Patents

Literature

275results about "Mercerising of indefinite length fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for mercerized knitted bedding fabric

InactiveCN102433678AMoisturize evenlySoft touchMercerising of indefinite length fabricsSingeingTextile printerPolymer science

The invention discloses a processing method for a mercerized knitted bedding fabric. The processing method mainly adopts a production technology of double-calcination single yarn, first refining and then mercerizing, and grey yarn is sequentially subjected to yarn singeing, yarn steaming, knitting, grey cloth singeing, refining, dewatering, cylinder drying, mercerizing, dyeing, dewatering, scutching, drying, printing, forming and pre-shrinking and finally is checked and stored in a cabin. The mercerized knitted bedding fabric has the advantages of high conformality, low shrinkage, wide width and the like, and can meet the requirement on the knitted bedding fabric; compared with a woven fabric, the mercerized knitted bedding fabric has higher elasticity, water absorption and air permeability, is more smooth and fine in handfeel, and has better comfortableness.

Owner:WUHU SHENGLUO TEXTILE INDAL

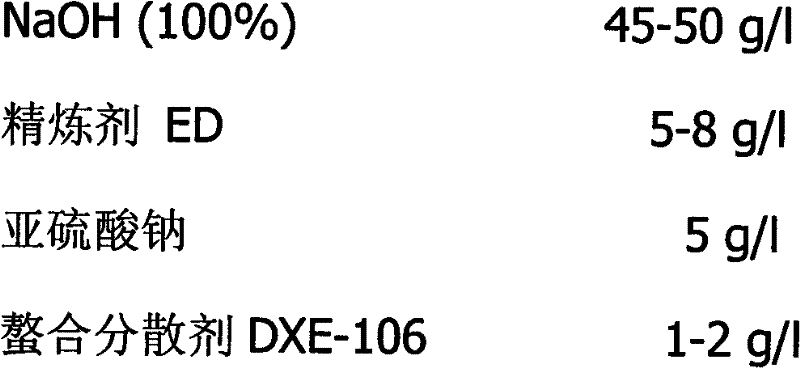

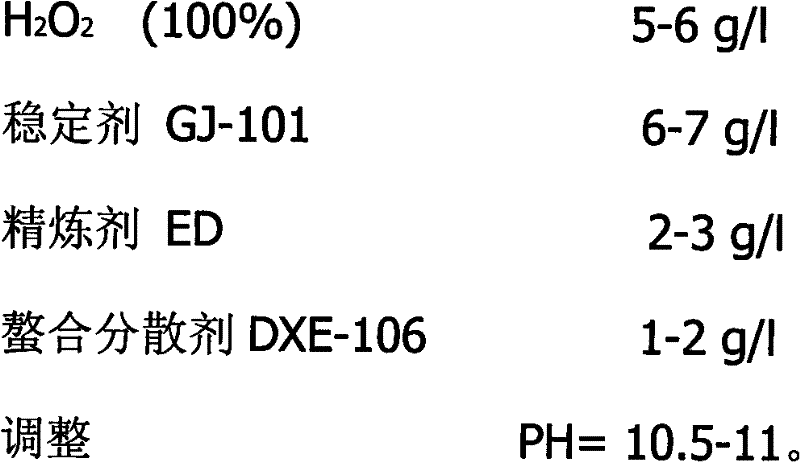

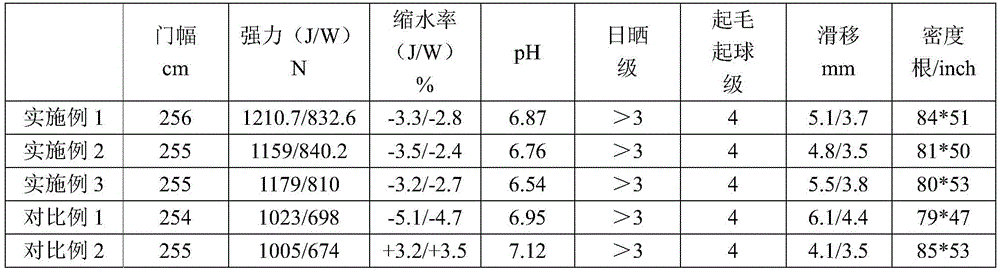

New anti-fluffing and anti-pilling technology for polyester-cotton fabric under special standards

ActiveCN102561040AImprove refining effectReduce slipMercerising of indefinite length fabricsFibre treatmentPolyesterEngineering

The invention relates to the technical field of dyeing and finishing production of polyester-cotton anti-fluffing and anti-pilling fabrics. A new anti-fluffing and anti-pilling technology for a polyester-cotton fabric under special standards comprises the following steps of: (1) grey cloth seam turning, (2) primary singeing, (3) flat bleaching, (4) secondary singeing, (5) sizing, (6) mercerizing, (7) dyeing (dispersion / reduction), (8) finishing with a compound solution of ironing-free resin and an anti-fluffing and anti-pilling agent, (9) baking, (10) tentering, (11) pre-shrinking, (12) inspection, and (13) formation of a finished product. The product prepared by the technology meets the special quality requirement of customers for washing for 5 times, 30 minutes in each time, in hot water at 92 DEG C, the anti-fluffing and anti-pilling quality index of the fabric is detected, and the anti-fluffing and anti-pilling quality index of the product for clothes reaches the export standard, namely level 3-4.

Owner:辽宁宏润源印染有限公司

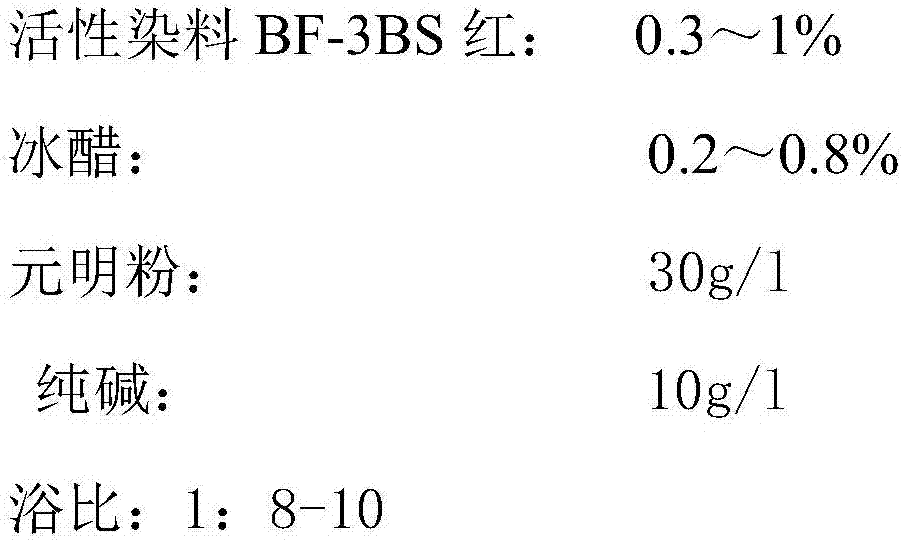

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

Production method for polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process

ActiveCN104213398AOxygen bleachingTo achieve the purpose of cost reductionMercerising of indefinite length fabricsSingeingDisperse dyeOxygen

The invention a printing and dyeing method, and especially relates to a production method for a polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, mercerizing, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, designing a dyeing formula, carrying out jar dyeing on the cloth sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The production method for the polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process has obvious energy saving and emission reduction effects, and the handle elasticity, the color fullness and various quality indexes of fabrics obtained in the invention can meet requirements of different clients.

Owner:ZHEJIANG HANGMIN STOCK

Anti-infrared military camouflage fabric and printing and dyeing process thereof

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

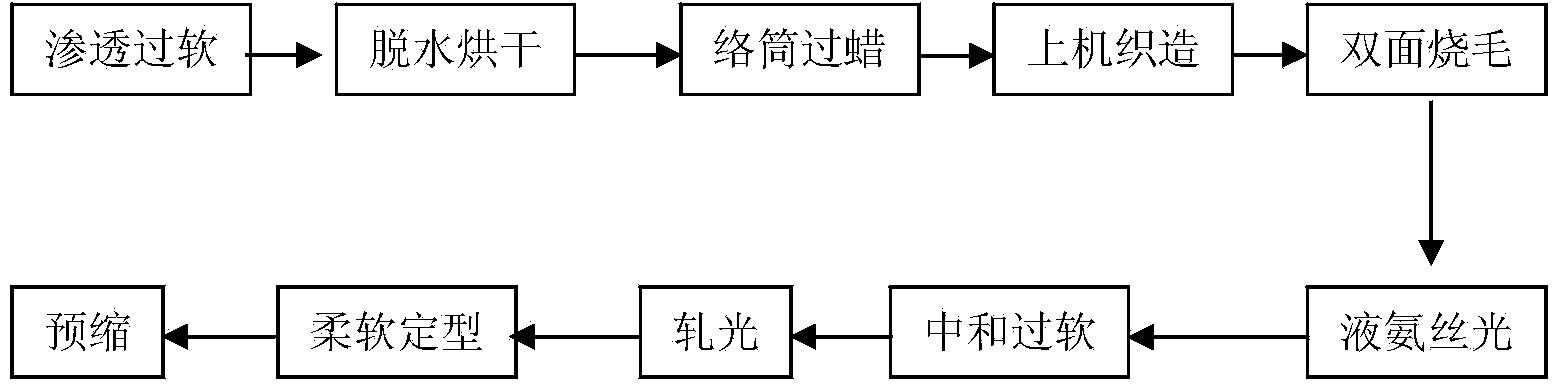

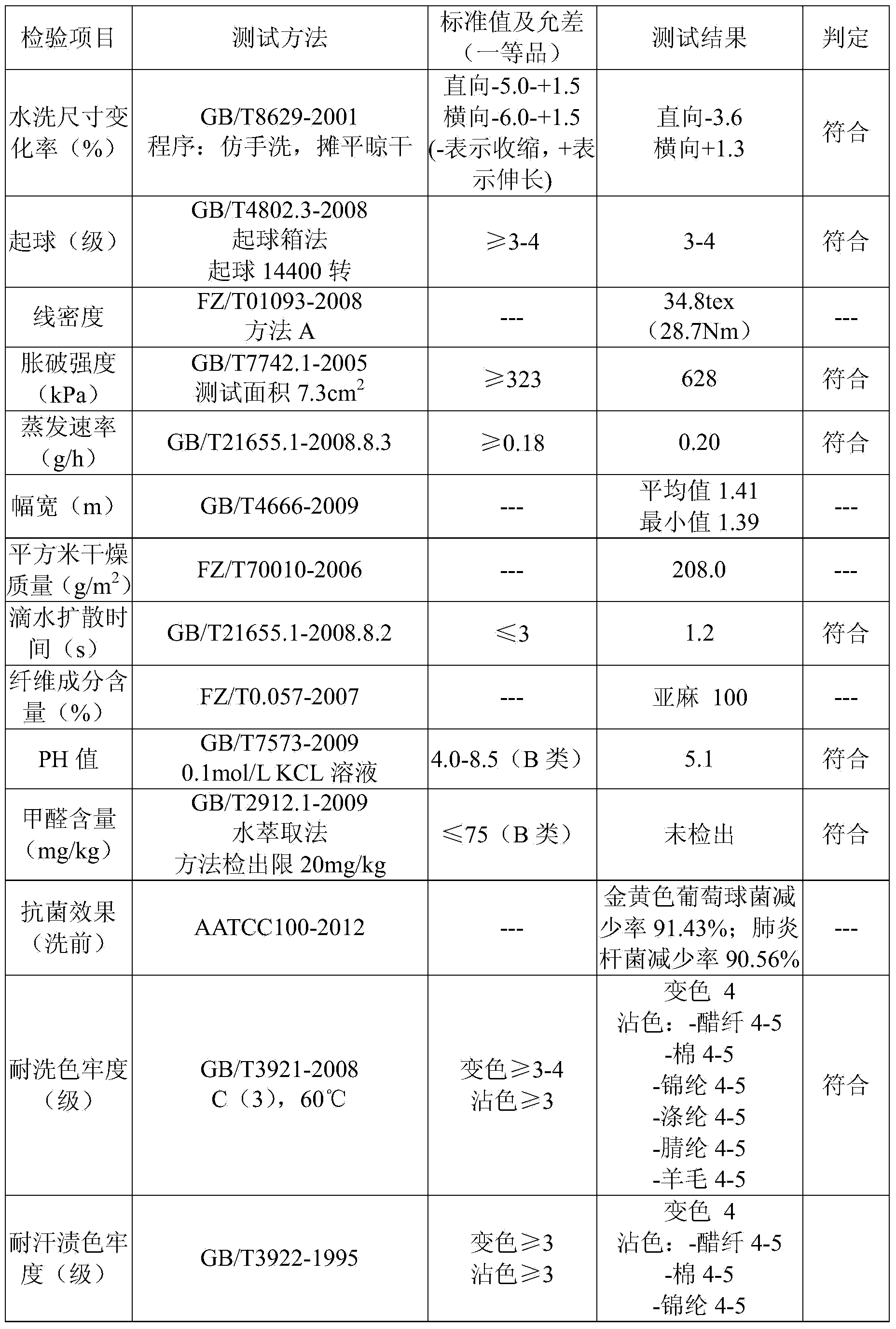

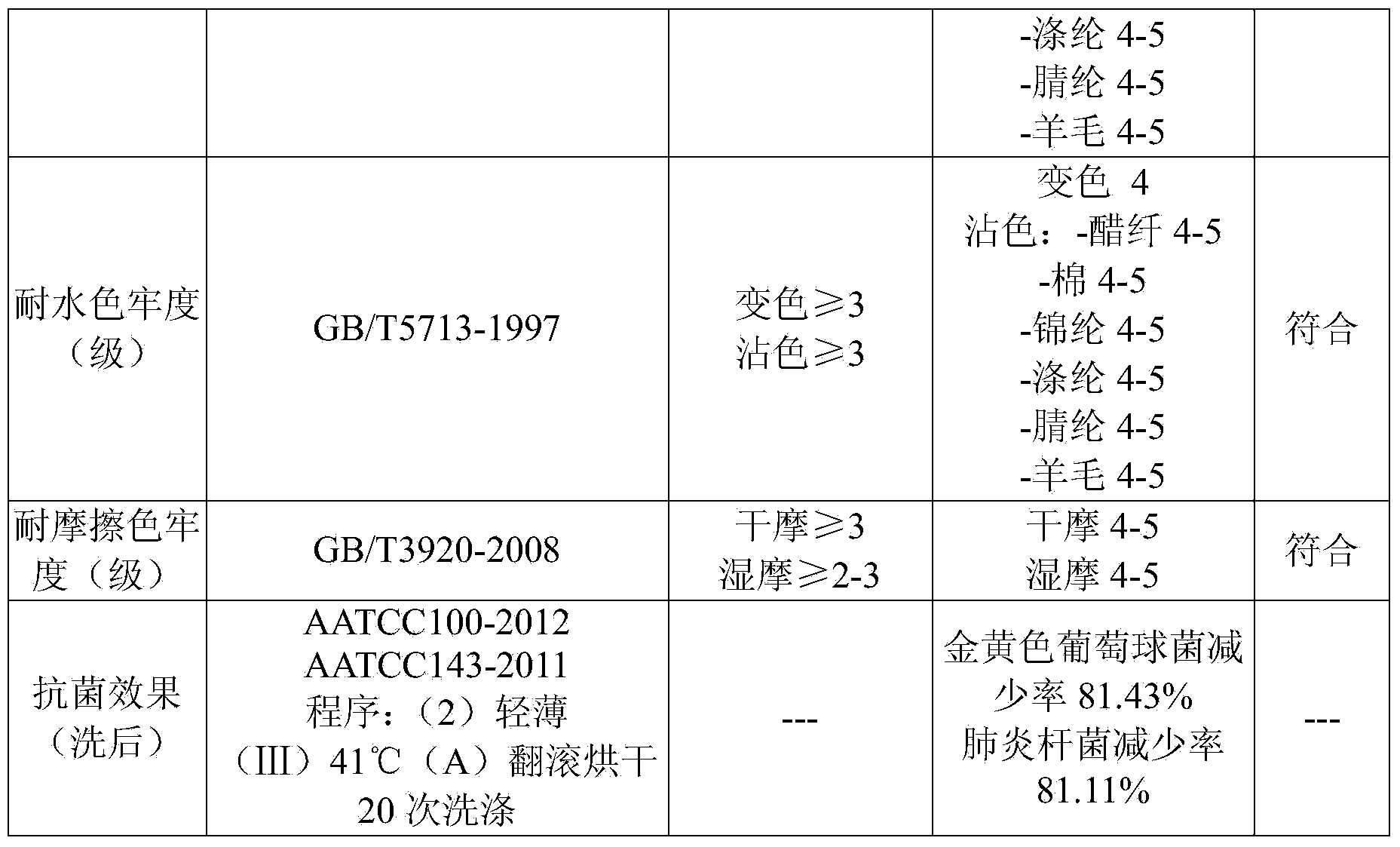

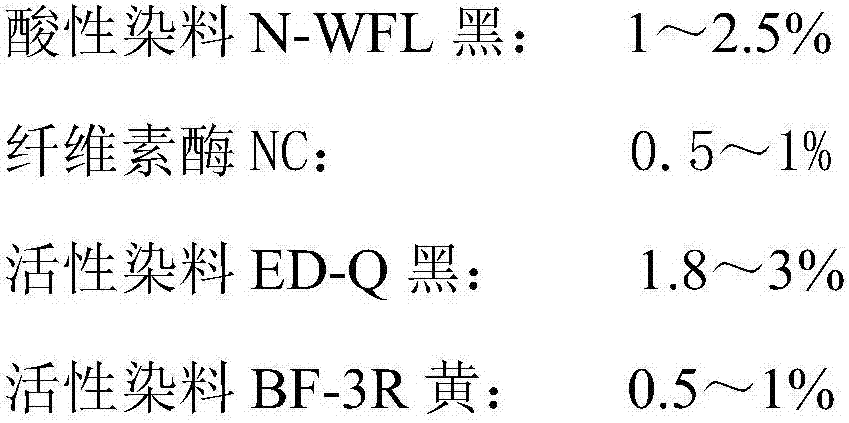

Method for manufacturing flax knitted fabric

ActiveCN103866480AReduce stealthReduce yarn breakageMercerising of indefinite length fabricsWeft knittingYarnWax treatment

The invention provides a method for manufacturing flax knitted fabric. The method comprises the following steps: performing osmotic super-softening treatment on flax grey yarns; performing high-frequency drying treatment on the flax grey yarns after being subjected to osmotic super-softening to enable the moisture content of the grey yarns to be 15-20 percent; performing spooling waxing treatment on the flax grey yarns after being subjected to high-frequency drying, and keeping the moisture content of the grey yarns 15-30 percent; weaving the waxed and sealed flax grey yarns to obtain grey cloth; performing two-sided singeing treatment on the obtained grey cloth; performing liquid ammonia mercerization on the grey cloth after being subjected to the two-sided singeing treatment, and then, performing neutral super-softening treatment; calendaring the grey cloth after being subjected to neutral super-softening, and setting and preshrinking by using a hydrophilic softener to obtain the flax knitted fabric. According to the method for manufacturing the flax knitted fabric provided by the invention, the yarns can be softened, faulty products can be reduced, the efficiency and the quality of knitting can be improved, and the wearability of the fabric can be improved while good breathable moisture absorption and mold resistance of the flax knitted fabric are kept.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Nylon/cotton fabric hair removal and reactive dye dyeing one-bath process

InactiveCN106958152AReduce consumptionReduce production processShrinkingMercerising of indefinite length fabricsHair removalNylon material

The invention relates to a one-bath dyeing process, in particular to a one-bath process for hair removal and reactive dye dyeing of brocade / cotton fabrics. Follow the steps below: select sample cloth → gray cloth desizing → gray cloth pre-setting → gray cloth mercerizing → dyeing formula design → sample vat dyeing → drying and setting → oiling and setting → pre-shrinking finishing → finished product inspection. A one-bath process of hair removal and reactive dye dyeing of nylon / cotton fabrics, which has obvious energy-saving and emission-reduction effects, and the hand-feel elasticity, color fullness, and various quality internal indicators of the processed fabrics can meet the requirements of different customers.

Owner:HANGZHOU AOMEI PRINTING & DYEING

Production process for cotton-linen knitted belt

InactiveCN107385877ASoft touchEasy to processShrinkingMercerising of indefinite length fabricsConvex structureMoisture permeability

The invention relates to a production process for a cotton-linen knitted belt. According to the invention, multiple steps of the production process for the cotton-linen knitted belt are improved from multiple aspects, so the produced cotton-linen knitted belt is ensured to be good in elasticity and wear resistance, stable in dimension, small in washing shrinkage, straight, not prone to creasing, easy to wash and fast to dry under dry and wet conditions; the linen component of the knitted belt is capable of preventing ultraviolet rays and suppressing and resisting bacteria; the production process for the cotton-linen knitted belt overcomes the inherent disadvantage of stiff and itchy handle feel of natural fibrilia fabrics; and the prepared cotton-linen knitted belt has a special concave-convex structure, excellent low irritability, moisture permeability and crease resistance, and good indexes like moisture absorption performance and permeability, is knitted by fully natural fiber, is a low-carbon environment-friendly belt, and accords with the current fashionable trend of international textiles and garments.

Owner:HUZHOU UNIFULL LABEL FABRIC CO LTD

Finishing method of warp cotton latitudinal double-core-spun non-ironing fabric

ActiveCN105714449AStable processingAvoid curlMercerising of indefinite length fabricsWrinkle resistant fibresSizingLiquid ammonia

The invention provides a finishing method of a warp cotton latitudinal double-core-spun non-ironing fabric. The finishing method is characterized in that warp yarns are pure cotton 11.7tex and weft yarns are formed by covering 5%-8% of low-elastic network yarns 105D and 2%-5% of spandex elastic yarns 70D with 90%-95% of pure cotton 14.5tex by mass. A process flow sequentially comprises the following steps: steaming yarns, weaving, turning cloth, singeing, desizing, scouring, bleaching, mercerizing, treating with liquid ammonia, carrying out wet crosslinking, piling, washing with water, tentering, pre-shrinking and checking. The yarns are subjected to high-temperature yarn steaming and part of stress of the spandex elastic yarns is released; in a dyeing and finishing process, machining and dry sizing are not carried out, and the problems that the fabric becomes yellow, the elasticity is low, edges are curled and the like can be improved; and after the fabric is washed with the water for 30 times under an AATCC 124 method through a wet crosslinking finishing technology, the appearance can reach more than or equal to 3.5 grades and the elasticity reaches more than or equal to 20% under an ASTM D3107-2011 method. The fabric treated by the method is soft and comfortable to wear, has moderate elasticity and good recovery, and has a good non-ironing effect.

Owner:鲁丰织染有限公司

Processing method of linen knitted double-mercerized fabric

InactiveCN103451953AStay Moisture WickingKeep breathableMercerising of yarns/threads/filamentsMercerising of indefinite length fabricsYarnPolymer science

The invention discloses a processing method of a linen knitted double-mercerized fabric. The following process flow is adopted for treatment: yarn singeing, yarn mercerizing, clear finishing, dyeing, soft finishing, drying, rewinding, weaving, fabric mercerizing, secondary clear finishing, super soft finishing, hydrophilic setting, preshrinking, examining and packaging. The process provided by the invention is characterized in that linen yarns are pretreated so that the strength of the linen yarns is improved, and therefore, burrs on the surface of the linen yarns are reduced, and the linen yarns are improved in strength, and smooth, and bright and clean in surface, and thus being convenient for next weaving and hand feeling improvement, and secondary mercerization, secondary clear finishing, super soft finishing and hydrophilic setting are adopted in after finishing. The process has the advantages that natural ducts and grooves in natural linen fibers are not blocked, the moisture absorption and sweat releasing properties and the air permeability of the linen fabric are kept, and the fabric is better, softer and smoother than the linen fabric in the prior art. Besides, the process provided by the invention avoids high-difficulty processes such as high-temperature boiling and demineralization; the process is simple and ingenious in design, and therefore, the production cost is effectively saved.

Owner:WUXI NATURAL GREEN FIBER TECH

Dyeing and finishing technology for cotton/viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment

ActiveCN105544227ASoft touchFluffyMercerising of indefinite length fabricsTextile storage in wounded formTextile printerRoom temperature

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a dyeing and finishing technology for a cotton / viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment. The dyeing and finishing technology comprises a pretreatment technology, a dyeing technology and a post-finishing technology. According to the printing and dyeing method for a cotton / viscose stretch fabric, room-temperature stacked desizing is carried out by a biologic desizing enzyme; and an efficient refining agent is selected, so that various pretreatment indexes are effectively improved; soft and fluffy hand feeling of the cotton / viscose stretch fabric is achieved; energy conservation and emission reduction are achieved through low-temperature desizing; potential drapes in the fabric processing process are eliminated; and smooth production of the dyeing procedure is facilitated. A light-colored fabric is dyed from pad dyeing, and a dark fabric is subjected to cold pad-batch dyeing, so that an improvement of various color fastness indexes is met; dyeing process parameters are optimized; and uniform and full dying material quality is obtained. A softening agent is preferably adopted in fabric post-finishing, so that the hydrophilicity of the fabric is achieved; and the wearing comfort of the fabric is achieved.

Owner:HUAFANG

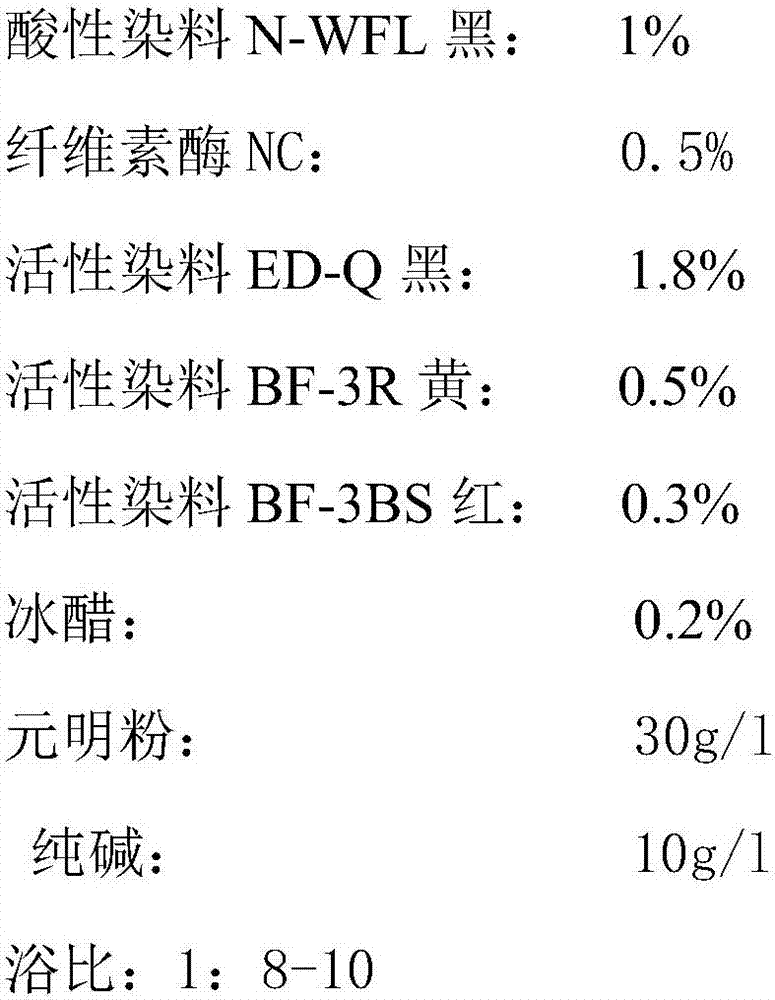

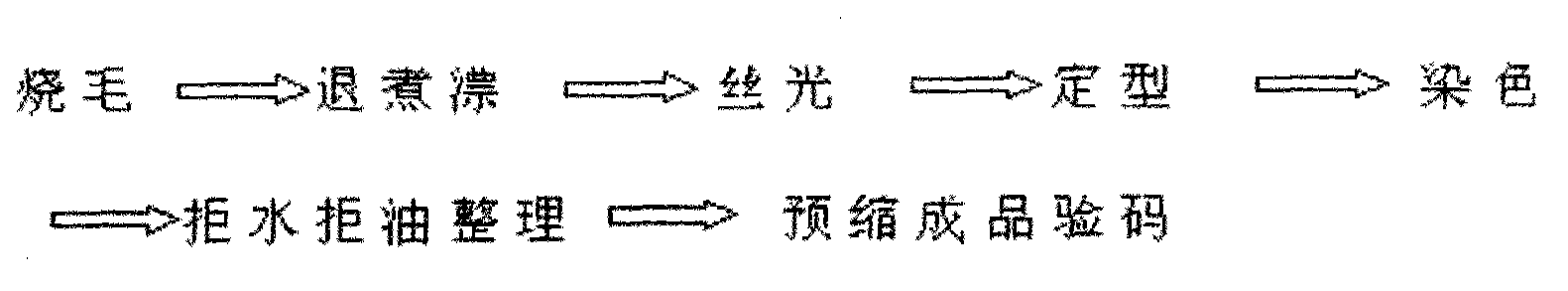

Polyester and cotton blended novel carbon filament anti-static water and oil repellent composite functional fabric

ActiveCN103015106AExcellent long-lasting anti-static effectOvercoming the fatal shortcoming of catalytic hydrogen peroxide splittingSucessive textile treatmentsMercerising of indefinite length fabricsCooking & bakingFiber

The invention relates to the field of textile, and in particular relates to a functional fabric. A polyester and cotton blended novel carbon filament anti-static water and oil repellent composite functional fabric is prepared by blending polyester, cotton and conductive carbon fibers through singeing, annealing, boiling, blanching, grinding, sizing, dyeing and water and oil repellent treatment; the dyed fabric is subjected to water and oil repellent treatment; the mangle expression is 60 percent; infrared is completely open; a pre-baking chamber I has the temperature of 80 DEG C, and a pre-baking chamber II has the temperature of 100 DEG C; the baking temperature is 190 DEG C; the baking time is 45 seconds; and a finished product checking code is pre-condensed. The conductive carbon fiber has the advantages and the water and oil repellent theory that the novel conductive carbon fiber has a good and durable anti-static effect; the critical defect of metal conductive fiber catalytic hydrogen peroxide decomposition is avoided; the refining and blanching resistance is relatively high; square grids formed by the conductive fiber on the surface of the fabric cannot be seen from the appearance of the fabric; and the composite functional fabric is more attractive than the metal conductive fiber.

Owner:辽宁宏润源印染有限公司

Dyeing and finishing method for core-spun single woven fabric

InactiveCN101082155AIncrease chromatic aberrationFeel goodMercerising of indefinite length fabricsBleaching apparatusYarnEngineering

The process of dyeing and finishing covered yarn fabric includes the steps of preparing gray cloth, singeing, boiling and rinsing in an overflow dyeing machine, finishing, mercerizing, dyeing or whitening, finishing and full decatizing. The process has combined overflow processing and open width processing, and includes overflow boiling and rinsing step, overflow dyeing step and other open width steps. Compared with conventional all open width process, the present invention has improved less dyeing defects, less color difference and improved hand feeling; and compared with common overflow process, the present invention has increased mercerizing treatment, raised fabric vividness and color fastness, and improved visual quality of the fabric.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

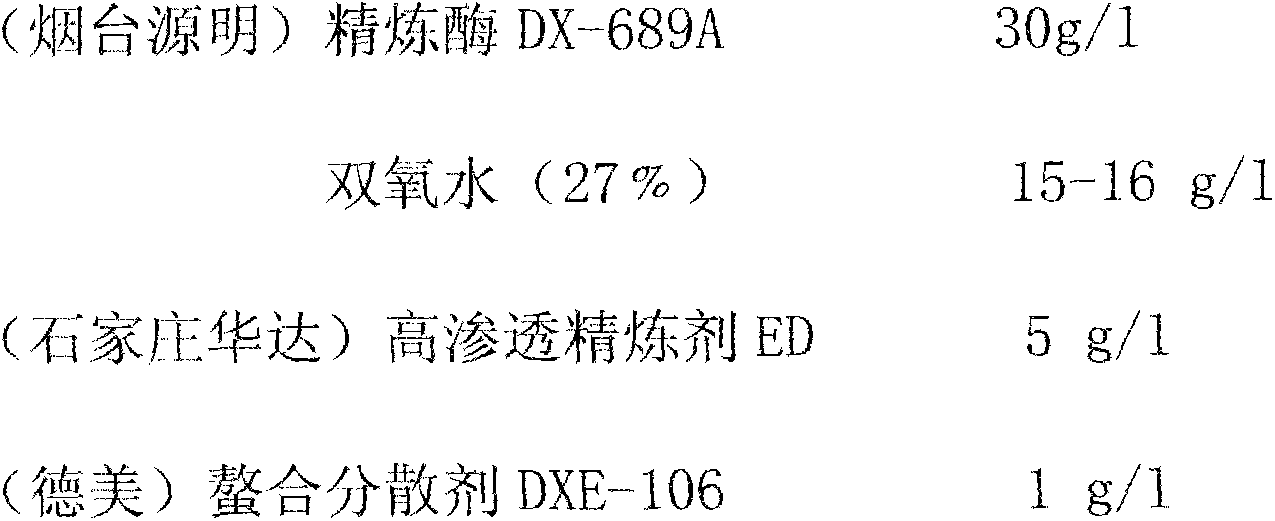

Printing and dyeing technology for pure cotton dyed twill fabric

InactiveCN109235090AInfluence of printing and dyeing processImprove user-friendly designMercerising of indefinite length fabricsSingeingEngineeringDyeing

The invention provides a printing and dyeing technology for a pure cotton dyed twill fabric. The printing and dyeing technology comprises the following eight steps: 1) preparing a gray cloth; 2) singeing; 3) desizing; 4) boiling off; 5) bleaching; 6) dyeing; 7) mercerizing; 8) after-finishing. According to the invention, a series of steps are arranged, so that workers can work by referring to theworkflow of the invention and the working efficiency of printing and dyeing the pure cotton dyed twill fabric can be increased.

Owner:佛山市三水南方天泽印染有限公司

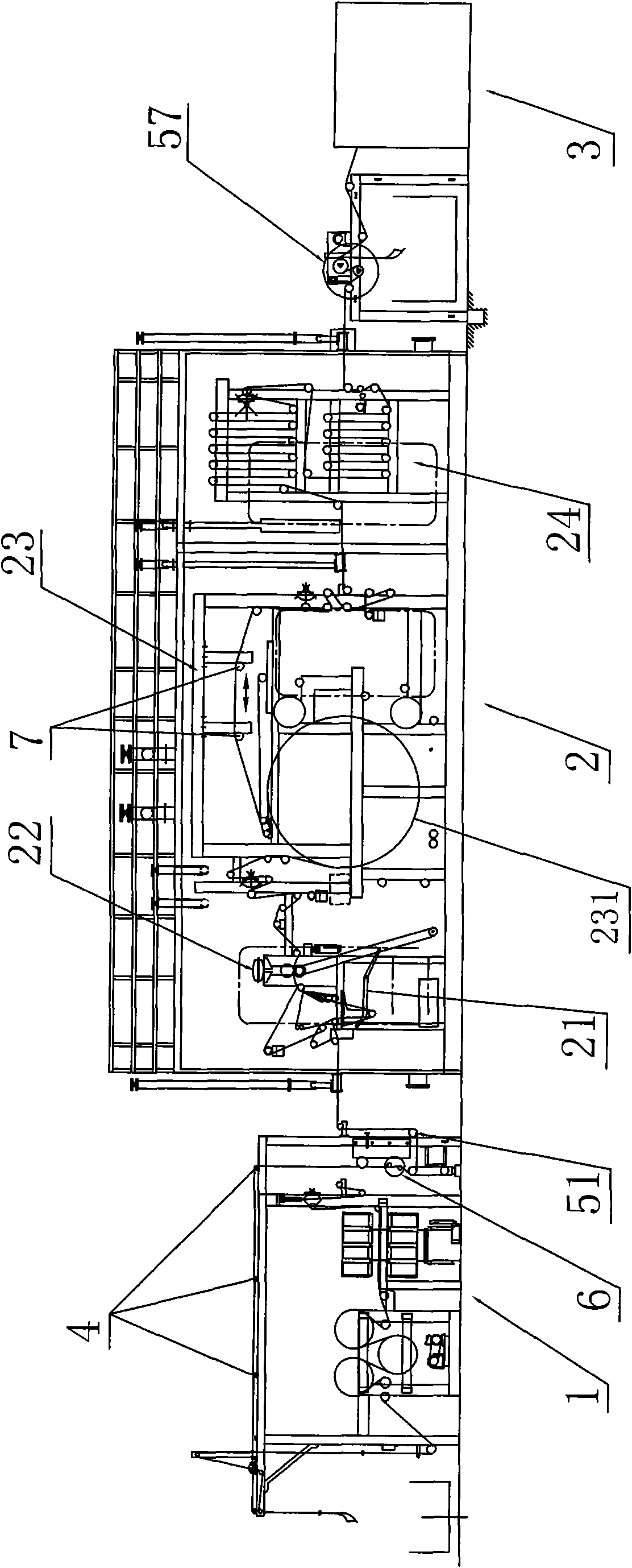

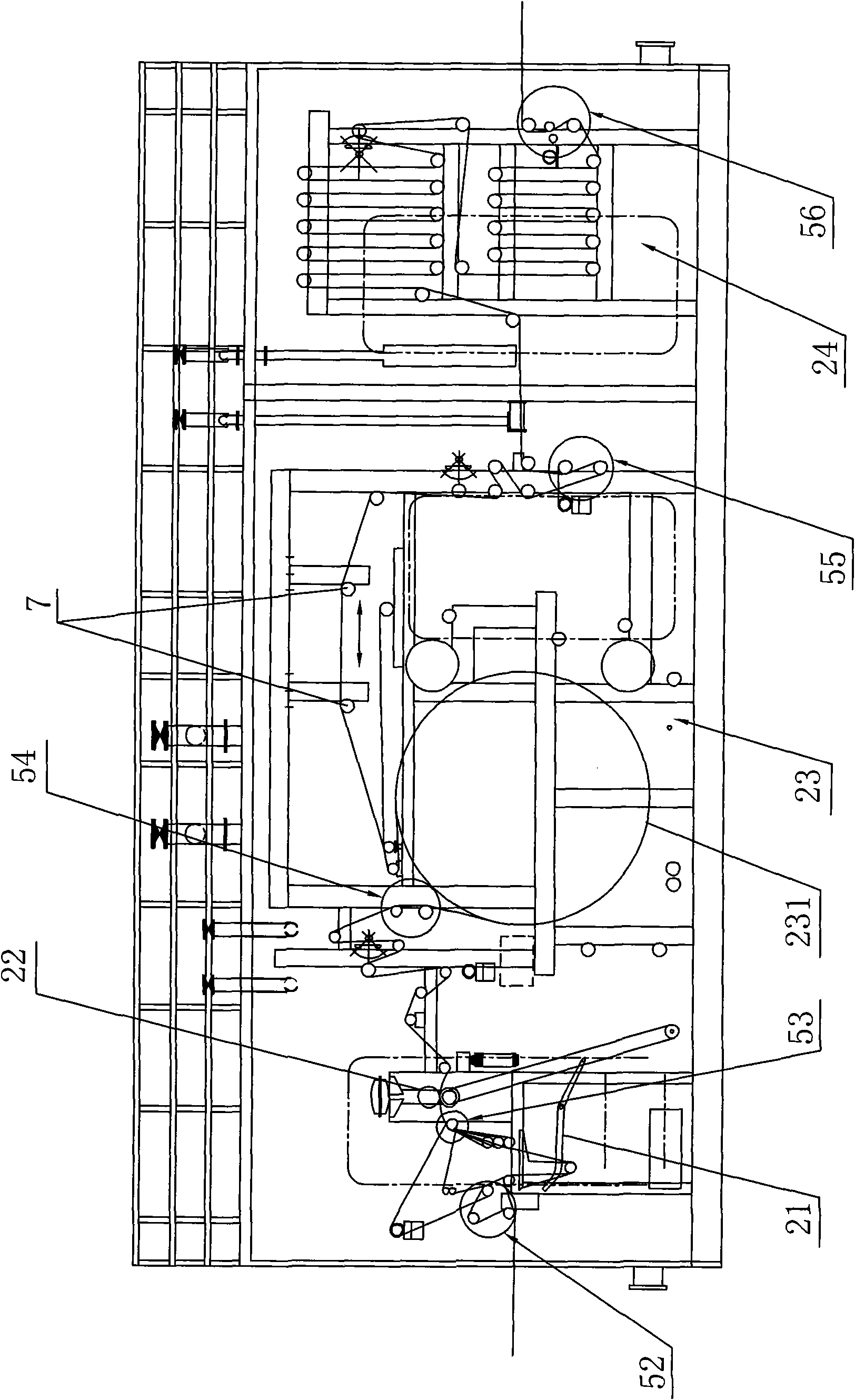

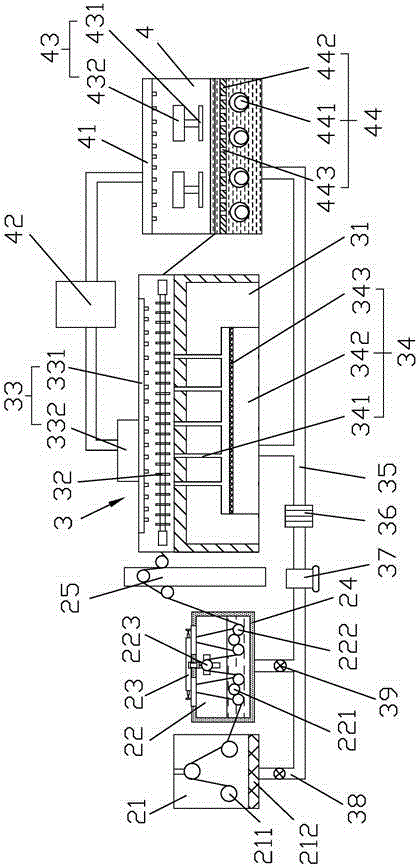

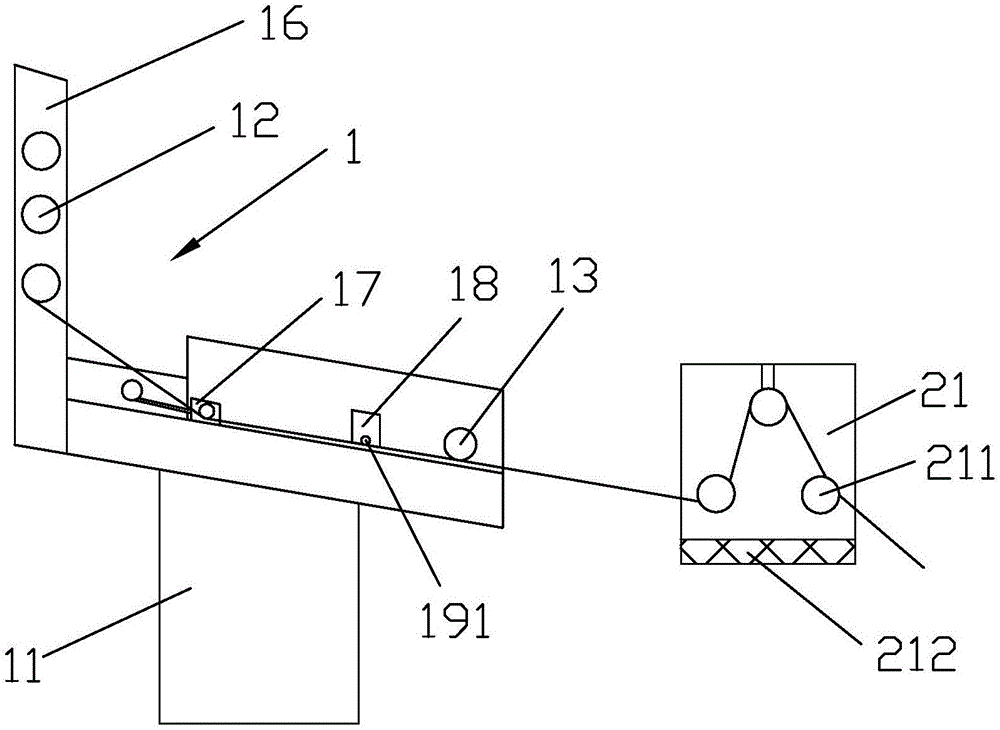

Liquid ammonia mercerizer equipment of knitting fabric

InactiveCN101565884AReduce tensionAvoid curlMercerising of indefinite length fabricsFibre treatmentTransfer procedureEngineering

The invention discloses a liquid ammonia mercerizer equipment of knitting fabric. The equipment comprises a woven fabric entering device, a liquid ammonia mercerization device and a liquid ammonia recovery device and is characterized in that a first group of cloth guide rollers is arranged above the woven fabric entering device, a group of scroll roller combination is arranged between the woven fabric entering device and the liquid ammonia mercerization device in which five groups of scroll roller combinations are arranged, and a group of scroll roller combination is arranged between the liquid ammonia mercerization device and the liquid ammonia recovery device. The equipment has the advantages of reducing the tension in the delivery process of the knitting fabric, simultaneously poking the turned edge of the knitting fabric aside to prevent edge curl and reducing the wrap-direction shrink. Besides, avoiding an original preliminary drying cylinder in the delivering process, the knitting fabric directly enters the liquid ammonia mercerization device through the first group of cloth guide rollers and is consequently prevented from being extruded and forming folds. Therefore, on the same improved liquid ammonia mercerizer, tatting fabric and knitting fabric can be smoothly mercerized as long as different fabric delivering routes are selected.

Owner:浙江盛泰服装集团股份有限公司

Dyeing and finishing method for tencel/bamboo pulp fiber blended fabric

ActiveCN105483904ASoft touchMercerising of indefinite length fabricsFabric breaking/softeningFiberYarn

The invention provides a dyeing and finishing method for tencel / bamboo pulp fiber blended fabric. Gray fabric is sequentially subjected to singeing, enzyme rolling and cold piling, washing, cold piling, mercerizing, tentering and whitening, printing, ageing, washing, softening and shaping, calendaring and pre-shrinking, and then the tencel / bamboo pulp fiber blended fabric is obtained, wherein the caustic soda concentration in the mercerizing process ranges from 80 g / L to 90 g / L. The dyeing and finishing method is mainly used for dyeing and finishing the tencel / bamboo pulp fiber blended fabric, and warp and weft of the fabric are tencel / bamboo pulp fiber blended yarn. The shrinkage rate of the obtained tencel / bamboo pulp fiber blended fabric is within the range from +2% to -4%, and the fabric is soft in hand feeling, smooth in fabric cover and free of deformation.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

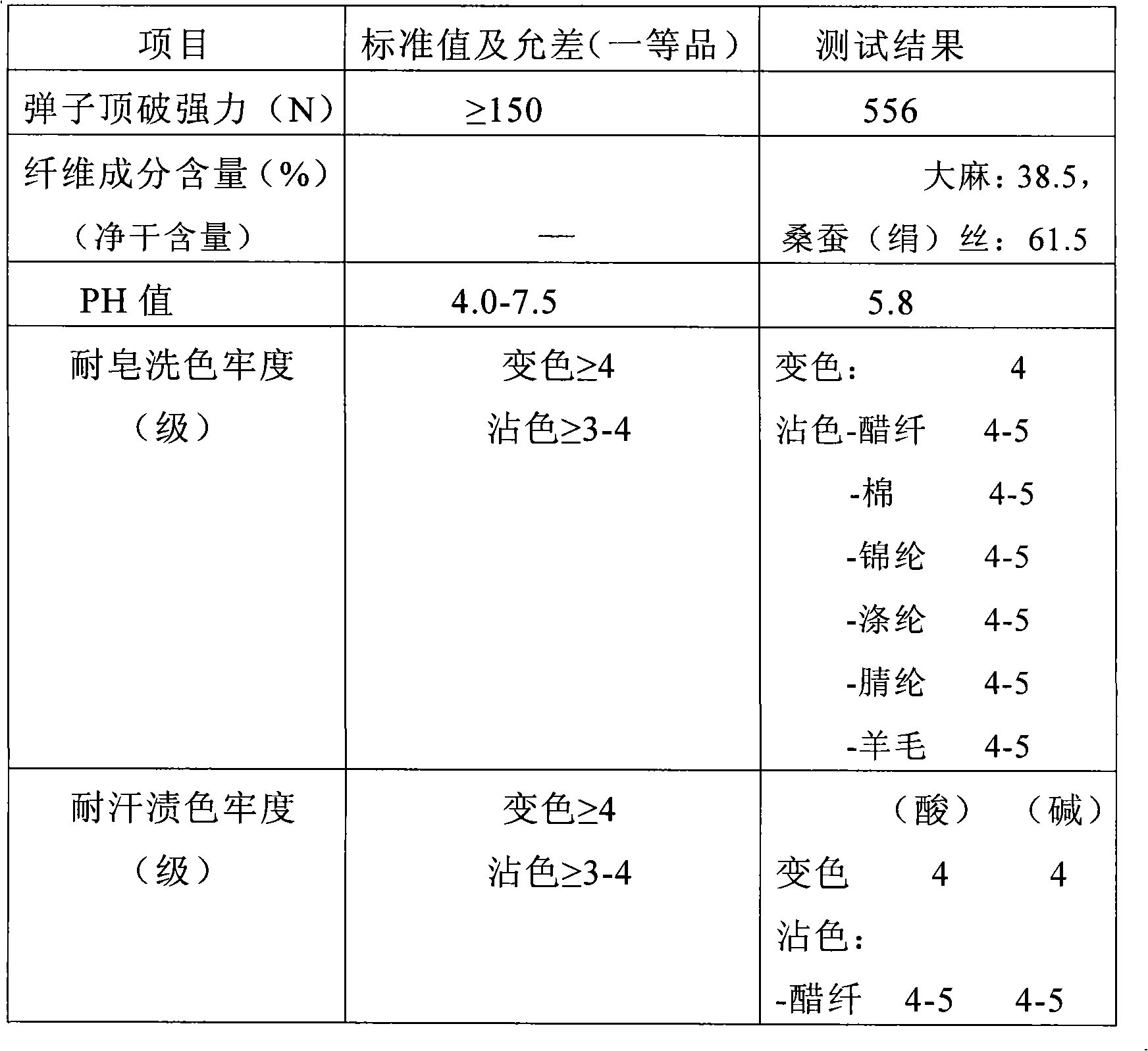

Hemp/silkworm (kiginu) silk high-count blended knitted fabric and manufacturing method thereof

InactiveCN102021725AEasy to absorb moistureMoisture-wickingMercerising of indefinite length fabricsWeft knittingYarnUltraviolet radiation

The invention belongs to the technical field of textile fabrics and relates to a manufacturing method of hemp / silkworm silk high-count blended knitted fabric. The manufacturing method comprises a line-forming technique and a cloth-forming technique, wherein the line-forming technique comprises the following steps: high-count blended yarn forming, triple singeing treatments, mercerization, degumming, dyeing, silk turning, spooling and the like of the hemp / silkworm silk; and the cloth-forming technique comprises the following steps: card nepremoval, humidifying, weaving, primary singeing treatment, mercerization, softening treatment, sizing, pre-shrinking, batching package and the like. The high-count blended knitted fabric has functions of antibacterium, bacteriostasis and ultraviolet radiation resistance, has good humidity-absorbing and air-permeable performances, high temperature resistance, softness and comfortableness, and can meet different requirements of crowds at all ages and all levels.

Owner:佛山市欧诗顿服饰有限公司

Tencel Jutecell dense weft clipped shell fabric

InactiveCN103628220AGood moisture absorption and air permeabilityGood drapabilityMercerising of indefinite length fabricsPattern makingEngineeringWeft yarn

The invention discloses Tencel Jutecell dense weft clipped shell fabric which is characterized by being formed by warp yarns, ground weft yarns and two sets of flower weft yarns in different colors in an interwoven mode. The warp yarns are made of cotton yarns, the ground weft yarns are Tencil / Jutecell blended yarns, the color of the Tencil / Jutecell blended yarns is the same as the color of the warp yarns, the flower weft yarns are two kinds of cotton yarn piled yarns in different colors, a ground part texture is a rhombus texture, dot weft flowers are arranged at a ground part, each dot weft flower is formed by two dots in different colors, the two dots are arranged in a slant mode, the arrangement directions of two adjacent rows or lines of dots are opposite, a flower part texture is a twilling texture or warp face satin woven texture, patterns on the Tencel Jutecell dense weft clipped shell fabric are characterized in that a large-rhombus area formed by the dot weft flowers serves as a cycle, the density of the warp yarns of the Tencel Jutecell dense weft clipped shell fabric finished product is 520-580cm per 10 yarns, and the density of the weft yarns is 450-500cm per 10 yarns. The Tencel Jutecell dense weft clipped shell fabric is light, thin, breathable, comfortable and good in gloss, and solves the problem that weft crackiness is prone to being generated in weft clipped shell fabric.

Owner:JIANGSU SHUNYUAN NEW MATERIAL TECH CO LTD

Production process for Tencel cotton spinning silk style fabric

InactiveCN106811857AColorfulIncrease elasticityShrinkingMercerising of indefinite length fabricsProduct inspectionEngineering

The invention relates to a silk-style fabric, in particular to a production process of Tencel cotton imitation silk-style fabric. Follow the steps below: select samples→cloth distribution→loose cloth→width cutting→grain cloth singeing treatment→mercerizing treatment→open width boiling and bleaching→setting and drying→cold dyeing→cold stacking→soaping→drying→finished product shaping→rubber Blanket shrinking → finished product inspection. The production process of a Tencel cotton imitation silk style fabric has the characteristics of flatness, bright colors, good elasticity, good moisture absorption, strong wrinkle resistance, stable size, good air permeability and melt hole resistance, and significantly reduces wool fabric fluffing and fluffing Balls and static electricity also reduce the price of woolen fabrics.

Owner:HANGZHOU HAORAN TEXTILE TECH CO LTD

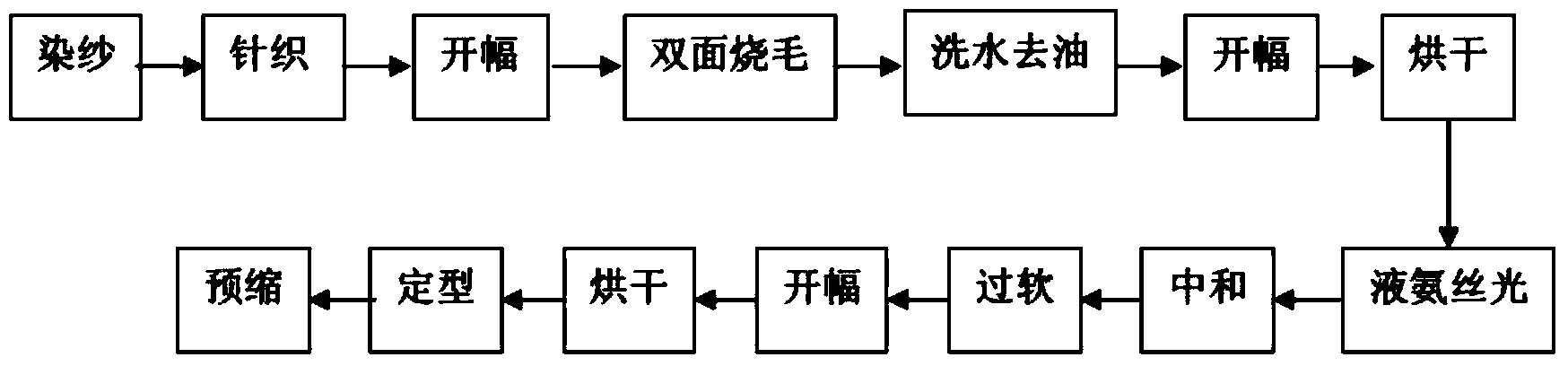

Production method of washable yarn-dyed knitted fabric

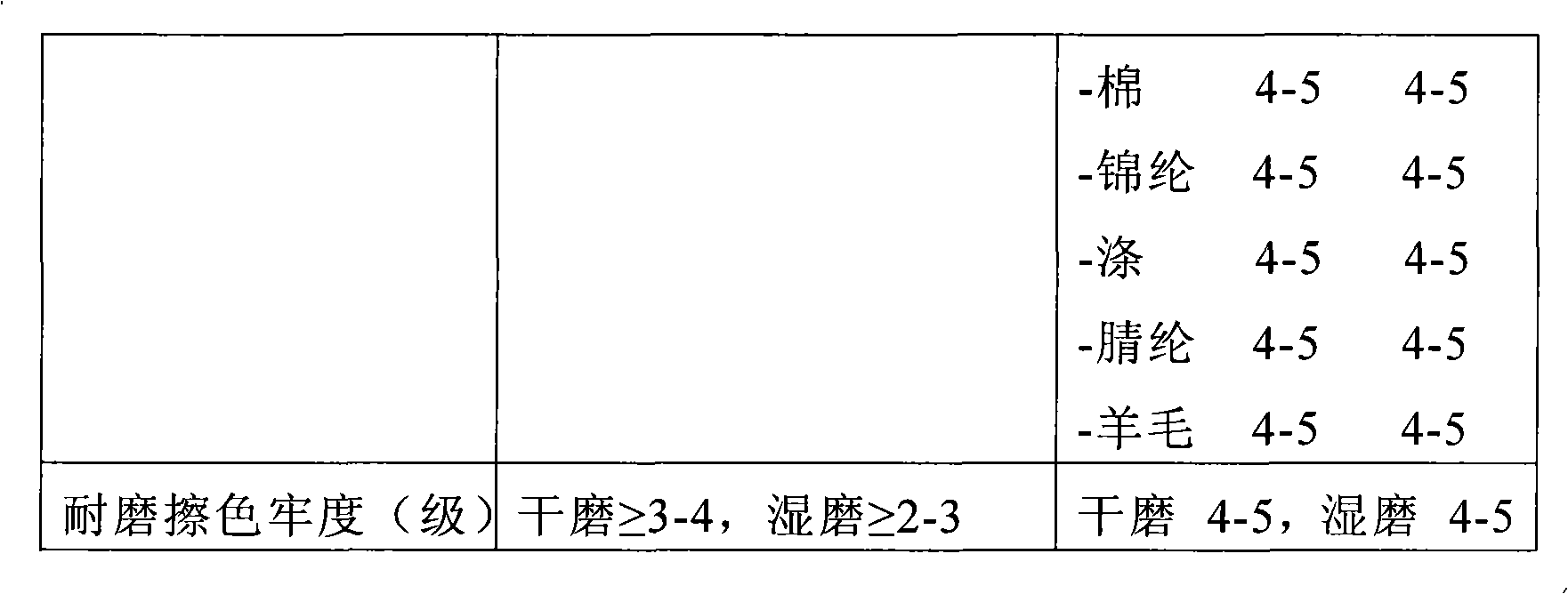

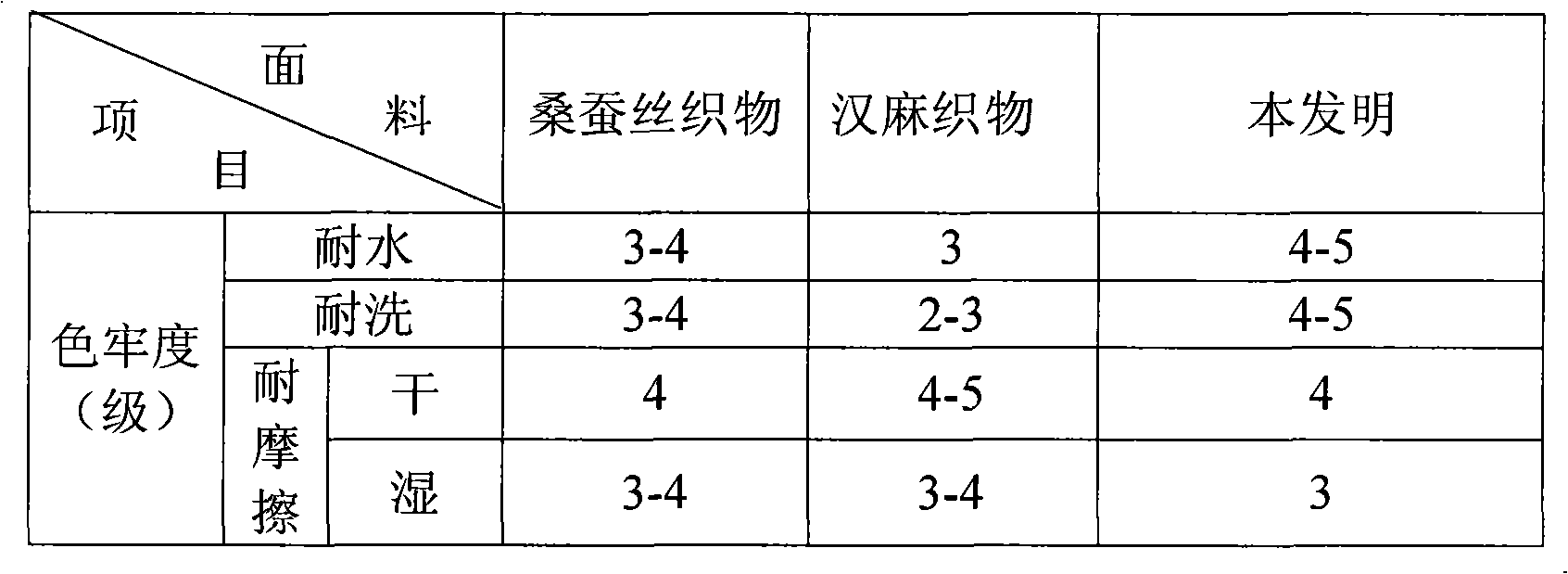

InactiveCN104264412AImprove responseImprove hydrophilicityMercerising of indefinite length fabricsFibre treatmentYarnAdditional values

The invention provides a production method of washable yarn-dyed knitted fabric. The production method comprises steps as follows: yarn is sequentially subjected to yarn dyeing, knitting, scotching, double-side singeing, washing for oil removal, scotching, drying, liquid ammonia mercerization, neutralization, softening, scotching, drying, setting and preshinking, and the washable yarn-dyed knitted fabric is obtained. The production method adopts steps of singeing, washing for oil removal and liquid ammonia mercerization sequentially, the liquid ammonia mercerization effect and the liquid ammonia recycling are facilitated, and resin treatment is combined, so that an obtained knitted product has better dimensional stability, and more durable hand feeling and color are kept; and the fabric has high flatness, touches comfortable and is soft, elastic and better in strength. By means of the production method, various properties of the knitted product are improved, the additional value and the technological content of the knitted product are increased, and recyclable liquid ammonia used for treatment is environment-friendly.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

High count single yarn double-sided mercerized fabric and processing method thereof

InactiveCN102926114AHigh strengthImprove dye uptakeMercerising of indefinite length fabricsWeft knittingYarnSilk cloth

The invention discloses a high count single yarn double-sided mercerized fabric and a processing method of the high count single yarn double-sided mercerized fabric, and belongs to the field of textile fabric processing. The technical scheme of the high count single yarn double-sided mercerized fabric and the processing method the high count single yarn double-sided mercerized fabric comprises special spinning, yarn processing, double-sized fabric weaving and fabric after-treatment. The special spinning means that a high-strength high-count yarn is manufactured by the adoption of special cotton collocation and the implementation of strong twisting on the special cotton collocation and the yarn processing. The double-sided fabric weaving means that the double-sided fabric is woven by a double-sided machine with high stitch length of 40 stitches or more than 40 stitches. The fabric after-treatment means that a finished production fabric is manufactured by singeing, mercerizing and sizing of the fabric. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric is characterized in that high-strength high-count yarns manufactured by adopting the special spinning method, and weaving requirement of high stitch distance double-sided machine strength is met. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric produce high-quality high count single yarn double-sided fabrics, and the fabrics are light and elegant, and comfortable, and have a silky and smooth touch, and the luster of the fabrics is soft and bright, and the fabrics are the best in double-sided fabrics.

Owner:WUXI NATURAL GREEN FIBER TECH

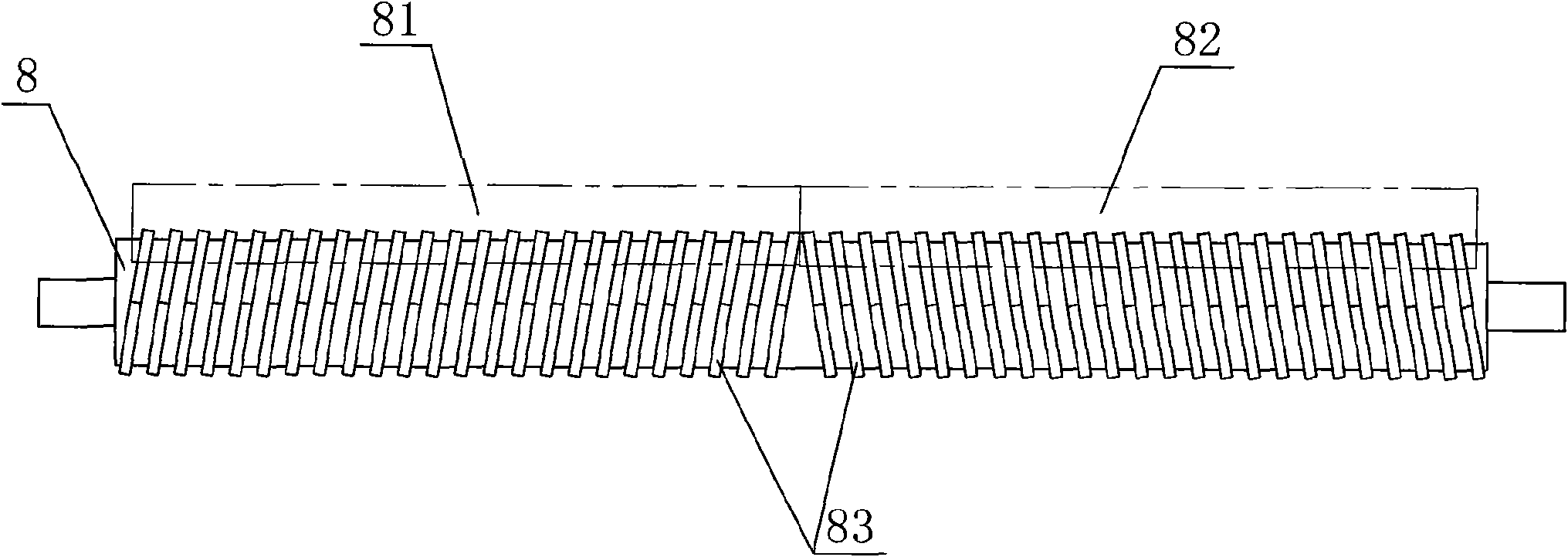

Single-yarn single-face double-mercerization fabric and processing method thereof

ActiveCN102965870AAvoid adverse effects of spinningHigh glossMercerising of yarns/threads/filamentsMercerising of indefinite length fabricsYarnTextile technology

The invention provides a single-yarn single-face double-mercerization fabric and a processing method thereof, belonging to the technical field of textile. The method comprises the following steps: a, fiber mercerization: performing tension mercerization processing on fiber by adopting caustic soda or liquid ammonia for the preparation of mercerized fiber; b, fiber spinning: performing spinning process on the mercerized fiber for the preparation of single yarns; c, fabric waving: weaving yarns into a single-face knitted fabric; d, fabric mercerization: performing mercerization processing on the fabric; and e, sizing: preparing the fabric into a certain-specification finished-product fabric through high temperature sizing, e.g. the fabric is sized by a sizing machine through the adoption of auxiliaries such as resin and softening agents. The single-yarn single-face double-mercerization fabric provided by the invention is prepared via a mode that the fiber is subjected to tension mercerization for the preparation of the single yarns, the single yarns are woven into the single-face fabric, and the single-face fabric is subjected to secondary mercerization; the single yarns cannot be effectively mercerized through the adoption of the conventional technology; the single-yarn single-face double-mercerization fabric cannot be prepared through the double-mercerization processing process of the conventional yarn mercerization and the fabric mercerization; meanwhile, the technologies such as reeling and rewinding during the yarn mercerization are omitted; therefore, the cost is saved; and moreover, the dyeing mode is not limited to hank dyeing and the bobbing dyeing also can be implemented, so that the output and the efficiency are improved greatly.

Owner:无锡市鳌尊生态科技有限公司

Sorting method for improving gloss and flatness after all-cotton fabric is washed

ActiveCN105088740AHigh glossImprove flatnessMercerising of indefinite length fabricsSingeingShrinkage rateEngineering

The invention provides a sorting method for improving gloss and flatness after all-cotton fabric is washed. Singeing, preprocessing, pre-tentering, mercerizing, whitening tentering, printing or dyeing, washing, pre-sorting, high-temperature washing, soft sizing, calendaring and preshrinking are conducted on grey cloth, and then the fabric is obtained. According to the sorting method, a moist-crosslinking technology is not needed so that a better washable effect can be achieved, the fabric cover is good in gloss and flatness after the obtained fabric is washed, the gloss is bright after multiple times of washing is conducted, a lifting effect is achieved on the shrinkage rate, and formaldehyde testing conforms to the national detecting standard.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

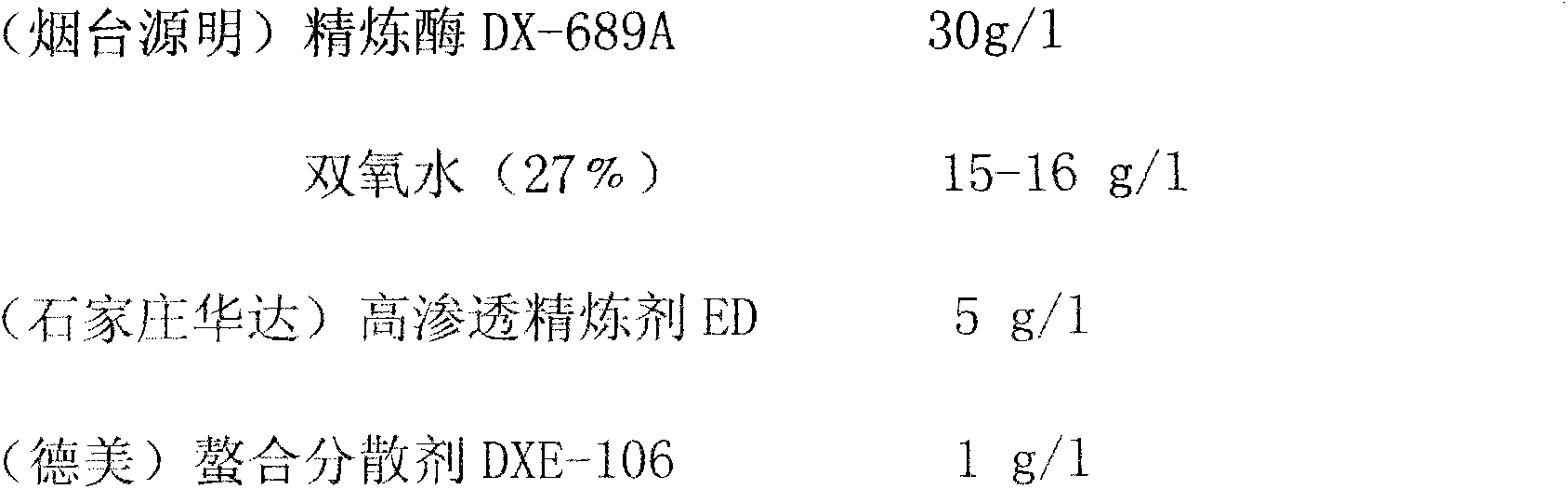

Pretreatment process for combed polyester cotton bleached cloth

InactiveCN103437140AStrong damageHigh whitenessMercerising of indefinite length fabricsBiochemical fibre treatmentPolyesterEthylene diamine

The invention relates to a pretreatment process for combed polyester cotton bleached cloth. The pretreatment process comprises the procedures of singeing, desizing, bleaching, mercerizing and heat-shaping, wherein during desizing, the enzyme-desizing cold-dwelling process that desizing anzyme and a penetrant are added into the desizing procedure is adopted; in the bleaching procedure, the following materials are adopted: 0.2-0.4 part of potassium borate serves as the bleaching liquor, 0.8-1.2 part(s) of diethylenetriaminepenta acid (DTPMP), 0.8-2 part(s) of acrylic acid maleic acid copolymer, 0.5-1 part of 1, 5-anhydrous glucitol, 1-2 part(s) of caprolactam activator, 0.4-0.7 part of tetraacetylethylenediamine (TAED), 3-8 parts of sodium hydroxide, 3-7 parts of hydrogen peroxide and 900-1000 parts of water. When the pretreatment process is used for processing fabrics, prominent damage to the fabrics is small; as enzyme desizing is adopted, the desizing ration is improved; the bleaching liquor adopted in the bleaching procedure can effectively improve the whitenness of the fabrics; meanwhile, the pretreatment cost is lowered.

Owner:如皋市五山漂染有限责任公司

Terylene regeneration staple spandex-free mechanical elastic CVC drill fabric and production method thereof

InactiveCN101838878AClaritySoft and smoothMercerising of indefinite length fabricsBiochemical fibre treatmentYarnCotton fibre

The invention discloses a terylene regeneration staple spandex-free mechanical elastic CVC drill fabric, belonging to the field of textile, and being produced by blending terylene regeneration staples, pure cotton yarns and cotton fibers, wherein the warp direction adopts the pure cotton yarns, the weft direction adopts blended yarns which are produced by the terylene regeneration staples and the cotton fibers, the weight percentage preparation ratio of the terylene regeneration staples and the cotton fibers is 65-75:35-25, the fabric has elasticity after a reasonable mechanical elastic organization design and a finishing technology, and the elasticity reaches 10-15% (ASTM D3107); ideal planeness effect can be realized without noniron finish, and the planeness of the fabric reaches 3.0-3.5 level (being washed for 30 times after pressing, AATCC 124); and the fabric is particularly suitable to make leisure wears of men, each index meets the requirements of customers of world brands, and the handfeel and the style are received great favor by customers.

Owner:YIXING XINLEQI TEXTILE PRINTING & DYEING

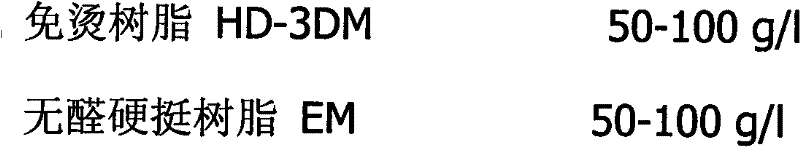

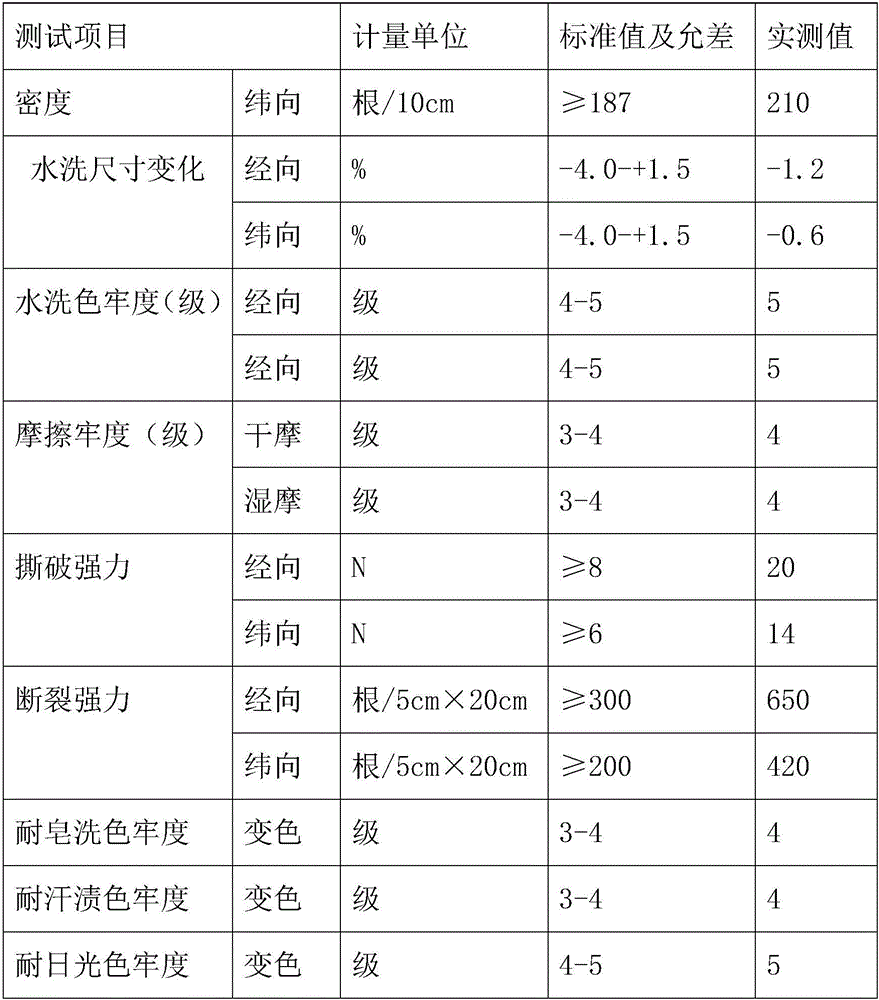

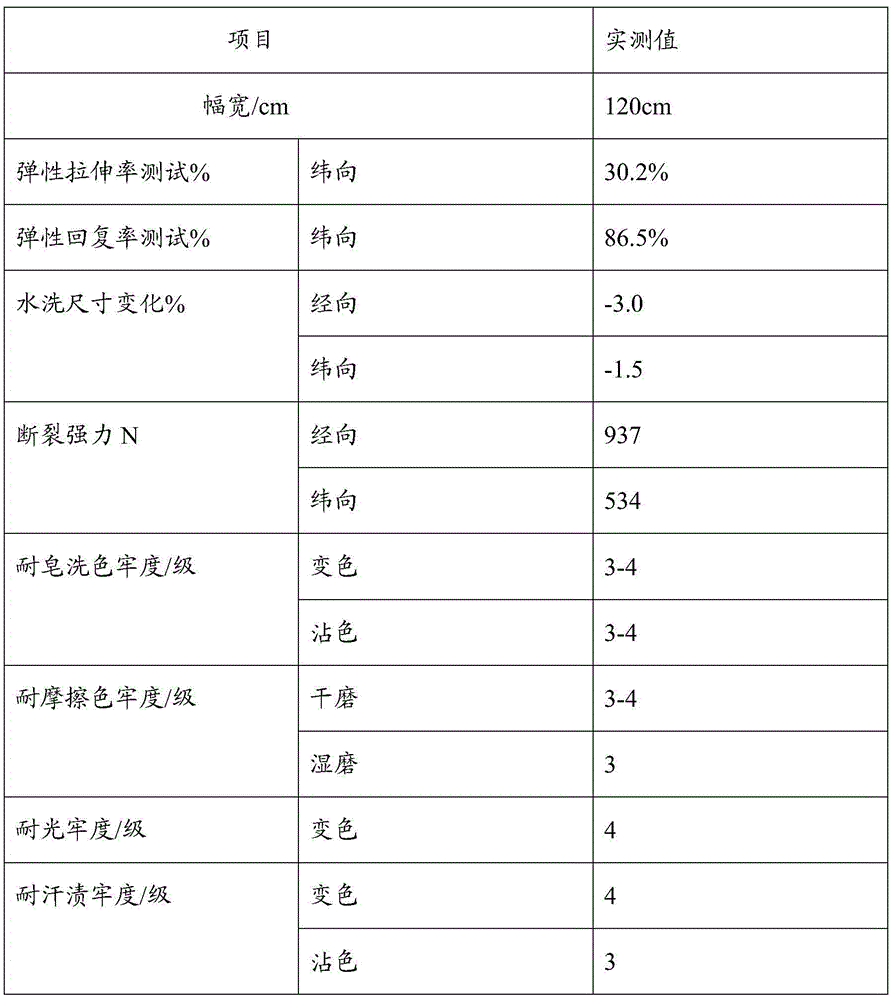

Production method of pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness

InactiveCN107326595AReasonable production process designEasy to operateMercerising of indefinite length fabricsSingeingBreaking strengthOperability

The invention discloses a production method of a pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness. A main production process flow comprises: turnover sewing, primary singeing, alkali-rolling cold-batch desizing, scouring and bleaching, secondary singeing, pre-stentering for wrinkle removal, mercerizing, cold-rolled batch dyeing or dye jigger dyeing, formaldehyde-free shrink resistant finishing, stentering finishing, mechanical pre-shrinking, calendering, checking and packing. The pure-cotton bright-red extra-wide breadth woven fabric is high in surface gloss, the wet rubbing fastness of the product reaches a level 3, the warp and weft washing dimension change rate is in a range of -3.0 percent to +1.0 percent, the pilling resistance is more than or equal to a level 4, the breaking strength is more than or equal to 250N, and a cotton fabric printing and dyeing standard for a superior product is completely reached. The production process is reasonable in design, high in operability, and environmentally-friendly.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

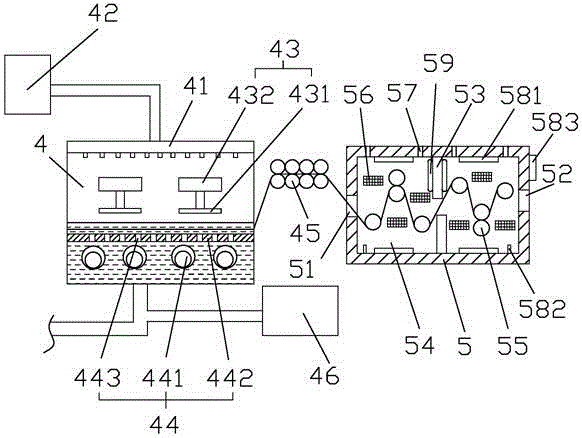

Intelligent chainless and clip mercerizing machine adopting wet cloth and thermal alkali for knitted fabric

ActiveCN106245252AAdjustable distanceEasy to useMercerising of indefinite length fabricsTextile treatment machine arrangementsEngineeringWater washing

The invention mainly discloses an intelligent chainless and clip mercerizing machine adopting wet cloth and thermal alkali for knitted fabric. The technical scheme of the machine is characterized in that the mercerizing machine comprises an open width fabric feeding device, a concentrated alkali dipping tank, a clip expanding device, an oscillating water washing tank, a drying machine and an open width fabric discharging device, wherein the concentrated alkali dipping tank comprises a pre-dipping tank and a concentrated alkali tank, pre-dipping rollers and a heating unit are arranged in the pre-dipping tank, and a first roller group, a second roller group, a fabric guide roller and an adjusting device are arranged in the concentrated alkali dipping tank; the clip expanding device comprises a spray tube, a spray tank, an alkali absorption tube and a collection tank provided with a filter layer, a recovery tube is connected to the collection tank and connected with the pre-dipping tank, the concentrated alkali tank, the spray tank and the oscillating water washing tank, and a second spray device, a water supplementing tank, a patting device and an oscillating device are arranged in the oscillating water washing tank. The mercerizing machine can adjust the reaction degree of the fabric and an alkali liquid, the mercerizing effect is good, alkali is fully removed, the later dimensional stability and quality of the fabric are improved, the waste alkali liquid is recycled, and accordingly, the properties of energy conservation and environment friendliness of a mercerizing processing technology are improved.

Owner:浙江瑞格机械科技有限公司

Processing method of wash-and-wear shirt containing bast fiber or regenerated cellulose fiber

ActiveCN109577004ADoes not affect hydrophilicityEasy to clean and removeMercerising of indefinite length fabricsLiquid/gas/vapor removalEmulsionRegenerated cellulose

The invention discloses a processing method of a wash-and-wear shirt containing bast fiber or regenerated cellulose fiber. The processing method comprises the steps of fabric processing and garment making, wherein fabric processing comprises yarn preparation, yarn dyeing, yarn softening, drying, spooling, warping, slashing, weaving, cloth preparation, singeing, desizing, mercerizing, sizing and preshrinking; the garment making comprises cloth preparation, piece tailoring, sewing, pre-washing, drying, spraying, pre-drying, pressing, baking, moisture regaining, washing, drying, button cuffing, ironing and packaging; yarn softening involves that a polyethylene wax emulsion is used for treating fabric after yarn dyeing, the use concentration of the polyethylene wax emulsion is 2-4 g / L, and thebath ratio is 1:5-10. The processing method of the wash-and-wear shirt containing the bast fiber or the regenerated cellulose fiber has the advantages that the polyethylene wax emulsion is taken as asoftening agent of the yarn softening process, the softening agent is easy to clean off in the subsequent dyeing and finishing process, the hydrophilia of the fabric and the combination of resin andfiber in the non-iron finishing stage of ready-made garment are not affected, so that the processed wash-and-wear shirt has excellent appearance flatness and good dimensional stability after washing.

Owner:雅戈尔服装控股有限公司 +1

Summer smooth moisture-permeable knitted jeans fabric

InactiveCN105734802AImprove qualityGood hygroscopicityMercerising of indefinite length fabricsWeft knittingPolyesterYarn

The invention provides a summer smooth and moisture-permeable knitted jeans fabric, which is knitted by a first yarn, a second yarn and a third yarn, the first yarn is an S-twisted blended yarn, and the second yarn It is a Z-twist blended yarn, the above-mentioned third yarn is a polyester yarn, and the above-mentioned S-twist blended yarn is blended with a weight ratio of 25%-30% Tencel yarn and 70%-75% cotton yarn, and the above-mentioned Z The twisted blended yarn is formed by blending 25%-30% Tencel yarn and 70%-75% cotton yarn by weight ratio, and the cross-section of the polyester yarn is T-shaped. Compared with the existing technology, the denim fabric obtained by knitting the blended yarn obtained by blending mercerized yarn and cotton yarn and polyester yarn with T-shaped section has strong hygroscopicity, good hand feeling, good ventilation and comfortable wearing, and is very suitable for summer It is a novel fabric for wearing; in addition, through the interweaving of S-twisted and Z-twisted blended yarns, the force can be restrained left and right, so that the coils will be offset, thereby forming a smooth feel, which greatly improves the fabric's durability. quality.

Owner:LILANG CHINA

Finishing technology of warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyed fabric

InactiveCN107794671AGuaranteed four-way flexibilityGuaranteed smooth productionShrinkingSucessive textile treatmentsYarnCooking & baking

The invention discloses a finishing technology of a warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyed fabric, and relates to a finishing technology of a cotton type elastic easy-care fabric. The technology comprises the steps of singeing, desizing, mercerizing, washing, preshrinking, high-temperature setting, easy-care finish and baking. An ordinary yarn-dyed fabric production route is changed in the technology process, wherein washing is conducted after mercerizing is conducted, and then sufficient alkali removing can be guaranteed; preshrinking is conducted directly,it is guaranteed that large enough elasticity is achieved in the radial direction. Accordingly, it can be guaranteed that the warp and weft cotton wrapped spandex four-way-stretch easy-care yarn-dyedshirt fabric is produced smoothly, a shirt is made by adopting the warp and weft cotton type elastic easy-care fabric, when people do body movement, limitation does not exist in the four directions, and people feel comfortable and free when wearing the shirt; due to the fact that elastic yarns exist in four directions, after deformation, the elastic yarns can return to the original position, and the aesthetic feeling of being neat in shape is guaranteed.

Owner:JIANGSU JAMES TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com