Metal structural part machining device and machining method thereof

A technology for metal structural parts and processing devices, which is applied in the field of metal structural parts processing devices, can solve the problems that the free microbead friction-assisted electroforming technology cannot meet the manufacturing requirements and other problems, and achieve the effect of smooth appearance and surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

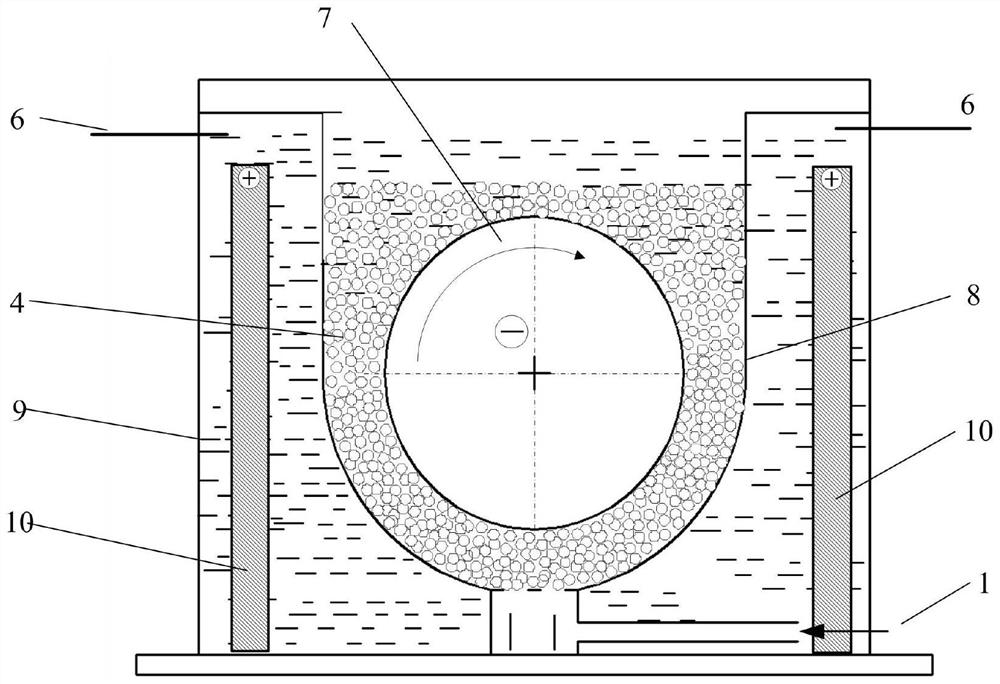

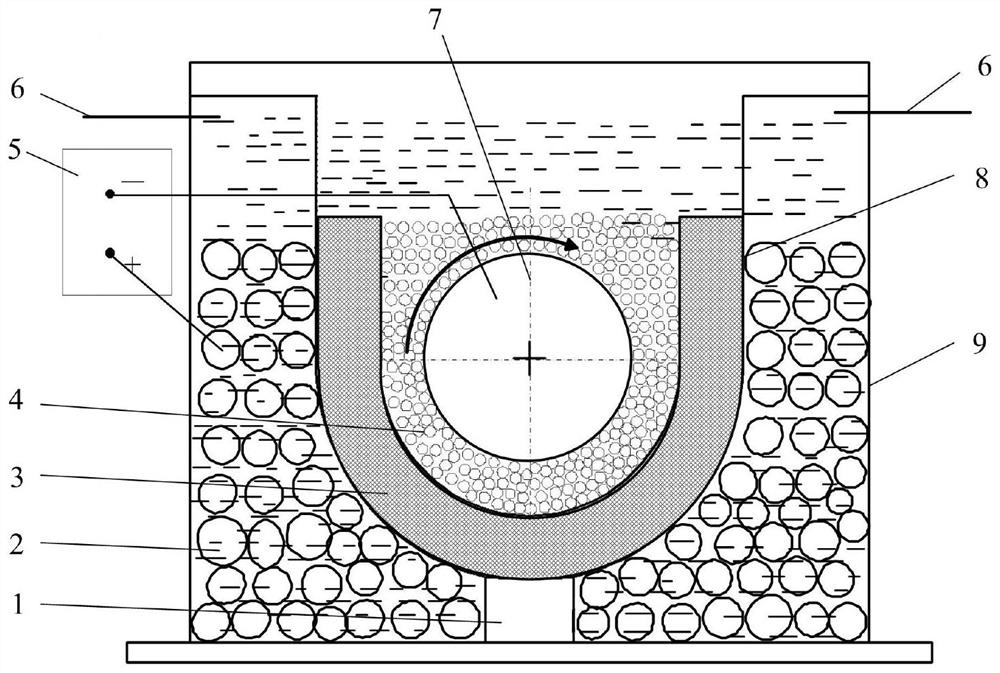

[0045] Aiming at the problem that the frictional strength of microbeads cannot be controlled when the free microbead friction-assisted electroforming technology is used to process metal structural parts with large wall thickness, this embodiment provides a method for adjusting the friction-assisted electroforming of microbeads in the large thickness electroforming layer. Friction-strength metal structure processing device.

[0046] like image 3 and Figure 7 As shown, the metal structure processing device in this embodiment includes an electroforming working tank 9, an anode unit 12 located inside the electroforming working tank 9, and a porous elastic material for accommodating the metal structure (hereinafter referred to as the cathode core mold 7). Support structure 3; wherein, the inner wall surface of the porous elastic support structure 3 is an elastic surface, and the inner wall surface, the outer wall surface and the area between the inner wall surface and the outer ...

Embodiment 2

[0065] like Figure 8 As shown, the present invention also provides a processing method using the metal structure processing device described in Embodiment 1, including:

[0066] Step S1: After the metal structure is placed in the porous elastic support structure, put microbeads between the porous elastic support structure and the metal structure.

[0067] The particle size of the microbeads in this step is 0.5-1.2 mm, which is hard and has good wear resistance.

[0068] Preferably, microbeads are evenly added between the porous elastic support structure and the metal structure to form a thin layer.

[0069] Step S2: After the microbeads cover the metal structure, inject an electroforming liquid into the electroforming working tank.

[0070] Step S3: After the metal structure is submerged in the electroforming solution, electroforming is performed on the metal structure.

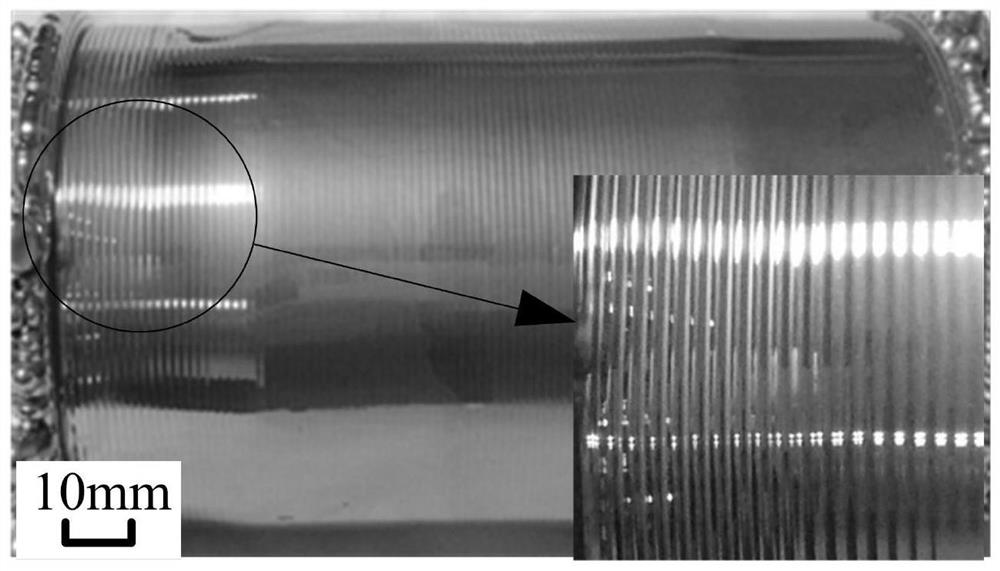

[0071] During the electroforming process, the micro-grinding of the electroformed layer is achieved by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com