High-temperature-resisting lithium-ion battery membrane with plurality of types of coatings and preparation method of high-temperature-resisting lithium-ion battery membrane

A technology for lithium-ion batteries and battery separators, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as restricting the development of lithium-ion batteries, low lithium-ion conductivity, and increasing battery impedance, and achieve consistent voltage and quality. High, shrinkage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

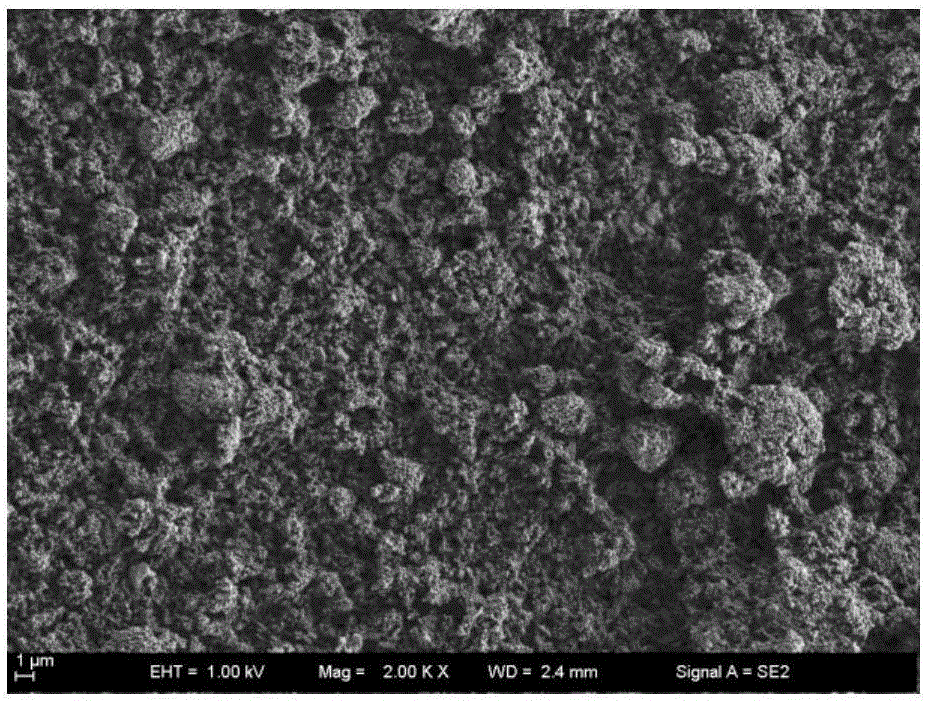

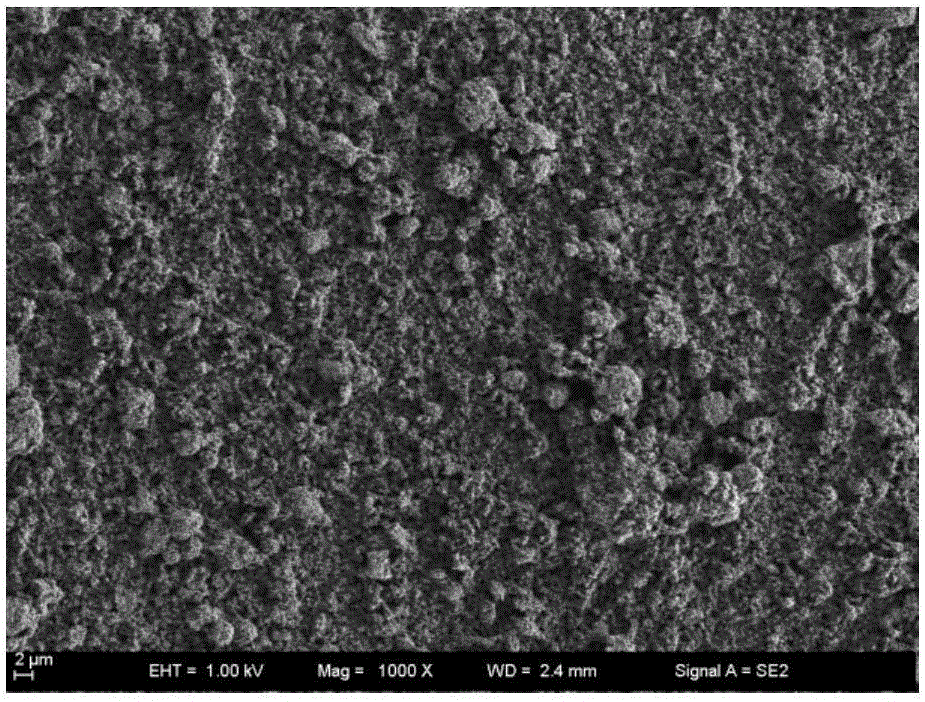

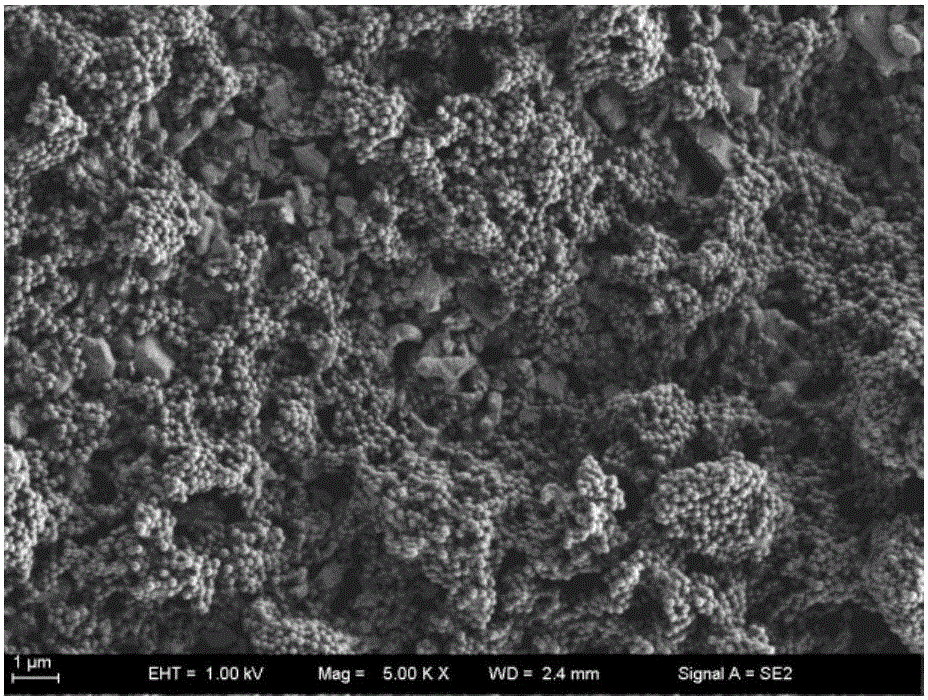

Image

Examples

preparation example Construction

[0044] ①Al 2 o 3 Preparation of coating slurry:

[0045] Add N-methylpyrrolidone and aluminum oxide powder to a vacuum, high-speed, planetary stirring device with ultrasonic oscillation function at the same time. h, to obtain slurry;

[0046] Add one or more mixtures of sodium polyacrylate, sodium polymetaphosphate, sodium orthophosphate, sodium silicate, sodium lauryl sulfate, and ammonia water to the slurry in an amount of 0.5% of the slurry; Add static eliminator, the addition amount is 0.3% of the slurry, high-speed stirring and ultrasonic oscillation for 0.5h;

[0047] Add one or more mixtures of alcohol, propylene carbonate, glycerin, dimethyl sulfoxide, polyoxyethylene alkylphenol ether, polyoxyethylene fatty alcohol ether, polyvinyl alcohol, and the amount added is the slurry 0.5%; high-speed stirring and ultrasonic oscillation for 0.5h;

[0048] Add PVDF glue with a slurry amount of 5%, and sodium carboxymethylcellulose with a slurry amount of 0.3%; high-speed st...

Embodiment 1

[0085] Take a 16um wet-process PE separator, select one side of the wet-process PE separator and use a micro-gravure roller to coat 2um thick Al 2 o 3 Apply the slurry to form a coating film, and then use a dipping coating device to coat 1um oily SiO on both sides of the coating film 2 Coating the slurry to obtain Al with a thickness of 20 μm 2 o 3 and SiO 2 Two kinds of slurry-coated composite Li-ion battery separators with a structure of SiO 2 Coating-Al 2 o 3 Coating-PE Separator-SiO 2 coating.

[0086] The preferred preparation method of the lithium-ion battery diaphragm in this embodiment is:

[0087] A. Preparation of coating slurry: preparation of Al 2 o 3 Coating paste and SiO 2 Coating slurry, standby;

[0088] B. Pretreatment of battery diaphragm: Use ozone with a flow rate of 0.5L / min to pretreat the diaphragm for 120s, and reserve it; if the pretreatment time is too short, it will affect the surface adhesion of the diaphragm and the appearance quality o...

Embodiment 2

[0092] Take a 10um wet-process PP diaphragm, and coat 2um-thick SiO on both sides of the wet-process PP diaphragm with a dip coating device 2 Apply the slurry to form a coating film, and then use a dip coating device to coat 1um oily Al on both sides of the coating film 2 o 3 Coating the slurry to obtain SiO with a thickness of 16 μm 2 and Al 2 o 3 Two kinds of slurry-coated composite Li-ion battery separators with a structure of Al 2 o 3 Coating - SiO 2 Coating - PP Separator - SiO 2 Coating-Al 2 o 3 coating.

[0093] The preferred preparation method of the lithium-ion battery diaphragm in this embodiment is:

[0094] A. Preparation of coating slurry: preparation of Al 2 o 3 Coating paste and SiO 2 Coating slurry;

[0095] B. Pretreatment of battery diaphragm: use ozone with a flow rate of 1L / min to pretreat the diaphragm for 100s, and reserve it; if the pretreatment time is too short, it will affect the surface adhesion of the diaphragm and the appearance quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com