Method for improving unwinding ratio of silk

A technology of unwinding rate and silk, which is applied in silk fiber production, chemical post-treatment of fibers, animal raw materials, etc. It can solve the problems of poor cocoon cooking effect and low unwinding rate, so as to inhibit continuous dissolution and improve unwinding High efficiency and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

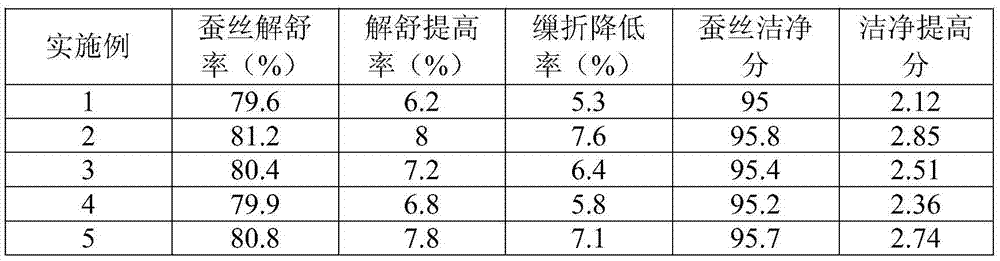

Examples

Embodiment 1

[0030] A method for improving silk unwinding rate, comprising the following steps:

[0031] S1. Preparation of soothing agent: the preparation concentration is 0.1mol / LNa 2 SiO 3 The soothing agent of the solution, the pH value of the soothing agent is 10;

[0032] S2, osmosis: mix the solution A in a ratio of 0.15:1 with the mass ratio of the relaxing agent described in step S1 and ammonium water, adjust the pH value of the solution A to 7.3, and then place the cocoons A in the solution A Soak for 6min, then infiltrate silkworm cocoon A for 5min under low temperature vacuum at a vacuum degree of 0.91Mpa and a temperature of 20°C to obtain silkworm cocoon B;

[0033] S3. Cocoon cooking: the silkworm cocoon B and the solution A described in step S2 are heated at 96° C. for 6 min to obtain silkworm cocoon C;

[0034] S4, rinsing and tidying up: mix the soothing agent described in step S1 with water at a mass ratio of 1:100 to form solution B, add softener to the solution B to...

Embodiment 2

[0042] A method for improving silk unwinding rate, comprising the following steps:

[0043] S1. Preparation of anti-relieving agent: the preparation concentration is 0.14mol / LNa 2 SiO 3 The anti-relieving agent of the solution, the pH value of the anti-relieving agent is 9.5;

[0044] S2, osmosis: mix the solution A with the mass ratio of the relaxing agent described in step S1 and water ammonium to 0.2:1, adjust the pH value of the solution A to 7.6, and then place the cocoon A in the solution A Soak for 4min, then infiltrate silkworm cocoon A for 3min under low-temperature vacuum immersion at a vacuum degree of 0.95Mpa and a temperature of 25°C to obtain silkworm cocoon B;

[0045]S3. Cocoon cooking: the silkworm cocoon B and the solution A described in step S2 are heated at 98° C. for 4 min to obtain silkworm cocoon C;

[0046] S4, rinsing and tidying up: mix the soothing agent described in step S1 with water at a mass ratio of 1:200 to form solution B, add softener to t...

Embodiment 3

[0054] A method for improving silk unwinding rate, comprising the following steps:

[0055] S1. Preparation of soothing agent: the preparation concentration is 0.12mol / LNa 2 SiO 3 The anti-relieving agent of the solution, the pH value of the anti-relieving agent is 9.8;

[0056] S2, osmosis: mix the solution A with the mass ratio of the relaxing agent described in step S1 and water ammonium to 0.18:1, adjust the pH value of the solution A to 7.5, and then put the cocoon A in the solution A Soak for 5min, then under vacuum degree of 0.93Mpa and temperature of 22°C, low-temperature vacuum impregnation infiltrates cocoon A for 4min to obtain cocoon B;

[0057] S3. Cocoon cooking: the silkworm cocoon B and the solution A described in step S2 are heated at 97° C. for 5 min to obtain silkworm cocoon C;

[0058] S4, rinsing and tidying up: mix the soothing agent described in step S1 with water in a mass ratio of 1:150 to form solution B, add softener to the solution B to prepare a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com