Patents

Literature

460results about How to "Improve alcohol resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

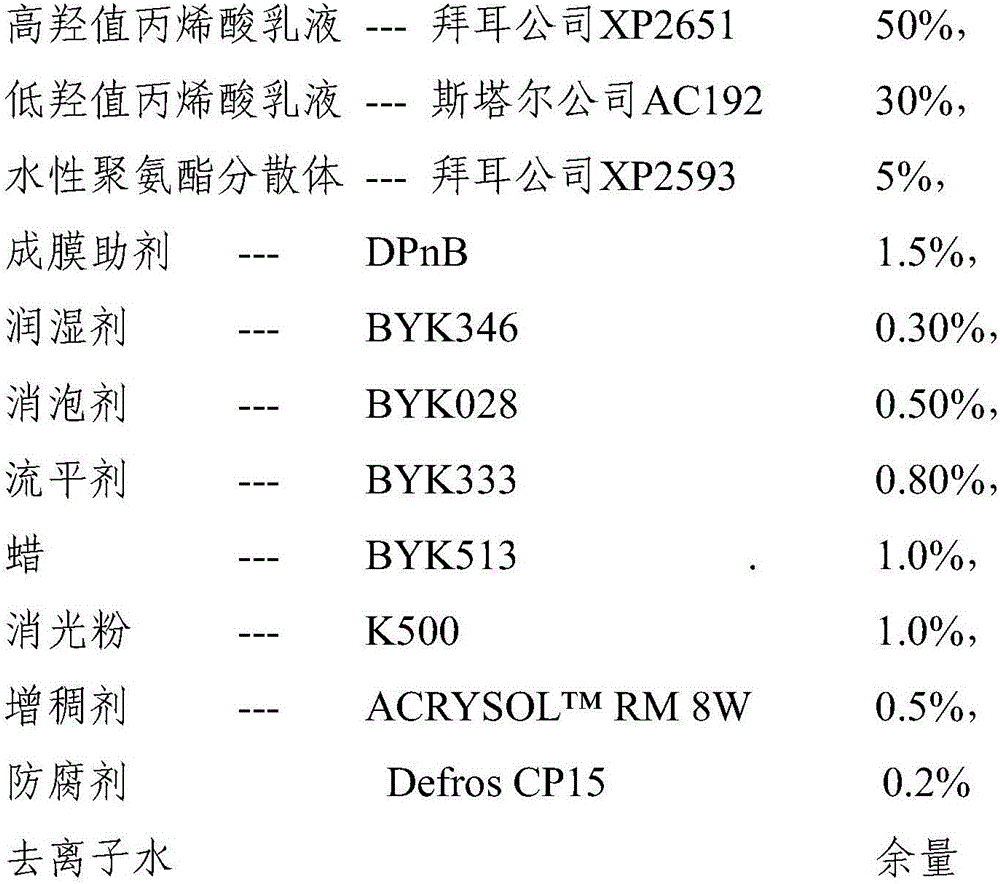

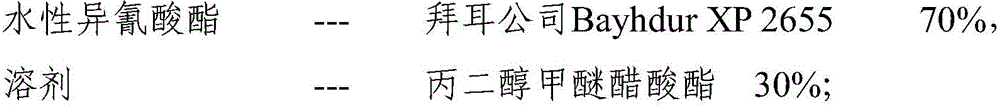

Waterborne two-component woodware coating and preparation method thereof

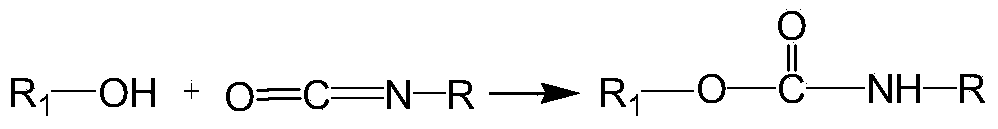

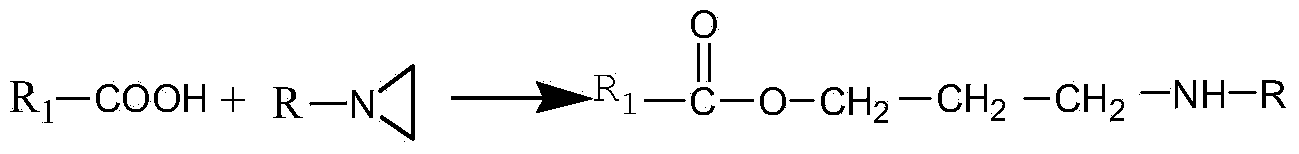

The invention discloses a waterborne two-component woodware coating and a preparation method thereof. The waterborne two-component woodware coating is prepared from main agent A and curing agent B. The main agent A comprises high-hydroxyl-value acrylic emulsion, low-hydroxyl-value acrylic emulsion, an aqueous polyurethane dispersion, a film forming auxiliary, a moistening agent, a leveling agent, an antifoaming agent, wax, extinction powder, a thickening agent, a preservative and deionized water, and the curing agent B comprises waterborne isocyanate and a solvent. The waterborne two-component woodware coating uses hydroxyl acrylic and the aqueous polyurethane dispersion as main film forming matters, the waterborne isocyanate serves as a cross-linking agent, the extinction powder and a wax auxiliary are added, curing reaction is performed at the normal temperature, and the coating has the advantages of high hardness, excellent chemical resistance, good scratch resistance, better transparence and simple, economical and reasonable production process, and can be widely applied to products such as wooden furniture and doors and windows.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Polyurethane aqueous dispersion and preparation method thereof

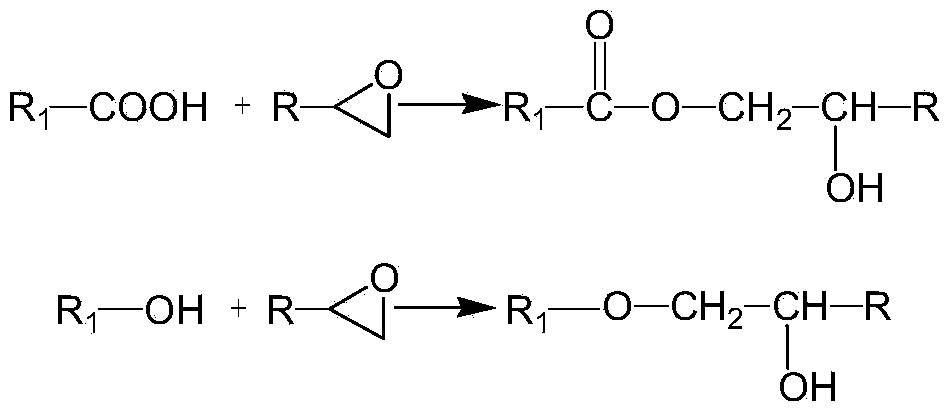

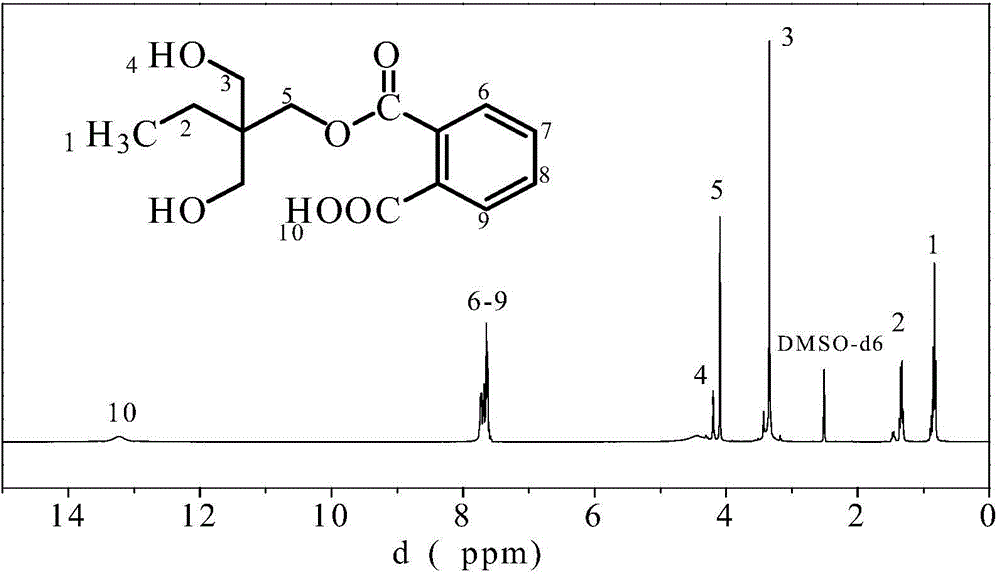

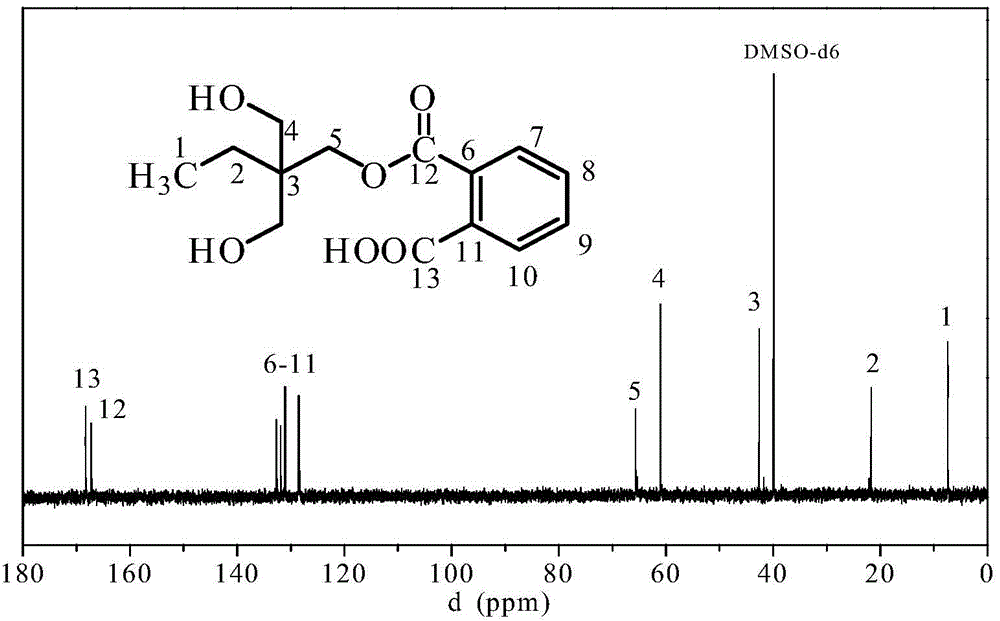

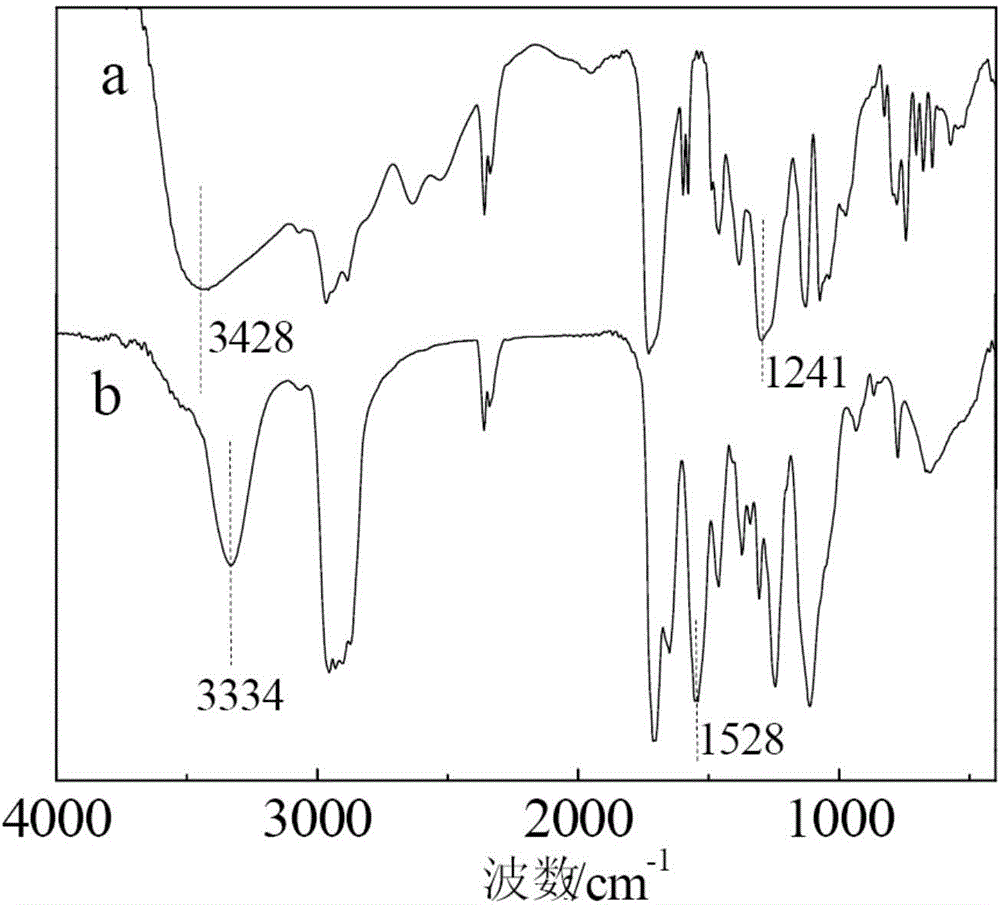

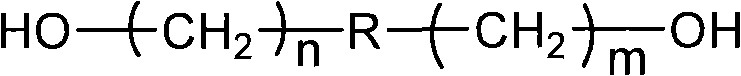

InactiveCN104311778AReduce manufacturing costLow priceOrganic compound preparationCarboxylic acid esters preparationCross-linkHydrophilic monomer

The invention discloses a polyurethane aqueous dispersion and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing trimethylolpropane or glycerol and acid anhydride and preparing a carboxylic acid type hydrophilic monomer; on the basis of molar parts, adding 20-60 parts of polymer dibasic alcohol, 4-10 parts of carboxylic acid type hydrophilic monomer and 30-60 parts of a diisocyanate monomer into a reactor, heating to 60 DEG C-100 DEG C and carrying out heat preservation; adding1-10 parts of small-molecular dibasic alcohol, 2-10 parts of a non-ionic hydrophilic chain extender and 1-6 parts of a cross-linking agent and reacting until the content of NCO is less than 5%; and adjusting the viscosity of the reactant, cooling, adding a neutralizing agent for neutralizing, adding water for emulsifying, adding an amine chain extender and removing the solvent by distillation to obtain the polyurethane aqueous dispersion. The carboxylic acid type hydrophilic monomer has stable performance and low cost, the polyurethane aqueous dispersion prepared from the carboxylic acid type hydrophilic monomer has high content of solids and the coating has relatively high hardness and excellent chemical product resistance.

Owner:SOUTH CHINA UNIV OF TECH

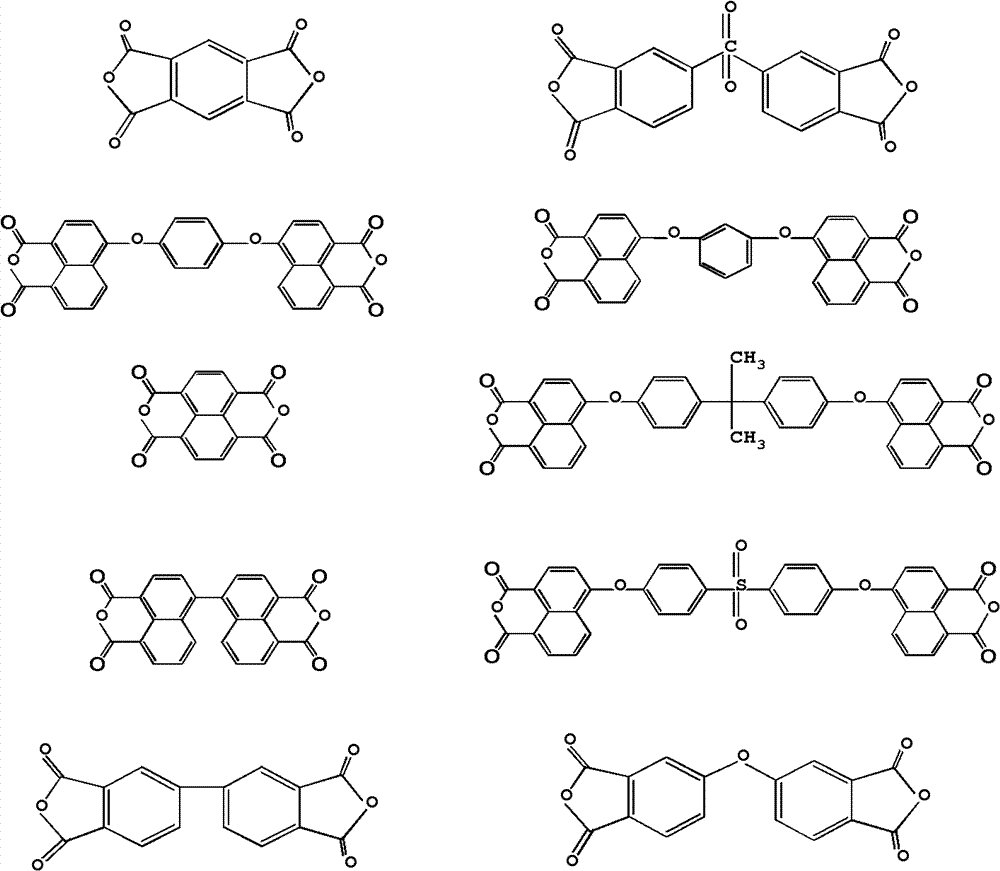

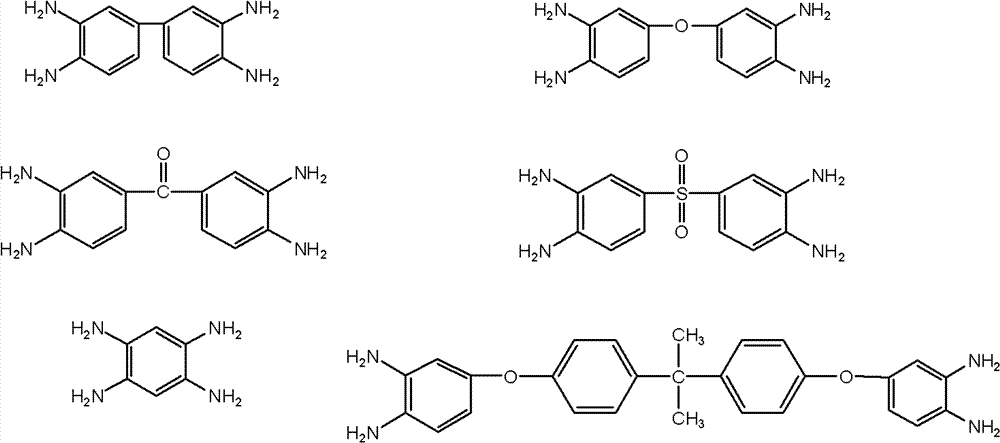

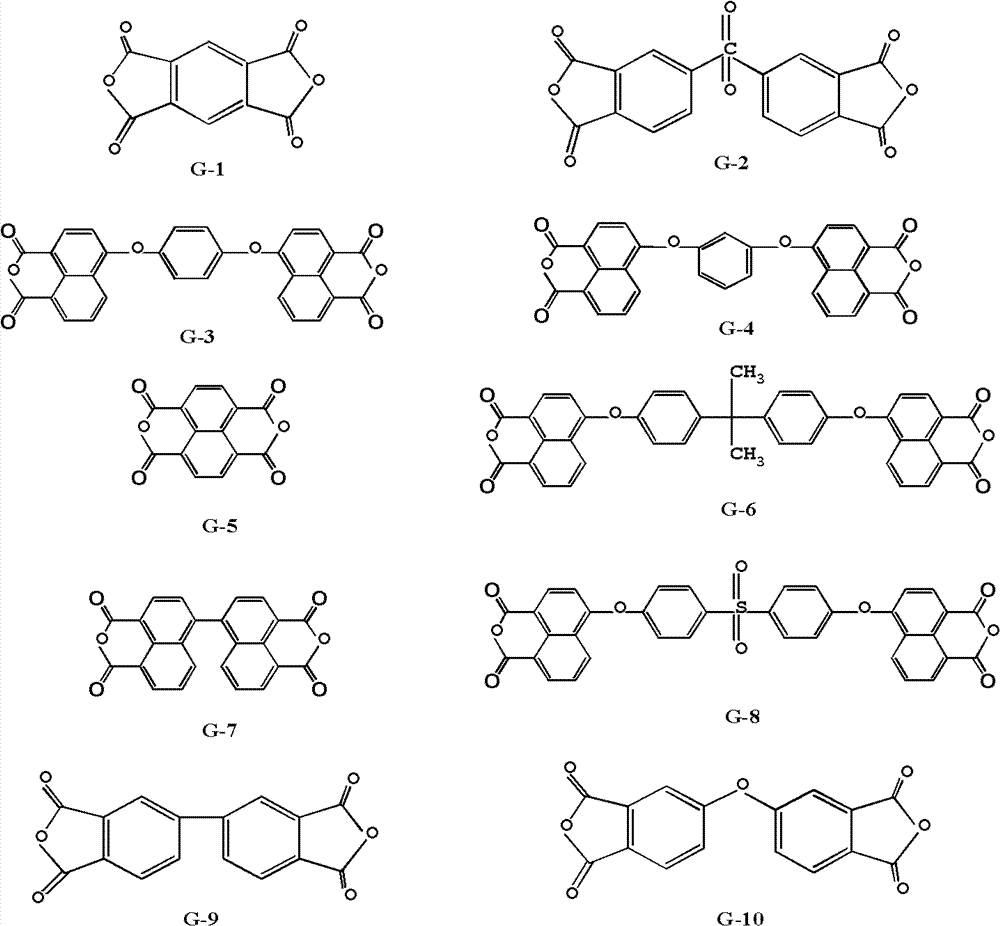

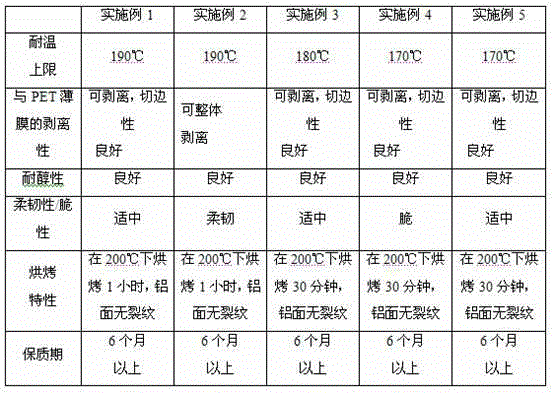

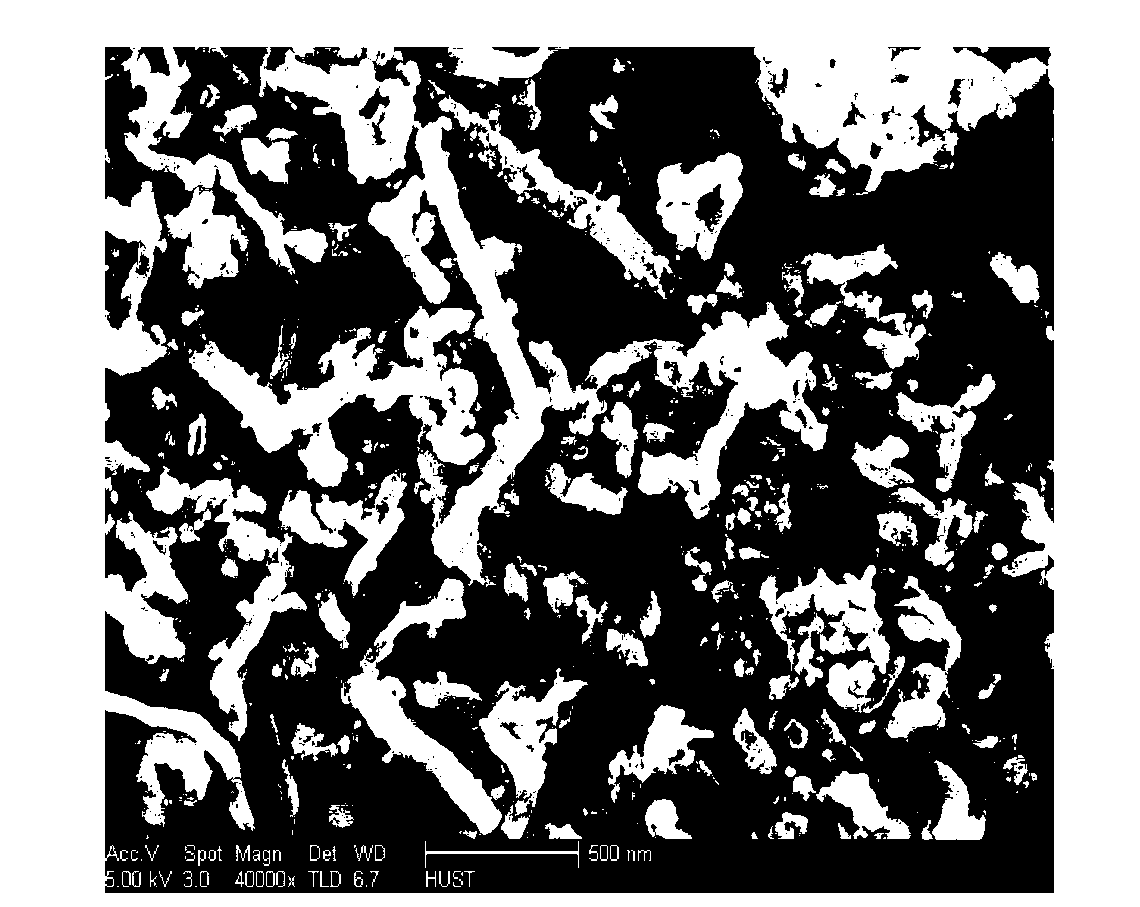

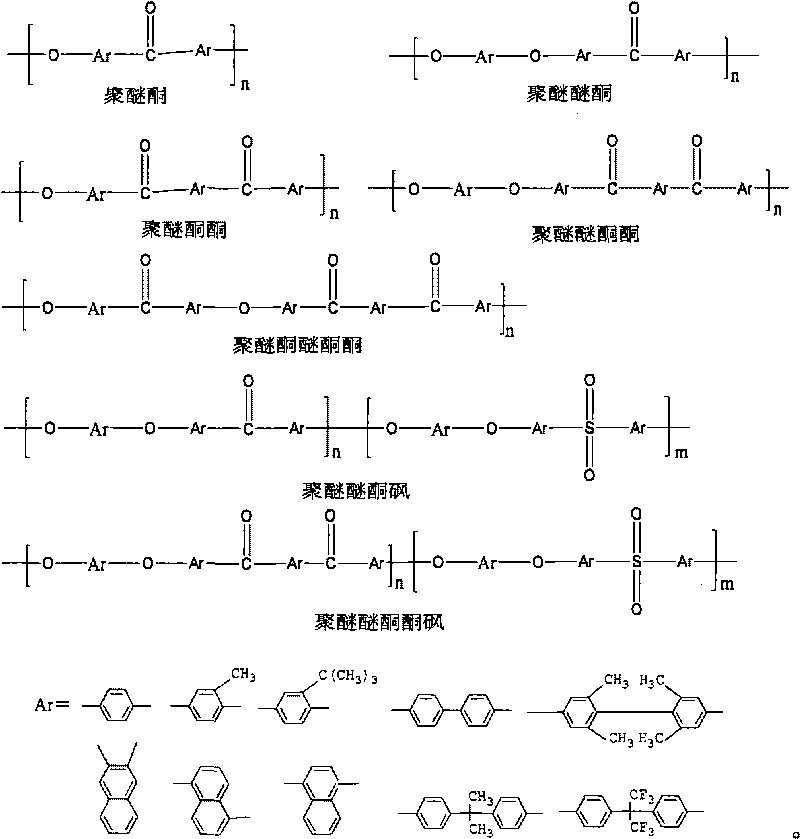

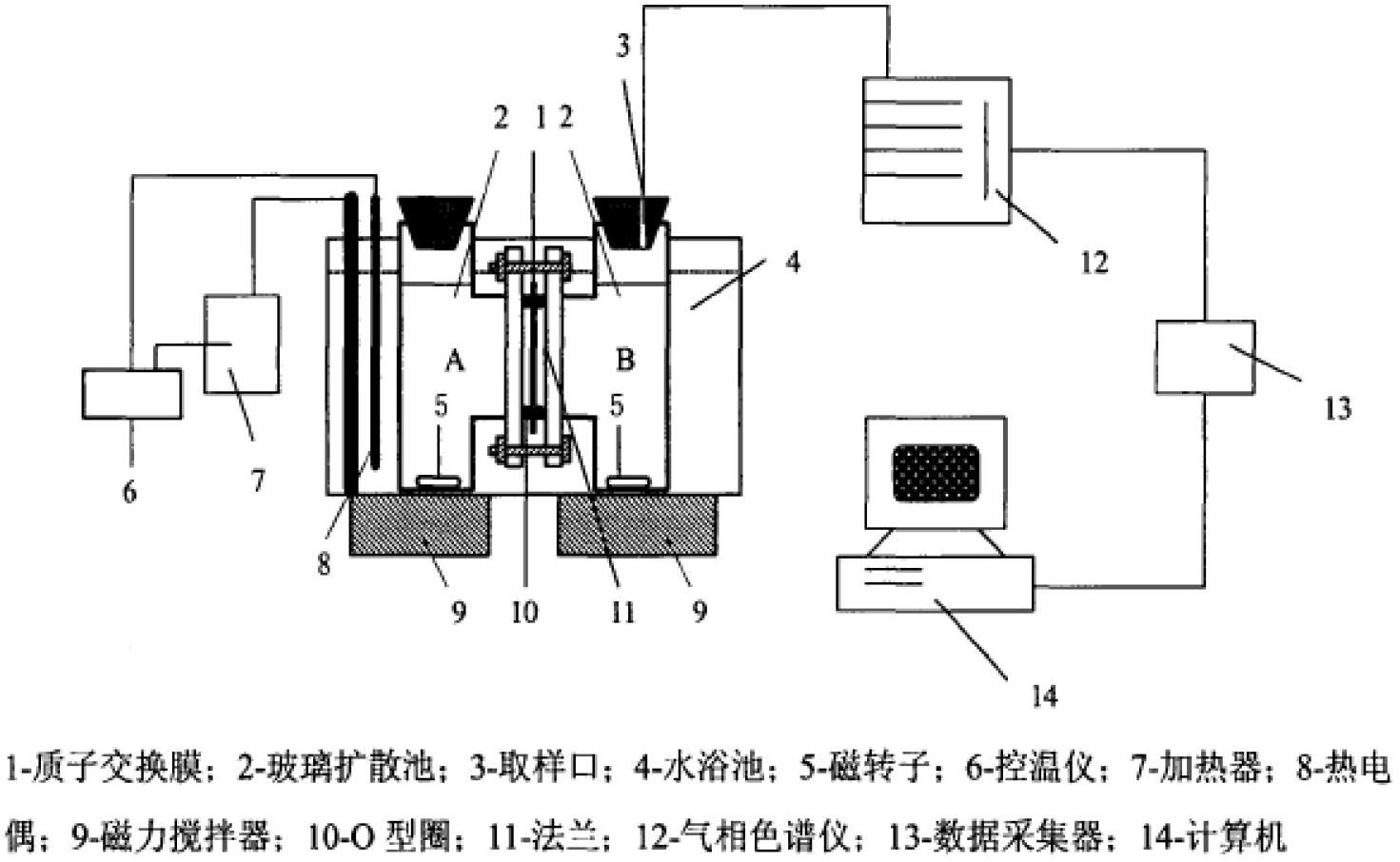

Polypyrrolone/sulfonated polymer composite proton exchange membrane material, and preparation method and application thereof

ActiveCN103087337AHigh mechanical strengthImprove conductivityCell component detailsSolid electrolyte fuel cellsPtru catalystIn situ polymerization

The invention discloses a polypyrrolone / sulfonated polymer composite proton exchange membrane material, and a preparation method and an application thereof. The composite proton exchange membrane material is prepared with the method comprising the steps that: (1) under the protection of an inert atmosphere, aromatic tetraamine monomer, aromatic dianhydride monomer, and a catalyst are subjected to an in-situ polymerization reaction in a sulfonate polymer solution, such that a membrane-forming liquid comprising a polypyrrolone prepolymer is obtained; and (2) the membrane-forming liquid is coated on a carrier, and heating treatment membrane preparation is carried out; cooling and demolding are carried out after membrane preparation is finished; the obtained membrane is transformed by washing by using an acid solution, such that the polypyrrolone / sulfonated polymer composite proton exchange membrane material is obtained. With the method provided by the invention, the components are dispersed more uniformly, and operation is simpler. The prepared composite membrane has good mechanical strength and conductivity. Compared with a non-modified sulfonated polymer, size stability and alcohol resistance are greatly improved. The membrane material can be used in fields such as proton exchange membrane of proton exchange membrane fuel cell, ion exchange resin, membrane separation, sensor, and the like.

Owner:TSINGHUA UNIV

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

The invention discloses a water-based laser transfer coating for wine bottle glass baking paper, and a preparation method thereof. The coating is prepared by mixing the following components in percentage by mass: 10-30% of water-based acrylic resin, 25-40% of water-based polyurethane resin, 0-8% of cosolvent, 20-45% of deionized water, 0-0.4% of water-based defoaming agent, 0.1-0.4% of base material wetting agent, and 0-0.2% of pH value regulating agent. The water-based laser transfer coating for the wine bottle glass baking paper is an environment-friendly laser transfer coating which meets national VOC detection standard by taking the water-based resin and deionized water as main raw materials. In addition, the composite water-based resin endows a curing film with good temperature resistance, aluminum adherence, strippability, alcohol resistance and the like, thus meeting the index requirement of the wine bottle glass baking paper.

Owner:三友(天津)高分子技术有限公司

High-performance water-based polyurethane dispersoid and application thereof

ActiveCN101265318AImprove water resistanceImprove alcohol resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsWater basedAdhesive

The invention discloses a high-performance aqueous polyurethane dispersion, which adopts polyurethane prepolymer liquid, chain extender, neutralizer and water for preparation; the polyurethane prepolymer liquid adopts polymer polyol containing a cyclic structure with the weight percentage of 2 to 80 percent as the main raw material and polyisocyanate for preparation. The polymer polyol of the polyurethane prepolymer liquid which is prepared by screening contains 2 to 80 percent cyclic structure, the aqueous polyurethane dispersion film forming substance can not be whitened by being soaked in the water for 24 hours and being soaked in liquor with 50 degrees for 2 hours, the hardness is not lower than H, the heat-resistant temperature is not lower than 65 DEG C, the water-resistant performance, the alcohol-resistant performance, the heat-resistant performance and the hardness are completely improved, and the novel high-performance aqueous polyurethane dispersion can be used as an aqueous paint base material and a waterproof adhesive.

Owner:海聚高分子材料科技(广州)有限公司

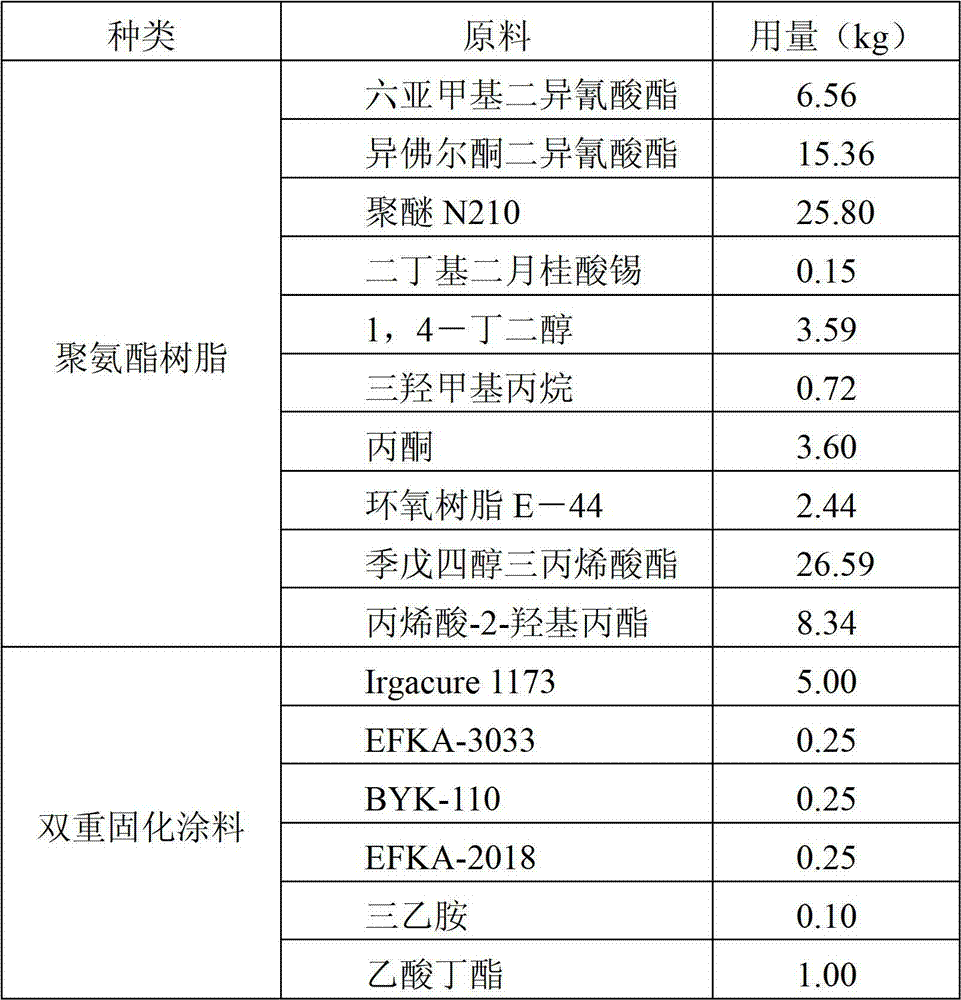

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

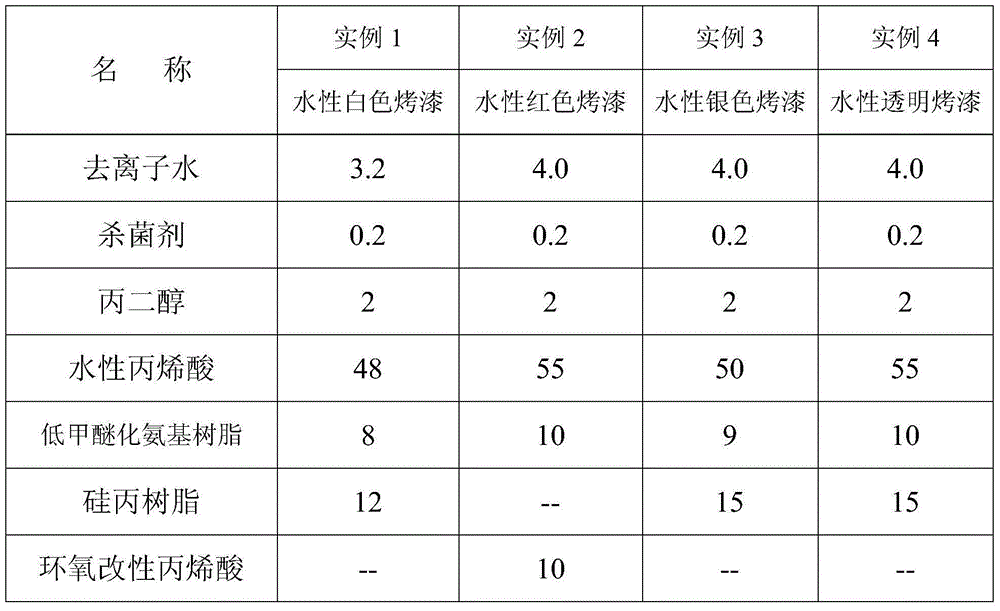

Preparation method of low-temperature curing water-based glass baking paint

ActiveCN103937360AIncrease the degree of cross-linkingLow curing temperatureCoatingsWater basedAcrylic resin

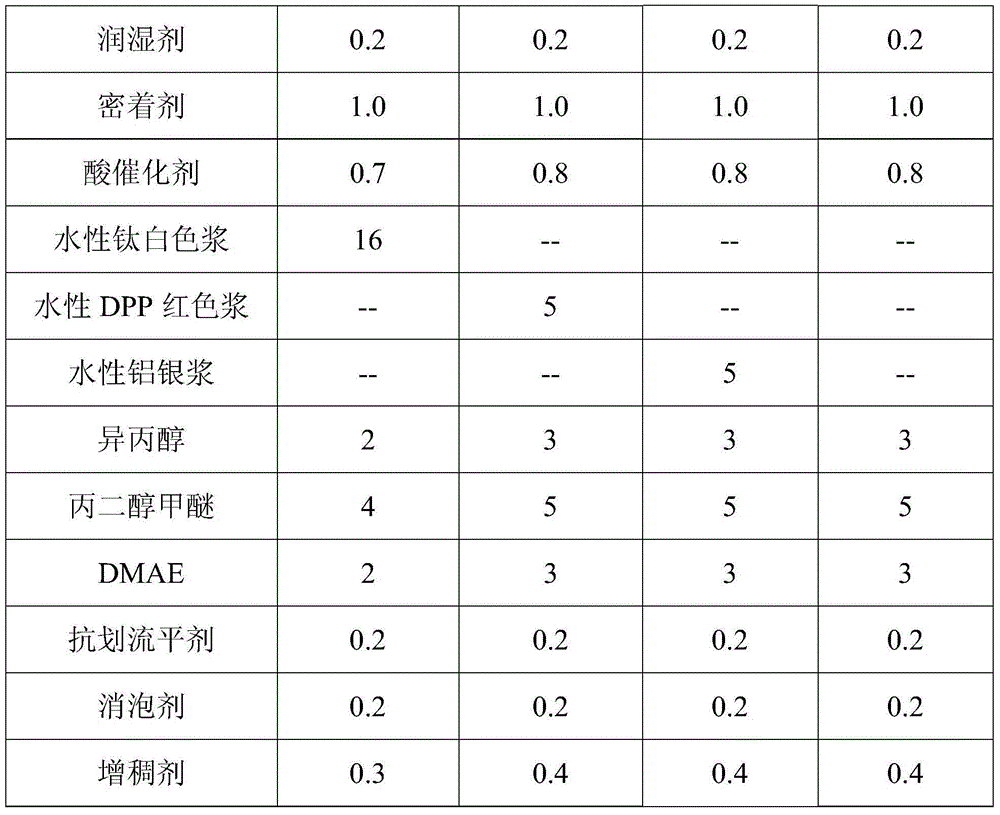

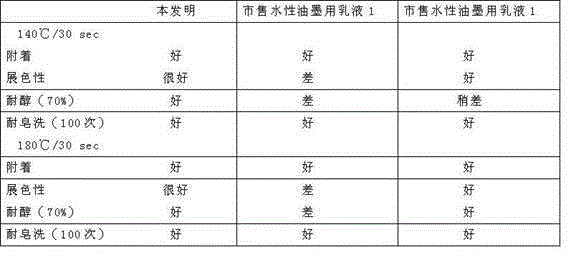

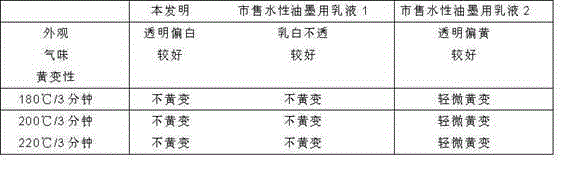

The invention relates to a preparation method of a low-temperature curing water-based glass baking paint composed of acrylic resin, amino resin, hydroxyl resin, a pigment or a colorant, a wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared low-temperature curing water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage; and a prepared paint film has the hardness reaching 2 H or more, has excellent anti-scratch wear-resisting properties, and is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

Water-based single-component matte varnish

InactiveCN102719163APromote environmental protectionHigh fullnessPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention discloses water-based single-component matte varnish, which comprises the following components in parts by weight: 20-50 percent of water-based pure polyacrylic emulsion, 20-50 percent of self-extincted polyacrylic emulsion, 5-30 percent of water-based aliphatic polyurethane and mixture emulsion, 3-10 percent of film-forming auxiliary agent, 0.01-2 percent of defoaming agent, 0.01-2 percent of dispersing agent, 0-2percent of wetting agent, 0.01-2 percent of rheological auxiliary agent, 0.01-2 percent of wax auxiliary agent, 0.01-2 percent of hand-feeling auxiliary agent, 0.01-2 percent of thickening agent, 0.01-2 percent of pH regulator and 5-30 percent of water. The water-based single-component matte varnish has the advantages of high environment-friendly property, high fullness, high rigidity, high hand feeling, high construction property and high chemical resistance, and meanwhile, the self-extincted emulsion is adopted in the formula for extinction, so that the water resistance and the alcohol resistance of a varnish film are greatly enhanced, and the harsh requirements of partial customer services on the water resistance and the alcohol resistance are met.

Owner:HUIZHOU CHANGRUNFA PAINT

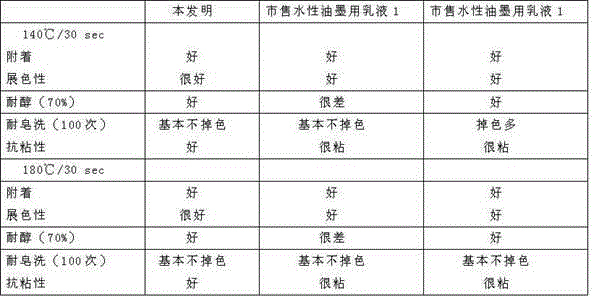

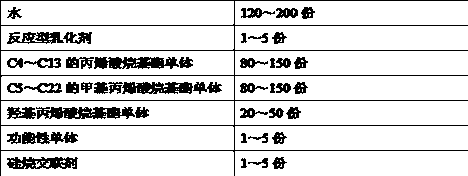

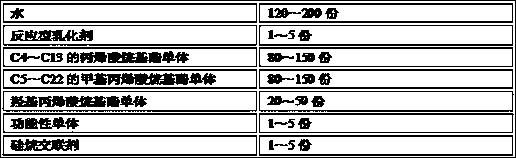

Anti-after tack acrylic latex for water-based ink

ActiveCN102911559AGood yellowing resistanceExcellent color paste stabilityInksMethacrylatePolymer science

The invention discloses anti-after tack acrylic latex for water-based ink. The latex comprises 5-18% of water, 0.1-0.8% of initiator, 40-60% of self-made alkali-soluble resin solution, 4-20% of C4-C12 alkyl acrylate monomer, 15-40% of C4-C20 methacrylate monomer and 0.2-5% of functional monomer. In a preparation method of the latex, firstly (methyl) acrylic acid, methyl methacrylate and C4-C12 alkyl acrylate are used as comonomers, persulfate is used as the initiator, a chain transfer agent is adopted, and then the alkali-soluble resin solution is obtained through emulsion polymerization; and then, the C4-C12 alkyl acrylate unsaturated monomer, the C4-C20 methacrylate unsaturated monomer and the functional monomer are used as comonomers, the alkali-soluble resin serves as a protective colloid, and then the anti-after tack acrylic latex is prepared by soap-free emulsion polymerization. According to the invention, the technology is simple, the operation is convenient, and the energy consumption and cost of production are reduced; and the latex has excellent yellowing resistance and color paste stability, and can effectively improve the alcohol resistance, soaping resistance, color development property and anti-after tack property of the water-based ink.

Owner:NANJING REGAL POLYMER +1

Ink

The invention provides ink. Based on the total weight of the ink, the ink is mainly prepared from the following ingredients in percentage by weight: 5-30% of epoxy resin, 10-40% of polyester resin, 0.5-2% of defoamer, 5-20% of wear-resistant emulsion and 40-60% of solvent. According to actual needs, the ink provided by the invention can also contain the following ingredients in percentage by weight: 0.5-2% of pigment and 0.5-2% of dispersant. The ink provided by the invention has relatively strong adhesion and wear resistance and good chemical resistance, and the resins and the solvent are relatively environmental-friendly, so that the ink is particularly applicable to an elastomer surface and has a good application prospect.

Owner:威海凯虹精密化工有限公司

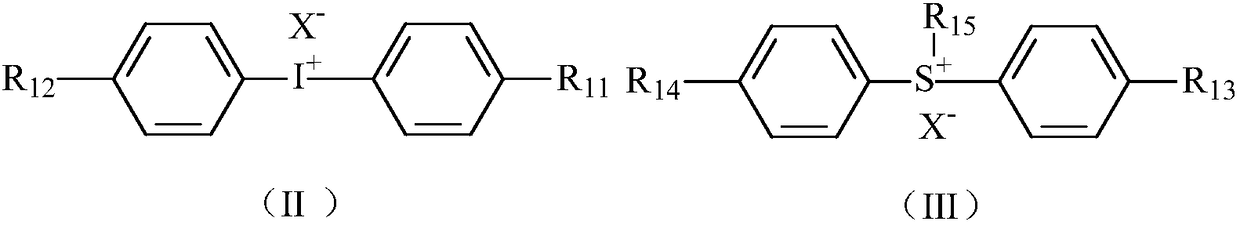

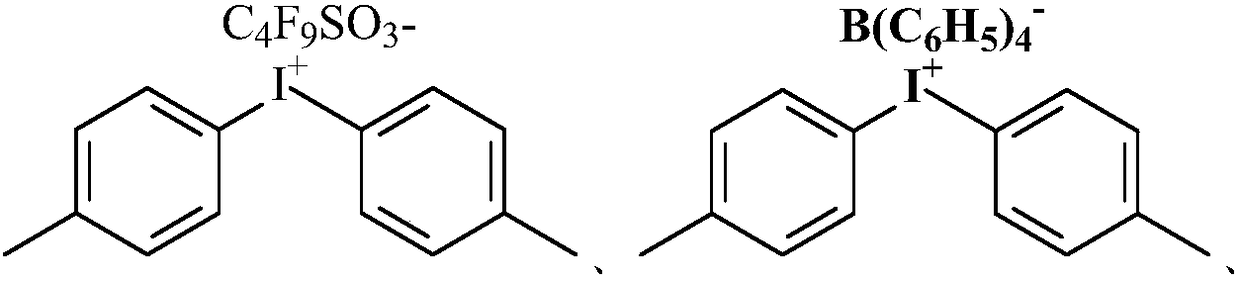

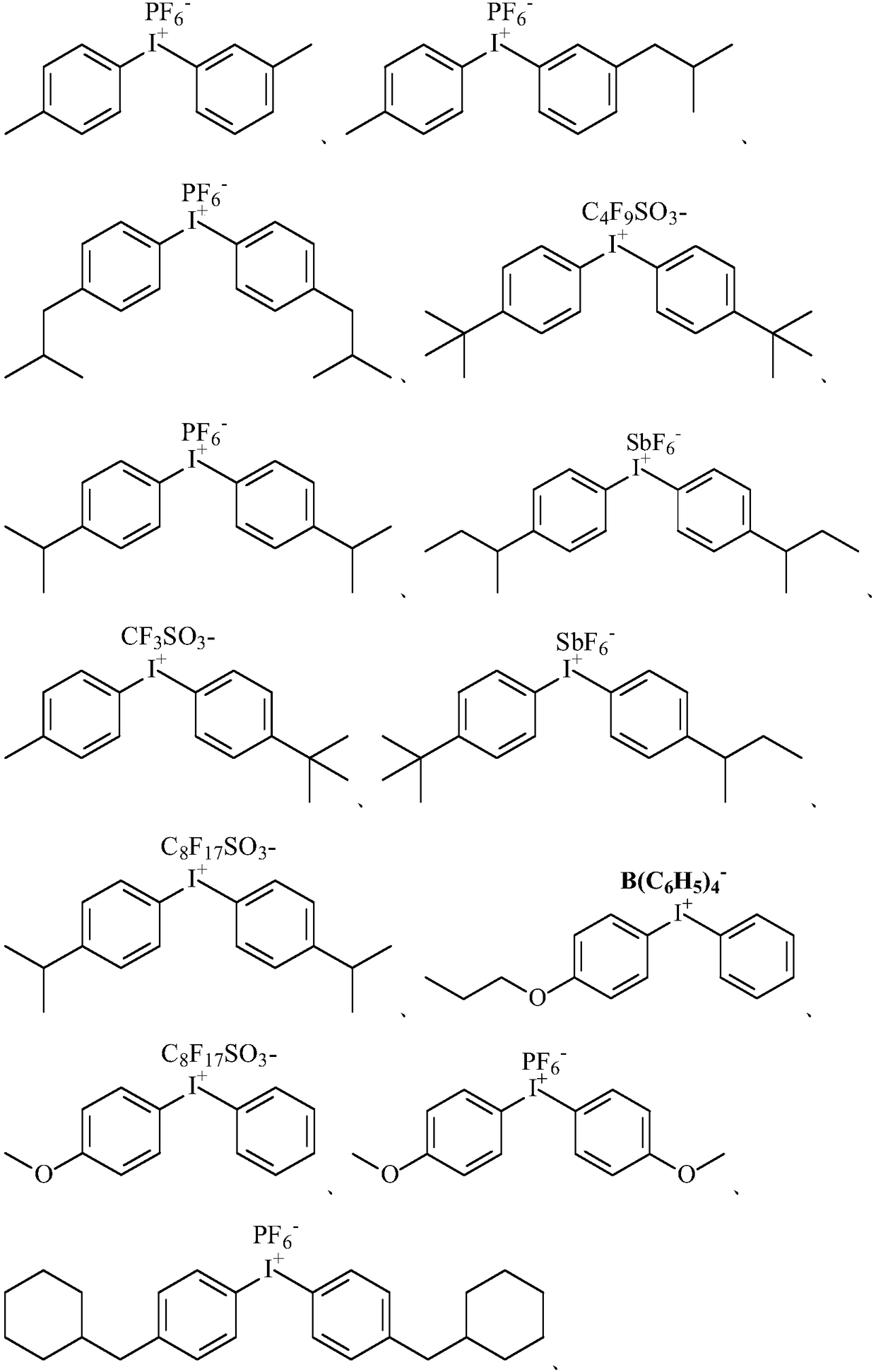

UVLED light-curing wood coating

InactiveCN108314911AGood storage stabilityFast curingEpoxy resin coatingsChemistryCycloaliphatic epoxy

The invention discloses an UVLED light-curing wood coating and application thereof, the coating comprises an oxetane compound, an epoxy compound selected from the group consisting of at least one of bisphenol A type epoxy resin, bisphenol F type epoxy resin or an alicyclic epoxy compound, a (methyl) acrylate compound, a cationic and a radical photoinitiator, and optionally a sensitizer. The coating has excellent response to an UVLED light source in the wavelength range of 200 to 450 nm, and the curing speed is fast. The cured coating is excellent in hardness, wear resistance, flexibility, adhesion, alcohol resistance and yellowing resistance and the like. The coating is odorless and has strong technical and market competitiveness.

Owner:CHANGZHOU GREEN PHOTOSENSITIVE MATERIALS CO LTD

Room temperature multiple self-crosslinking nano acrylate copolymer emulsion and preparation method and water-based woodenware paint using emulsion as base material

The invention discloses a room temperature multiple self-crosslinking nano acrylate copolymer emulsion and a preparation method thereof and water-based woodenware paint using the emulsion as a base material, preparation synthesis components of the room temperature multiple self-crosslinking nano acrylate copolymer emulsion include vinyl-unsaturated carboxylic acid, methacrylate, acrylate, styrene, a modified SiO2 and acrylate monomer dispersion liquid, a crosslinking monomer A, vinyl siloxane, a crosslinking monomer B and the like, and by use of three methods of introduction of three components of modified nano-SiO2, the cross linking monomers and the vinyl siloxane for crosslinking through the preparation of the room temperature multiple self-crosslinking nano acrylate copolymer emulsion, the three crosslinking methods are in mutual coordination, so that finally the water-based woodenware paint prepared from the emulsion as the base material forms a dense protective film, and has excellent water resistance, alcohol resistance, scratch resistance, high temperature after-tack resistance and relatively high hardness, and the paint film properties can be comparable to that of solvent-based furniture paint.

Owner:HENGSHUI XINGUANG CHEM

Composite type proteon exchange film for high-temp. direct methanol fue cell and preparation process thereof

InactiveCN1385915AImprove proton conductivityReduce penetrationLead-acid accumulator electrodesFuel cellsFuel cellsMethanol fuel

This invention relates to electric chemical fuel battery technology, the raw material of the compound proton exchange film with millimicron micropore structure used in the high temperature direct, carbinol fuel battery is processed with PVDF and PVA added by mixed inorganic multi-element acid millimicron ceramic powder by doctoblade hot pressure, brie-coated, rolling process or imprenated methods. The carbinol permeability at 80-180 deg.c in smaller than Nafion film with good performance of cardinal resistance, available in the operation at high temperature (above 100deg.c) of direct carbinolfuel battery proton exchange film.

Owner:SOUTH CHINA UNIV OF TECH

High solid content acrylic varnish, and preparation method and application thereof

The invention discloses a high solid content acrylic varnish which comprises the following raw materials in percentage by mass: 50-60% of hydroxy acrylic resin, 20-30% of polyurethane curing agent, 12.6-18% of organic solvent, 0.1-2% of wetting agent, 0.1-2% of flatting agent and 0.1-1% of antifoaming agent. The high solid content acrylic varnish disclosed by the invention can be applied in bamboo and wood tableware, is combined with a high solid content coating technology and technologies of cross-linked film curing and organic solvent removal and is a new development direction for bamboo and wood coatings and coating materials.

Owner:CARPOLY CHEM GRP

Coloring agent for electrochemical aluminum paint and its preparing method

InactiveCN1944552AGood suitability for hot stampingImprove performancePigment pastesPolymer scienceHeat resistance

The present invention relates to one kind of coloring agent for electrochemical aluminum paint and its preparation process. The coloring agent consists of polyurethane resin 60-70 weigh portions, resin modifier 20-50 weigh portions, and solvent 80-120 weigh portions. The preparation process of the coloring agent includes stirring solvent, mixing material and other technological steps. Compared with available technology, the present invention has the advantages of excellent stability, high thermoprinting adaptability, good stripping property and high heat resistance.

Owner:上海绘兰材料科技有限公司

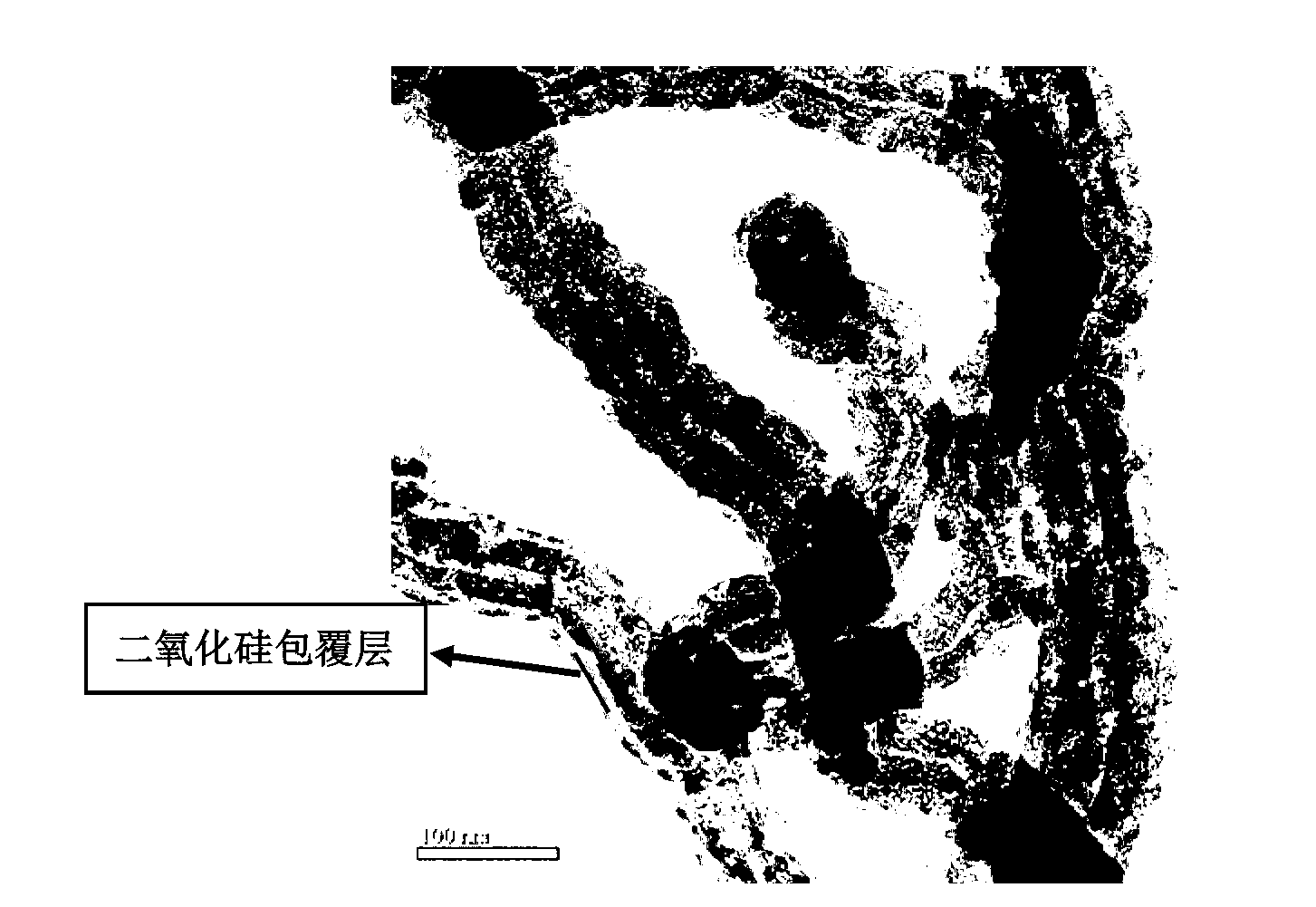

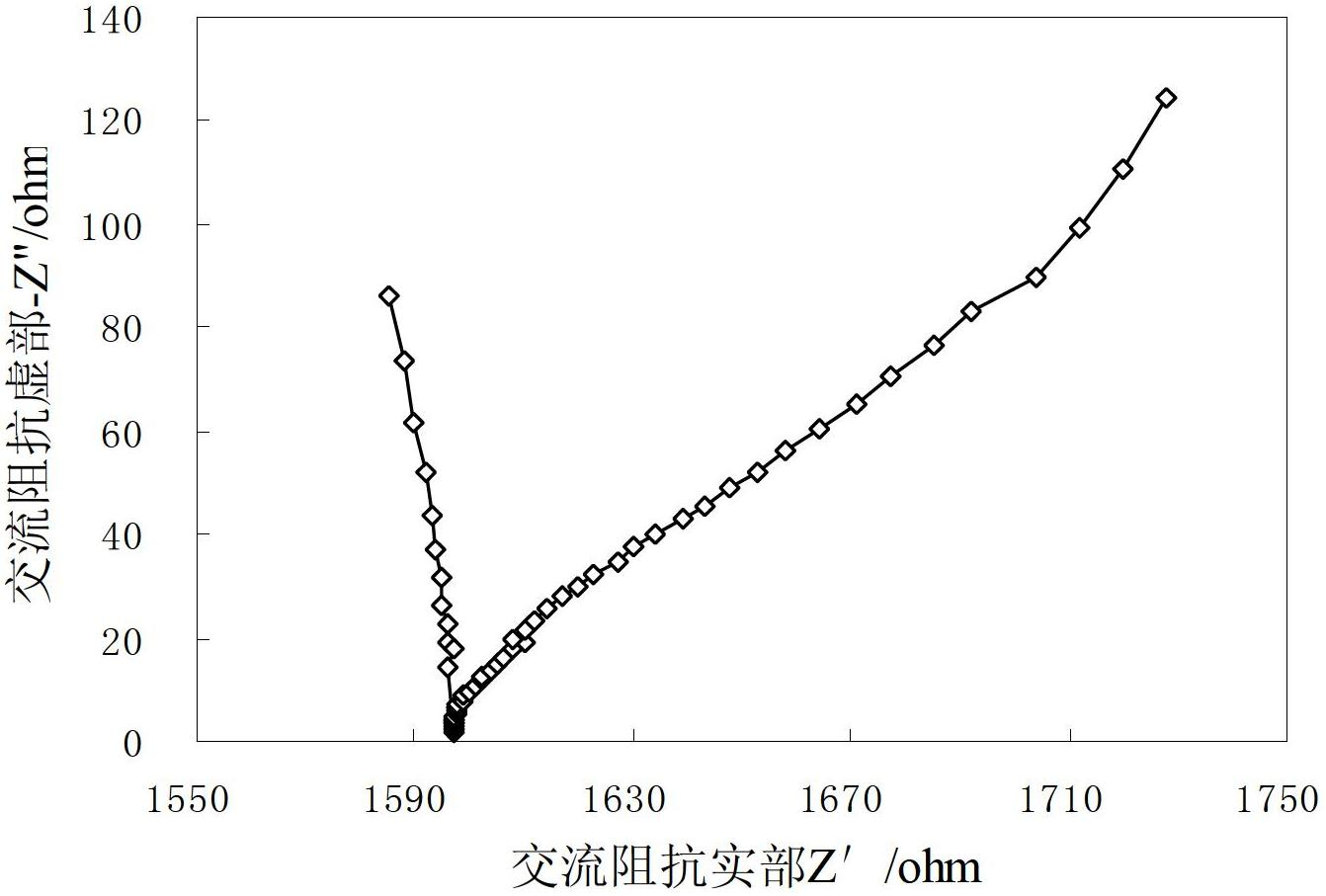

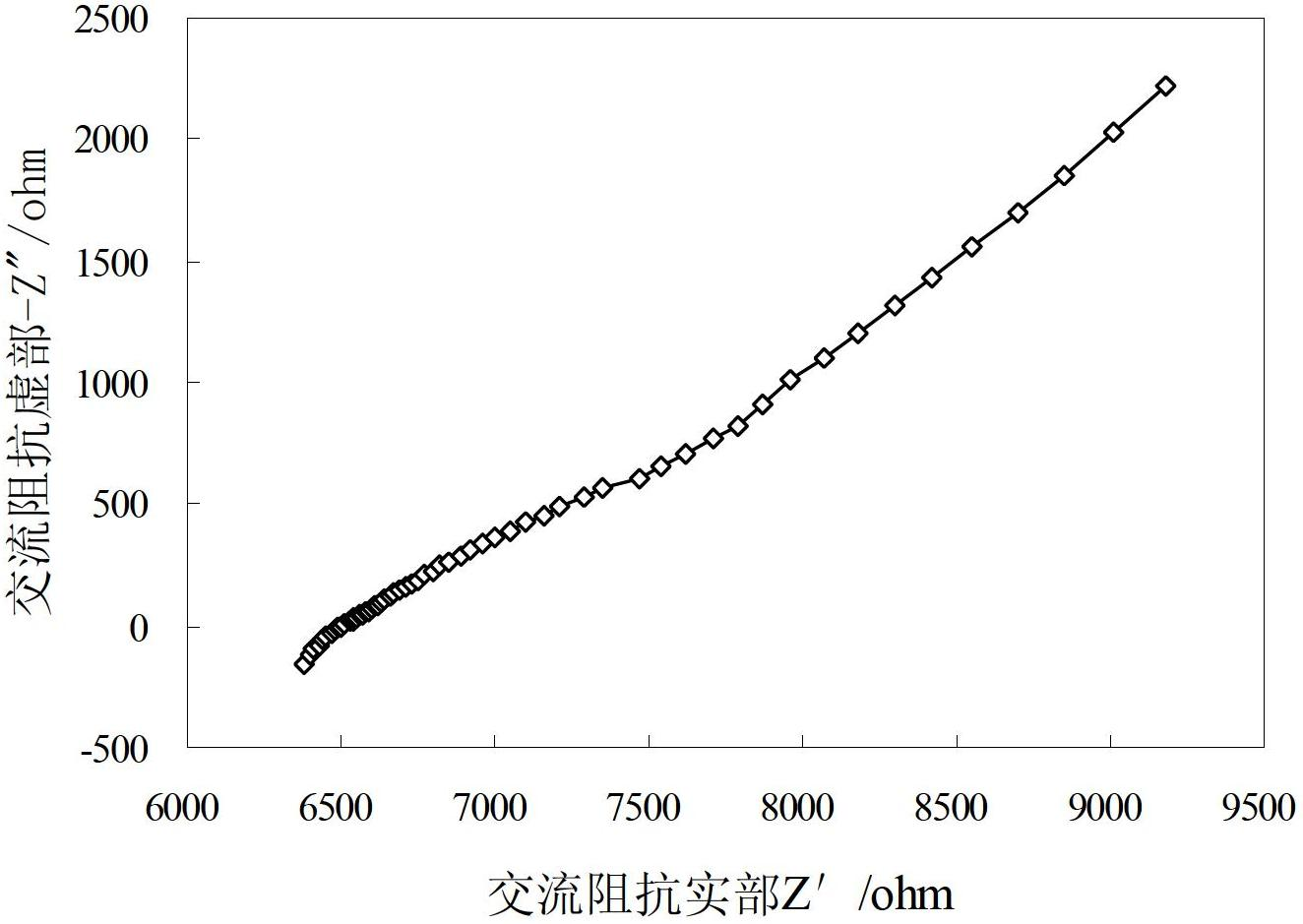

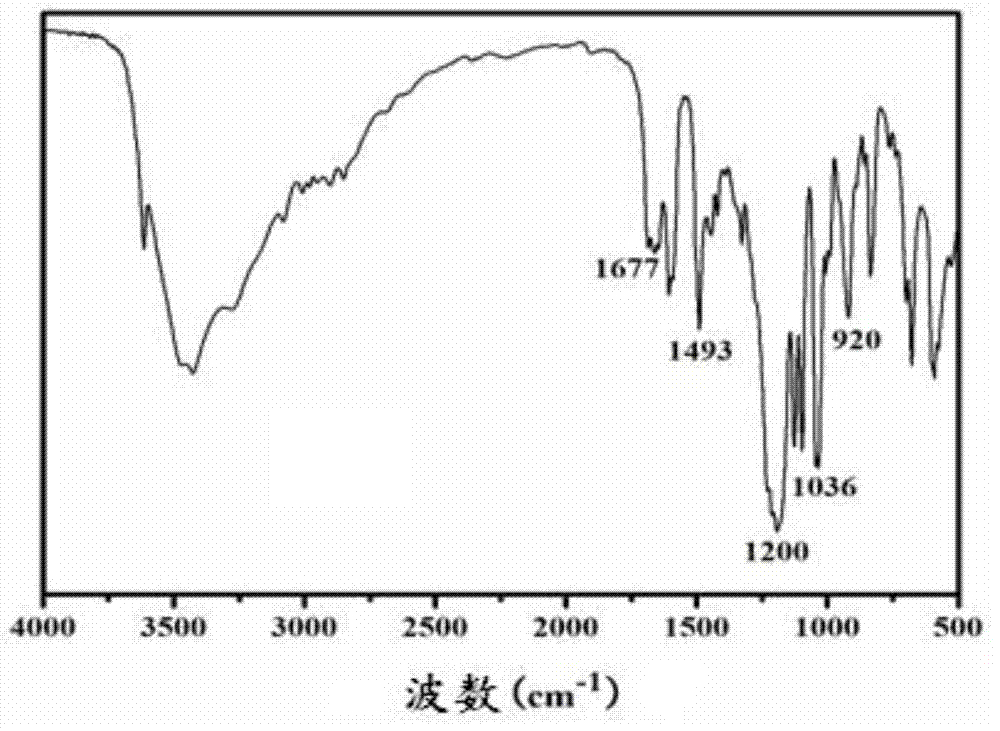

Preparation method of organic-inorganic composite proton exchange membrane for fuel cell

ActiveCN103296297AGood hygroscopicityStructurally intactSolid electrolyte fuel cellsFuel cell detailsFuel cellsSulfonated polymer

The invention belongs to the technical field of fuel cells, and in particular discloses a preparation method of an organic-inorganic composite proton exchange membrane for a fuel cell. The preparation method comprises the following steps of: oxidating a carbon nano tube first, then preparing the carbon nano tube coated by silicon dioxide by using a sol-gel method, and mixing dispersion liquid of the carbon nano tube coated by silicon dioxide with dispersion liquid of sulfonated polymers to prepare a solution casting membrane. The prepared composite proton exchange membrane has high water-absorbing performance and high alcohol resistant performance.

Owner:HUBEI ENG UNIV

Water-based paint for quick-drying alcohol-resistance plastics and preparation method thereof

The invention discloses a water-based paint for quick-drying alcohol-resistance plastics, comprising the following components by weight parts: 20-80 parts of modified polyacrylic ester water dispersoid, 1-25 parts of coloring pigment paste, 0-10 parts of filler pump, 5-25 parts of film formation assistant, 0.5-10 parts of assistant for water-based paint, and 10-50 parts of water. The invention further discloses a preparation method of the water-based paint, comprising the following steps: the water, the film formation assistant, polymer water dispersoid resin and the assistant for partial water-based paint are added in a make-up tank and are stirred uniformly, and then the coloring pigment paste and the assistant for the remaining partial water-based paint are sequentially added in and are stirred uniformly, the viscosity and pH value are regulated, filtering and discharging are carried out to obtain the water-based plastic paint finished products. The water-based paint is used for coating surface of the plastics, so as to achieve good decoration effect; in addition, the performance of the water-based paint is equivalent to that of solvent plastic paint, the water-based paint has good alcohol resistance and can be dried at 50 DEG C for 10 minutes, so as to meet the process requirements of manufacturers who use the solvent plastic paint at present.

Owner:GUANGZHOU KINTE IND

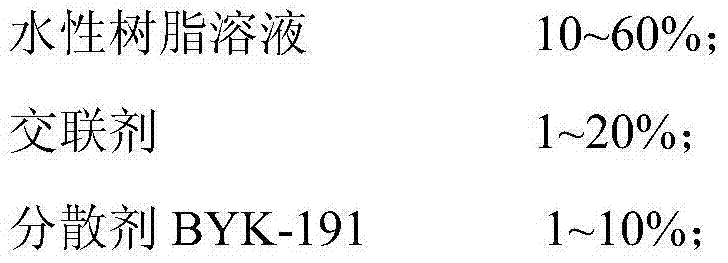

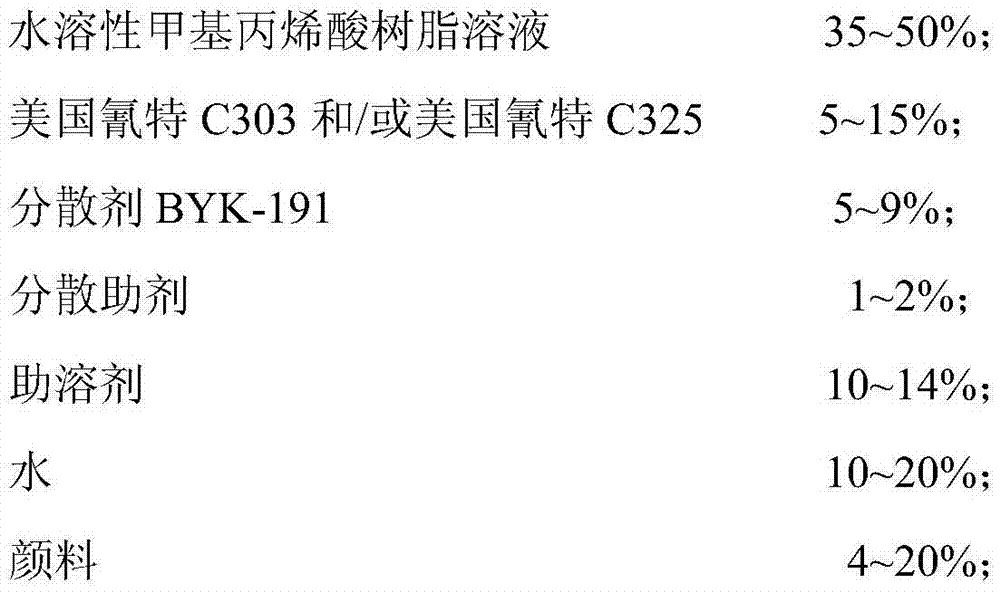

Water-based thermosetting glass printing ink and preparation method thereof

The invention discloses a water-based thermosetting glass printing ink and a preparation method thereof. The ink is composed of a water-based resin solution, a crosslinking agent, a dispersing agent BYK-191, an assistant, water and a pigment. The preparation method comprises the following steps: mixing part of the water-based resin solution with the dispersing agent BYK-191, assistant and pigment, and carrying out shear dispersion to obtain a slurry with the particle size of not greater than 20 micrometers; and adding the rest of water-based resin solution, assistant, crosslinking agent and water into the slurry, and sufficiently stirring. The preparation method is simple and cheap in raw materials; and the prepared water-based thermosetting glass printing ink has the characteristics of low cost, environment friendliness, favorable adhesive force with the glass substrate, favorable alcohol resistance, favorable water resistance, favorable abrasion resistance, high hardness and the like.

Owner:徐立新

Saccharomyces cerevisiae strain and method for preparing blueberry fruit wine by using saccharomyces cerevisiae strain

ActiveCN102911885AFruityStrong targetingFungiMicroorganism based processesBiotechnologyNutritive values

The invention discloses a saccharomyces cerevisiae strain and a method for preparing a blueberry fruit wine by using the saccharomyces cerevisiae strain. The saccharomyces cerevisiae strain is used for preparing the blueberry fruit wine by fermentation, and can maintain the blueberry flavor and the nutritive value of the fruit wine. The method comprises the following steps: activating the saccharomyces cerevisiae strain in a liquid seed culture medium; crushing blueberry and then adding an activated strain for carrying out primary fermentation for 7-9 days, filtering to obtain a fermentation liquor; and adding SO2 into the fermentation liquor for secondary fermentation for 12-14 days, and filtering to obtain a wine base. The blueberry fruit wine obtained through the method is fruity enough, and is high in nutritive value and stability.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Multi-layer carbinol resistance compound film for decomposition-resisting fuel battery and its making method

InactiveCN101034750AImprove resistance to degradationImprove mechanical propertiesCell electrodesFinal product manufactureDistillationDecomposition

The invention relates to the proton exchange membrane which is used for the fuel cell; put concretely it is an multi layered anti-alcohol compound membrane for anti- degenerating the fuel cell; is compound a layer Nafion proton exchange membrane which includes H2O2 decomposition catalyst on the altogether amixing hydrocarbon compound proton exchange membrane side or two sides. Its preparation method is, Nafion alcohol solution with the same volume high boiling point solvent, sets in the flask to reduce pressure distillation, removes alcohol, prepares the Nafion-high boiling point solvent solution, joins the H2O2 decomposition catalyst, the super-sonic surges 30 minutes, match the solution with H2O2 decomposition catalyst / (H2O2 decomposition catalyst +Nafion) load ratio is 1-10%, the solution compound altogether mixing hydrocarbon compound proton exchange membrane side or two sides, after treats solvent volatility, puts in the vacuum drying oven, under 120-160 degree centigrade, handing 2-8 hours, namely obtains the multilayered anti- mellow compound membrane which is used for anti- degeneration fuel cell. The multi layered anti-alcohol compound membrane for anti- degenerating the fuel cell in the invention has good anti-alcohol performance, high conductivity, the high anti-degeneration ability, good mechanics machine capability,the low cost and so on characteristic.

Owner:BEIJING JIAOTONG UNIV

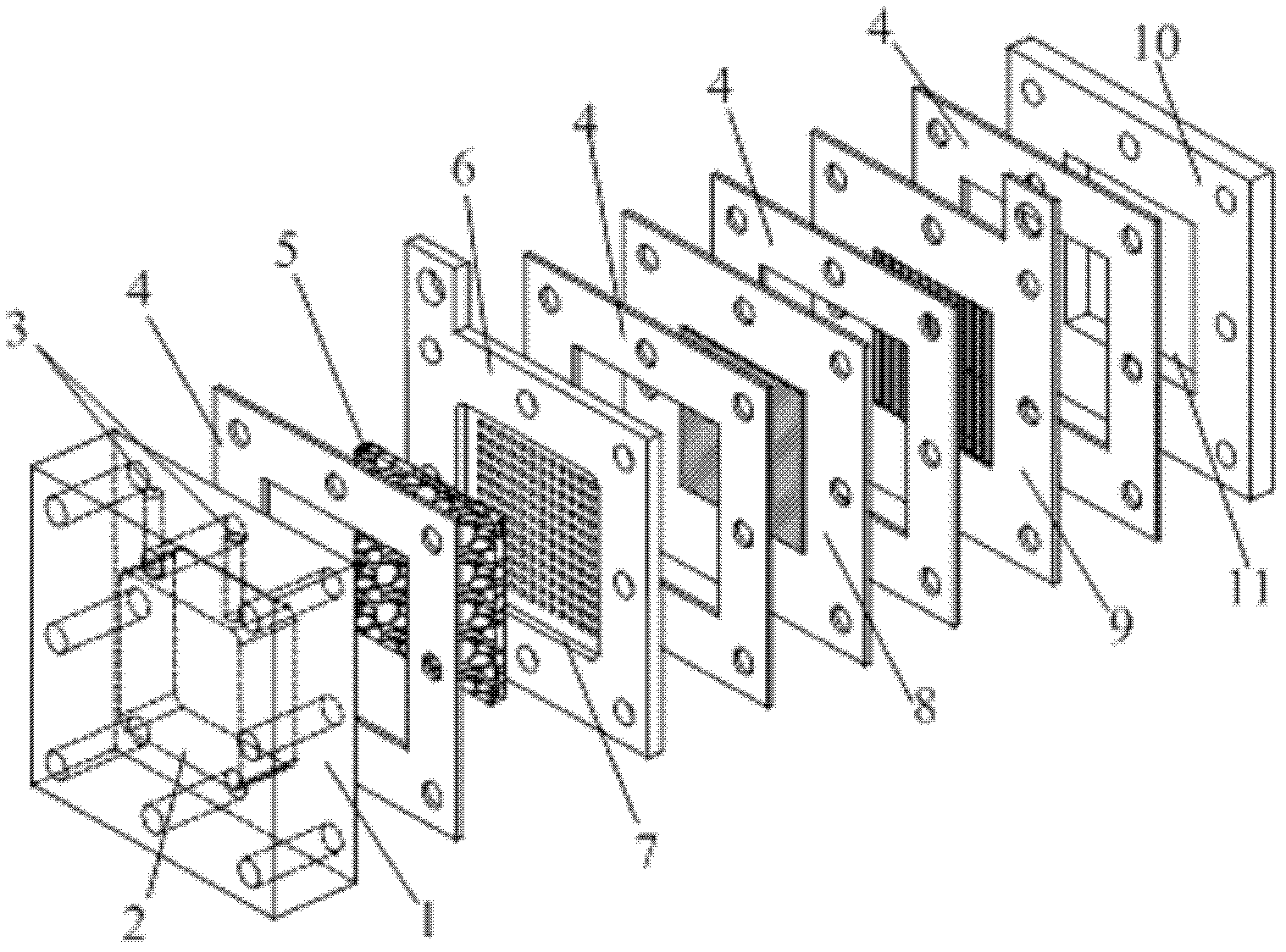

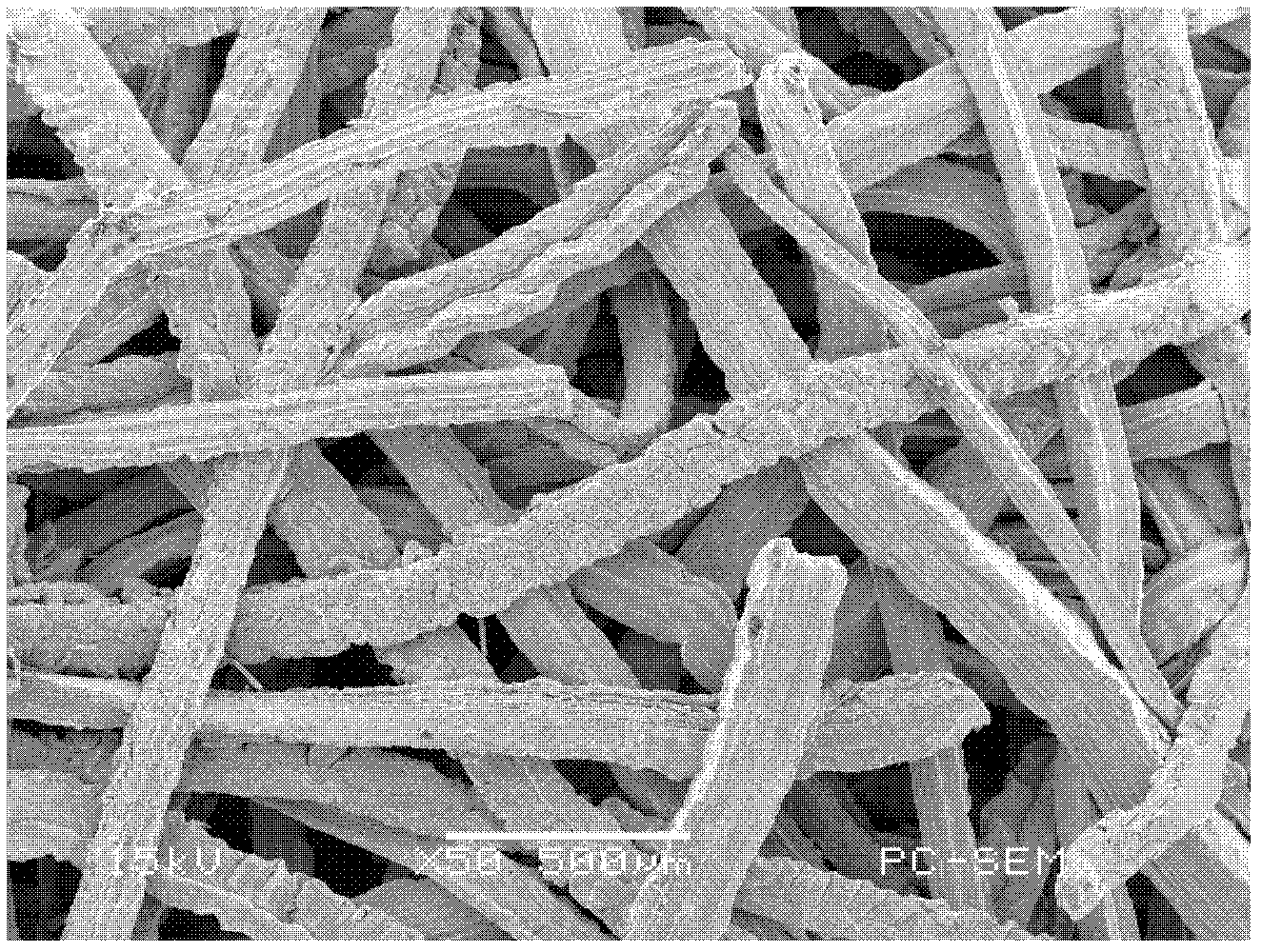

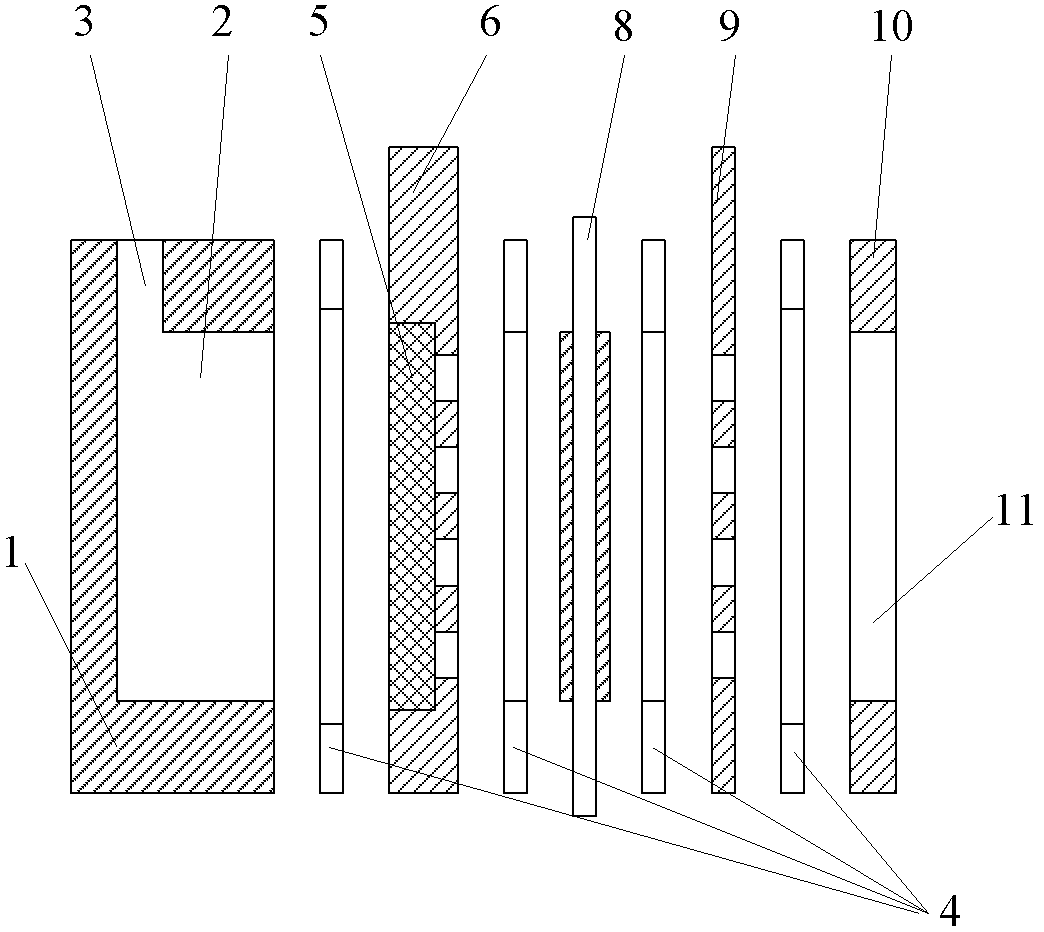

Self-breathing direct methanol fuel cell monomer based on porous metal fiberboard

InactiveCN102324533AExcellent hydrophobic propertiesImprove alcohol resistanceSolid electrolyte fuel cellsFuel cell detailsFiberFuel cells

The invention discloses a self-breathing direct methanol fuel cell monomer based on a porous metal fiberboard. The cell monomer comprises an anode fuel chamber, a cell working unit and a cathode open type end plate, wherein the cell working unit comprises an anode collector plate, a membrane electrode and a cathode collector plate; two sides of the membrane electrode are respectively provided with the anode collector plate and the cathode collector plate; the anode fuel chamber and the cathode open type end plate used as a cell shell are respectively arranged at the outer sides of the anode collector plate and the cathode collector plate; the middle part of the anode collector plate is provided with a porous metal fiberboard, the porous metal fiberboard is formed by sintering copper metal fibers with diameter of 20-200 mu m, the porosity is 70%-90%, the permeability is 10<-12>-10<-9>m<2>, and the average pore size is 50 mu m to 500 mu m. According to the invention, because of the adoption of the porous metal fiberboard, the methanol penetration problem can be effectively solved and effective water management is realized, thus the fuel availability of the passive self-breathing direct methanol fuel cell can be improved and the output performance of the cell can be improved.

Owner:SOUTH CHINA UNIV OF TECH

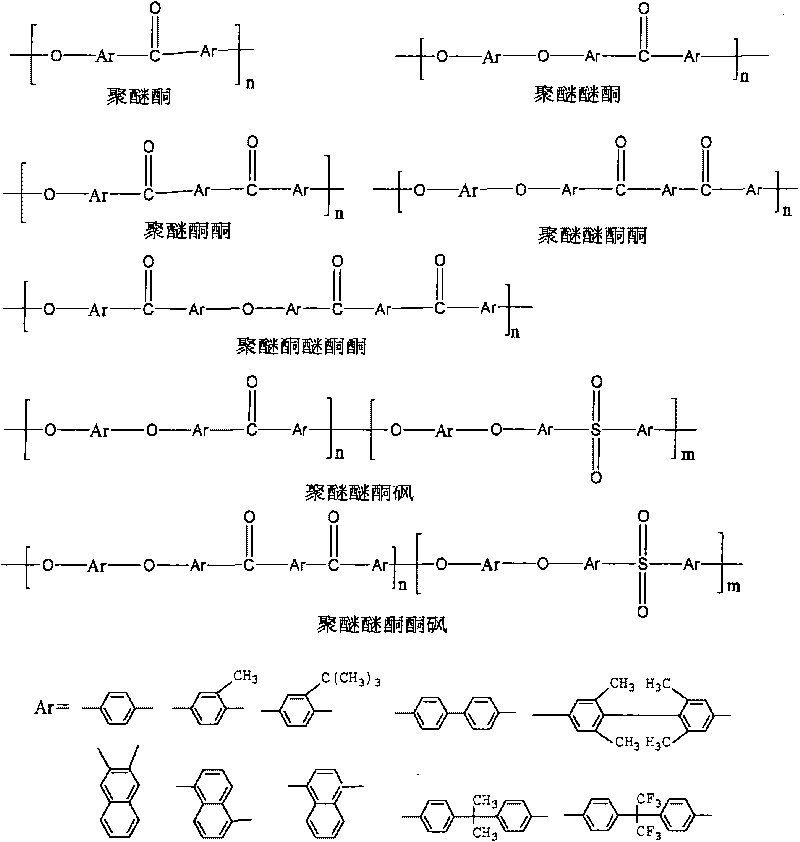

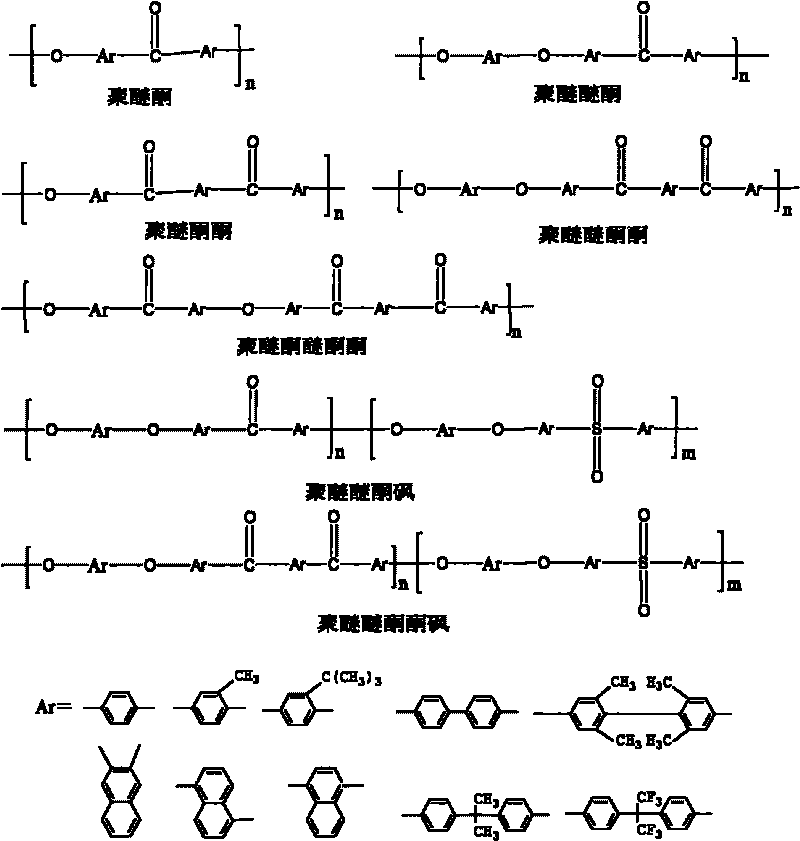

Method for modifying sulfonated polyaryetherketone and method for preparing polymer electrolyte material

The invention relates to a method for modifying sulfonated polyaryetherketone and a method for preparing a polymer electrolyte material, and belongs to the technical field of the preparation of functional polymer materials. The method comprises the following steps: dissolving the sulfonated polyaryetherketone in a solvent; introducing inert gas and adding a reducing agent with stirring; performing vacuum drying to obtain reduced and modified sulfonated polyaryetherketone; adding a catalyst and a crosslinker into the solution of reduced and modified sulfonated polyaryetherketone under the inert gas, and stirring the mixture to prepare membrane liquor; performing membrane preparation; completing a crosslinking reaction in the process of membrane forming; and performing demoulding and washing for airing to obtain a cross-linked polymer electrolyte membrane material, wherein the crosslinker is polyaldehyde or polybasic carboxylic acid. The modification method has the characteristics of easily obtained raw materials and simple operation; the prepared cross-linked polymer electrolyte material has the advantages of excellent mechanical strength, conductivity, methanol-blocking performance and dimensional stability, can be directly used in the fields of methanol fuel cells, proton exchange membranes of proton exchange membrane fuel cells, ion exchange resin, membrane separation, sensors and the like, and has important application value.

Owner:TSINGHUA UNIV

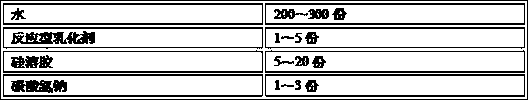

Silica sol hybrid hydroxyl acrylate emulsion and preparing method thereof

InactiveCN108084359AImprove water resistanceHigh glossAntifouling/underwater paintsPaints with biocidesSulfonateEmulsion

The invention relates to a silica sol hybrid hydroxyl acrylate emulsion and a preparing method thereof. A semi-continuous seed emulsion polymerization method is adopted, a hard monomer serves as a core, hard and soft monomers and a hydroxyl acrylatemonomer serve as a housing, organic silane is added into the housing to conduct modification, emulsifiers are all reactive emulsifiers, a sulfonate-modified HDI curing agent (Aquolin-268) of Wanhua Company is selected, and the ratio of the reactive emulsifiers tothe sulfonate-modified HDI curing agent is 10:1. The hardness of film reaches 3H, the silica sol hybrid hydroxyl acrylate emulsion is high in gloss and adhesive force and excellent in water resistance and alcoholresistance, and all other physical and chemical propertiescan meet nationalstandard requirements.

Owner:江苏日出化工有限公司

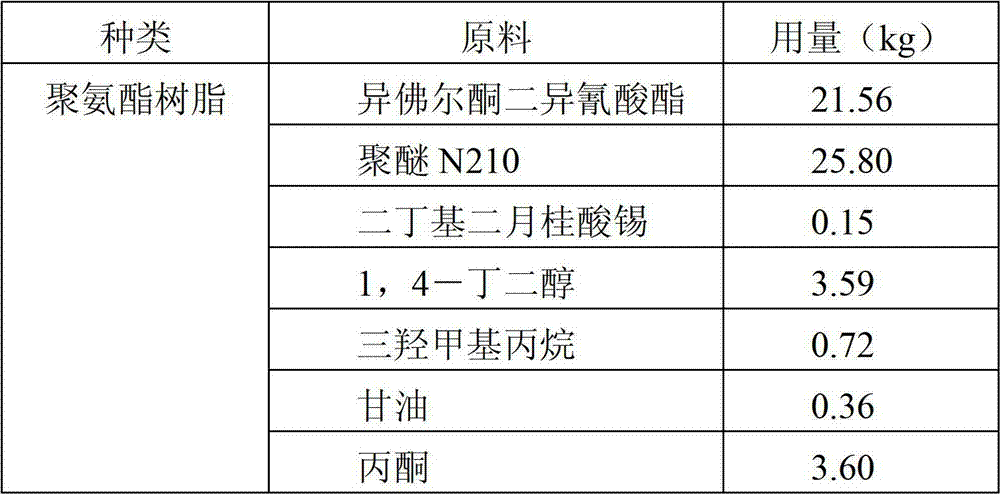

Water-based polyurethane solution and preparation process thereof

InactiveCN102002143AReduce usageImprove water resistancePolyurea/polyurethane coatingsPolyesterWater based

The invention discloses water-based polyurethane solution and a preparation process thereof. The preparation process comprises the following steps of: dewatering polyester polyol for 1 to 2h under vacuum at the temperature of 120 DEG C; cooling to 80 DEG C and adding isophorone diisocyanate into the dewatered polyester polyol; heating to 90 DEG C and reacting for 2h; cooling to 80 DEG C and adding dimethylol propionic acid (DMPA) and N-methylpyrrolidone into the mixed solution and continuously reacting for 1h; cooling to 60 DEG C, adding AS-15, 1,4-butanediol and dibutyltin dilaurate into the mixed material, adding acetone for adjusting viscosity and reacting; cooling to below 50 DEG C, adding triethylamine, stirring for 0.5h and obtaining a pre-polymer; cooling to below 15 DEG C, dispersing distilled water at the temperature of below 15 DEG C into the prepolymer for 5 minutes at a high speed, instantly adding ethylenediamine for chain extension, dispersing for 0.5h at a high speed and then dispersing for 1h at an intermediate speed; removing acetone under vacuum, adjusting pH to 7.5 with ammonia water and then adding SC-100 into the mixed solution; stirring uniformly, filtering and then packaging. The water-based polyurethane solution has high water resistance, alcohol resistance and hardness; and water is used as a solvent, so that the use of energy resources such as petroleum is reduced and environment is protected at the same time.

Owner:ZHEJIANG FEIDA ZHONGKE FINE CHEM

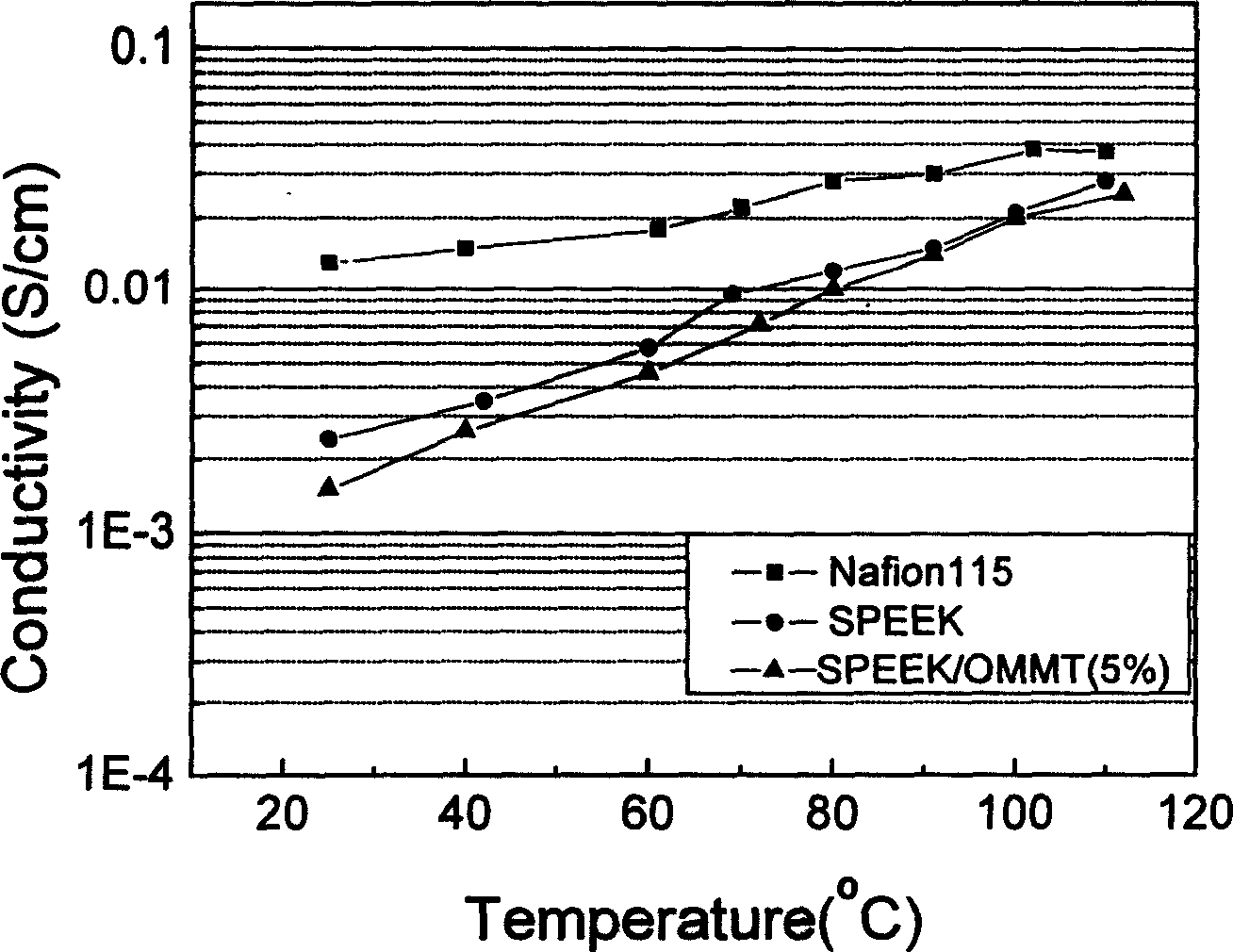

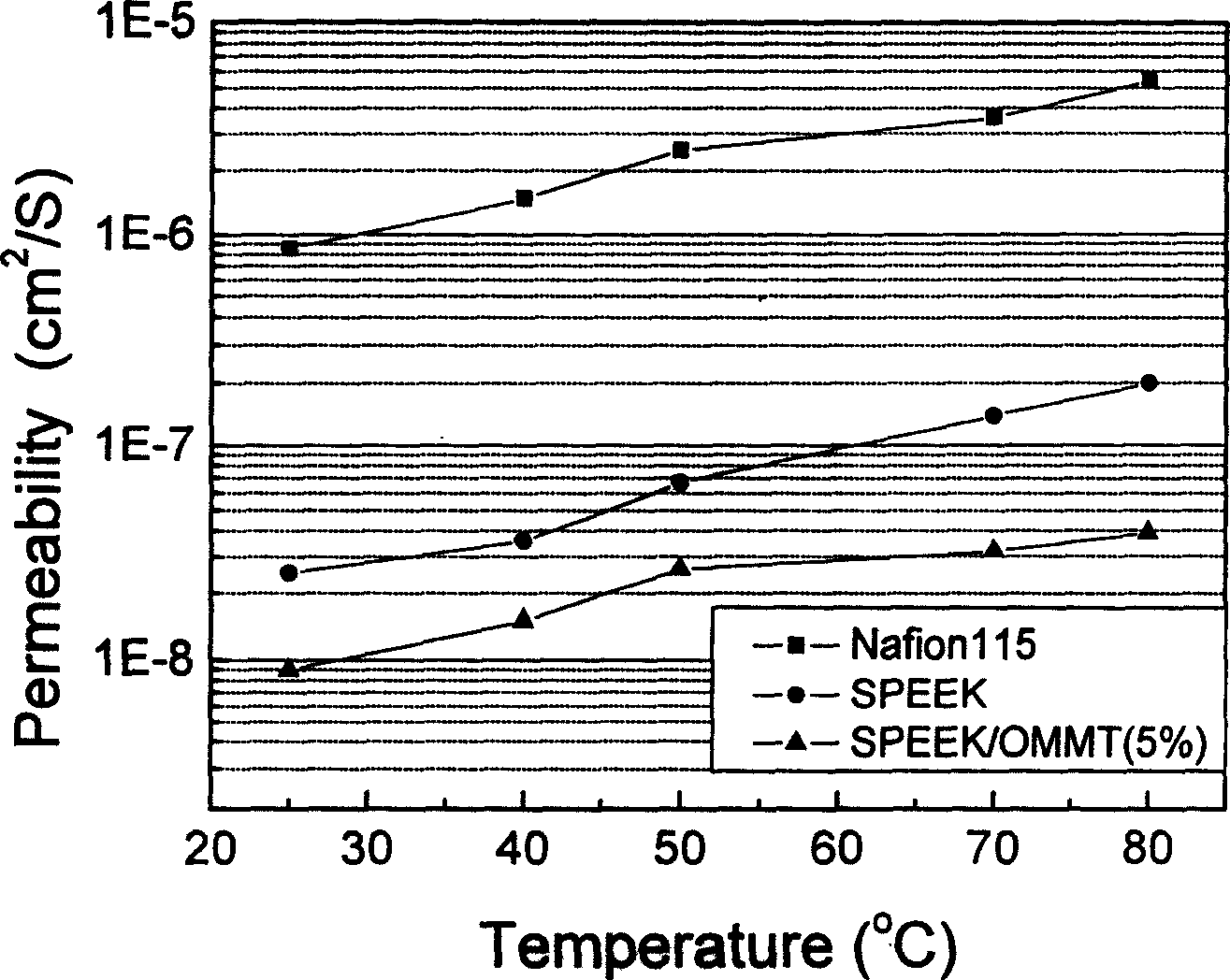

Organic-inorganic compoiste proton exchange film and preparing method

InactiveCN1677732AReduce penetrationIncrease profitCell electrodesFuel cellsPolymer scienceFuel cells

In the method, sulfonated polymer is dissolved in organic solvent. Added organic modified montorillonite clay is dispersed on basal body of polymer evenly. Membrane is formed through slobbering method. Through drying and stripping membrane in water produces membrane needed. Solving difficult problem of methanol infiltration of proton exchange membrane in use for direct fuel cell of methanol, the invention possesses features of simpler technique, and low cost of material etc.

Owner:SOUTH CHINA UNIV OF TECH

Bacterial cellulose-Nafion sandwich proton exchange membrane and preparation and application thereof

ActiveCN102694139AImprove proton conductivityImprove thermal stabilitySynthetic resin layered productsCell component detailsFuel cellsMethanol fuel

The invention relates to a bacterial cellulose-Nafion sandwich proton exchange membrane. The sandwich proton exchange membrane is in a BC-Nafion-BC or Nafion-BC-Nafion structure. The preparation comprises the following steps: soda boiling and washing the bacterial cellulose membrane to acquire a gel-like bacterial cellulose membrane; stacking the gel-like bacterial cellulose membrane, the treated Nafion membrane and the gel-like bacterial cellulose membrane in sequence, or stacking the treated Nafion membrane, the gel-like bacterial cellulose membrane and the treated Nafion membrane in sequence, or drying and soaking the gel-like bacterial cellulose membrane in a Nafion solution, drying the soaked bacterial cellulose membrane; and finally toughening the dried bacterial cellulose membrane. According to the invention, the sandwich proton exchange membrane has lower methanol permeability, higher proton conductivity and high thermal stability, and a good application prospect in a methanol fuel cell. The preparation process is simple and easy, and has little pollution to the environment.

Owner:DONGHUA UNIV

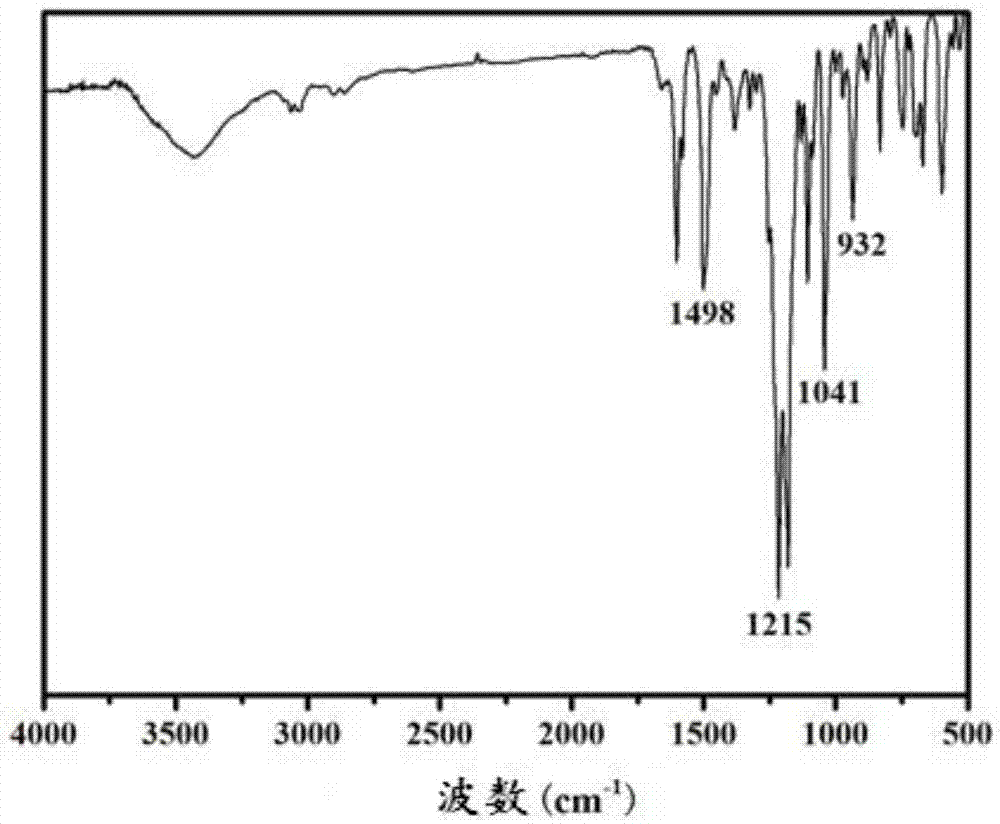

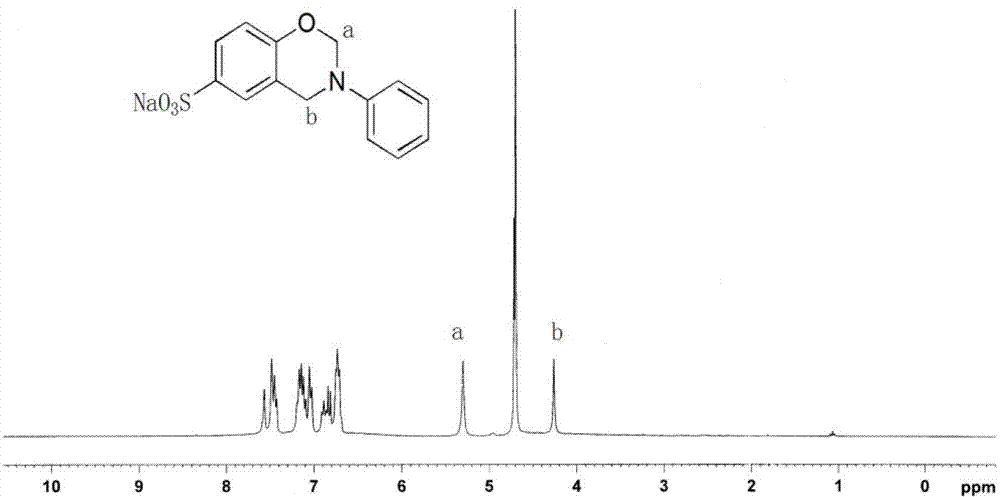

Benzoxazine resin containing sulfonic group, and preparation method and application thereof

ActiveCN103044348AImprove thermal stabilityStrong acid resistanceOrganic chemistrySolid electrolyte fuel cellsAlcoholMannich reaction

The invention discloses a benzoxazine resins containing sulfonic groups. The method of the invention uses phenol or aminated compounds containing sulfonic groups and formaldehyde as raw materials, by Mannich reaction, to synthesize a series of novel benzoxazine monomers containing sulfonic groups. The benzoxazine monomers are heated to form a polybenzoxazine film containing sulfonic groups by ring-opening polymerization. The new synthesis process directly introduces sulfonic groups onto benzene rings, so the products have advantages of high heat stability, strong acid resistance, good dimension stability, good alcohol rejecting performance, low synthesis cost, and vast application prospect in the proton exchange membrane fuel cell field.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com