Preparation method of organic-inorganic composite proton exchange membrane for fuel cell

A proton exchange membrane and inorganic composite technology, which is applied to fuel cell components, fuel cells, solid electrolyte fuel cells, etc., can solve the problem that the comprehensive performance of the composite membrane cannot meet the actual needs, the damage of the carbon tube structure is large, and it is not easy to control, etc. problems, achieve excellent water absorption and water retention properties, increase alcohol resistance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of an organic-inorganic composite proton exchange membrane for a fuel cell, the steps are as follows:

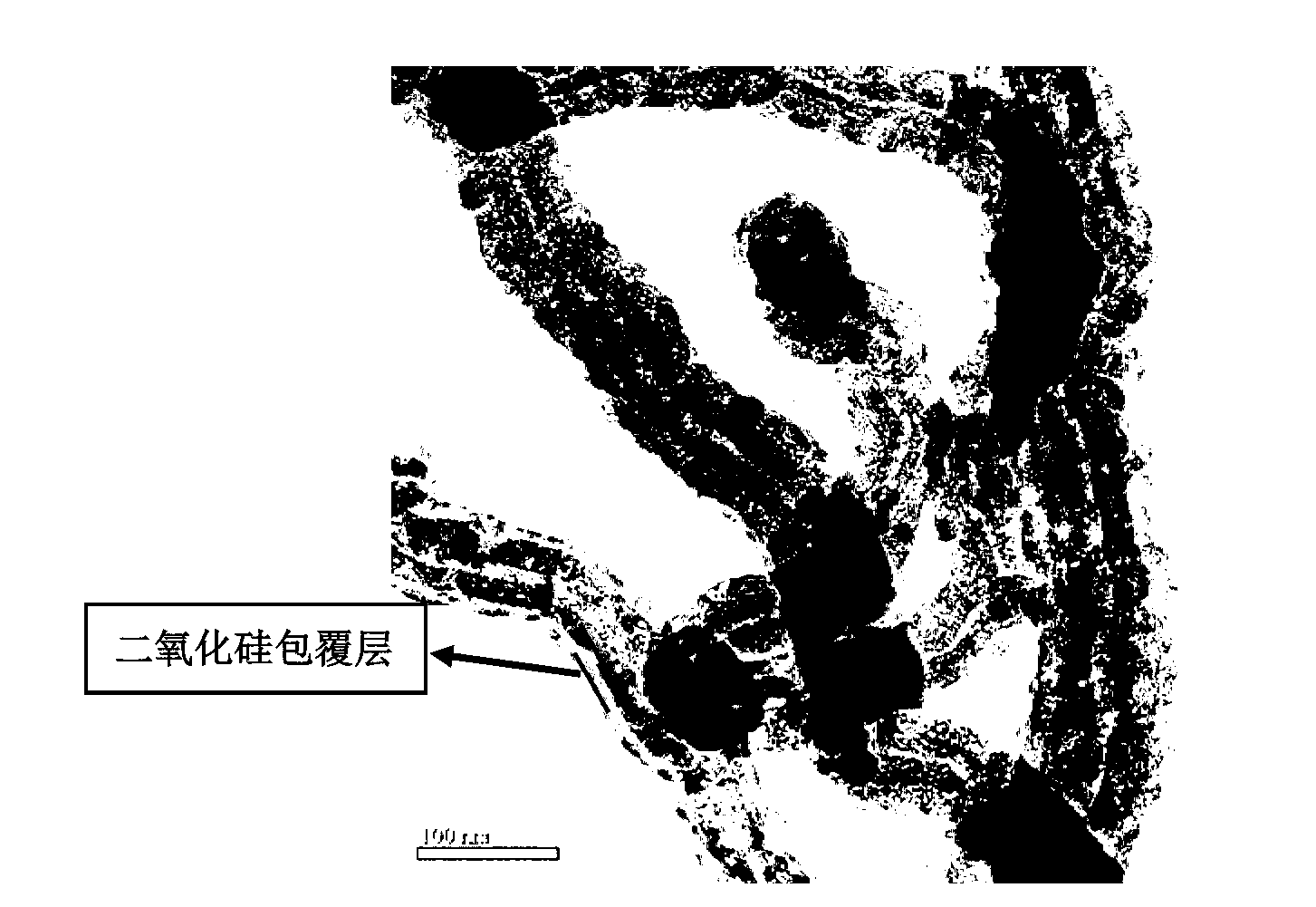

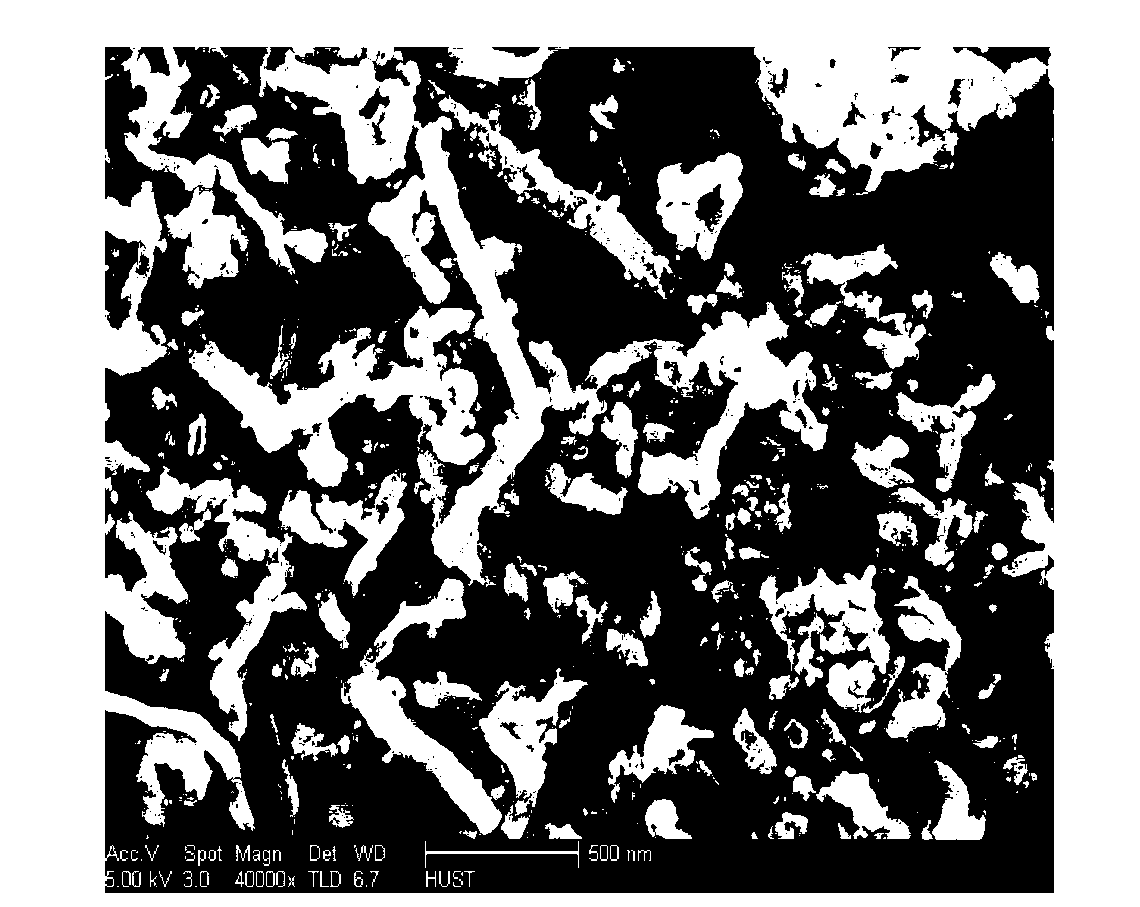

[0037] Put 1g of carbon nanotubes in 50mL of 30wt% hydrogen peroxide, stir and oxidize at room temperature for 3 hours, then filter, wash the solid repeatedly with deionized water until the filtrate pH=7, and dry in vacuum at 60°C for 24 hours to obtain oxidized carbon nanotubes . Take 0.8g of oxidized carbon nanotubes and disperse them in a mixed solution consisting of 12.6mL of tetraethyl orthosilicate and 167mL of absolute ethanol, add dropwise an ammonia solution containing 67mL of water at pH=8.5, after the dropwise addition, continue to Stir for 10 hours, filter, wash repeatedly with deionized water until the filtrate pH=7, filter with suction, and dry to obtain carbon nanotubes coated with silicon dioxide (transmission electron microscope as shown in figure 1 As shown, the scanning electron microscope image is shown in figure 2 shown). ...

Embodiment 2

[0051] A preparation method of an organic-inorganic composite proton exchange membrane for a fuel cell, the steps are as follows:

[0052] Put 1g of carbon nanotubes in 75mL of 30wt% hydrogen peroxide, stir and oxidize at 50°C for 3 hours, cool to room temperature, filter, wash the solid repeatedly with deionized water until the filtrate pH=7, and dry in vacuum at 60°C for 24 hours to obtain the oxidation processed carbon nanotubes. Disperse 0.8g of oxidized carbon nanotubes in a mixed solution consisting of 10mL of tetraethyl orthosilicate and 150mL of absolute ethanol, add dropwise an ammonia solution containing 60mL of water at pH=9, after the dropwise addition, continue to stir at room temperature After 8 hours, filter, wash repeatedly with deionized water until the pH of the filtrate is 7, filter with suction, and dry to obtain carbon nanotubes coated with silicon dioxide. Disperse 0.5 g of silica-coated carbon nanotubes in 35 mL of isopropanol, and ultrasonically vibrat...

Embodiment 3

[0054] A preparation method of an organic-inorganic composite proton exchange membrane for a fuel cell, the steps are as follows:

[0055] Put 1g of carbon nanotubes in a mixture of 25mL65wt% concentrated nitric acid and 75mL98wt% concentrated sulfuric acid, stir and oxidize at 60°C for 8 hours, cool to room temperature, filter, and wash the solid repeatedly with deionized water until the pH of the filtrate=7 , 60 ° C vacuum drying for 24 hours to obtain oxidized carbon nanotubes. Disperse 0.8 g of oxidized carbon nanotubes in a mixed solution consisting of 8 mL of tetraethyl orthosilicate and 60 mL of absolute ethanol, add dropwise a pH=3 hydrochloric acid solution containing 56 mL of water, and continue stirring at room temperature after the dropwise addition After 6 hours, filter, wash repeatedly with deionized water until the filtrate pH=7, filter with suction, and dry to obtain carbon nanotubes coated with silicon dioxide. Disperse 0.5g of silica-coated carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com