Waterborne polyurethane resin for synthetic leather fabric and preparation method of waterborne polyurethane resin

A water-based polyurethane and synthetic leather technology, applied in the field of macromolecular polymers, can solve the problems of poor folding resistance, poor abrasion resistance, and development limitations of synthetic leather fabrics, and achieves good wear resistance, good folding resistance at room temperature, and is beneficial to Environmental and physical and mental health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

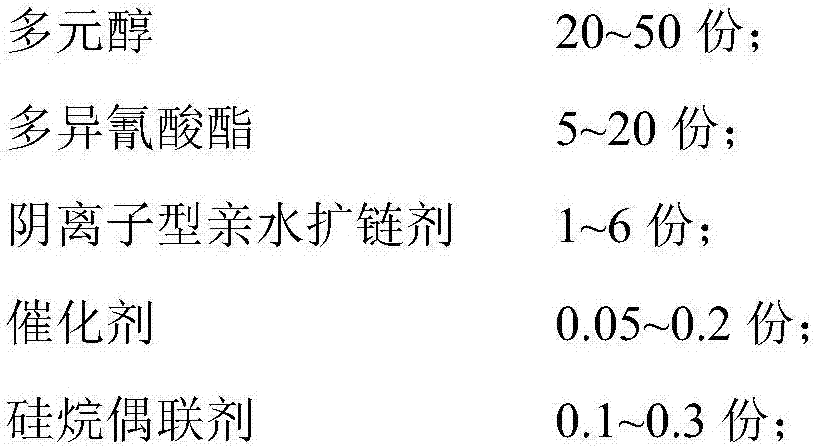

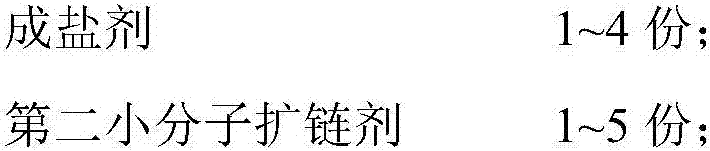

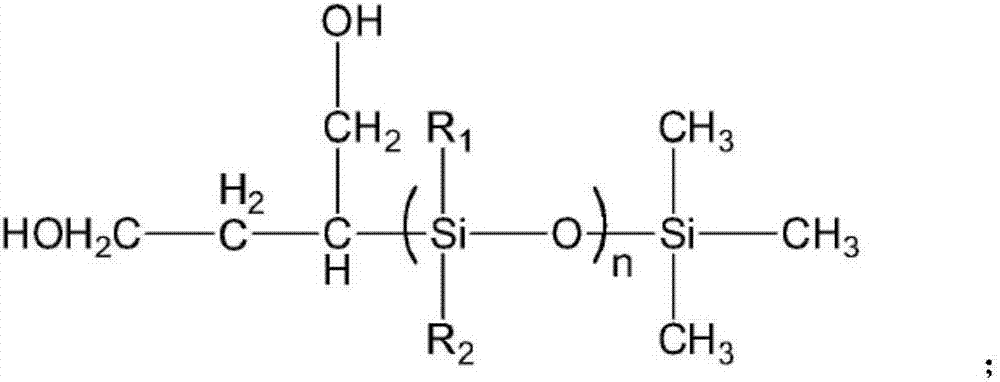

Method used

Image

Examples

Embodiment 1

[0045] Add 65g of polytetrahydrofuran diol, 58g of polycarbonate diol with a molecular weight of 900, 21g of polycarbonate diol with a molecular weight of 2000 and 9g of hydroxyl-terminated polysiloxane diol in a three-necked flask, and heat to 100° C. Press dehydrate for 1 hour. Then add 28.5g of toluene diisocyanate and 14.5g of diphenylmethane diisocyanate, heat up to 85°C, react for 2h, cool down to 50°C, add 7.5g of dimethylol propionic acid, 0.4g of organic bismuth catalyst and 70g of acetone, stir After uniformity, heat to 70°C, react for 6 hours, cool down to 40°C, add 9.6g γ-glycidyl etheroxypropyl trimethoxysilane, react for 10min, cool down to 5°C, add 5.2g triethylamine to neutralize, add 440g After emulsification and dispersion in ice water, 5 g of isophorone diamine and 14.4 g of ethylenediamine were added for post-chain extension, the emulsification and dispersion were continued, and then the acetone was removed by distillation under reduced pressure to obtain a...

Embodiment 2

[0047] Add 60g polytetrahydrofurfuryl ester diol, 55g polycarbonate diol with a molecular weight of 900, 26g polycarbonate diol with a molecular weight of 2000 and 8g hydroxyl-terminated polysiloxane diol in a three-necked flask, heat to 100° C. Press dehydrate for 1 hour. Then add 28.5g toluene diisocyanate and 14.5g diphenylmethane diisocyanate, heat up to 85°C, react for 2h, cool down to 50°C, add 7.5g dimethylol propionic acid, 0.4g organic bismuth catalyst and 70g acetone, stir After that, heat to 70°C, react for 6 hours, cool down to 40°C, add 9.6g of γ-glycidyl etheroxypropyl trimethoxysilane, react for 10min, cool down to 3°C, add 5.2g of triethylamine to neutralize, add 440g of ice Water emulsified dispersion, while adding 5g of isophorone diamine and 14.4g of ethylenediamine for post-chain extension, continued emulsification and dispersion, and then removed acetone by vacuum distillation to obtain a water-based polyurethane resin emulsion.

Embodiment 3

[0049] Add 64g of polytetrahydrofurfurate diol, 67g of polycarbonate diol with a molecular weight of 900, 23g of polycarbonate diol with a molecular weight of 2000 and 8g of hydroxyl-terminated polysiloxane diol in a three-necked flask, and heat to 100°C for vacuum decompression Dehydrate for 1 hour. Then add 28.5g toluene diisocyanate and 14.5g diphenylmethane diisocyanate, heat up to 85°C, react for 2h, cool down to 50°C, add 7.5g dimethylol propionic acid, 0.4g organic bismuth catalyst and 70g acetone, stir Afterwards, heat to 65-70°C, react for 6 hours, cool down to 40°C, add 9.6g of γ-glycidyl etheroxypropyl trimethoxysilane, react for 10min, cool down to 3°C, add 5.2g of triethylamine to neutralize, add 440g of ice water was emulsified and dispersed, and 5g of isophoronediamine and 14.4g of ethylenediamine were added at the same time for post-chain extension, and the emulsification and dispersion was continued. Then, acetone was removed by vacuum distillation to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com