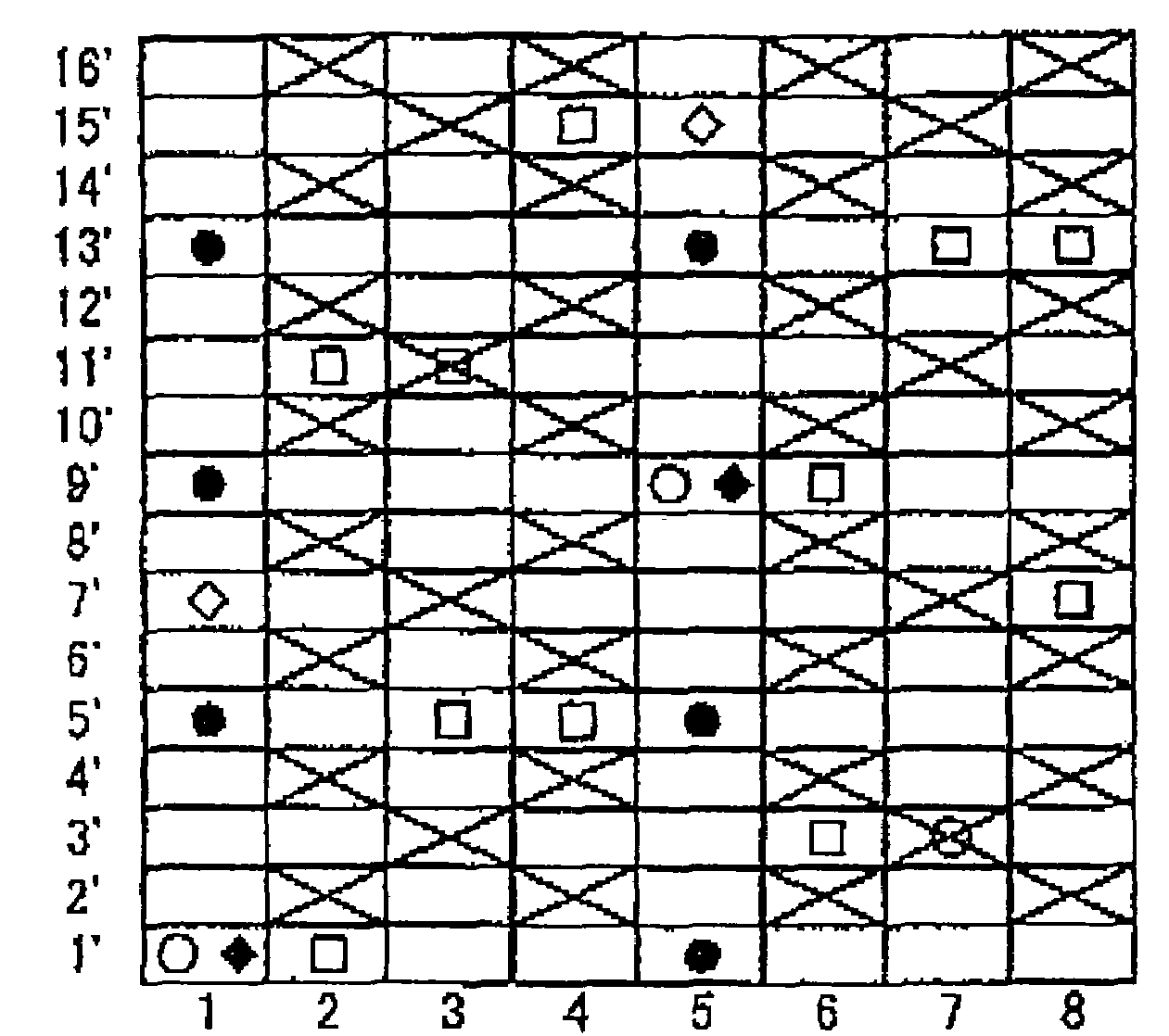

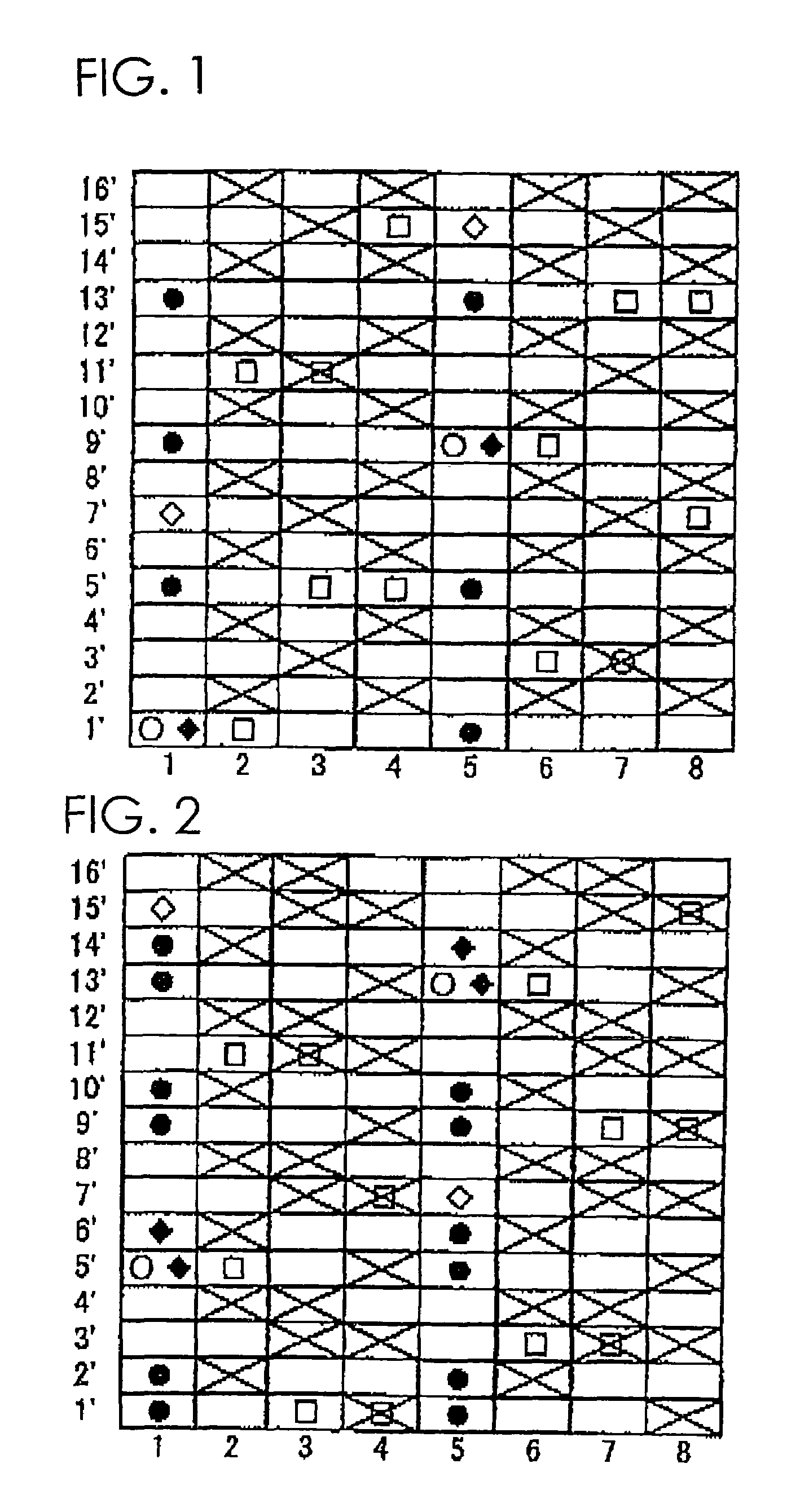

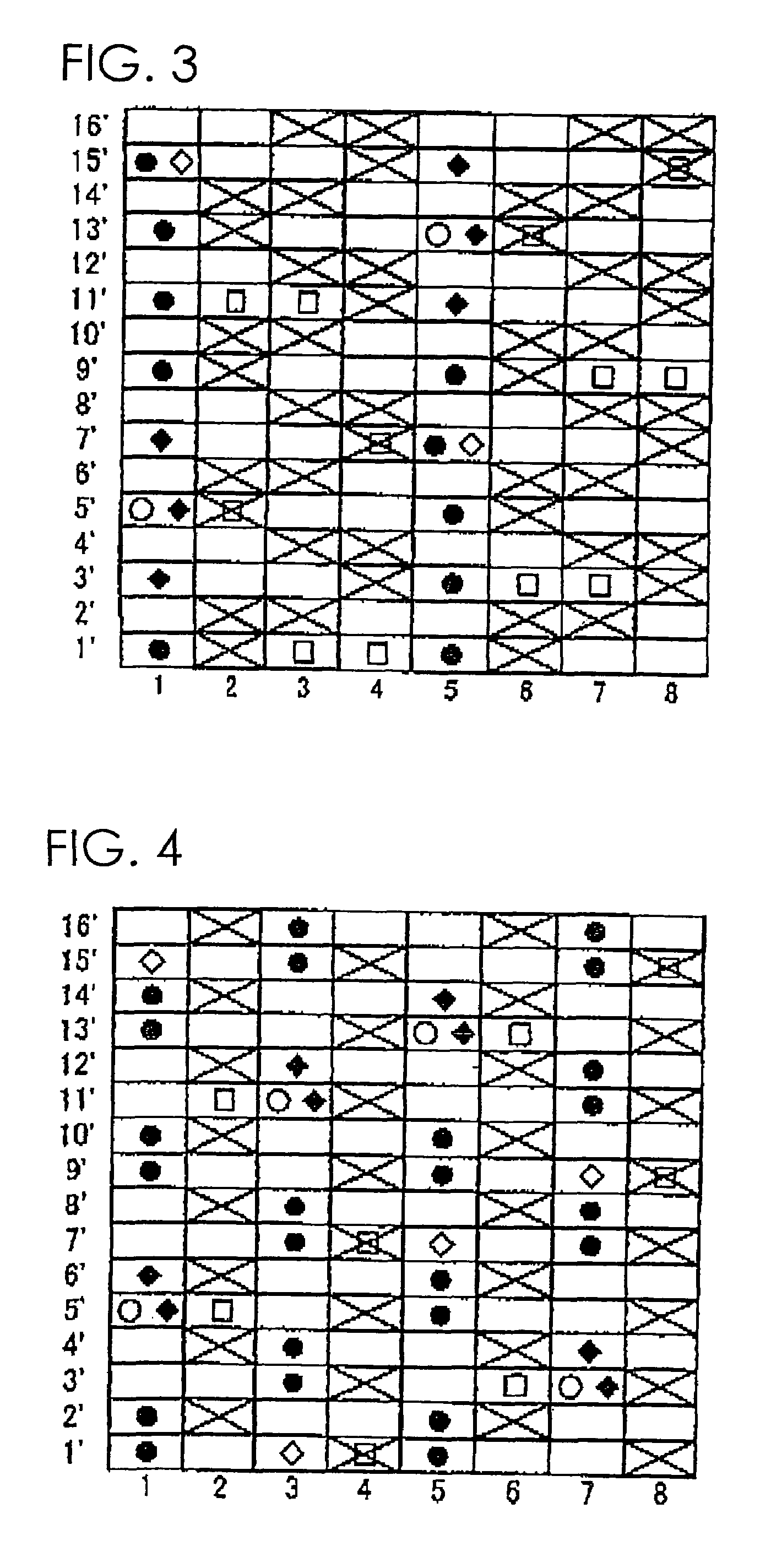

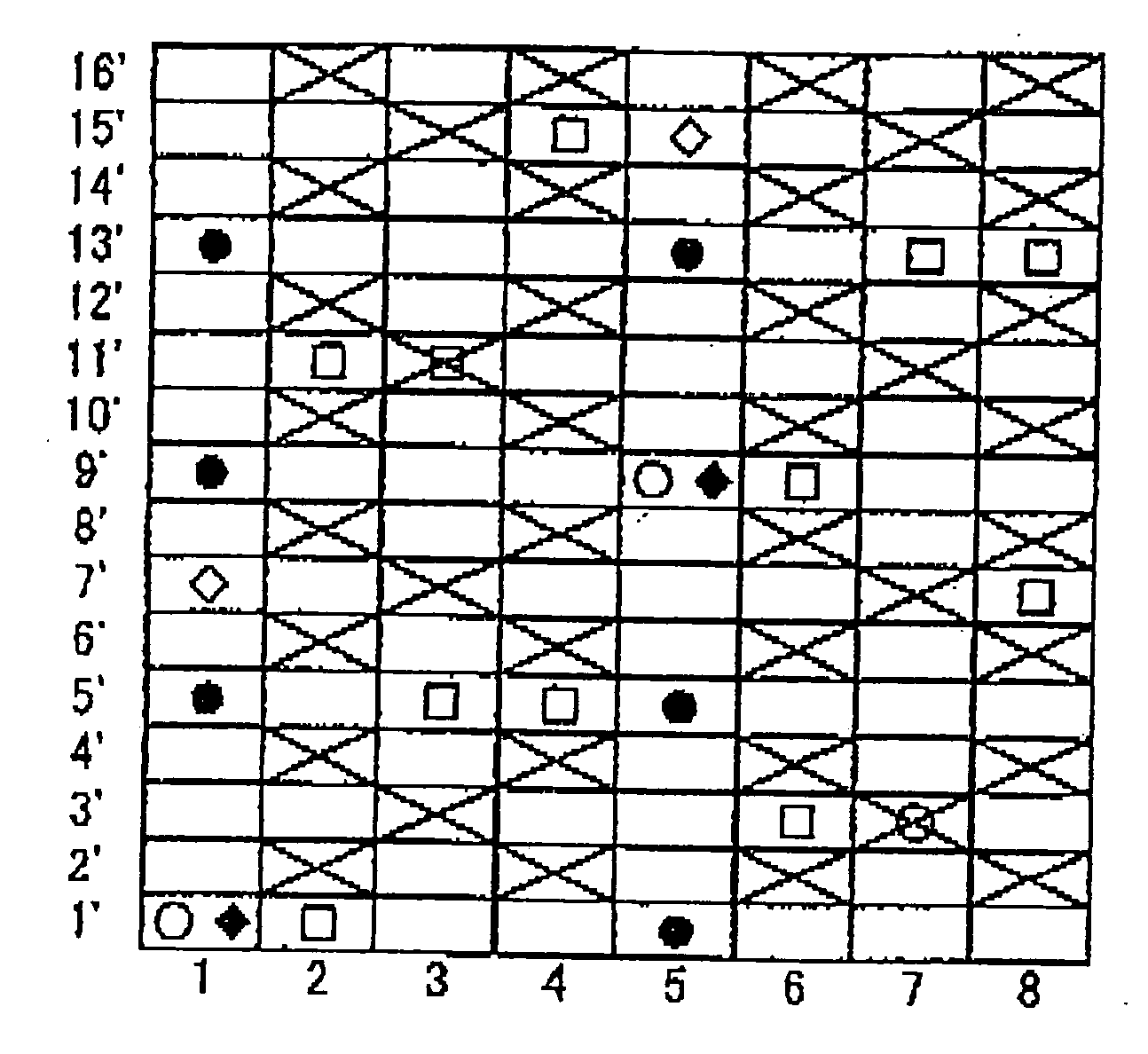

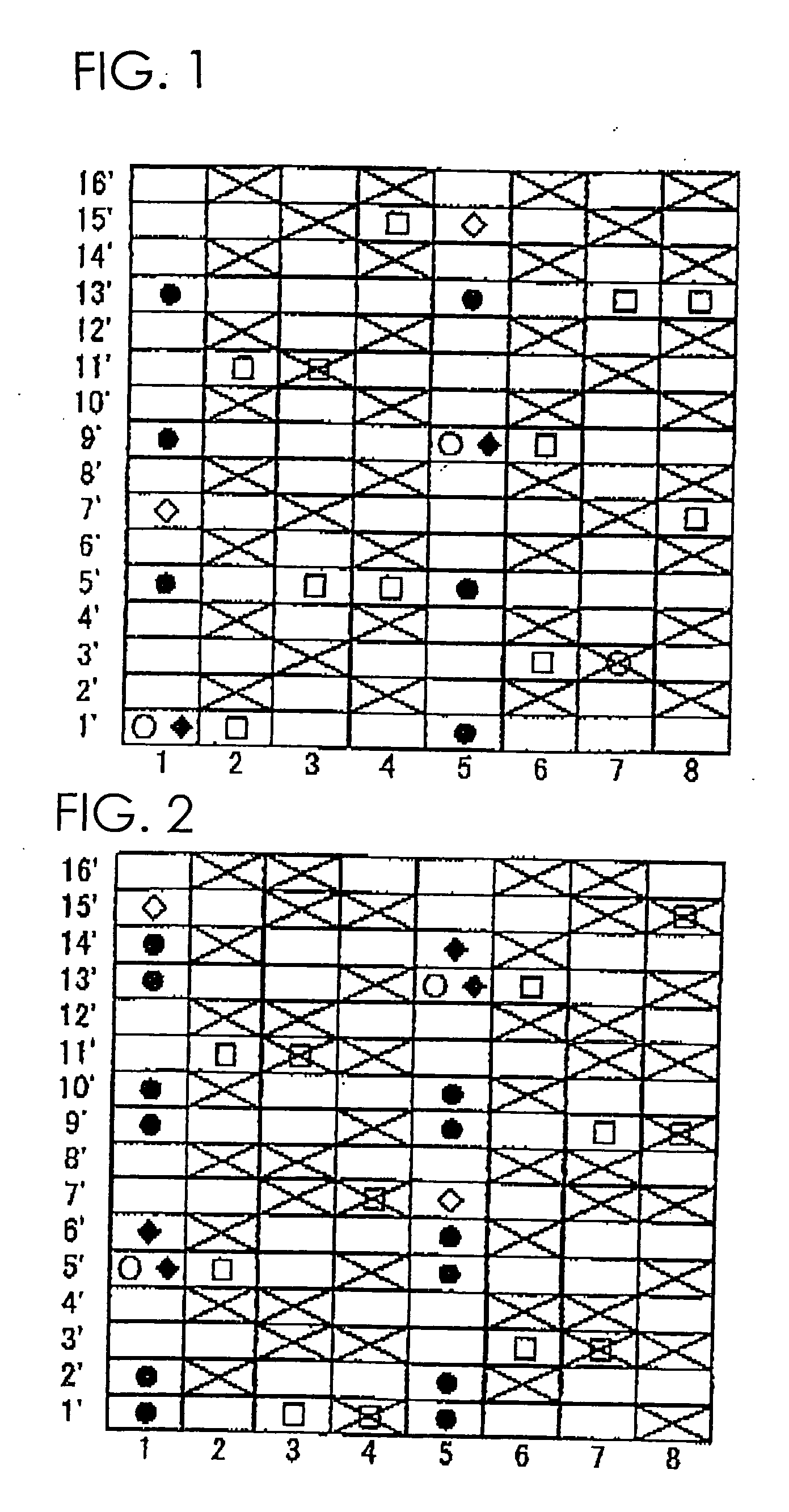

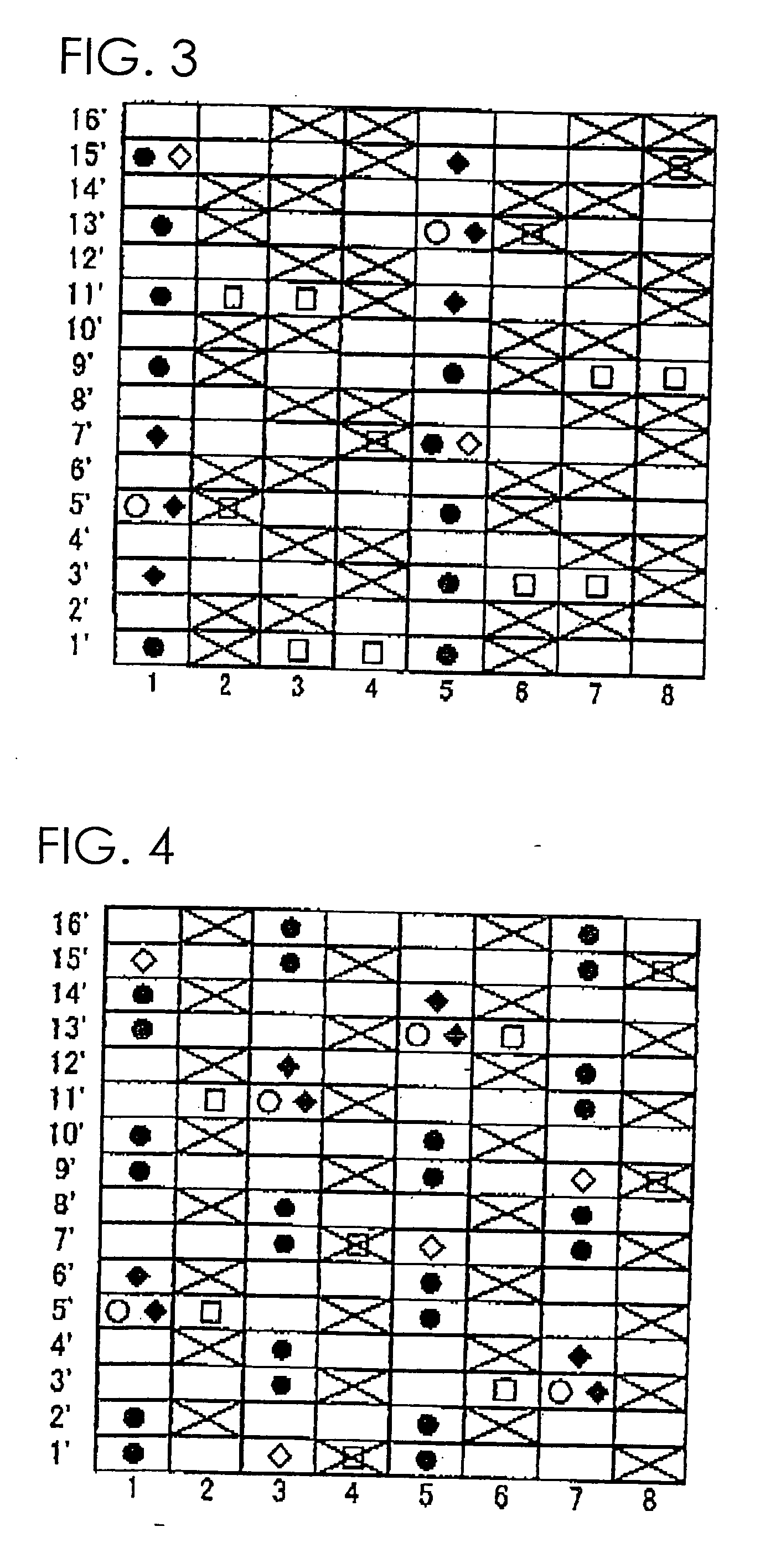

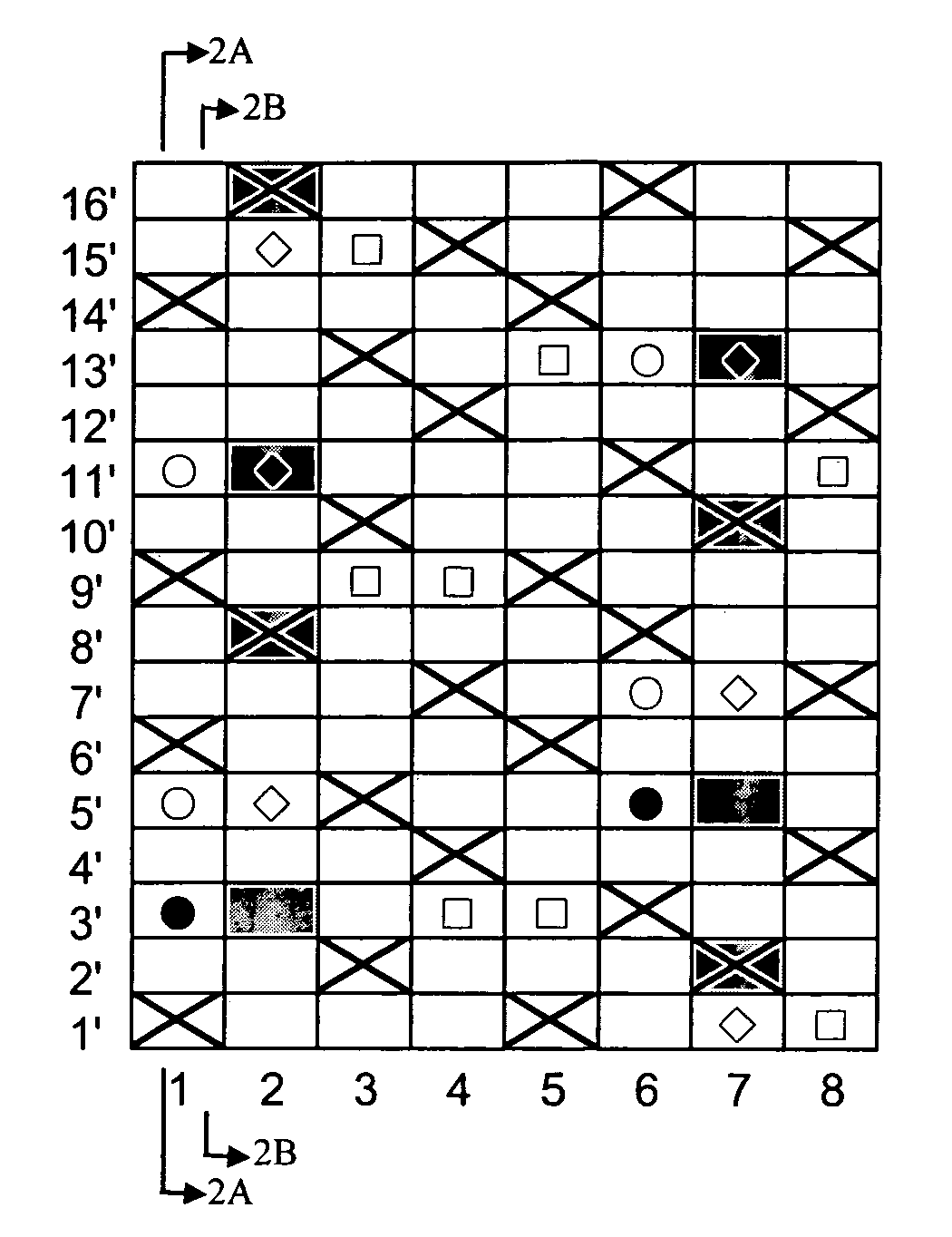

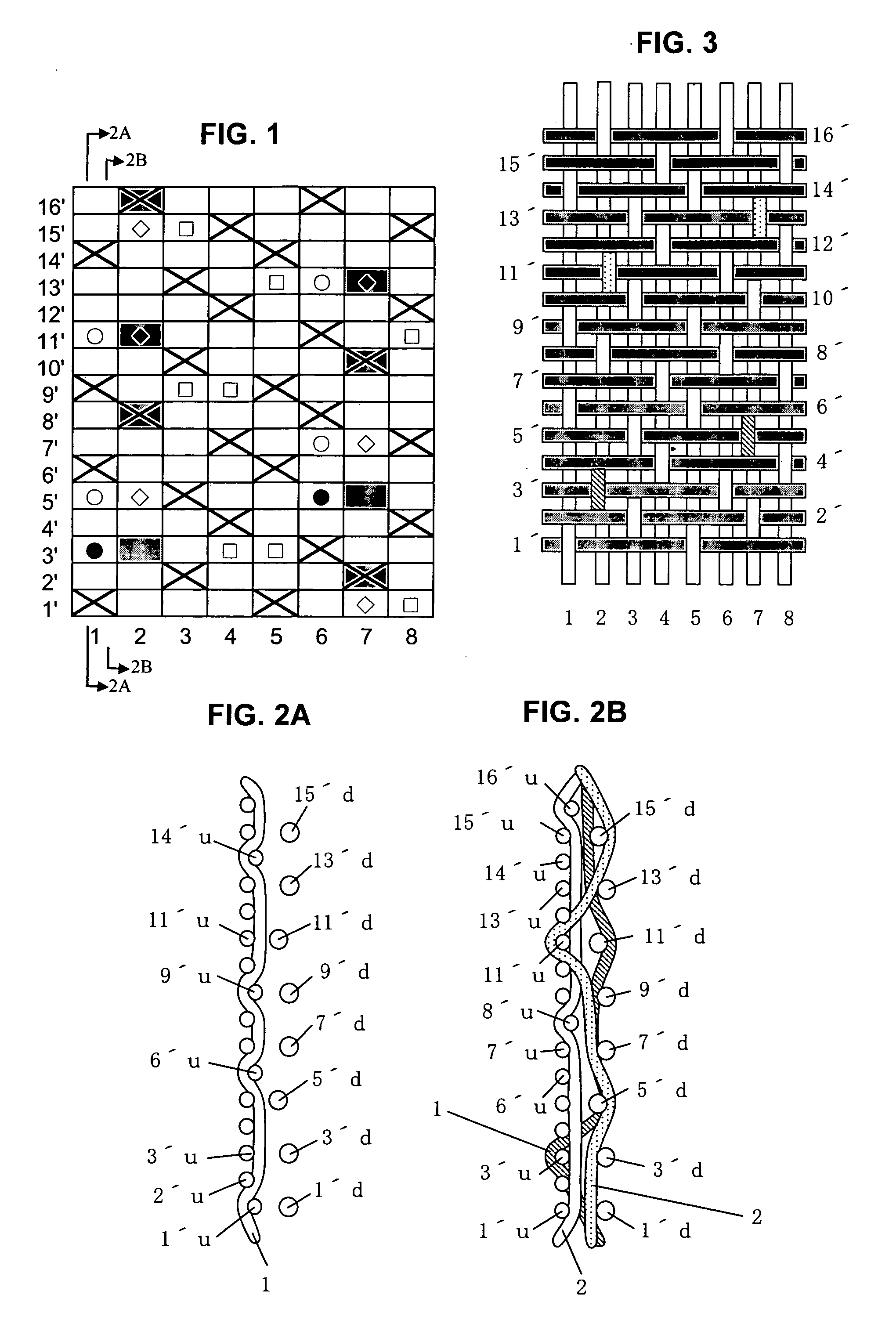

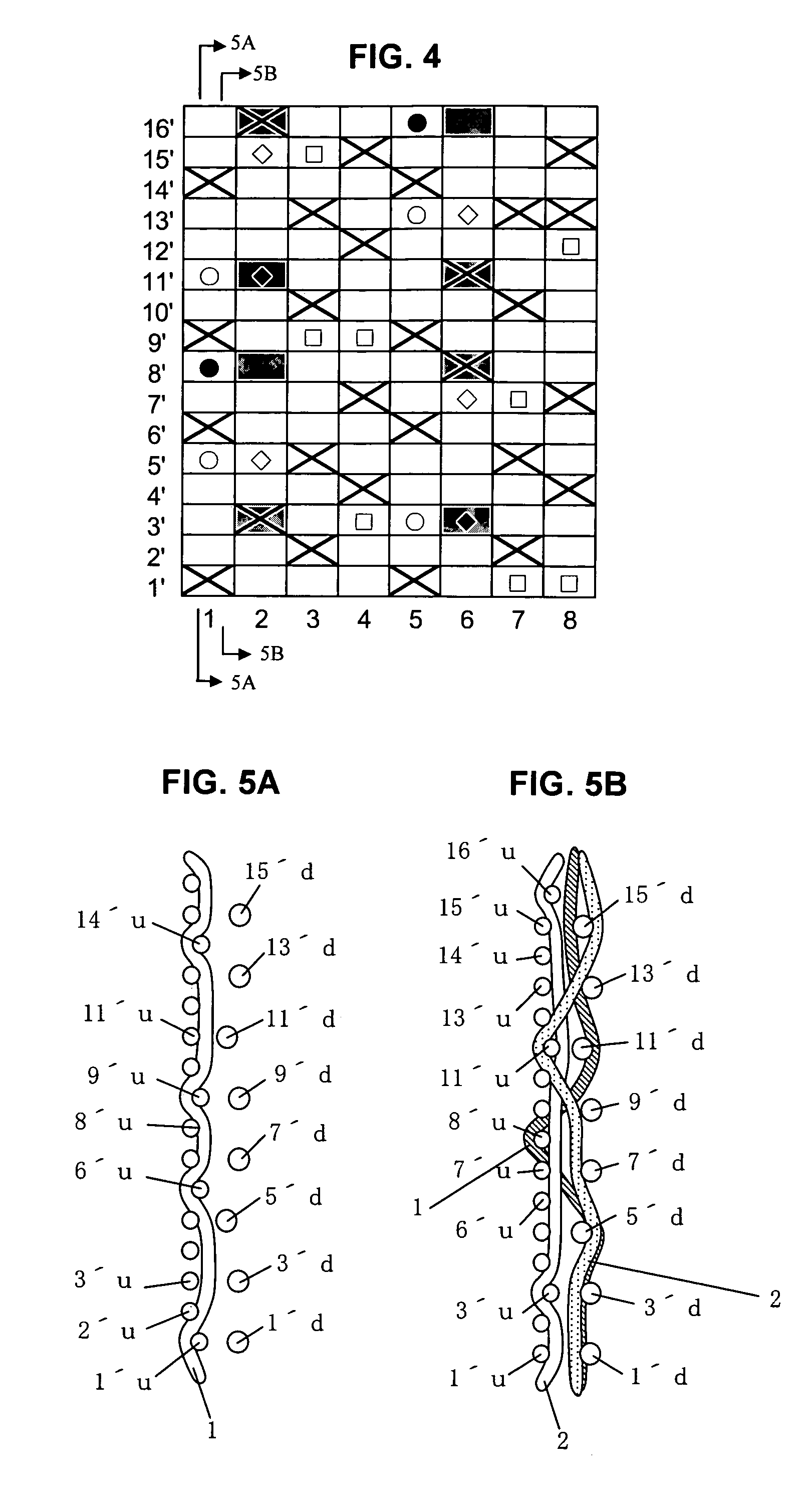

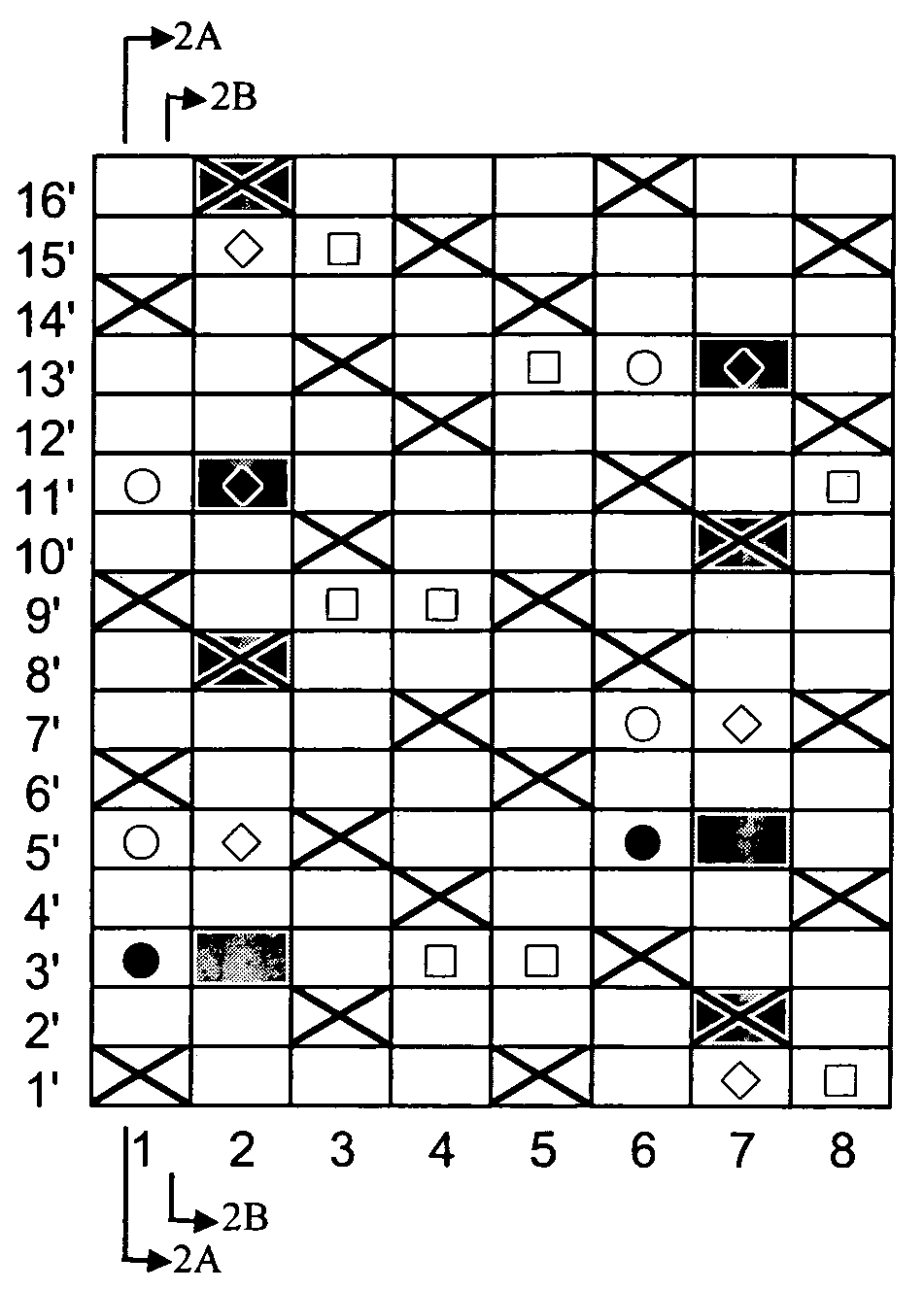

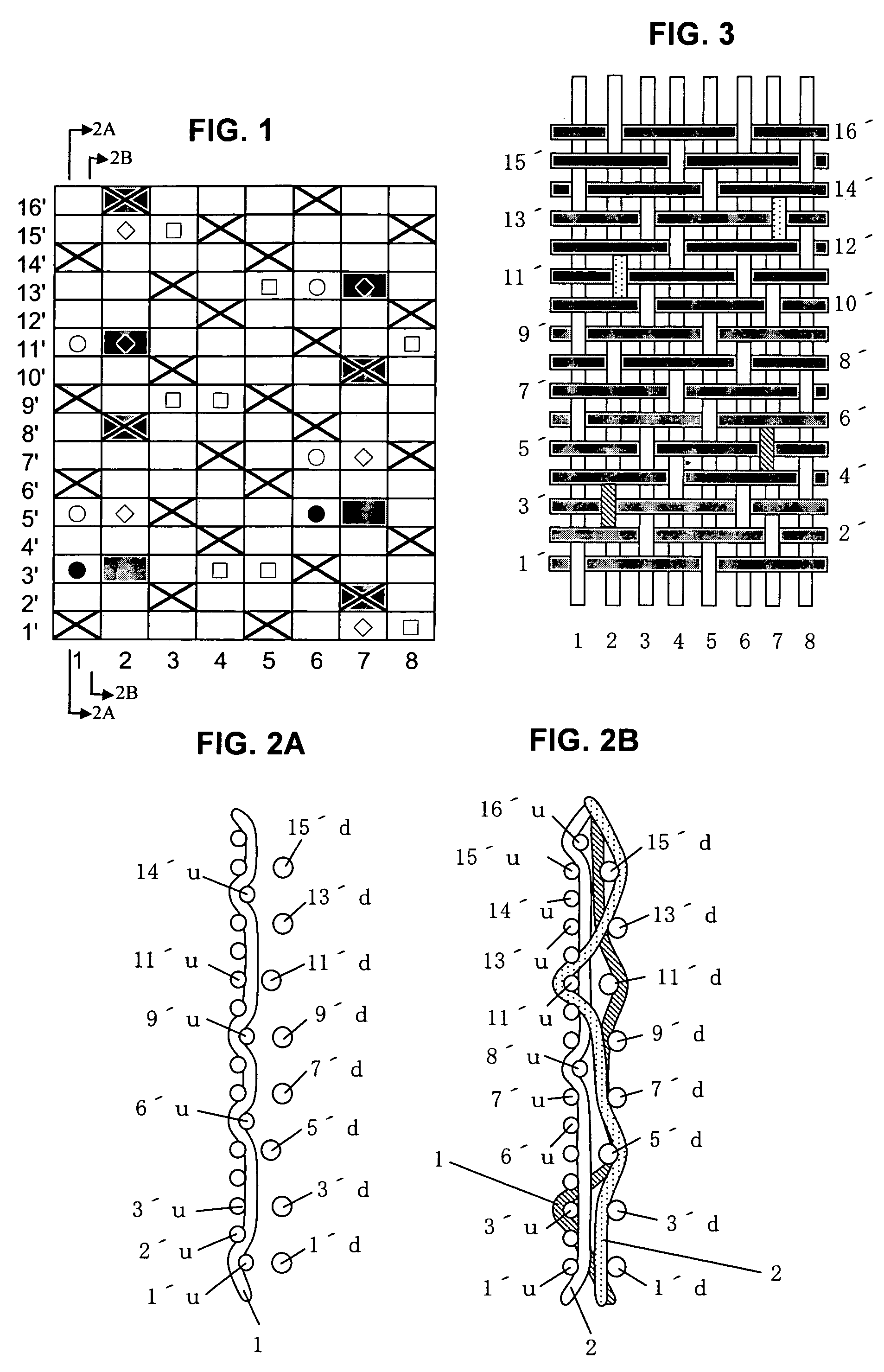

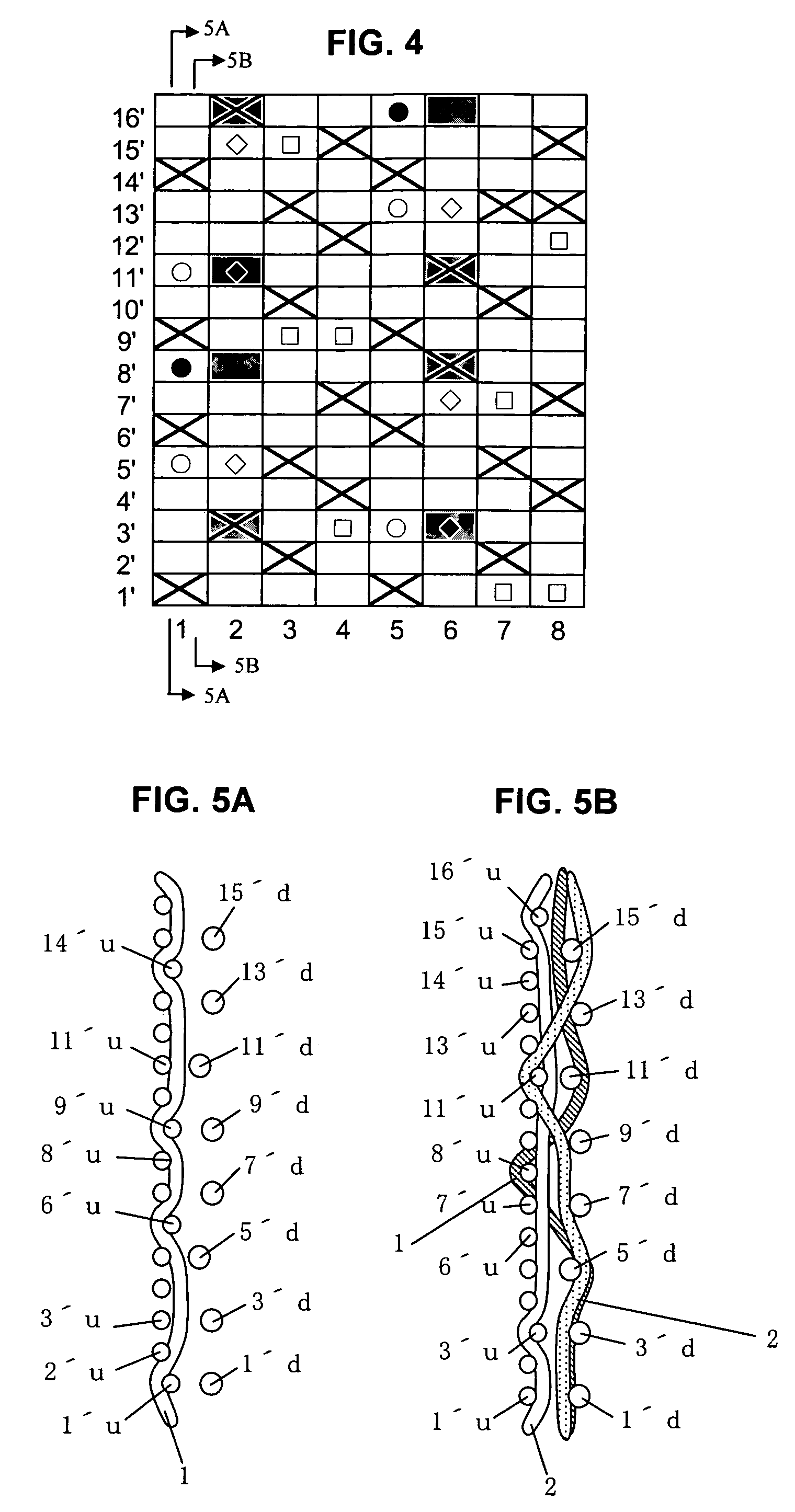

Industrial two-layer fabric

An industrial two-layer fabric composed of an upper surface side fabric having an upper surface side warp and an upper surface side weft and a lower surface side fabric having a lower surface side warp and a lower surface side weft, the upper surface side warp and lower surface side warp being arranged vertically and constituting a pair, and the upper surface side fabric and lower surface side fabric being bound with a yarn in a warp direction. The lower surface side fabric is made of a repeating design unit in which one of warp binding yarns constituting a pair to be woven with an upper surface side weft and a lower surface side weft or a lower surface side warp passes under one lower surface side weft and then passes over a plurality of lower surface side wefts; a warp on one adjacent side to the above-described warp has the same design and passes over and under the same lower surface side wefts. A complete design repeating unit of the lower surface side fabric is formed by shifting the design of a set of these two warps and then arranging the shifted design one after another; and a lower surface side weft has a design in which the weft passes over two successive warps and then passes under a plurality of warps to form a long crimp on the lower surface side surface.

Owner:NIPPON FILCON

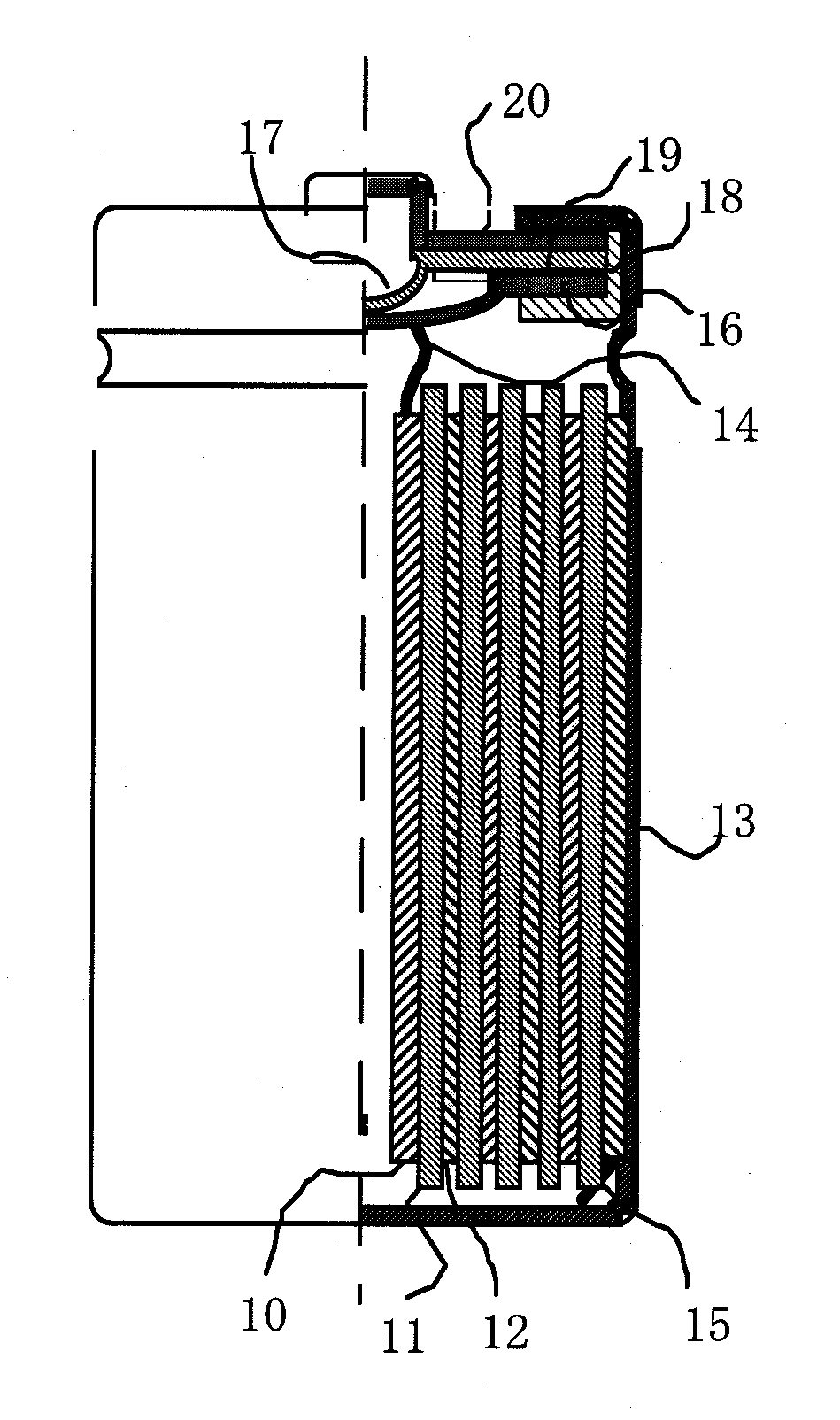

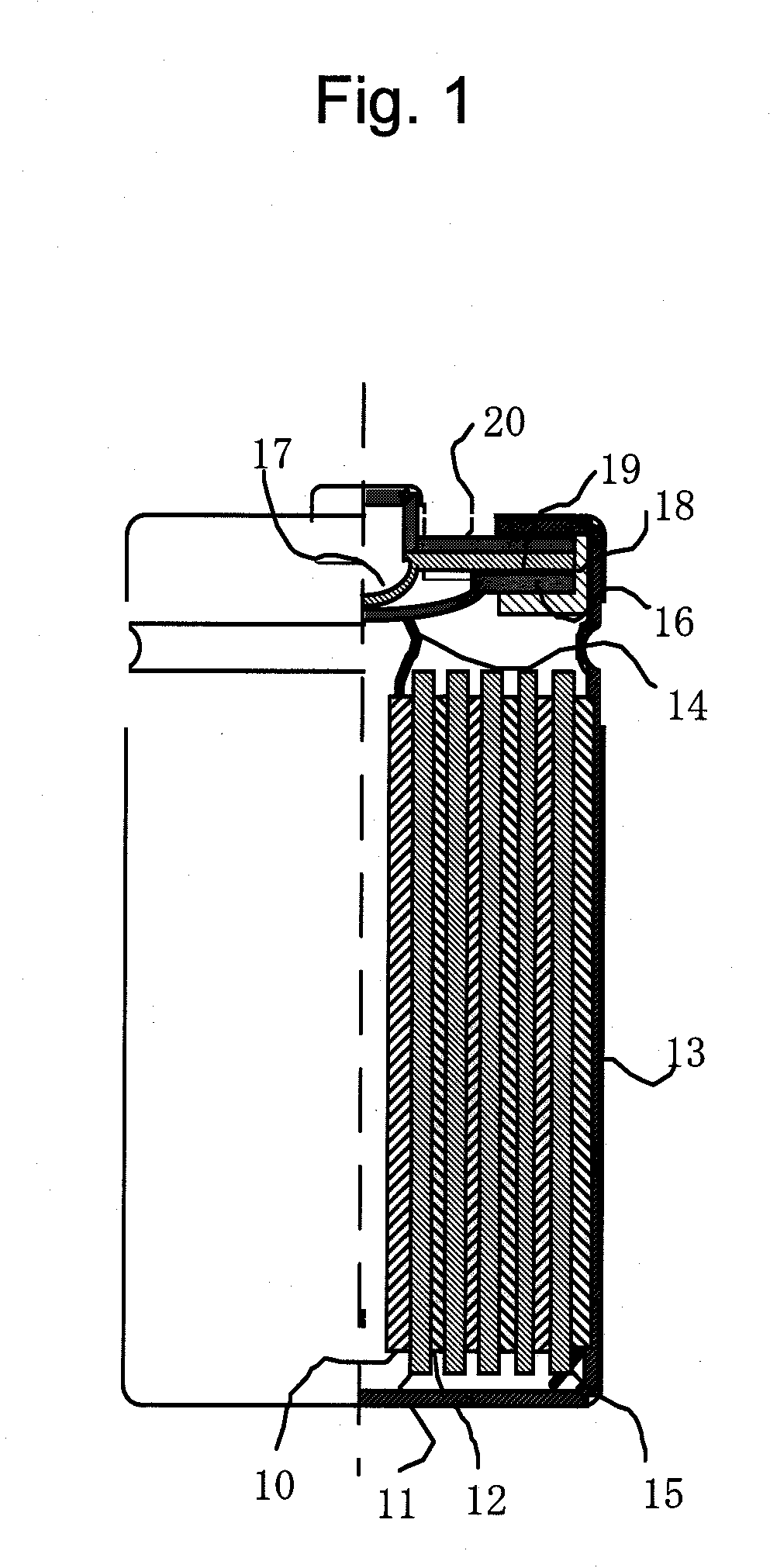

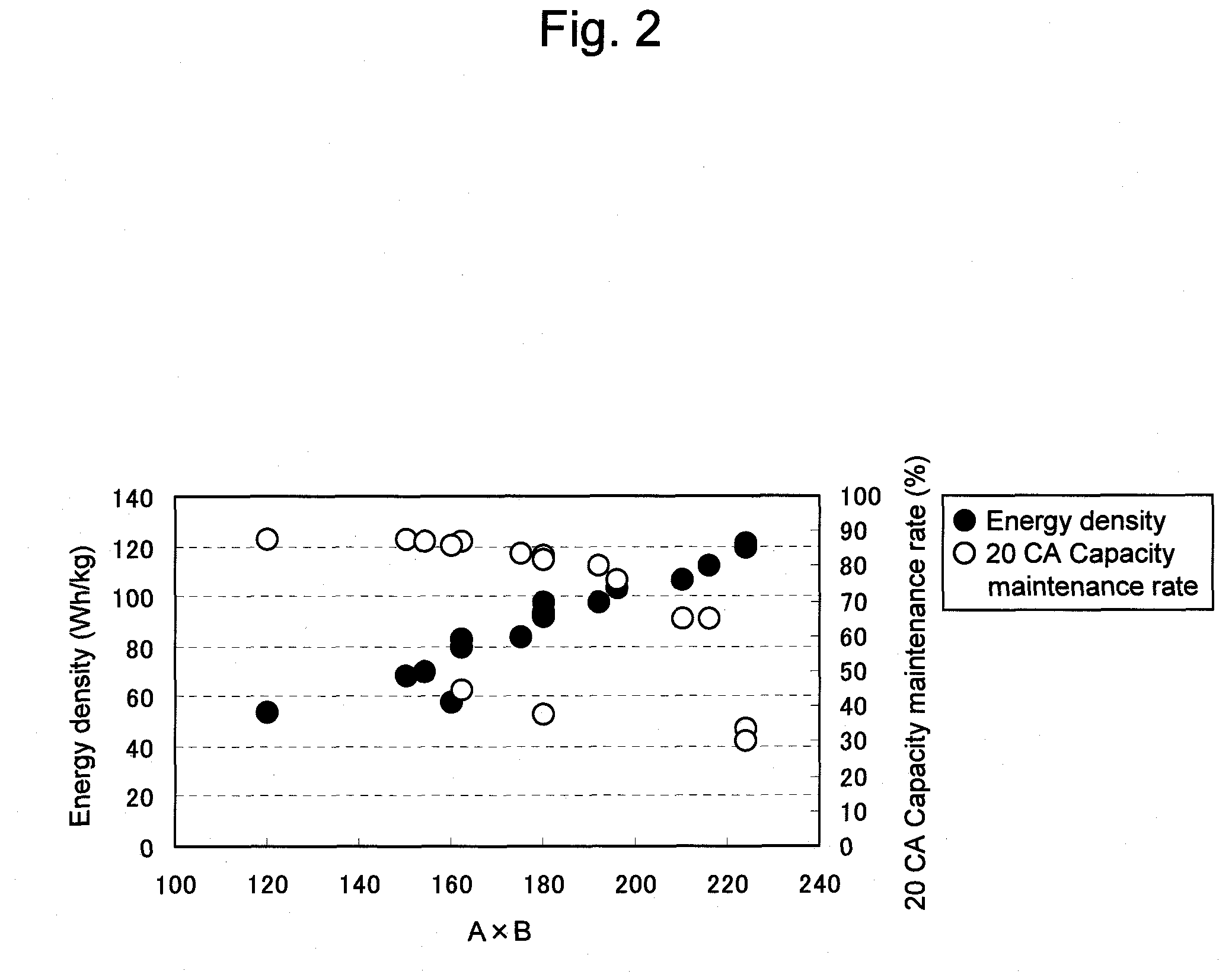

Lithium ion battery

ActiveUS20110206988A1Satisfactory propertyHigh currentElectrode carriers/collectorsSecondary cellsPhysical chemistryGraphite

An object of the present invention is to provide a lithium ion battery which is excellent in properties at large current and can be applied to applications requiring high output power even when the mixture layers are made thick. The present invention provides a lithium ion battery including a positive electrode including a positive electrode mixture layer formed on a current collector, a negative electrode including a negative electrode mixture layer formed on a current collector and an electrolyte, the positive electrode and the negative electrode being disposed through the intermediary of a separator, wherein the positive electrode includes as a positive electrode active material a lithium composite oxide represented by LiNiaMnbCOcMdO2 (in the formula, M is at least one selected from the group consisting of Fe, V, Ti, Cu, Al, Sn, Zn, Mg, B and W, a+b+c+d=1, 0.2≦a≦0.8, 0.1≦b≦0.4, 0≦c≦0.4 and 0≦d≦0.1), the negative electrode includes graphite as a negative electrode active material, the interlayer distance (d002) of the graphite is 0.335 nm or more and 0.338 nm or less, the one-side thickness A (μm) of the positive electrode mixture layer is 60 or more and 85 or less, the product A×B between the one-side thickness A and the density B (g / cm3) of the positive electrode mixture layer is 160 or more and 220 or less, the one-side thickness C (μm) of the negative electrode mixture layer is 40 or more and 75 or less, and the product C×D between the one-side thickness C and the density D (g / cm3) of the negative electrode mixture layer is 65 or more and 105 or less.

Owner:HITACHI VEHICLE ENERGY

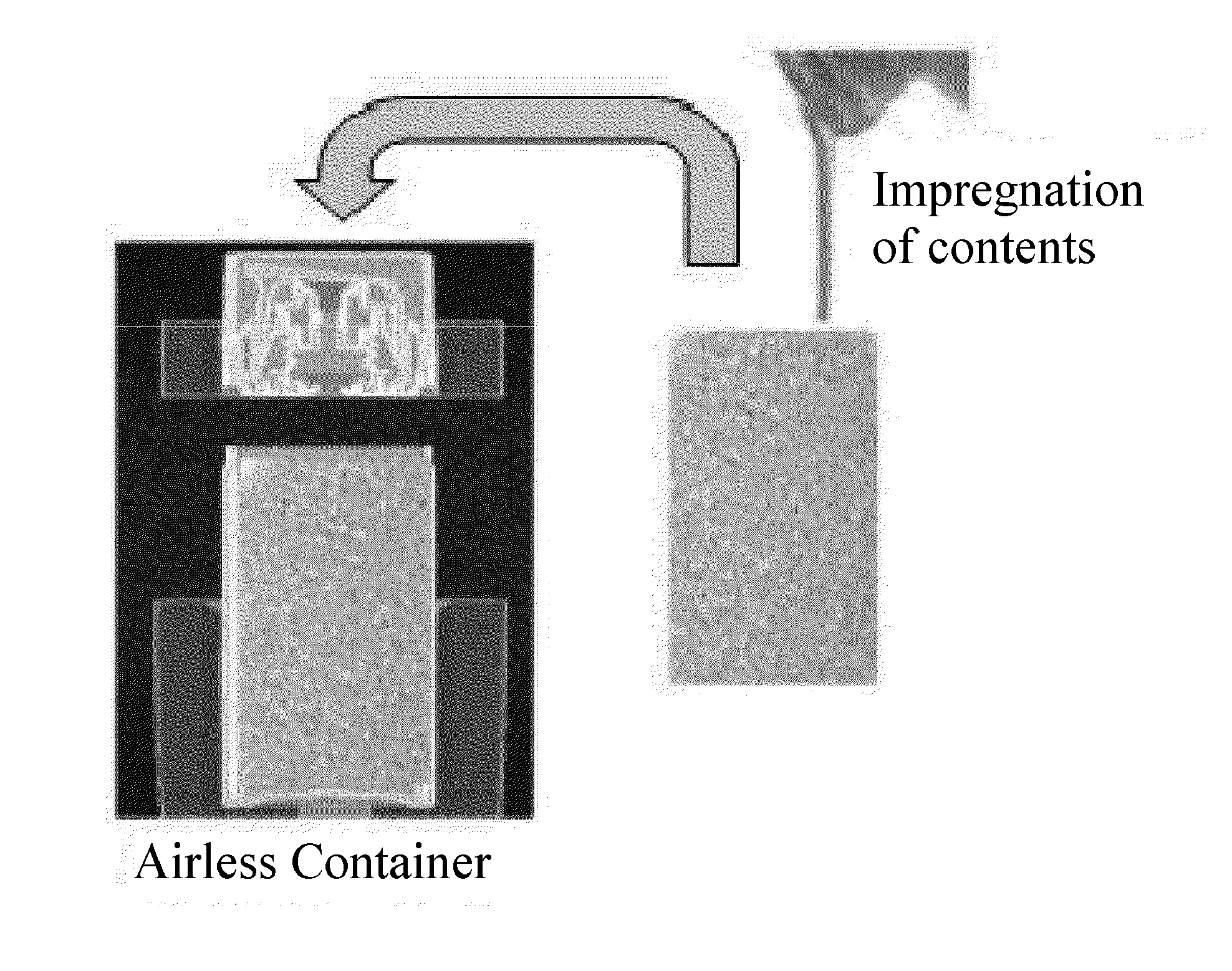

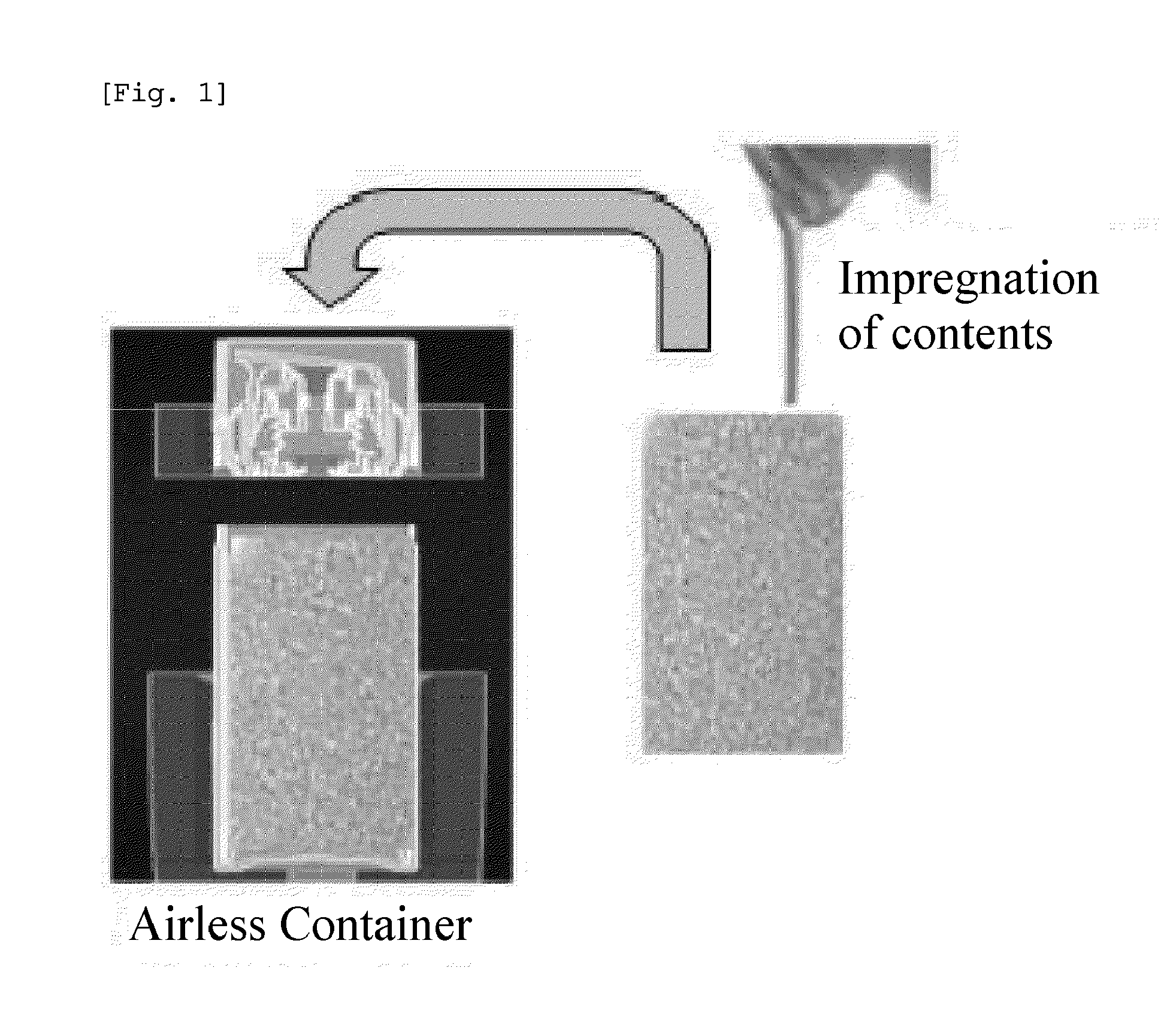

Cosmetic composition prepared by impregnation in urethane foam

The present invention relates to a cosmetic composition in which a W / O (water in oil) cosmetic composition with low viscosity is packaged in an airless container, and more specifically, to a cosmetic composition with low viscosity which enhances the stability of easily-separable low viscosity materials and improves user convenience by impregnating the W / O cosmetic composition with low viscosity into a urethane foam and packaging the composition in the airless container.

Owner:AMOREPACIFIC CORP

Industrial two-layer fabric

ActiveUS7270152B2Satisfactory propertyImprove propertiesMachine wet endPress sectionStructural engineeringMechanical engineering

Owner:NIPPON FILCON

Industrial two-layer fabric

ActiveUS20060102244A1Improve surface propertiesImproved property fiber supporting property propertyMachine wet endPress sectionMechanical engineeringTwo layer

Owner:NIPPON FILCON

Iminochlorinaspartic acid derivatives

InactiveUS6063777AGood water solubilityImprove stabilityBiocidePeptide/protein ingredientsAspartic acid residuePhotosensitizer

PCT No. PCT / JP97 / 03484 Sec. 371 Date Jun. 15, 1999 Sec. 102(e) Date Jun. 15, 1999 PCT Filed Sep. 30, 1997 PCT Pub. No. WO98 / 14753 PCT Pub. Date Apr. 9, 1998The present invention provides an iminochlorin aspartic acid derivative represented by the following formula (I): Wherein Asp represents an aspartic acid residue, or a pharmaceutically acceptable salt thereof. The compound of the present invention is useful as a photosensitizer for photophysico-chemical diagnosis and therapy of cancer, because it has a high accumulability to cancerous cells, reactivity to external energy and a cancerous cell destroying effect which is effective even against cancers developing in deep site, while it is rapidly excreted from normal cells and therefore causes no damage thereto.

Owner:PFIZER JAPAN +1

Schottky barrier semiconductor device and method for manufacturing the same

InactiveUS7902054B2Power Loss MinimizationSatisfactory propertyTransistorSemiconductor/solid-state device manufacturingSchottky barrierCarbide

A silicon carbide Schottky barrier semiconductor device provided with a Ta electrode as a Schottky electrode, in which the Schottky barrier height is controlled to a desired value in a range where power loss is minimized without increasing the n factor. The method for manufacturing the silicon carbide Schottky barrier semiconductor device includes the steps of depositing Ta on a crystal face of an n-type silicon carbide epitaxial film, the crystal face having an inclined angle in the range of 0° to 10° from a (000-1) C face, and carrying out a thermal treatment at a temperature range of 300 to 1200° C. to form the Schottky electrode.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

Industrial two-layer fabric

ActiveUS20060278297A1Improve surface propertiesImprove breathabilityMachine wet endPaper/cardboardYarnEngineering

In a repeating unit of a two-layer fabric, a first upper surface side warp forms a first upper surface side warp design. A second upper surface side warp forms a latent portion in which the second upper surface side warp passes between the two layers of the fabric. A first lower warp binding yarn and a second lower warp binding yarn form first and second knuckles respectively by passing over one or two upper surface side wefts at a position not adjacent to two knuckles of the second upper surface side warp in the latent portion. The first and second knuckles are formed at different positions. The first lower warp binding yarn, second upper surface side warp and second lower warp binding yarn cooperatively form a second upper surface side warp design similar to the first upper surface side warp design.

Owner:NIPPON FILCON

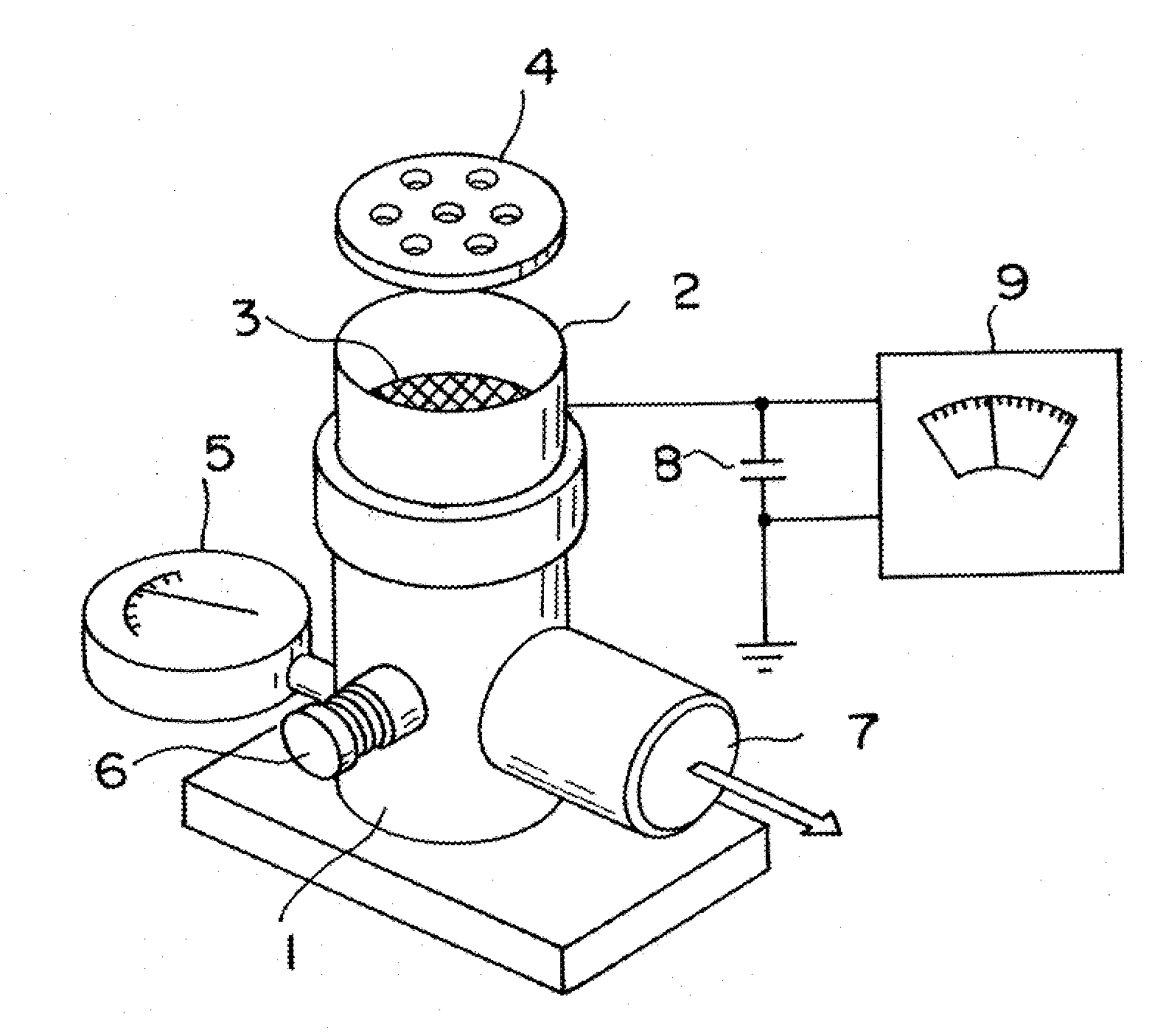

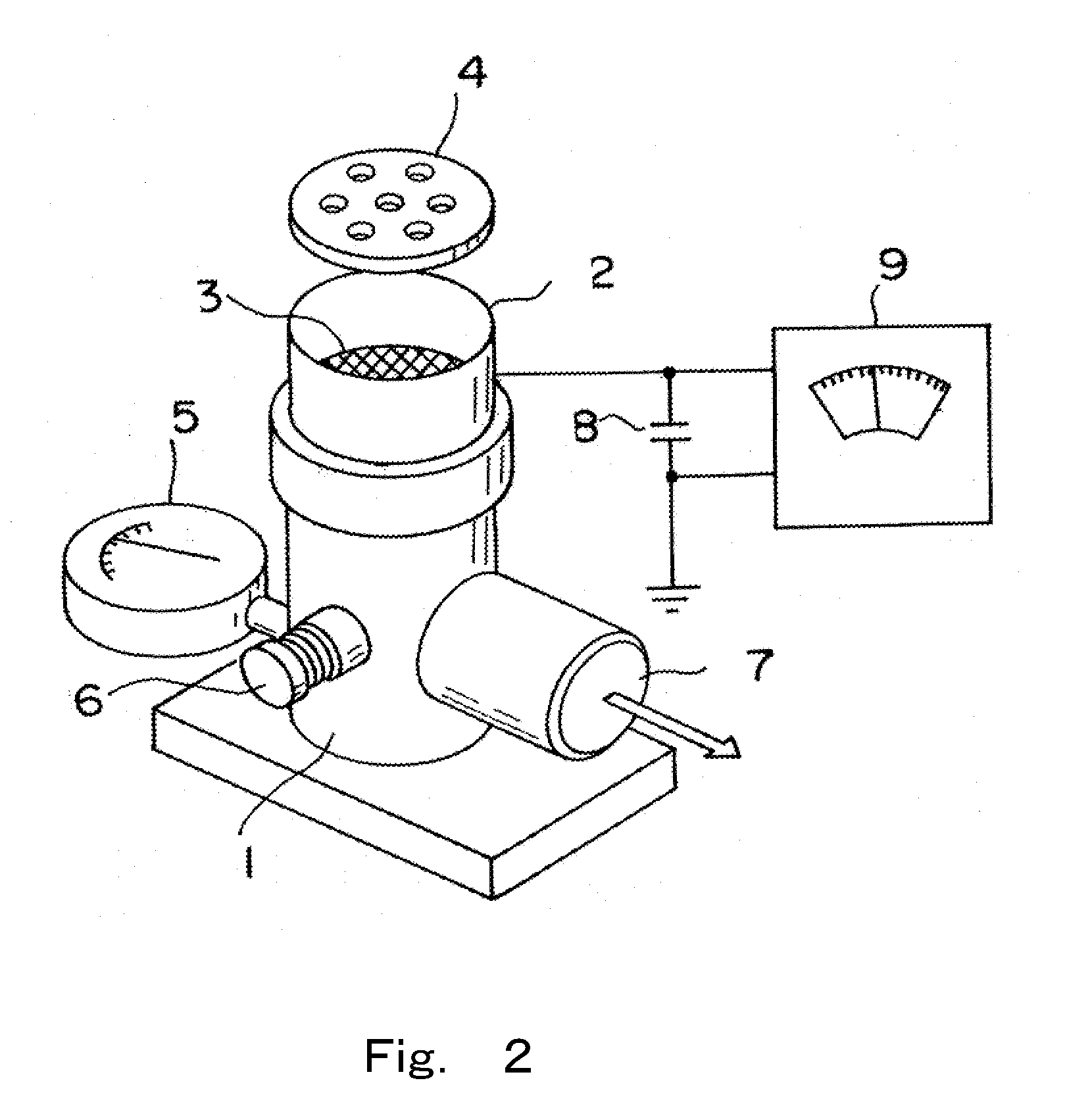

Semiconductor thin film forming system

InactiveUS20100006776A1Good qualitySatisfactory propertyTransistorSemiconductor/solid-state device manufacturingState densityOptical beam

A thin film processing method for processing the thin film by irradiating the optical beam to the thin film, wherein one set of irradiation includes the first optical pulse irradiation to the thin film and the second optical pulse irradiation to the thin film which substantially starts with a delay to the first optical pulse irradiation, the one set of irradiation being repetitively carried out for processing the thin film, and the relationship between the first and the second pulse satisfies (the pulse width of the first optical pulse)>(the pulse width of the second optical pulse). Preferably, the relationship between the first and the second pulse satisfies (the irradiation intensity of the first optical pulse)≧(the irradiation intensity of the second optical pulse). A silicon thin film with a small trap state density is thus manufactured by the optical irradiation.

Owner:NEC CORP +1

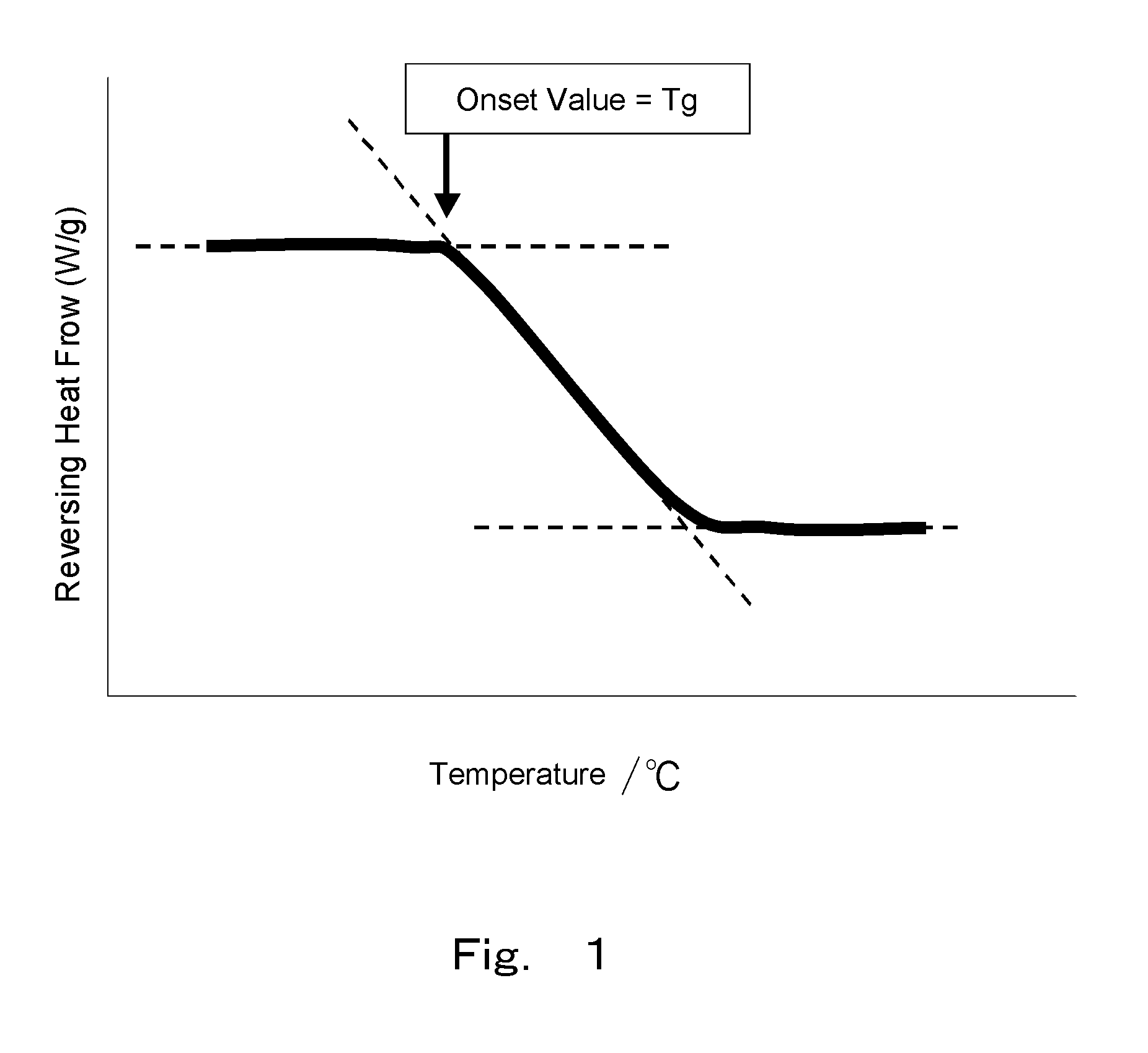

Polypropylene copolymer, composition containing the same, and process for producing the same

ActiveUS20060025535A1Satisfactory propertyImprove solubilityGraft polymer adhesivesSolubilityPolymer science

A problem of the invention is to provide a propylene copolymer which is excellent in adhesion to crystalline propylene-based polymers and which is excellent in solubility and compatibility with polar resins, a process for producing the same, and a composition containing the subject polypropylene copolymer. The invention is concerned with a polypropylene copolymer, which is characterized by having a polymer principal chain (A) derived from a propylene-based polymer having (1) a prescribed requirement as defined by the 13C-NMR spectral measurement and having (2) a melting point [Tm] by a differential scanning calorimeter of not higher than 100° C., or a crystal melting heat of less than 5 J / g; and a side chain containing a polymer chain (B) which is different from the principal chain, with a weight ratio of (A) / (B) being in the range of from 20 / 1 to 1 / 20, a composition containing the subject copolymer, and a process for producing the subject copolymer.

Owner:MITSUBISHI CHEM CORP

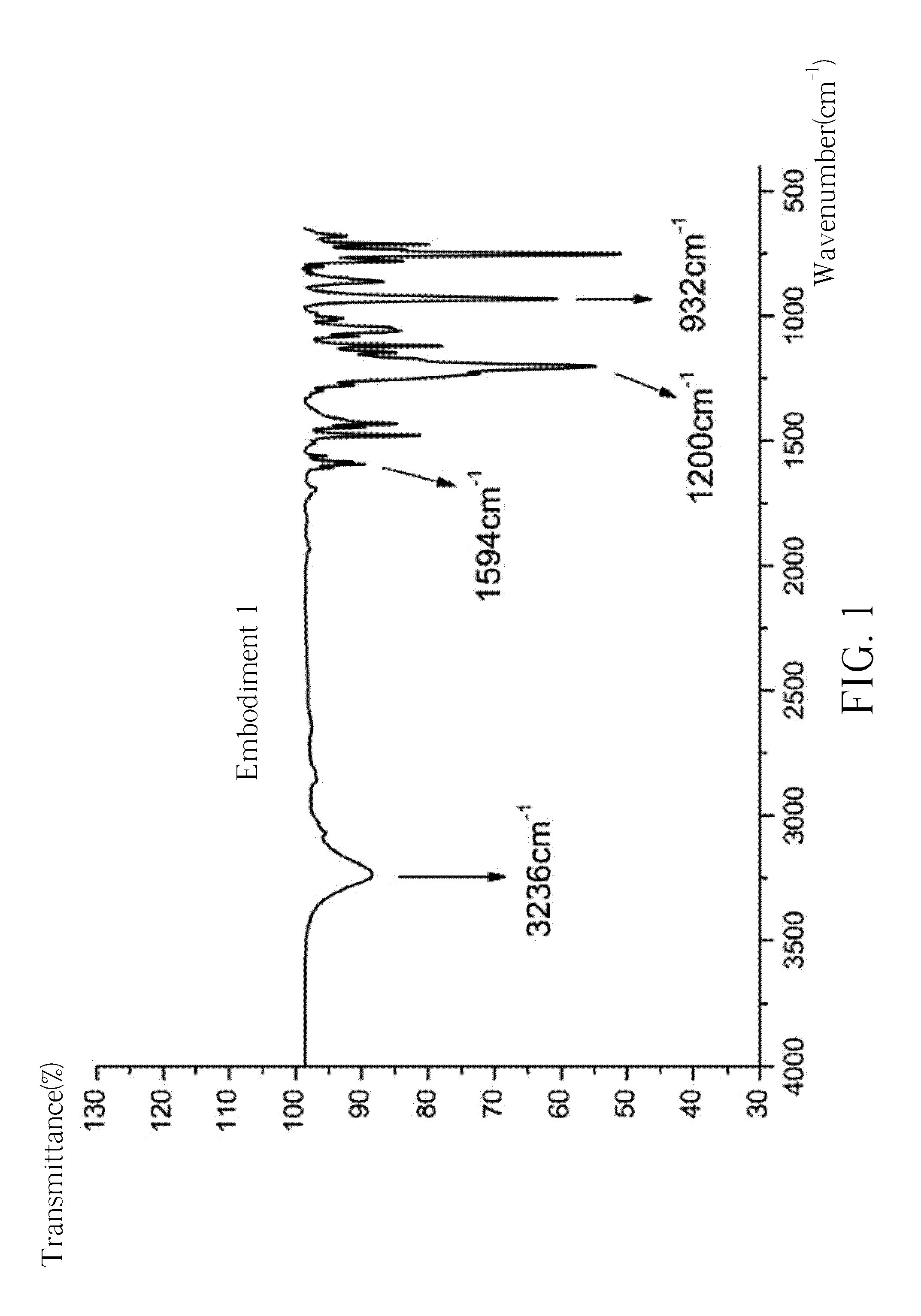

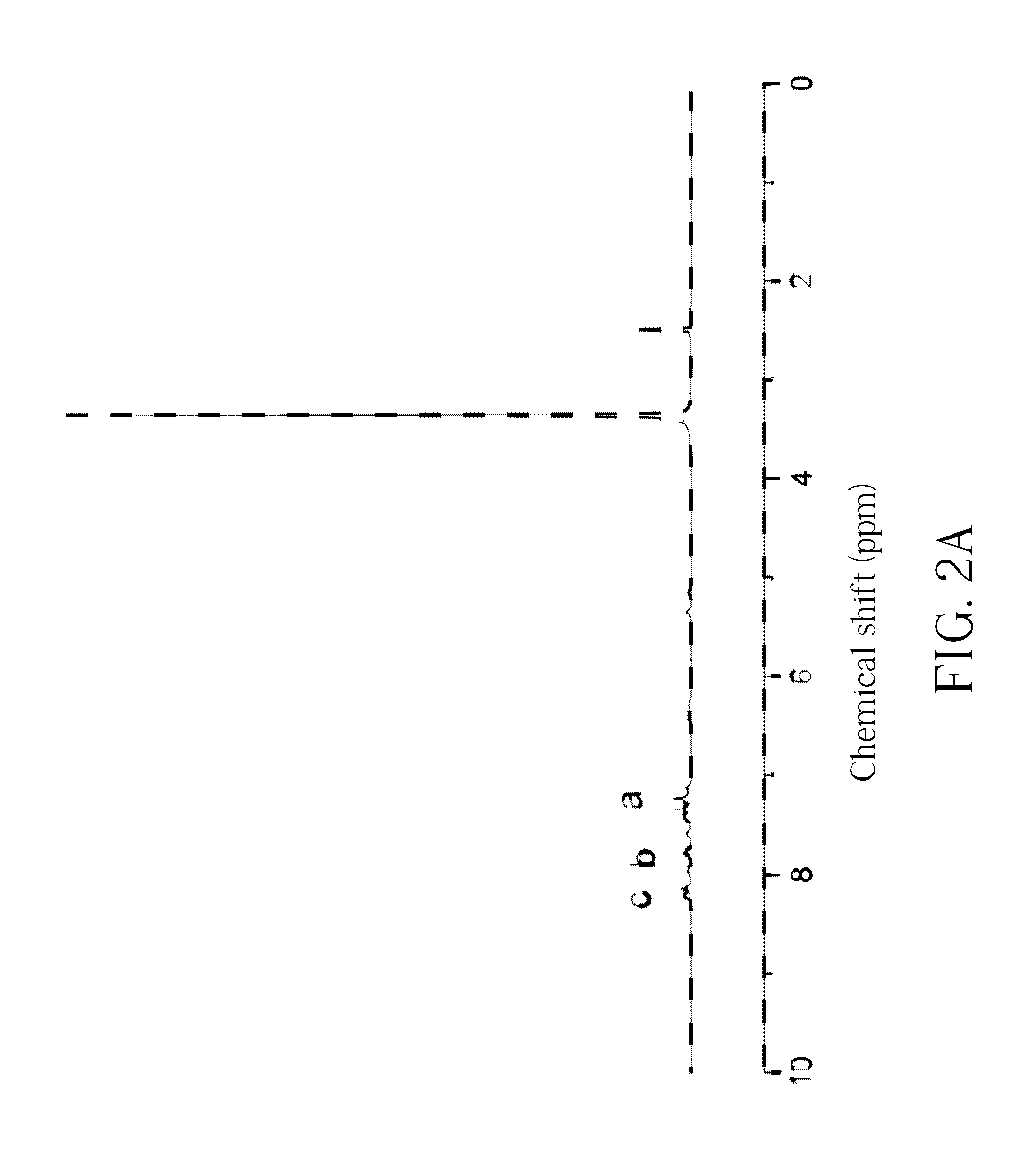

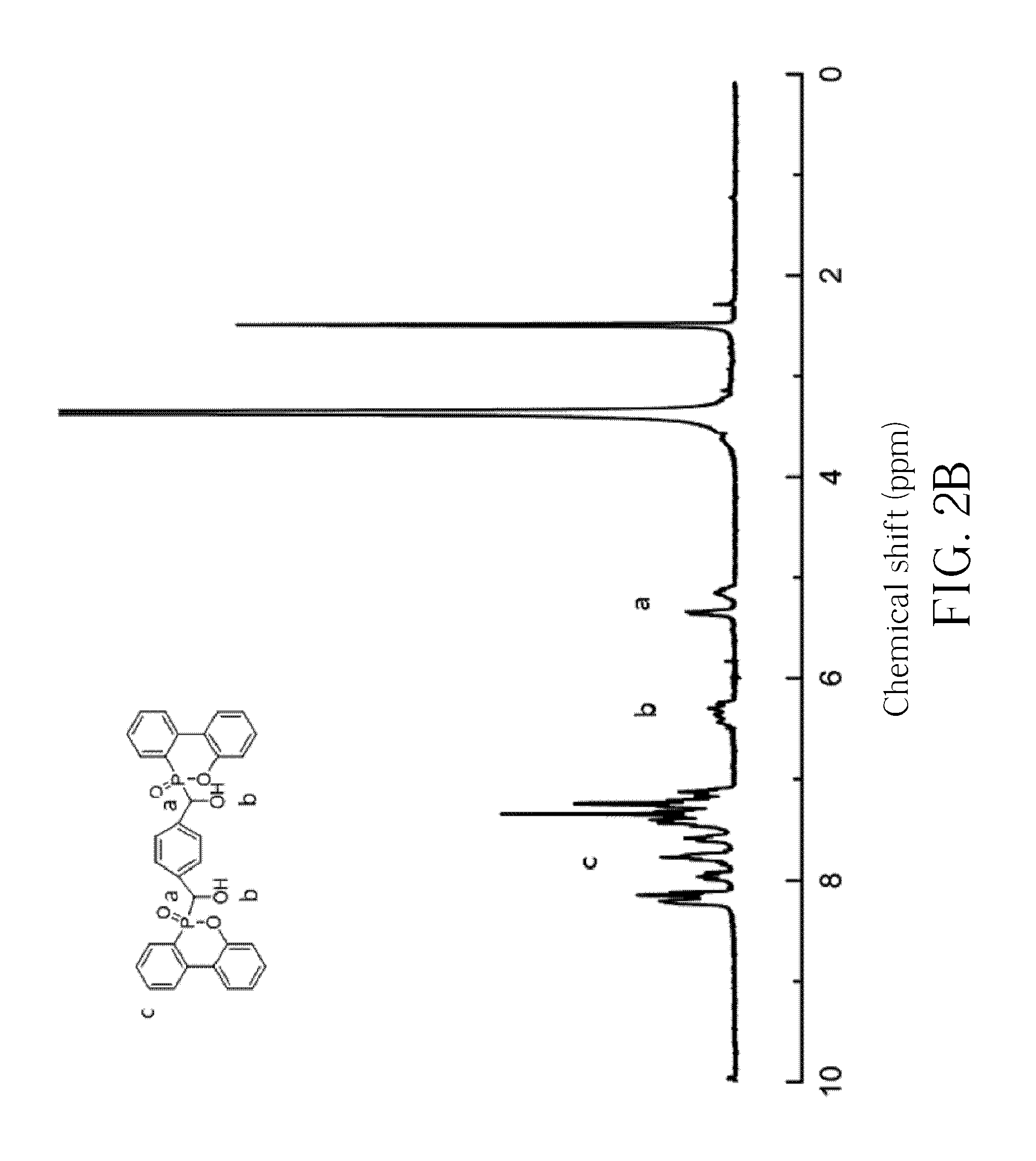

Phosphaphenanthrene-based compound and related preparation method and application

ActiveUS20170022228A1Reduction factorLow thermal expansionGroup 5/15 element organic compoundsPolymer sciencePrinted circuit board

Provided is a phosphaphenanthrene-based compound represented by the following chemical structure:The phosphaphenanthrene-based compound can be added in a resin composition and made into a prepreg or resin film. The prepreg or resin film made from such resin composition has low coefficient of thermal expansion, low dielectric constant and dissipation factor, and flame retardancy, thereby being suitable for copper-clad laminate or printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Industrial two-layer fabric

ActiveUS7357157B2Satisfactory propertyImprove surface propertiesPaper/cardboardMachine wet endYarnEngineering

In a repeating unit of a two-layer fabric, a first upper surface side warp forms a first upper surface side warp design. A second upper surface side warp forms a latent portion in which the second upper surface side warp passes between the two layers of the fabric. A first lower warp binding yarn and a second lower warp binding yarn form first and second knuckles respectively by passing over one or two upper surface side wefts at a position not adjacent to two knuckles of the second upper surface side warp in the latent portion. The first and second knuckles are formed at different positions. The first lower warp binding yarn, second upper surface side warp and second lower warp binding yarn cooperatively form a second upper surface side warp design similar to the first upper surface side warp design.

Owner:NIPPON FILCON

Toner

ActiveUS20090263738A1Excellent low temperature fixabilityHigh offset resistanceDevelopersPolyesterPolymer science

An object of the present invention is to provide a spherical toner that has a sharp particle size distribution and a small particle diameter. This is a capsule-type toner that exhibits an excellent low-temperature fixability, while at the same time having a high offset resistance and excellent charging properties and having the ability to provide a high-quality image in which the characters, lines, and dots are precisely defined. The object is achieved by a toner comprising a toner particle that comprises at least (a) resin having polyester as the main component, colorant, wax, and (b) urethane resin, wherein the hydroxyl value per specific surface area of the toner particle is fall into the specific range, and wherein a Tg(0.5) and a Tg(4.0)-Tg(0.5) of the toner fall into specific range.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com