Alkaline thiourea disentangled straw/resin composite board making method

A technology of resin compounding and disentanglement, which is applied in the field of material compounding, can solve the problems of high energy consumption, pollution, and a large amount of waste liquid, and achieve the effects of reducing pollution, simple and convenient operation, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

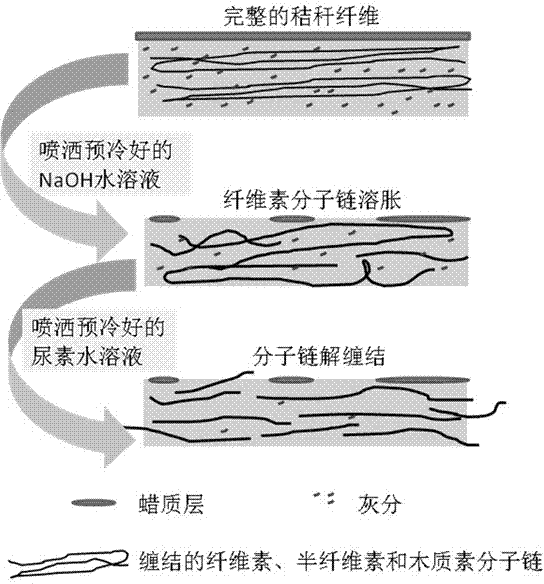

[0028] The preparation method of the alkali urea disentangling straw / resin composite board involved in the present invention mainly includes the following two steps:

[0029] a) Preparation of straw fibers by alkaline urea disentanglement

[0030] Straw fibers are broken into short fibers of 40-50mm; the pre-cooled 7wt%-28wt% NaOH aqueous solution that is 1-2 times the mass of straw is sprayed on the short fibers, stirred and kneaded for 30 minutes to 2 hours; then the mass of straw is 1-2 times the pre-cooled 14wt%-42wt% urea aqueous solution is sprayed on the short fiber, and the stirring and kneading is continued for 30 minutes to 2 hours; finally, it is dried and crushed to 60 mesh powder to obtain the alkali urea deentangled straw fiber.

[0031] b) Alkaline urea disentanglement of straw fiber and resin composite

[0032] The alkali urea deentanglement straw fibers are mixed with plastic on double rollers, compatibilizers, lubricants, fillers, etc. are added, mixed evenl...

Embodiment 1

[0036] Example 1 Preparation of Alkaline Urea Disentanglement Straw / Resin Composite Board

[0037] Get 50 parts of straw fibers and break into 50mm short fibers. Spray 80 parts of precooled 14wt% NaOH aqueous solution onto 50 parts of short straw fibers, stir and knead for 30 minutes; then spray 80 parts of precooled 28wt% urea aqueous solution on the short fibers, and continue stirring and kneading for 30 minutes ; Finally drying and crushing to 60-mesh powder to obtain alkali urea disentangling straw fibers. Add 50 parts of alkali urea disentangling straw fibers to 50 parts of HDPE, add 1 part of maleic anhydride grafted polyethylene, 2 parts of zinc stearate, and 1.3 parts of titanium dioxide, and press them into shape after kneading with double sticks to obtain alkali urea Disentangling straw / resin composite panels. The mechanical properties of the obtained composite materials are listed in Table 1.

Embodiment 2

[0038] Example 2 Preparation of Alkaline Urea Disentanglement Straw / Resin Composite Board

[0039]Get 30 parts of straw fibers and break into 50mm short fibers. Spray 50 parts of precooled 14wt% NaOH aqueous solution onto 30 parts of straw short fibers, stir and knead for 30 minutes; then spray 50 parts of precooled 28wt% urea aqueous solution onto short fibers, and continue stirring and kneading for 30 minutes Minutes; finally dried and crushed to 60 mesh powder to obtain alkali urea detangled straw fibers. Add 30 parts of alkali urea disentangling straw fibers to 70 parts of HDPE, add 1 part of maleic anhydride grafted polyethylene, 2 parts of zinc stearate, and 1.3 parts of titanium dioxide, and press them into shape after kneading with double sticks to obtain alkali urea Disentangling straw / resin composite panels. The mechanical properties of the obtained composite materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com