Patents

Literature

117results about How to "Enhance friction strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composition

InactiveUS20060089466A1Improve accuracyEnhance friction strengthLiquid surface applicatorsPlastic/resin/waxes insulatorsEpoxyCationic polymerization

An embodiment of the invention relates to a novel epoxy resin composition. The epoxy resin composition comprises (i) a first epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, and having a number average molecular weight ranging from 8,000 to 22,000 and a polydispersity ranging from 3.5 to 5.0, (ii) a second epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, having a number average molecular weight ranging from 2,500 to 8,000 and a polydispersity ranging from 1.5 to 3.0, and (iii) a cationic polymerization catalyst.

Owner:CANON KK

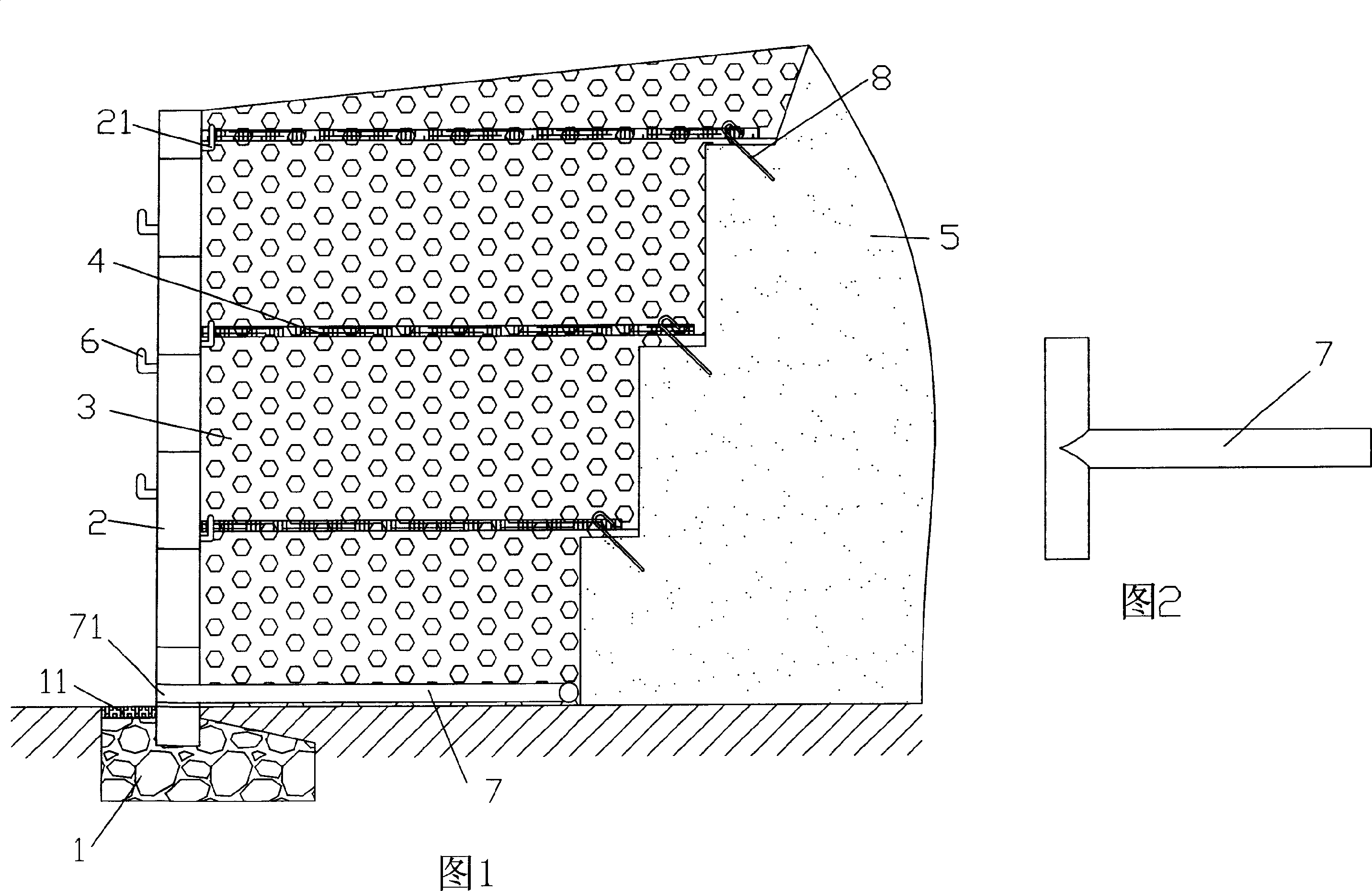

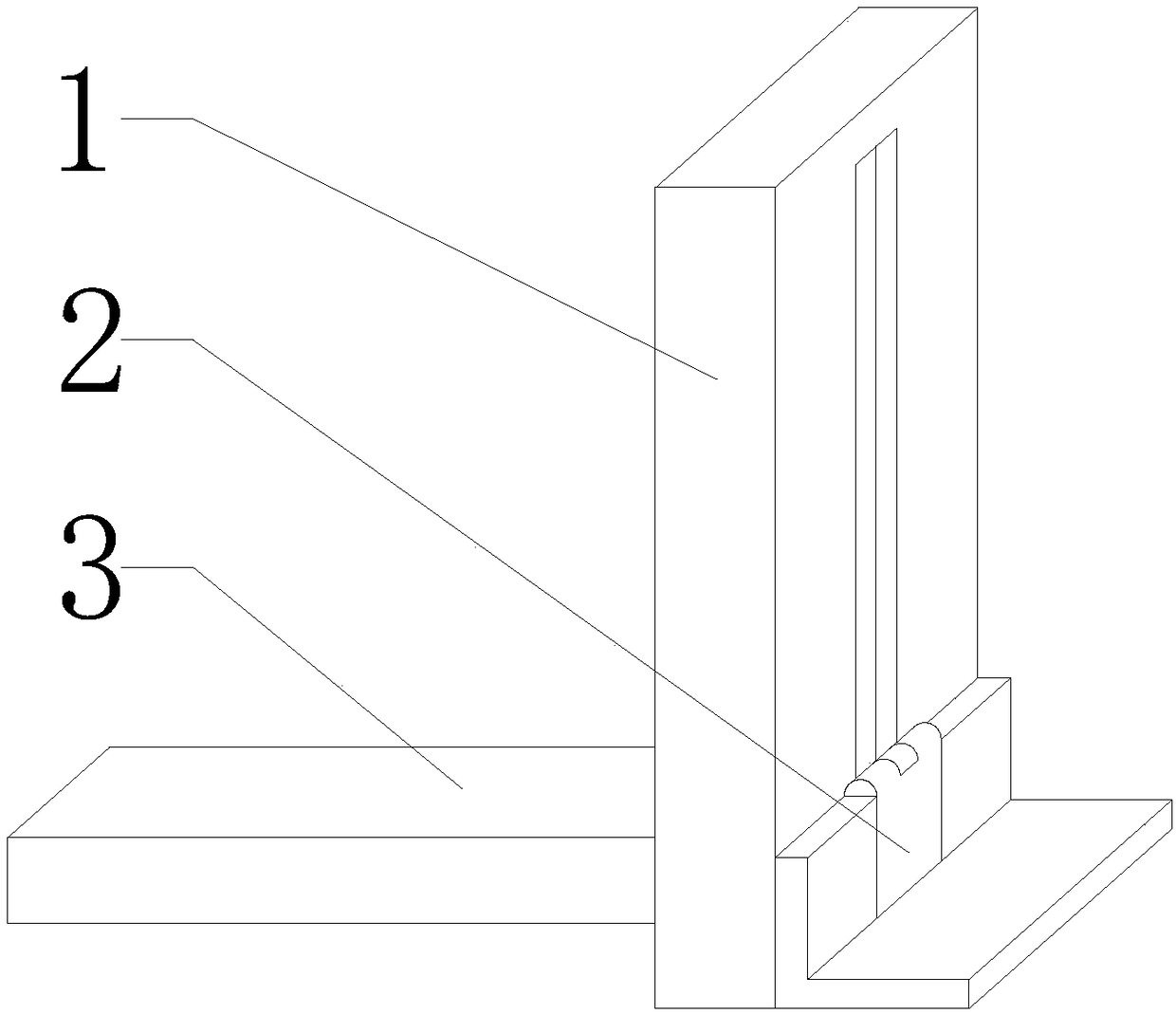

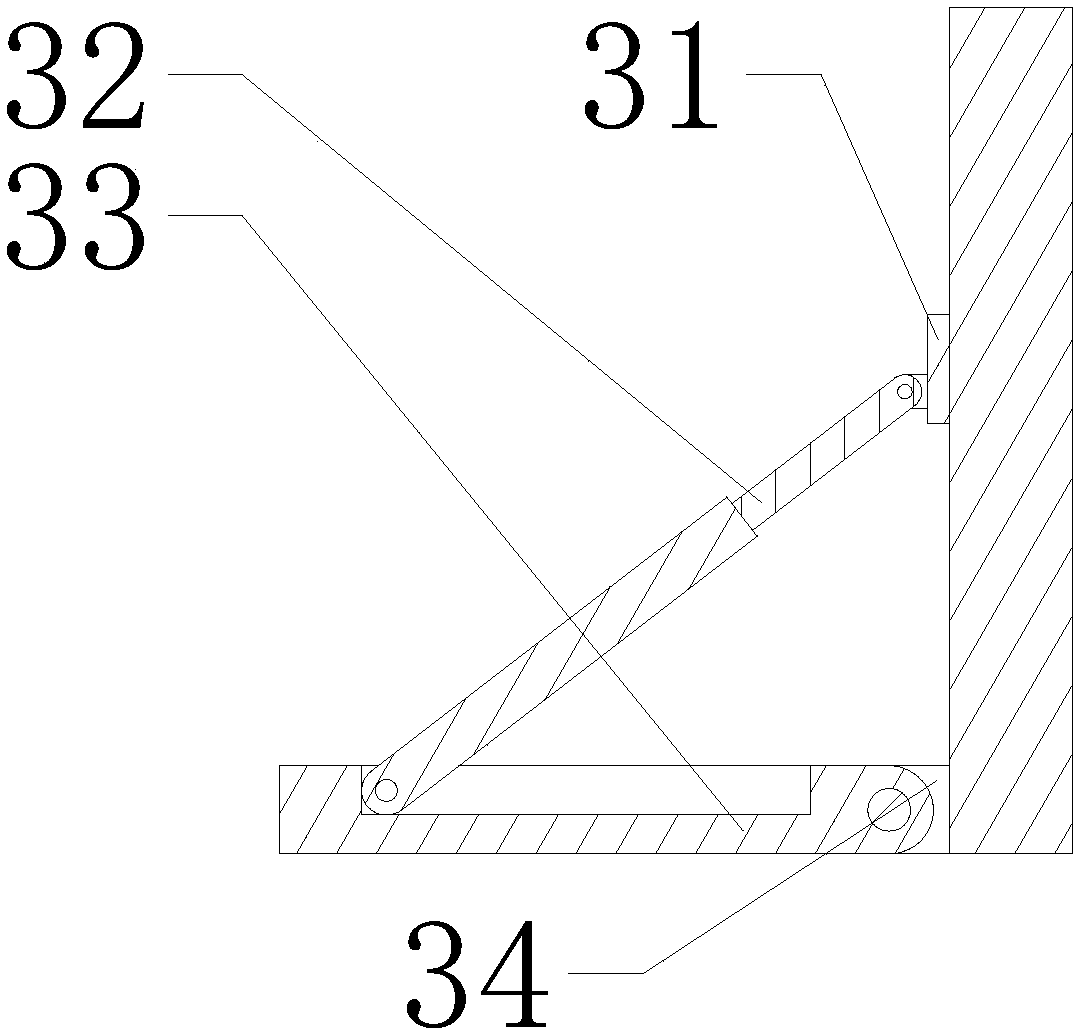

Retaining wall in lightweight, and construction method

InactiveCN101003975AMeet the needs of vertical greeningReduce side pressureArtificial islandsUnderwater structuresFilling materialsCement mortar

The present invention discloses a light retaining wall and its construction method. Said method includes the following steps: firstly, building foundation, laying cement mortar on the foundation and making cement mortar surface be parallel to the horizontal plane, inserting first layer of wall panel into the cement mortar and making the plane of wall panel be perpendicular to the cement mortar surface, after the cement mortar is solidified and the wall panel and foundation are connected into one body, after the wall panel laying first layer of light filling material, then laying reinforcing bar on the compacted light filling material, making one end of reinforcing bar be firmly connected with wall panel and making its another end be inserted into light filling material, then successively mounting second layer of wall panel, laying second layer of filling material and setting reinforcing bar according to the above-mentioned steps until the predefined height is reached so as to obtain the light retaining wall.

Owner:程卫国

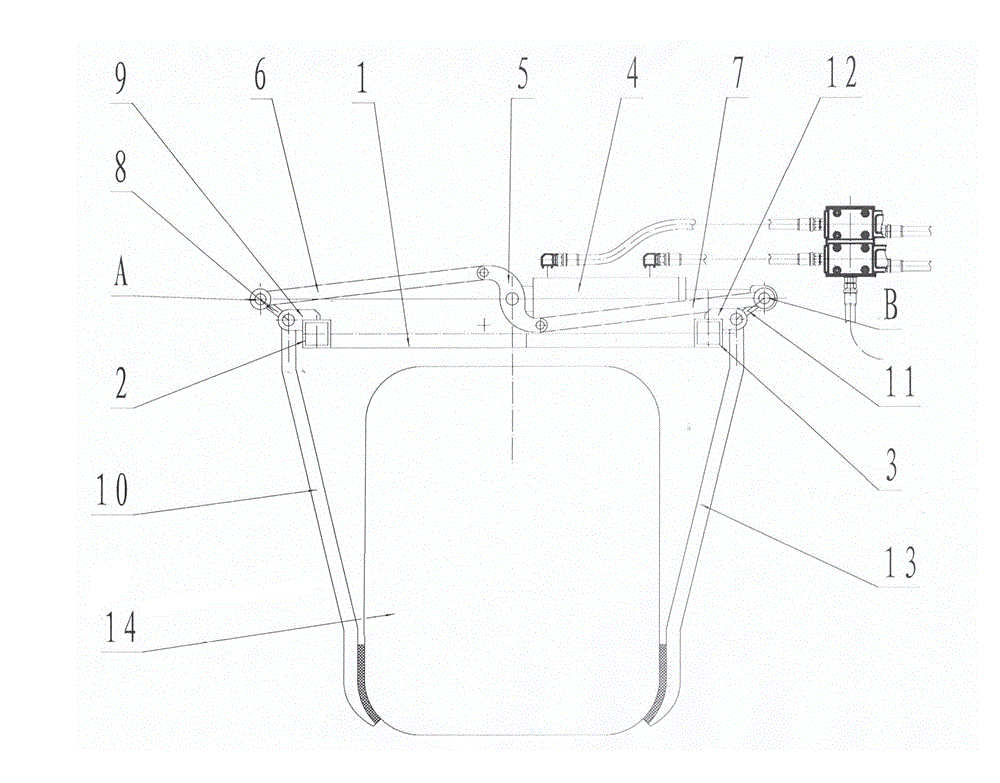

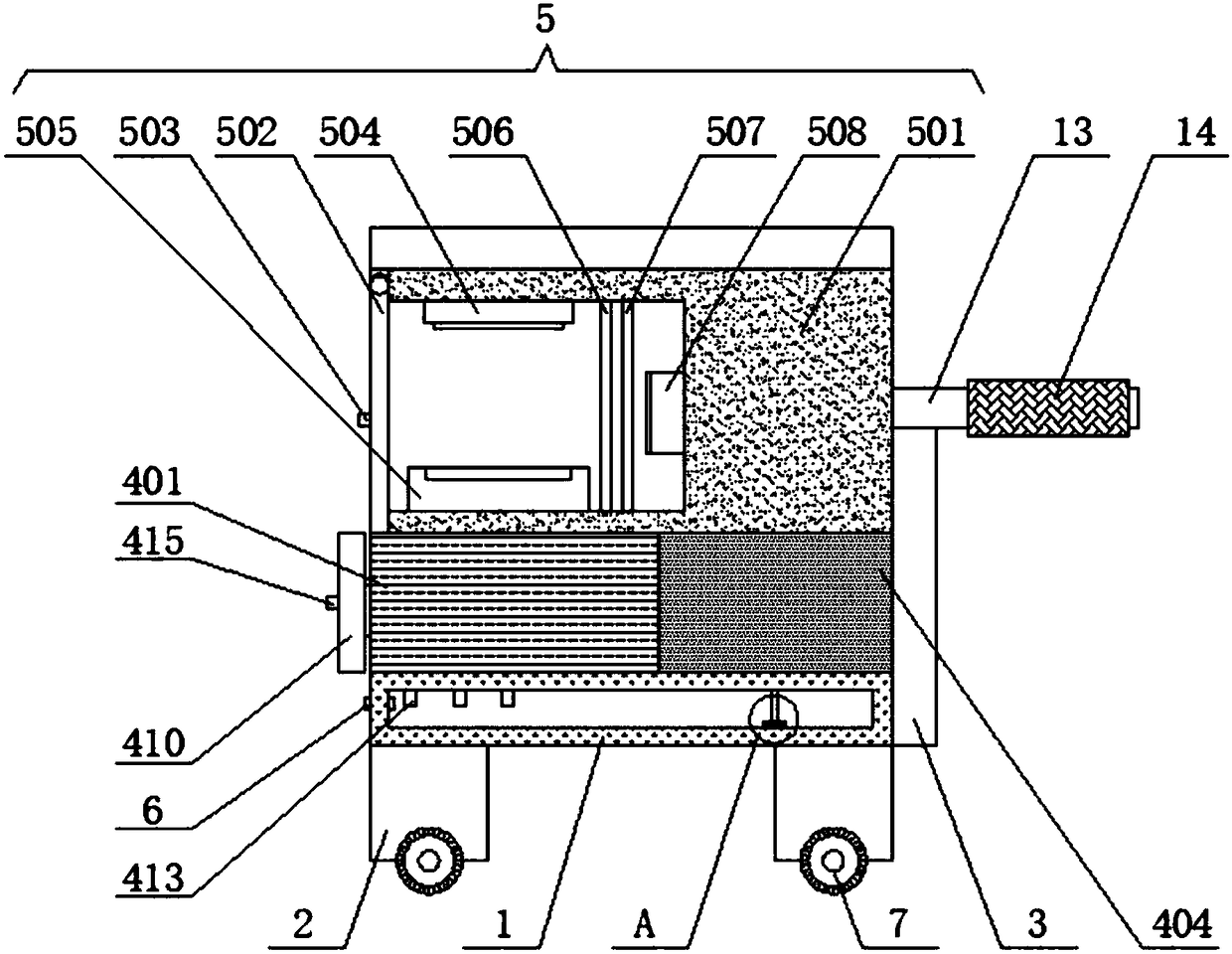

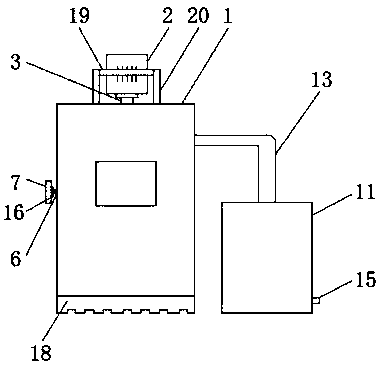

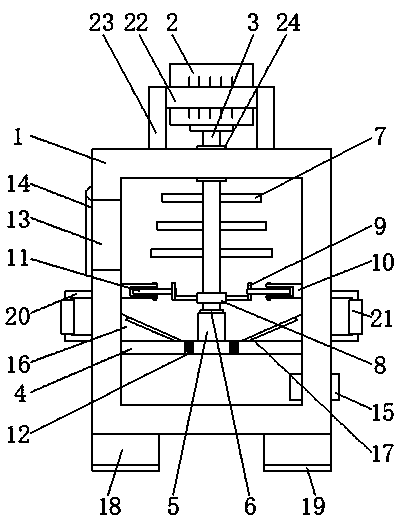

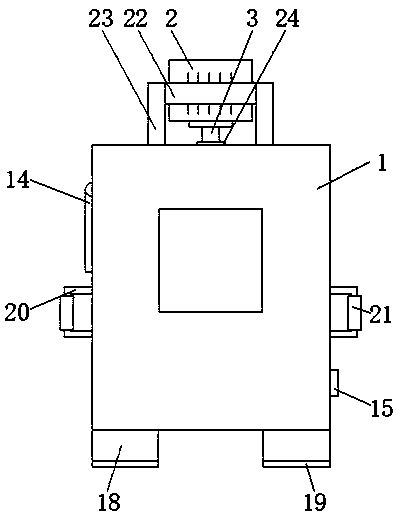

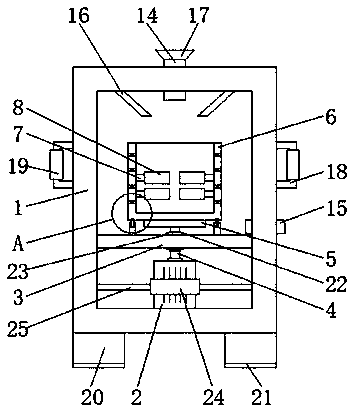

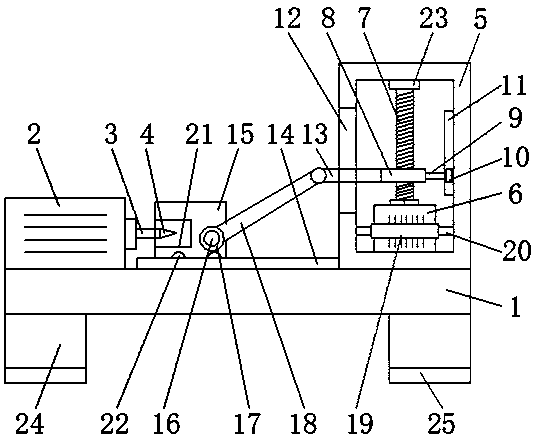

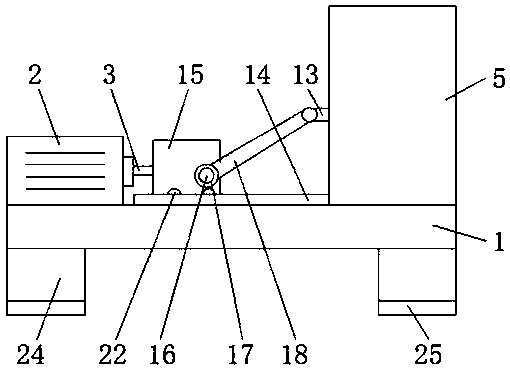

Hydraulic garbage can holding device

The invention relates to equipment for garbage trucks, in particular to a hydraulic garbage can holding device which is suitable for garbage can turning operation. The hydraulic garbage can holding device comprises a hydraulic cylinder, a synchronized block, a first connecting rod, a first garbage can holding arm assembly, a second connecting rod and a second garbage can holding arm assembly. According to the hydraulic garbage can holding device, the device is driven by hydraulic pressure to drive the synchronized block to swing, then by means of transmission of the first connecting rod and the second connecting rod, the first and the second garbage can holding arm assemblies are operated synchronously to perform holding or loosening operation for a garbage can, the structure is simple, and the operation is convenient; the hydraulic garbage can holding device is arranged on a garbage can hanging plate, the hydraulic garbage can holding device is lifted upwards with the garbage can hanging plate, simultaneously a garbage can holding action is performed for the garbage can to provide an excellent safe protection measurement for turning of the garbage can, the phenomenon of garbage can swinging under the centrifugation action caused by the fact that the turning speed is rapid or the outer wall of the garbage can is slippery is effectively prevented, and the damage to the garbage can is reduced.

Owner:QINGDAO ALLITE AUTO TECHNIC

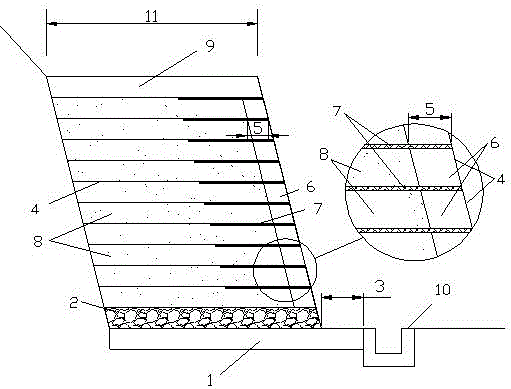

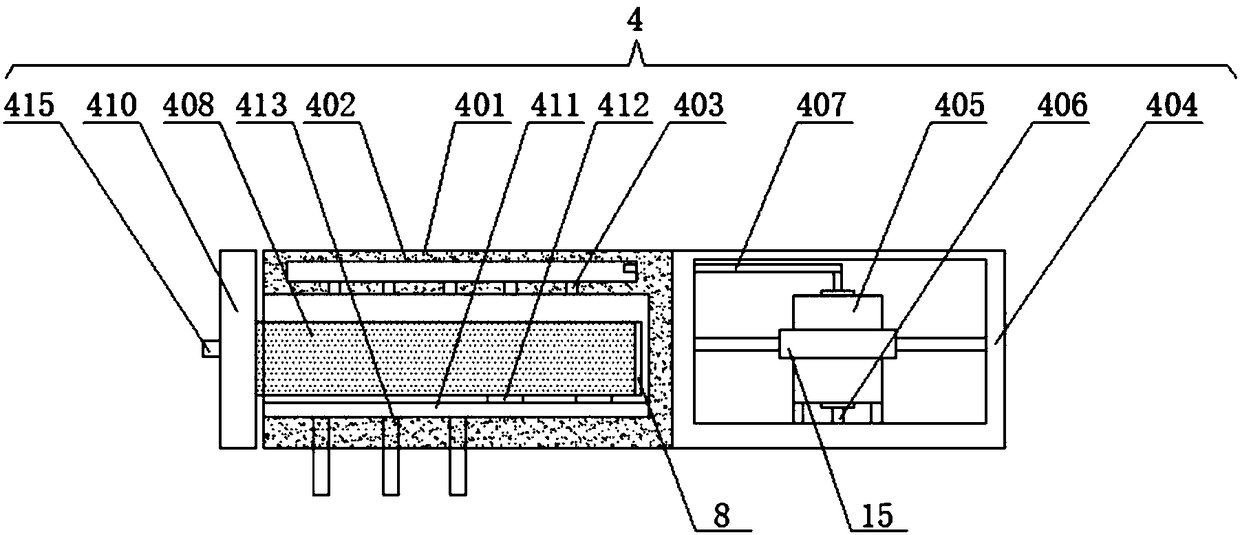

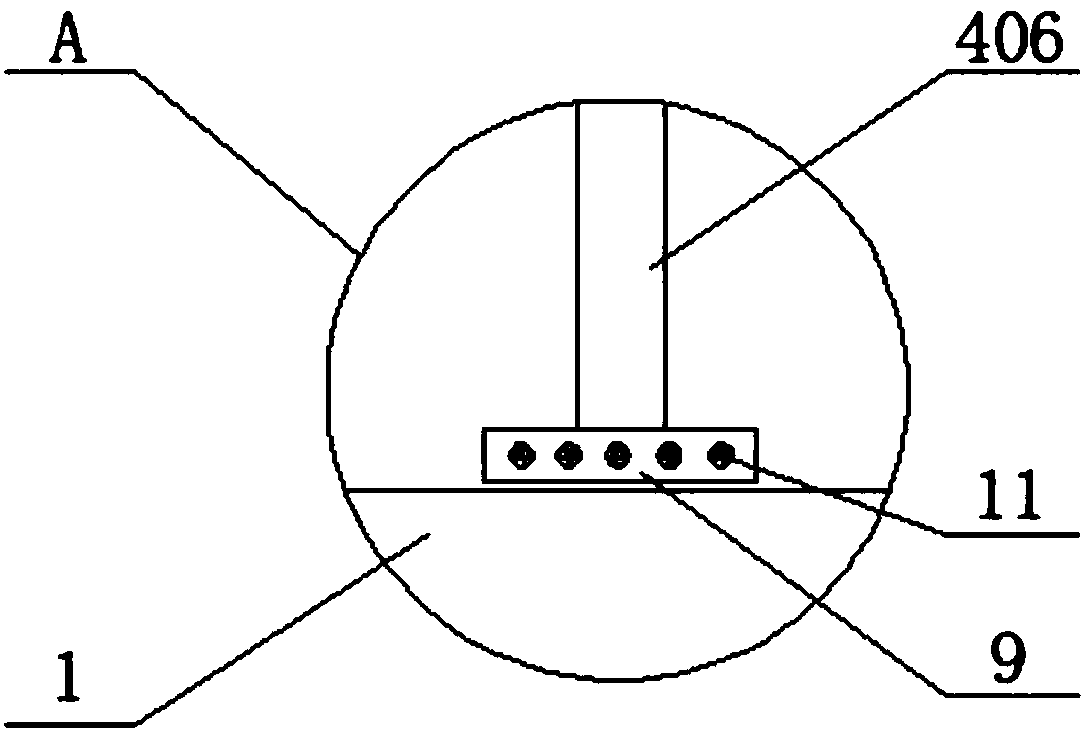

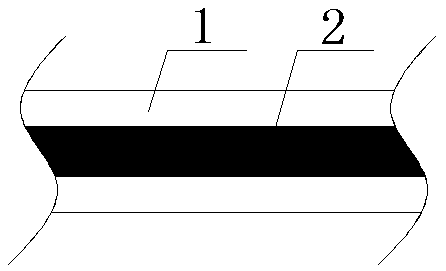

Cement modified soil strengthened geogrid reinforced soil structure and construction method thereof

The invention discloses a cement modified soil strengthened geogrid reinforced soil structure and a construction method thereof. The cement modified soil strengthened geogrid reinforced soil structure (shown in a figure 1) is composed of four parts including a base layer (1) and a cover layer (9) composed of cement modified soil, a water drainage layer (2) and a cement modified soil strengthened geogrid reinforced soil layer thereof, and is a novel geogrid reinforced soil structure which is formed by improving similar structures through utilizing good properties including solidification, high wetting resistance, high anti-scouring and flood damage resisting properties, high shearing strength and the like of cement modified soil. Compared with an existing similar structure, the novel geogrid reinforced soil structure and the construction method thereof, provided by the invention, can realize panel-free construction of an abrupt-slope reinforced soil structure, and can also remarkably improve the wetting resistance, anti-scouring property and whole shearing strength of the geogrid reinforced soil structure; the cement modified soil strengthened geogrid reinforced soil structure is especially suitable for protecting and reinforcing edge slopes, which are easy to scour and damage by flood, of abrupt-slope sections.

Owner:湖南高速华达工程有限公司

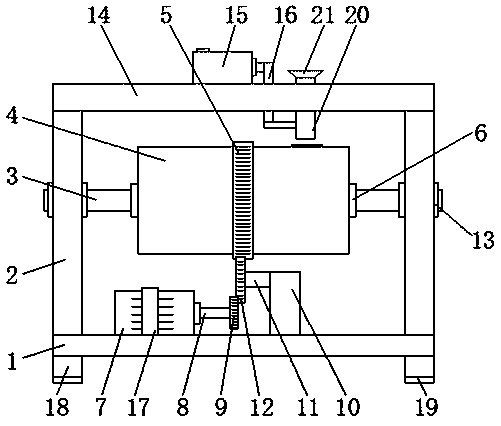

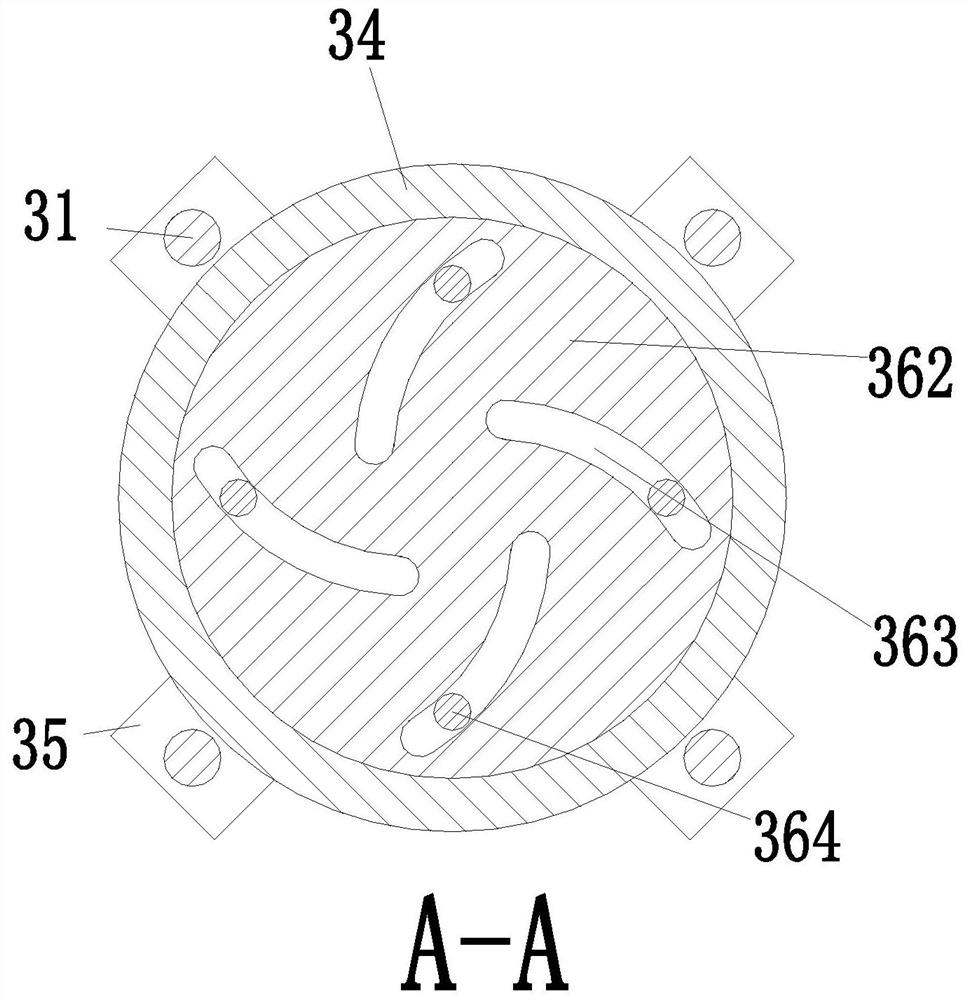

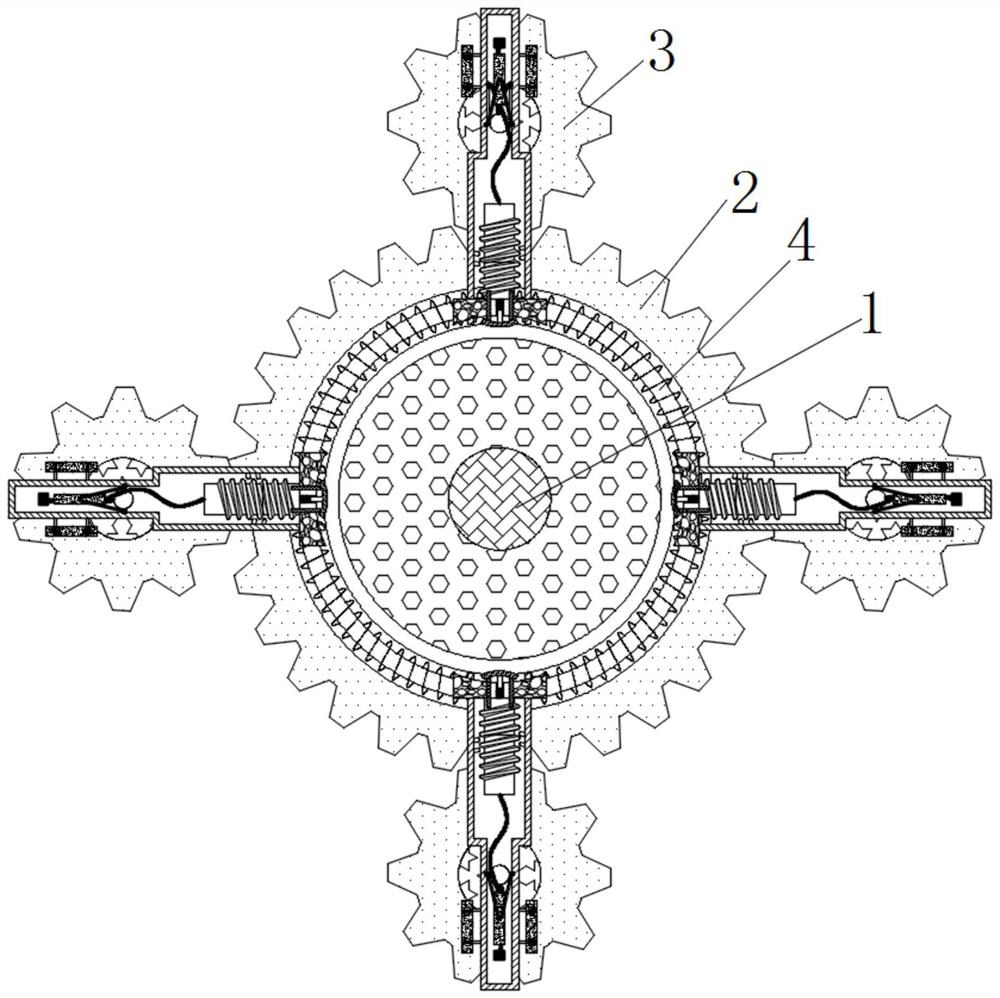

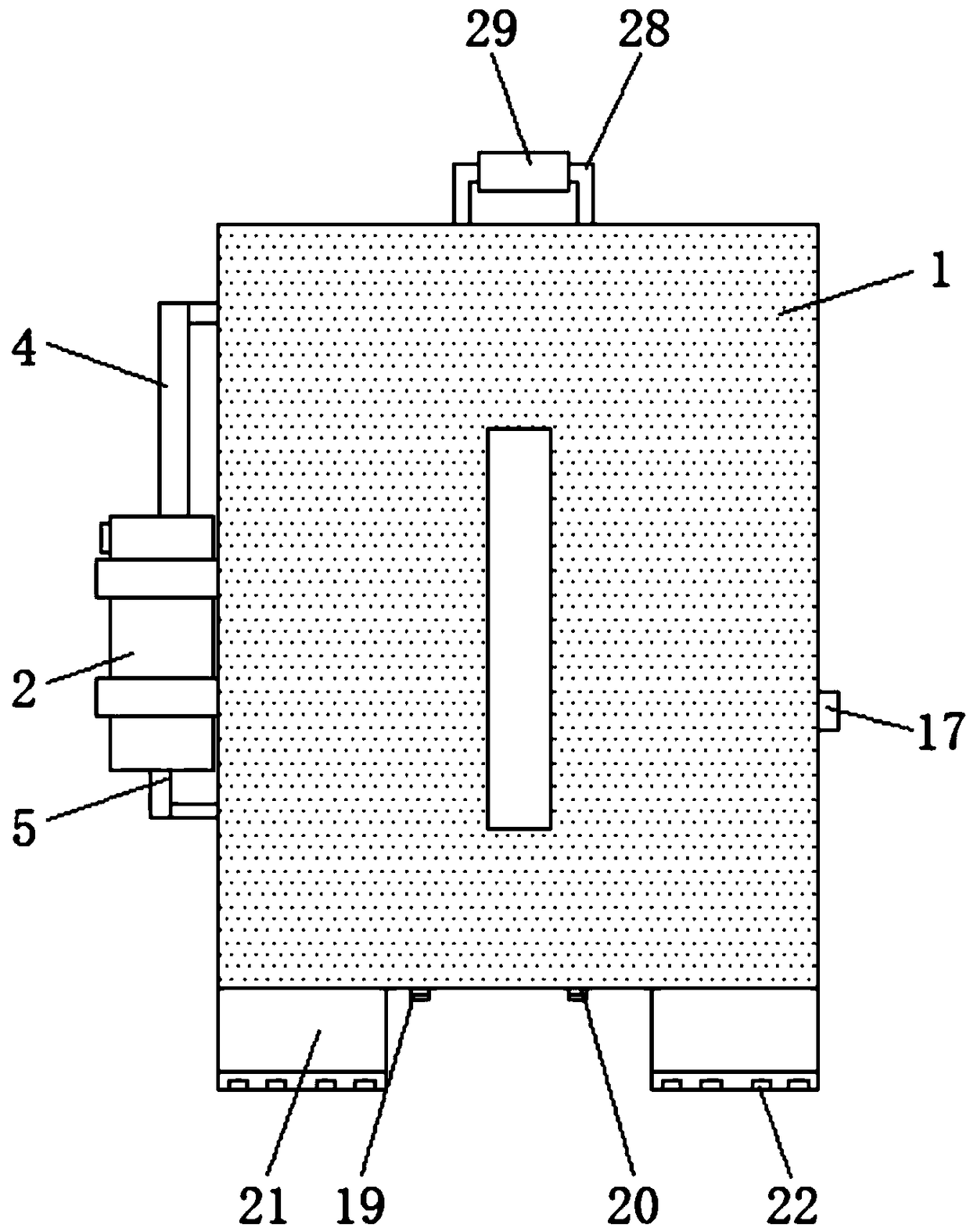

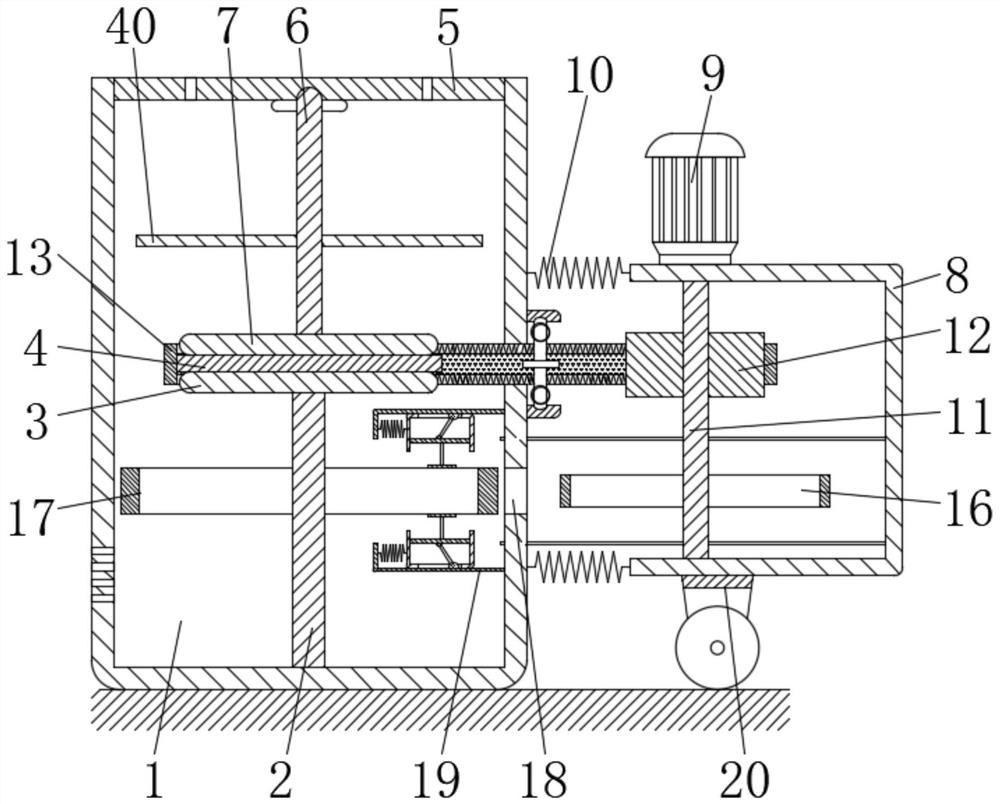

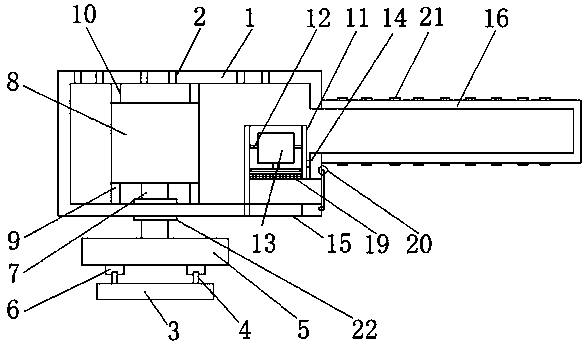

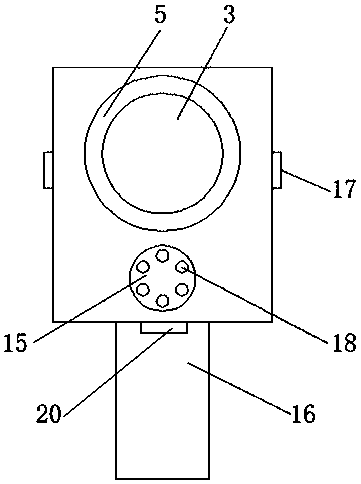

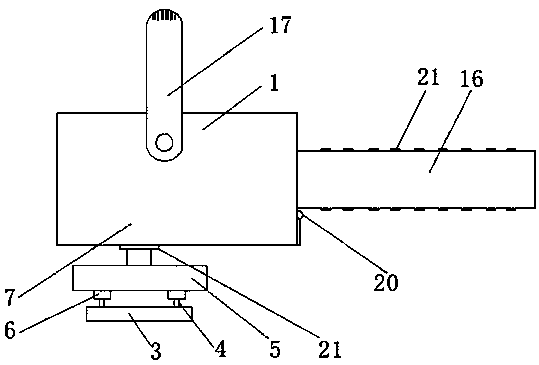

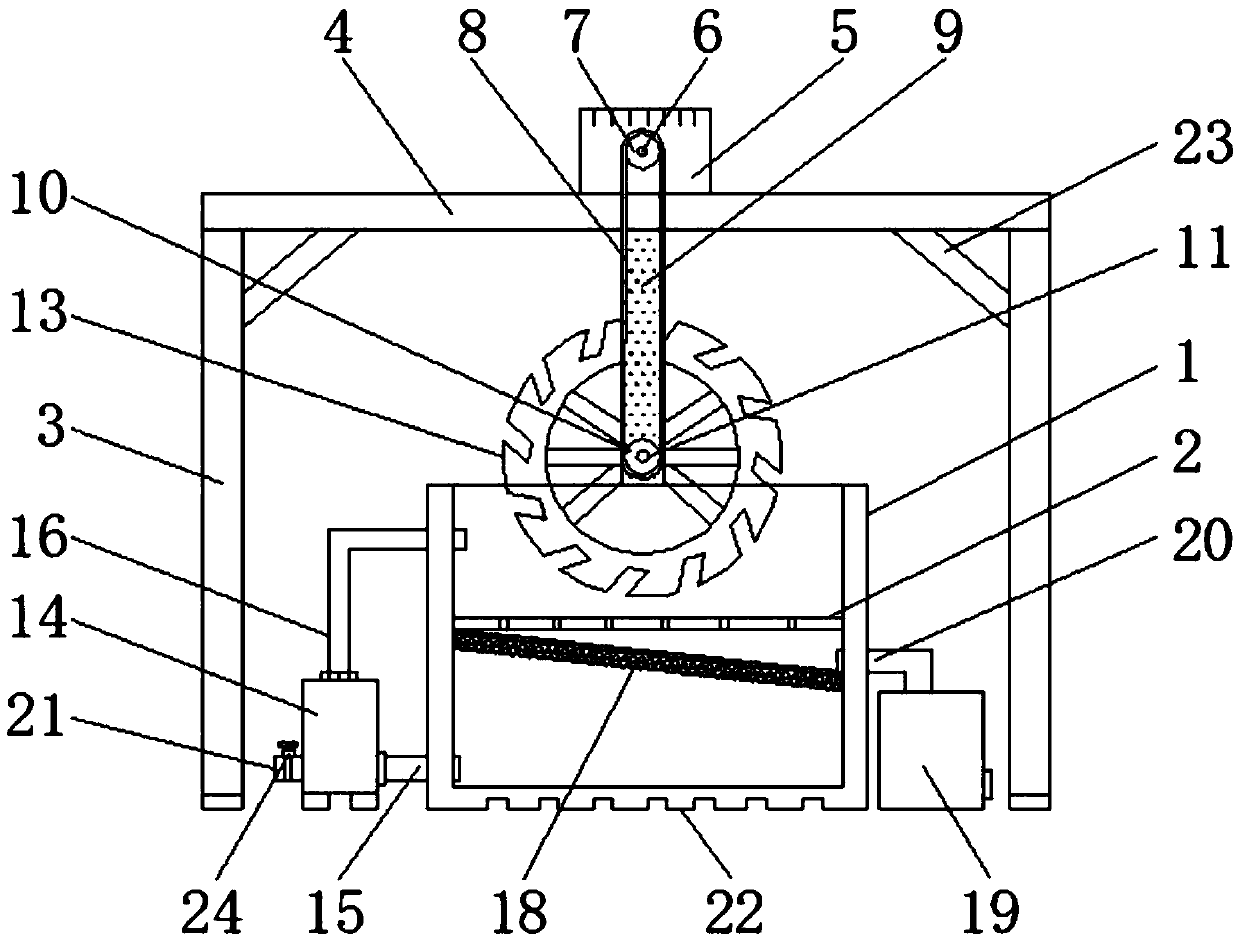

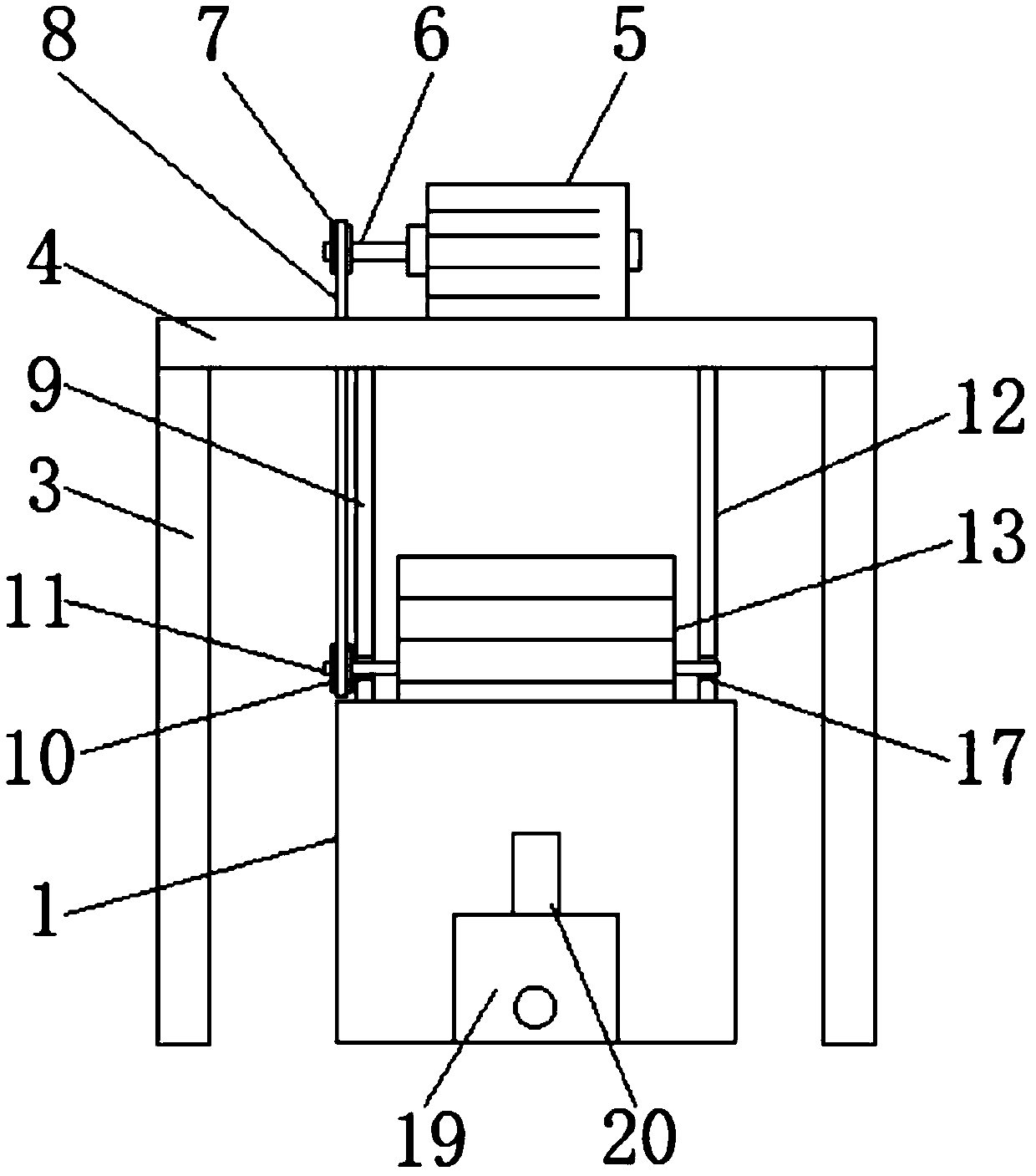

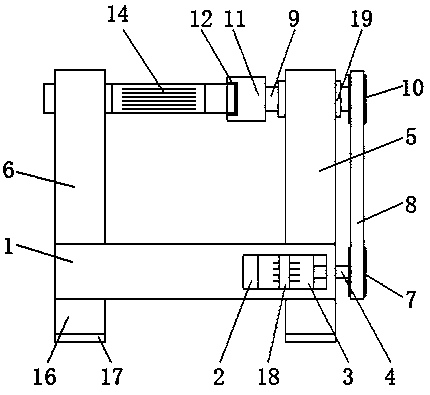

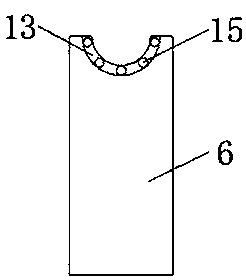

Concrete rotary mixer for constructional engineering

InactiveCN108437201APrevent sideslipImprove stabilityCement mixing apparatusGear wheelArchitectural engineering

The invention discloses a concrete rotary mixer for constructional engineering. The concrete rotary mixer for constructional engineering comprises a fixed base, two symmetrical supporting columns arefixedly connected to the upper surface of the fixed base, a driven rod is arranged between the two supporting columns, and a stirring barrel is arranged on the outer surface of the driven rod in a sleeving mode. A first bearing is arranged at the position, in contact with the stirring barrel, of the outer surface of the driven rod in a sleeving mode, an inner ring of the first bearing is fixedly connected to the outer surface of the driven rod, and the left and right ends of the driven rod both penetrate through the outer surfaces of the supporting columns and extend outside the supporting columns. A rack is arranged on the outer surface of the stirring barrel in a sleeving mode, the inner wall of the rack is fixedly connected with the outer surface of the stirring barrel, a driving motoris fixedly connected to the upper surface of the fixed base, a rotating rod is fixedly connected to the output end of the driving motor, and a gear is fixedly connected to one end, away from the driving motor, of the rotating rod. The concrete rotary mixer for constructional engineering has the advantages of simple structure, high work efficiency and long service life.

Owner:周玉翔

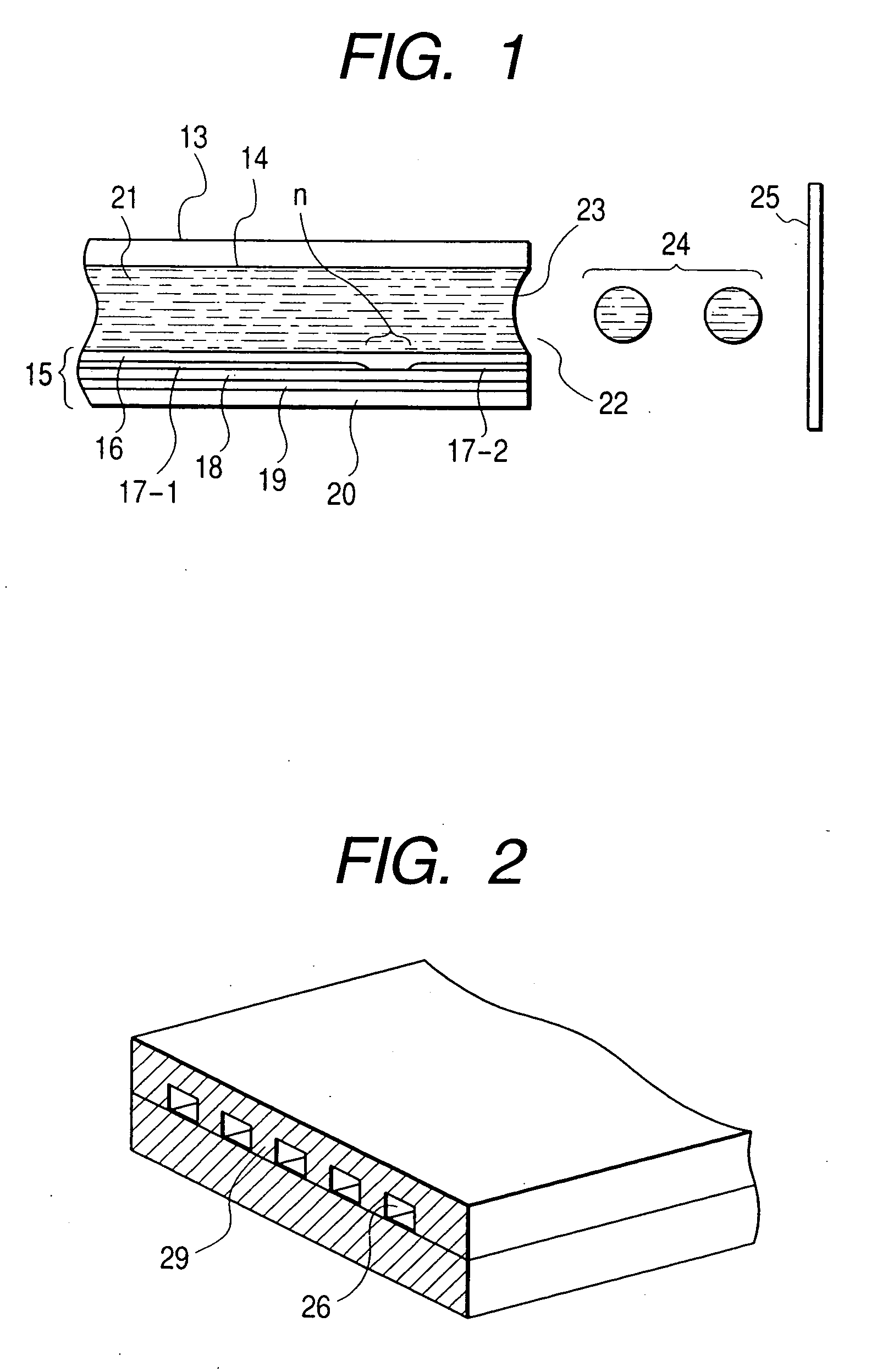

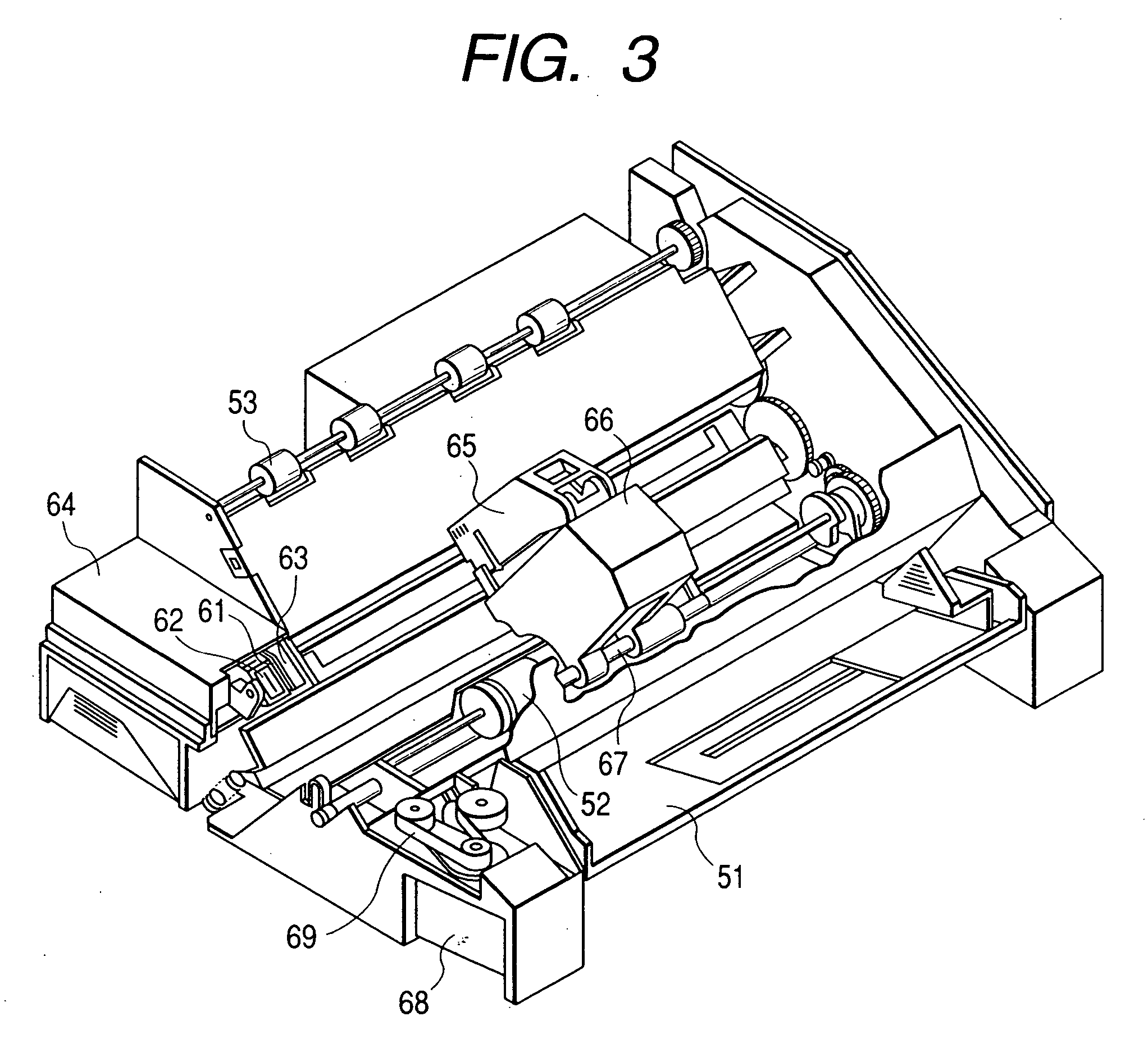

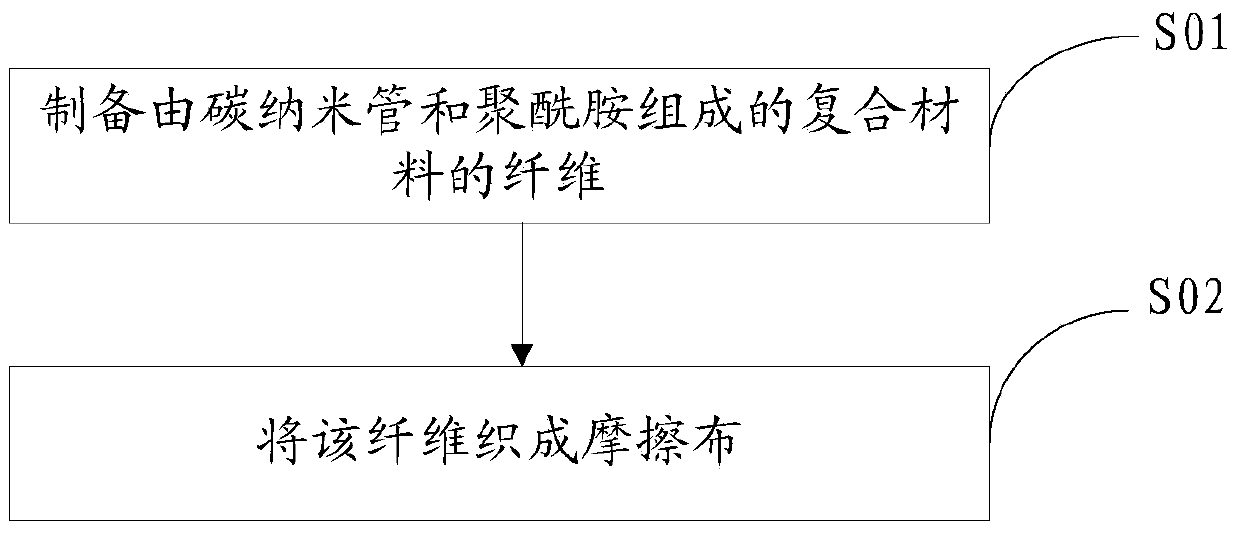

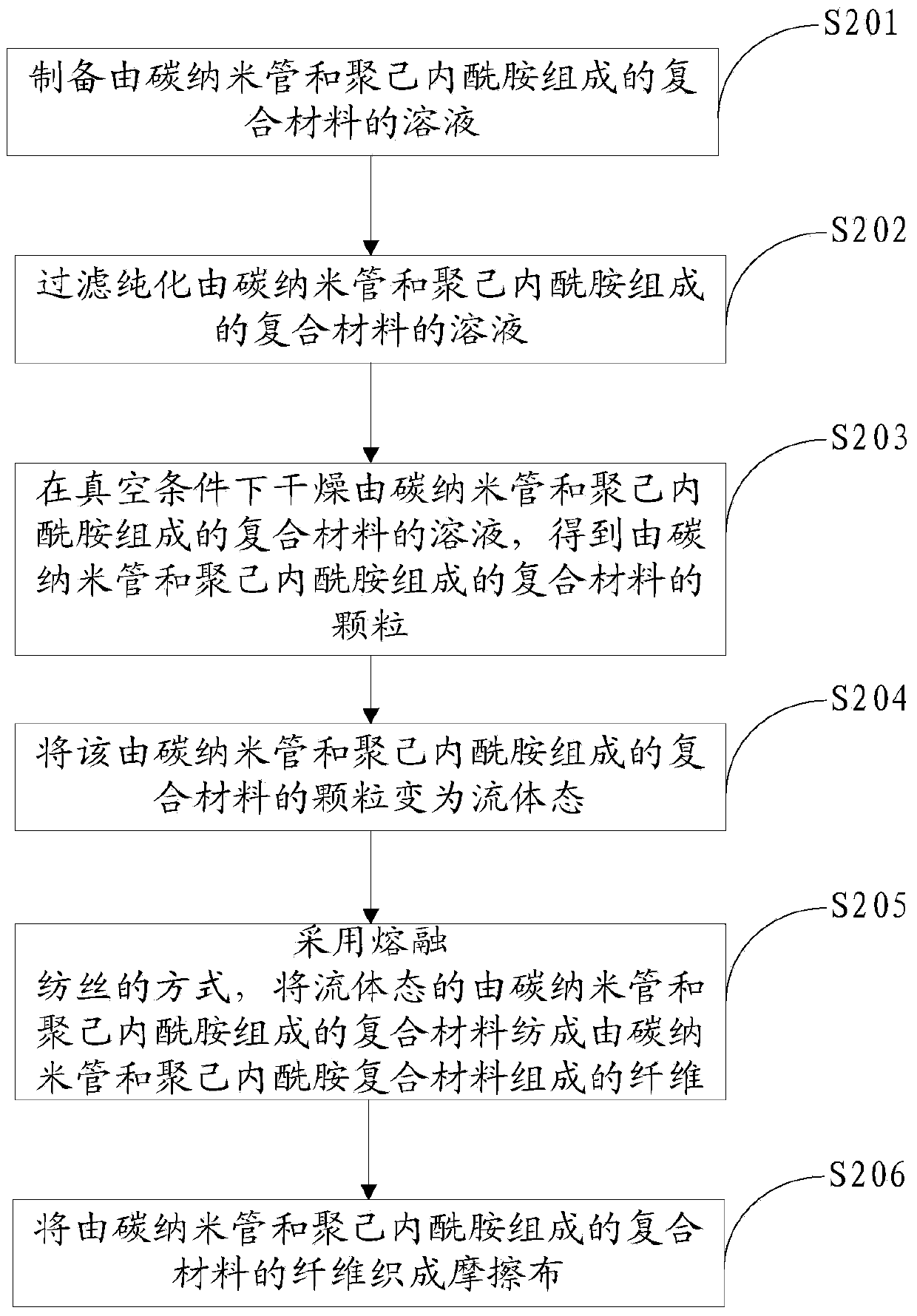

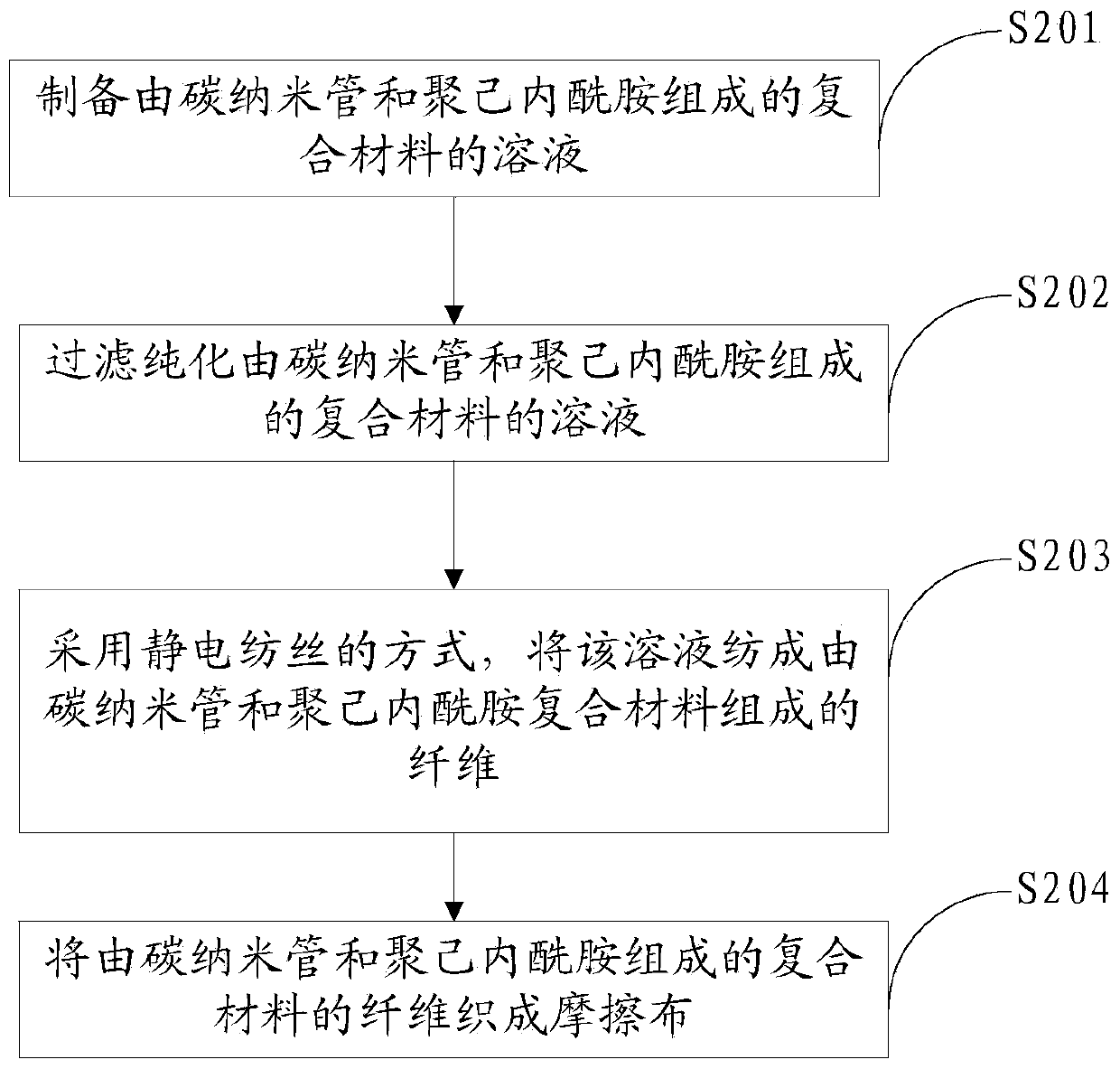

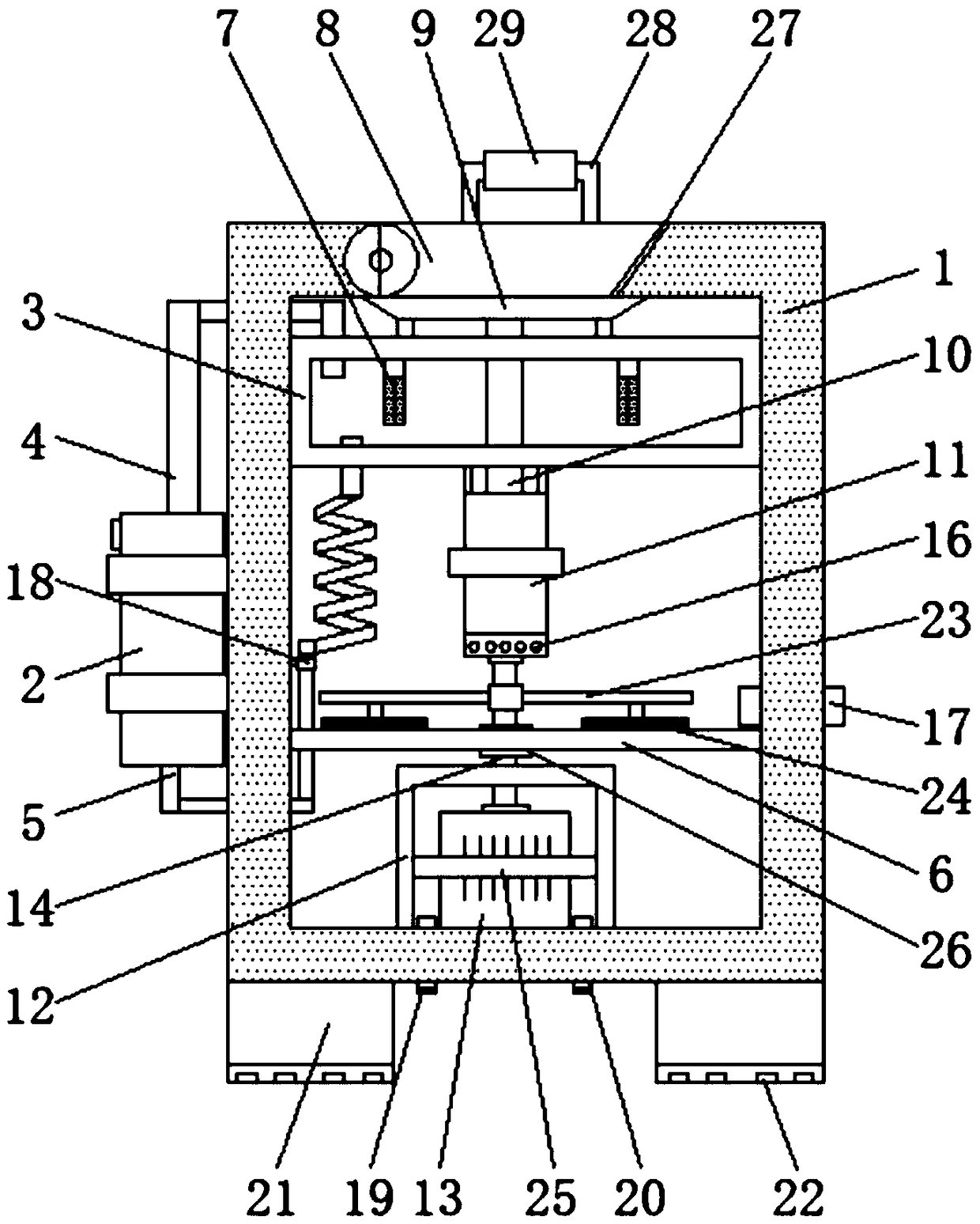

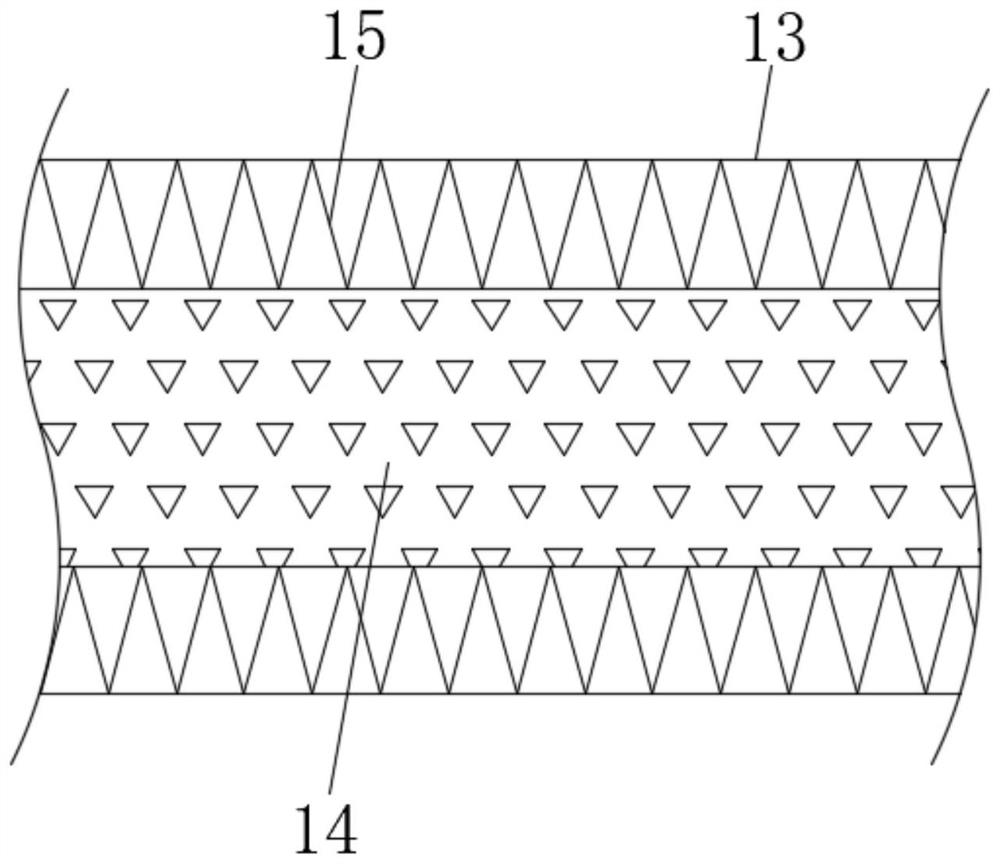

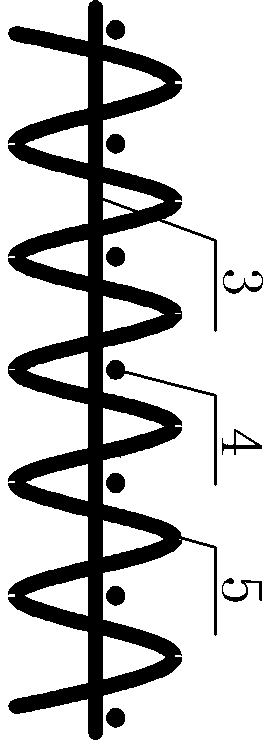

Rubbing cloth and preparation method and preparation device thereof

InactiveCN103472625AWarp and weft density is easy to controlNot easy to shed hairNon-linear opticsLiquid-crystal displayImaging quality

The invention discloses rubbing cloth and a preparation method and a preparation device thereof. The rubbing cloth is made of a composite material composed of carbon nano tubes and polyamide; since the carbon nano tubes have excellent antistatic property and the polyamide has excellent rubbing capability, the composite material composed of the carbon nano tubes and the polyamide has excellent antistatic property as well as excellent rubbing capability; moreover, as the composite material is an artificial material, wrap and weft density of the cloth are easily controlled during weaving, and further the rubbing cloth made of the composite material is high in uniformity; besides, the rubbing cloth made of the composite material is less prone to fur shedding. Therefore, the rubbing cloth is not only high in antistatic property and less prone to fur shedding, but also capable of realizing uniformity of orientation directions of orientation grooves under the condition of high rubbing strength, and further contrast and image quality of a liquid crystal display device are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

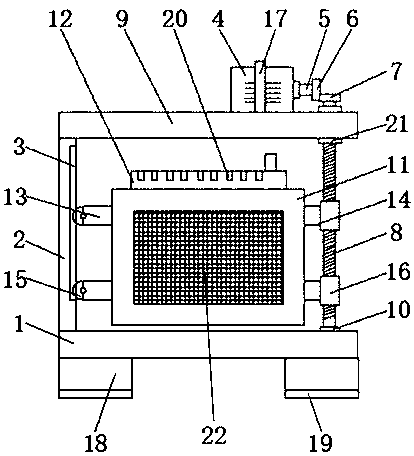

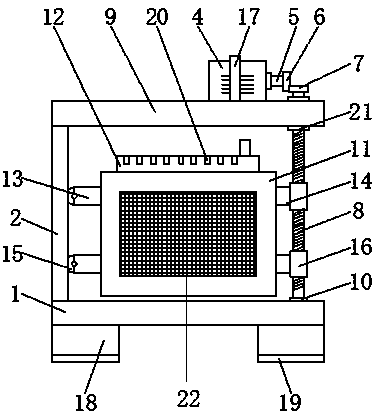

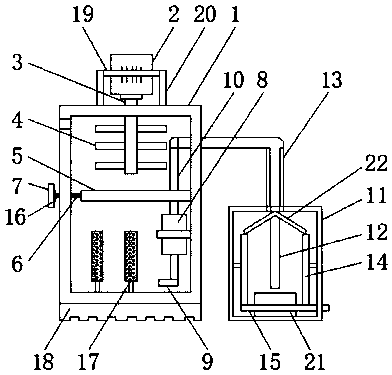

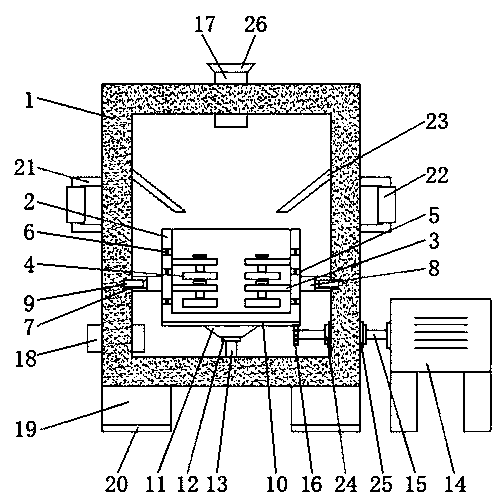

Disinfection equipment based on surgical operating instruments

InactiveCN108434493AEasy to usePrevent splashDrying gas arrangementsLavatory sanitoryWater leakageDisinfectant

The invention discloses disinfection equipment based on surgical operating instruments and relates to the technical field of medical disinfection equipment. The disinfection equipment comprises a liquid storage box, wherein the bottom surface of the liquid storage box is fixedly connected with bottom feet; one side surface of the liquid storage box is fixedly connected with a fixing rod; a disinfection mechanism is arranged on the upper surface of the liquid storage box; a drying mechanism is arranged at the top of the disinfection mechanism; the outer surface of the liquid storage box is fixedly communicated with a water injection pipe; the disinfection mechanism comprises a disinfection box, a water sprinkling cavity, water sprinkling holes, a water pumping box, a water pump, a water pumping pipe, a water delivery pipe, a fixing frame, a screen mesh, a sealing plate, a slide rail, a slide block, a water leakage pipe, a port and a first pull ring; the bottom surface of the disinfection box is fixedly connected with the upper surface of the liquid storage box; the water pumping box is positioned at the right side of the disinfection box; and the bottom surface of the water pumpingbox is fixedly connected with the upper surface of the liquid storage box. The disinfection equipment based on surgical operating instruments has the advantages of circularly washing disinfectants andquickly drying surgical instruments.

Owner:南通康江医疗器械科技有限公司

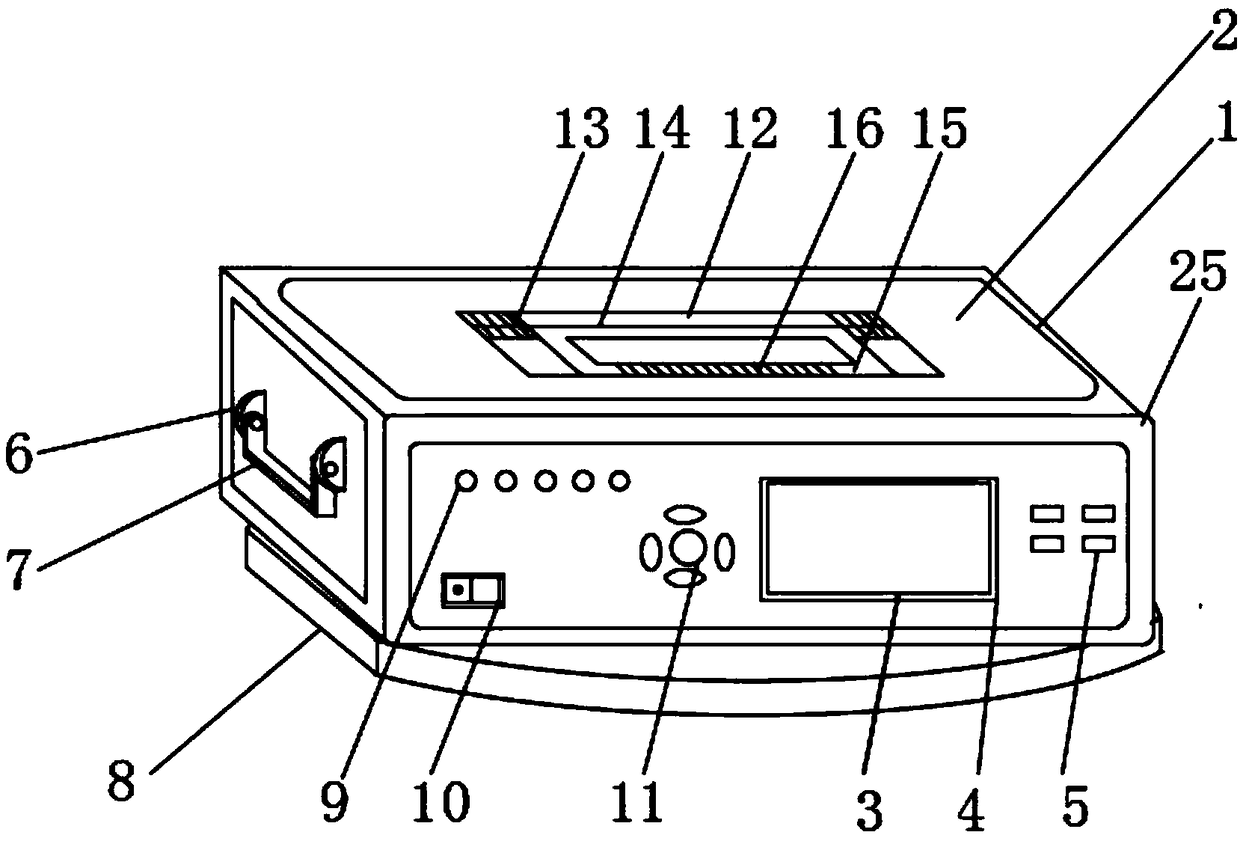

Agricultural big data analysis apparatus

InactiveCN108549466AEasy to operateImprove cooling efficiencyDigital processing power distributionComputer moduleBig data security

The invention discloses an agricultural big data analysis apparatus. The apparatus comprises an analysis apparatus body and an agricultural big data analysis module; a fixed handle is arranged on oneside wall of the analysis apparatus body; and the agricultural big data analysis apparatus comprises an agricultural big data collection module, an agricultural big data input module, an agriculturalbig data processing module, an agricultural big data output module and an agricultural big data security encryption protection module. The agricultural big data analysis apparatus is simple in structure and easy in operation, can be cooled, and is high in cooling efficiency, convenient to carry and good in sealing performance; an involved system can perform collection, input, analysis processing and output on the agricultural big data more conveniently, so that scheduling and management of the agricultural big data-based system are facilitated; and the agricultural big data can be subjected tosecurity protection conveniently, so that data leakage is prevented and the security is high.

Owner:TAIZHOU BIAOMENG INTPROP AGENCY

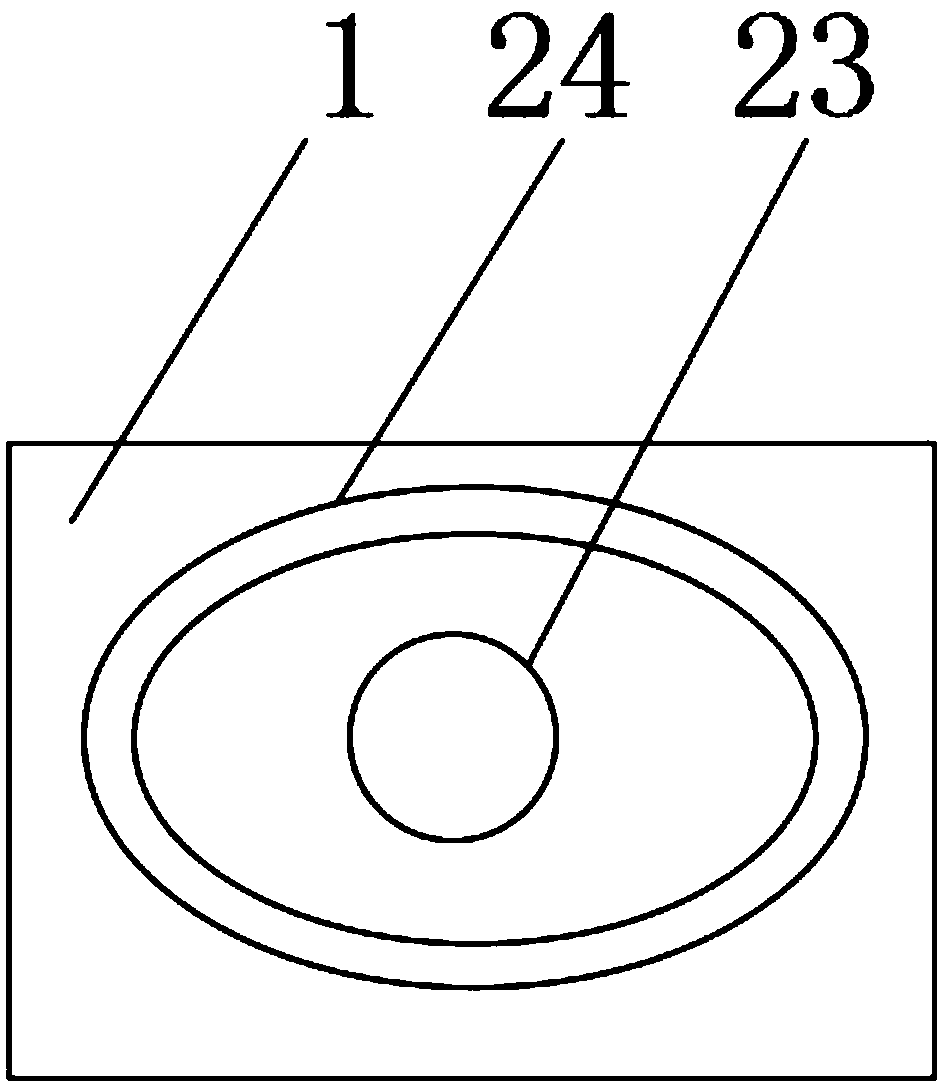

Eco-friendly energy-saving middle-temperature bronze glaze and method for preparing eco-friendly energy-saving middle-temperature bronze glazed ceramic through eco-friendly energy-saving middle-temperature bronze glaze

The invention discloses eco-friendly energy-saving middle-temperature bronze glaze and a method for preparing an eco-friendly energy-saving middle-temperature bronze glazed ceramic through the eco-friendly energy-saving middle-temperature bronze glaze and belongs to the technical field of ceramics. The eco-friendly energy-saving middle-temperature bronze glaze is prepared from 49-56 parts by mass of Sanming potassium feldspar, 14-17 parts by mass of barium carbide, 4-7 parts by mass of Longyan kaolin, 14-17 parts by mass of calcium carbide, 6-11 parts by mass of quartz, 1-4 parts by mass of copper mine tailings and 9-14 parts by mass of frits 2#. The frits 2# are prepared from 9-14 parts by mass of potassium oxide, 14-17 parts by mass of sodium oxide, 2-4 parts by mass of calcium oxide, 21-25 parts by mass of zinc mine tailings and 4-8 parts by mass of magnesium oxide. The method for preparing an eco-friendly energy-saving middle-temperature bronze glazed ceramic comprises material blending, ball milling, sieving, immersion in glaze and sintering. The eco-friendly energy-saving middle-temperature bronze glazed ceramic saves energy, is environmentally friendly, has high wear resistance, has low cadmium and lead content and has no toxic or side effect on the human body.

Owner:FUJIAN DEHUA HUATAI CERAMICS CO LTD

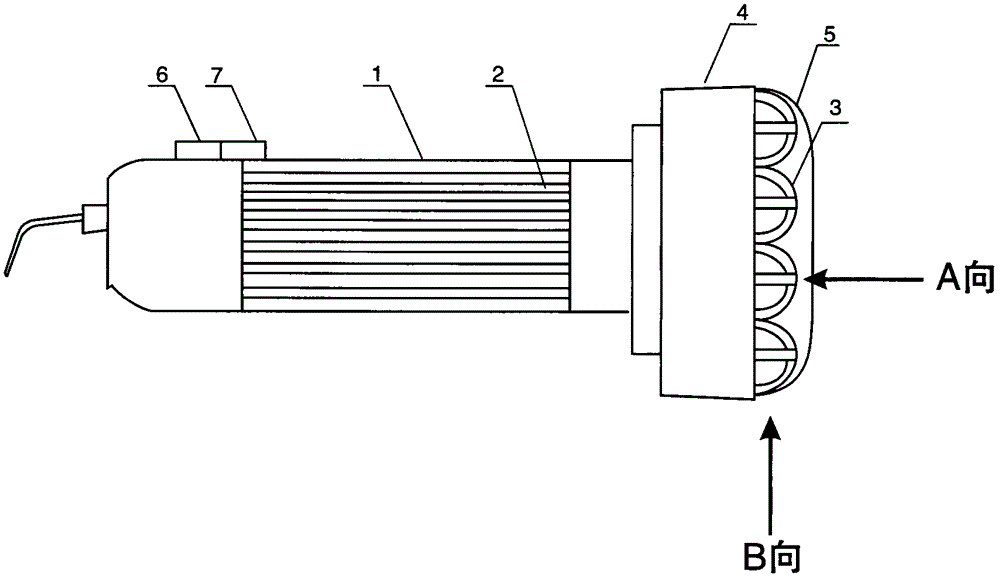

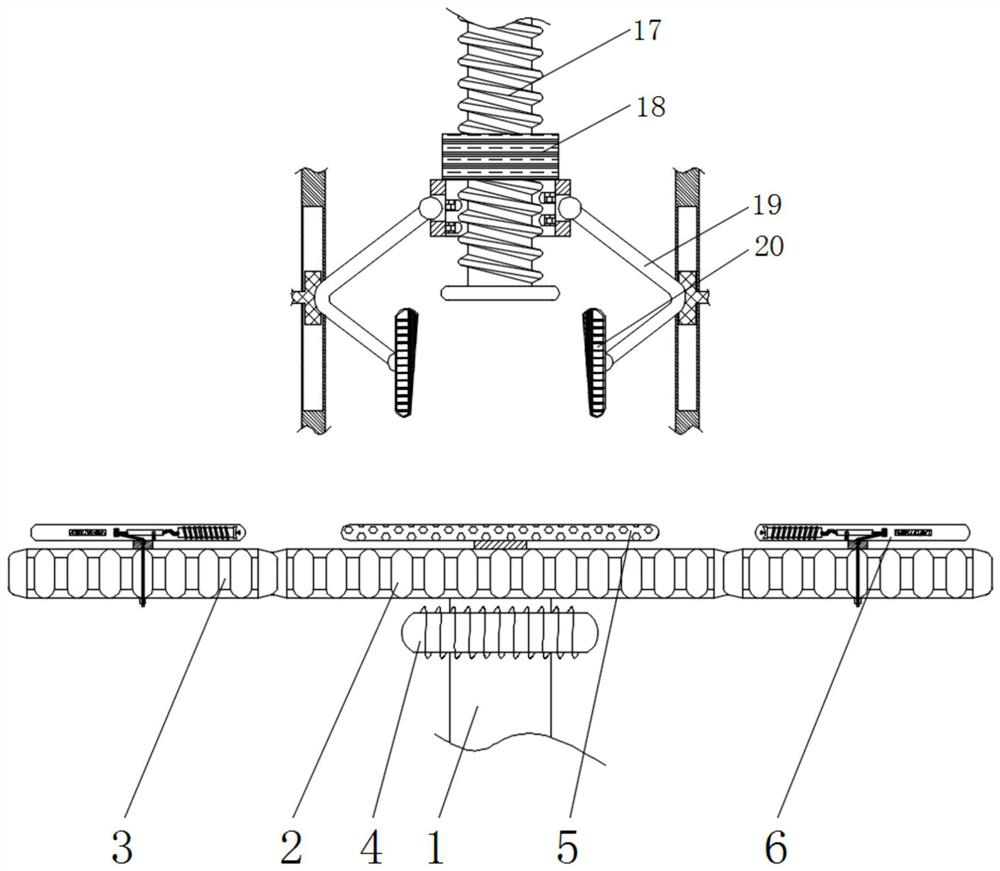

Ointment massage device

InactiveCN105877905AReduce the stress areaReduce crush strengthMedical devicesTherapeutic coolingDiseaseTreatment effect

Medicinal massage in traditional Chinese medicine is called ointment massage in ancient time and is first seen in Synopsis of Golden Chamber. Ointment massage is a comprehensive therapy method with traditional Chinese medicine ointment as massage medium, can be applied to exterior and interior diseases, tri-jiao diseases, viscera diseases and main and collateral channel diseases, and has a better treatment effect than massage alone or external application of medicine alone, and thus popular for thousands of years. Based on the principles of warming by rubbing and drilling wood to make fire, an ointment massage device is composed of a machine shell, a motor, a drill bit-shaped semicircular friction head, a fixing sleeve, a salve mull, an ointment massage switch and a cutaneous penetration switch. The shape of a protrusion on the friction head is improved, the friction head is driven by the motor to rotate at a high speed, friction is generated between the friction head and the salve mull covering skin so as to generate high-intensity squeezing impact force and high temperature, ointment massage and friction cutaneous penetration are conducted under combined action, and then the overall treatment effect of ointment massage is improved remarkably; besides, the defects of existing manual ointment massage methods that labor intensity is high and hands get hurt easily are overcome.

Owner:李复生

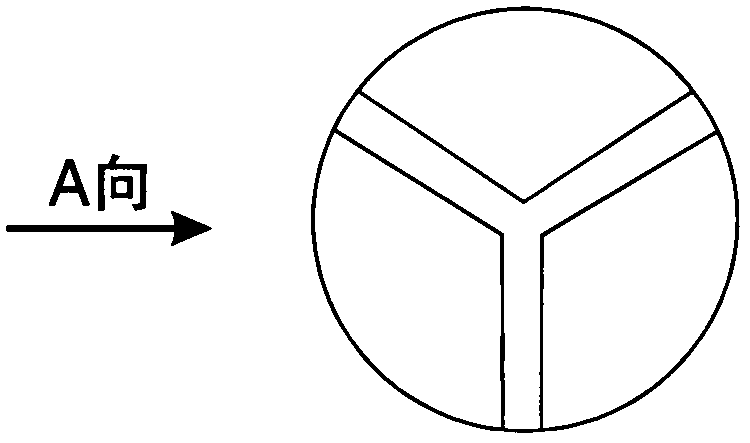

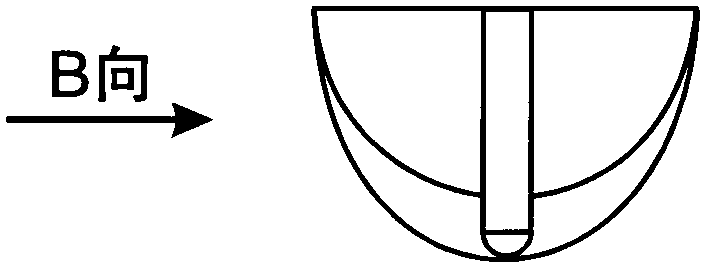

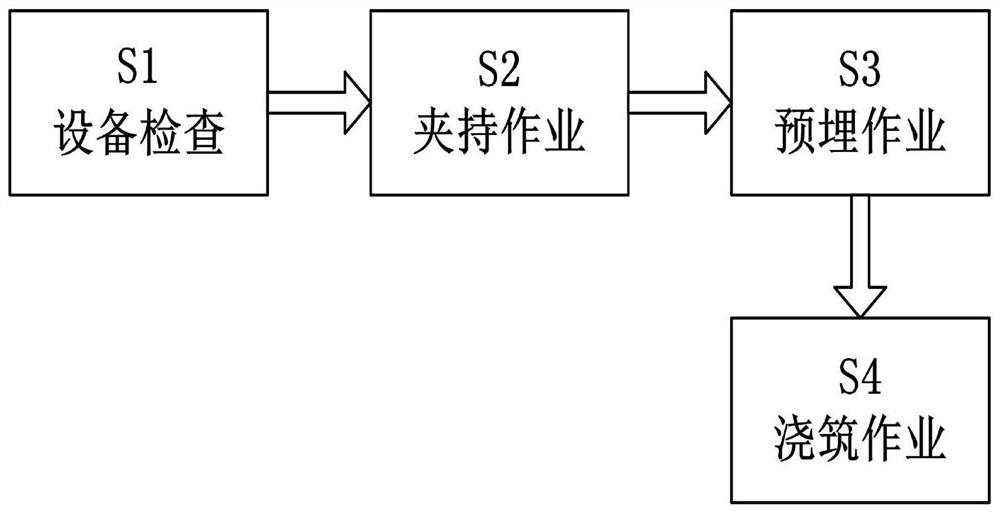

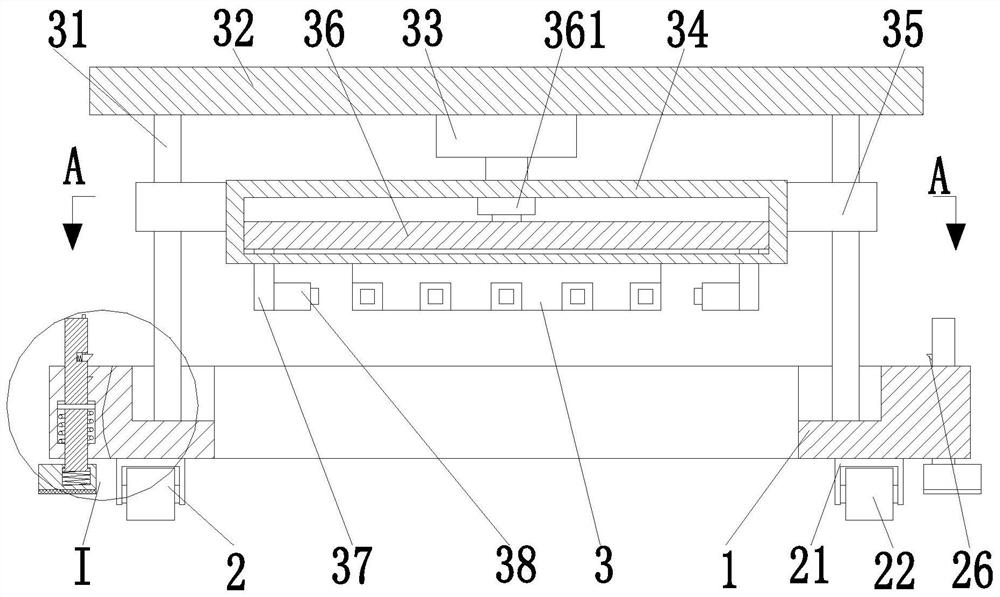

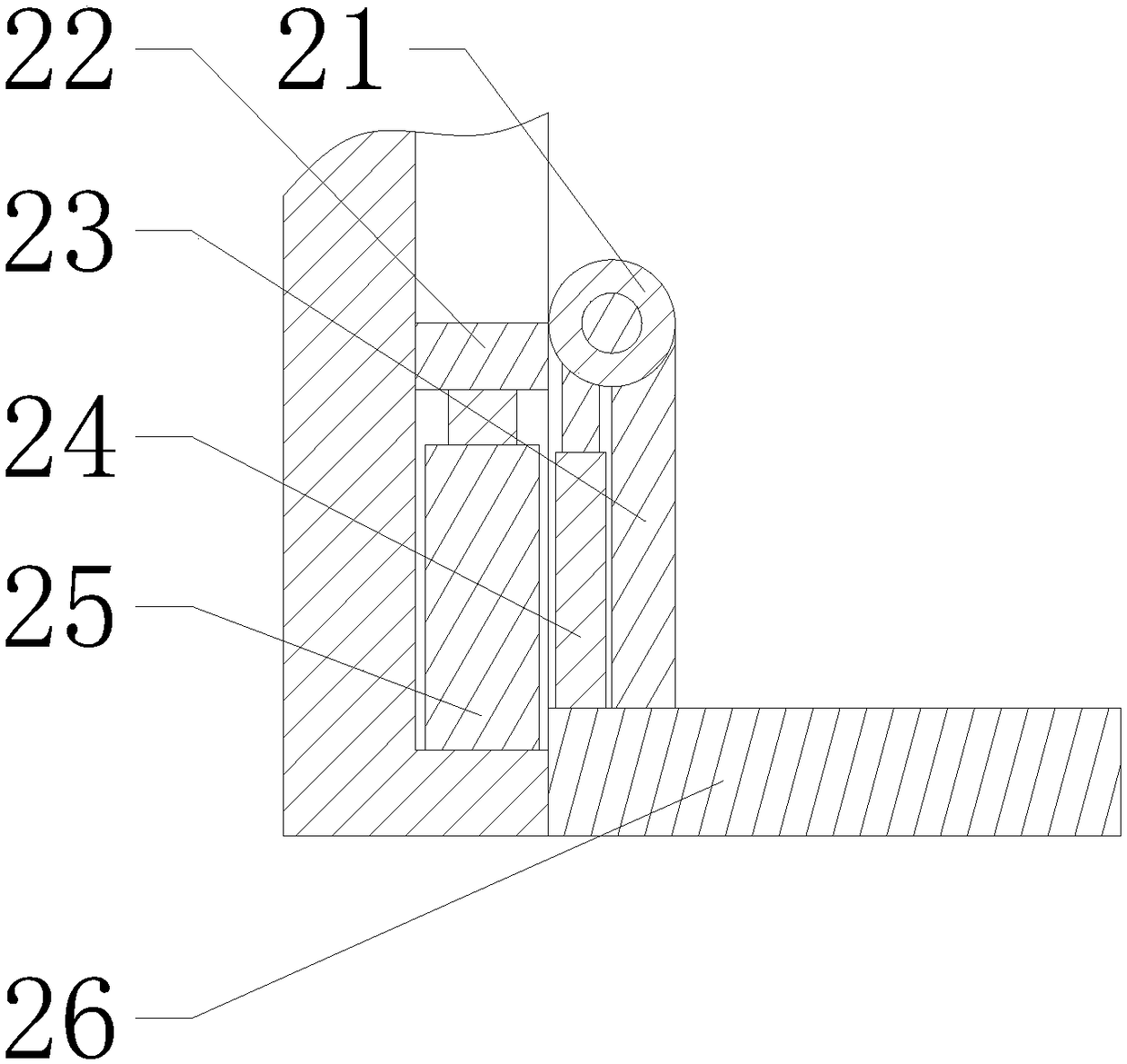

Installation and construction method for large steel structure fixing foundation embedded parts

InactiveCN111945774ASolve the problem that the overall effective clamping cannot be carried outReduce labor intensityFoundation engineeringArchitectural engineeringCivil engineering

Owner:方志兰

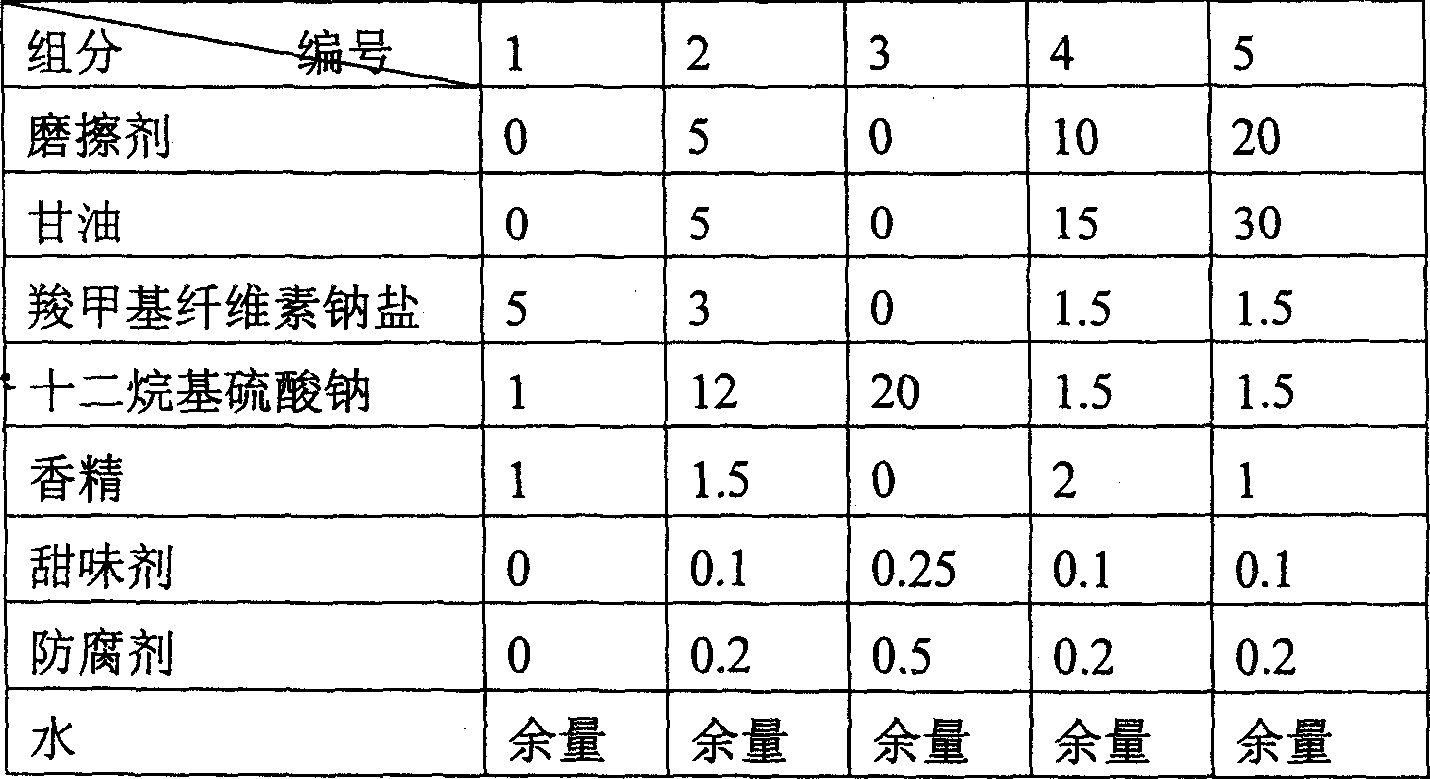

Toothpaste without or with little abradant and toothbrush using same

InactiveCN1813655AKeep healthyHigh tensile strengthCosmetic preparationsToilet preparationsAbrasive agentToothpaste

The present invention relates to a tooth-paste containing no abrasive agent or containing small quantity of abrasive agent and its matched toothbrush containing abrasive agent. Said toothpaste is characterized by that its abrasive agent content is reduced to 0-20% from original 50%, and its toothbrush is characterized by that in the course of making toothbrush mustache about 2%-20% of abrasive agent is added into high polymer, then the high polymer in which the abrasive agent is contained is undergone the processes of spinning and forming to obtain toothbrush mustache, then the toothbrush mustache also is undergone the grinding process so as to make the abrasive agent be bared on the surface of toothbrush mustache.

Owner:JIANGNAN UNIV

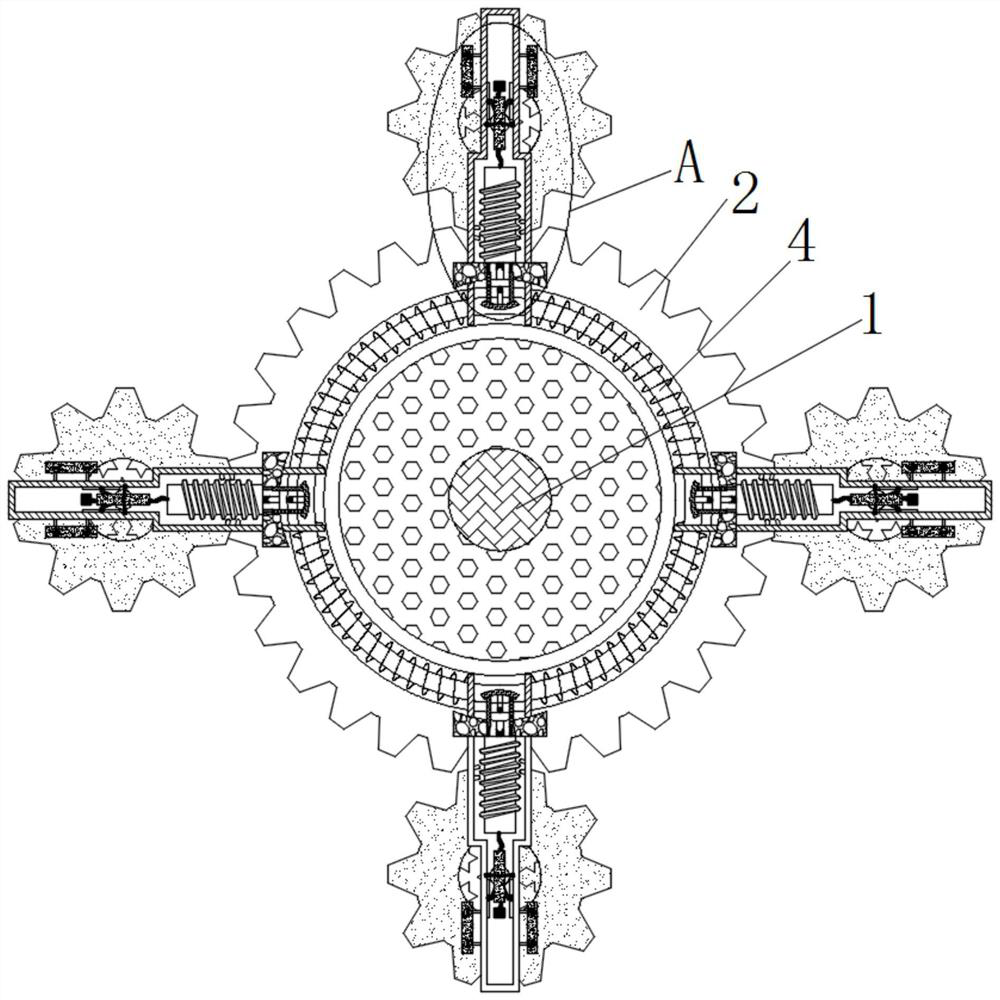

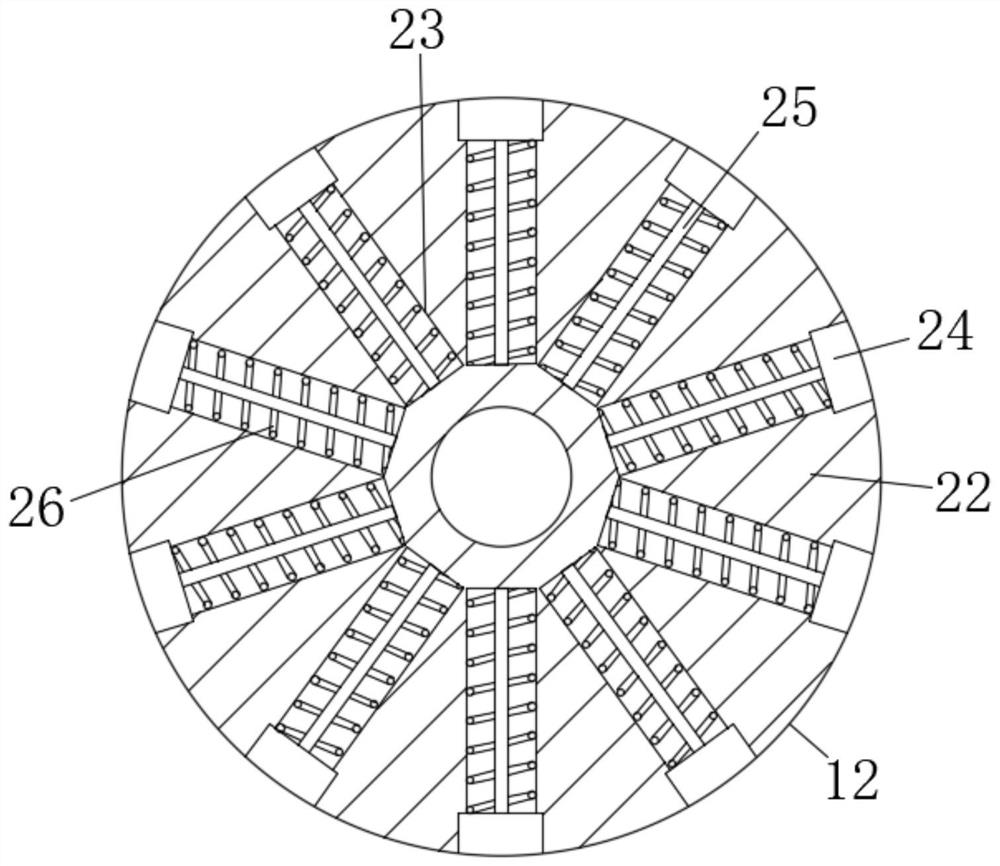

Intelligent manufacturing rust-proof equipment for fixing hardware machines of different sizes

InactiveCN112589637ALarge capacityIncrease the current intensityGrinding drivesGrinding machinesDrive shaftMachining

The invention relates to the technical field of hardware machining, and discloses intelligent manufacturing rust-proof equipment for fixing hardware machines of different sizes. The intelligent manufacturing rust-proof equipment comprises a driving shaft, the surface of the driving shaft is fixedly connected with a sun wheel, and the edge of the sun wheel is in engaged connection with planet wheels. A coil bundle is fixedly mounted on the surface of the part, below the sun wheel,of the driving shaft, a mounting table is fixedly mounted at the top end of the sun wheel, a fixing table is fixedlymounted at the top of each planet wheel, a fixing groove is fixedly formed in the surface of each fixing table, and a screw rod is rotatably connected into each fixing groove. According to the intelligent manufacturing rust-proof equipment for fixing the hardware machines of different sizes, iron products of different shapes and sizes can be clamped, clamping damage to a to-be-machined workpieceis prevented under the condition that clamping is stable, the friction strength of rust removal is gradually improved in the rust removal process of the to-be-machined workpiece, and processing of aniron product is more thorough.

Owner:杭州锐霓机械科技有限公司

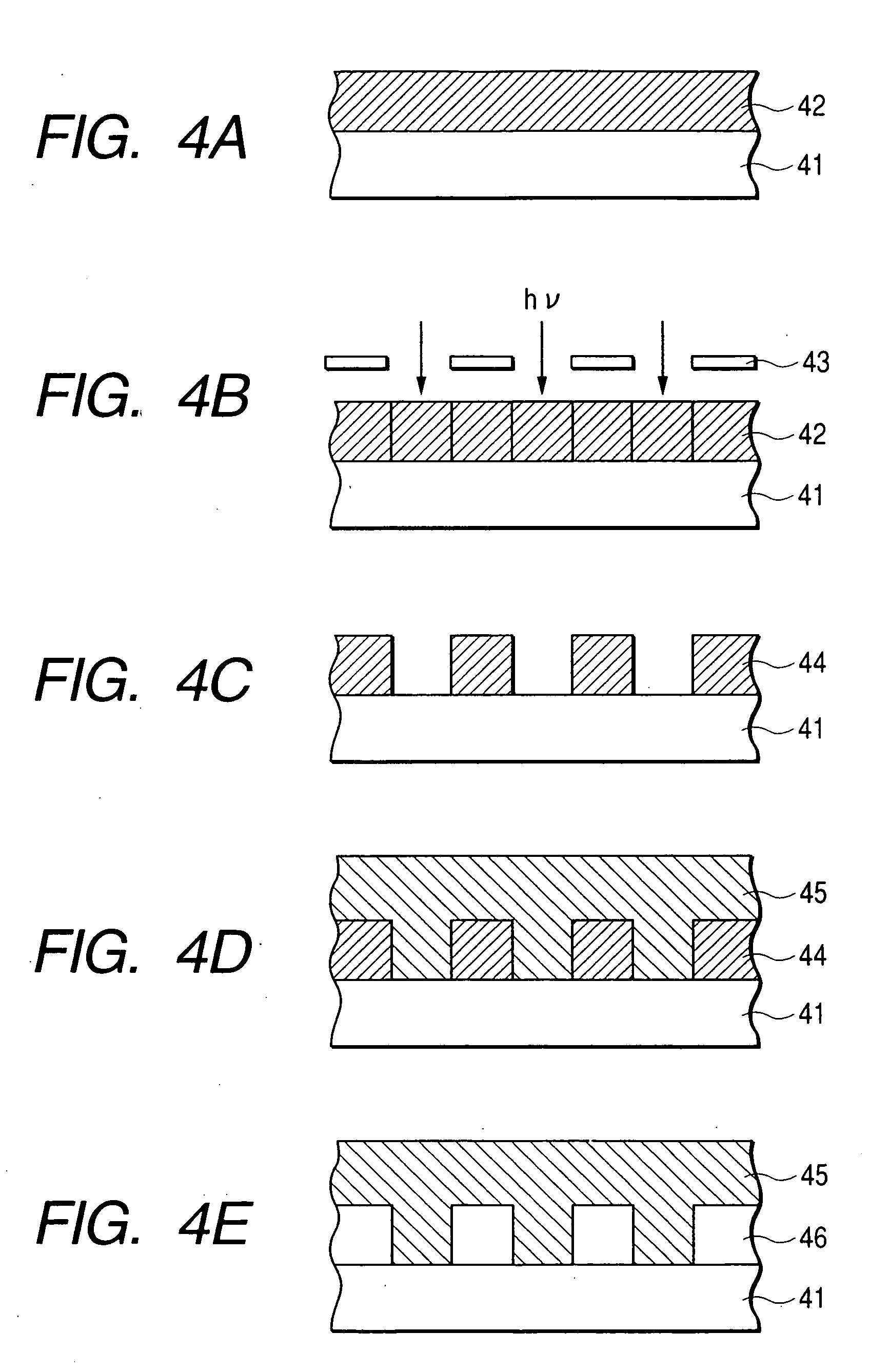

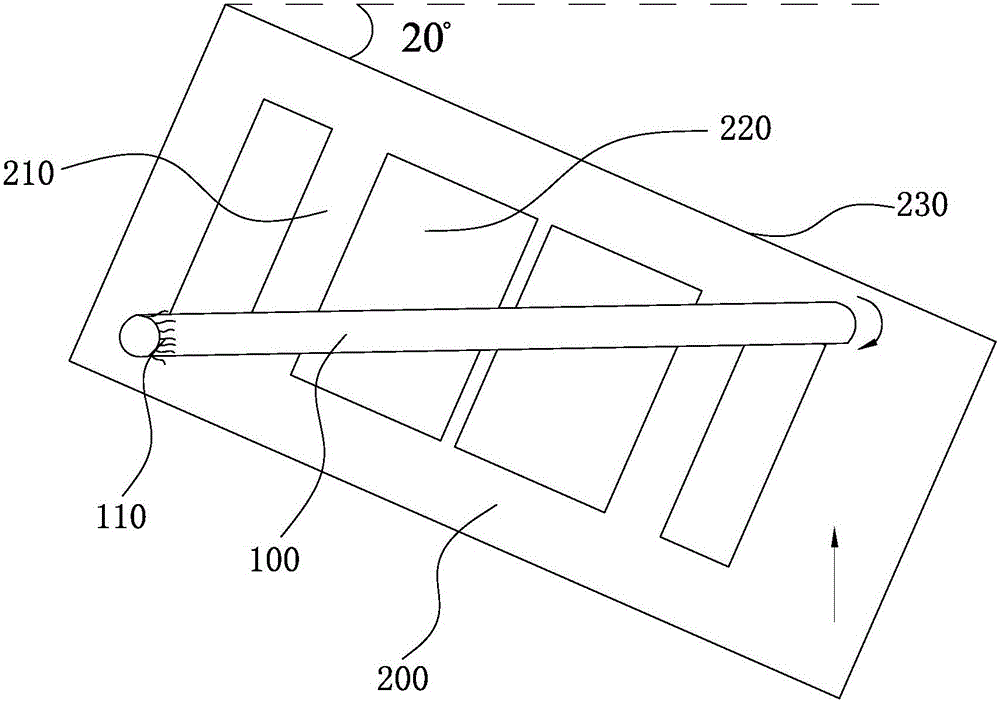

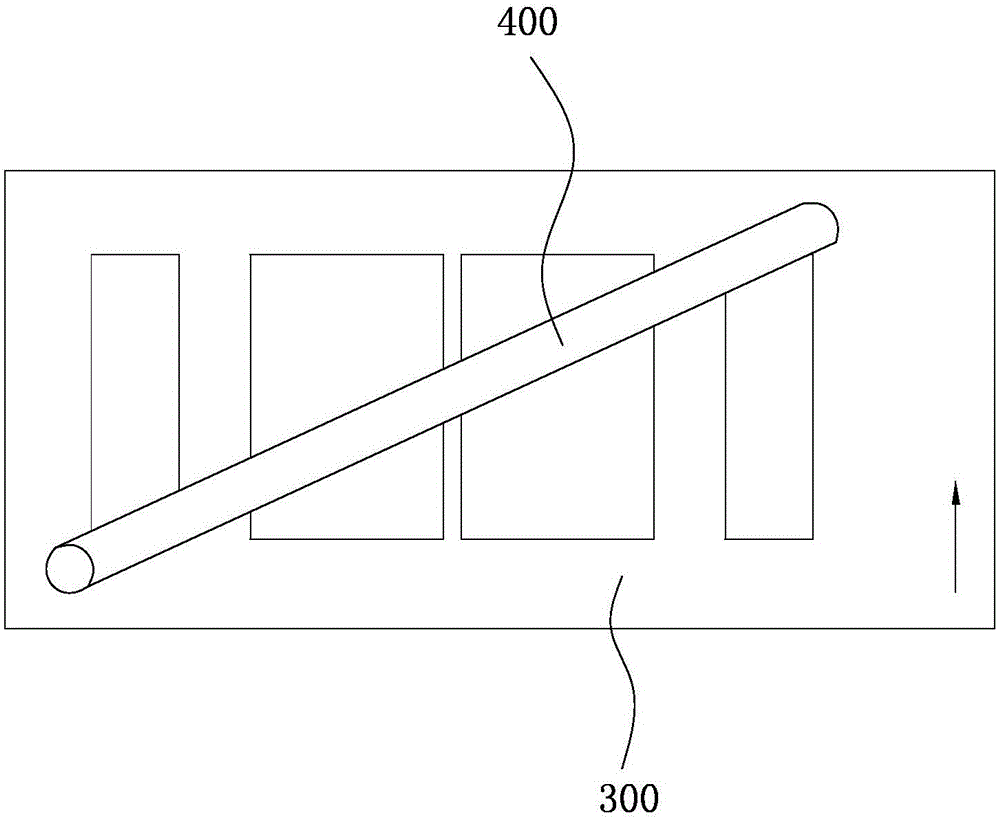

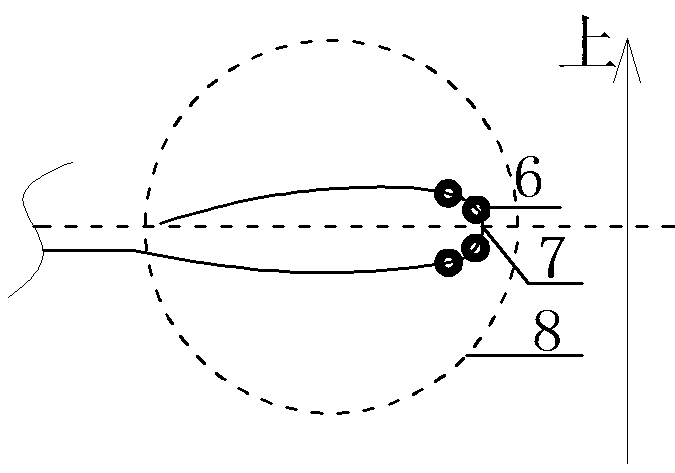

Method for eliminating unevenness of LED friction grooves

The invention discloses a method for eliminating unevenness of LED friction grooves. Friction orientation is conducted on an ITO glass substrate coated with a PI layer through a friction roller, and the ITO glass substrate is provided with PIN regions, electrode patter regions and a side edge. The method comprises that step S10, the friction roller is tightly attached to the surface of the ITO glass substrate, wherein the axis of the friction roller is parallel to the side edge; step S20, the friction roller rotates along the surface of the ITO glass substrate so as to enable the axis of the friction roller and the side edge of the ITO glass substrate to form an included angle; step S30, the friction roller is turned, and meanwhile the ITO glass substrate is linearly moved, wherein the linear moving direction of the ITO glass substrate is perpendicular to the axis direction of the friction roller. The scheme is simple and easy to achieve and does not need additional auxiliary equipment, the unevenness phenomenon of the LED friction grooves can be eliminated only by changing the angle of the friction roller and an operating angle of a product to be subjected to friction, a temporary glass storage process before friction can be omitted, production efficiency can be improved, friction cloth consumption can be reduced, and the yield and quality of the product can be ensured.

Owner:CONHUI HUIZHOU SEMICON

Electric heater with height convenient to adjust

InactiveCN108488897AEasy height adjustmentPrevent sideslipLighting and heating apparatusSpace heating and ventilation detailsEngineeringThreaded rod

The invention discloses an electric heater with height convenient to adjust. The electric heater comprises a fixed base, the top of the fixed base is fixedly connected with a supporting column, a sliding groove is formed in one side face of the supporting column, and a supporting plate is fixedly connected to the upper surface of the supporting column; a motor is fixedly connected to the top of the supporting plate, and a rotating rod is fixedly connected to the output end of the motor; the end, far away from the motor, of the rotating rod is fixedly connected with a first gear, and one side of the first gear is provided with a second gear; the outer surface of the second gear is meshed with the outer surface of the first gear, the bottom surface of the second gear is fixedly connected with a threaded rod, and the bottom end of the threaded rod penetrates through the upper surface of the supporting plate and extends to the lower part of the supporting plate; and the end, far away fromthe supporting plate, of the threaded rod is in contact with the upper surface of the fixed base. The electric heater with height convenient to adjust has the advantages of being high in safety performance, capable of adjusting height and long in service life.

Owner:黄永怀

Grinding and mixing device for coating processing

InactiveCN109261011AAvoid enteringAvoid shakingRotary stirring mixersTransportation and packagingWater pipeHeat pipe

The invention discloses a grinding and mixing device for coating processing. The device comprises a body, the outer surface of the body is fixedly connected with an electric water pump, a heating water tank is arranged inside the body, the outer surface of the heating water tank is fixedly connected with the inner side wall of the body, a water outlet end of the electric water pump is fixedly communicated with a flow pipe, one end, far away from the electric water pump, of the flow pipe sequentially penetrates the outer surface of the body and the outer surface of the heating water tank and extends to the inside of the heating water tank, the inner side wall of the body is fixedly connected with a sealing plate, a water inlet end of the electric water pump is fixedly connected with a waterpumping pipe, one end, far away from the electric water pump, of the water pumping pipe penetrates the outer surface of the body, the bottom of the sealing plate and the bottom of the heating water tank and extends to the inside of the heating water tank, and the inner top wall of the heating water tank is fixedly connected with a heating pipe. The grinding and mixing device for coating processing has the advantages that freezing is prevented, and coatings are grinded before mixing.

Owner:ZHEJIANG HUANZHOU POLYMER MATERIAL TECH CO LTD

Preparation method of paper-based friction material

ActiveCN109837802ASimple production processReduce manufacturing costDefoamers additionCoatings with pigmentsFiberPaper based

The invention discloses a preparation method of a paper-based friction material. The friction material is mainly composed of plant fiber paper and a functional coating. The preparation method of the friction material mainly relates to high-performance coating design, paper surface coating process adjustment, drying and finishing process and the like, and finally a friction coating is formed, and the paper-based friction material with a certain thickness is obtained after being coated for a plurality of times. According to the method, a coating method is innovatively used for replacing a traditional hot-pressing method to prepare an automotive friction lining sheet, the automotive friction lining sheet is riveted or adhered to an aluminum alloy brake shoe or clutch, forming without a mold can be realized, the binding property between coated paper base paper and a coating is good, the phenomenon of shed hair and powder is not easy to generate, the preparation process is simple, the production cost is low, and the thickness of the base paper and the thickness of the coating can be regulated and controlled, so that the preparation of the paper-based friction material has certain flexibility, and the requirements of different motor vehicles on friction materials can be met to a great extent.

Owner:LONGYOU COUNTY JINLONG PAPER

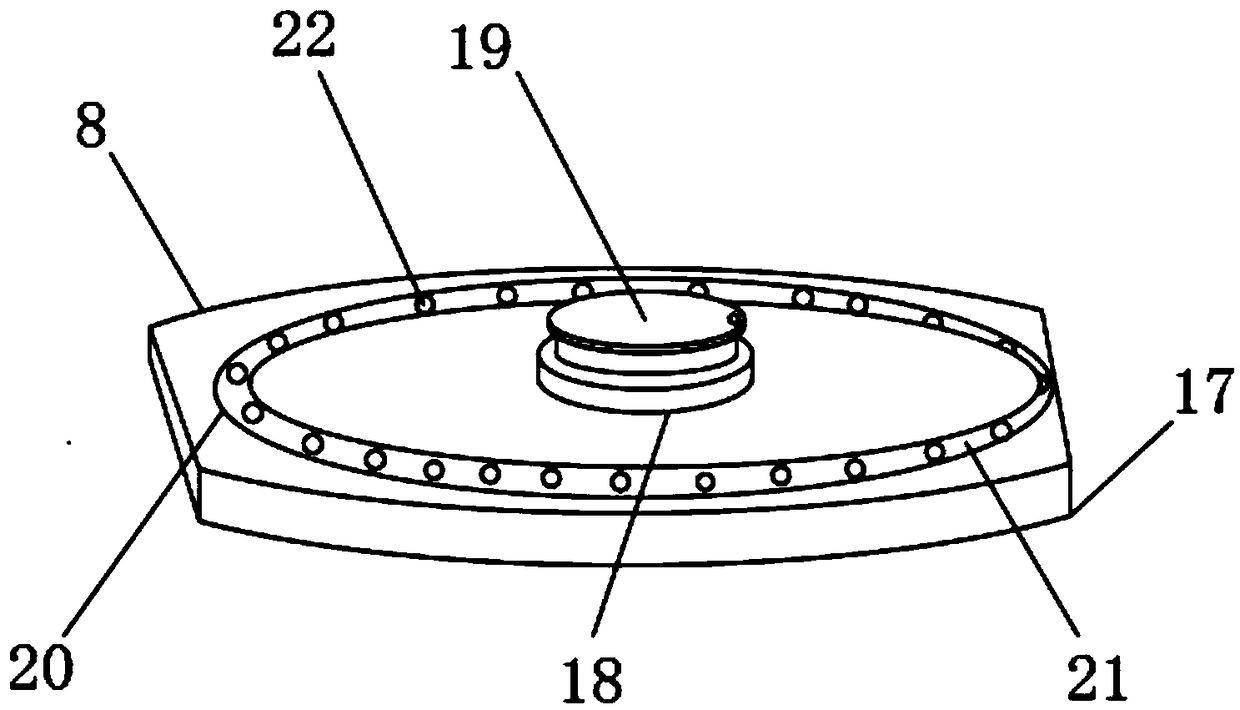

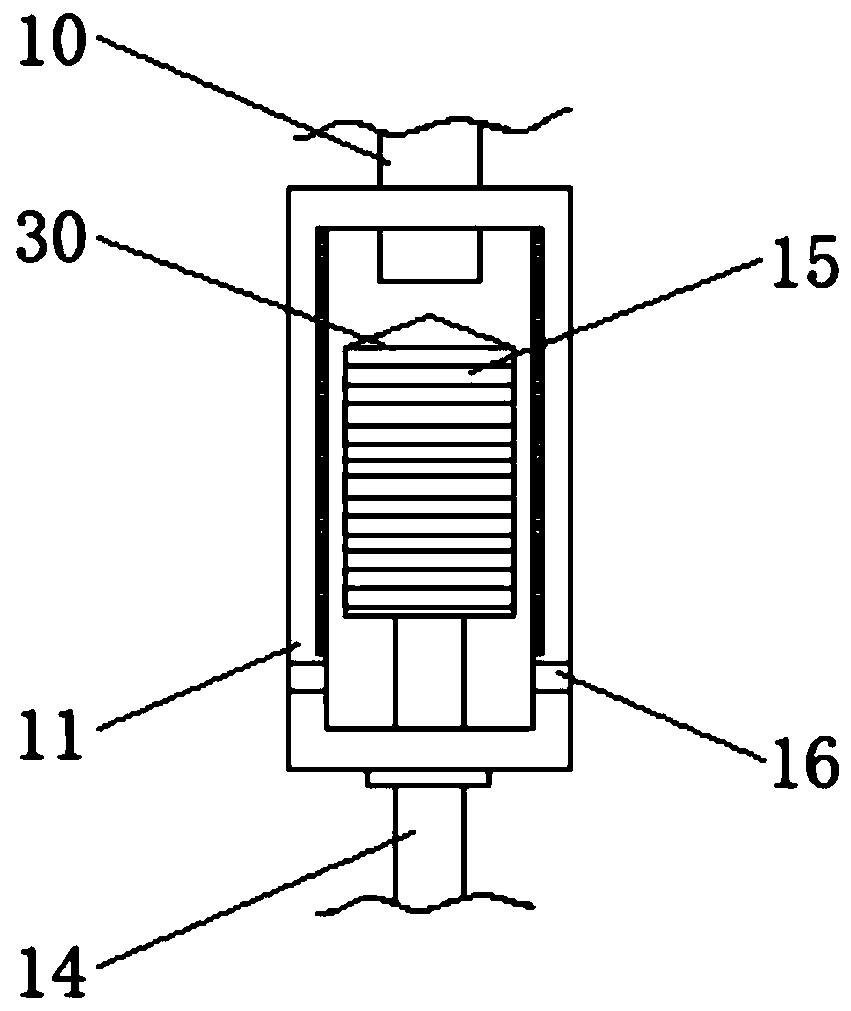

Oval optical lens integrated grinding device

InactiveCN112139906AEasy to moveEnhance friction strengthEdge grinding machinesGrinding feedersEngineeringOptic lens

The invention discloses an oval optical lens integrated polishing device. The oval optical lens integrated polishing device comprises a grinding bin; a shaft I is rotatably connected to the bottom ofthe inner wall of the grinding bin in a limited mode; a clamping plate I is fixedly connected to the top of the shaft I; an oval glass sheet is arranged on the upper surface of the clamping plate I; acover plate is fixedly connected to the inner wall, close to the top, of the grinding bin; a shaft II is rotatably connected to the lower surface of the cover plate in a limited mode; a clamping plate II is fixedly connected to the bottom of the shaft II; the oval glass sheet is located on the opposite faces of the clamping plate I and the clamping plate II; and a supporting frame is arranged onthe right side of the grinding bin. According to the oval optical lens integrated grinding device provided by the invention, through cooperative use of the above structures, the problems that in the actual use process, due to the fact that the actual use effect of a traditional grinding block is poor, it is difficult to conduct complete grinding on the arc-shaped outline of oval glass, the grinding efficiency is low, and complete grinding of the oval glass can be achieved only through multiple times of adjustment are solved, and inconvenience is brought to use.

Owner:冀敏敏

Purifying device for sewage treatment

InactiveCN107840513AImprove applicabilityImprove stabilityWater/sewage treatment by electrochemical methodsTreatment involving filtrationQuality of lifeEngineering

The invention discloses a purification device for sewage treatment, which comprises a separation box, a motor is arranged on the top of the separation box, the output end of the motor is fixedly connected with a rotating rod, and the end of the rotating rod far away from the motor penetrates through the separation The outer surface of the separation box extends to the inside of the separation box, the outer surface of the rotating rod is fixedly connected with a stirring rod, the inner side wall of the separation box is fixedly connected with a chute, and the inside of the chute is provided with a filter plate, so The outer surface of the filter plate is clamped with the inner wall of the chute, one end of the filter plate penetrates the inner wall of the separation box and extends to the outside of the separation box, and the end of the filter plate away from the separation box is fixedly connected with a push rod, so A water pump is provided at the bottom of the separation box, and a water inlet end of the water pump is fixedly connected with a suction pipe. The purification device for sewage treatment has the advantages of simple structure, good decontamination effect and no impact on our quality of life.

Owner:无锡德力成机电科技有限公司

Reaction kettle for processing of chemical raw materials

InactiveCN108404833AImprove applicabilityImprove aggregation efficiencyChemical/physical/physico-chemical stationary reactorsDrive motorRaw material

The invention discloses a reaction kettle for processing of chemical raw materials. The reaction kettle comprises a body provided with a driving motor at the top. An output end of the driving motor isfixedly connected with a revolving shaft; the end, away from the driving motor, of the revolving shaft penetrates the upper surface of the body and extends into the body; a partition plate is arranged in the body, both left and right ends of the partition plate are fixedly connected with the inner side wall of the body; a supporting post is fixedly connected with the upper surface of the partition plate, and a first bearing is fixedly connected to the top of the supporting post; the end, away from the driving motor, of the revolving shaft penetrates the inside of the first bearing; the outersurface of the revolving shaft is fixedly connected with an inner ring of the first bearing, a stirring rod and a connecting ring. The reaction kettle for processing of chemical raw materials has theadvantages of simple structure, high operation efficiency and long service life.

Owner:陈洁

Cleaning machine for vegetable surface pesticides

The invention discloses a cleaning machine for vegetable surface pesticides. The cleaning machine comprises a machine body. A driving motor is arranged in the machine body. A partition plate is arranged on the top of the driving motor. The left end and the right end of the partition plate are fixedly connected with the inner side wall of the machine body. An output end of the driving motor is fixedly connected with a rotating rod. The end, away from the driving motor, of the rotating rod penetrates through the bottom face of the partition plate and extends to the upper side of the partition plate. A connecting block is fixedly connected with the top end of the rotating rod. A cleaning cylinder is fixedly connected with the upper surface of the connecting block. A cleaning rod is fixedly connected with the inner side wall of the cleaning cylinder. The outer surface of the cleaning rod is sleeved with a cleaning sponge. A drain outlet is formed in the outer surface of the cleaning cylinder. A filter screen is fixedly connected with the inner wall of the drain outlet. A slide groove is formed in the bottom face of the cleaning cylinder. A slide rod is fixedly connected with the uppersurface of the partition plate. The cleaning machine has the advantages of being simple in structure, high in work efficiency and long in service life.

Owner:XISHAN XIANFENG FAMILY FARM

Metal structural part machining device and machining method thereof

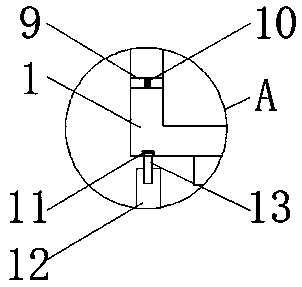

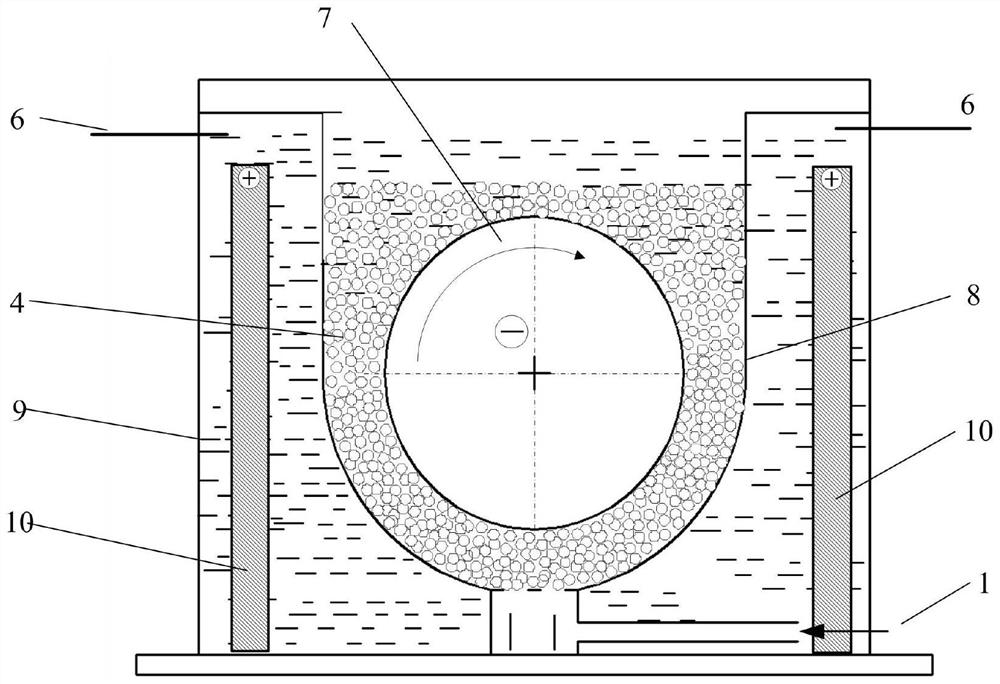

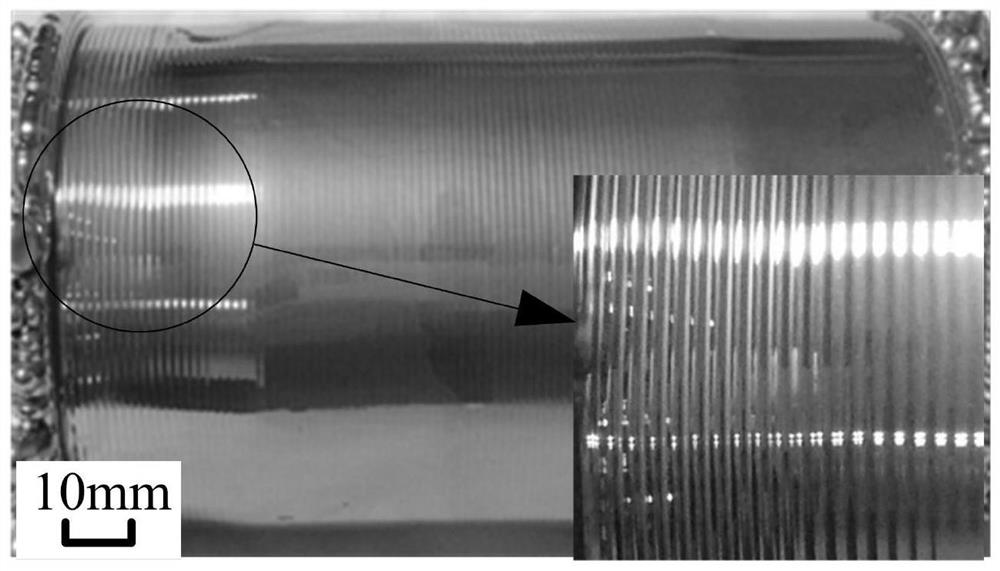

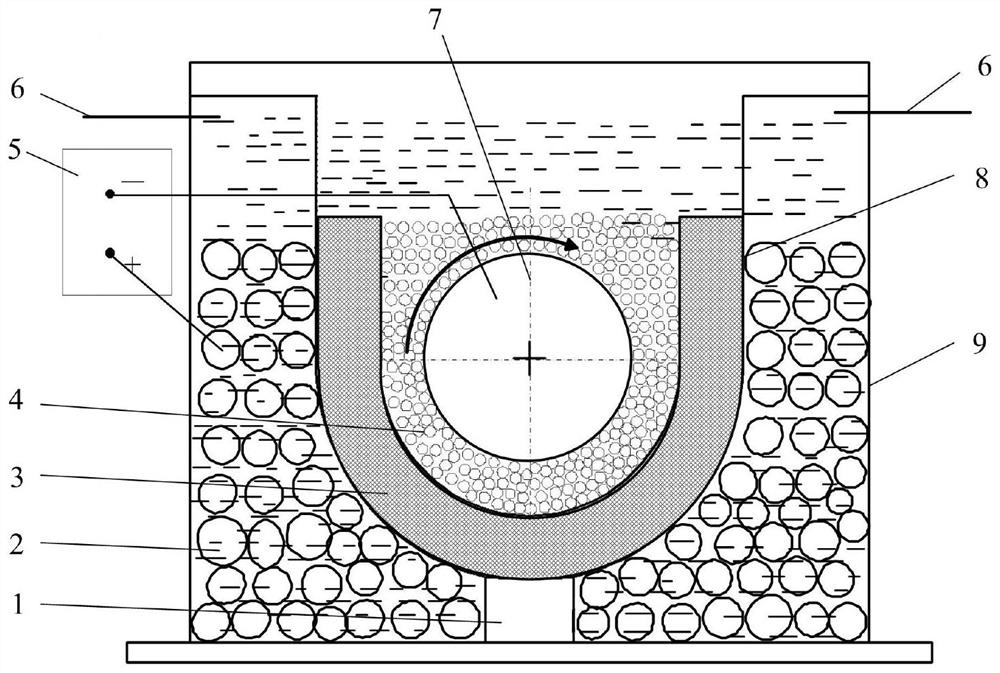

The invention discloses a metal structural part machining device and a machining method thereof and relates to the technical field of electroforming machining. The device comprises an electroforming working tank, an anode unit located in the electroforming working tank, and a porous elastic supporting structural part for containing a metal structural part, wherein the inner wall surface of the porous elastic supporting structural part is an elastic surface; in a working state, micro-beads are arranged between the elastic surface and the metal structural part; and the microbeads cover the metal structural part. When the distance between the surface of the metal structural part and the anode unit is gradually reduced, a large number of hard microbeads extrude the porous elastic supporting structural part, the pressure of the hard microbeads and the surface of a cathode core mold is released on the porous elastic supporting structural part, and the requirement for manufacturing the large-wall-thickness metal structural part with the larger thickness is met.

Owner:SHANDONG UNIV OF TECH

Portable-type dust-collecting polishing machine for automobile machining

InactiveCN107932273AEasy to replaceImprove replacement efficiencyPortable grinding machinesGrinding/polishing safety devicesMachiningAutomotive engineering

The invention discloses a portable-type dust-collecting polishing machine for automobile machining. The portable-type dust-collecting polishing machine comprises a machine body. An air exhaust openingis formed in the outer surface of the machine body, and the bottom of the machine body is provided with a polishing disc. The top of the polishing disc is fixedly connected with a buckle and providedwith a rotary disc, and the bottom of the rotary disc is fixedly connected with a clamping groove block. The top of the rotary disc is fixedly connected with a rotary rod, and the end, away from therotary disc, of the rotary rod penetrates through the outer surface of the machine body and extends into the machine body. The end, away from the rotary disc, of the rotary rod is provided with a motor, and the output end of the motor is fixedly connected with end, away from the rotary disc, of the rotary rod. The bottom of the motor is fixedly connected with a first supporting rod, and the top ofthe motor is fixedly connected with a first fixing rod. One side of the motor is provided with a dust-collecting box. The portable-type dust-collecting polishing machine for automobile machining hasthe advantages that the polishing machine is overall light, violent shaking cannot occur during using, and flying chip disorderly flying can be avoided.

Owner:高峰

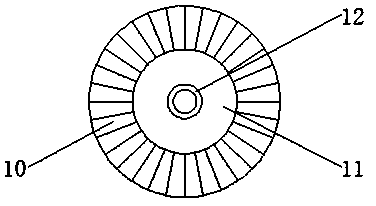

Sand washer used for water conservancy equipment production

InactiveCN107755080AEnhance friction strengthImprove overall stabilityWet separationHydraulic equipmentEquipment use

The invention discloses a sand washing machine for the production of water conservancy equipment, which comprises a cleaning box, a sand washing plate is arranged inside the cleaning box, fixing rods are arranged on both sides of the cleaning box, and a support frame is fixedly connected to the top of the fixing rod , the top of the support frame is fixedly connected with a motor, the output end of the motor is fixedly connected with a rotating rod, the end of the rotating rod away from the motor is fixedly connected with a first gear, the outer surface of the first gear is provided with a rack, and the inner wall of the rack is connected to the second gear. The outer surface of a gear meshes, and the end of the rack away from the first gear runs through the top of the support frame and extends to the outside of the support frame. The top of the cleaning box is fixedly connected with a first fixed plate and a second fixed plate, and the first fixed plate Both the top and the top of the second fixing plate are fixedly connected with the bottom of the support frame, and a second gear is provided on one side of the first fixing plate. The sand washing machine used in the production of water conservancy equipment has the advantages of simple structure, high work efficiency and no waste of water resources.

Owner:江苏天康光电缆仪表有限公司

Dye mixer for textile printing and dyeing

InactiveCN108654509APrevent sideslipImprove stabilityRotary stirring mixersTransportation and packagingTextile printerRotating disc

The invention discloses a dye mixer for textile printing and dyeing. The mixer comprises a body, wherein a stirring barrel is arranged inside the body; a stirring rod is fixedly connected with the inner side wall of the stirring barrel; a mixing plate is fixedly hinged with the outer surface of the stirring rod through a hinge pin; a water outlet is formed in the outer surface of the stirring barrel; a filtering screen is arranged inside the water outlet; the outer surface of the filtering screen is fixedly connected with the inner wall of the water outlet; an annular sliding groove is formedin the inner side wall of the body; a sliding rod is fixedly connected with the outer surface of the stirring barrel; a pulley is fixedly hinged with one end, far from the stirring barrel, of the sliding rod through a hinge pin; the pulley is clamped to the interior of the annular sliding groove; a tooth ring and a rotating disc are fixedly connected with the bottom surface of the stirring barrel;a first bearing is fixedly embedded to the bottom of the rotating disc; a fixed rod is fixedly connected with the inner ring of the first bearing. The dye mixer has the advantages of high work efficiency and small staining fluid residue particles.

Owner:芜湖市涵润智能科技有限公司

Multifunctional loading and unloading equipment for road transportation

The invention provides multifunctional loading and unloading equipment for road transportation. The multifunctional loading and unloading equipment comprises a lantern ring, a support block, a pressing plate, a first electric cylinder, a second electric cylinder, a support plate, a supporting plate, a third electric cylinder, a bracket plate and a support rod. The support block is assembled to theupper end of the second electric cylinder, the support block is assembled to the left end of the support plate, the lantern ring is arranged at the upper end of the pressing plate, the lantern ring is fixed to the upper end of the first electric cylinder, the pressing plate is arranged at the right end of the support plate, the pressing plate is assembled to the right side of the first electric cylinder, and goods are clamped to the support plate through the design. The third electric cylinder is arranged at the left end of the supporting plate, the third electric cylinder is inlaid at the upper end of the bracket plate and connected with the bracket plate through a rotation shaft, the bracket plate is assembled to the left end of the support rod, the bracket plate and the support rod areconnected through a pin shaft, and folding is achieved through the design. The multifunctional loading and unloading equipment is convenient to use and operate, high in using effect and convenient tostore.

Owner:WUXI JUNHAO COMPOSITES CO LTD

Industrial film winding machine

InactiveCN108455334AEnhance friction strengthImprove stabilityWebs handlingDrive motorWinding machine

The invention discloses an industrial film winding machine. The industrial film winding machine comprises a fixed base. The fixed base is internally provided with a cavity. A driving motor is fixedlyconnected to the internal bottom wall of the cavity. The output end of the driving motor is fixedly connected with a rotary rod. The end, far away from the driving motor, of the rotary rod penetratesthrough the inner sidewall of the cavity and extends to the outer portion of the fixed base. The end, far away from the fixed base, of the rotary rod is fixedly connected with a first gear. The outersurface of the first gear is sleeved with a rack. A first supporting column and a second supporting column are fixedly connected to the upper surface of the fixed base. A driven rod is arranged on oneside of the first supporting column. One end of the driven rod penetrates through the outer surface of the first supporting column and extends to the outer portion of the first supporting column. Oneend of the driven rod is fixedly connected with a second gear. The outer surface of the second gear is sleeved with the end, far away from the first gear, of the rack. The industrial film winding machine has the advantages of being simple in structure, high in working efficiency and long in service life.

Owner:博艳萍

Perforating machine with automatic clamping function for precision machining

InactiveCN108500381AReduce frictional strengthExtended service lifeAutomatic control devicesFeeding apparatusEngineeringThreaded rod

The invention discloses a perforating machine with an automatic clamping function for precision machining. The perforating machine comprises a fixing base, the upper surface of the fixing base is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a rotating rod, and the end, far away from the first motor, of the rotating rod is fixedly connected witha perforating knife; a driving box is fixedly connected to the upper surface of the fixing base, a second motor is fixedly connected to the inner bottom wall of the driving box, and the output end ofthe second motor is fixedly connected with a threaded rod; the inner side wall of the driving box is fixedly connected with a first sliding rail, and the side surface, far away from the first slidingrail, of the driving box is provided with a through hole; and a threaded ring sleeves the outer surface of the threaded rod, one side surface of the threaded ring is fixedly connected with a sliding rod, the end, far away from the threaded ring, of the sliding rod is fixedly connected with a sliding block, and the sliding block is clamped inside the first sliding rail. The perforating machine withthe automatic clamping function for precision machining has the advantages of being simple in structure, high in working efficiency and capable of carrying out automatic clamping.

Owner:周佩龙

Leather-like fabric

InactiveCN102444029AImprove frictional strengthGood anti-scratch performanceSynthetic resin layered productsTextiles and paperEngineeringCoating

The invention discloses a leather-like fabric, comprising a basic cloth and a coating surface, wherein a permeable coating is disposed between the basic cloth and the coating surface, the basic cloth is a knitted fabric, and the coating surface is PVC (polyvinyl chloride). The leather-like fabric disclosed by the invention chooses a permeable coating; on one hand, the layer surface of the coating is thin, so that the coating is not easy to peel off; on the other hand, the product has an enhanced antifriction strength and a great scratch-proof performance via the permeable coating.

Owner:SUZHOU CHUANGYU WEAVING

Novel hotel floor towel production process

InactiveCN110983556AEvenly wrappedFacilitated DiffusionFibre treatmentDry-cleaning apparatus for textilesSpinningHot melt

The invention discloses a novel hotel floor towel production process. The process comprises the following steps of 1, warping a spool, replacing a common cotton spool corresponding to four strands ofwarp yarns at the bending position with a special spinning hot melt adhesive warp spool; 2, performing sizing and drawing-in; 3, performing weaving; 4, performing grey cloth bleaching, wherein hot melt adhesives on special spinning hot melt adhesive warp yarns are dissolved to be bonded with weft yarns to form special spinning hot melt adhesive side yarns; 5, performing grey cloth rinsing; and 6,performing sewing, wherein four strands of side yarns at the bending position of the ear edge are folded, and large edge sewing and subsequent label sewing processes of a floor towel are performed. According to the production process, a traditional floor towel production process is changed, the special spinning hot melt adhesive warp yarns and the weft yarns are bonded at the high temperature to form the special spinning hot melt adhesive side yarns, and during sewing, the special spinning hot melt adhesive side yarns are uniformly distributed on a folding head part in an up-down manner, so that the friction resistance of the folding head part of the ear edge of the floor towel is greatly enhanced and the washing life is doubled nearly.

Owner:JIANGSU CANASIN WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com