Wear-resisting sand pump and casting method thereof

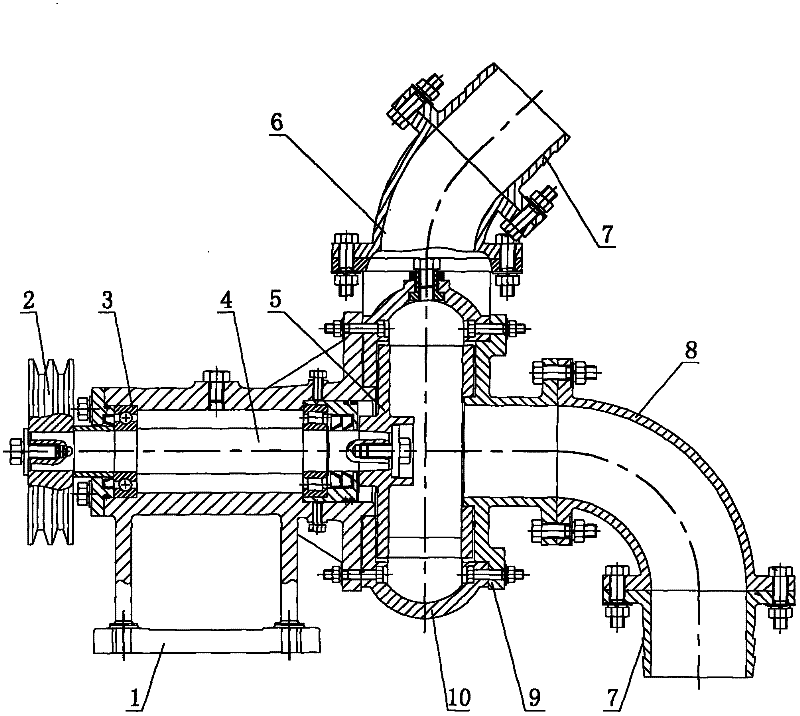

A sand pump and precision casting technology, applied in the field of centrifugal pumps, can solve the problems of limited durability, irreconcilable cutting and processing, complex structure, etc., and achieve the effects of long service life, reduced scrap rate, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

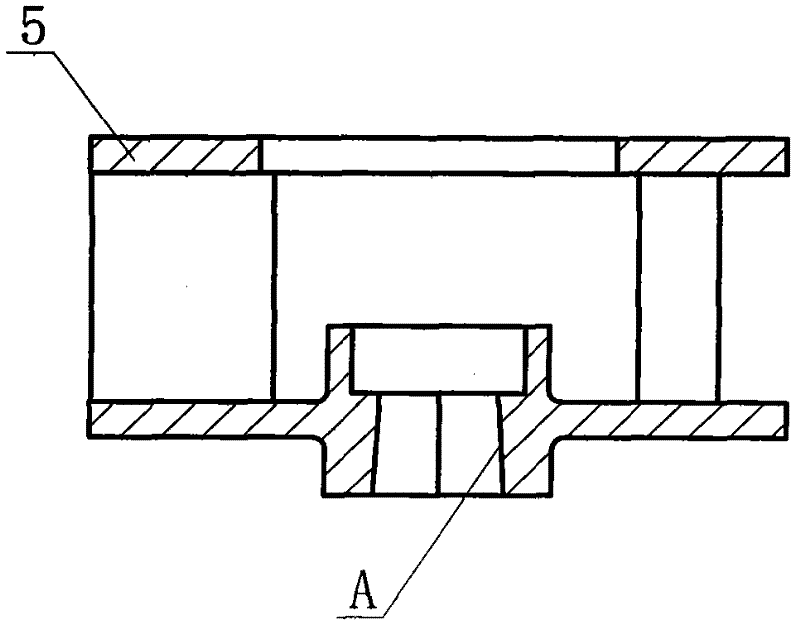

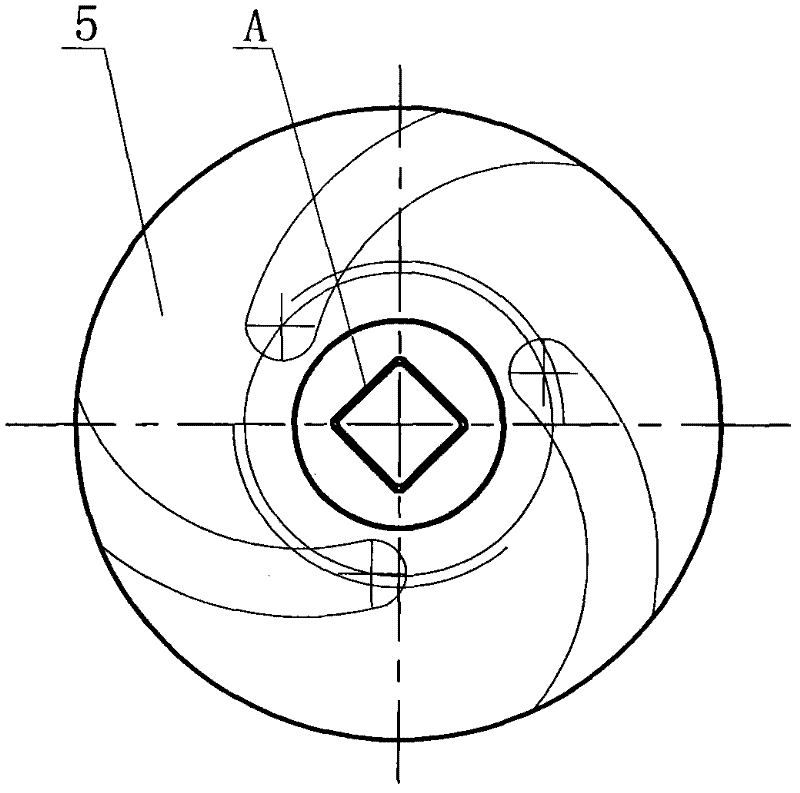

[0043] Taking the casting process of the pump blade 5 of the sand pump of the present invention as an example, the wear-resistant sand pump and its casting method are described.

[0044] 1. Divide the polystyrene ERS foam material into several pieces with reference to the shape of the pump blade 5, and use an adhesive to bond the overall shape of the pump blade 5 (see Figure 2~3 As shown), the inner hole of the pump blade 5 is a prismatic inner taper shape structure, and the reserved amount of the inner taper A surface is 4‰.

[0045] 2. Spray and dry. The parts by weight of mica-based coating components are: magnesia powder 40, pearl powder 30, mica powder 12, white latex 10, starch 0.8, carboxymethyl cellulose sodium 0.6, flame retardant 1, and the above coatings are beaten into slurry Paste, stir, apply to the surface of the foam pump leaf 5 model, and dry.

[0046] 3. Put it into the sand box. The foam pump vane 5 model of drying is put into sand box 11, fills sand box...

Embodiment 2

[0053] Taking the casting process of the pump body 10 of the sand pump of the present invention as an example, the wear-resistant sand pump and its casting method are described.

[0054] 1. Divide the polystyrene ERS foam material into several pieces with reference to the shape of the pump body 10, and use an adhesive to bond the overall shape of the pump body 10 (see Figure 6~7 As shown), the amount reserved on the B side of the screw reserved hole of the pump body 10 is 2‰; the reserved amount on the C side of the hexagonal reserved hole is 4‰.

[0055] 2. Spray and dry. The parts by weight of mica-based paint components are: magnesia powder 35; pearl powder 28; mica powder 15; white latex 8; starch 0.5; carboxymethylcellulose sodium 0.5; flame retardant 1.5.

[0056] 3. Put it into the sand box. Put the dried foam pump body 10 model into the sand box 11, fill the sand box 11 with dry sand 12, and carry out three-dimensional vibration compaction (such as Figure 11 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com