Patents

Literature

140results about How to "Fully swollen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

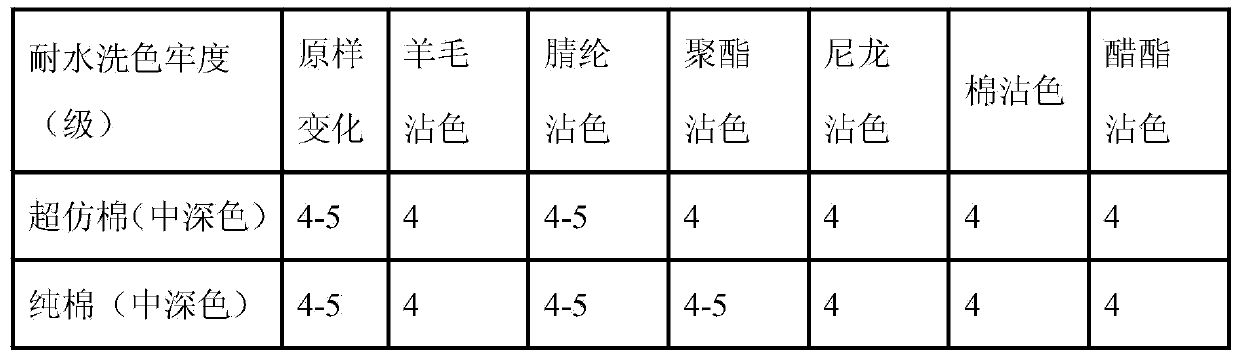

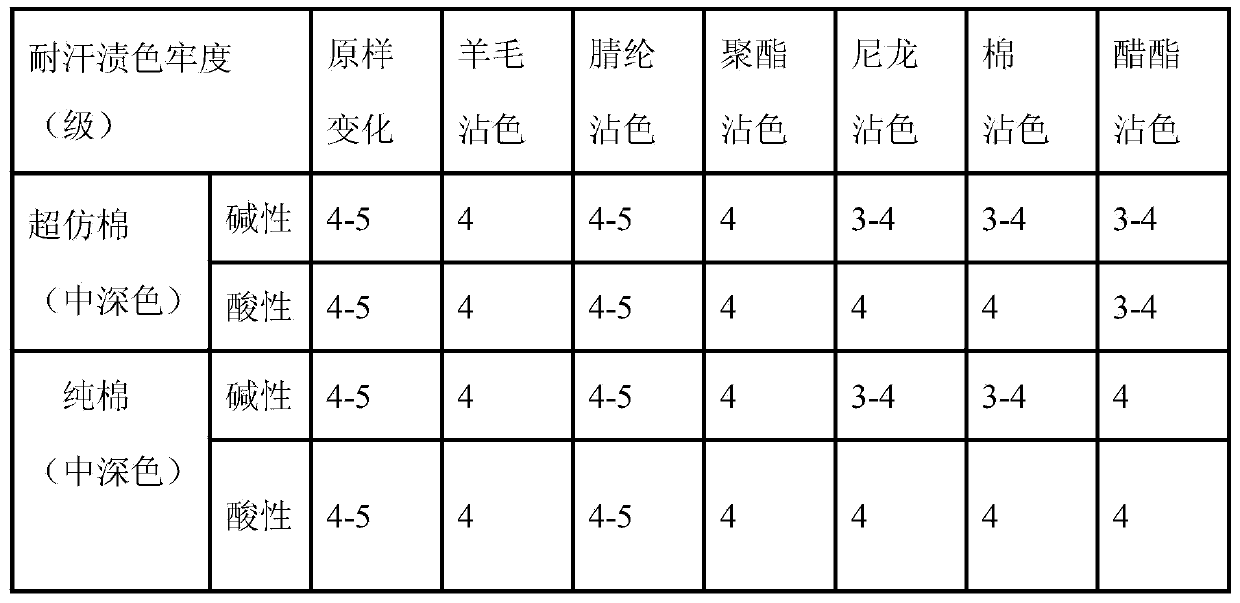

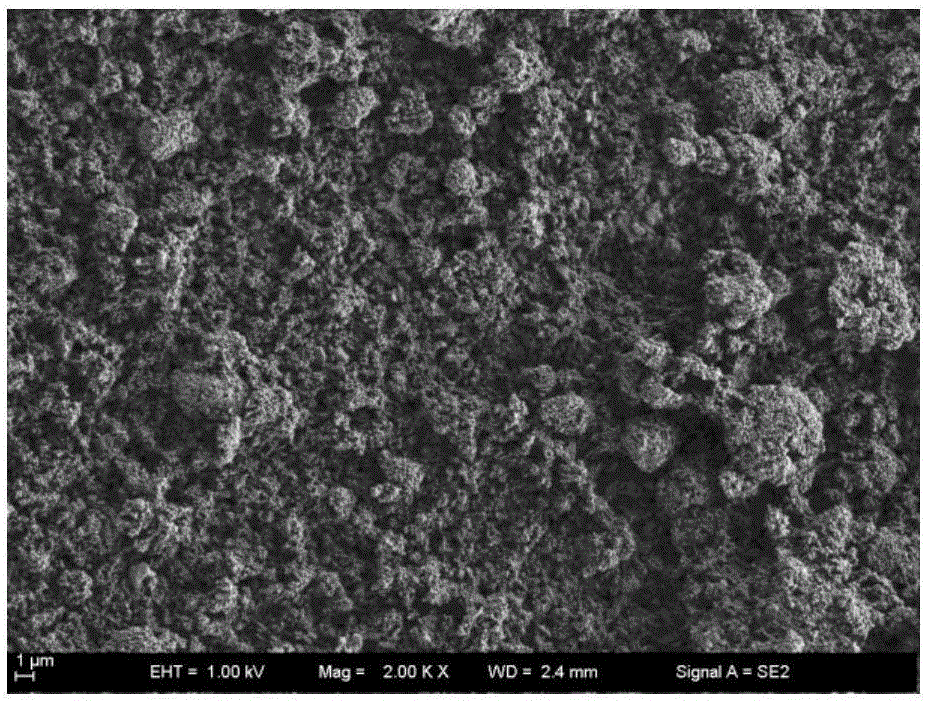

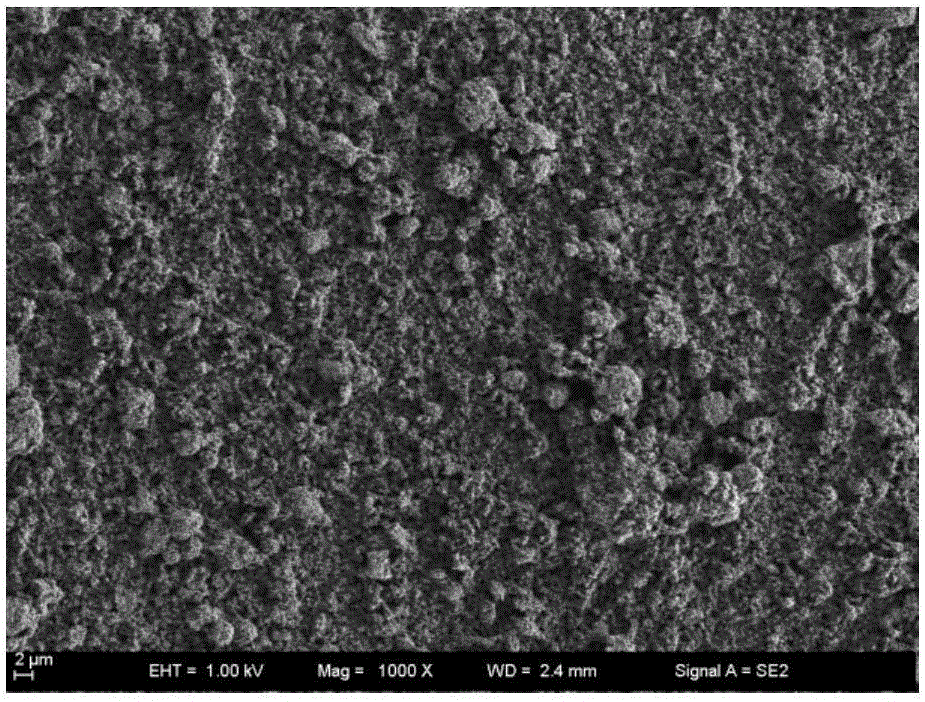

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

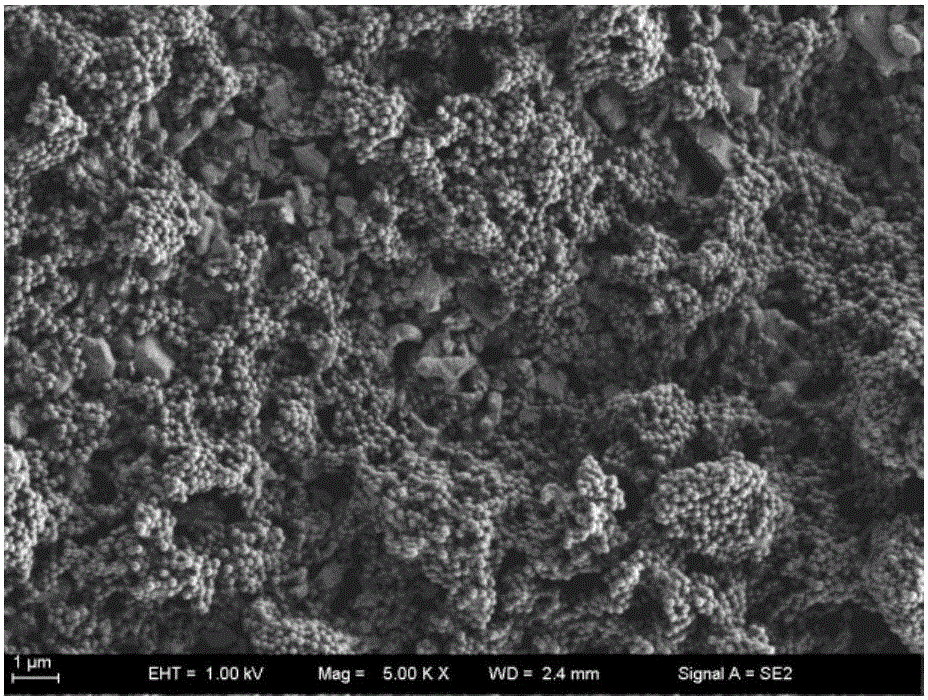

High-temperature-resisting lithium-ion battery membrane with plurality of types of coatings and preparation method of high-temperature-resisting lithium-ion battery membrane

The invention provides a high-temperature-resisting lithium-ion battery membrane with a plurality of types of coatings and belongs to the technical field of battery membranes. The high-temperature-resisting lithium-ion battery membrane is prepared from a coating membrane composed of a battery membrane with one surface or double surfaces coated with coating slurry; one surface or double surfaces of the coating membrane are coated with slurry additional layers; each slurry additional layer comprises at least one layer of coating composed of the coating slurry. The invention further provides a preparation method of the high-temperature-resisting lithium-ion battery membrane with the plurality of types of coatings; the battery membrane has the advantages that a coating membrane has relatively high safety on a battery; meanwhile, the battery membrane can also be used for resisting high temperature, reducing the shrinkage rate of the membrane under a high-temperature condition and prolonging the service life of the battery; the high-temperature-resisting lithium-ion battery membrane can be used for improving the affinity of the membrane and electrolyte and can guarantee that the membrane is sufficiently swollen through the electrolyte and the service life of the battery is prolonged.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

Method for desizing cotton yarn-dyed fabrics

ActiveCN104018336AIncrease effective contactConducive to decompositionDry-cleaning apparatus for textilesChemistryYarn

The invention discloses a method for desizing cotton yarn-dyed fabrics and belongs to the cotton yarn-dyed fabric pretreatment technology field of printing and dyeing industries. The cotton yarn-dyed fabrics are subjected to compound bio-enzyme desizing treatment after being pretreated by hot water, are subjected to enzyme deactivation treatment after stacking to remove active enzyme remaining in the fabrics, and then are washed and dried. The method aims at solving the technical problem that starch sized cotton yarn-dyed fabrics alpha-amylase padding-steaming stacking method is poor in desizing effect and starch size still remains on desized yarn-dyed fabrics, so that after-treatment quality of the yarn-dyed fabrics is influenced, thus the purpose of improving the desizing effect of the yarn-dyed fabrics is achieved.

Owner:JIANGSU LIANFA TEXTILE +1

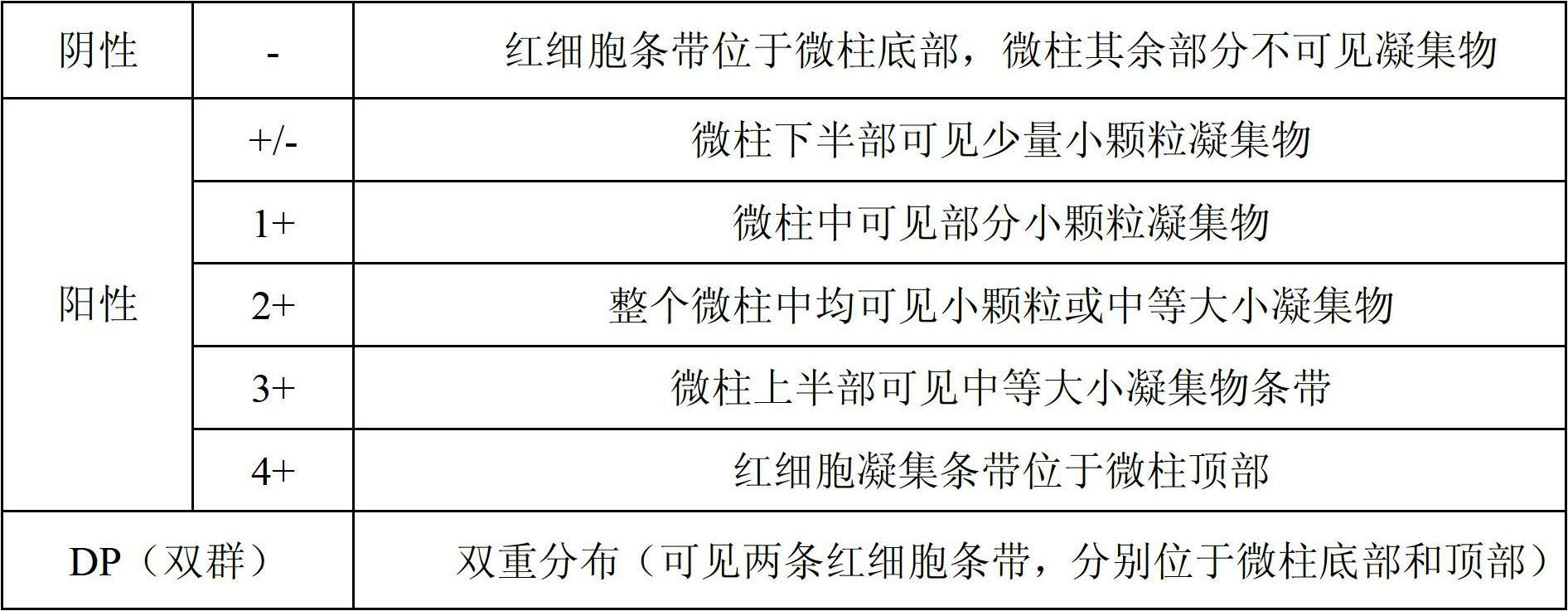

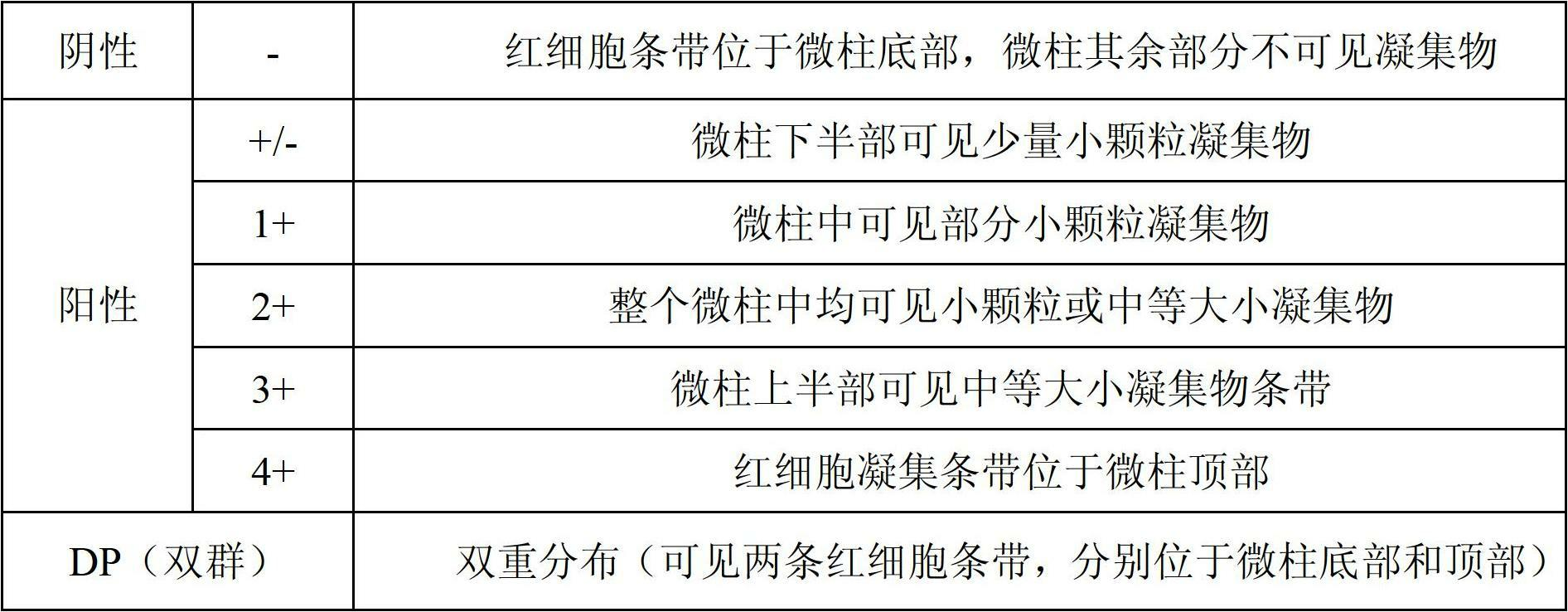

Forward and reverse ABO typing and RhD blood type detecting card

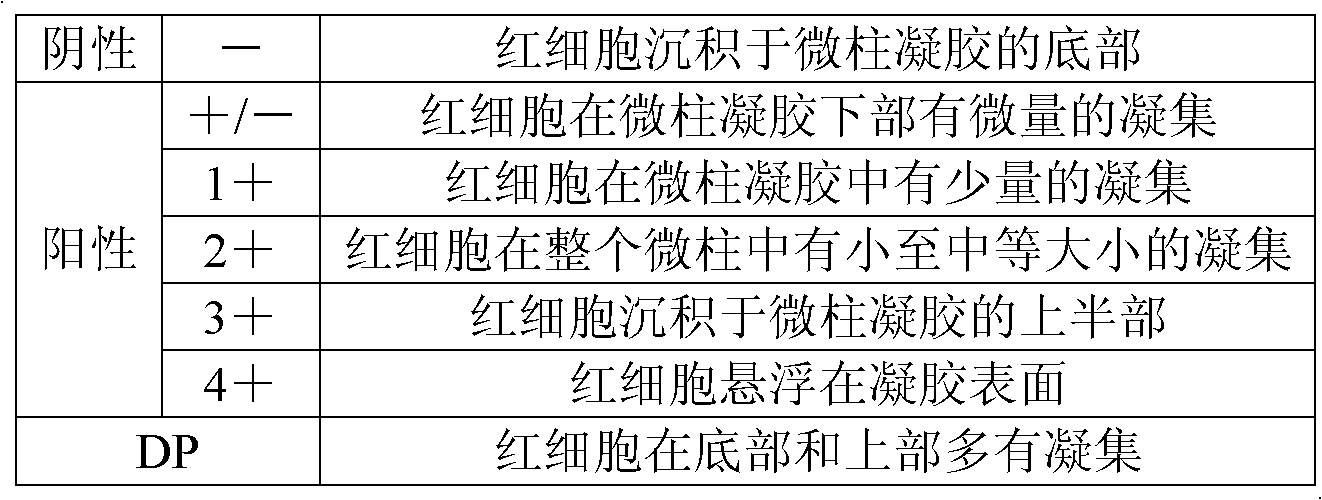

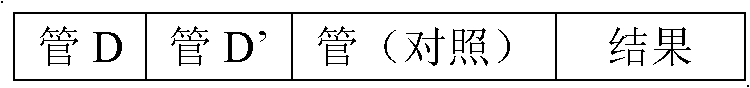

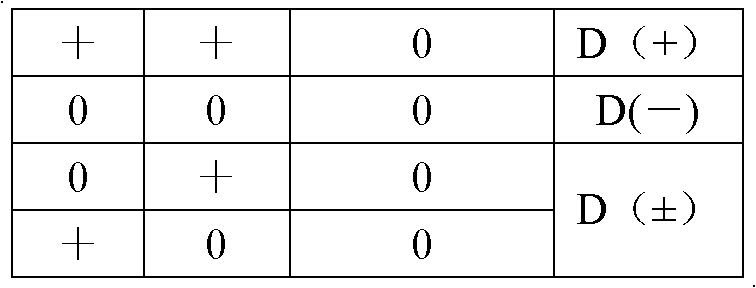

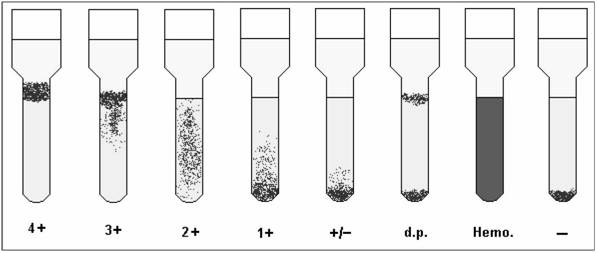

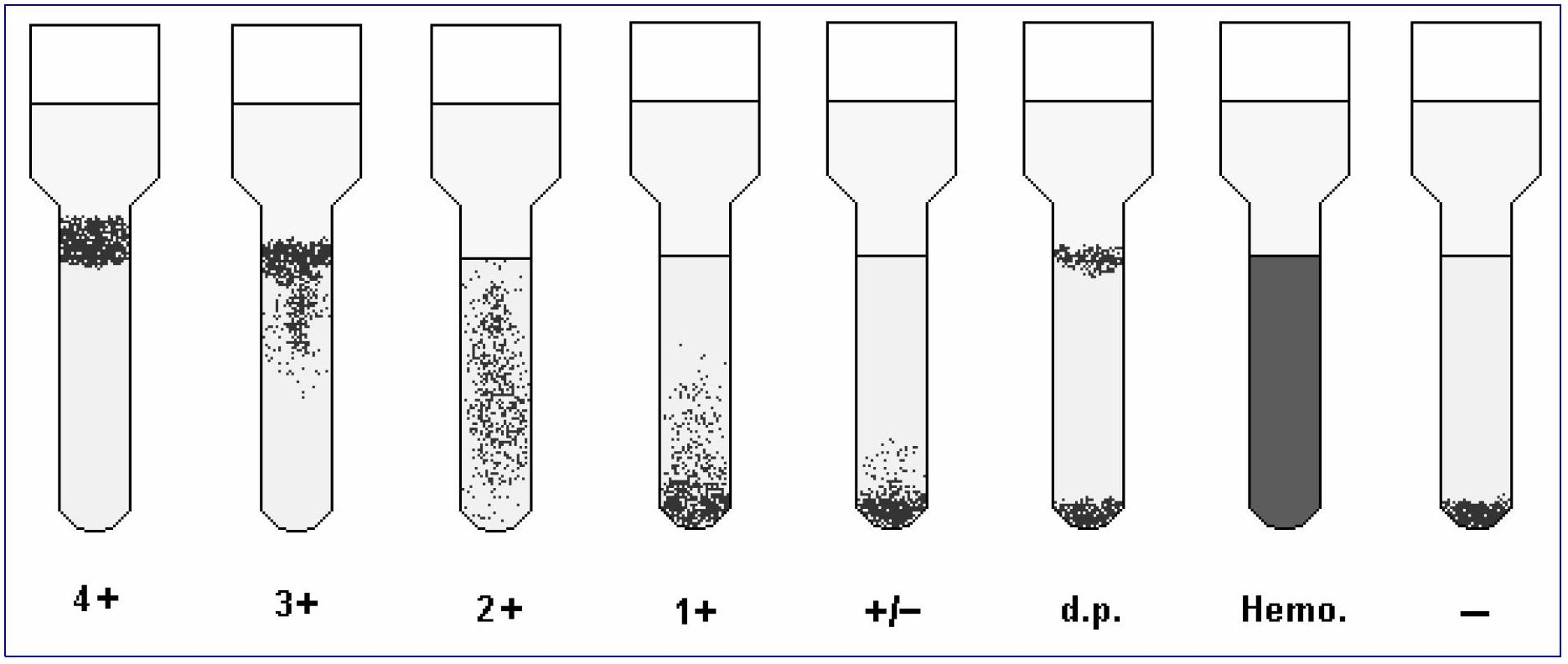

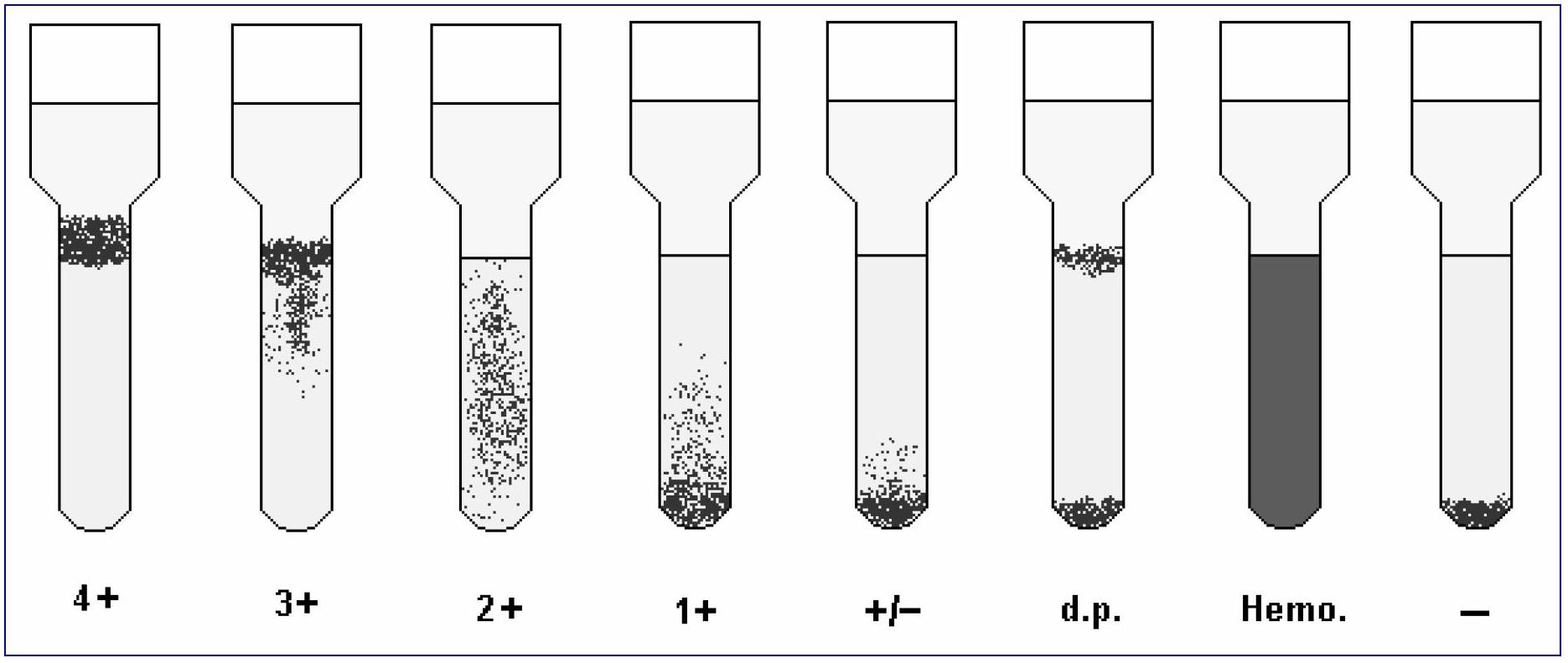

ActiveCN104569444AGuaranteed specificityGuaranteed FeaturesBiological testingIonic strengthMicro column

The invention discloses a forward and reverse ABO typing and RhD blood type detecting card comprising a detecting card with six micro-columns, wherein the first three micro-columns in the six micro-columns are respectively filled with equivalent A-resistant gel, B-resistant gel and D-resistant gel, and the left three micro-columns are filled with equivalent blank gel. The forward and reverse ABO typing and RhD blood type detecting card is prepared by using the following method comprising the steps of swelling dextran gels; preparing all antibody diluents; preparing all antibody working solutions; washing the gels; and subpackaging to form the RhD blood type detecting card. According to the forward and reverse ABO typing and RhD blood type detecting card, crosslinked dextran gels with different sizes and sieving ranges are mixed and swelled by using purified water, so that the specificity is effectively ensured, meanwhile, the forward and reverse ABO typing and RhD blood type detecting card has very high sensitivity, and the ion strength of a system is effectively ensured.

Owner:合肥天一生物技术研究所有限责任公司

Desizing method for pure cotton fabrics sized by starch and PVA (Polyvinyl Acetate) mixing pulp

ActiveCN104018337AAvoid damageImprove qualityBiochemical fibre treatmentDry-cleaning apparatus for textilesSewage treatmentChemistry

The invention discloses a desizing method for pure cotton fabrics sized by a starch and PVA (Polyvinyl Acetate) mixing pulp and belongs to the pretreatment technology field of pure cotton fabrics. The pure cotton fabrics are subjected to bio-enzyme desizing treatment dip-padding after being pretreated by using hot water and subjected to stacking treatment, active enzyme remaining in the fabrics is removed by an enzyme deactivation treatment, and then the pure cotton fabrics are washed and dried. According to desizing method provided by the invention, the fiber damage is less, the treated fabrics are high in quality and soft in hand feel; particularly, the chromaticity, pH value and COD value of wastewater treated by the desizing method are greatly lower than that of a conventional process, thus the desizing method is in favor of protection of ecological environment, and the load of sewage treatment is greatly reduced. Because dip-padding-stacking continuous treatment processes are used, the desizing method has characteristics of high production efficiency and low labor intensity, and saves energy and water.

Owner:JIANGSU LIANFA TEXTILE +1

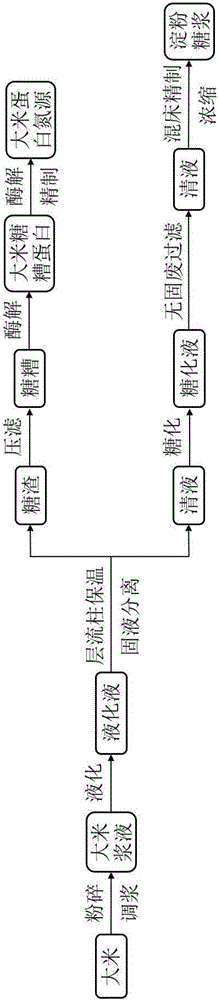

Production process for preparing starch syrup from rice

ActiveCN106191159AIncrease added valueHigh solid contentFermentationHigh concentrationAdditional values

The invention discloses a production process for preparing starch syrup from rice. The production process comprises the following steps: (1) crushing and pulping; (2) liquefying; (3) carrying out column laminar flow heat preservation and solid-liquid separation; (4) extracting a rice protein nitrogen source; (5) saccharifying; (6) carrying out solid-waste-free filtering; (7) carrying out mixed bed refining and concentrating. According to the process disclosed by the invention, in a process of preparing the starch syrup, the energy consumption is reduced through blending high-concentration starch syrup, a pulping water temperature is controlled and the liquefying time is shortened; residual sugar is recycled from sugar-free grains produced in a production process and fat in the sugar-free grains is hydrolyzed by adopting alkaline lipase; protein of the rice sugar-free grains is hydrolyzed by proteinase to prepare an organic nitrogen source, and fermentation raw materials for foods and medicines. The process disclosed by the invention is remarkably better than a traditional process for preparing the starch syrup from the rice; the production cost is low and an additional value of a product is improved; the content of produced solid wastes is extremely less and the production process is economical and environmentally friendly.

Owner:双桥(湖北)有限公司

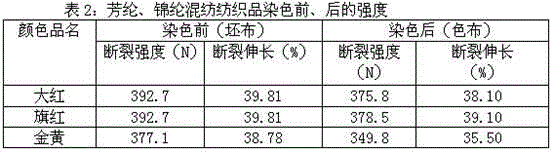

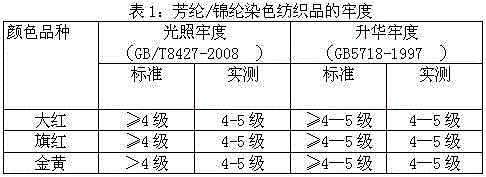

Dyeing method suitable for polyamide fiber and aramid fiber blended textile

ActiveCN104358140AAvoid strong damageExtended service lifeFibre typesDyeing processOrganic acidSewage

The invention discloses a dyeing method suitable for polyamide fiber and aramid fiber blended textile. The method is implemented by the following steps: treating the polyamide fiber and aramid fiber blended textile to be dyed by mechanical sizing before dyeing; then, dyeing the treated polyamide fiber and aramid fiber blended textile; firstly, dyeing aramid fiber by dye liquor containing cationic dye and carrier, and then washing; then, dyeing polyamide fiber by acid dye liquor, washing, discharging sewage, feeding 2g / L of a softening agent CA, 5g / L of an anti-ultraviolet finishing agent CTA and 0.12g / L of organic acid ACR into the washed polyamide fiber, treating for 20 minutes at the temperature of 40 DEG C, carrying out dehydration, and drying to obtain the colored polyamide fiber and aramid fiber blended textile. The dyeing method has the characteristics of being simple in technology, environment-friendly, short in process and free from damage to the inherent excellent properties of the fiber; after the dyeing method is adopted, the aramid fiber of the blended textile can be smoothly dyed, and the polyamide fiber of the blended textile is not damaged, so that the application field of the blended textile is greatly expanded.

Owner:ANHUI HUAMAO TEXTILE

Newborn ABO/Rh blood grouping reagent card and preparation method thereof

The invention discloses a newborn ABO / Rh blood grouping reagent card and a preparation method thereof. Eight microcolumn gel tubes are provided, including: a gel tube containing a monoclonal anti-A antibody with an Ig (Immunoglobulin) M property, a gel tube containing a monoclonal anti-B antibody with the Ig M property, a gel tube containing a monoclonal anti-AB antibody with the Ig M property, a gel tube containing a monoclonal anti-D antibody with the Ig M property, a gel tube containing a monoclonal anti-D antibody with the Ig M property and an Ig G property, a gel tube which contains gel suspending medium and is used as negative control, a gel tube containing an anti-Ig G reagent and a gel tube containing the anti-Ig G reagent and an anti-C3d reagent. The reagent card disclosed by the invention has the advantages that standardization is provided for newborn ABO / Rh (D) blood grouping and conditions are created for accurate determination of ABO / Rh (D) blood group and early diagnosis and treatment of hemolytic diseases of newborn.

Owner:JIANGSU ZHONGSHENG MEDICAL DIAGNOSTIC REAGENT

ABO/RhD blood typing detection reagent card and preparation thereof

InactiveCN102707074AEasy to detectReliable test resultsBiological testingMicro columnMonoclonal antibody

The invention relates to an ABO / RhD blood typing detection reagent card and preparation of the ABO / RhD blood typing detection reagent card. The ABO / RhD blood typing detection reagent card is characterized in that the detection reagent card is provided with 8 micro-column gel tubes, wherein one micro-column gel tube contains gel and an anti-A monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-B monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-D RhD blood type monoclonal antibody of IgM property, and the rest five gel tubes contain gel suspending medium buffer solutions and gels.

Owner:BEIJING KINGHAWK PHARMA

Finishing agent for coal washing water

InactiveCN101045571AFully swollenFast dissolutionWater/sewage treatment by flocculation/precipitationCoalPolyacrylamide

Owner:柴方战

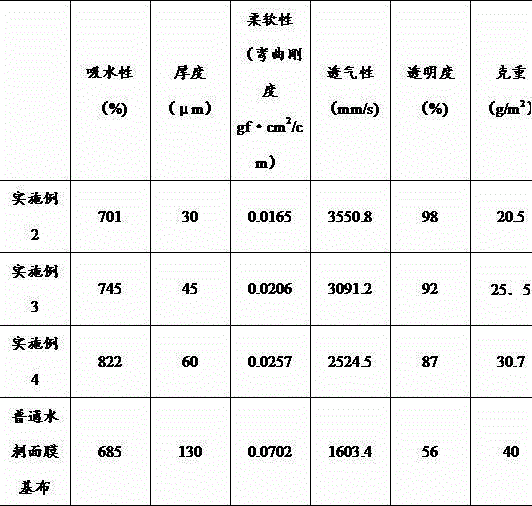

Non-woven mask base cloth and manufacturing method thereof

The invention relates to a non-woven mask base cloth and a manufacturing method thereof, and belongs to the field of beautifying and skin care. The method comprises the steps that cellulose fiber is unpacked, coarse opening, mixing, fine opening, cotton feeding, carding, cross lapping and drafting are performed and then a lower layer fiber web is formed; water-soluble polyvinyl alcohol fiber is unpacked, secondary opening, airflow cotton feeding and disordered carding are performed and then the fiber is laid on the lower layer fiber web so as to form an upper layer fiber web; the upper layer fiber web and the lower layer fiber web are fed into a high-pressure jetting area together for spunlace reinforcing, so that fiber in the upper layer fiber web and fiber in the lower layer fiber web are entwisted to form a composite fiber web; the composite fiber web is fed into a water soluble area and dissolved to remove polyvinyl alcohol fiber to obtain the single-layer fiber web; the single-layer fiber web is dried, wound and slit to obtain the non-woven mask base cloth. The obtained non-woven mask base cloth has multiple fiber gaps and capillary pores, the problem that a non-woven base cloth for a mask is large in gram weight and poor in skin attachment is solved, and the effects that the non-woven base cloth for the mask is light and thin, can absorb water and is breathable and good in moisturizing and attachment are achieved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

ABO/RhD blood group antigen detection reagent card and preparation method thereof

InactiveCN102680716AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingMonoclonal antibodyGroup A - blood

The invention relates to a preparation method of an ABO / RhD blood group antigen detection reagent card. Eight microcolumn gel tubes are arranged on the detection reagent card, wherein two gel tubes contain gel and anti-A monoclonal antibodies with an immunoglobulin m (IgM) property, two gel tubes contain gel and anti-B monoclonal antibodies with the IgM property, two gel tubes contain gel and anti-D monoclonal antibodies of RhD blood type with the IgM property, and two gel tubes contain a gel suspending medium buffer solution and gel.

Owner:BEIJING KINGHAWK PHARMA

Method for producing saccharide by using biomass

The invention discloses a method for producing saccharide by using biomass. The method comprises the following steps of: reacting raw material size consisting of a biomass raw material, inorganic metal salt, and surfactant at the temperature of between 120 and 180 DEG C for 5 to 30 minutes, and performing enzyme hydrolysis on a solid-liquid mixture which is not separated after reaction to obtain hydrolyzate containing saccharide. The method is short in an operation process, low in energy consumption, and high in biomass utilization rate and a saccharification effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal washing water treating agent and preparation method

InactiveCN101041493ALess investmentFast dissolutionWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationCoal waterWater content

The invention disclose washing coal water and preparing method, which comprises the following steps: allocating magnesium chloride with grain size at 0.2-2.0 millimeter and moisture capacity at 4%-15% and polyacrylamide with fineness at 40-100 order; spreading polyacrylamide on magnesium chloride; stirring evenly.

Owner:王春梅

Open width vinylon dissolution method

ActiveCN102134794AFully swollenFlat surfaceTextile treatment machine partsWoven fabricsBreaking strengthSoluble fiber

The invention discloses an open width vinylon dissolution method which is characterized by including the steps as follows: conducting open-width continuous crabbing on blended greige cloth of fur, cotton and fibers after raw finish by an open-width continuous crabbing machine, then winding the open width of the textile on a scroll, storing the scroll for certain time, alternately repeating the steps of open-width continuous crabbing and scroll storing, and after the last open-width continuous crabbing, directly drying the greige cloth instead of scroll storing so as to obtain the textile after vinylon dissolution. With the method, soluble fiber is swelled, puffed, shrunk and dissolved completely; thoroughly vinylon dissolution is ensured; the surface of the textile after vinylon dissolution is flat, and smooth and glutinous but no mushy in handfeel; and all the indexes of warp-weft directional tensile breaking strength, warp-weft directional tearing strength and the like of the textile can meet the requirements of corresponding national standards.

Owner:SHANDONG NANSHAN TEXTILE GARMENT +1

Sandwich candy floss with donkey hide glue and preparation method thereof

InactiveCN102499303AFully swollenImprove solubilityConfectionerySweetmeatsHealth protectionWater use

The invention relates to a sandwich candy floss with donkey hide glue and a preparation method thereof. The candy floss comprises the following ingredients according to parts by weight: 0.3-0.5 parts of donkey hide glue, 2-3 parts of modified starch, 35-40 parts of white granulated sugar, 2-4 parts of gelatin, 0.3-0.5 parts of pectin, 55-60 parts of water, 0.1-0.2 parts of vitamin C and 0.1-0.2 parts of vitamin E. Based on the traditional candy floss formula, the sandwich candy floss is added with the donkey hide glue and the pectin, the water using amount is increased, the using amounts of the modified starch and the gelatin are reduced, the added pectin can retain water completely, so that the cost is lowered, simultaneously, the candy floss body is good in elasticity, and is softer, can be dissolved upon entry into the mouth, and has the same health protection function as that of the donkey hide glue, which can nourish blood and beautify a human body. The preparation method of the sandwich candy floss has the advantages of low cost and high production efficiency.

Owner:SHAN DONG DONG E E JIAO

Preparation method of direct antihuman globulin reagent card

ActiveCN101718785AImprove buffering effectKeep the bufferBiological testingAntihuman globulinBlood corpuscles

The invention relates to a preparation method of a direct antihuman globulin reagent card. The preparation method is characterized in that the reagent card comprises six microcolumn gel tubes respectively comprising two gel tubes containing anti-IgG, two gel tubes containing anti-C3d and two gel tubes containing gel suspension mediums, and each reagent card is shared by two persons. The method comprises the technical processes of preparation of the gel suspension mediums, preparation of gel, selection of antibody as well as preparation and split charging of gel. The direct antihuman globulin reagent card prepared by the method has high sensitivity, good specificity and stable quality, red blood corpuscles having sensitization to IgG antibodies and the red blood corpuscles having sensitization to C3d alexin can be detected by using the same card at the same time, and the red blood corpuscles having sensitization to IgG antibodies or the C3d alexin can be accurately determined.

Owner:JIANGYIN LIBO MEDICINE BIOTECH

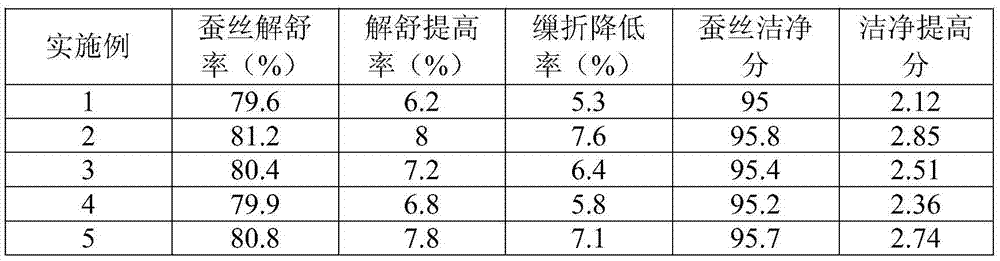

Method for improving unwinding ratio of silk

InactiveCN105442061AInhibition of dissolutionThe method is scientifically feasibleAnimal materialSilk filament obtainingDissolutionSericin

The invention discloses a method for improving the unwinding ratio of silk, and belongs to the technical field of silk processing. The method comprises the following steps: preparing a silk unwinding agent, penetrating, boiling cocoons, rinsing, regulating silks, spinning, and reeling. The method is scientific and feasible, the operation is feasible, the sericin in the inner layer of cocoons is fully swelled, the temperatures of cocoon boiling and silk regulation are reduced, the inner layer can be cooked, while the dissolution of sericin in the outer layer is inhibited; the cocoon boiling is optimized according to the physical and chemical properties of silk, after the cocoons are processed by the provided method, the silk unwinding ratio can reach 79.6 to 81.2%; the unwinding ratio is improved by 6.2 to 8%; the broken rate of silk during reeling process is reduced by 5.3 to 7.6%, the silk cleanness score reaches 95 to 95.8, and the cleanness score is improved by 2.12 to 2.85.

Owner:张莘蔓

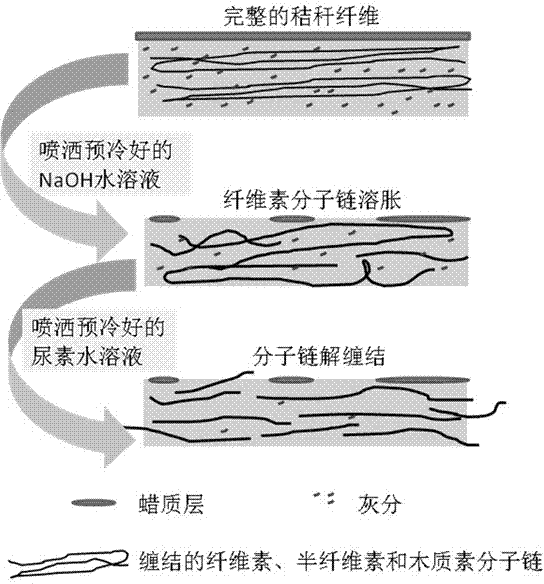

Alkaline thiourea disentangled straw/resin composite board making method

The invention discloses an alkaline thiourea disentangled straw / resin composite board making method. The method comprises the following steps: sprinkling short fibers of straws with a pre-cooled aqueous NaOH solution, and stirring and kneading for 30min-2h; sprinkling the short fibers with a pre-cooled aqueous urea solution, and continuously stirring and kneading for 30min-2h; drying, and crushing to 60 mesh powder to obtain alkaline thiourea disentangled straw fibers; and blending the obtained alkaline thiourea disentangled straw with resin, a compatilizer, a lubricant and a filler, compacting or extruding, and carrying out continuous production to obtain alkaline thiourea disentangled straw / resin composite boards. The alkaline thiourea disentangled straw / resin composite boards made by utilizing the method can be widely applied to the fields of building materials, decoration materials, packaging materials and the like because of the advantages of light weight, low price, good strength and the like.

Owner:HUBEI UNIV OF TECH

Broad spectrum antihuman globulin reagent assay card and preparation thereof

InactiveCN102692510AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingAntihuman globulinGlobulin

The invention relates to a broad spectrum antihuman globulin reagent assay card and preparation thereof. The assay card is provided with 8 microcolumn gel tubes, wherein broad spectrum IgG (immunoglobulin globulin) and C3D antibody reagents are contained in 8 microcolumn gel tubes.

Owner:BEIJING KINGHAWK PHARMA

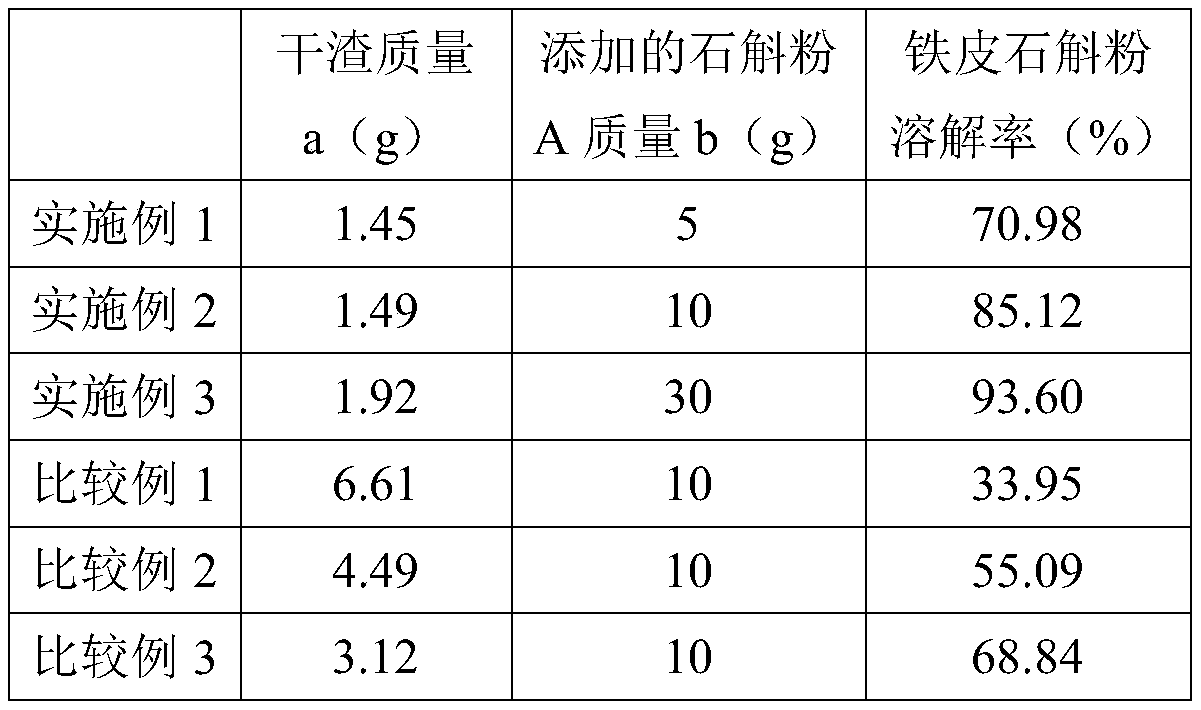

Dendrobium officinale powder preparation method

The invention relates to dendrobium officinale powder preparation method which is characterized by including the steps: (1) material pretreatment; (2) cutting and stirring; (3) freeze-drying; (4) enzymatic hydrolysis; (5) high-pressure homogenizing; (6) fermentation; (7) vacuum concentration; (8) spray-drying. Compared with the prior art, the method has the advantages that the enzymatic hydrolysisis matched with fermentation to generate biochemical doubling effect, preliminary enzymolysis of dendrobium officinale fibers can be achieved by enzymatic hydrolysis treatment, cellulose and hemicellulose in the dendrobium officinale can be converted into fermentable glycogen, nutrients are provided for metabolic acid production of follow-up lactobacillus and acetic bacteria, cellulose is hydrolyzed under acid condition, fibers are further hydrolyzed by enzymes generated after bacillus metabolizes, a firm ester bond formed between lignin and cellulose is destroyed, the prepared dendrobium officinale powder is high in dendrobium officinale fiber content and good in dispersibility, and the utilization rate of dendrobium officinale raw materials is high.

Owner:宁波工程学院奉化研究院 +2

Microfiber collagen hemostatic material and preparation method thereof

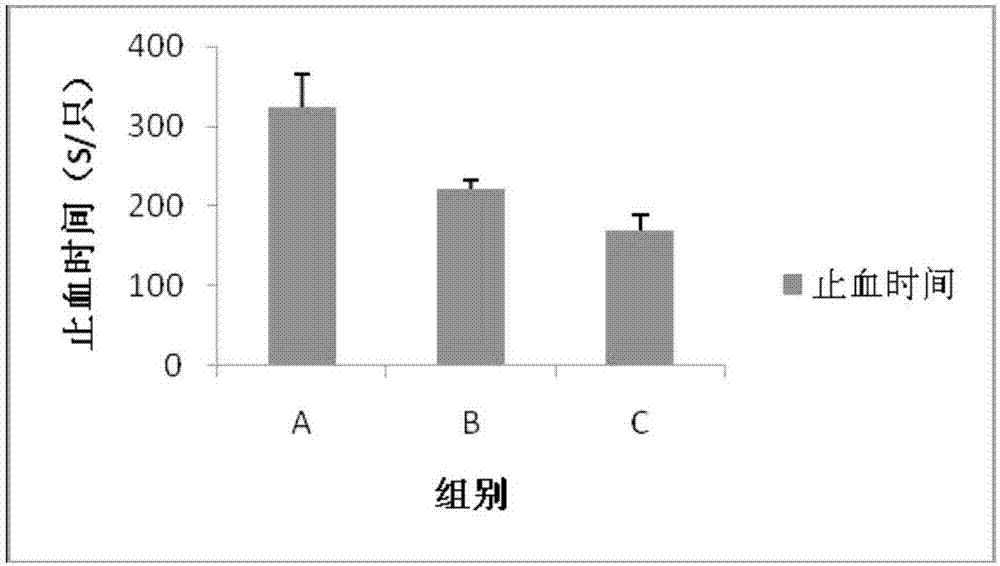

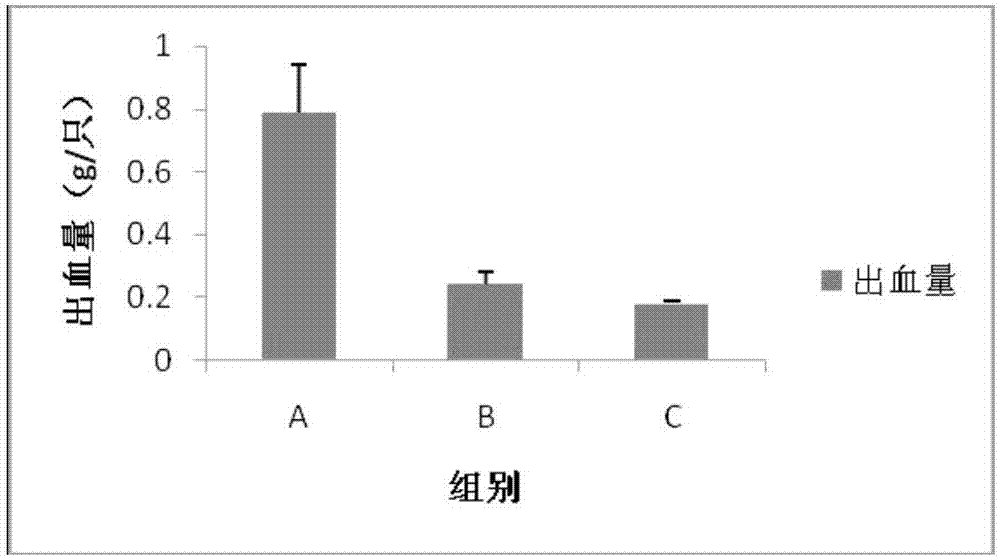

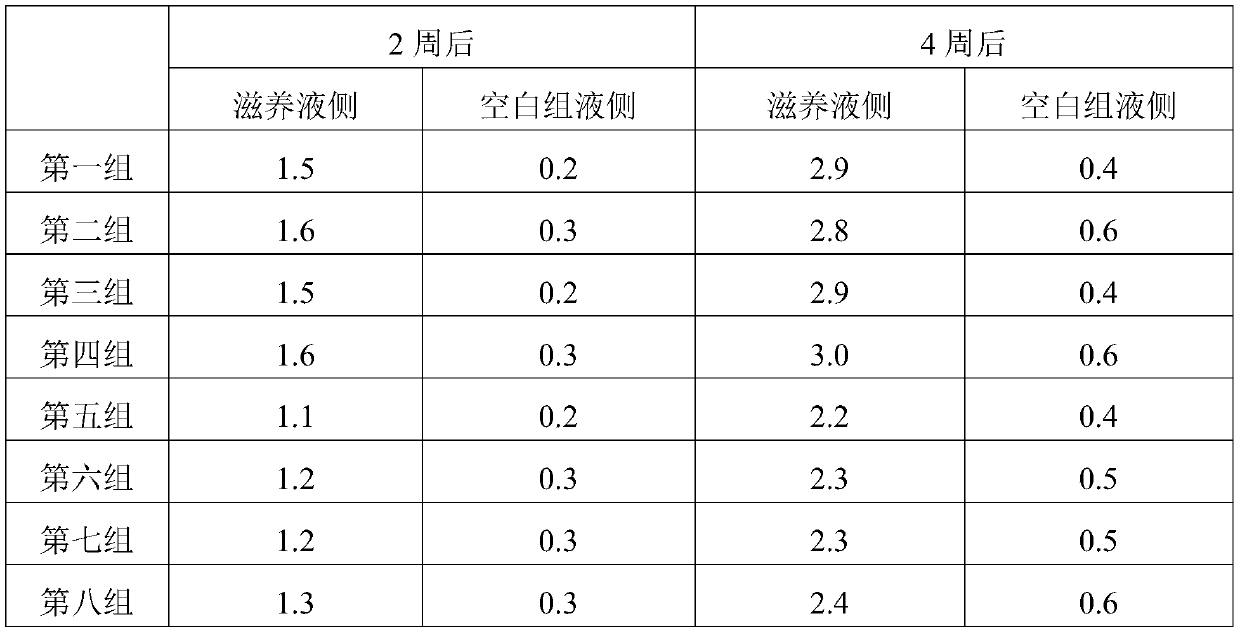

ActiveCN107137758ASufficient tensile strengthGood hemostatic effectSurgical adhesivesHeatFibrosisRadiation Sterilization

The invention relates to a microfiber collagen hemostatic material and a preparation method thereof. The preparation method of the material includes the first step of sodium sulfide unhairing, the second step of shredding and fibrosis, the third step of swelling control, the fourth step of drying, the fifth step of depolymerisation and fluffing, and the sixth step of Co60 radiation sterilization, wherein in the fifth step, the obtained fasciculus is treated using a hammer mill to obtain a microfiber collagen product. According to the method, the use concentration of sodium sulphide is reduced, the efficiency of unhairing is improved, and degreasing and impure protein removal are effectively conducted; collagen materials are not oxidized and degenerated, the activity of microfiber collagen is easy to maintain, and the hemostatic effect is improved. Acid is introduced in the treating process, the degreasing and protein removal are more effective, and the adhesion property of the hemostatic material is guaranteed.

Owner:林贵梅

Loss preventing and hair strengthening nourishing solution and preparation method thereof

PendingCN110420131APromotes collagen synthesisRepairing Elastic Mesh BreaksCosmetic preparationsHair cosmeticsNutrientResting Cell

The invention discloses a loss preventing and hair strengthening nourishing solution. The nourishing solution comprises components in percentage by mass as follows: 0.0005%-0.002% of a hair follicle activation factor, 0.01%-1% of vitamins, 0.05%-5% of amino acid, 0.01%-1% of microelements, 0.01%-20% of a transdermal agent, 0.02%-10% of a conditioner and the balance of water. Meanwhile, the invention discloses a preparation method of the nourishing solution. The hair follicle activation factor is taken as the core effective component of the loss preventing and hair strengthening nourishing solution and matched with other auxiliary scalp nutrients, all the components cooperate and can balance microcirculatory system of scalp and reconstruct scalp barriers; the nourishing solution can activate resting cells, repair damaged hair follicle and rapidly stop loss and strengthen hair. Besides, the nourishing solution directly supplies hair growth nutrients through scalp hair follicle, can strengthen hair roots, activate activity of hair follicle, dredge blood vessels and promote rapid growth of hair, and has significant effects on soft hair, dry hair, splitting, no gloss, scalp itching, more dandruff, more hair oil, climacteric hair loss, alopecia areata and sebrrheic alopecia.

Owner:楚桥五月(江苏)科技有限公司

Rh blood type detecting card

The invention provides an Rh blood type detecting card comprising a detecting card with six micro-columns, wherein the six micro-columns are internally and respectively filled with equivalent D-resistant gel, C-resistant gel, c-resistant gel, E-resistant gel, e-resistant gel and blank gel. The Rh blood type detecting card is prepared by using the following method comprising the steps of swelling dextran gels; preparing all antibody diluents; preparing all antibody working solutions; washing the gels; and subpackaging to form the Rh blood type detecting card. According to the Rh blood type detecting card, crosslinked dextran gels with different sizes and sieving ranges are mixed and swelled by using purified water, so that the specificity is effectively ensured, meanwhile, the Rh blood type detecting card has very high sensitivity, and the ion strength of a system is effectively ensured.

Owner:合肥天一生物技术研究所有限责任公司

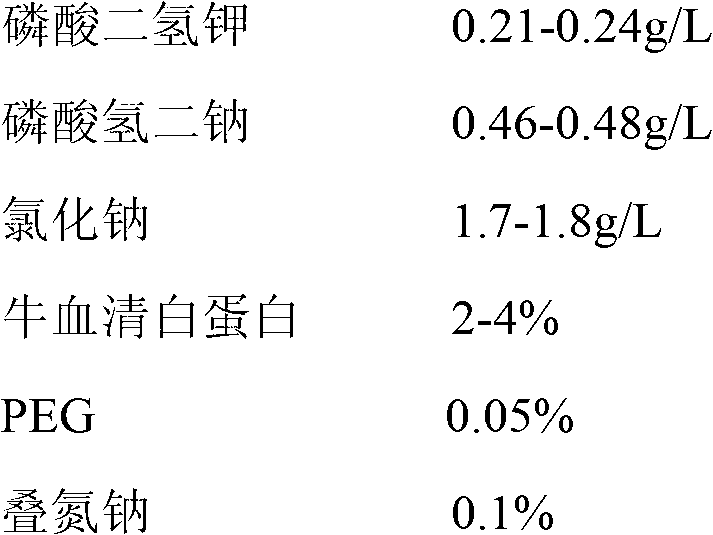

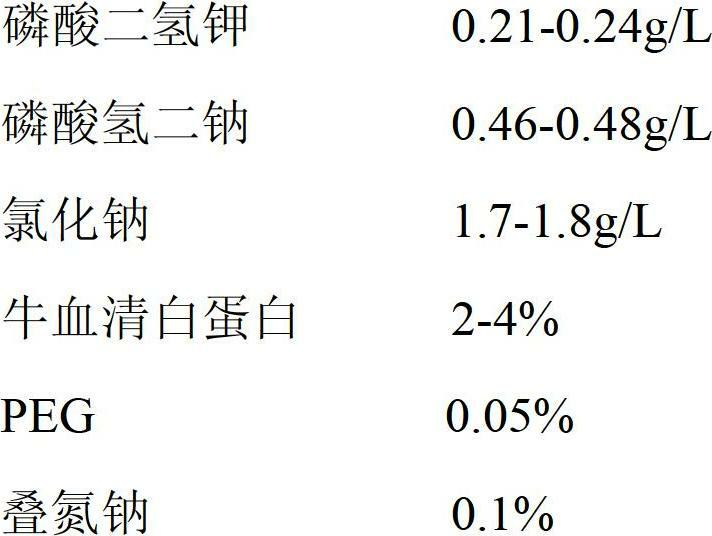

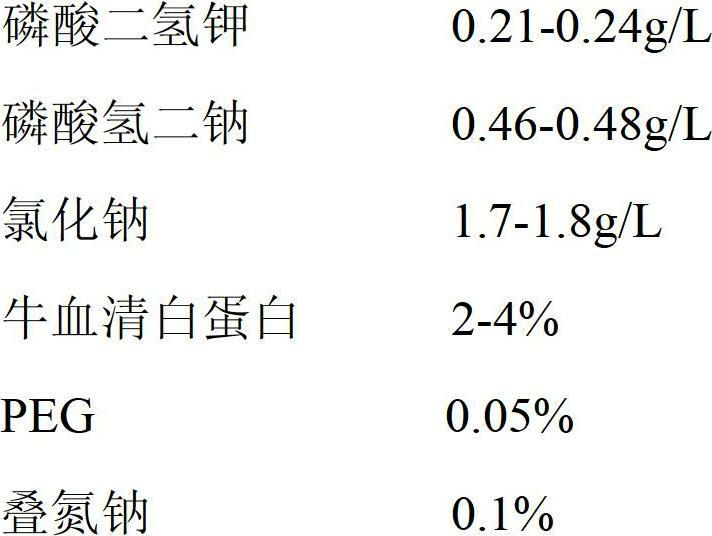

Method for preparing broad spectrum antihumanglobulin cards

ActiveCN101718783AImprove buffering effectKeep the bufferBiological testingMicro columnMonopotassium phosphate

The invention relates to a method for preparing broad spectrum antihumanglobulin cards. Six micro-column gel tubes are arranged on the cards, and the six micro-column gel tubes are gel tubes containing an antibody for resisting IgG+C3d. The method comprises the following processes of preparation of a gel suspension medium, preparation of a gel, selection of the antibody, and preparation and sub-package of the gel. The gel suspension medium comprises the reagents of (5.5-6.5)*10-4g / ml methyl- p-hydroxybenzoate, (1.0-1.5)*10-4g / ml propyl p-hydroxybenzoate, (1.6-1.9)*10-2g / ml glycine, (1.7-1.9)*10-3g / ml sodium chloride, (2.1-2.4)*10-4g / ml monopotassium phosphate, (4.6-4.8)*10-4g / ml disodium hydrogen phosphate and less than or equal to 2 percent of bovine serum albumin. The reagents are dissolved by using distilled water; and the pH value is adjusted into 6.6-6.8. The broad spectrum antihumanglobulin cards prepared by the method have the advantages of high sensitivity, favorable specificity and stable quality.

Owner:JIANGYIN LIBO MEDICINE BIOTECH

Method for manufacturing high-activity silk mask by use of silkworm cocoon

ActiveCN104814883AMaintain glossGuaranteed activityCosmetic preparationsToilet preparationsProteaseEngineering

The invention discloses a method for manufacturing a high-activity silk mask by use of silkworm cocoon. The method is characterized by comprising the following steps: (1) cocoon cleaning: washing away dust and sundries on cocoon with clear water; (2) cocoon dissolving: placing the cleaned silkworm cocoon into a protease solution with the concentration of 0.1-5%, and enabling silk gum to be fully swelled and a cocoon shell to be opened; (3) cocoon stripping: pulling apart the cocoon shell to remove silkworm chrysalis; (4) film forming: sleeving the silkworm cocoon from which the silkworm chrysalis is removed on an arch-shaped die to make a silk web; (5) drying: naturally airing or drying at low temperature; and (6) punch forming. The method is short in technological process and simple to manufacture; the whole technological process is completed at low temperature without soaking in an alkali liquor or high-temperature cooking, so that the protein activity is preserved to the utmost extent, silk gum is not subject to denaturation or loss, and the manufactured mask is excellent in compactness and convenient to use.

Owner:四川丝玛帛科技有限公司

ABO-CDE blood type grouping reagent card and preparation method thereof

InactiveCN102331504AEnsure stabilityImprove buffering effectBiological testingE AntibodyStandardization

The invention discloses an AB / CDE blood type grouping reagent card. The reagent card is provided with eight microcolumn gel tubes, namely a gel tube containing an immune globulin (IgM) monoclonal anti-A antibody, a gel tube containing an IgM monoclonal anti-B antibody, a gel tube containing an IgM monoclonal anti-D antibody, a gel tube containing an IgM monoclonal anti-C antibody, a gel tube containing an IgM monoclonal anti-E antibody, a gel tube which is used for negative control and contains a gel buffer solution and two gel tubes which are used for reverse typing and contain gel buffer solutions. The invention provides standard for the ABO-CDE blood type grouping; and the ABO-CDE blood type grouping reagent card which conforms to standard can be used in all hospitals and blood transfusion services to accurately group ABO-CDE blood types, so conditions are created for guaranteeing transfusion safety.

Owner:JIANGSU ZHONGSHENG MEDICAL DIAGNOSTIC REAGENT

Method for dyeing chemical-fiber textile cloth

InactiveCN105951477AAvoid strong damageExtended service lifeDyeing processPolyvinyl alcoholDark color

A method for dyeing chemical fiber woven fabrics, belonging to the technical field of dyeing methods, comprising the following steps: Step 1: Mechanically sizing the chemical fiber woven fabrics to be dyed, and placing them in a dye vat for pre-dyeing treatment: Step 2: Putting the chemical fiber woven fabrics in step 1 The obtained processed chemical fiber textile cloth is dyed; step 3: the chemical fiber textile cloth dyed in step 2 is subjected to press dehydration and sizing treatment: the sizing agent is compounded by polyvinyl alcohol and modified starch, and the sizing agent The concentration is 3.0%, and then dried, the moisture content of the dehydrated chemical fiber textile cloth is controlled at 50-60%, the drying temperature is controlled at 90°C-105°C, and the moisture regain is controlled, that is, the colored chemical fiber textile cloth is obtained. Through the study of the dyeing process, the invention can solve the problems of low color uptake and inability to dye medium-dark colors when dyeing chemical fiber woven fabrics and the problem of strong damage to chemical fiber woven fabrics. The invention uses conventional equipment and has the characteristics of simple process, environmental protection, short process and no damage to inherent excellent performance of fibers.

Owner:XINCHANG COUNTY ZHUOYUAN TEXTILE CO LTD

Anhydrous water-base forsterite powder paint

InactiveCN1748900ALarge specific surface areaGood suspensionFoundry mouldsFoundry coresCarboxymethyl celluloseWater based

The anhydrous water-base forsterite powder paint has the main components of forsterite powder, white latex, suspending agent, dextrin, and sodium carboxymethyl cellulose. Through adding forsterite powder and other matter, mixing and grinding, the powder paint is made to í‹matureíŒ, homogenize, disperse, swell, increase in specific surface and become favorable to form film. The present invention can raise the suspension performance and stability of paint, reduce fermentation, and make the casting produced with the paint no chemical sand adhesion and easy to clean. The present invention is especially suitable for use in producing casting of high manganese steel, stainless steel and other high alloy steel to result in excellent use effect.

Owner:高申明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com