Preparation method of silver dollar-shaped aluminum pigment

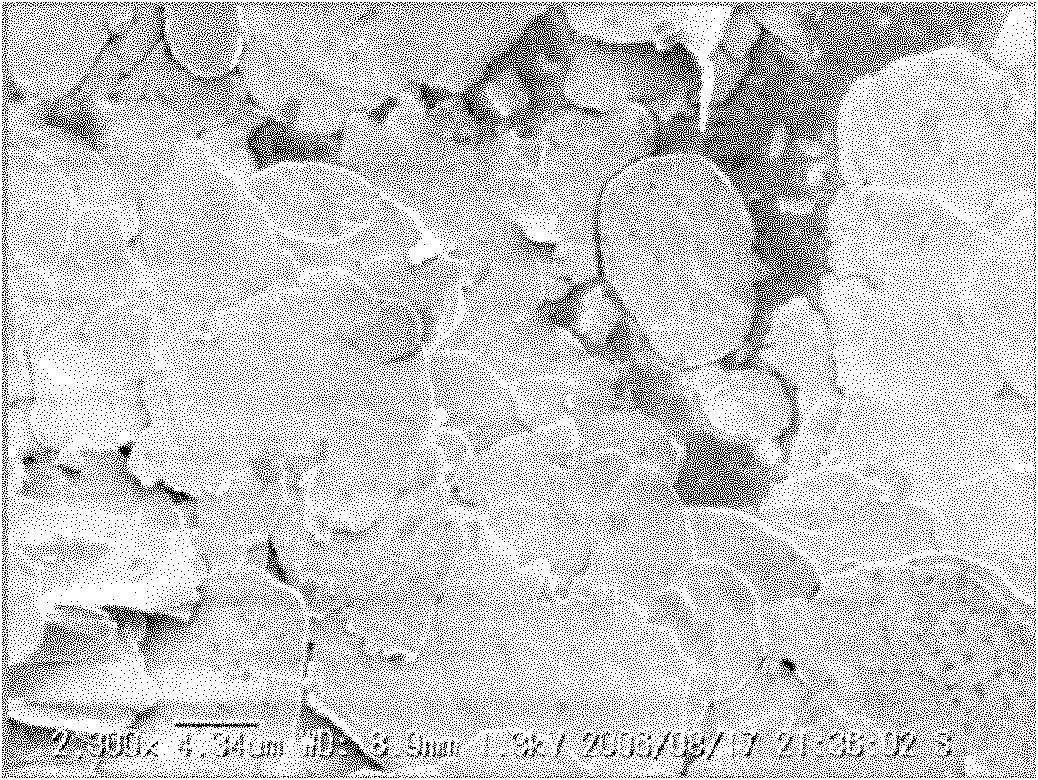

A technology of aluminum pigments and silver dollars, applied in the field of metallic pigments, can solve problems such as poor metallic feeling, low gloss, and irregular shape of aluminum pigment particles, and achieve the effect of narrow particle size distribution, smooth and clean surface, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

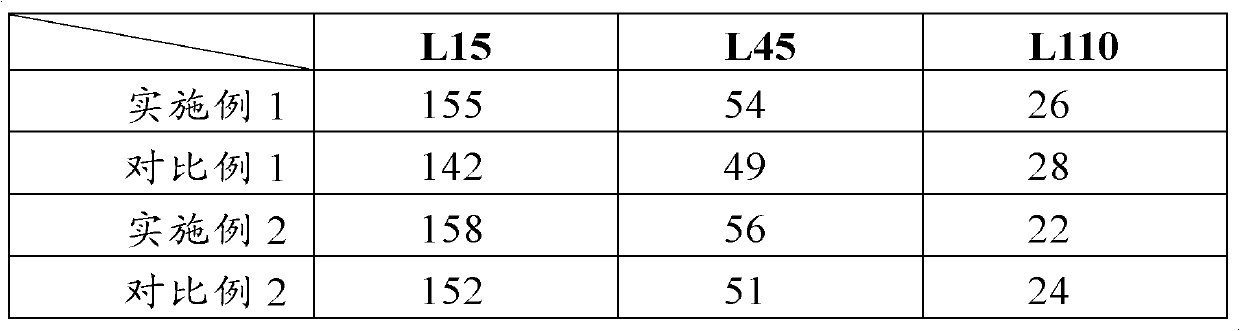

Embodiment 1

[0028] Put 2000kg of high-carbon steel balls with a diameter of 2mm into the Φ1100×1200 horizontal ball mill, add 300kg of 200# solvent oil (naphtha), D 5080kg of fine spherical aluminum powder atomized by nitrogen gas of 5-6 microns, 3kg of oleic acid, ball milled for 10h, discharged, and press-filtered. The filtrate is returned to the ball milling process, and the filter cake is added to a Φ1100×1200 horizontal ball mill equipped with 1500kg, 2.0mm zirconium balls, 300kg of 200# solvent oil, 1.5kg of oleic acid, and ball milling for 15 hours. Add the filter cake to the Φ1100×1200 horizontal ball mill equipped with 1000kg of 1.5mm glass balls, add 300kg of 200# solvent oil, 1kg of oleic acid, ball mill for 20h, discharge, 500 mesh sieve, press filter, and the filtrate returns to the ball mill process . The filter cake is put into the kneader, and after adding a small amount of antioxidant, a small amount of dispersant and an appropriate amount of solvent at the same time, th...

Embodiment 2

[0032] Put 2000kg of 3mm stainless steel balls into the Φ1100×1200 horizontal ball mill, add 300kg of 200# solvent oil, D 50 80kg of nitrogen atomized fine spherical aluminum powder of 7-8μm, 3kg of stearic acid, ball milled for 8h, discharging, and press filtration. The filtrate is returned to the ball milling process. Add the filter cake to a Φ1100×1200 horizontal ball mill equipped with 1500 kg of 2mm zirconia balls, add 300 kg of 200# solvent oil, 2 kg of stearic acid, and mill for 10 hours. Add 300kg of 200# solvent oil and 2kg of stearic acid to a Φ1100×1200 horizontal ball mill with 1,000kg of 1.5mm glass balls, and mill for 15 hours, discharge, sieve with 500 mesh, press filter, return the filtrate to the ball milling process; add the filter cake In the kneader, after adding a small amount of antioxidant, a small amount of dispersant and an appropriate amount of solvent at the same time, the solid content becomes 70%. After kneading for 1 hour, the packaging is a sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com