Ceramic tile surface waxing treatment production line

A production line and wax treatment technology, which is applied to the surface pretreatment, the device for coating liquid on the surface, the spray device, etc., can solve the problems of lack of integrated continuous processing, uneven manpower waxing, low efficiency and low consumption, etc. Achieve the effect of high waxing efficiency, low production cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

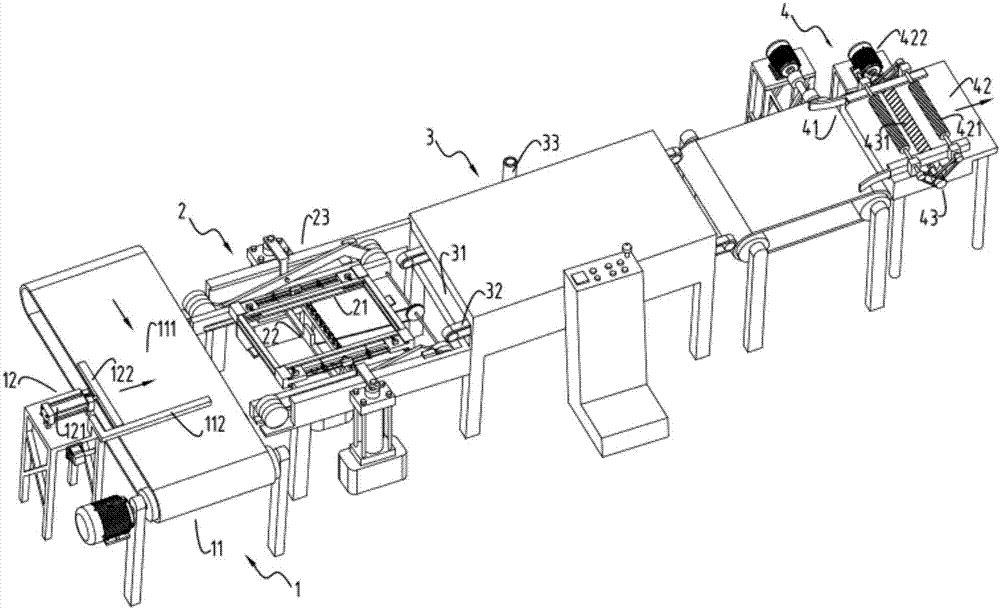

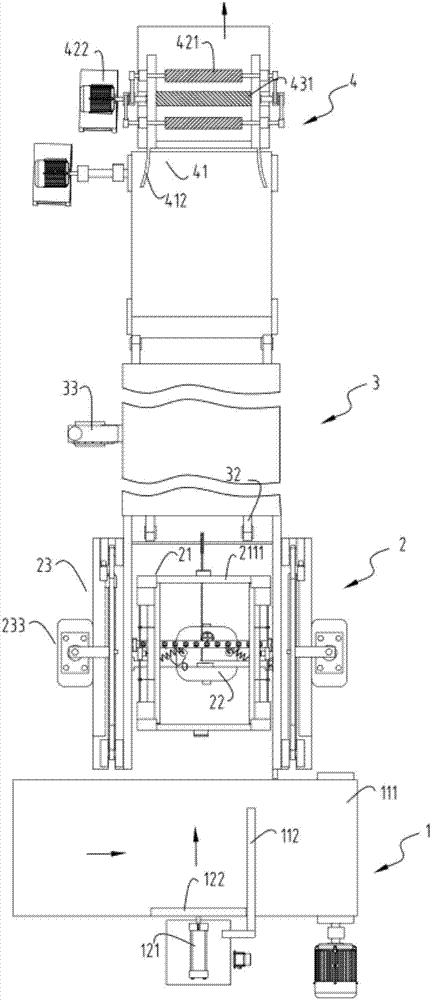

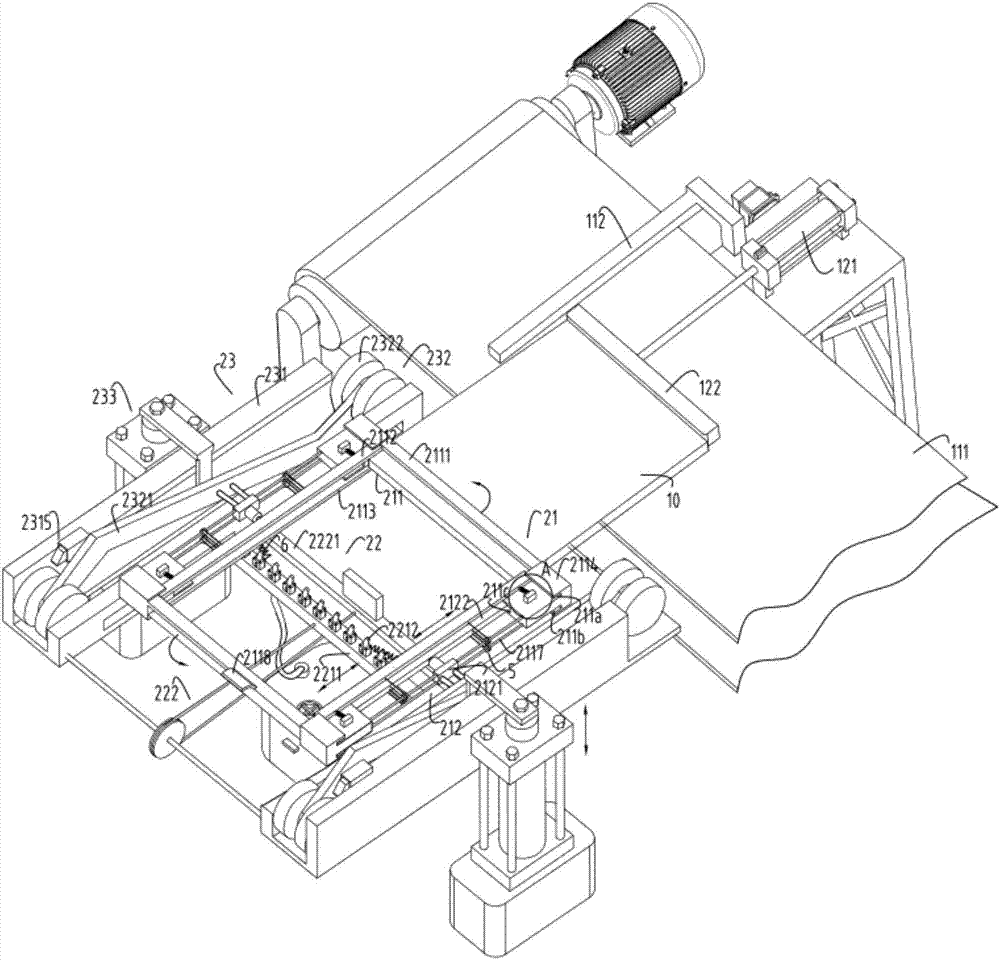

[0062] figure 1 Schematic diagram of the production line for waxing the surface of ceramic tiles, figure 2 The schematic diagram of the top view of the waxing treatment production line for the surface of ceramic tiles, image 3 Schematic diagram of the structure for positioning the feeding part and turning the waxing part, Figure 4 is an enlarged schematic diagram of reset device a or reset device b, Figure 5 Schematic diagram of the structure during the inversion process of the waxing part of the inversion, Figure 6 Schematic diagram of dismantling part of the mechanism for flipping the waxing part, Figure 7 Schematic diagram of the enlarged structure of the sliding restraint device, Figure 8 It is a schematic diagram of the structure when the clamping positioning mechanism clamps the tiles, Figure 9 The schematic diagram of the enlarged structure of the pulley mechanism, Figure 10 It is a schematic diagram of the structure when the clamping block clamps the til...

Embodiment 2

[0093] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 as well as Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the clamping block 2122 is linked with the support block a2112 and the support block b2113 through the pulley mechanism 5, and the pulley mechanism 5 includes a The pulley b51, the pulling rope a52 that goes around the pulley b51 and is fixedly connected to the clamping block 2122 and the support block a2112 at both ends, the pulley c53, and the pulley c53 that goes around the pulley c53 and connects the two ends to ...

Embodiment 3

[0095] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 as well as Figure 15 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is: the positioning device 41 includes a limit chute 411 and a guide block 412 arranged at the entrance of the limit chute 411; the power device 42 includes a driving wheel 421 and Motor 422 ; the grinding device 43 includes a grinding roller 431 , and both the grinding roller 431 and the driving wheel 421 work under the drive of the motor 422 .

[0096] The moving power of the ceramic tile 10 in the grinding process is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com