Manufacturing method for a golf club head

a manufacturing method and golf club head technology, applied in the field of golf club head manufacturing method, can solve the problems of increased manufacturing cost and time, difficult machining, etc., and achieve the effect of increasing the overall quality of the golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

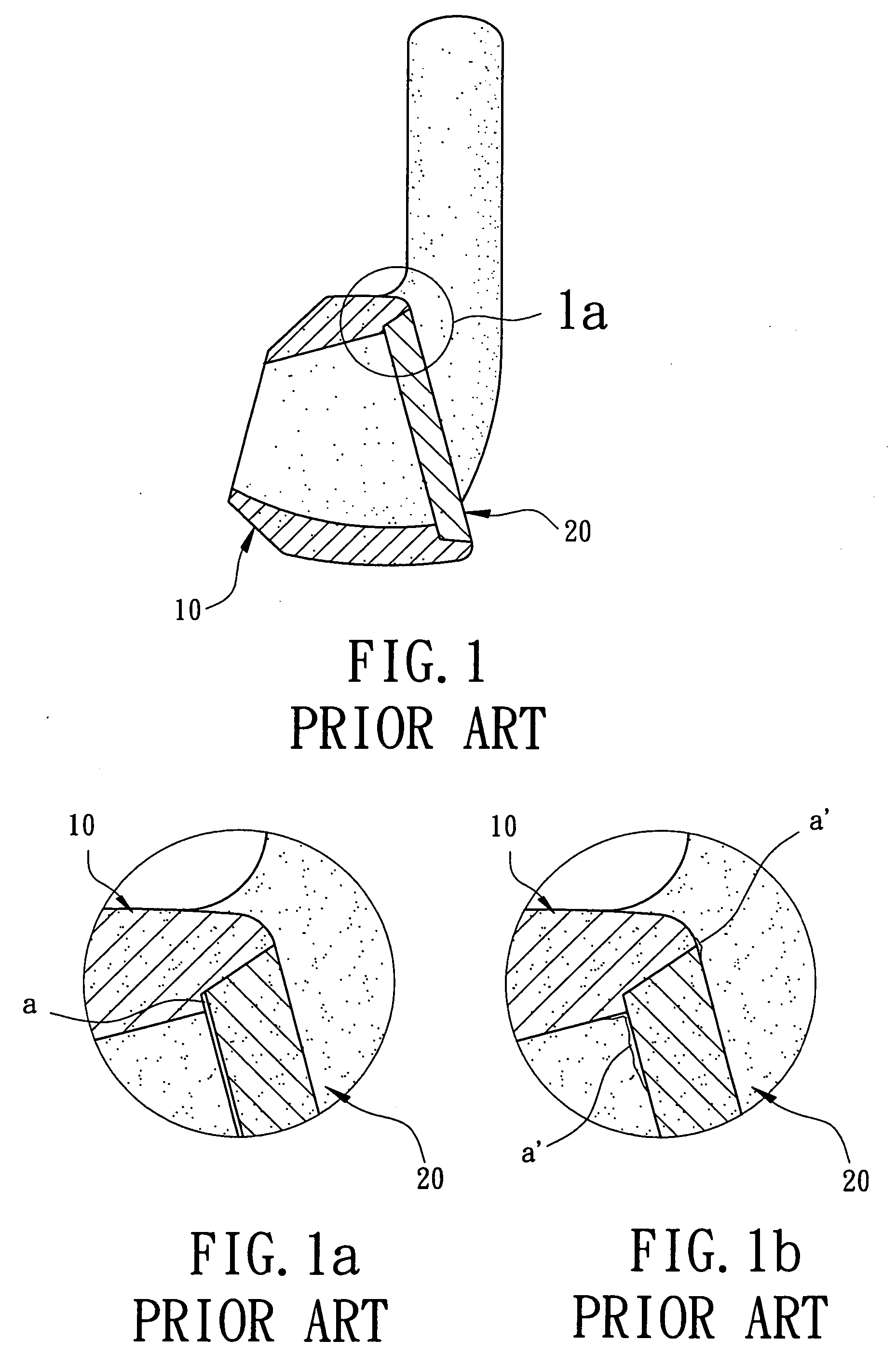

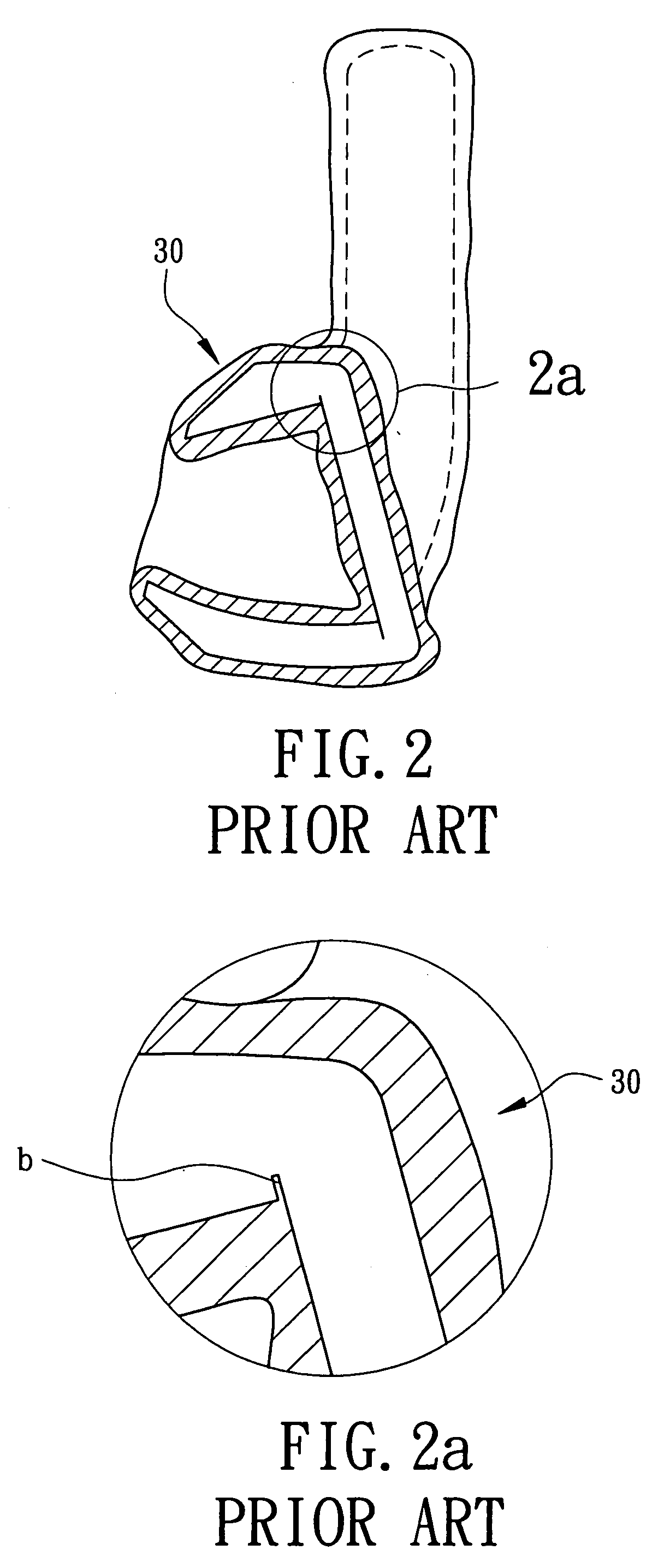

[0032] The reference numerals of the first and second embodiments of the present invention have applied the identical numerals of the conventional golf club head members, as shown in FIGS. 1 through 3. The construction of golf club head member members in accordance with embodiments of the present invention have similar configuration and same function as that of the conventional golf club head members and detailed descriptions may be omitted.

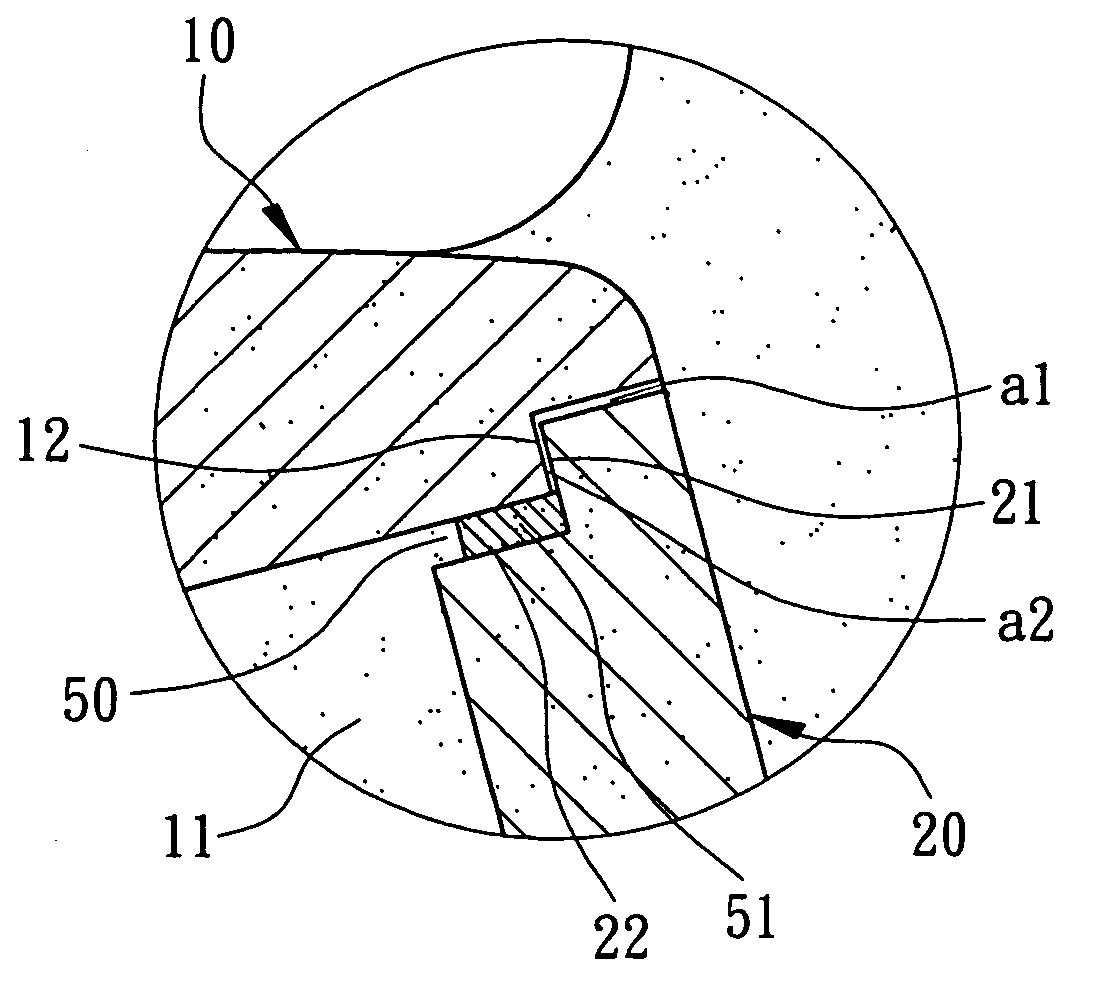

[0033] Referring to FIGS. 4 and 5, a first step of the manufacturing method for the golf club head in accordance with the first embodiment of the present invention prefabricates a main-body wax pattern 10 and a striking-plate wax pattern 20. The construction of the main-body wax pattern 10 provides with a rear opening 11 while that of the striking-plate wax pattern 20 providing with a stepped portion 21 at its rear side. First, wax liquid is injected into a mold assembly (not shown) for separately prefabricating the main-body wax pattern 10 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com