Patents

Literature

88 results about "Wax treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraffin wax treatments are luxurious spa treatments that are intended to moisturize and soften the skin. Paraffin wax treatments are most often applied to the hands and feet as components of manicures and pedicures respectively. Paraffin wax is unlike more common spa wax that is used for hair removal on the face and body.

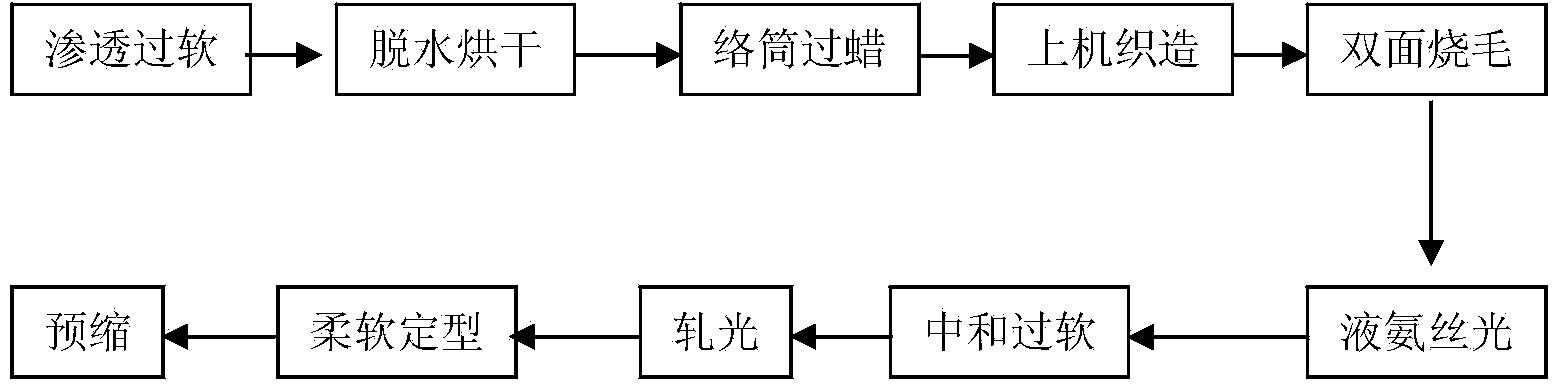

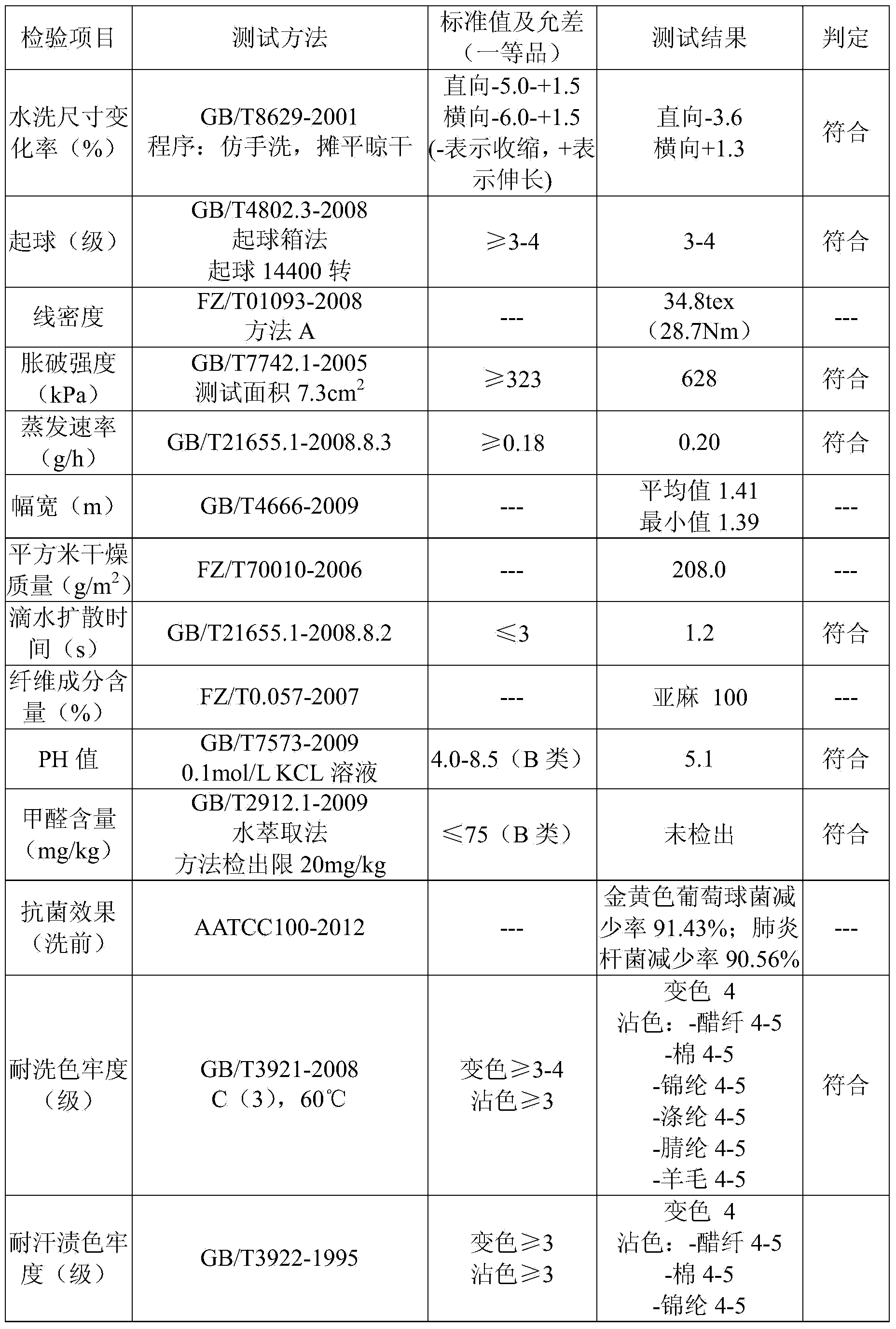

Method for manufacturing flax knitted fabric

ActiveCN103866480AReduce stealthReduce yarn breakageMercerising of indefinite length fabricsWeft knittingYarnWax treatment

The invention provides a method for manufacturing flax knitted fabric. The method comprises the following steps: performing osmotic super-softening treatment on flax grey yarns; performing high-frequency drying treatment on the flax grey yarns after being subjected to osmotic super-softening to enable the moisture content of the grey yarns to be 15-20 percent; performing spooling waxing treatment on the flax grey yarns after being subjected to high-frequency drying, and keeping the moisture content of the grey yarns 15-30 percent; weaving the waxed and sealed flax grey yarns to obtain grey cloth; performing two-sided singeing treatment on the obtained grey cloth; performing liquid ammonia mercerization on the grey cloth after being subjected to the two-sided singeing treatment, and then, performing neutral super-softening treatment; calendaring the grey cloth after being subjected to neutral super-softening, and setting and preshrinking by using a hydrophilic softener to obtain the flax knitted fabric. According to the method for manufacturing the flax knitted fabric provided by the invention, the yarns can be softened, faulty products can be reduced, the efficiency and the quality of knitting can be improved, and the wearability of the fabric can be improved while good breathable moisture absorption and mold resistance of the flax knitted fabric are kept.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

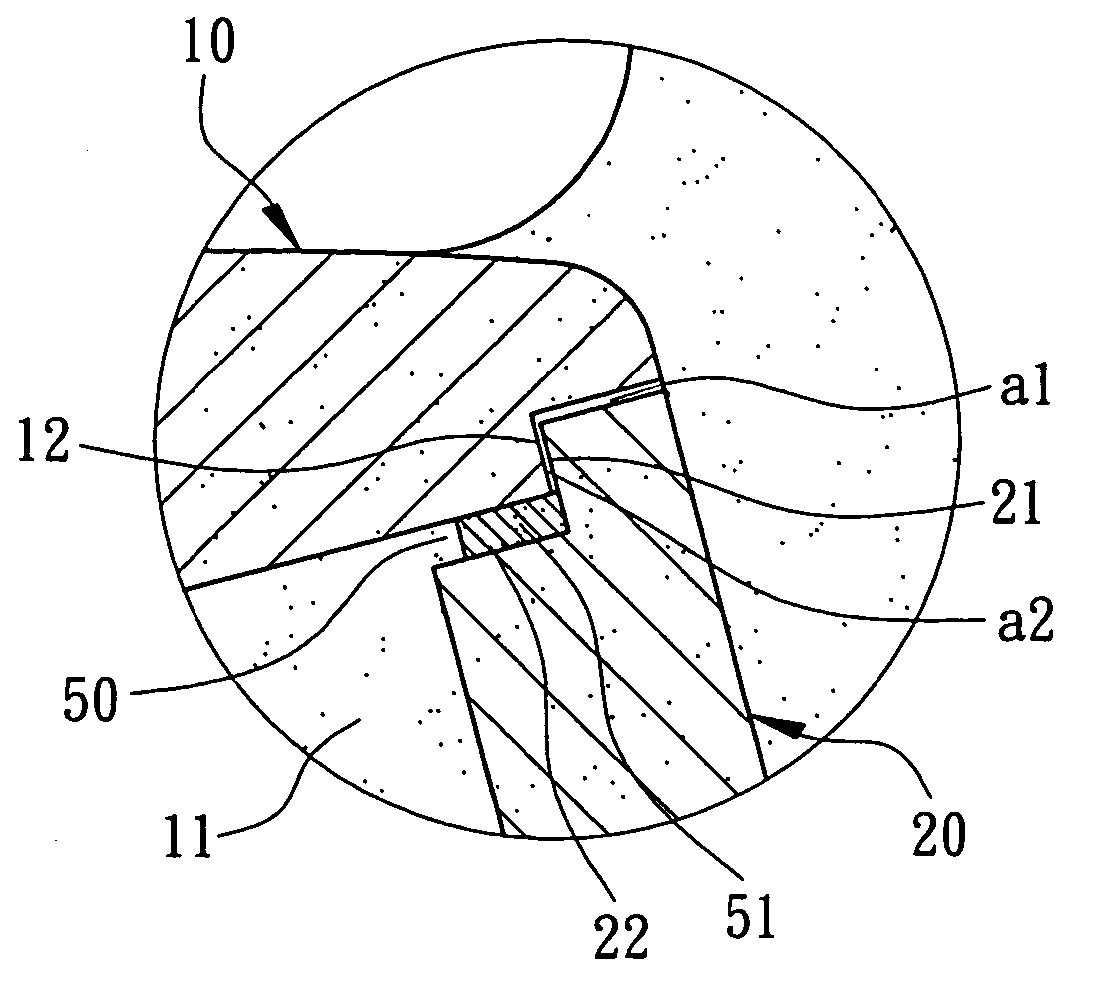

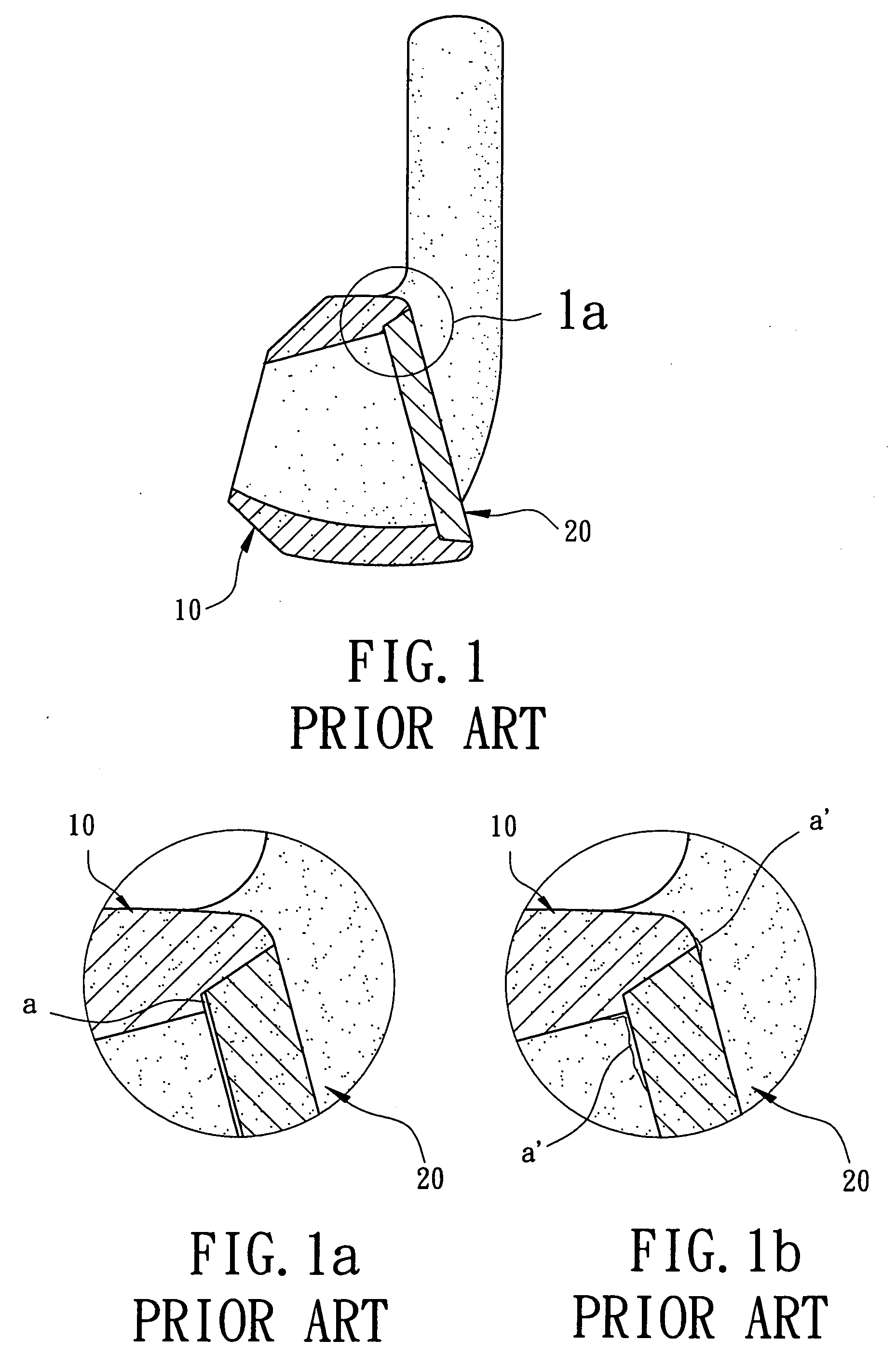

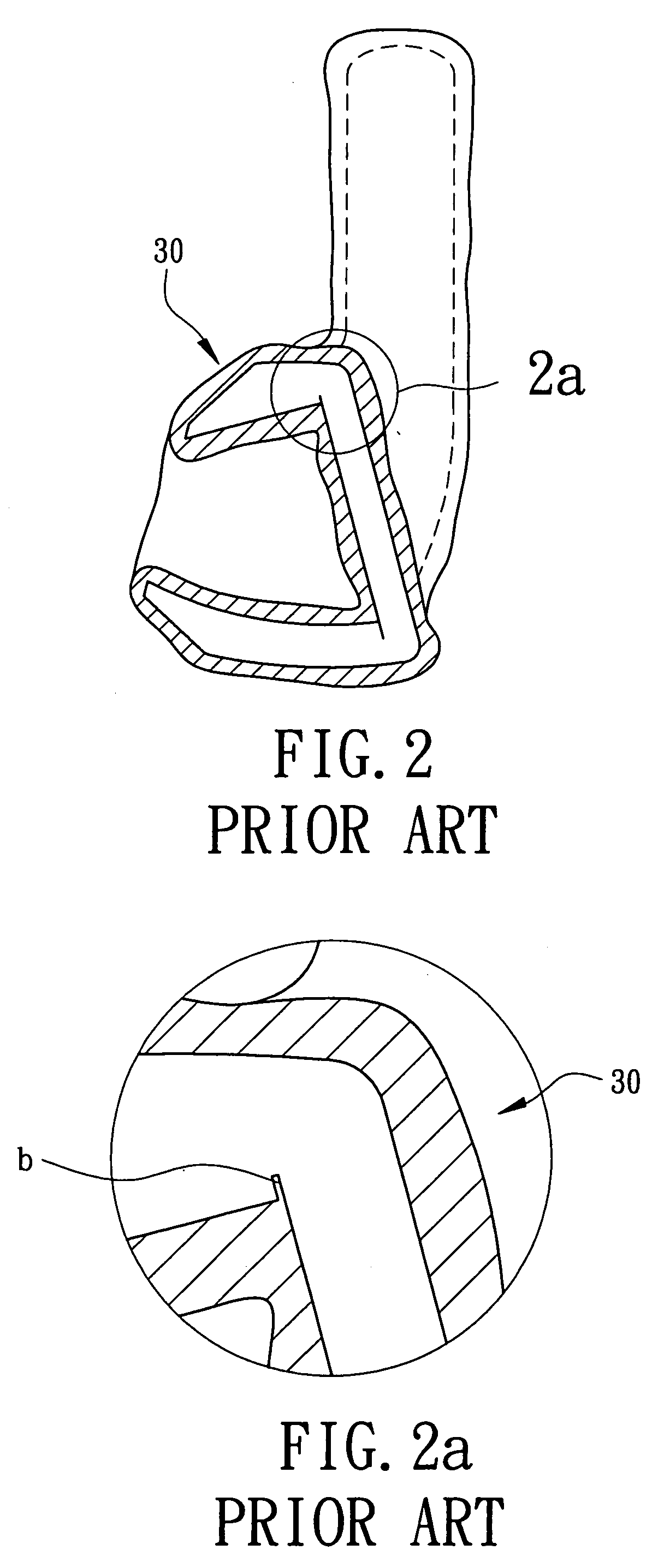

Manufacturing method for a golf club head

A manufacturing method for a golf club head includes the steps of: prefabricating a main-body wax pattern and a striking-plate wax pattern, the main-body wax pattern providing with a rear opening and the striking-plate wax pattern providing with a stepped portion; initially combining the main-body wax pattern with the striking-plate wax pattern that remains an adhesive-filling groove between the rear opening of the main-body wax pattern and the stepped portion of the striking-plate wax pattern; filling adhesive into the adhesive-filling groove to constitute a combination member of the main-body wax pattern and the striking-plate wax pattern; immersing the combination member in slurry to form a ceramic shell and heating the ceramic shell for lost-wax processing; and pouring a melting alloy into the ceramic shell to form a club head casting.

Owner:NELSON PRECISION CASTING

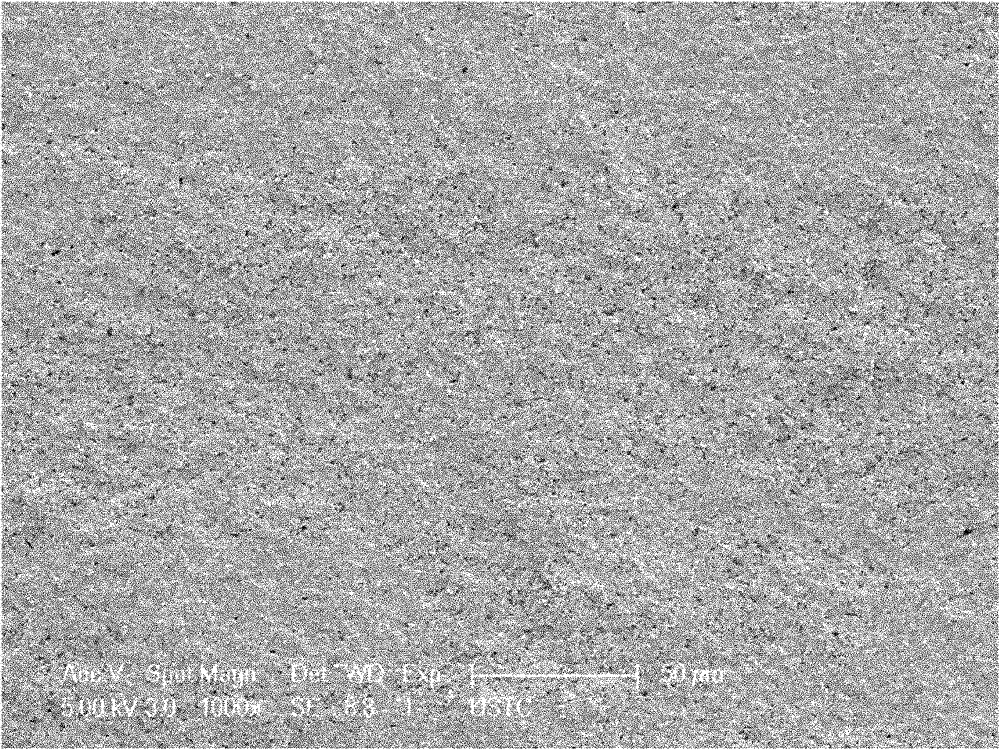

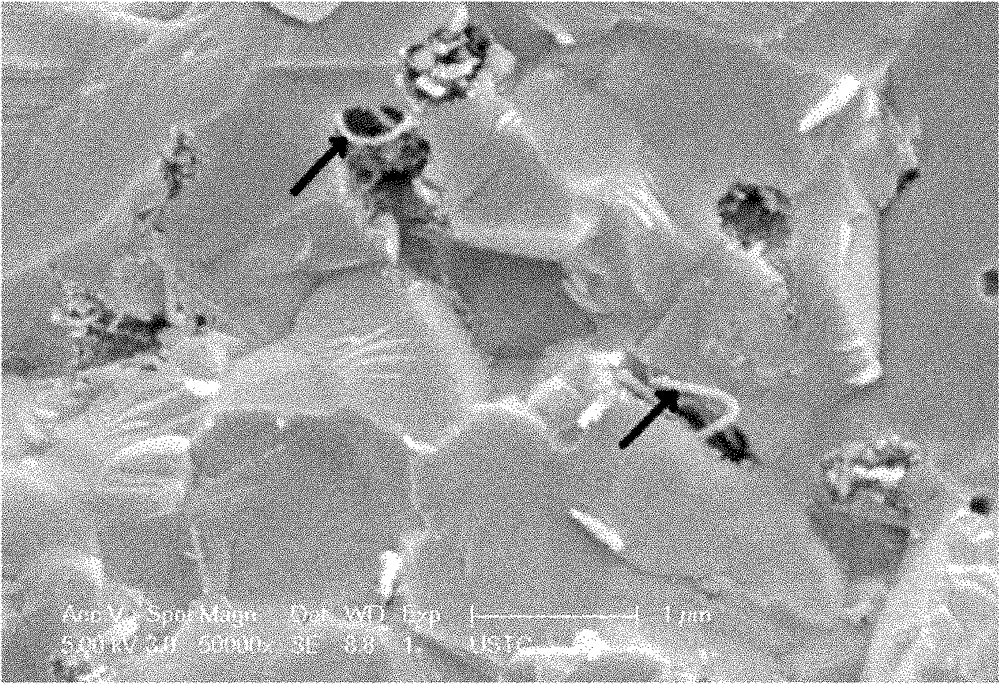

Carbon nanotube reinforced alumina ceramic composite material and its preparation method

A carbon nanotube reinforced alumina ceramic composite material contains the following ingredients of: 91-98 wt% of Al2O3, 0.5-8 wt% of CNTs, 0.5-1.5 wt% of MgO and 0.05-0.15 wt% of Y2O3. The method for preparing the carbon nanotube reinforced alumina ceramic composite material comprises the following steps of: crushing the above Al2O3, MgO and Y2O3 materials by wet milling for 24-72 hours; adding the pretreated CNTs and continuously crushing by wet milling for 8-12 hours to produce a mixed slurry; drying the mixed slurry and crushing to obtain mixed powders (I); adding the mixed powders (I) into a paraffin-containing gasoline solvent to perform ultrasonic dispersion for 1-2 hours; drying, crushing and sieving through a 60 to 200-mesh sieve to obtain mixed powders (II); carrying out tabletting and de-waxing treatments on the mixed powders (II) to obtain sample sheets; placing the sample sheets into a graphite oven and performing the powder embedded pressureless sintering in Ar atmosphere at the temperature of 1500-1800 DEG C for 0.5-4 hours to produce the composite material. The composite material provided by the invention is characterized in that its density can reach more than 95%, its three point bending strength is raised by over 40% and its fracture toughness is increased by about 15%.

Owner:HEFEI UNIV OF TECH

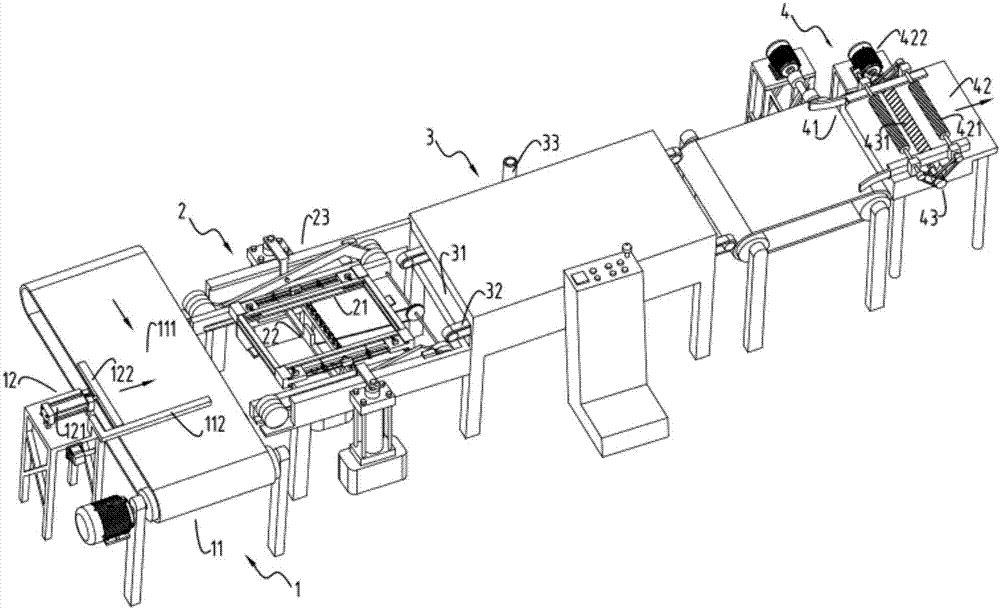

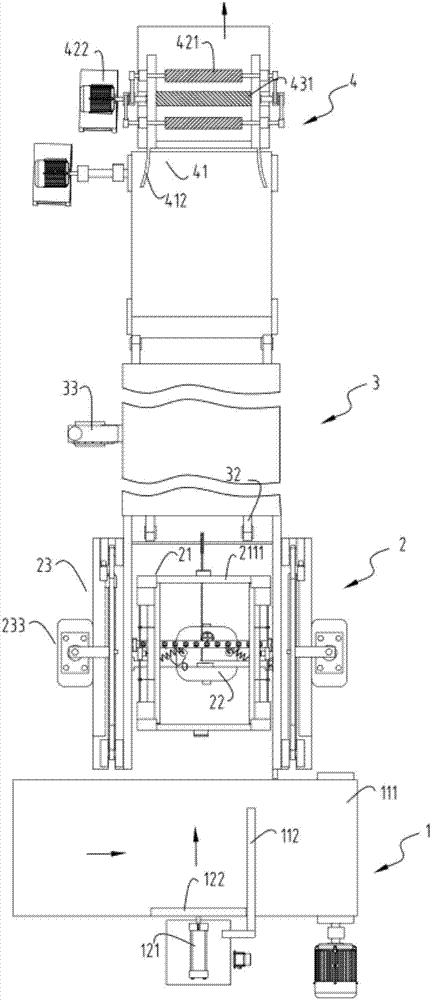

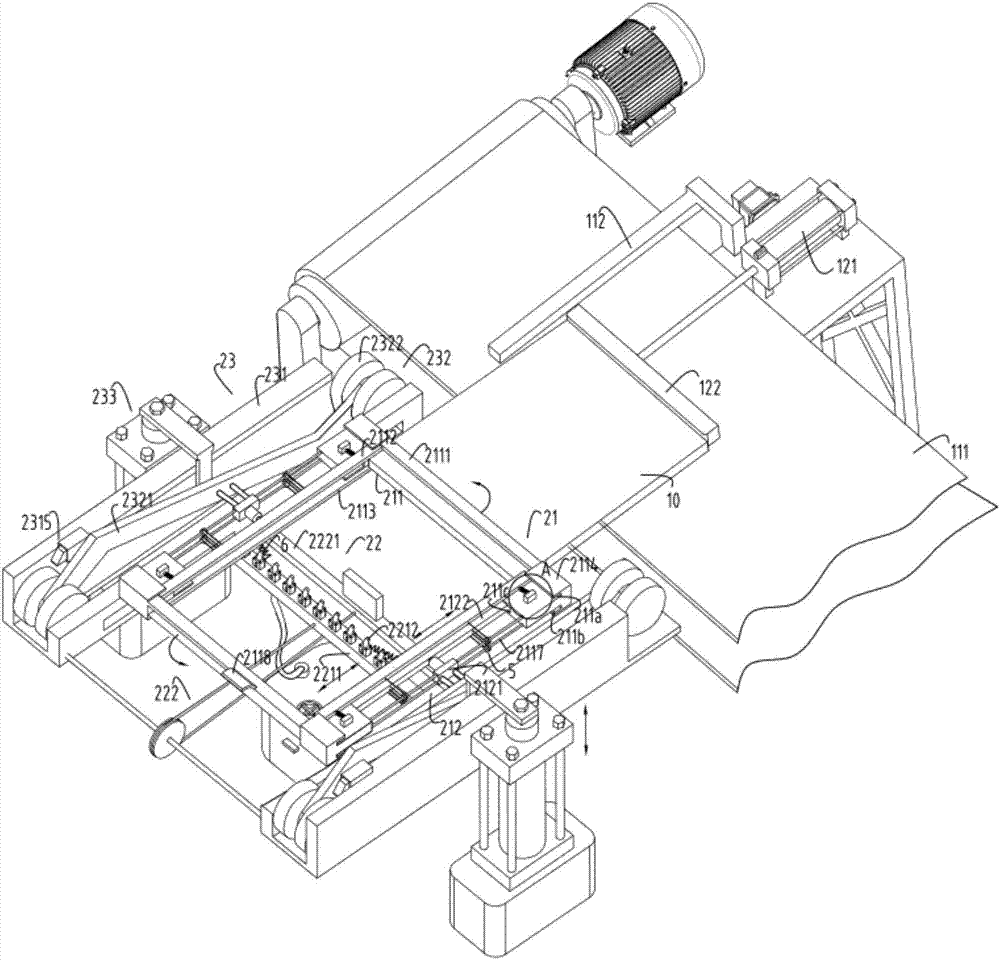

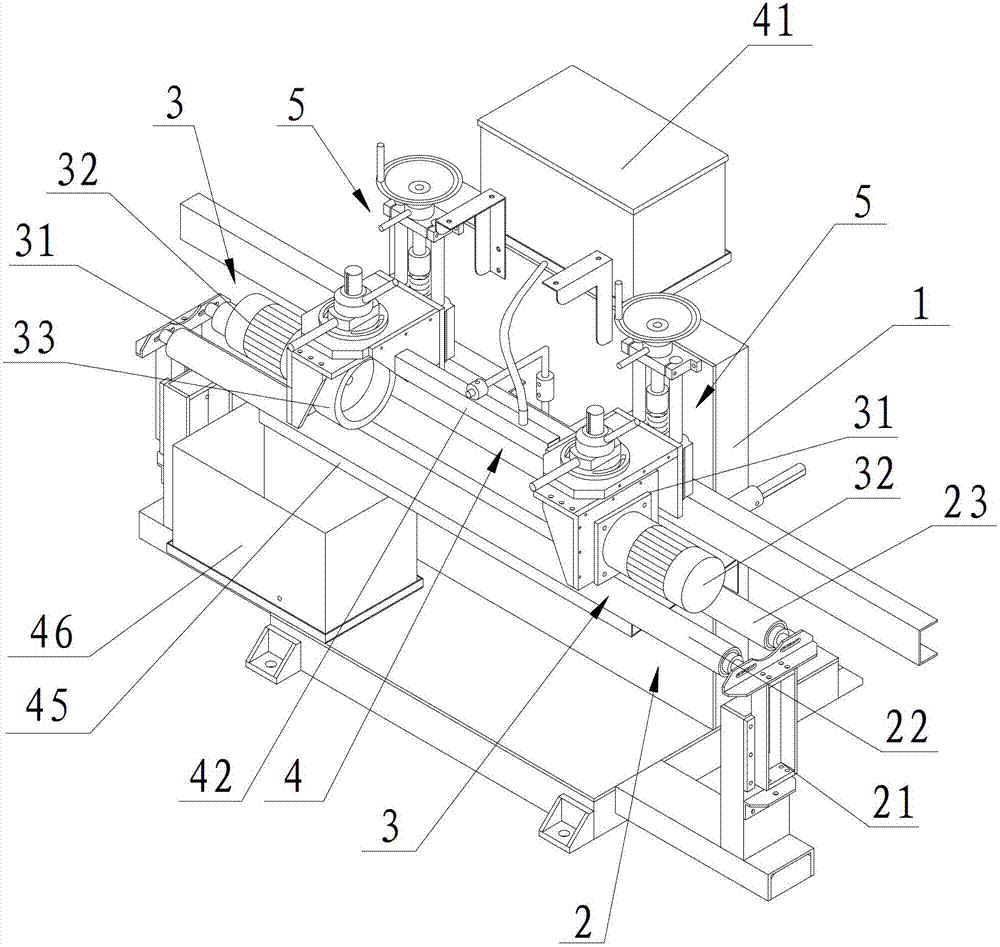

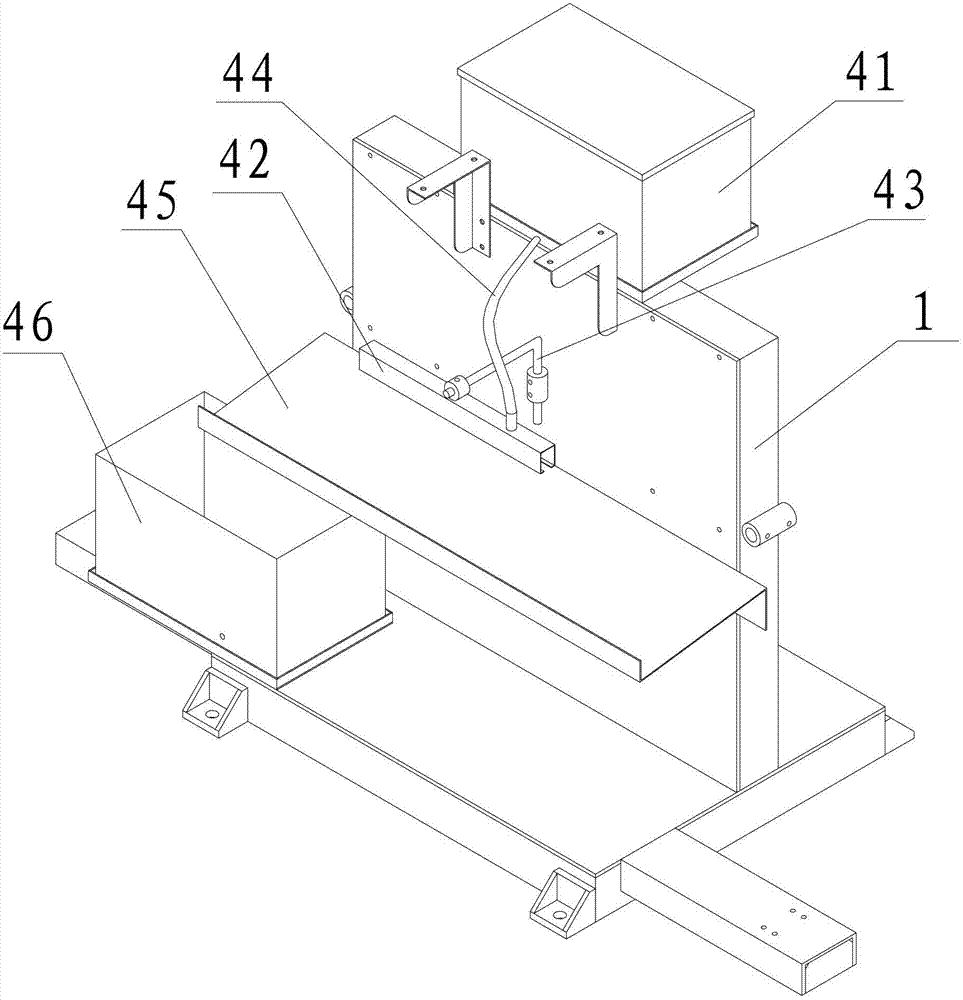

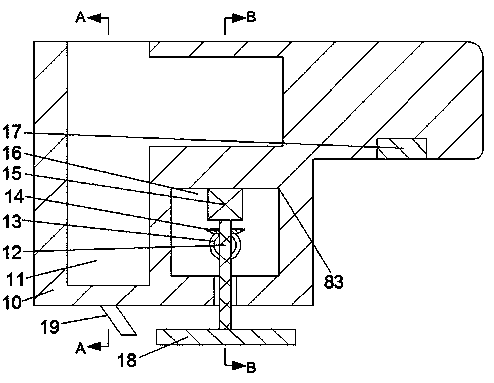

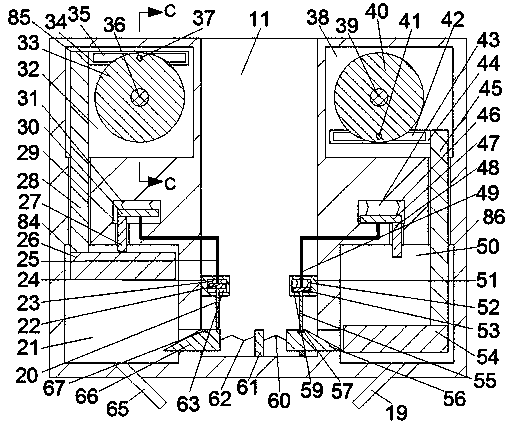

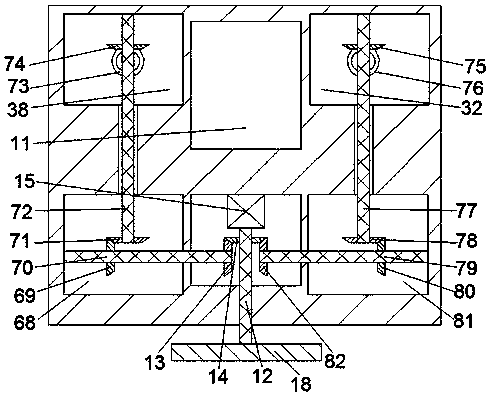

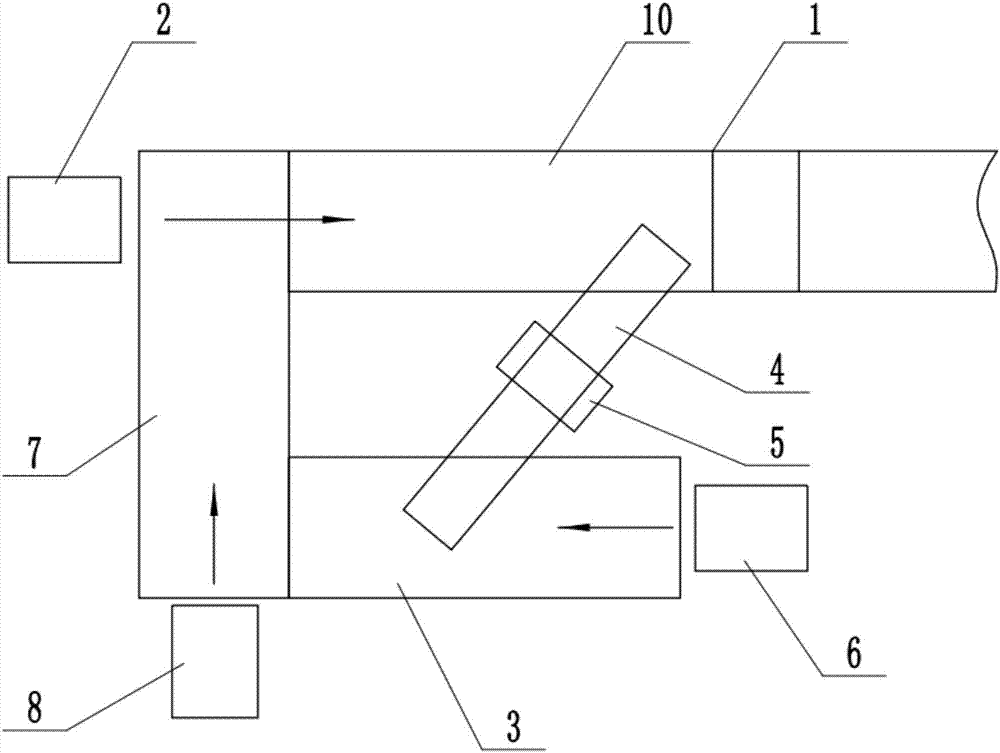

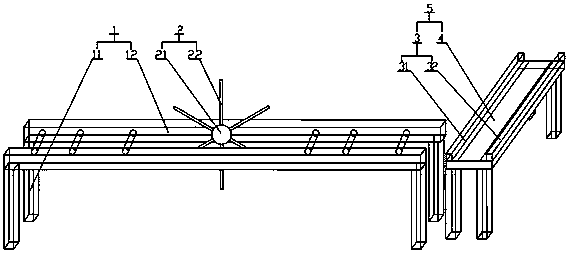

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

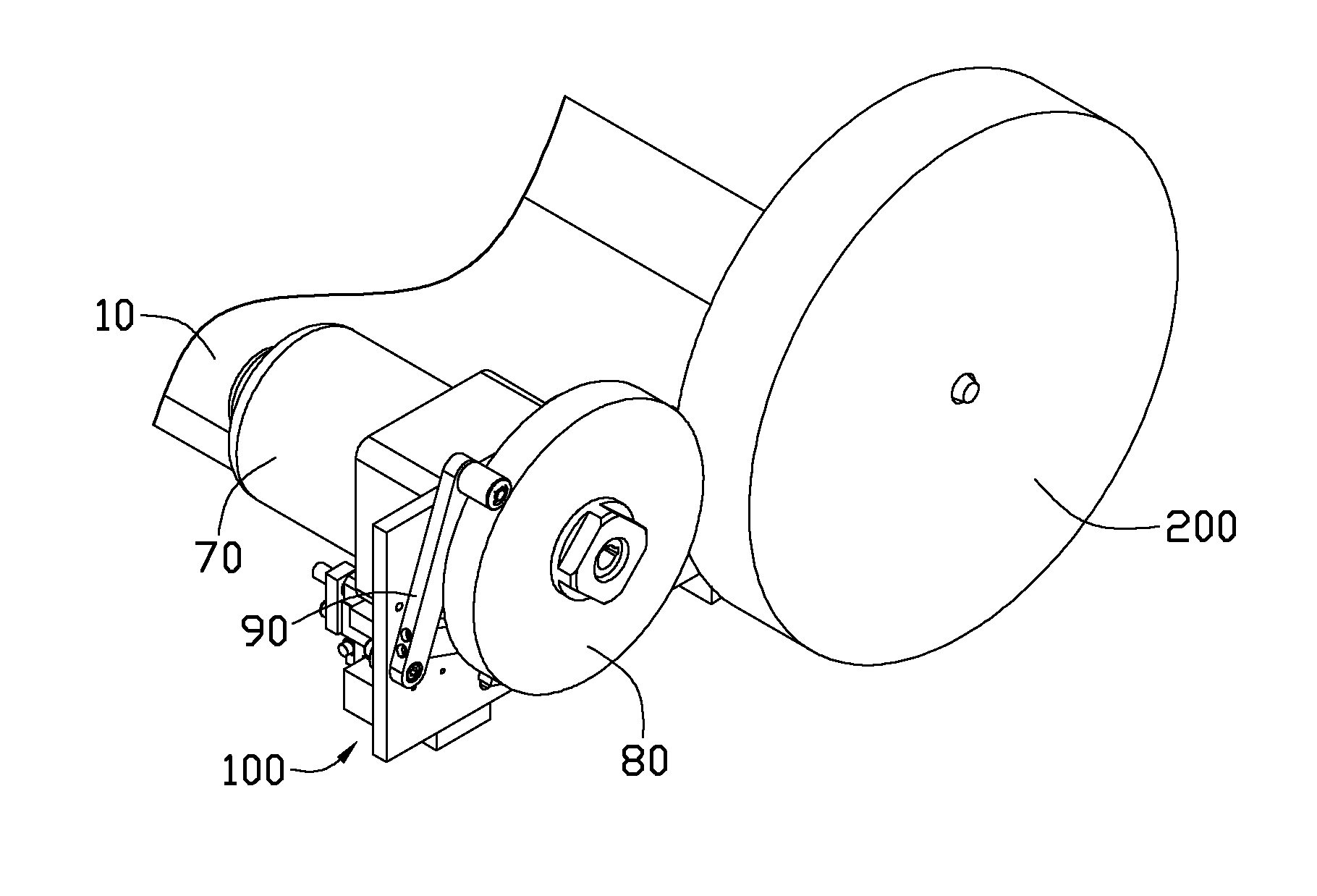

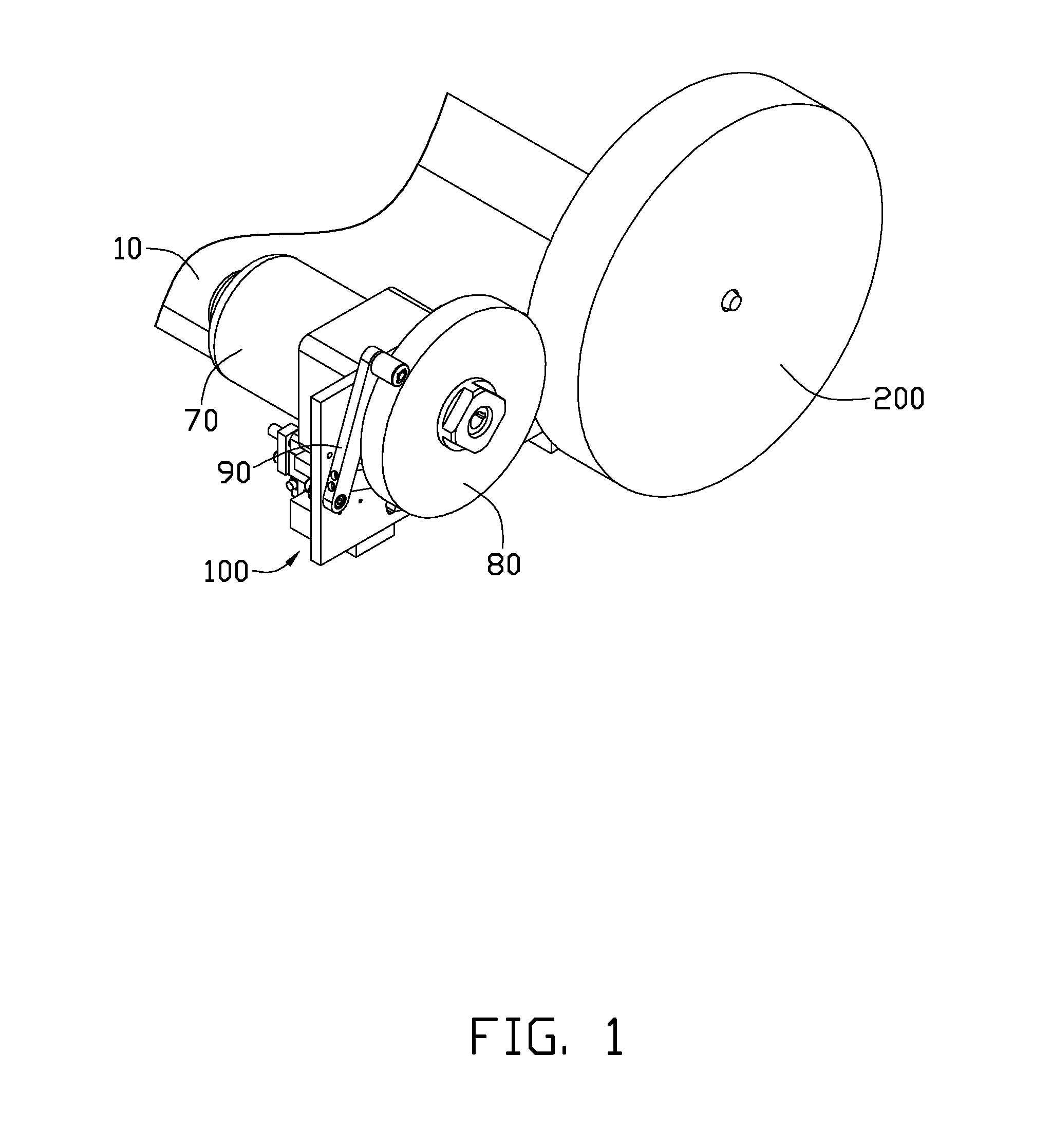

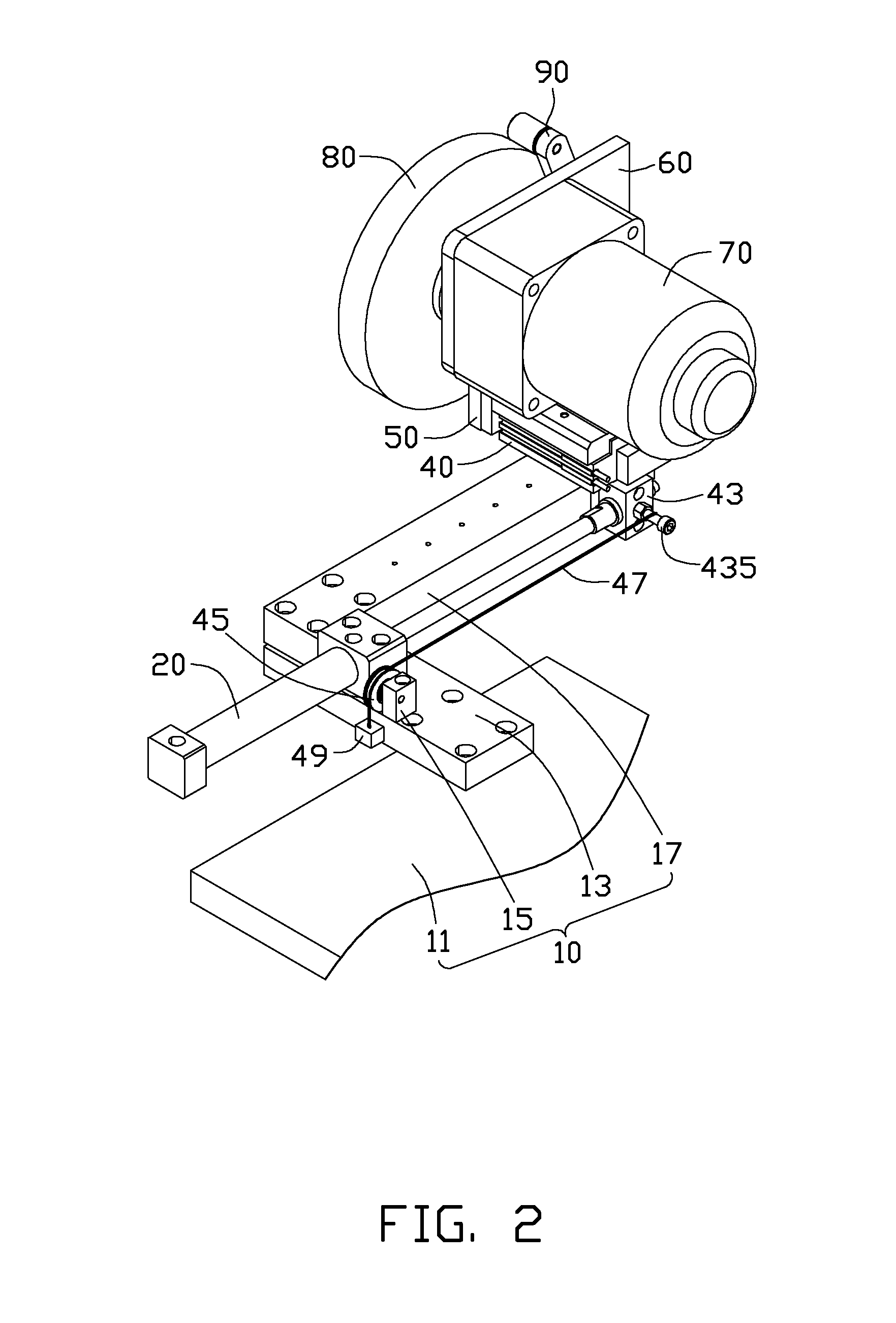

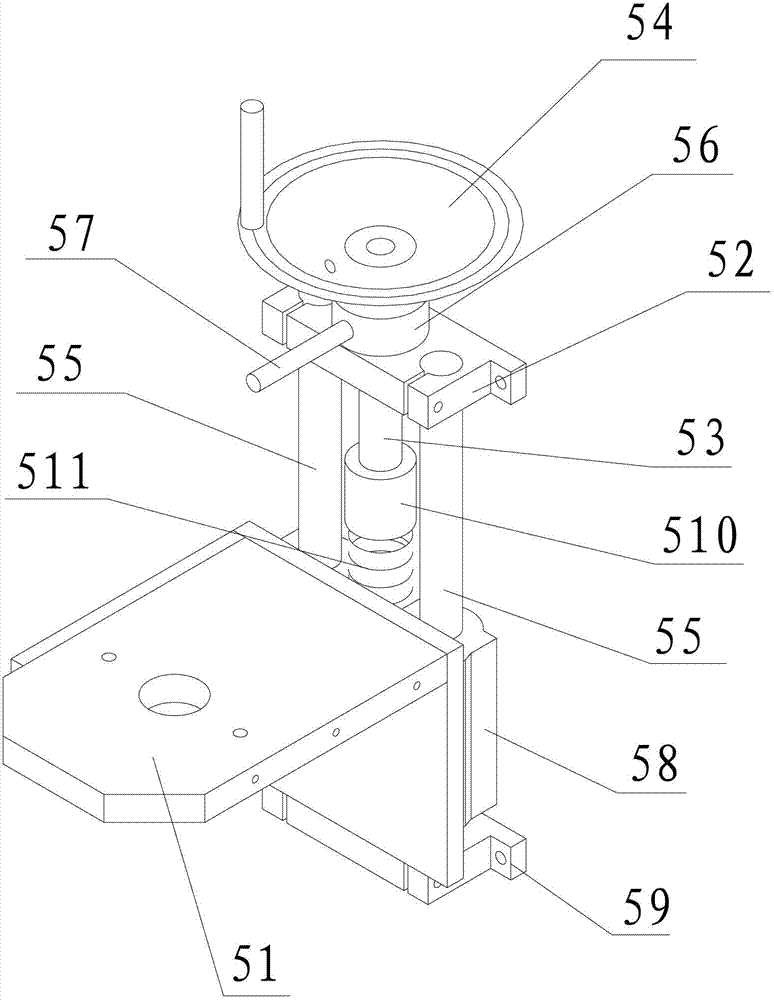

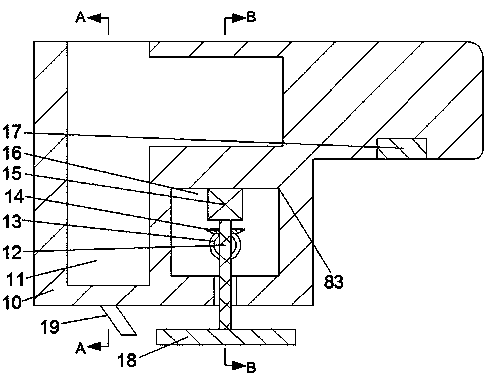

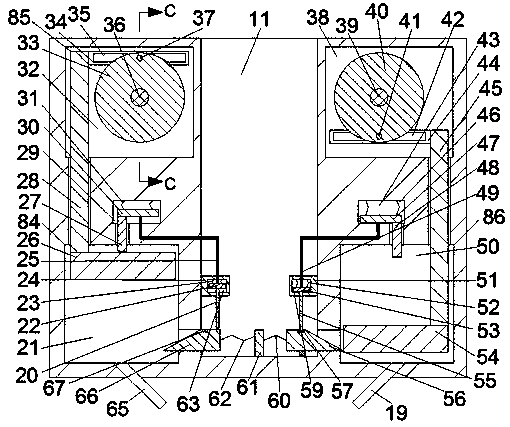

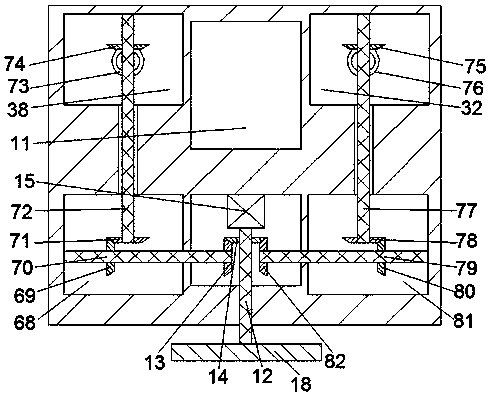

Waxing device

InactiveUS20130019800A1Time consumingLiquid surface applicatorsPolishing machinesWax treatmentElectric machinery

A waxing device is used for applying a waxing treatment to a polishing wheel, and includes a supporting assembly, an adjusting assembly, a driving mechanism, a mounting assembly, a motor, a wax block and a resisting mechanism. The supporting assembly includes a sliding rail, and the adjusting assembly is slidably positioned on the sliding rail; the driving mechanism is mounted on the adjusting assembly; the mounting assembly includes a mounting member positioned on the driving mechanism; the motor is mounted on mounting member; the wax block is positioned on the motor and rotated by the motor; the resisting mechanism is positioned on the supporting assembly and resists the adjusting assembly for adjusting a pressure applied to the polishing wheel during the waxing process.

Owner:HON HAI PRECISION IND CO LTD

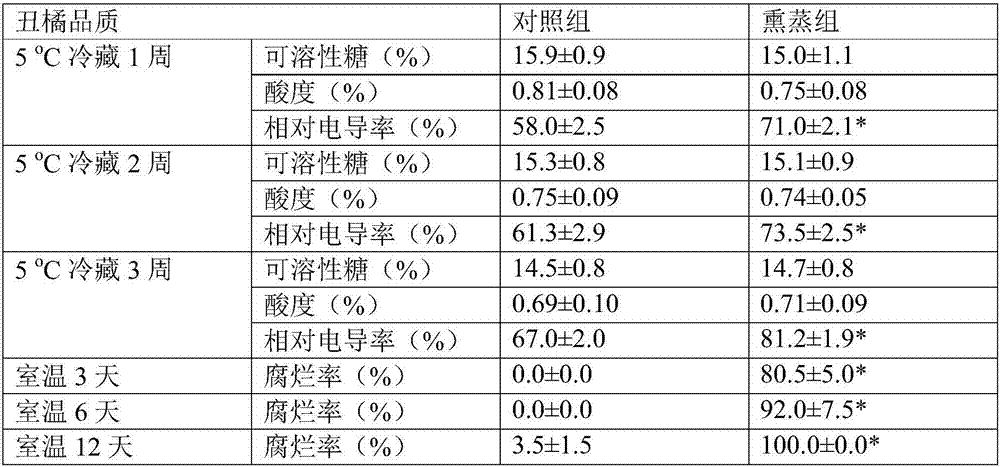

Whole supply chain green fresh-keeping method for citrus sinensis (l.) osbeck

ActiveCN106560042AEnhanced water penetration rateProlong shelf lifeFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingWax treatmentLate stage

The invention relates to a whole supply chain green fresh-keeping method for citrus sinensis (l.) osbeck. According to the present invention, treatment is performed with an excitation type fruit and vegetable fresh-keeping agent, the temperature fluctuation during the storage is controlled at less than or equal to + / -0.1 DEG C, the humidity is controlled at 85-90%, gas regulating is performed to achieve the low oxygen content and the high carbon dioxide so as to maintain the fruit acidity quality, and waxing treatment is performed to protect the peel of citrus sinensis (l.) osbeck, reduce the generation of low water content and browning at the late stage, and improve the quality of citrus sinensis (l.) osbeck; and with the application of the method to perform the fresh keeping on citrus sinensis (l.) osbeck, the fruit pedicle is brightly green, the peel is brightly orange, the citrus sinensis (l.) osbeck can be stored for 6 months, and the good fruit rate is 96.2%.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

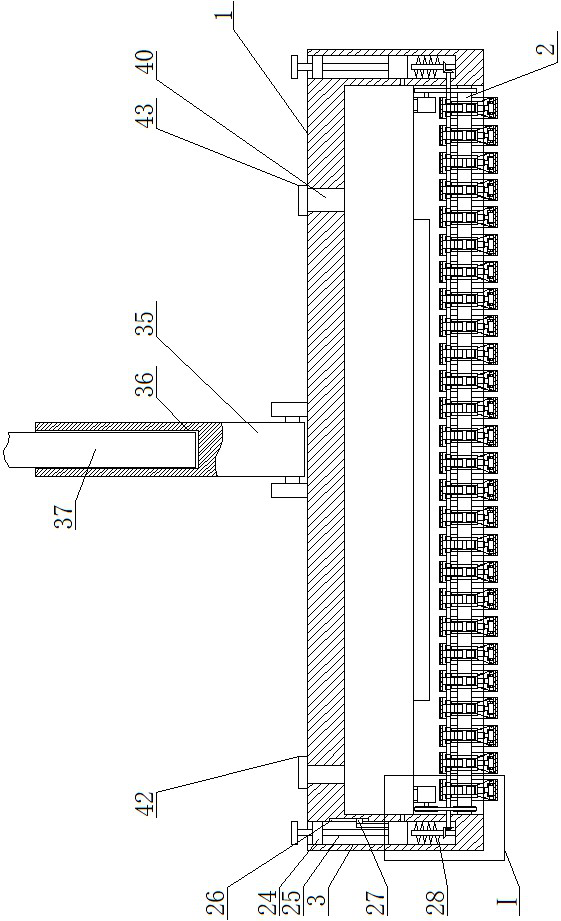

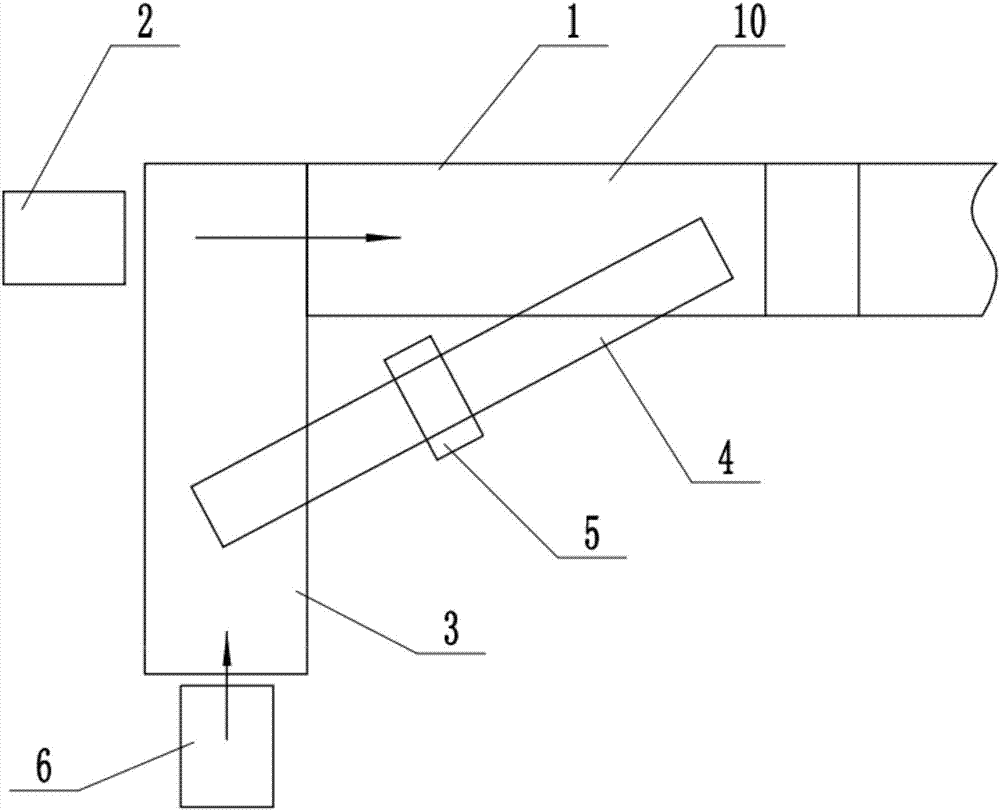

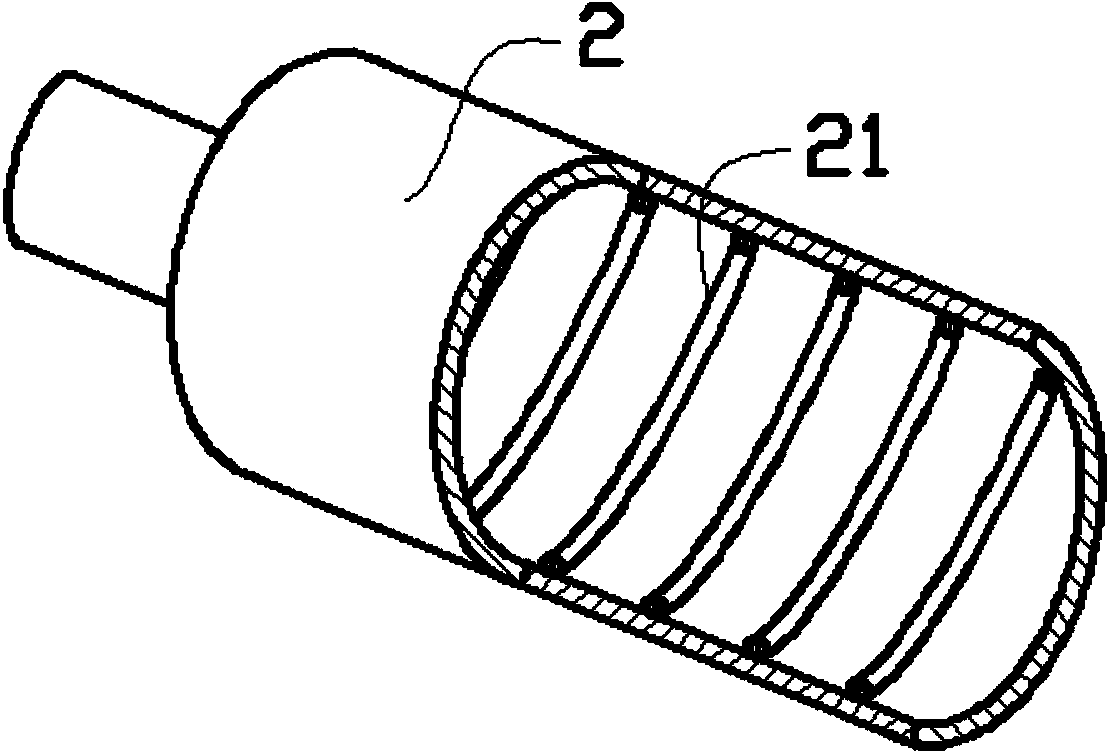

Paper tube waxing machine

InactiveCN102950078ASimple structureEasy to operateLiquid surface applicatorsCoatingsWax treatmentElectrical and Electronics engineering

The invention discloses a paper tube waxing machine, which comprises a feeding device, a feeding drive device, a waxing component and a height adjusting mechanism for adjusting the height of the feeding drive along a vertical direction, wherein the feeding drive device can be matched with the feeding device to drive a to-be-waxed paper tube on the feeding device to rotate, so that the to-be-waxed paper tube moves forwardly while rotating around the axial line self; the waxing component can coat waxing liquids on the outside circumference of the to-be-waxed paper tube in the process of forward moving of the to-be-waxed paper tube; the paper tube after finishing waxing is delivered out from the other end of the feeding device to receive the materials. The paper tube waxing machine is simple in structure; when waxing, the to-be-waxed paper tube is only delivered from one end of the feeding device to the feeding device and delivered out from the other end to receive the materials; and the paper tube waxing machine is convenient to operate and improves the production efficiency of waxing.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

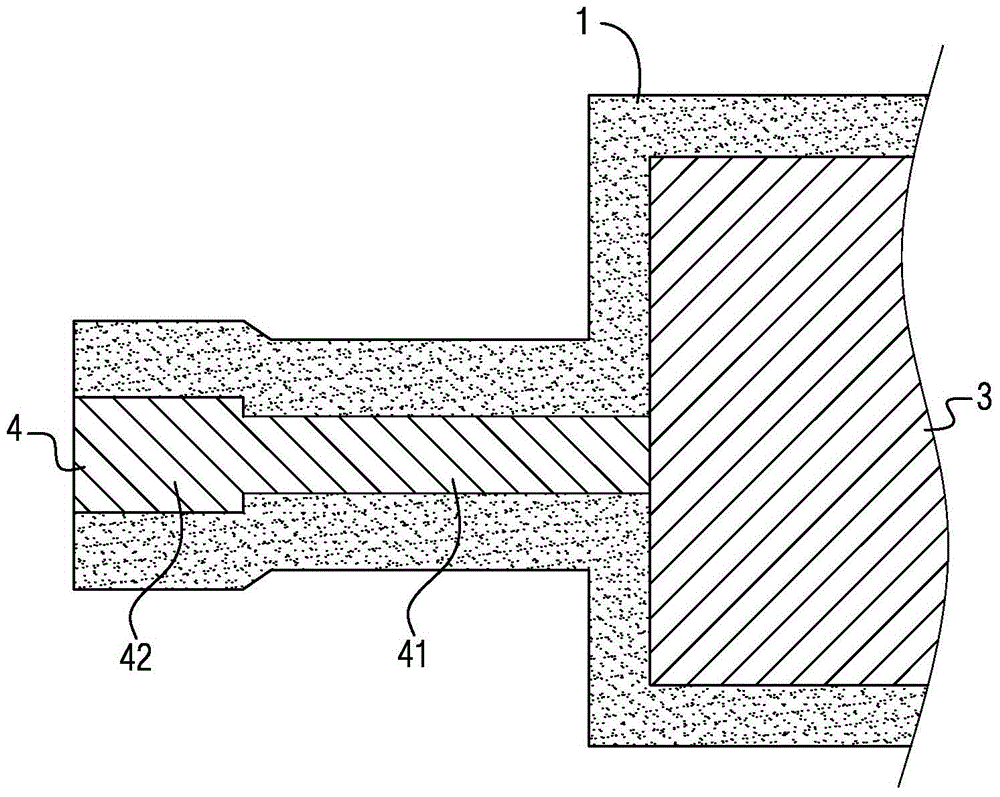

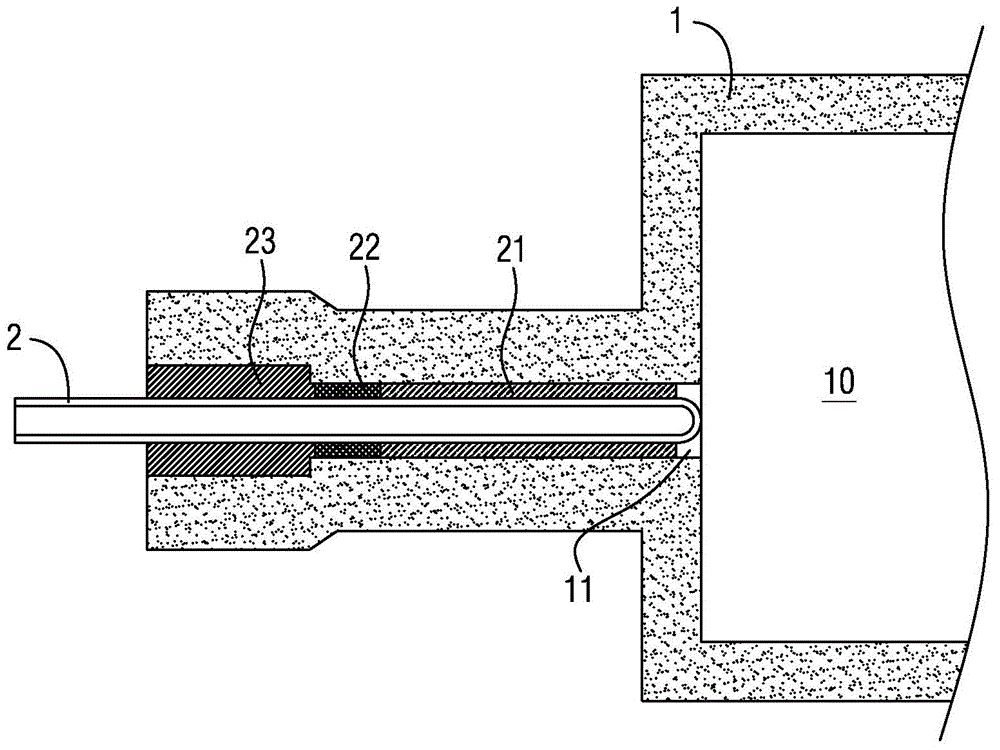

Mold for measuring temperature in casting process and production method of mold

ActiveCN104439062APrecise positioningAccurate temperature measurementThermometers using electric/magnetic elementsFoundry mouldsWax treatmentSlurry

The invention provides a production method of a mold for measuring the temperature in a casting process. The production method comprises the following steps: step A, producing a wax mold of a part, and welding a wax rod on a temperature measuring point of the wax mold; step B, preparing a mold shell by using the wax mold in the step A; and step C, after carrying out de-waxing treatment on the mold shell of the step B, putting a quartz tube into a pipeline, and filing a gap between the quartz tube and the pipeline with fireproof cotton, fireproof sand, and a mixture of shell producing slurry and the fireproof sand in sequence from inside to outside, and drying the mixture of the shell producing slurry and the fireproof sand on the outermost layer so as to produce the mold. By virtue of the production method of the mold for measuring the temperature in the casting process, the mold for measuring the temperature of the part and any part of the mold shell in the casting process can be produced, and the positioning of the measuring point is accurate and the temperature measurement is accurate. The invention further provides the mold produced by adopting the method.

Owner:CHINA HANGFA SOUTH IND CO LTD

Color-changing PVC (Poly Vinyl Chloride) artificial leather

InactiveCN103046319AImprove mechanical propertiesWith color changing functionFibre typesWax treatmentColor changes

The invention discloses color-changing PVC (Poly Vinyl Chloride) artificial leather which adopts a surface treatment process. Particularly, a process of carrying out wax treatment on the surface of the artificial leather is adopted, and more particularly, a blade coating process is adopted for coating wax on the surface of the leather. Color-changing size is made from the following components in parts by weight: 70-80 parts of a benzene-free diluting agent, 0.5-5 parts of color-changing wax powder, 5-10 parts of ink, 0.1-0.5 part of a dispersing agent and 15-25 parts of quick-drying resin. The color-changing PVC artificial leather has the characteristics of good mechanical property and color-changing property.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

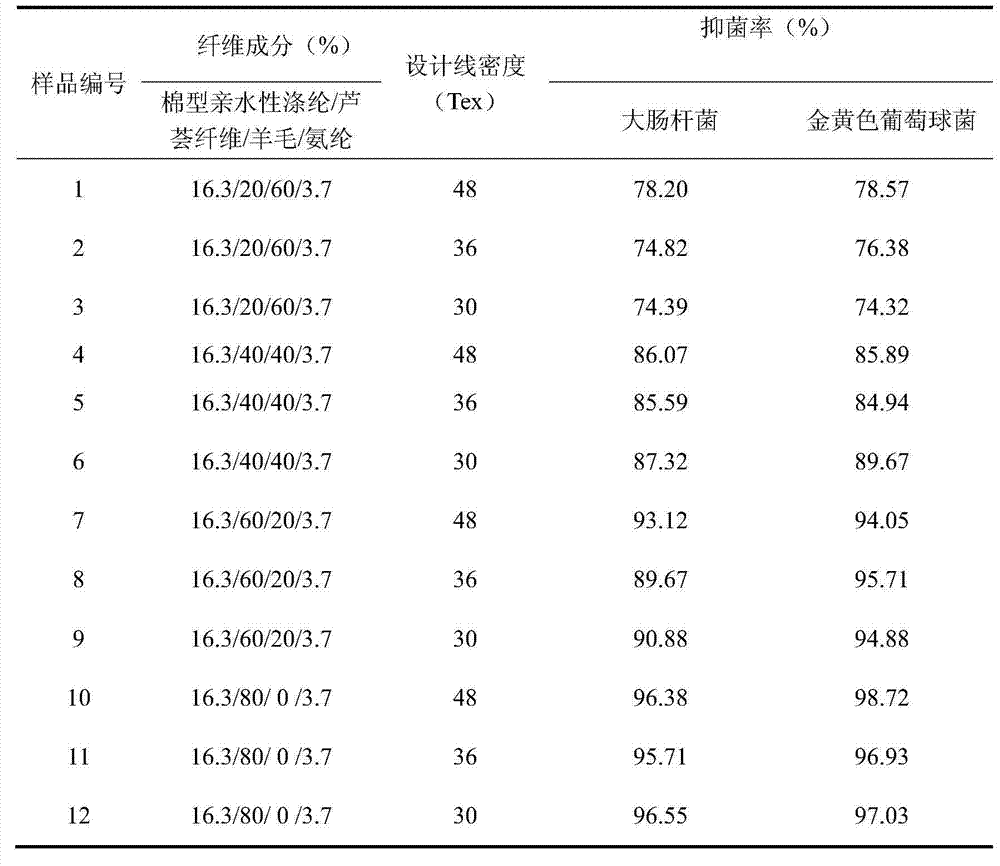

Four-component spandex covering composite yarn and preparation method of fabric made of four-component spandex covering composite yarns

ActiveCN103898652AImprove wear resistanceGood warmth retentionWeft knittingYarnWear resistantWax treatment

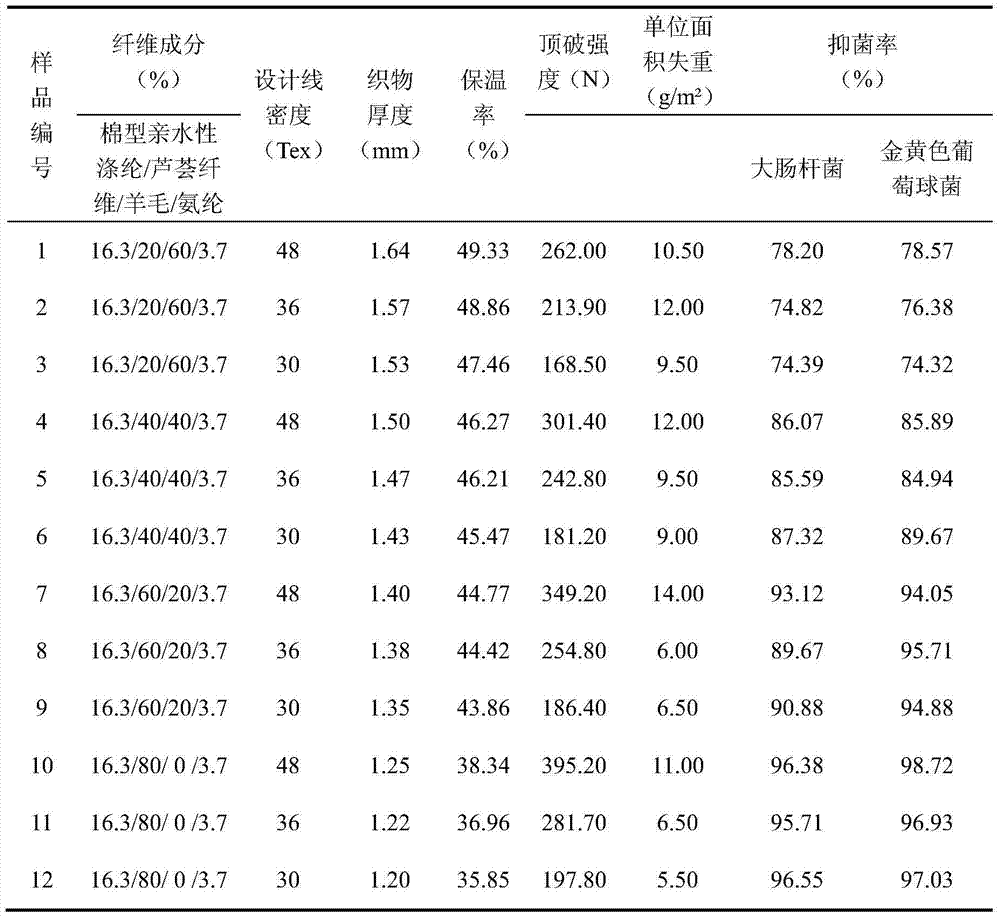

The invention discloses four-component spandex covering composite yarn and a preparation method of a fabric made of the four-component spandex covering composite yarn. The method includes the first step of preparing hydrophilic polyester fibers, aloe fibers, wool tops and spandex filaments, the second step of making the cotton-type hydrophilic polyester fibers and the aloe fibers into mixing stripes, carrying out drawing on the mixing stripes and the wool tops to obtain stripes C, spinning the stripes C into blending rough yarn, using the blending rough yarn as covering yarn and spinning the covering yarn and the spandex filaments on a spinning machine to form the four-component spandex covering composite yarn, the third step of carrying out waxing treatment on the four-component spandex covering composite yarn, and the fourth step of carrying out weaving on the four-component spandex covering composite yarn on a computerized flat knitting machine according to fabric weaves input in advance to obtain the four-component spandex covering composite yarn fabric. The four-component spandex covering composite yarn fabric has the wear-resistant and high-strength advantages of the cotton-type hydrophilic polyester fibers and also has the good antibacterial effect of the aloe fibers and the good heat insulation effect of wool, so the fabric has better wearing performance.

Owner:江苏唐盛纺织科技有限公司

Textile yarn waxing treatment method

ActiveCN110468532AImprove waxing effectUniform coatingTextile treatment containersTextile treatment machine arrangementsBobbinTextile yarn

The invention belongs to the technical field of textile equipment, and particularly relates to a textile yarn waxing treatment method, comprising the following steps: S1, washing and drying yarn to obtain the clean yarn; S2, winding the clean yarn on a yarn bobbin, enabling the yarn bobbin to fixedly sleeve a yarn feeding roller, and enabling an empty yarn bobbin to fixedly sleeve a yarn take-up roller; S3, passing one end of the clean yarn through a waxing device, fixing on the surface of the empty yarn bobbin, and starting the waxing device and the yarn take-up roller to wax the yarn; the waxing device in the step S3 is provided with a sponge block at the position of an outlet hole, the sponge block rubs with the yarn to spread liquid wax on the surface of the yarn evenly, a liquid box is internally provided with a waxing roller, one end of the waxing roller is open and internally forms a cavity, the outer surface of the waxing roller is provided with an annular yarn groove, the waxing roller is internally provided with a through hole communicating the cavity and the annular yarn groove, a vane wheel is mounted on a transmission shaft, the vane wheel is rotated to guide the wax liquid into the cavity, and the wax liquid makes contact with the yarn through the through hole, thus increasing the uniformity of waxing.

Owner:HUATEX INT HANGZHOU CO LTD

Damp-proof buffer material preparation method

InactiveCN110561849AHigh affinityImprove buffering effectSynthetic resin layered productsWax adhesivesCross-linkAlkane

The invention particularly relates to a damp-proof buffer material preparation method, and belongs to the technical field of functional material preparation. According to the invention, a waterproof buffer layer and a plant fiber foaming layer are adhered by using an adhesion layer as a middle layer, hot pressing is performed, and the surface of the obtained material is subjected to waxing treatment to obtain a damp-proof buffer material; the methoxyl in trimethylmethoxysilane is easily hydrolyzed, and can react with the amine substance in a protein adhesive to generate a methyl amino alkane substance, and the methyl amino alkane substance can be subjected to the potassium ions in plant ash to form potassium methyl silicate so as to easily improve the moisture-proof performance of the buffer material; the puffing of paper pulp fibers in foam can improve the buffer performance of the adhesion layer after being dried; during the film drawing, liquid paraffin is cross-linked with the hydroxyl in viscose fibers, such that the compactness of the liquid paraffin on the surface of the adhesion film can be improved so as to prevent the water absorption of the paper pulp fibers; and calciumoxide can form part of calcium carbonate in the environment of water and carbon dioxide so as to improve the use strength of the buffer material, such that the prepared material has wide applicationprospects.

Owner:马少婷

Environmental protective, energy saving cleaning liquid for lacquer finish of car

InactiveCN101092590ALess corrosiveImprove securityOrganic detergent compounding agentsSurface-active detergent compositionsLacquerNuclear chemistry

This invention relates to an environmentally friendly energy-saving cleaning solution for paint surfaces of automobiles. The cleaning solution comprises: carnauba wax 4.1-6 wt.%, coconut oil derivative 7-9 wt.%, active copper 2-4.15 wt.%, plant surface active emulsion 12-18 wt.%, silicone 1-4 wt.%, and distilled water 58.85-73.9 wt.%. The pH value is 7.1-8.5. The cleaning solution can rapidly suspend and loosen dirt on paint surfaces of automobiles, which can then be removed by manual wiping. The cleaning solution has such advantages as low corrosion, high safety and low energy consumption, and is suitable for paint surfaces of all automobiles and household hard objects. Cleaned paint surfaces do not need waxing treatment.

Owner:刘宏武

Method for producing carved magnetic wood board porcelain tile

The invention belongs to the technical field of production of porcelain tiles, and discloses a method for producing a carved magnetic wood board porcelain tile. A wood grain board with a concave and convex surface and a natural, smooth and realistic texture is produced by changing the thickness of the glazing amount and applying a carved ink, the specification of the product is 900 * 1800 MM, theproduct is cut as needed to obtain wood grain strips with various different specifications, the carved ink is also called sunken ink, and the ink has a certain pH value, is corrosive, and can form a surface concave-convex line when used in order to replace a wood carving machine. The product has the advantages of stable glaze color, strong glaze texture feeling, high hardness and ultralow water absorption rate (0.5% or below); compared with natural wood, the product of the invention is more durable, is not prone to be corroded and perforated, has a surface gloss of 10-15 DEG, avoids waxing treatment during use, has good anti-fouling and anti-slip performances, and is an ideal choice for home; and the product of the invention has better performances than real wood, so the felling of wood isreduced.

Owner:广东冠星陶瓷企业有限公司

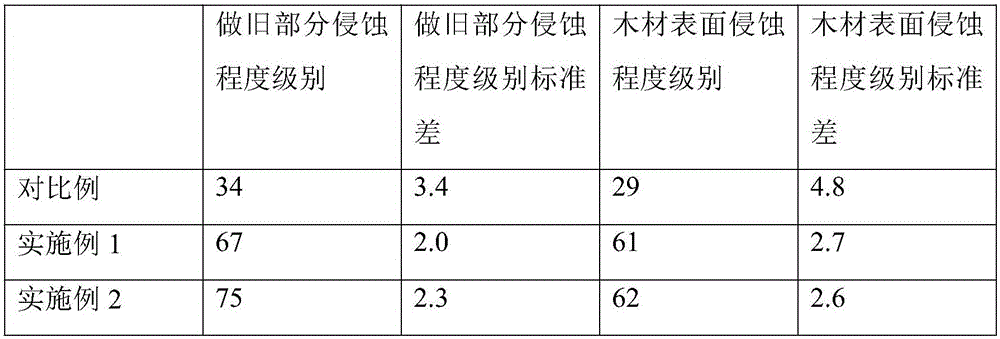

Wood antique finish technology for historic building

ActiveCN106217549AExtended service lifeControllableImpregnation spraying apparatusWood treatment detailsWax treatmentPreservative

The invention discloses a wood antique finish technology for a historic building. According to the technical scheme, the wood antique finish technology for the historic building comprises following steps: S1, the wood surface is cleaned and aired; S2, the portion, required to be subject to antique finish, of the wood is subject to waxing treatment, standing is carried out, and wax is solidified and molded; S3, the remaining portion, except for the antique finish portion, on the wood is coated with an anti-corrosion agent; S4, the antique finish portion in the S3 of the wood is subject to wax removal treatment until the antique finish portion of the wood is exposed in the air; S5, the wood in the S4 is immersed in a pit mud solution to be soaked for 20 min and then is taken out, a sodium bicarbonate solution is used for cleaning the pit mud solution on the surface of the wood, and clean water is used for cleaning the wood surface; S6, the wood in the S5 is treated for 2 h to 3 h at the high temperature, rapid cooling and standing are carried out, and a product is obtained; the technology has the following beneficial effects that the portion, required to be subject to antique finish, of the wood is subject to antique finish, the antique finish technology has the higher flexibility, and meanwhile the treated wood is good in moth prevention performance.

Owner:浙江鎏增古建园林工程有限公司

Special alloy having functions of inhibiting separation and agglomeration of wax in liquid

An object of the invention is to provide a novel special alloy having functions of inhibiting separation and agglomeration of wax in wax-containing liquid. The alloy has special electrochemical activities when being contacted with the wax-containing liquid, can effectively inhibit separation, precipitation and agglomeration of the wax and some other components in the liquid, and can be used for wax removal and prevention treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

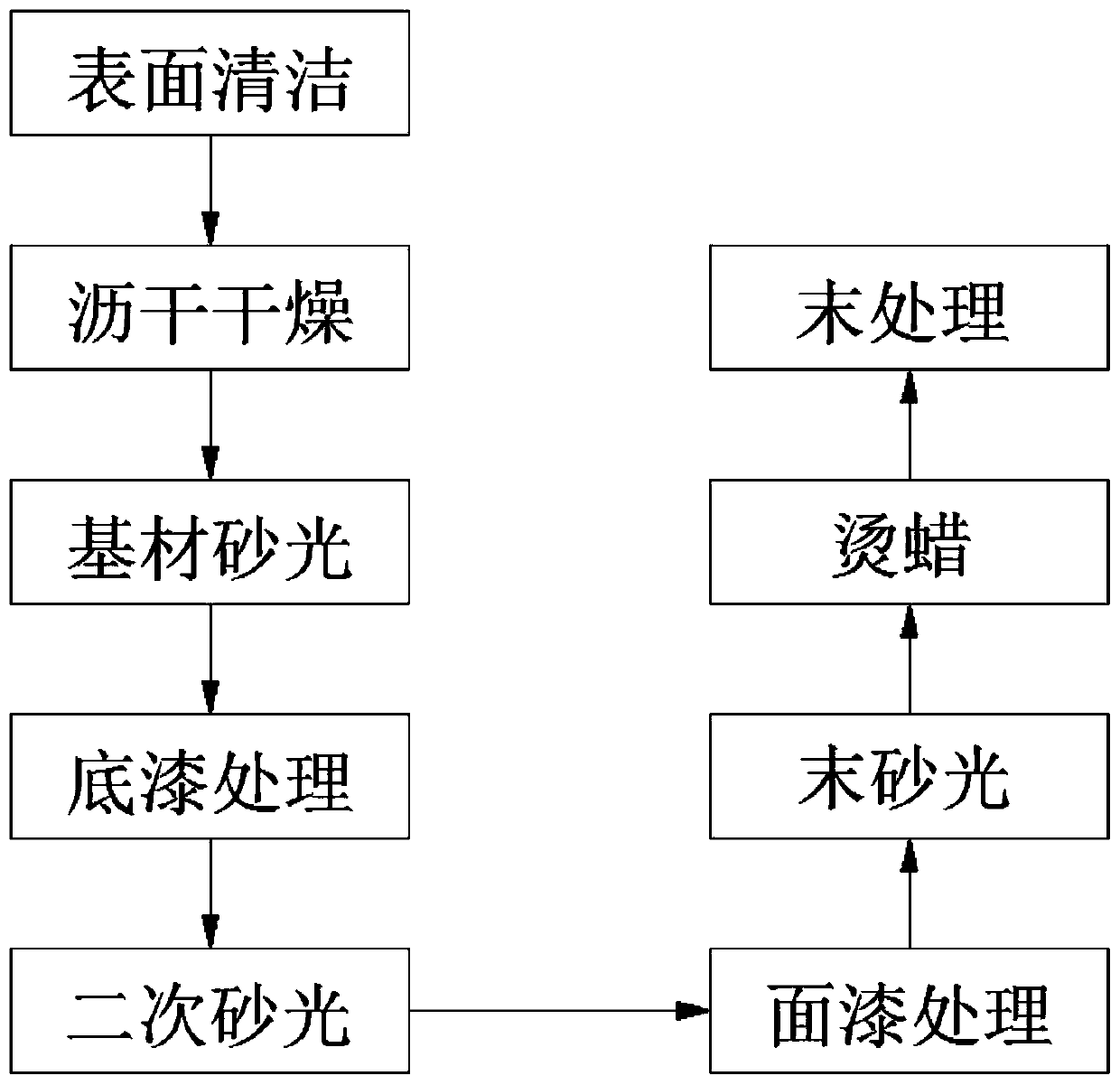

Surface paint waxing coating technology for outdoor tables and chairs

InactiveCN109732726AClean and comprehensiveAvoid poor resultsLiquid surface applicatorsCoating impregnationWax treatmentSolvent

The invention relates to the technical field of surface treatment of tables and chairs and especially relates to a surface paint waxing coating technology for outdoor tables and chairs. The inventioncan overcome the defect of the prior art that the protectiveness of waxing technology and excellent decorative property cannot be achieved at the same time. The surface paint waxing coating technologycomprises the following steps: S1) cleaning surface; S2) drying by draining; S3) sanding substrate; S4) treating with primer; S5) secondarily sanding; S6) treating with finish paint; S7) lastly sanding: sanding again by adopting 300#, 250# and 200# abrasive papers for sanding the outdoor tables and chairs along wood grains; S8) waxing; S9) finally treating: repeatedly and uniformly spraying a treating solvent on the surfaces of outdoor tables and chairs, and guaranteeing single-side coating quantity of 10g / m2-15g / m2. According to the invention, the outdoor tables and chairs are sanded for three times; a layer of painting is coated after sanding at each time; waxing treatment is performed at last; the defect of inferior protectiveness of the traditional waxing film can be overcome; excellent decorative property is kept; the technology is convenient and simple; the production cost is low.

Owner:余姚市荣大塑业有限公司

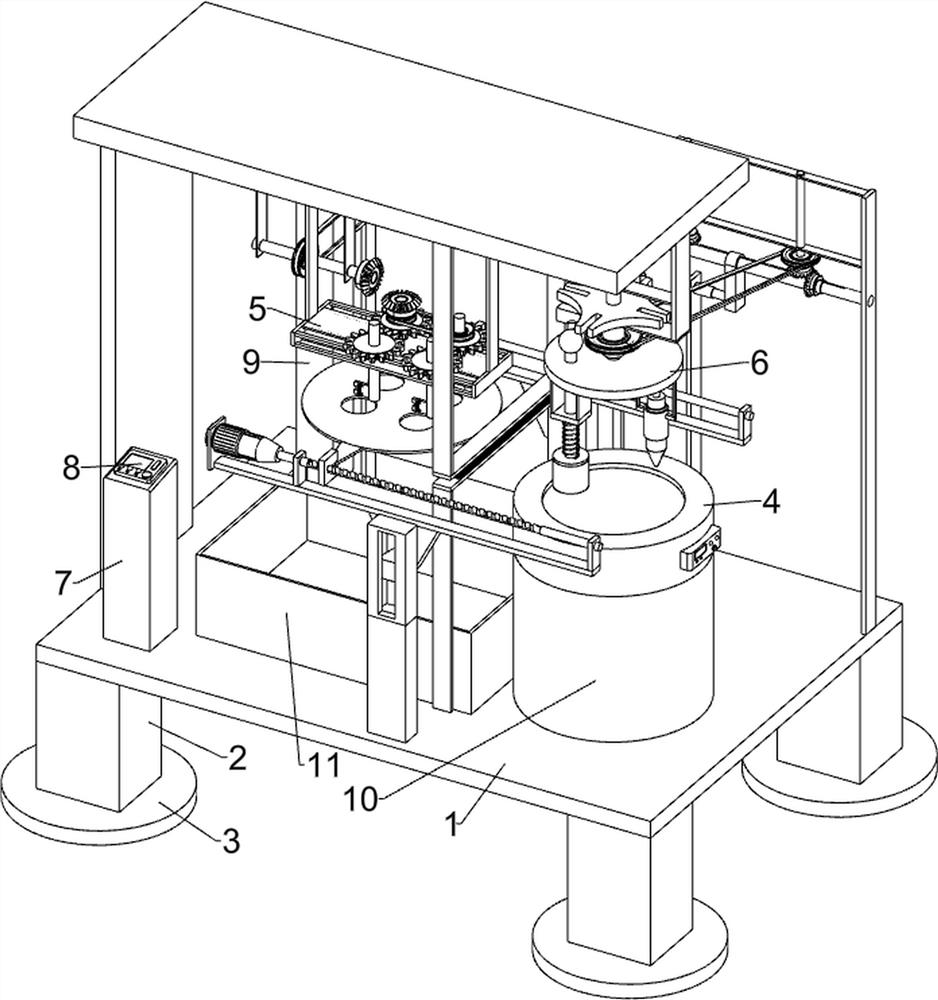

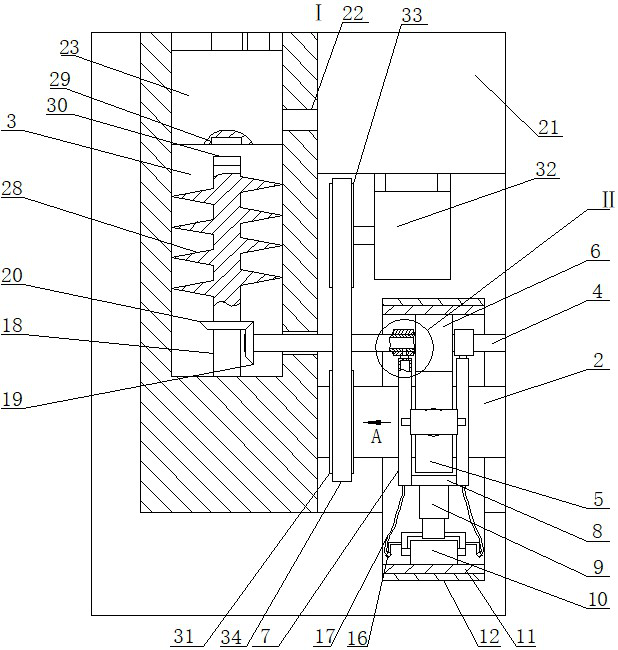

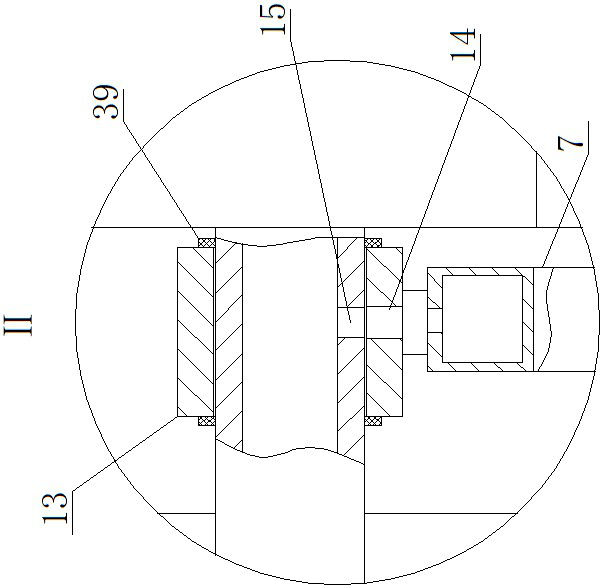

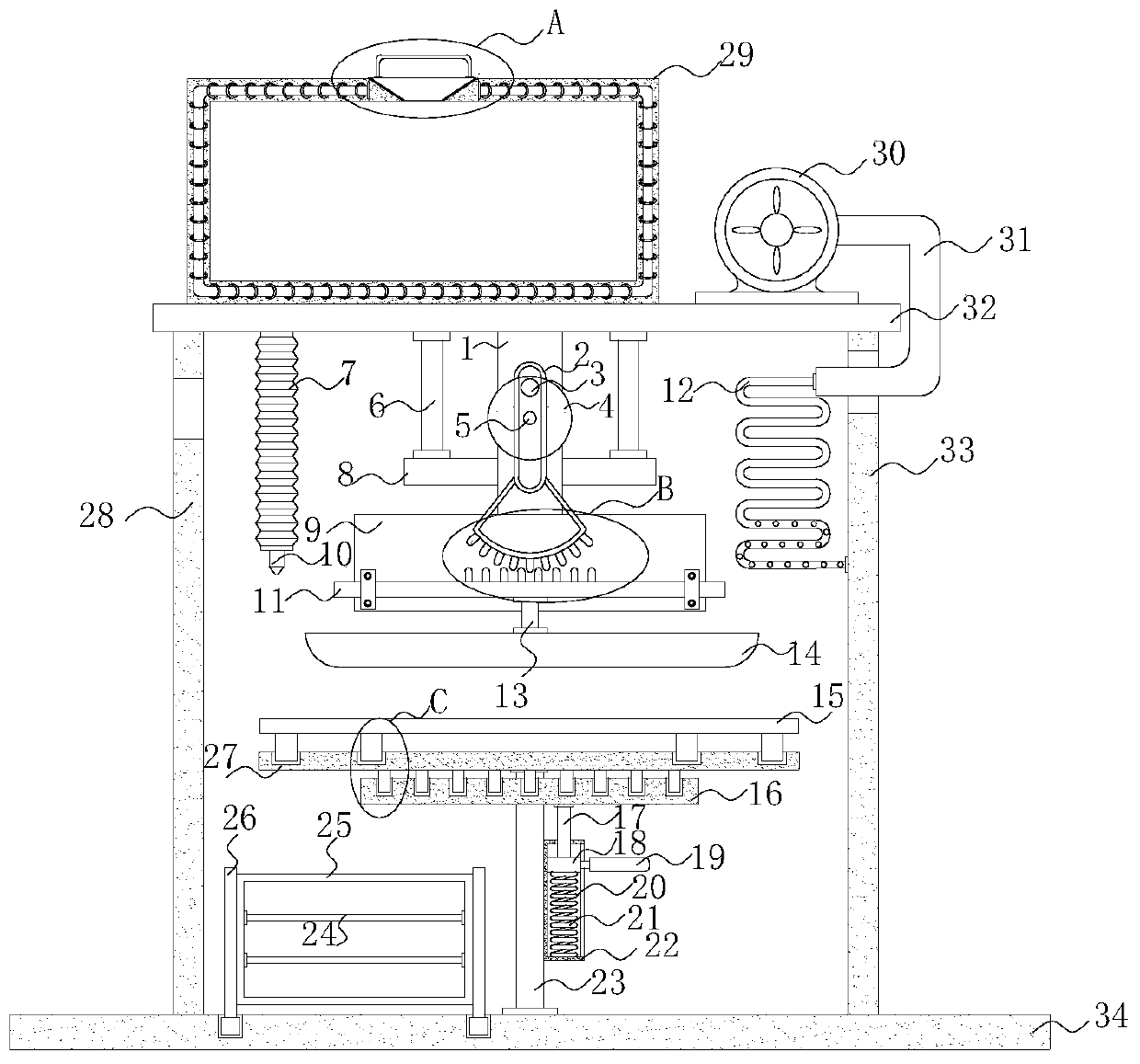

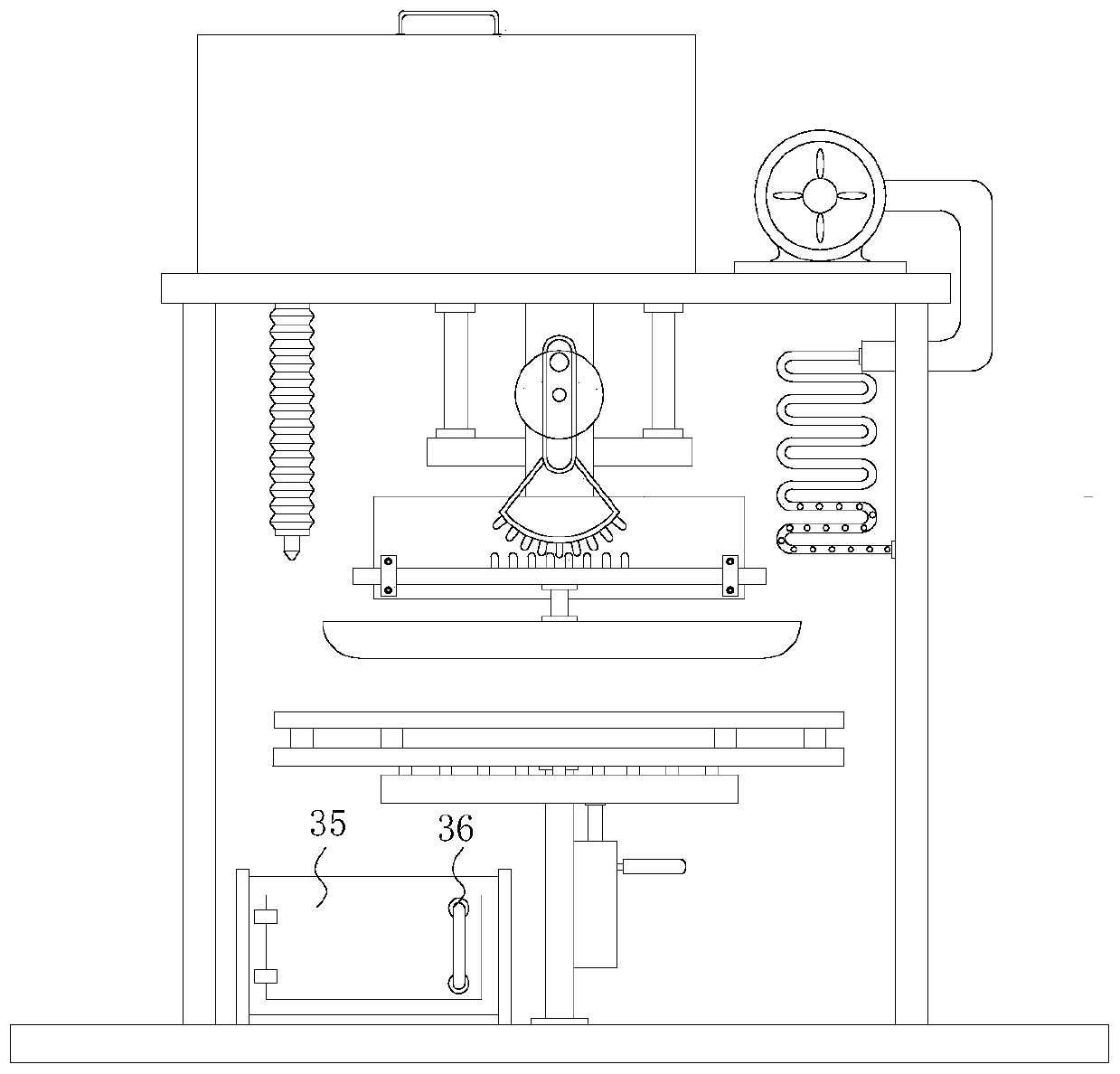

Waxing treatment device for intelligent community related LED wafer patch workpiece

PendingCN113522662AAvoid product qualityAvoid influenceLiquid surface applicatorsSpraying apparatusWaferingWax treatment

Owner:张安娜

Convenient waxing device

ActiveCN110732424ASimple structureEasy to operateLiquid spraying apparatusSpray boothsWax treatmentEngineering

The invention discloses a convenient waxing device. The device comprises a machine shell, the machine shell is internally provided with a storage cavity with an upper end opening communicating with the outside and used for adding and storing liquid wax, a switch is arranged in the right end wall of the upper side of the storage cavity, a driving mechanism for providing power and capable of carrying out grinding treatment is arranged in the right end wall of the lower side of the storage cavity, a front spraying mechanism capable of spraying the liquid wax from the front is arranged in the front end wall of the lower side of the storage cavity, a rear spraying mechanism capable of spraying the liquid wax from the rear is arranged in the rear end wall of the lower side of the storage cavity,and a transmission mechanism is arranged in the machine shell; and during working, people manually pour the liquid wax into the storage cavity and press the switch, the driving mechanism transmits power to the front spraying mechanism and the rear spraying mechanism through the transmission mechanism, the spraying mechanisms spray wax by turns, and meanwhile, the driving mechanism works to grindthe waxed surface to complete waxing. According to the device, people do not need to manually coat the wax on the surface of an object, and the integration of wax spraying and grinding can be completed.

Owner:WUHAN CHANGHENGRU ARTS & CRAFTS CO LTD

Waxing equipment for indoor floor furniture

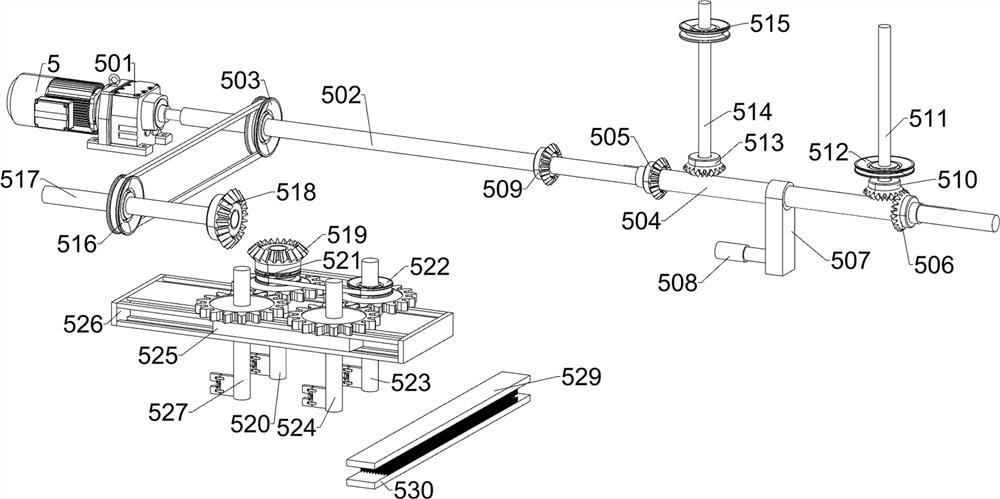

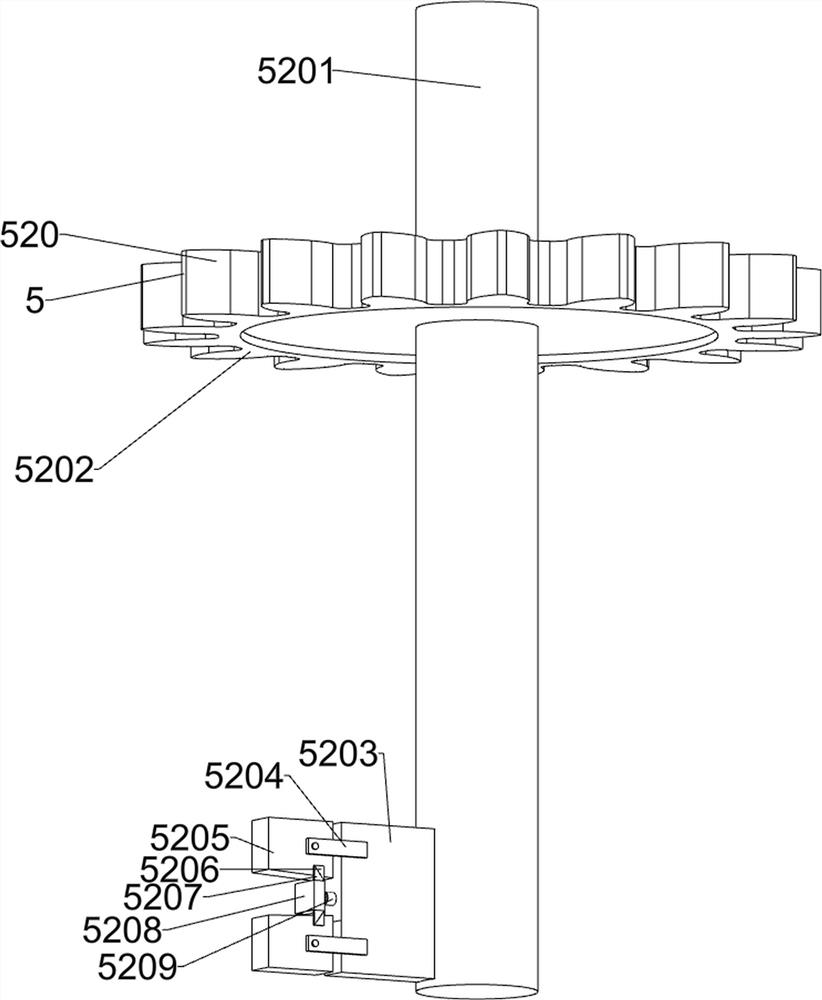

ActiveCN111743458AEasy to sprayEasy to grindLiquid surface applicatorsCarpet cleanersGear driveDrive shaft

The invention discloses waxing equipment for indoor floor furniture. The waxing equipment comprises a box body with an opening at the lower end, and a transverse shaft is arranged inside the box bodyclose to the lower end through a bearing; vertical blind holes are formed in the positions, corresponding to the ends of the transverse shaft, of the left side and the right side of the top of the boxbody and formed in the side wall of the box body, a transmission shaft parallel to the transverse shaft is arranged on the upper side of the transverse shaft and fixedly sleeved with a plurality of evenly-distributed driving gears, and driven gears are fixedly installed at the positions, corresponding to the driving gears, of the transmission shaft. According to the invention, wax oil spraying and uniform coating can be automatically carried out on the to-be-treated surface, meanwhile, polishing treatment can be conveniently carried out, when an uneven surface is treated, each inner toothed belt is supported through the three elastic telescopic rods at the bottom and on the two sides, the waxing equipment can be suitable for waxing treatment of the furniture surface with regular protrusions on the surface, the function is also an original design, the waxing equipment can be suitable for waxing treatment of floors and the furniture surface, and the waxing efficiency and effect can be greatly improved.

Owner:CHONGQING THREE GORGES UNIV

Energy-saving environmentally-friendly de-waxing kiln and de-waxing process

PendingCN107062895AReduce manufacturing costReduce lossFurnace typesEnvironmentally friendlyEngineering

The invention relates to an energy-saving environmentally-friendly de-waxing kiln. The de-waxing kiln comprises a first tunnel kiln body and a second tunnel kiln body, wherein the first tunnel kiln body and the second tunnel kiln body communicate with each other; a product is preheated to 180-300 DEG C through the second tunnel kiln body and then is pushed to the first tunnel kiln body after heat preservation is performed for certain time. The tunnel kiln bodies are additionally arranged on the original basis, the product is subjected to pre-heating and heat preservation in the first place, original low-temperature segment heat preservation time is prolonged, and high-temperature combustion and complete de-waxing processing are performed after heat preservation is performed; and in the pre-heating heat preservation (low-temperature semi-de-waxing) process, it can be well guaranteed that the temperature of a de-waxing product is not raised in a low-temperature range, therefore it is guaranteed that the de-waxing product cannot be cracked, the production cost is greatly saved, the loss is lowered, and huge economic benefits are achieved. Only structural transformation on the basis of an existing tunnel kiln is needed, the overall structure is simple, the transformation cost is low, and the energy-saving environmentally-friendly de-waxing kiln is easy to popularize.

Owner:新化县群华陶瓷科技有限公司

Leather waxing treatment device for garment production

InactiveCN110982962AReduce work intensityImprove work efficiencyLeather surface finishingWax treatmentElectric machinery

The invention discloses a leather waxing treatment device for garment production, and relates to the technical field of leather garment waxing. The leather waxing treatment device for garment production comprises a bottom plate. A first side rack, a vertical plate and a second side rack are welded to the outer surface of the top of the bottom plate. A top plate is welded to the top of the first side rack and the top of the second side rack. A heat preservation box is welded to the outer surface of the top of the top plate. A hose is fixedly installed on the outer surface of the bottom of the top plate. A nozzle is fixedly installed at the free end of the hose. A hole is formed in the first side rack. A limiting plate is welded to the outer surface of the bottom of the top plate. A motor iswelded to the outer surface of the rear side of the limiting plate, and an output shaft of the motor penetrates through the limiting plate. According to the invention, a traditional manual waxing mode is replaced, the working efficiency of workers is improved, a natural air drying cooling mode is replaced, and the rapid cooling performance of leather garments after waxing is improved.

Owner:湖州钧皓服饰有限公司

A convenient waxing equipment

ActiveCN110732424BSimple structureEasy to operateLiquid spraying apparatusSpray boothsWax treatmentStructural engineering

The invention discloses a convenient waxing device. The device comprises a machine shell, the machine shell is internally provided with a storage cavity with an upper end opening communicating with the outside and used for adding and storing liquid wax, a switch is arranged in the right end wall of the upper side of the storage cavity, a driving mechanism for providing power and capable of carrying out grinding treatment is arranged in the right end wall of the lower side of the storage cavity, a front spraying mechanism capable of spraying the liquid wax from the front is arranged in the front end wall of the lower side of the storage cavity, a rear spraying mechanism capable of spraying the liquid wax from the rear is arranged in the rear end wall of the lower side of the storage cavity,and a transmission mechanism is arranged in the machine shell; and during working, people manually pour the liquid wax into the storage cavity and press the switch, the driving mechanism transmits power to the front spraying mechanism and the rear spraying mechanism through the transmission mechanism, the spraying mechanisms spray wax by turns, and meanwhile, the driving mechanism works to grindthe waxed surface to complete waxing. According to the device, people do not need to manually coat the wax on the surface of an object, and the integration of wax spraying and grinding can be completed.

Owner:WUHAN CHANGHENGRU ARTS & CRAFTS CO LTD

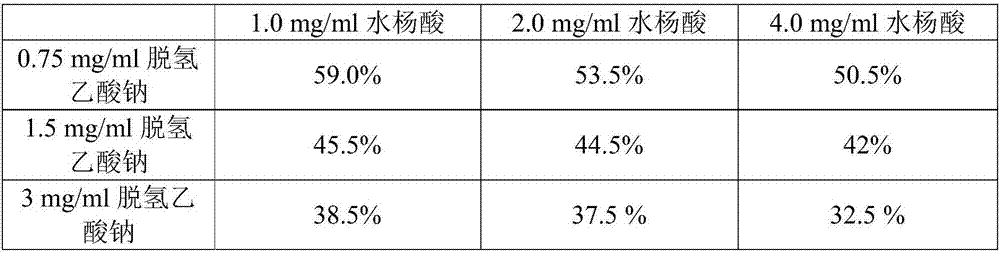

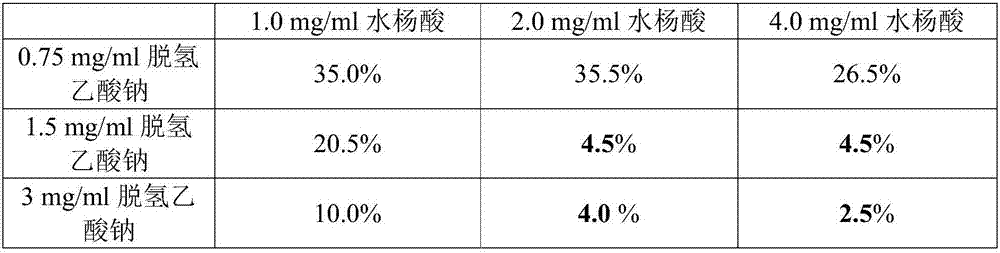

Method and composition for eliminating or alleviating phytotoxicity of methyl bromide fumigated citrus fruits

ActiveCN107372810AQuality impactPhytotoxicity suppressionAcidic food ingredientsNatural extract food ingredientsPhytotoxicityWax treatment

The present invention relates to a method and a composition for eliminating or alleviating phytotoxicity of methyl bromide fumigated citrus fruits, and the method comprises the steps of soaking the citrus fruits to be fumigated, draining, waxing, and fumigating, the soaking treatment is as follows: the citrus fruits to be fumigated are soaked with an aqueous solution containing salicylic acid and sodium dehydroacetate, and the waxing treatment is as follows: a wax solution containing cinnamic aldehyde is used for waxing the soaked and drained citrus fruits. The method can effectively inhibit the phytotoxicity caused by the methyl bromide fumigation, has no adverse effect on the quality of the citrus fruits, can fit post-harvest processing procedures of the citrus fruits, and has good application prospects in exporting citrus fruits.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Plastic wood floor manufacturing method

PendingCN110423482AReduce usageProtected wooden textureWood working apparatusDomestic articlesWax treatmentAdhesive

The invention discloses a plastic wood floor manufacturing method which comprises the following steps: I, crushing raw materials, namely firstly roughly washing recycled waste plastics and waste woodplates and bamboo poles by using a high-pressure spray gun to wash off mud dirt adhered to surfaces, and secondly, respectively shearing the waste plastics and the waste wood plates and bamboo poles into pieces by using a shearing device; and II, performing crushing and powdering, namely putting the sheared small pieces of the plastics, the wood plates and the bamboo poles into a crushing machine,and performing crushing. By adopting the plastic wood floor manufacturing method, the recycled waste plastics and waste wood plates and bamboo poles are crushed and used as a production raw material,so that the production cost can be lowered while the environment is protected; due to integral extrusion molding, the amount of adhesives is reduced, and a floor can be good in integration performance and not easy to crack; and finally, as the surface of a plastic wood floor is subjected to waxing treatment by using a PE (polyethylene) wax solution, the wood texture of the surface of the floor can be effectively protected, and a good protection function on the surface of the floor can be achieved.

Owner:浙江祥景科技有限公司

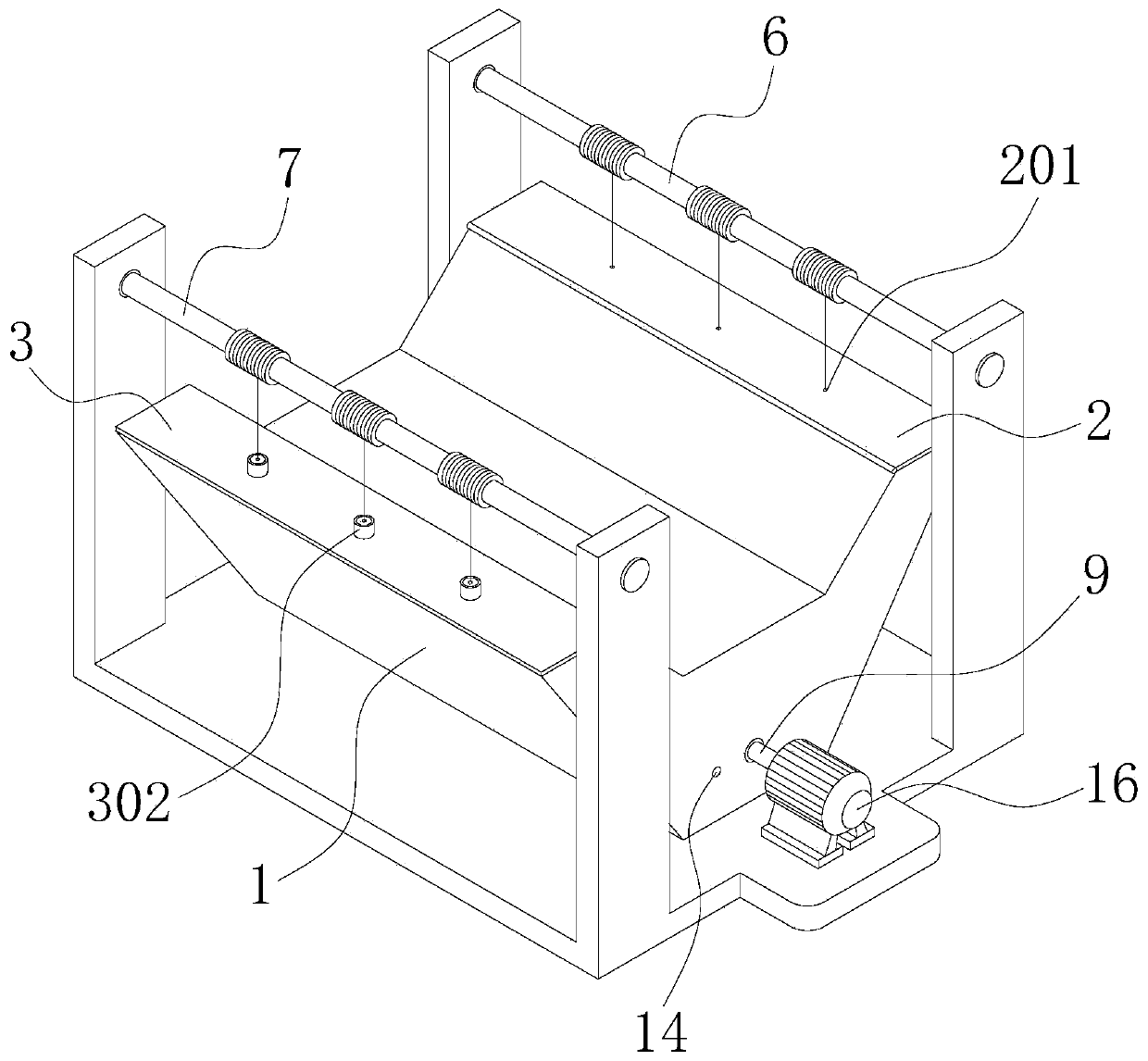

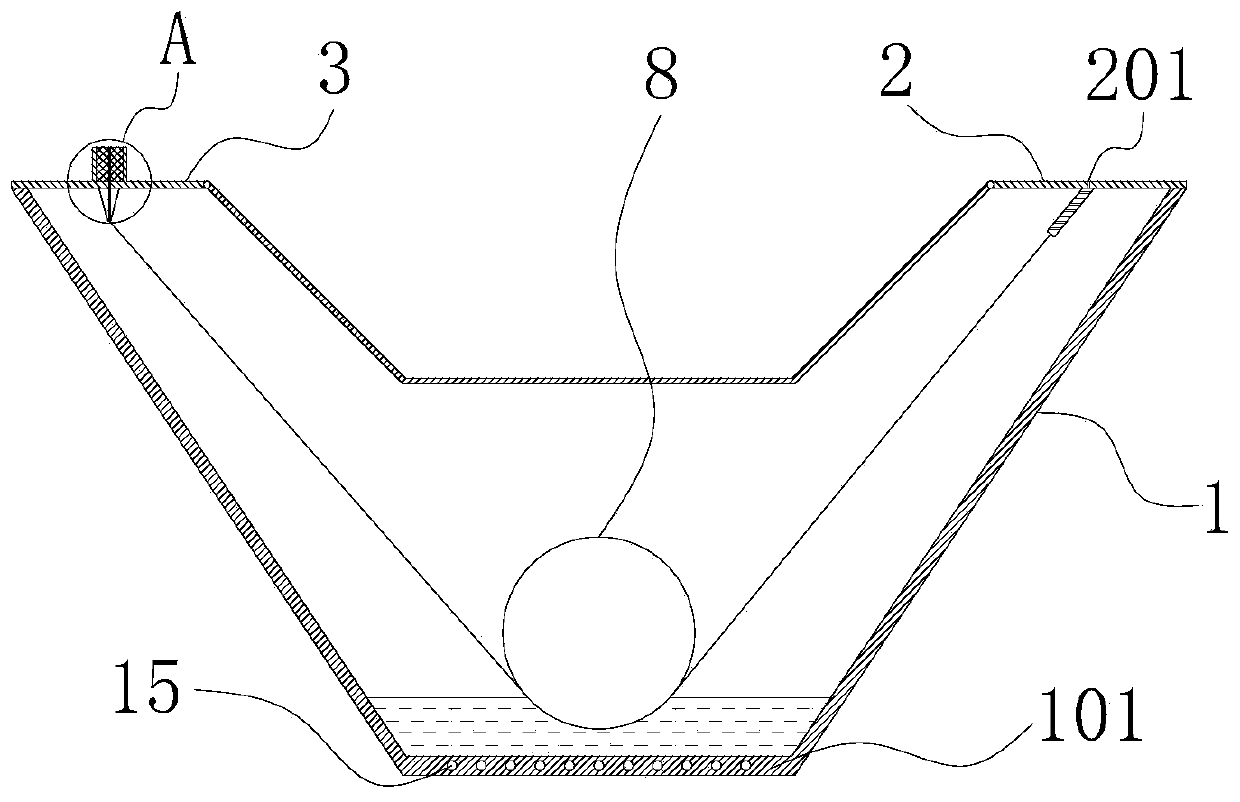

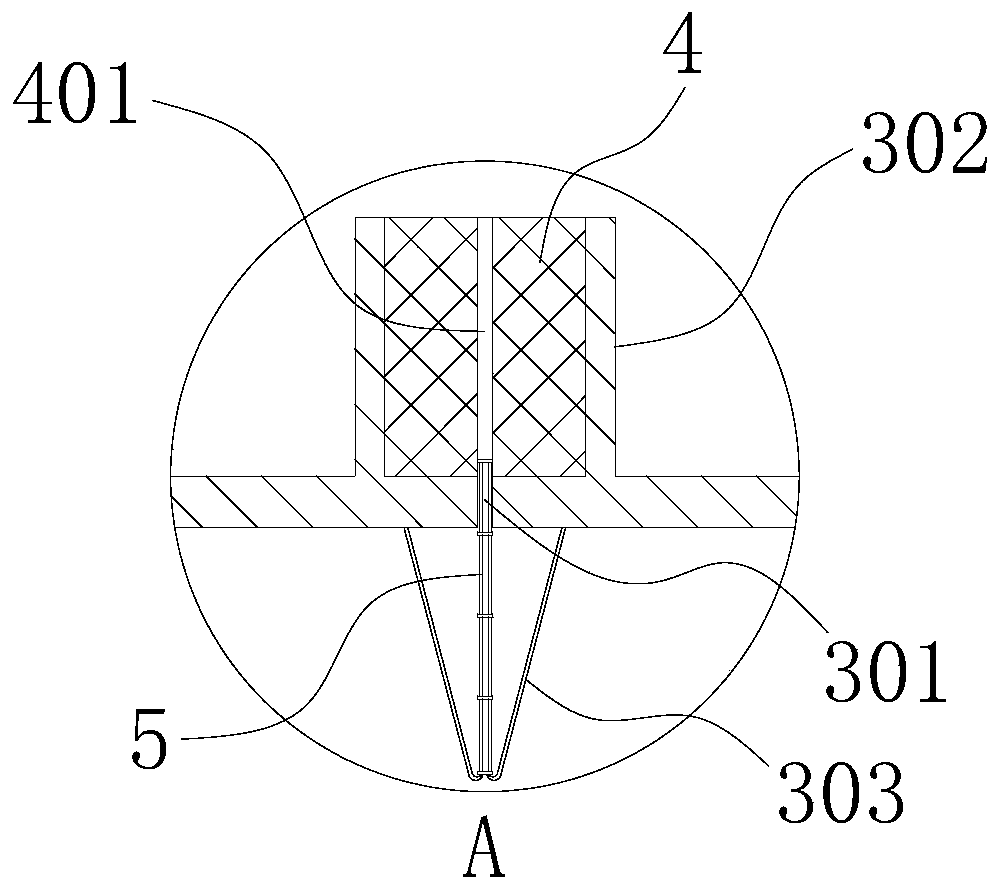

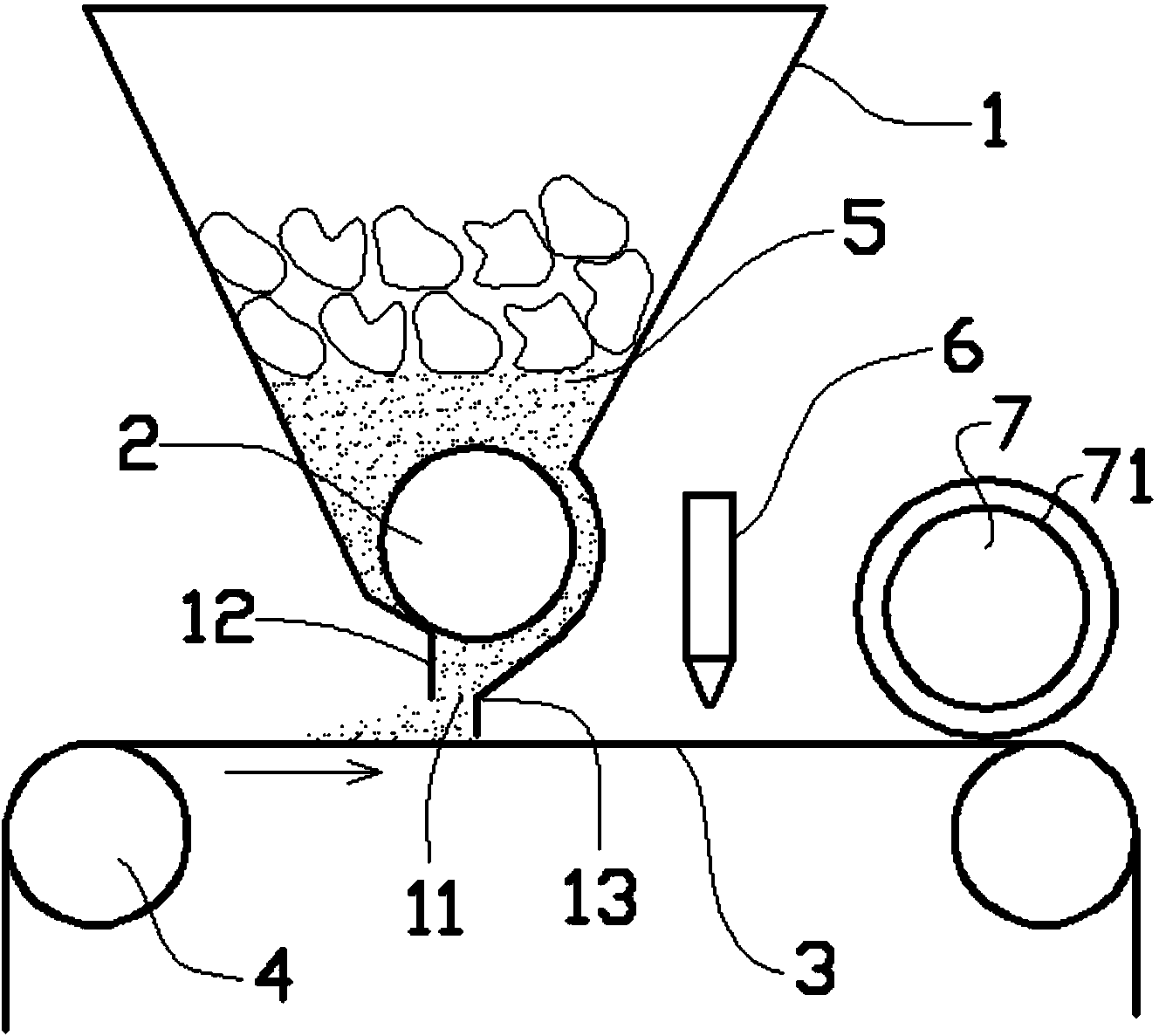

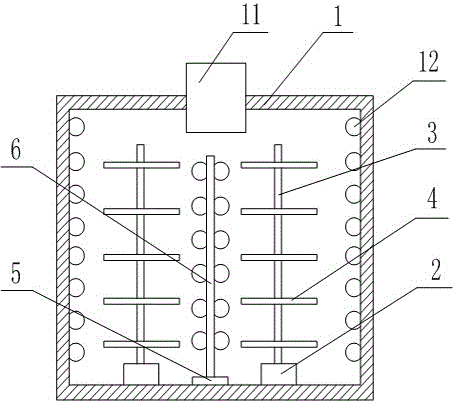

Fabric waxing device

InactiveCN104043556AFast wax applicationImprove efficiencyLiquid surface applicatorsCoatingsWax treatmentEngineering

The invention provides a fabric waxing device. The fabric waxing device comprises a hopper and a heating roller, wherein the hopper is assembled at the upper part of fabric passing horizontally; the heating roller is horizontally assembled at the outlet position of the hopper; a heating module is assembled in the heating roller; an outlet in the lower part of the hopper is strip-shaped and the hopper is horizontally positioned at the upper part of the fabric; the upper part of the rear edge of the outlet in the lower part of the hopper wraps the outer side of the surface of the heating roller in a circular arc manner; the distance from the horizontal assembling position of the lower side of the rear edge to the horizontal surface of the fabric is less than 2mm; waxing materials are arranged in the hopper. The fabric waxing device is used for carrying out waxing treatment on the surface of the fabric. The waxing materials are liquefied after being heated so as to flow to the surface of the fabric from the outlet in the lower part of the hopper, so that the wax is directly smeared on the surface of the fabric; due to the processing mode, the waxing speed is fast, the efficiency is high and the waxing is uniform.

Owner:WUJIANG TEXTILE SCI & TECH CENT

Turnover conveying device

InactiveCN107777307ASolve the problem of bright surface pollutionSmooth entryConveyorsConveyor partsWax treatmentMaterials processing

The present invention relates to the field of decoration material processing, in particular to a turning-over conveying device, including a conveying device, the conveying device includes a bracket and a symmetrically arranged track, a conveyor belt 1 is arranged on the track, and a driving belt is provided at the discharge end of the track. The driving device for the rotation of the conveyor belt. The middle part of the conveying device is clamped with a flipping device. The outlet of the conveying device is connected to the inlet of the conveying device. The wooden floor treated by the wax spraying process has a smooth surface Facing down, the conveyor belt transports the wooden floor, and through the function of the turning device installed in the middle of the conveying device, the glossy surface is turned upward, thereby solving the problem that the wooden floor is easily polluted by the bright surface during transportation.

Owner:中江德宝木业有限公司

Carbon nanotube reinforced alumina ceramic composite material and preparation method thereof

Owner:HEFEI UNIV OF TECH

Shoe making process based on drying effect improvement

The invention discloses a shoe making process based on drying effect improvement. The shoe making process includes the following steps that 1, a shoe sole is formed, wherein the shoe sole is made in a mold; 2, an upper material is made, wherein a vamp and a lining are compounded and formed through glue; 3, the upper material is cut, wherein the upper material made in the step 2 is cut into an upper matched with the shoe sole; 4, the upper made in the step 3 is glued or sewn to the shoe sole; 5, paint spraying and waxing treatment is carried out on the vamp; 6, a shoe obtained after paint spraying and waxing is placed in a drying system for drying; 7, shoe edge correction is carried out, wherein burrs and glue protrusions on shoe edges are removed through a tool. The problem that according to an existing shoe making process, drying efficiency is low is solved.

Owner:CHENGDU LIXIN SCI & TECH

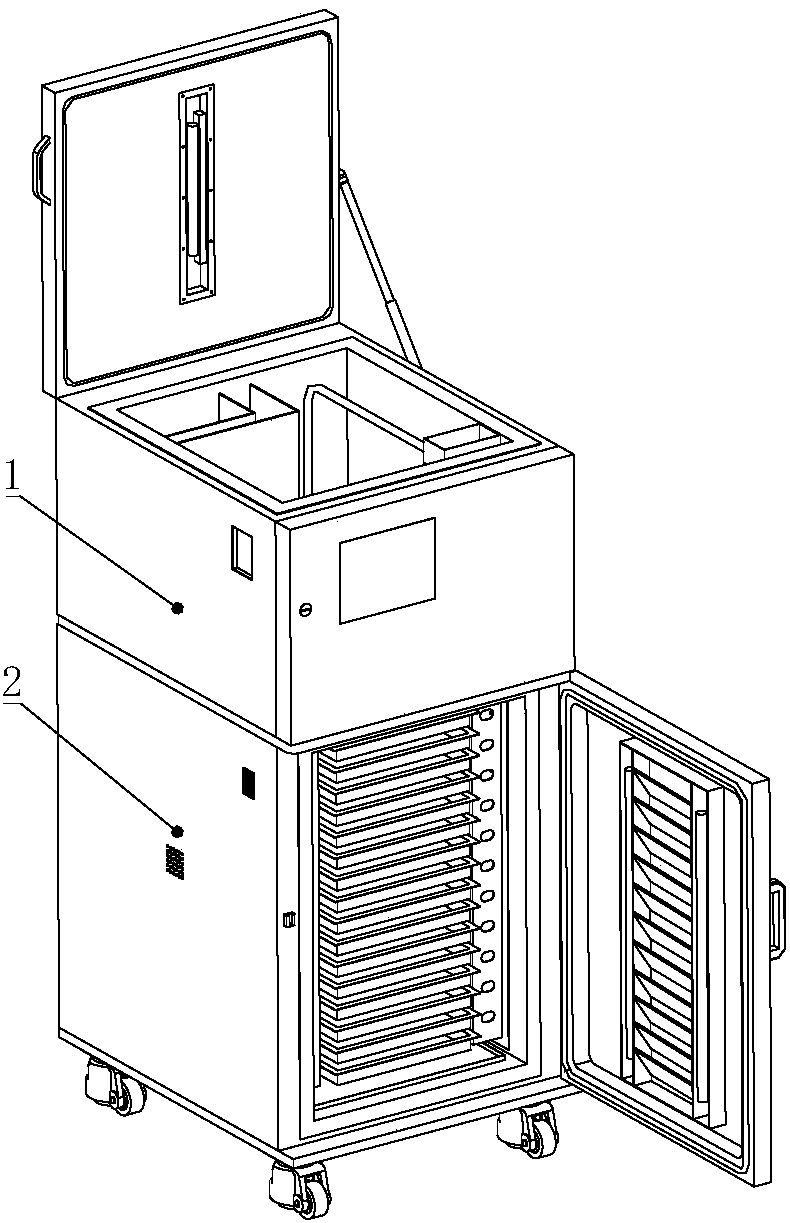

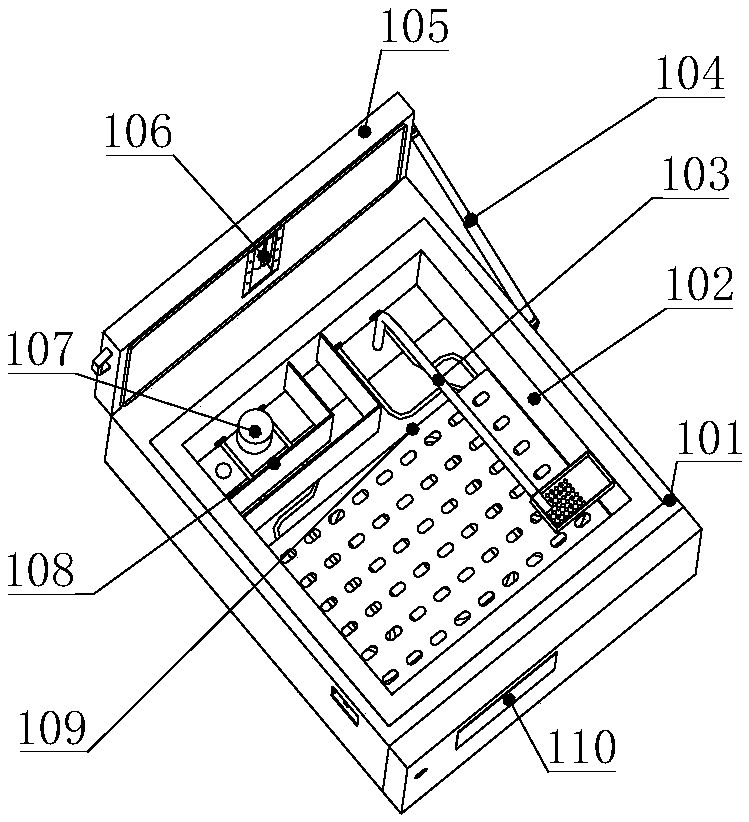

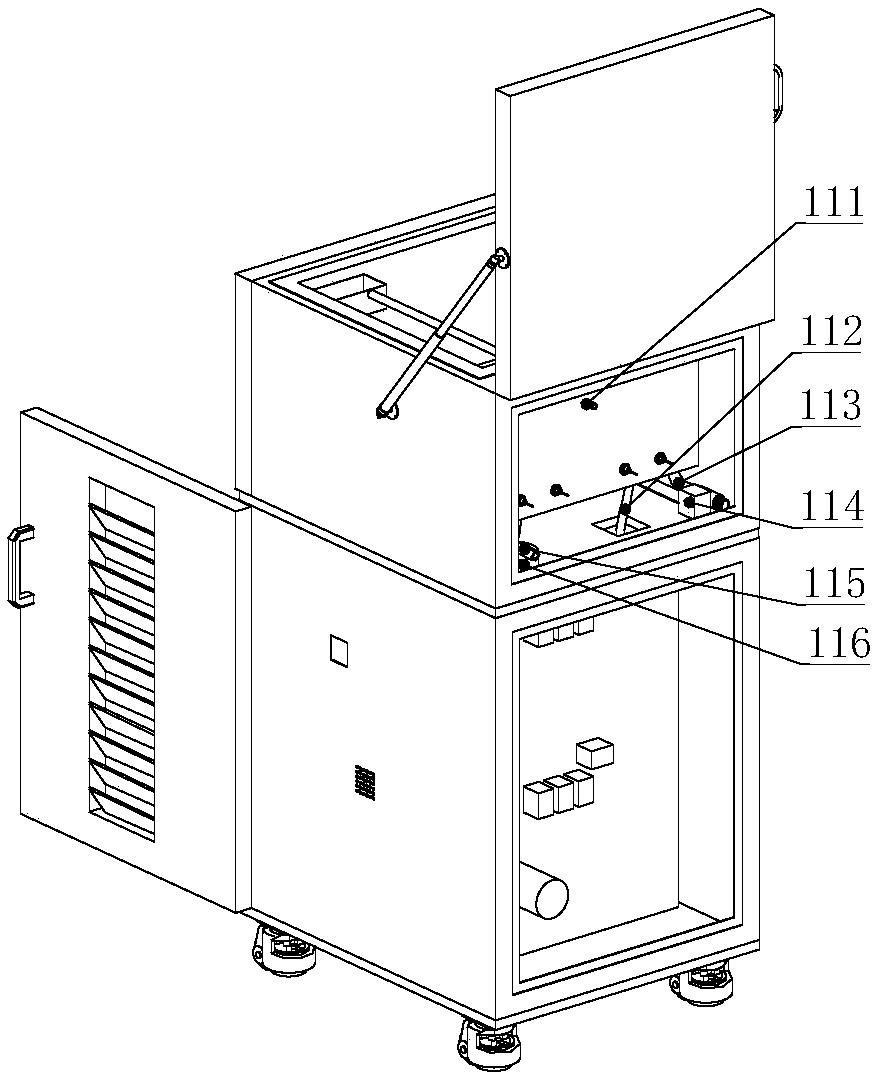

Wax-melting heating apparatus and wax therapy machine using same

PendingCN107708237AAvoid damageEasy to moveBathing devicesHeating element shapesMode controlWax treatment

The invention provides a wax-melting heating apparatus and a wax therapy machine using the same. The wax-melting heating apparatus comprises a first heating pipe and a second heating pipe; the first heating pipe surrounds the outer layer of the second heating pipe; the power of the second heating pipe is higher than that of the first heating pipe; a protection cover is arranged outside the first heating pipe and the second heating pipe; and a heating plate is arranged on the inner side wall of a wax-melting groove of the wax therapy machine using the wax-melting heating apparatus. The wax-melting heating apparatus has the beneficial effects as follows: the power value of the heating pipes can be set according to actual product requirement; by controlling the working states of the heating pipes and the heating plate, multiple heating patterns can be realized; the protection cover is arranged at the upper ends of the heating pipes, so that damage to the heating pipes caused by contact between the wax block and the heating pipes can be prevented; and ventilating holes are formed in the surface of the protection cover, so that medium water can flow inside and outside the protection cover conveniently.

Owner:吉林省亮达医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com