Method for manufacturing flax knitted fabric

A production method and technology of knitted fabrics, applied in knitting, weft knitting, fabric surface trimming, etc., can solve problems such as failure to meet customer needs, decreased strength, unstable shrinkage, etc., and achieve improved efficiency and quality, suitable size, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

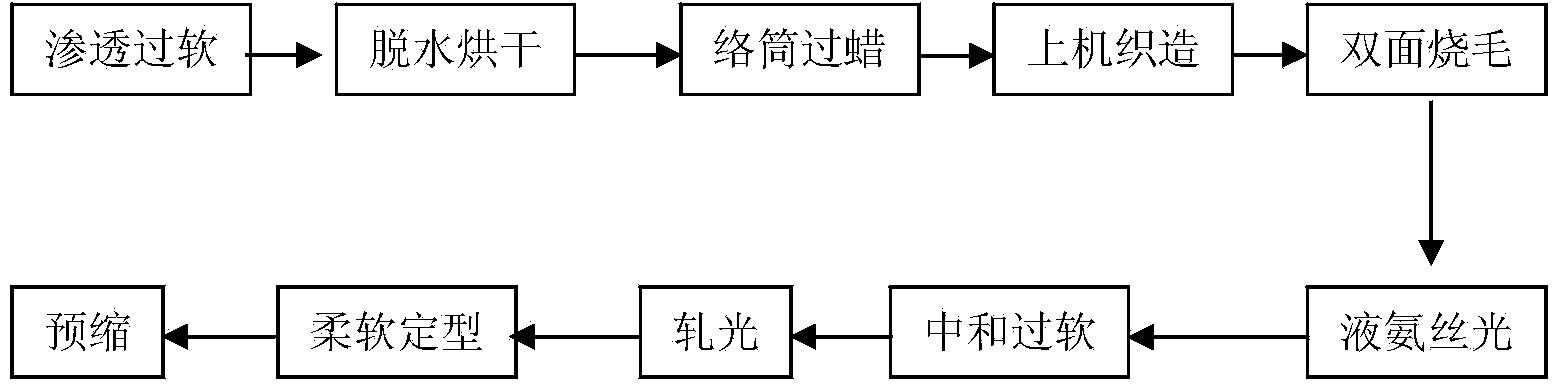

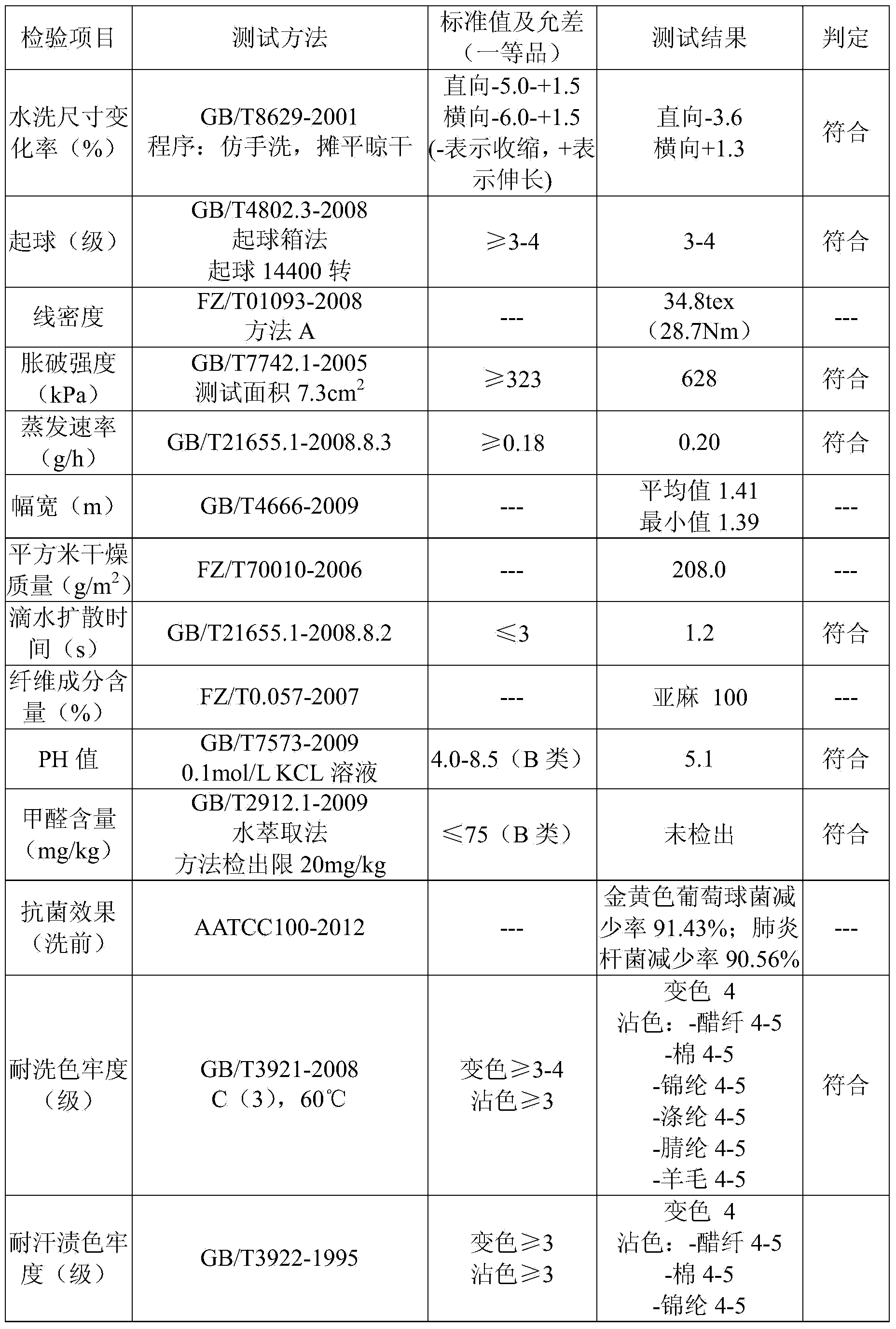

[0042] This embodiment provides a method for making a linen knitted fabric, which is used to make a single-sided plain linen knitted fabric with a finished product width of 54 inches, a finished product grammage of 230 GM, a CPI=44, and a WPI=32, such as figure 1 shown, including the following steps:

[0043] Step 1: Select 28NM / 1 flax knitting special yarn to loosen the tube, wrap socks into the vat to infiltrate and soften the flax raw yarn, place the flax raw yarn in a temperature of 100°C and a concentration of 1.5g / L Refining penetrating agent LCF-185 (LCF-185 is a product produced by Taiwan Fuying Chemical Technology Co., Ltd.) and boiled for 20 minutes, then put the boiled raw yarn into polyethylene wax with a temperature of 45°C and a concentration of 3g / L Soak in softener P250 (P250 is a product produced by Baiderui Textile Auxiliaries Co., Ltd.) for 20 minutes, and dehydrate it out of the cylinder;

[0044] Step 2: Carry out high-frequency drying treatment on the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com