Patents

Literature

114results about How to "Guaranteed to be firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

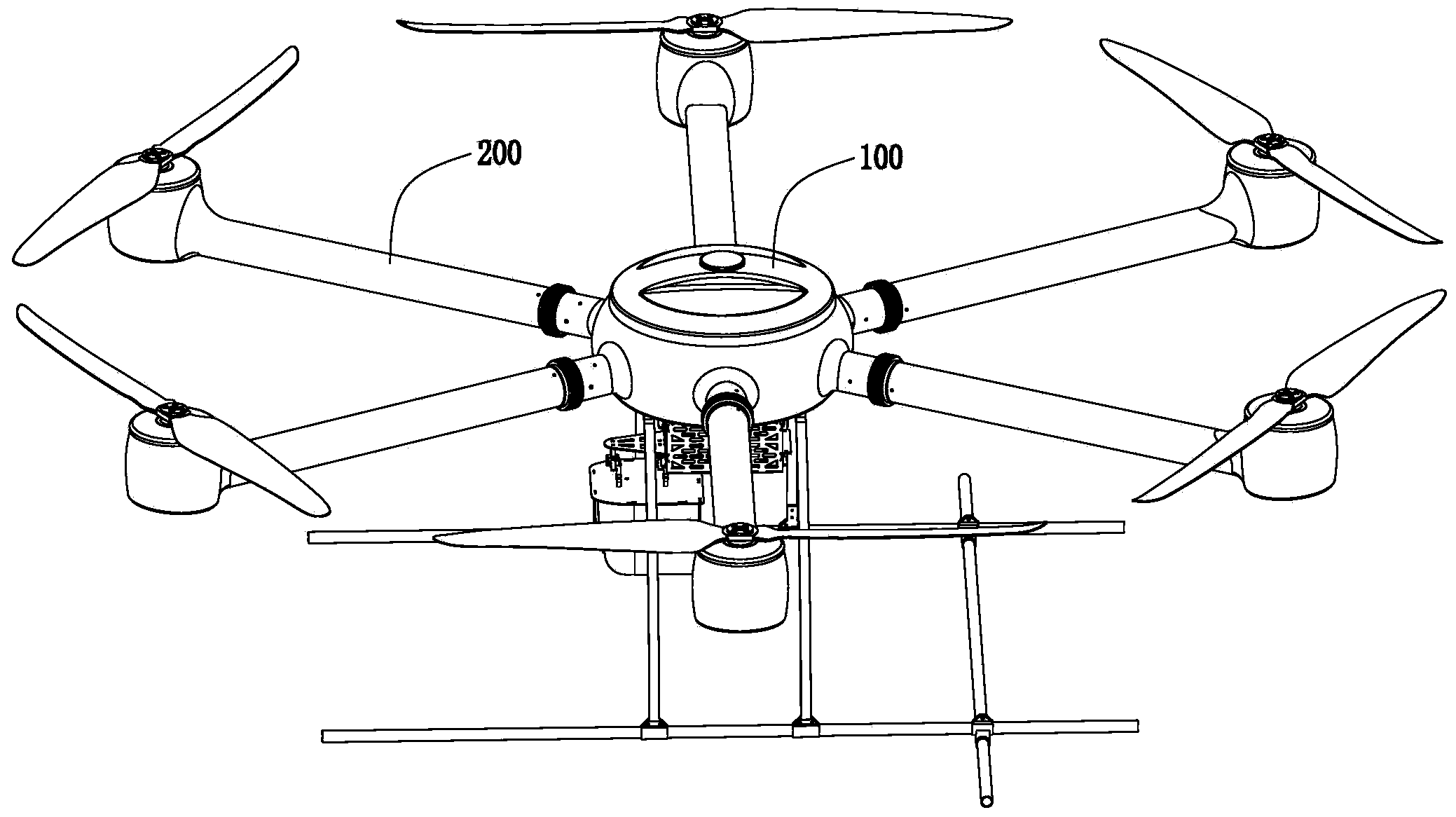

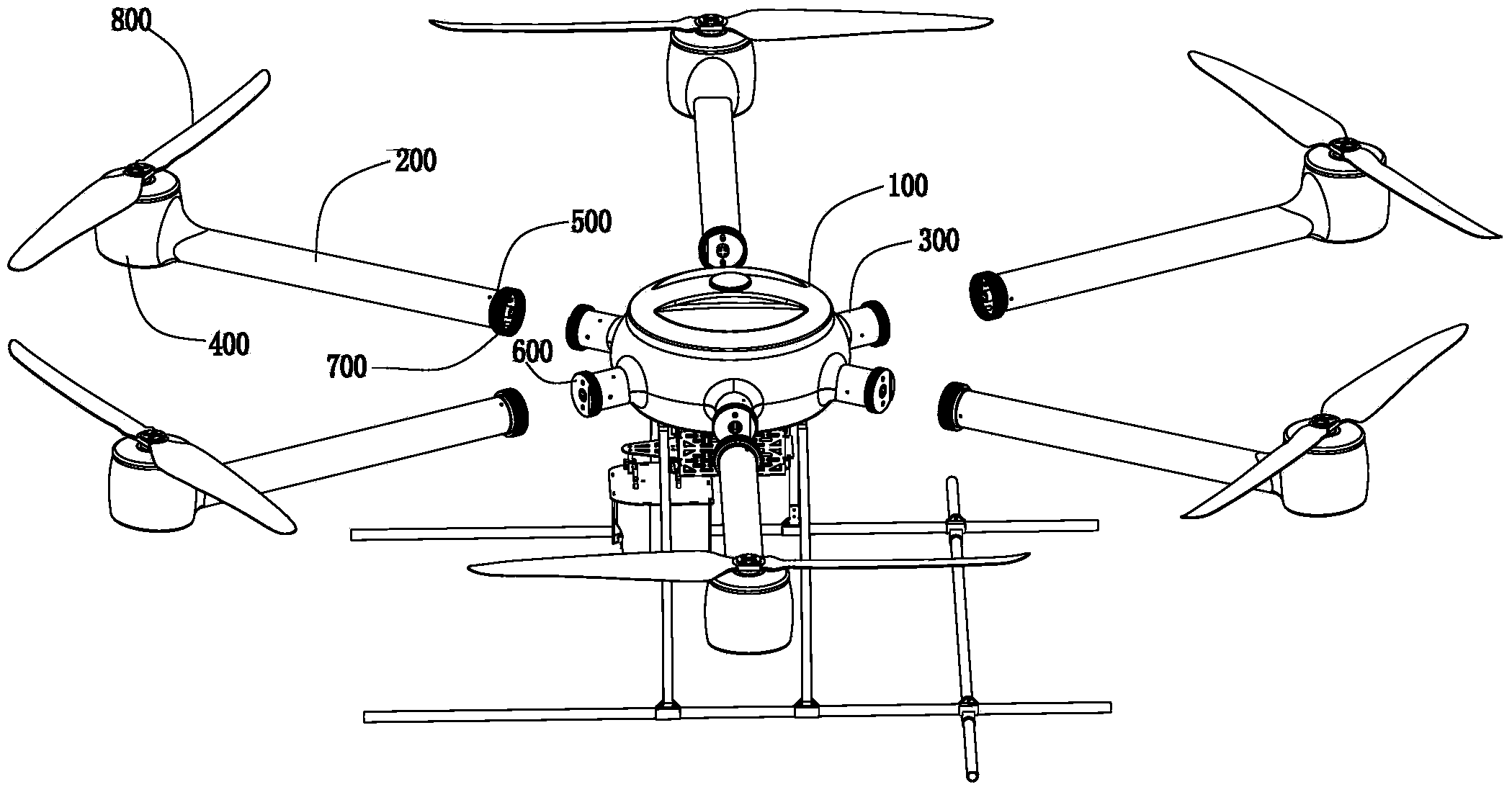

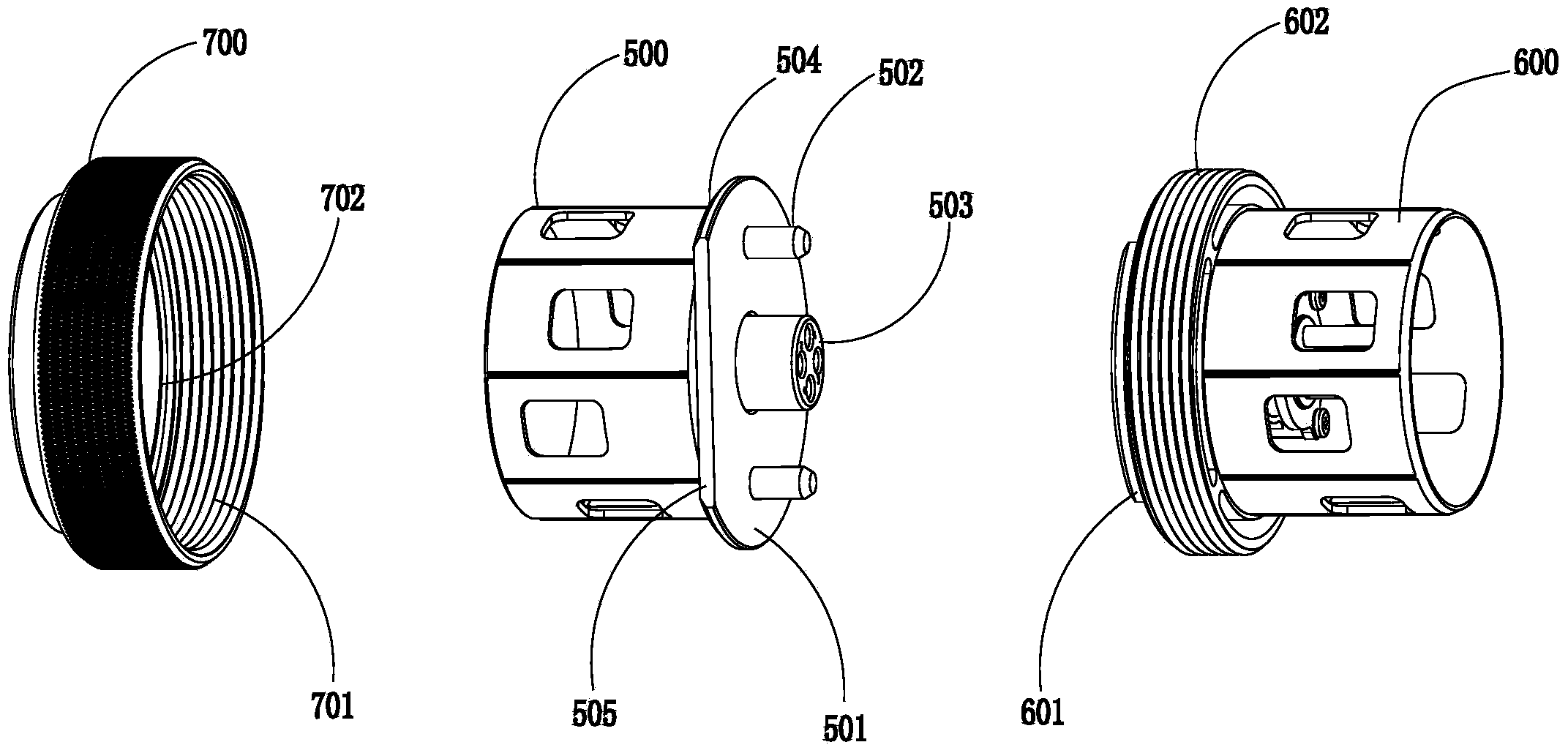

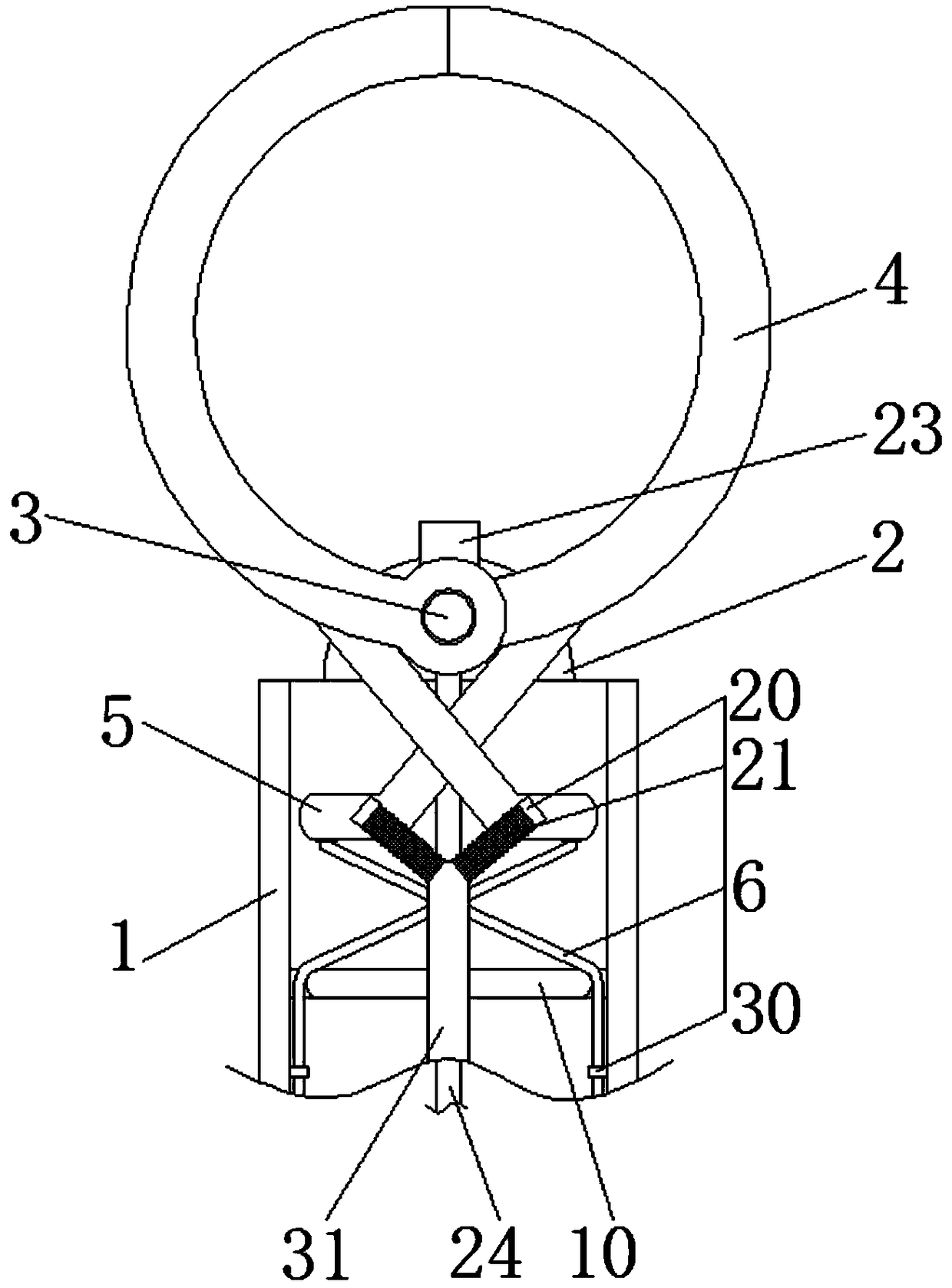

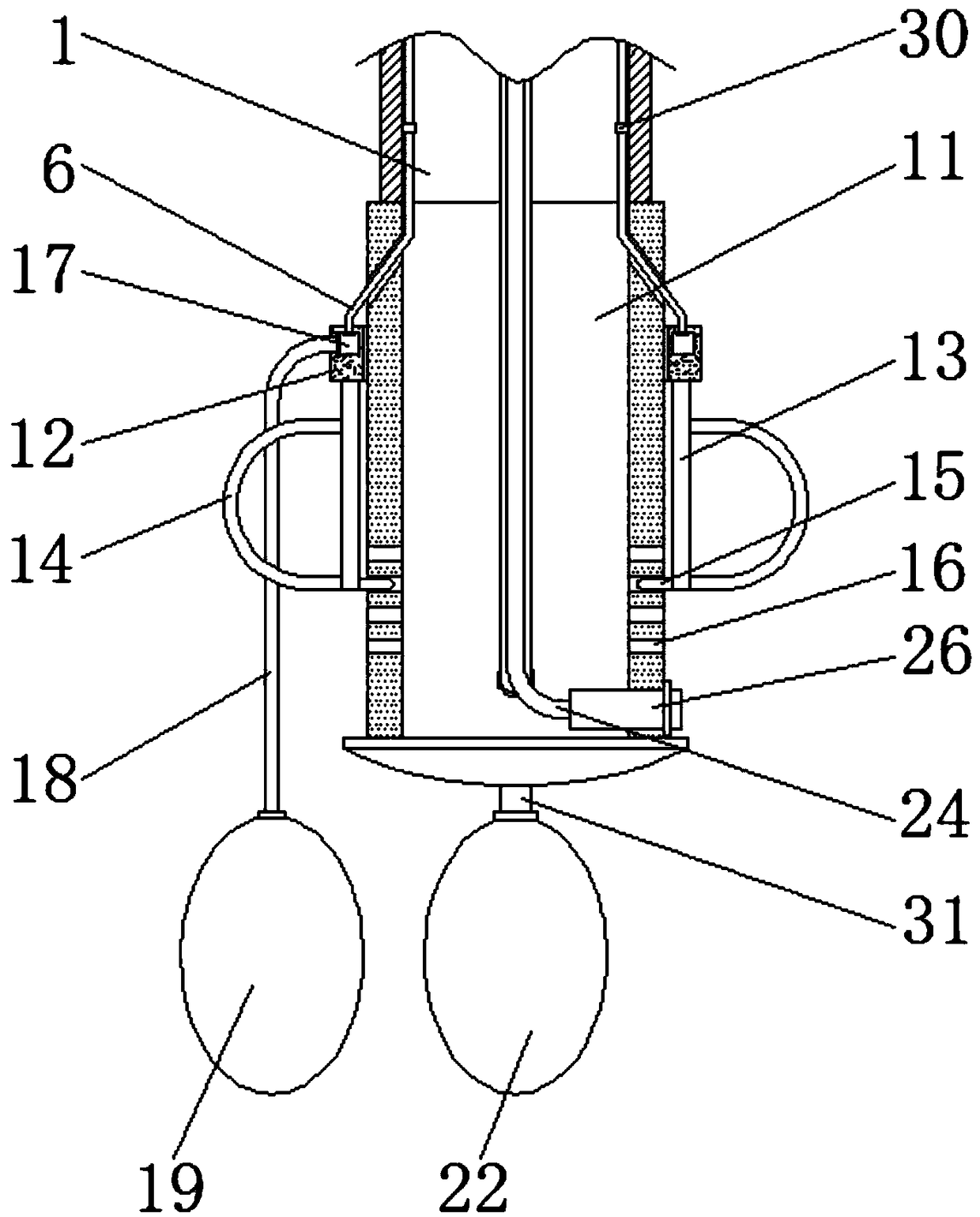

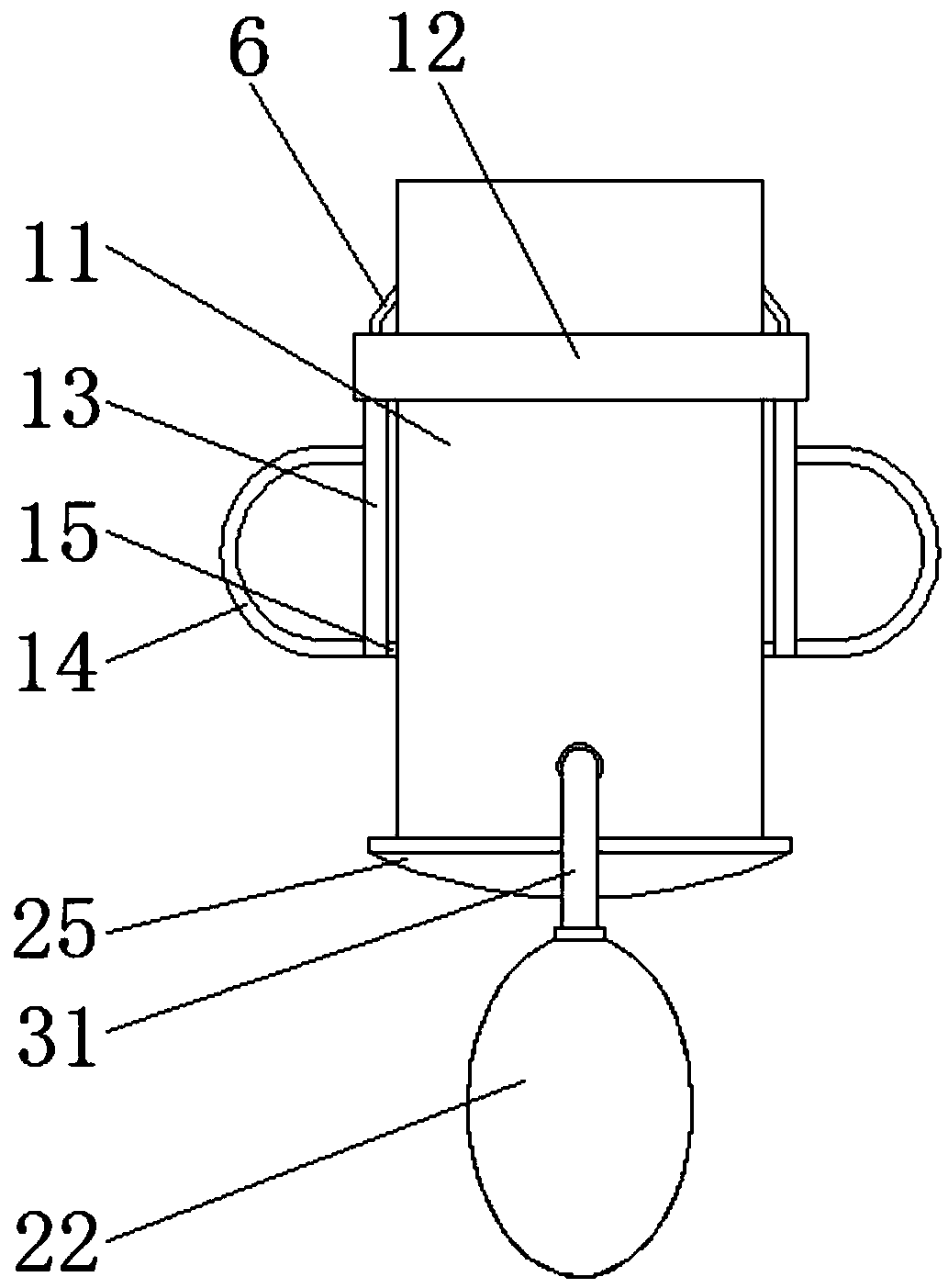

High-reliability high-stability multi-rotor-wing unmanned aerial vehicle with quick-dismounting function

Owner:深圳市科卫泰实业发展有限公司

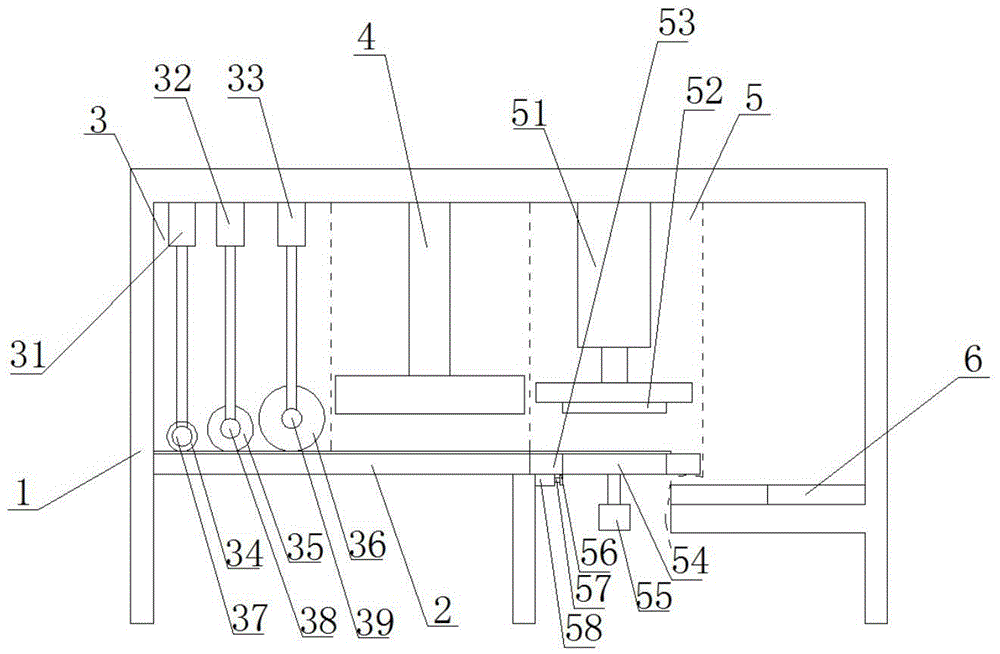

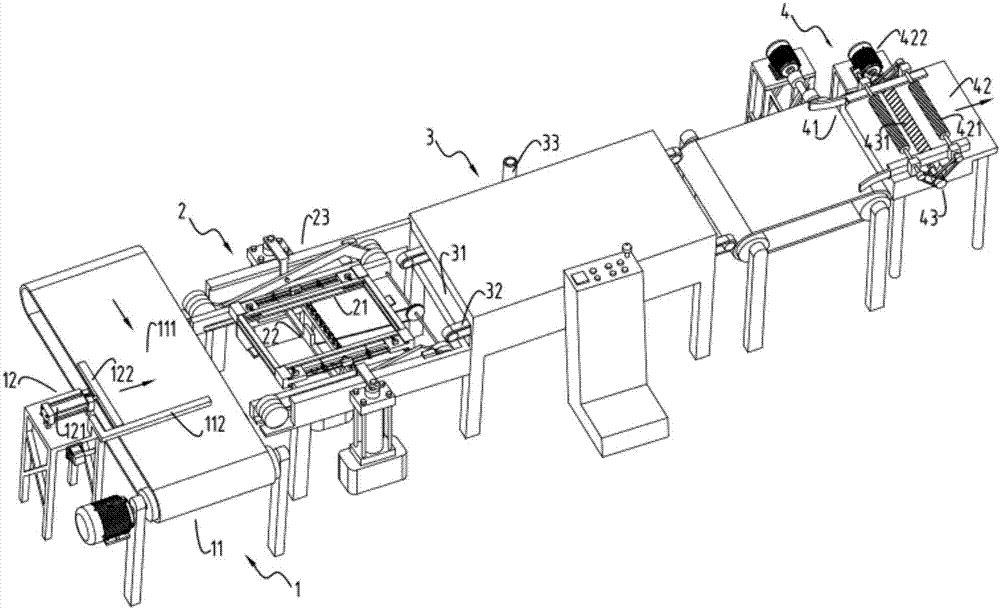

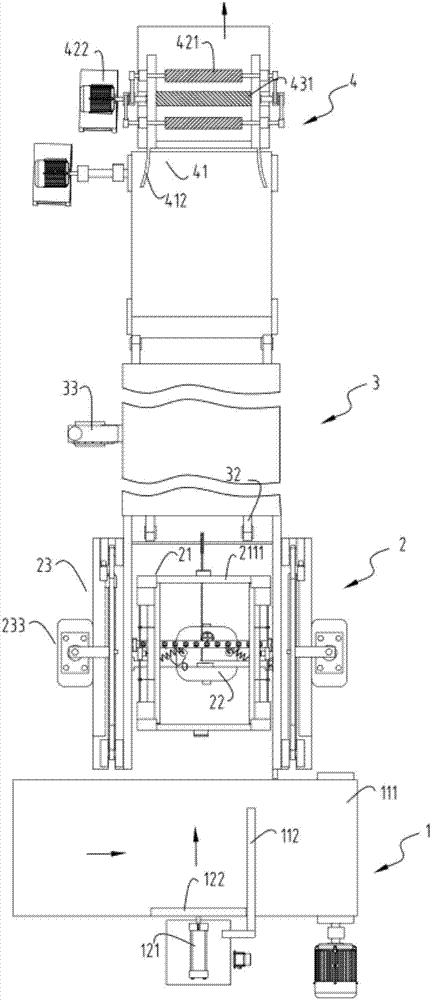

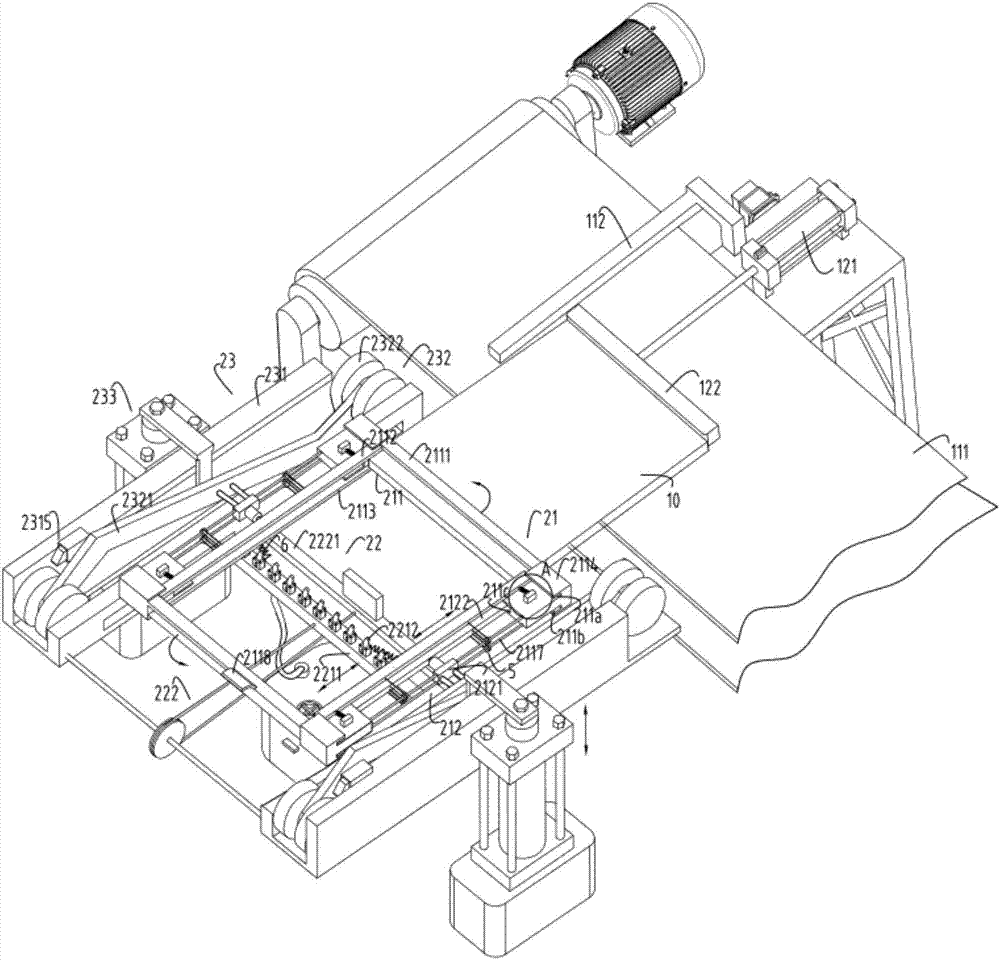

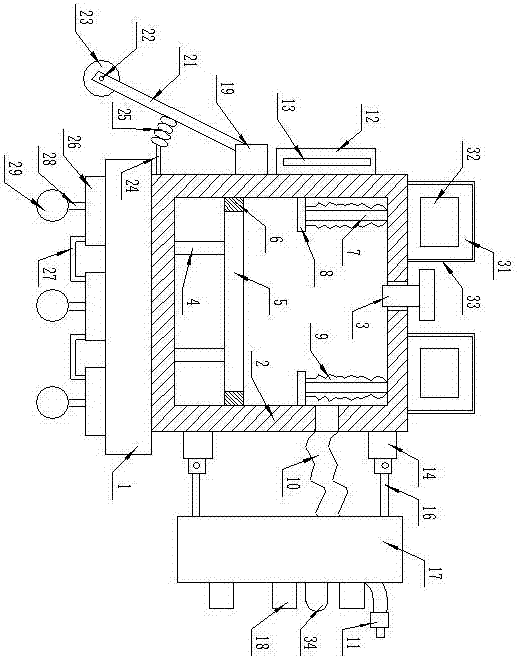

Production line machining equipment for packing boxes

InactiveCN105563886AGuaranteed to be firmIncrease profitBoxes/cartons making machineryBox making operationsProduction lineEngineering

The invention discloses production line machining equipment for packing boxes. The production line machining equipment comprises a rack, a conveying mechanism fixed on the rack and a film-covering mechanism, a drying mechanism, a stamping and cutting mechanism and an edge-folding mechanism which are sequentially fixed on the rack along the conveying direction of the conveying mechanism; the upper part of the conveying mechanism is provided with a conveying surface; the conveying surface is horizontally arranged; and the film-covering mechanism and the drying mechanism are located above the conveying surface. The production line machining equipment is compact and reasonable in structure; the working procedures of film-covering, drying, cutting and edge-folding for machining of the packing boxes can be sequentially and automatically finished on the same equipment; time is saved; the machining efficiency is improved; labor investment is reduced; each component in the film-covering mechanism is cooperative with the conveying mechanism, so that compact film-covering can be finished in the conveying process; one-step cutting and forming can be realized through the combination of tools, and the efficiency is high; and a support part, a material unloading part and the edge-folding mechanism cooperate with one another, so that while the unloading of box boards in the stamping and cutting mechanism is realized, loading on the edge-folding mechanism is realized, and the utilization rate of the mechanisms is improved.

Owner:BENGBU ZHONGBANG PACKAGING FACTORY

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

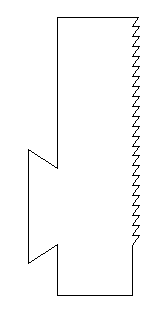

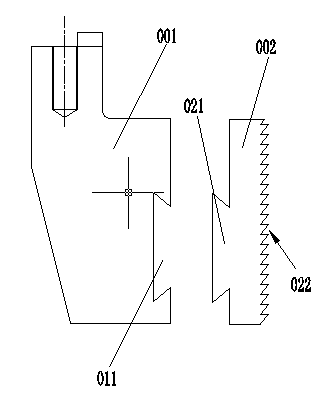

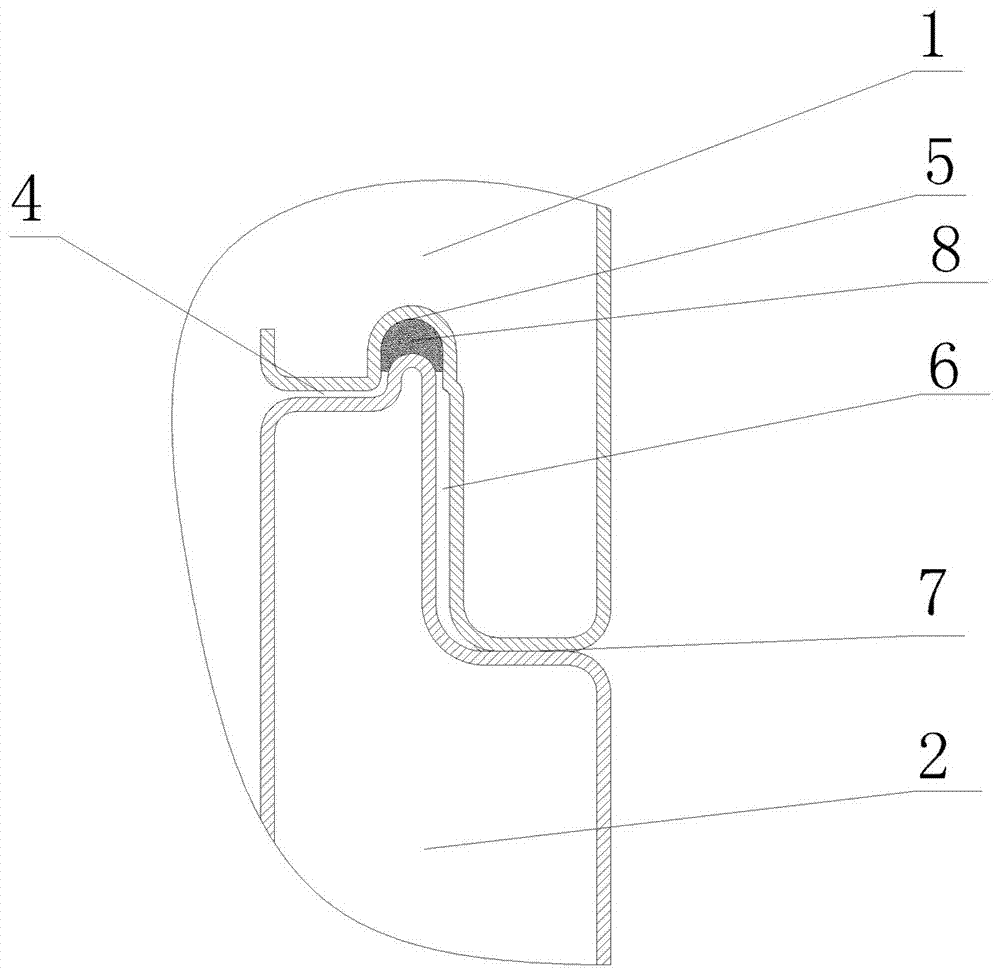

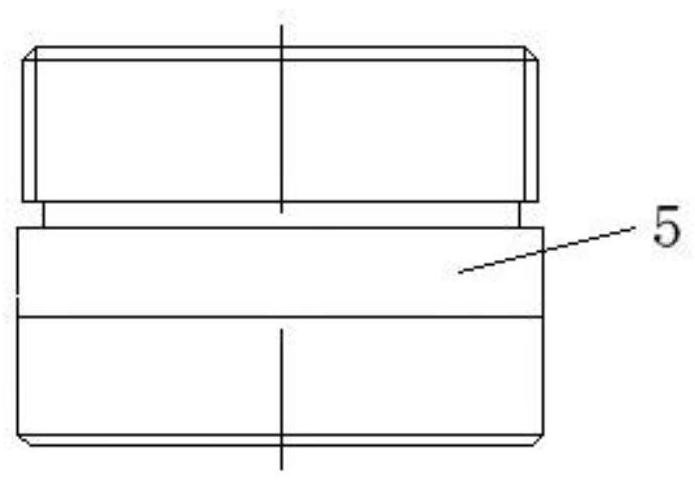

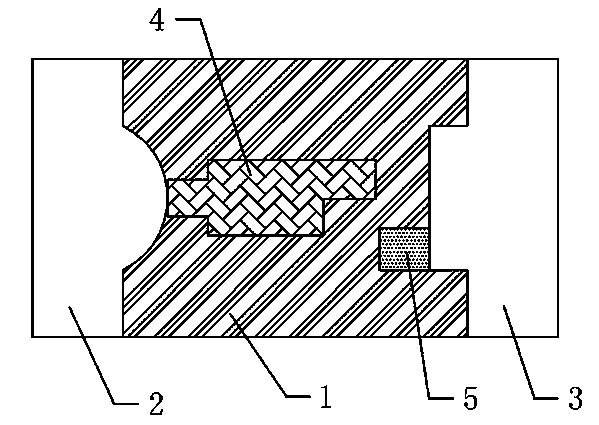

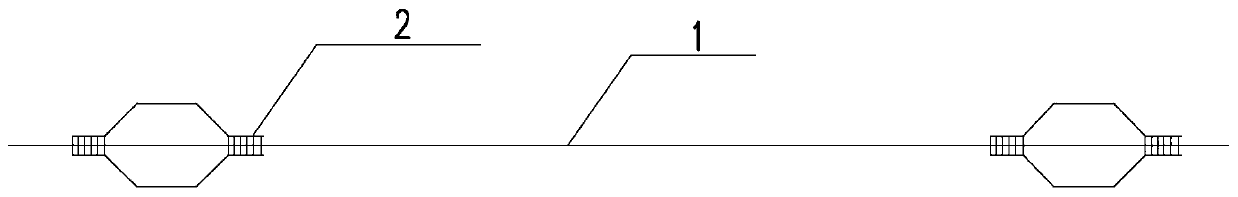

Combined hydraulic drawbench jaw plate

The invention relates to a combined hydraulic drawbench jaw plate, which comprises a clamping part and a jaw working part clamped and embedded in the clamping part. The clamping part is a square matrix. The sidewall center at one end of the matrix is provided with a horizontally perforating dovetail rabbet. One end of the jaw working part is provided with a dovetail shaped bulge matching the dovetail rabbet, and the surface of the other end is set in a jagged shape.

Owner:宜兴市创天管业有限公司

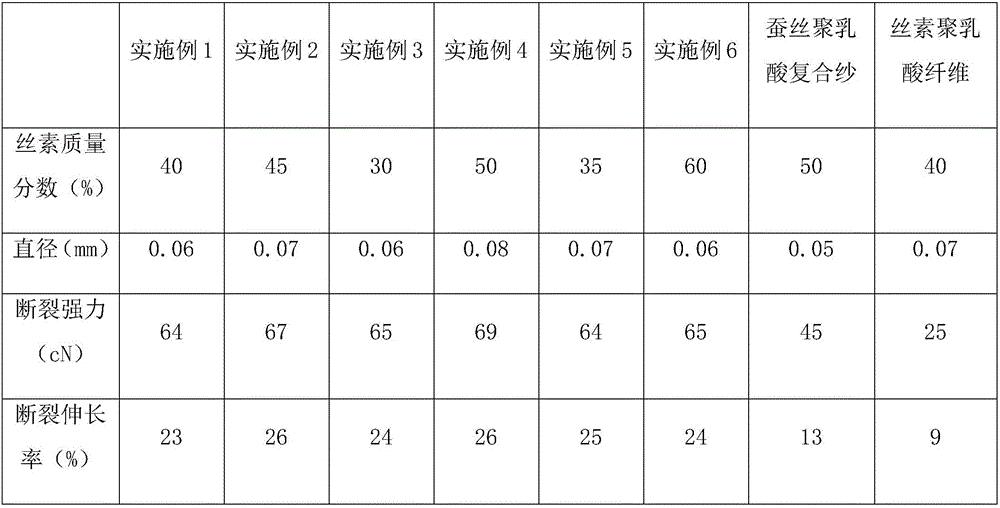

Fibroin polylactic acid fiber containing silk fibroin modified polylactic acid

ActiveCN105970344AHigh mechanical strengthImprove heat resistanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsYarnChemical Linkage

The invention provides a fibroin polylactic acid fiber containing silk fibroin modified polylactic acid. DL-lactide and polyethylene glycol are added into a silk fibroin water solution, silk fibroin modified polylactic acid solution is obtained after stirring and reaction, silk polylactic acid composite yarns after irradiation pretreatment are immersed into the silk fibroin modified polylactic acid solution and subjected to ultrasonic washing and drying to obtain the fibroin polylactic acid fiber containing the silk fibroin modified polylactic acid. The cross section of the fibroin polylactic acid fiber containing the silk fibroin modified polylactic acid is of a skin-core structure, a core layer includes the silk polylactic acid composite yarns, and a skin layer includes the silk fibroin modified polylactic acid and is connected with the core layer through chemical bonds and hydrogen bonds. The fibroin polylactic acid fiber containing the silk fibroin modified polylactic acid is fine in mechanical strength, green, skin-friendly and fine in serviceability, and can be used in the field of textiles and medical treatment.

Owner:广州迪柯尼服饰股份有限公司

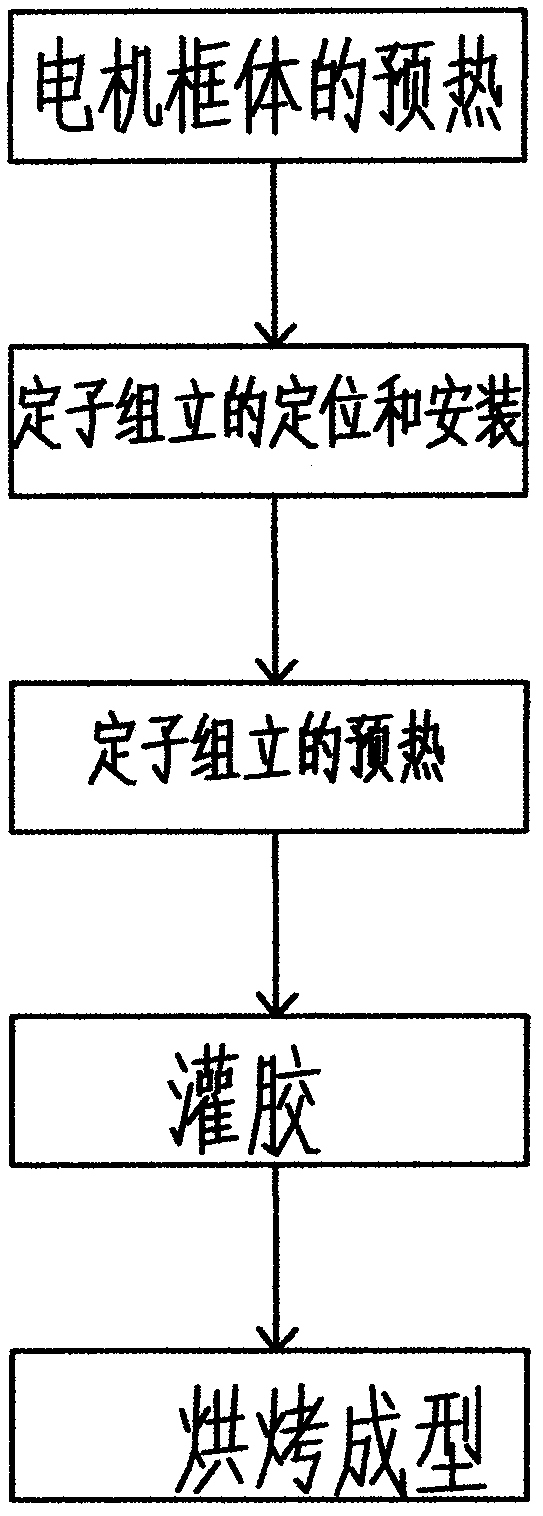

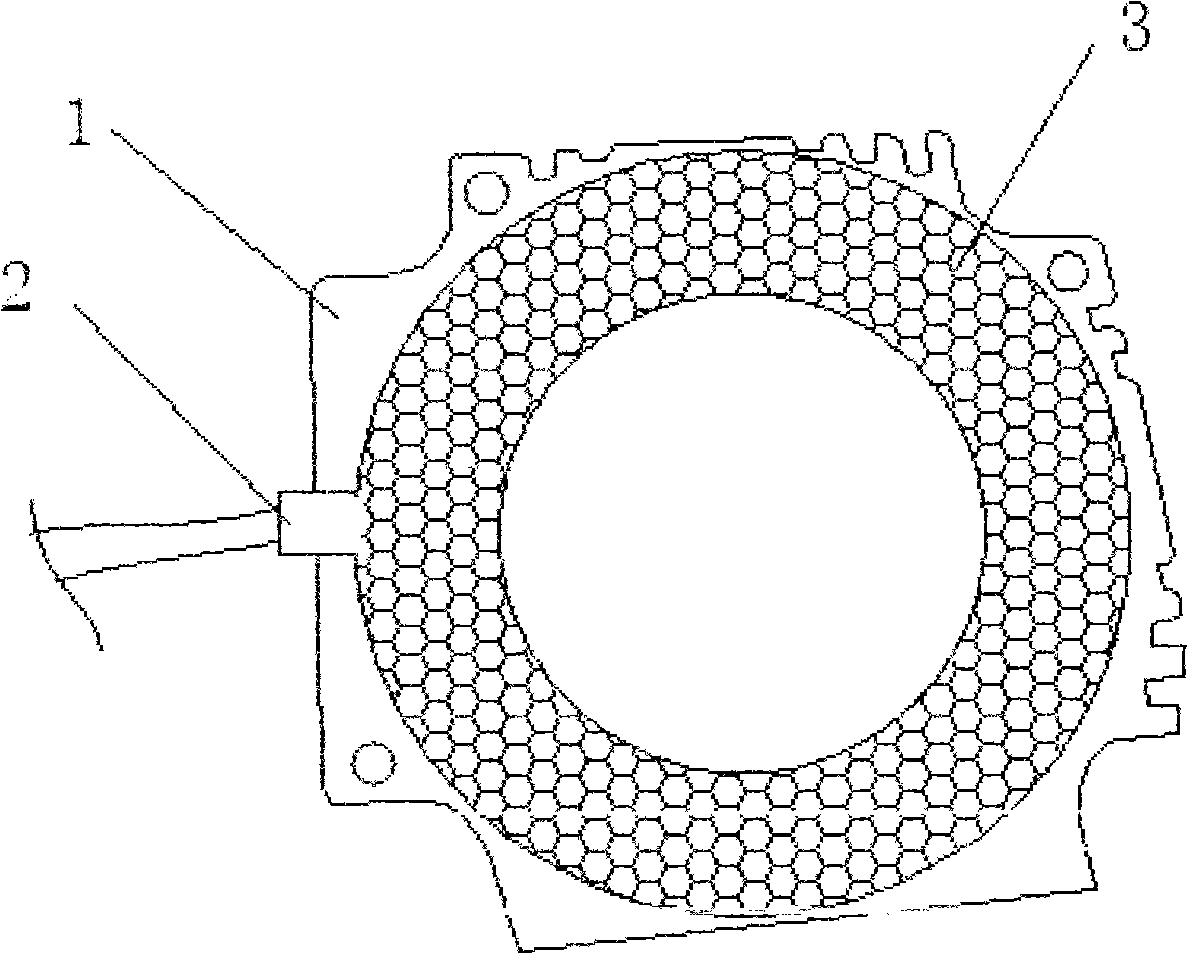

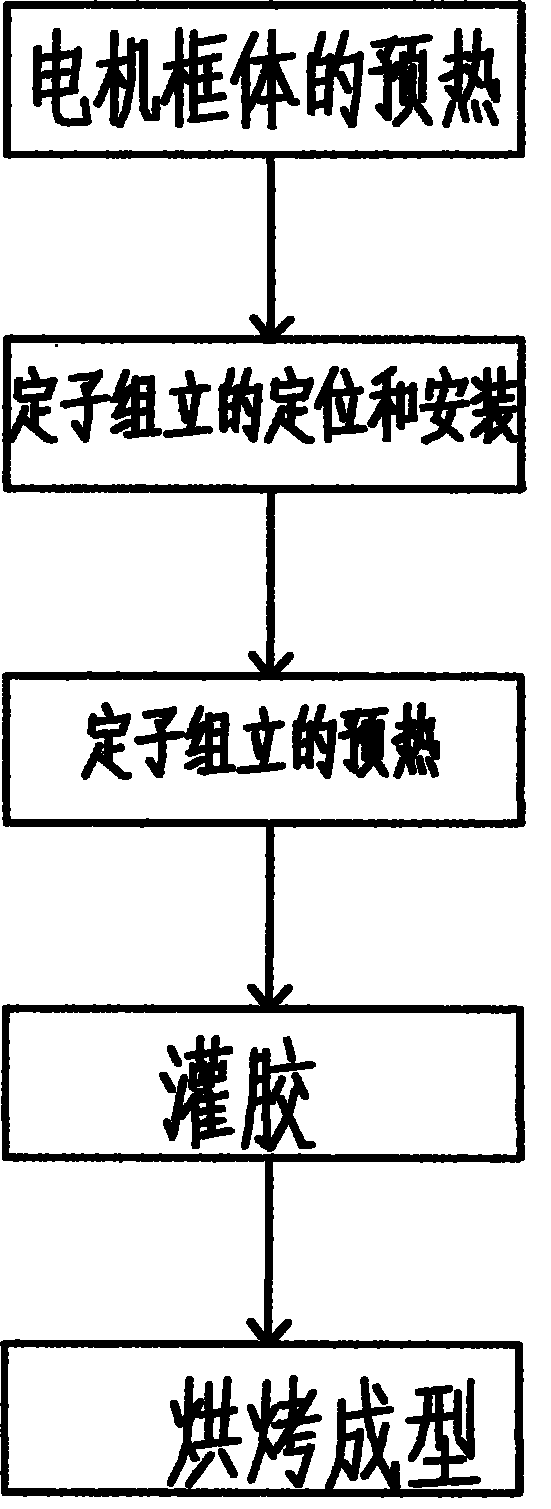

Process for encapsulating stator coil in motor

ActiveCN102468725AImprove cooling effectGuaranteed to be firmManufacturing dynamo-electric machinesInjection molding processEngineering

The invention discloses a process for encapsulating a stator coil in a motor. The process comprises the following steps of: preheating a motor frame, and putting a stator assembly into the motor frame to position and fix the stator assembly; arranging a pouring jig inside the stator assembly; and preheating the stator assembly which is loaded in the motor frame again, pouring prepared pouring glue on an enameled wire on the edge of the stator assembly to make the pouring glue flow into a stator, putting into an oven for baking when the poured pouring glue does not generate air bulbs, fully hardening the pouring glue to form an enclosed layer, and thus obtaining a finished encapsulation product. The process is high in heat conductivity, contributes to heat radiation, power promotion and cost reduction of a high-power device and is suitable for large scale production; furthermore, an epoxy injection molding process is finished in the encapsulating process, and the stator coil is easy to encapsulate, so that the sealing firmness and the optimal thickness of the pouring glue for the stator assembly of the motor are ensured.

Owner:腾禾精密电机(苏州)有限公司

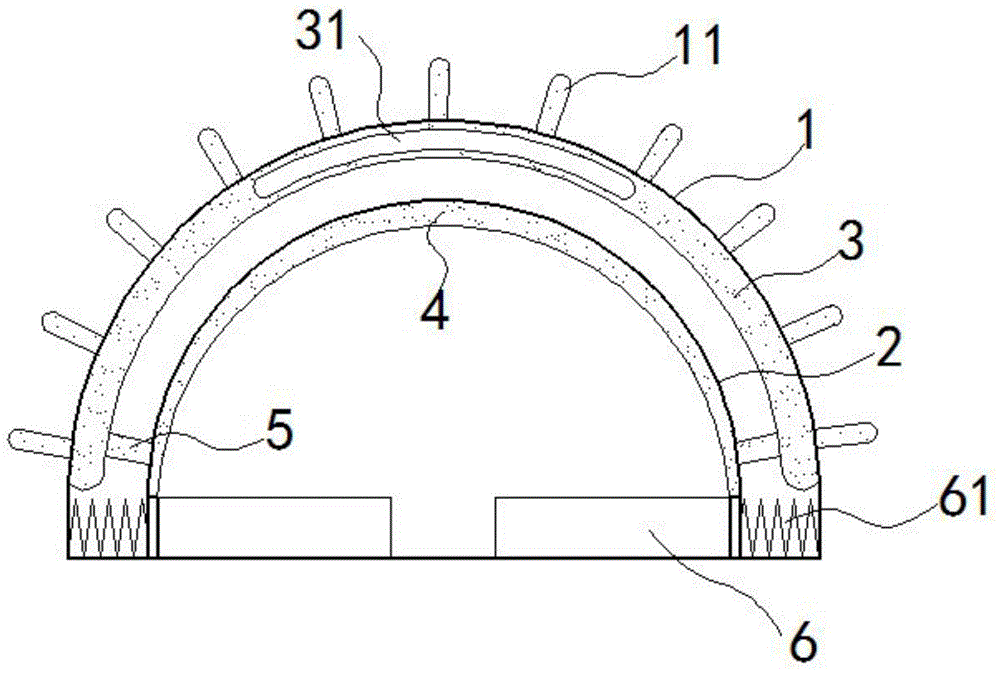

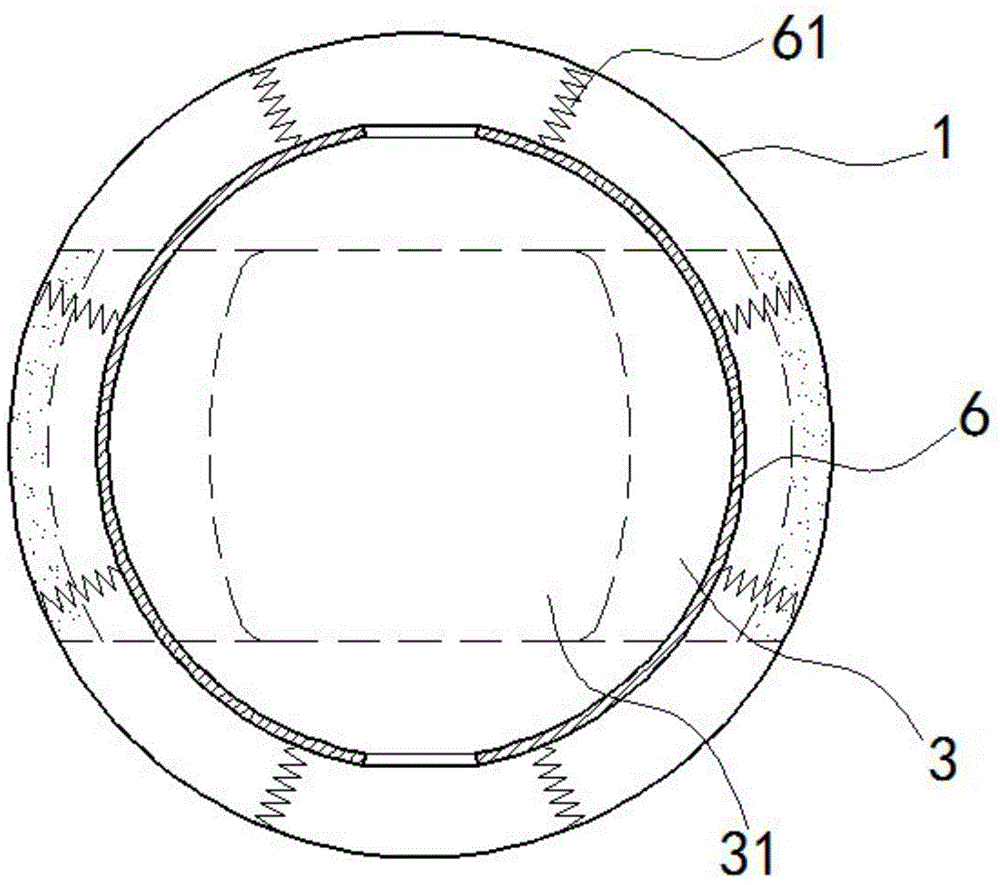

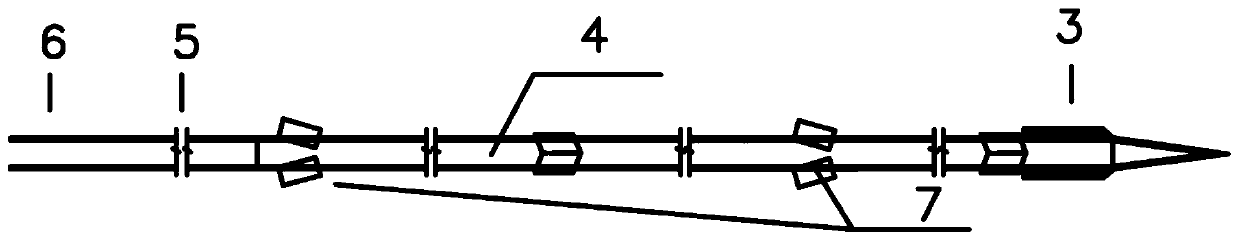

Monitoring instrument and method for deformation of tunnel surrounding rocks

InactiveCN103591880AGood environmental adaptabilityEasy to operateMechanical solid deformation measurementsSteel tubeRebar

The invention discloses a monitoring instrument and method for deformation of tunnel surrounding rocks. Displacement transmission rods of the monitoring instrument include a steel bar and multiple layers of steel pipes, wherein the steel pipes are sleeved on the steel bar, and the lengths of the steel pipes decrease layer by layer; steel rings are respectively welded at a position 10cm from the top of the steel bar, the tops of the steel pipes, and positions 10cm from the tops of the steel bars; a PVC (Polyvinyl Chloride) plastic pipe is sleeved on the exposed portion, which is not embedded into the adjacent steel pipe, of each steel pipe, and the PVC plastic pipe abuts against the top of the adjacent steel pipe; and the tail end of the PVC plastic pipe of the outermost steel pipe is equipped with an external sleeve, a probe is welded at the top of the external sleeve, measuring holes are formed in the probe, the number of the measuring holes equals that of the displacement transmission rods, and the size of measuring holes is consistent with that of a measuring rod of an electronic indicating gauge. According to the invention, the displacement transmission rods make point-to-point contact with the rocks, thereby ensuring firmness of the different contact points, preventing the displacement transmission rods from being disengaged from the rocks, and reducing the influence of the monitoring instrument on the rock displacement result to the largest extent. The monitoring instrument and method of the invention have good environmental adaptability, and operation is simple.

Owner:CHINA GASOLINEEUM ENG

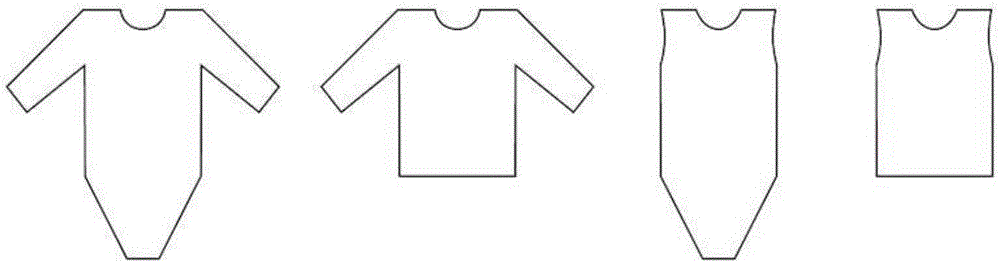

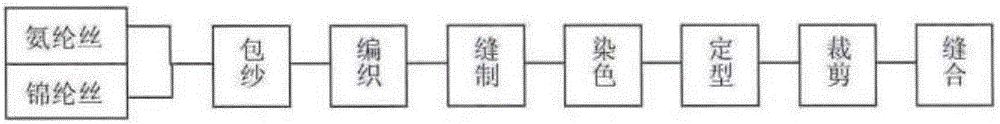

Ultra-thin run-resistant underwear produced by adopting cylinder loom and production process of ultra-thin run-resistant underwear

ActiveCN106263100AExtended service lifeCost-effectiveWeft knittingShaping/stretching tubular fabricsResistYarn

The invention provides ultra-thin run-resistant underwear produced by adopting a cylinder loom and a production process of the ultra-thin run-resistant underwear. The production process comprises the following steps: (1) wrapping by taking spandex as inner-wrapped silk and taking polyamide as outer-wrapped silk to obtain a wrapped yarn; (2) weaving: weaving the wrapped yarn by adopting the cylinder loom comprising a stocking machine to obtain a stocking blank; (3) sewing: cutting and sewing the socking blank to obtain stockings, so as to facilitate subsequent dyeing and sizing; (4) dyeing: bagging and dyeing the stockings to obtain colorful stockings; (5) sizing: sizing the colorful stockings by adopting an underwear sizing plate and endowing the colorful stockings with run-resist functions; (6) cutting: cutting the sized stockings according to a sample plate and cutting each of the stockings into two sleeveless underwear bodies; (7) sewing. In addition, the invention further provides the underwear produced by the production process. On the premise of not increasing the novel equipment investment, an ordinary cylinder loom (comprising the stocking machine) is directly adopted for producing the underwear, so that high quality and inexpensiveness are realized.

Owner:深圳市润薇服饰有限公司

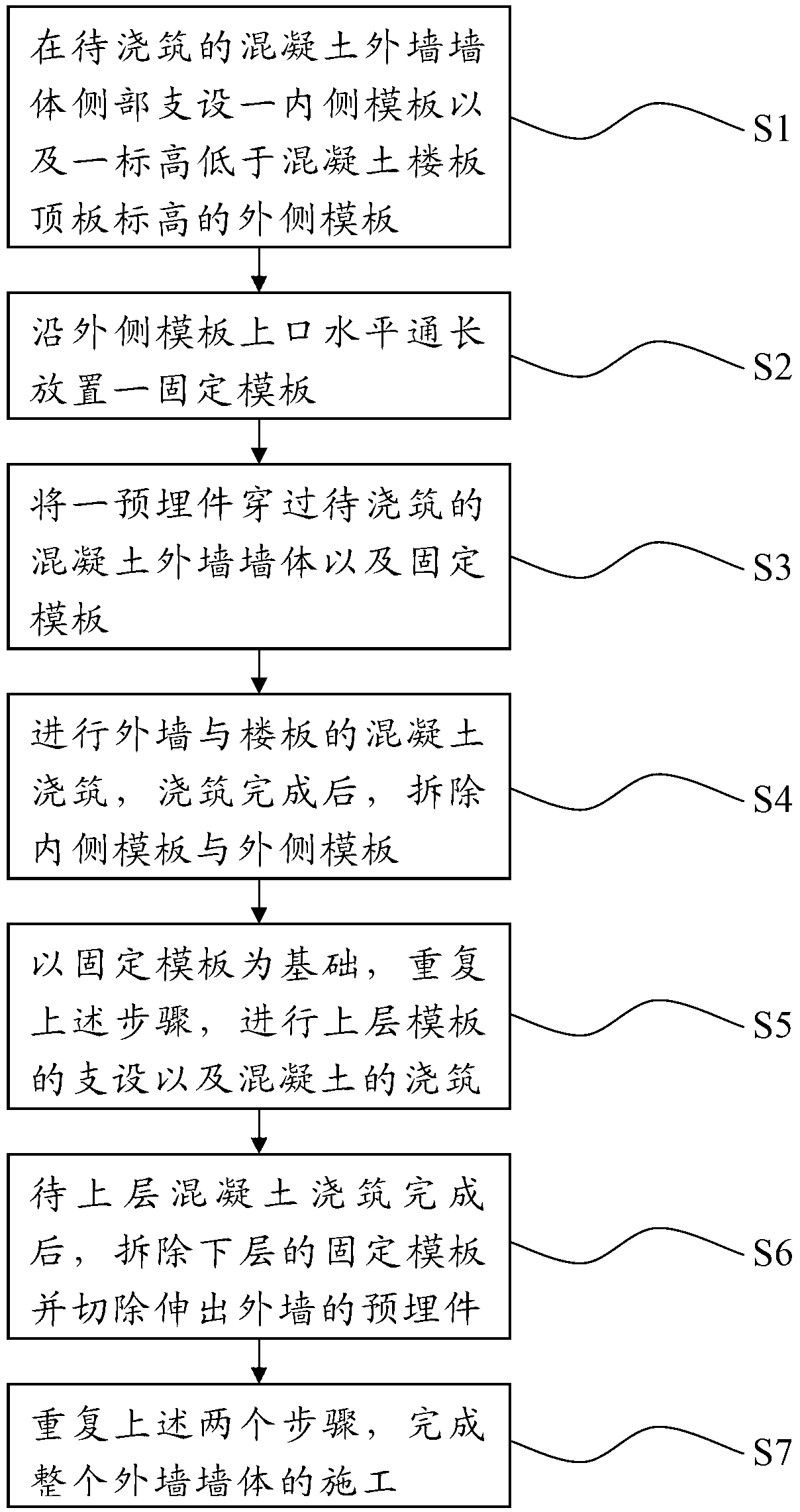

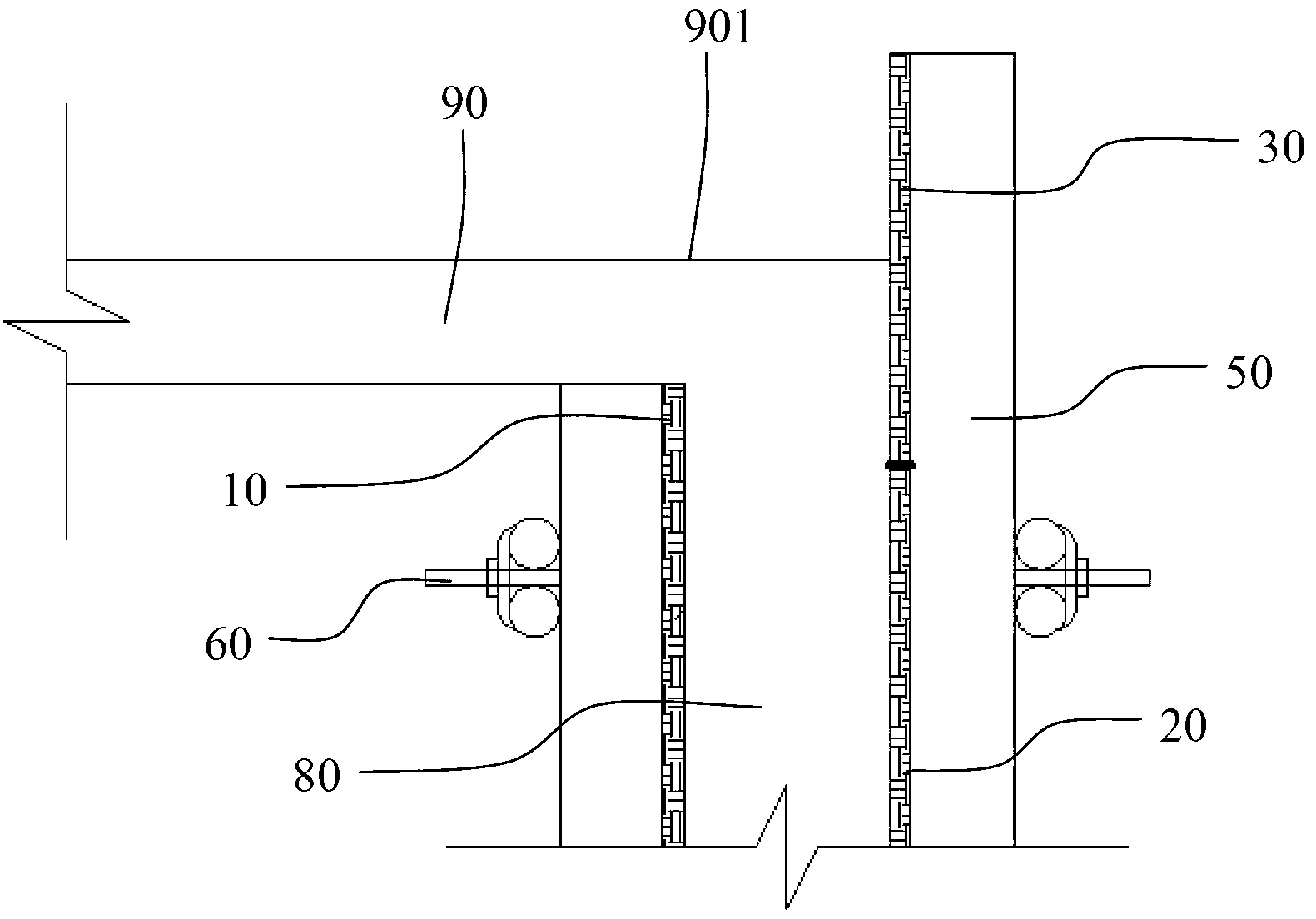

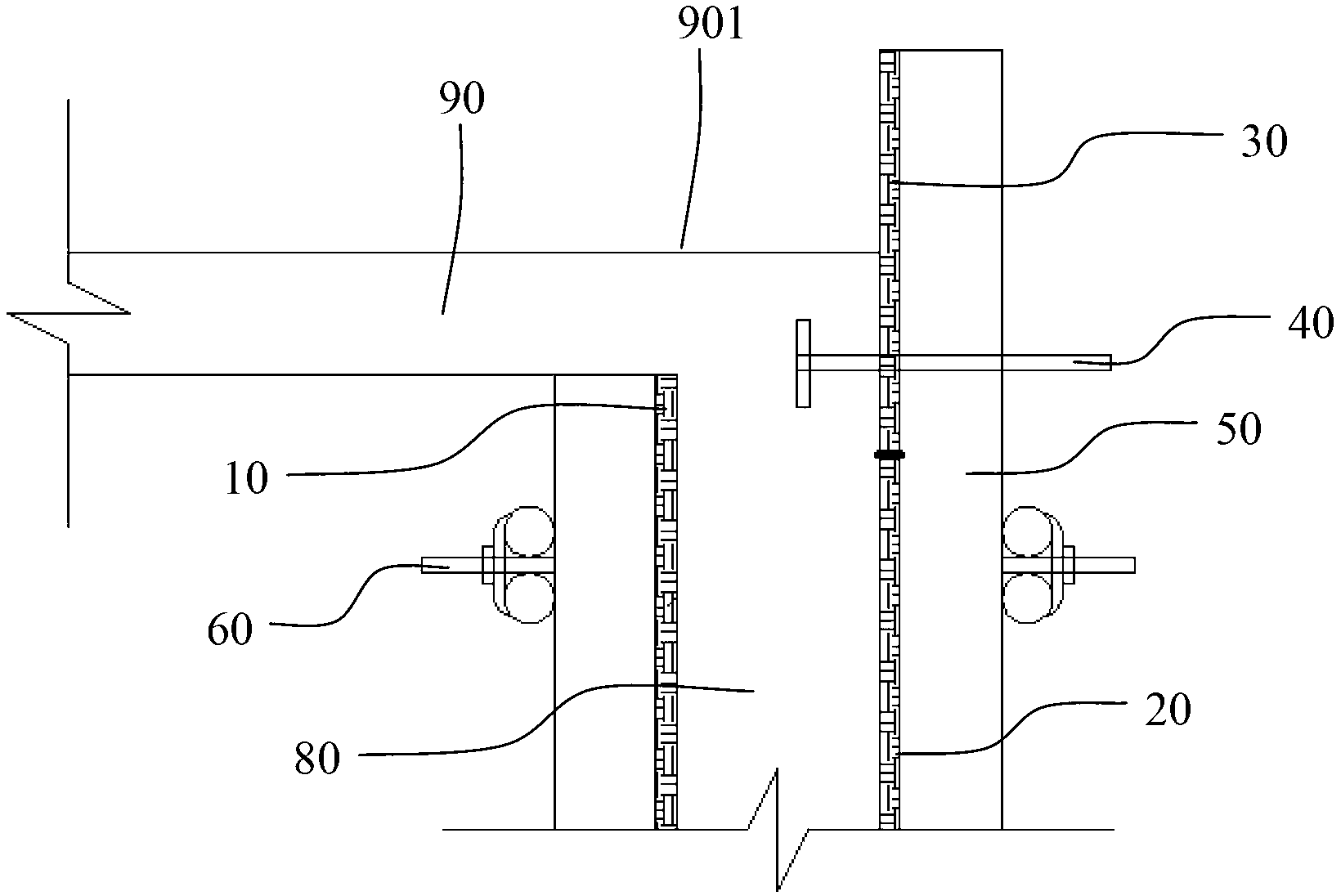

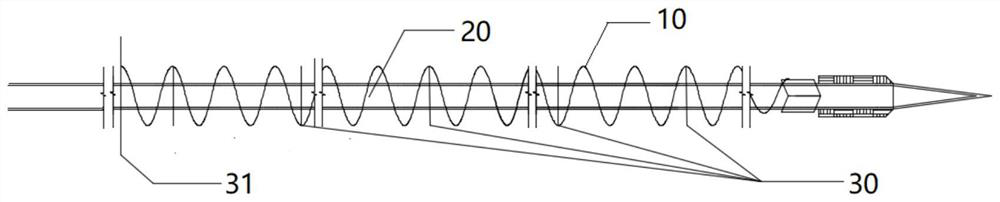

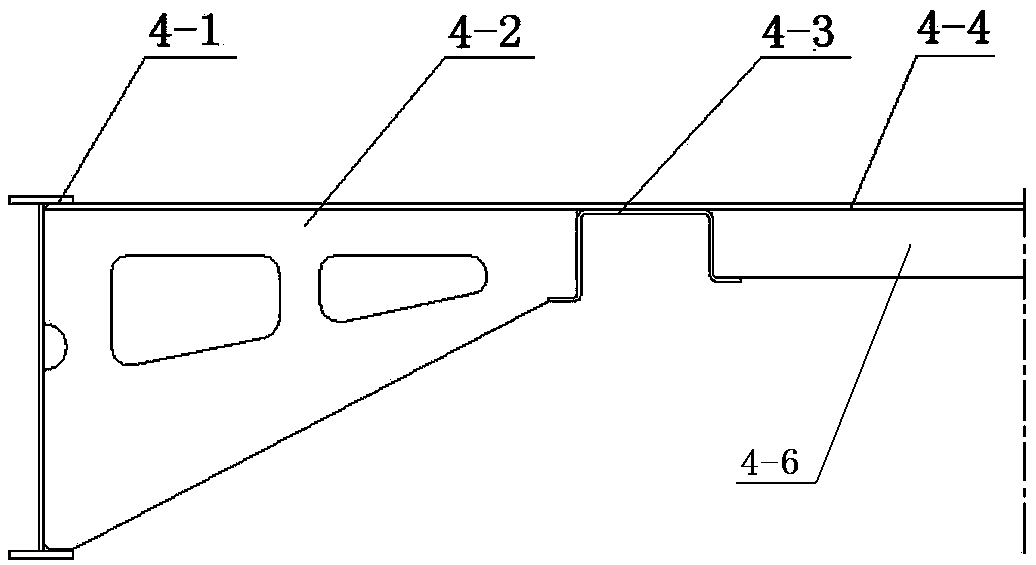

Erecting method and structure of piece-by-piece assembling formworks at position of interlayer outer wall construction joint

ActiveCN103321403AGuaranteed to be firmGuaranteed seamless integrationWallsForms/shuttering/falseworksFloor slabEngineering

The invention discloses an erecting method of piece-by-piece assembling formworks at the position of an interlayer outer wall construction joint. The method comprises the following steps of (1) erecting an inner side formwork and an outer side formwork with elevation lower than that of a concrete floor slab top plate at the side portion of a concrete outer wall body to be poured, (2) placing a fixed formwork along the horizontal pass length of an upper port of the outer side formwork, (3) enabling an embedded part to penetrate the concrete outer wall body to be poured and the fixed formwork, (4) performing concrete pouring of an outer wall and a floor slab and dismounting the inner side formwork and the outer side formwork after the pouring is finished, (5) using the fixed formwork as a basis, repeating the steps to perform erection of the upper-layer formworks and the concrete pouring, (6) dismounting the lower-layer fixed formwork and cutting off the portion of the embedded part extending out of the outer wall after the upper-layer concrete pouring is finished, (7) repeating the steps (5) and (6) to finish construction of the whole outer wall body. By means of the erecting method of the piece-by-piece assembling formworks at the position of the interlayer outer wall construction joint, joint-free combination of wall bodies is ensured, and grout leakage and slab staggering are avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

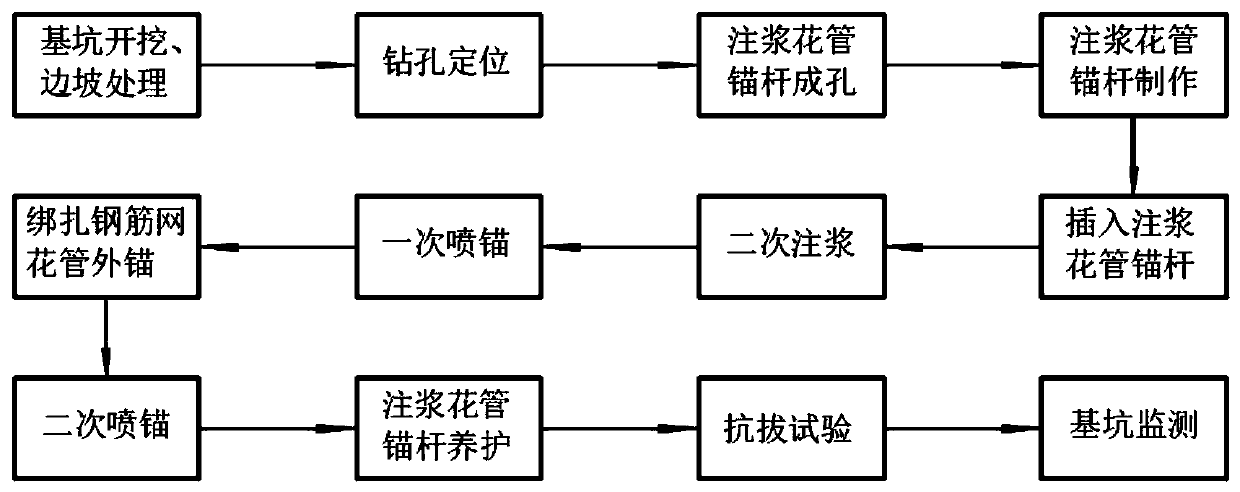

Construction method for slope supporting and reinforcing

InactiveCN111877369APrevent looseningAvoid separationExcavationsBulkheads/pilesShotcreteArchitectural engineering

The invention relates to a construction method for slope supporting and reinforcing. The construction method comprises the steps of excavating a foundation pit, and performing slope arrangement; drilling; manufacturing spiral grouting floral tubes, specifically, taking spiral ribs and the grouting floral tubes, forming a plurality of grout outlets in the grouting floral tubes, inserting the grouting floral tubes into the spiral ribs, enabling the grouting floral tubes and the spiral ribs to be connected and fixed through inner and outer cross ribs, and enabling the outer cross ribs to extend out of the spiral ribs; driving the spiral grouting floral tubes into the drilled holes, anchoring the bottom ends of the spiral grouting floral tubes into a soil layer at the bottom of the holes, andenabling the outer cross ribs to be located outside the drilled holes; grouting the spiral grouting floral tubes in two times; spraying concrete to the slope surface, paving a reinforcing mesh on theslope surface before final setting of the concrete, and enabling the reinforcing mesh to be fixedly connected with outer cross ribs; and spraying the concrete onto the slope concrete paved with the reinforcing mesh for the second time. The spiral ribs are combined with the grouting floral tubes, the spiral grouting floral tubes, the concrete spraying layer and the side slope form a combined actionsystem through grouting, secondary spraying and anchoring and the like, and loosening and separation of the soft soil side slope are prevented.

Owner:CHINA FIRST METALLURGICAL GROUP

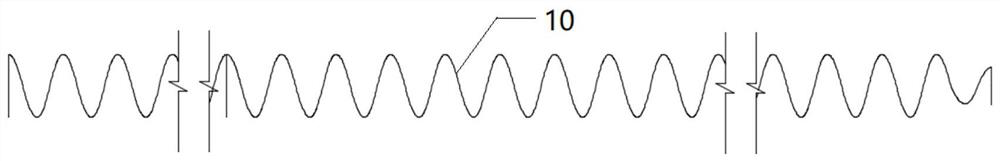

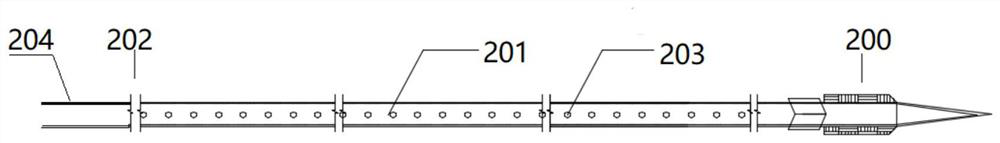

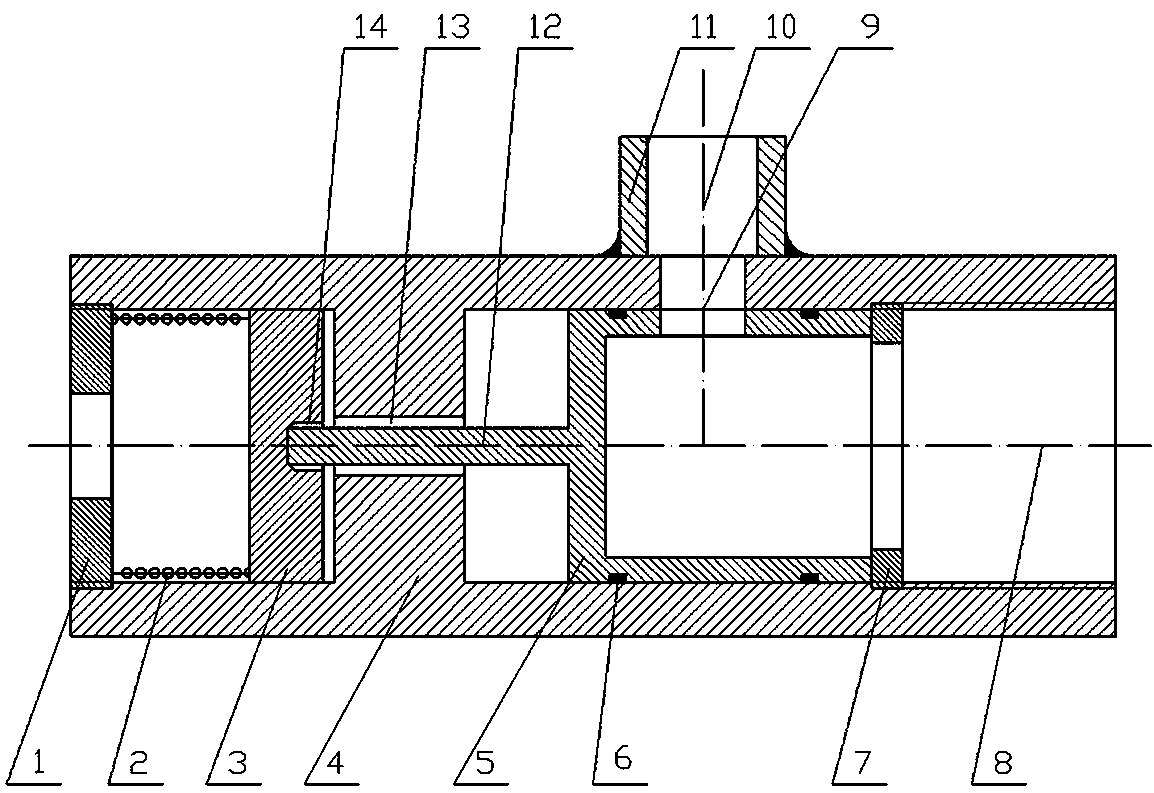

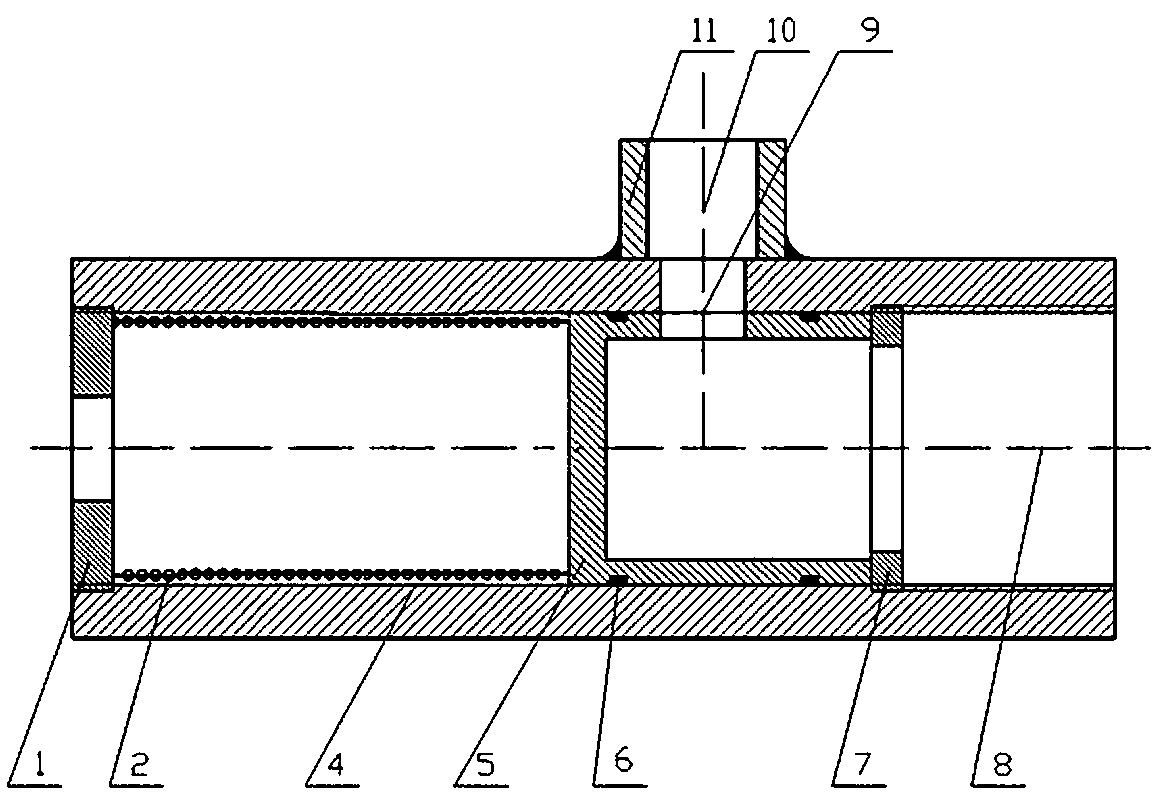

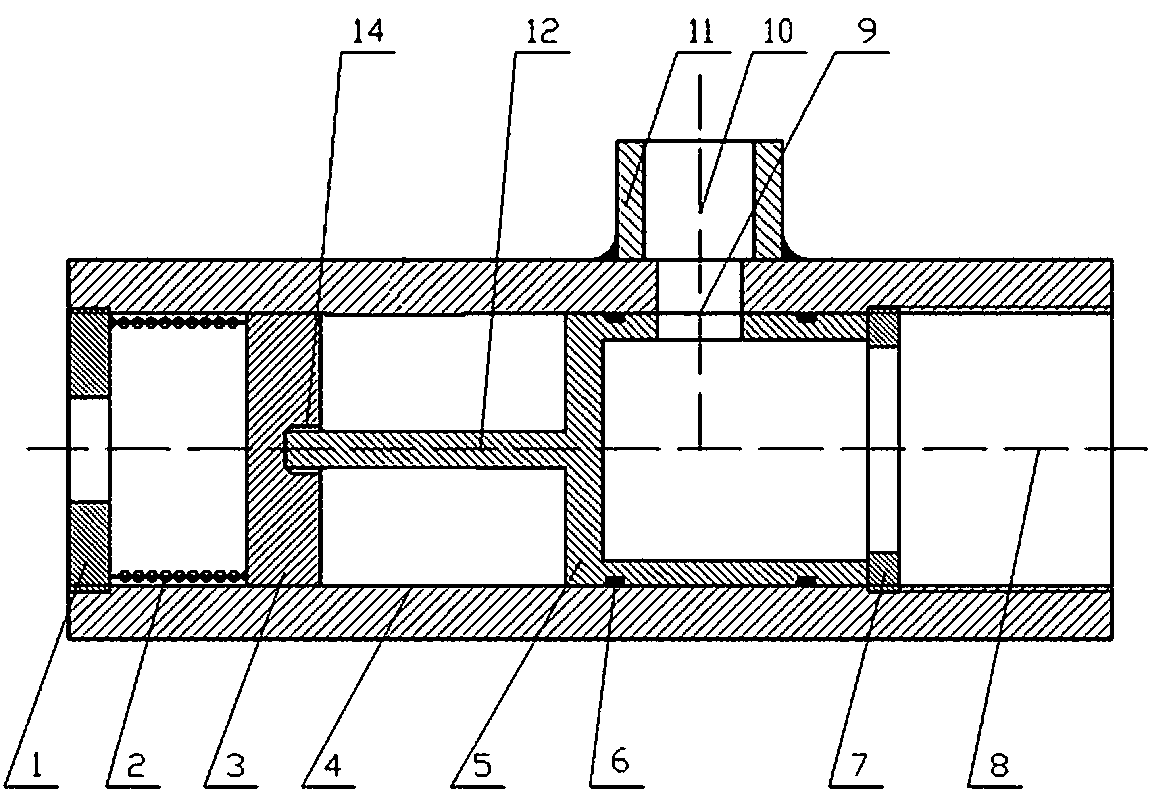

Constant pressure throttling device for natural gas well

ActiveCN109424332ANormal productionPrevent leakageWell/borehole valve arrangementsSealing/packingReciprocating motionEngineering

The invention relates to a constant pressure throttling device for a natural gas well. The constant pressure throttling device includes a shell and a piston capable of reciprocating in the shell; oneend of the piston is connected with an elastic device; the elastic device is fixed on a spring limit member; the other end of the piston is provided with an opening and is limited by a piston limit member; the shell and the piston corresponding to the outer circumference are respectively provided with flow limitation holes penetrating through a natural gas pipeline; and the flow limitation holes communicate with the opening of the piston through an inner cavity of the piston. The constant pressure throttling device can achieve automatic adjustment of the size of an air nozzle of the throttlingdevice, achieves constant pressure throttling, and enables the labor intensity to be reduced, the cost to be reduced and the work efficiency to be improved.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

Heat radiating building safety helmet

The invention relates to a heat radiating building safety helmet. The heat radiating building safety helmet comprises an outer housing made of a hard material and an inner housing made of an elastic expansion material. A protection cavity in a flat long strip shape is fixed and abutted close to the inner side surface of the outer housing. The protection cavity is internally provided with a piston block which can slide along the inner wall of the protection cavity. The inner side surface of the inner housing is fixed and abutted with a heat radiation cavity in a bowl shape. The heat radiation cavity is communicated with two ends of the protection cavity through two liquid guiding pipes. The heat radiation cavity and the protection cavity are filled with cooling liquid. The lower edge of the inner housing is symmetrically provided with two semicircular adaptive hoops. Each adaptive hoop is fixed by a pressure spring which is installed on the inner side surface of the outer housing. The axis of each pressure spring extends along the radial direction of the outer housing. The safety helmet is novel in structure and relatively light in texture, and fits scalp, and has good heat radiation effect while having security guarantee.

Owner:柳州市康安劳保物资有限公司

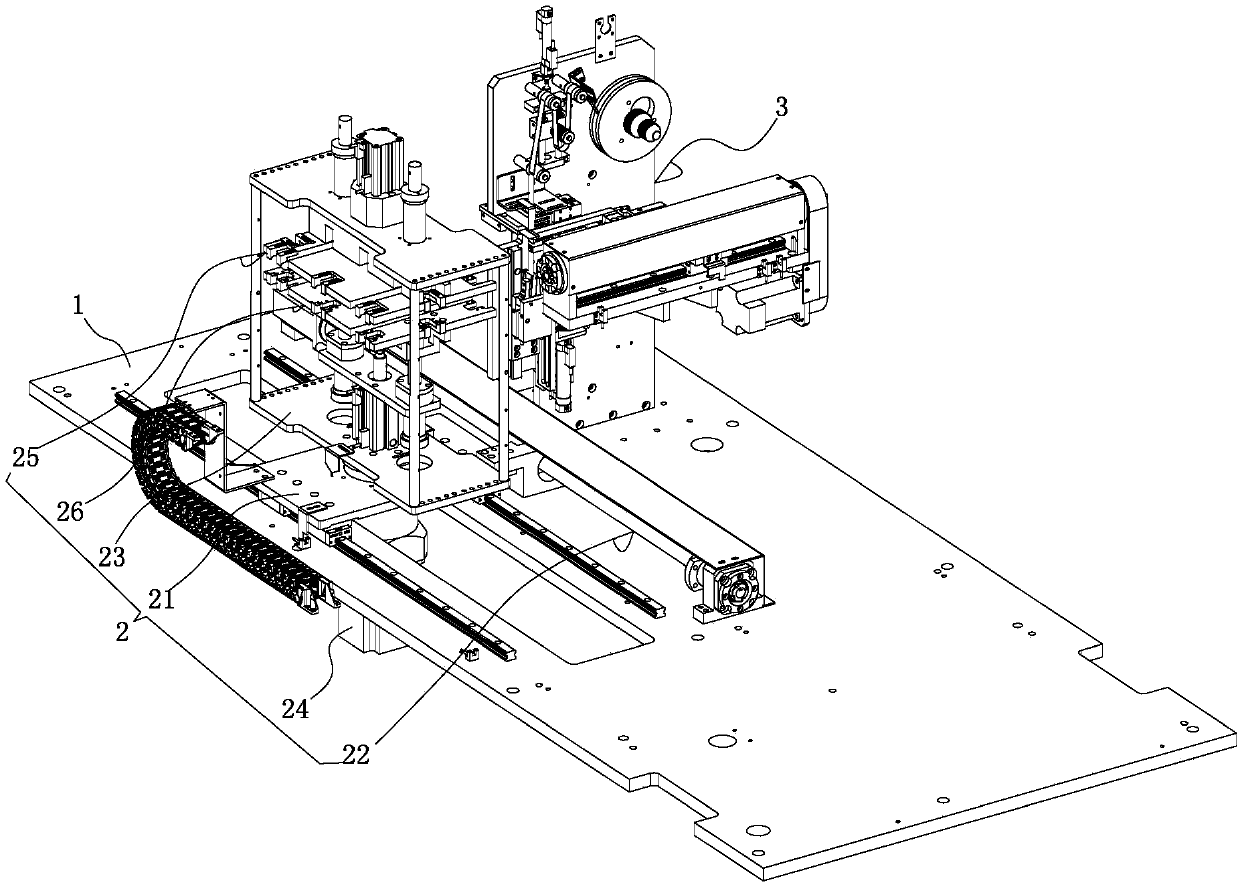

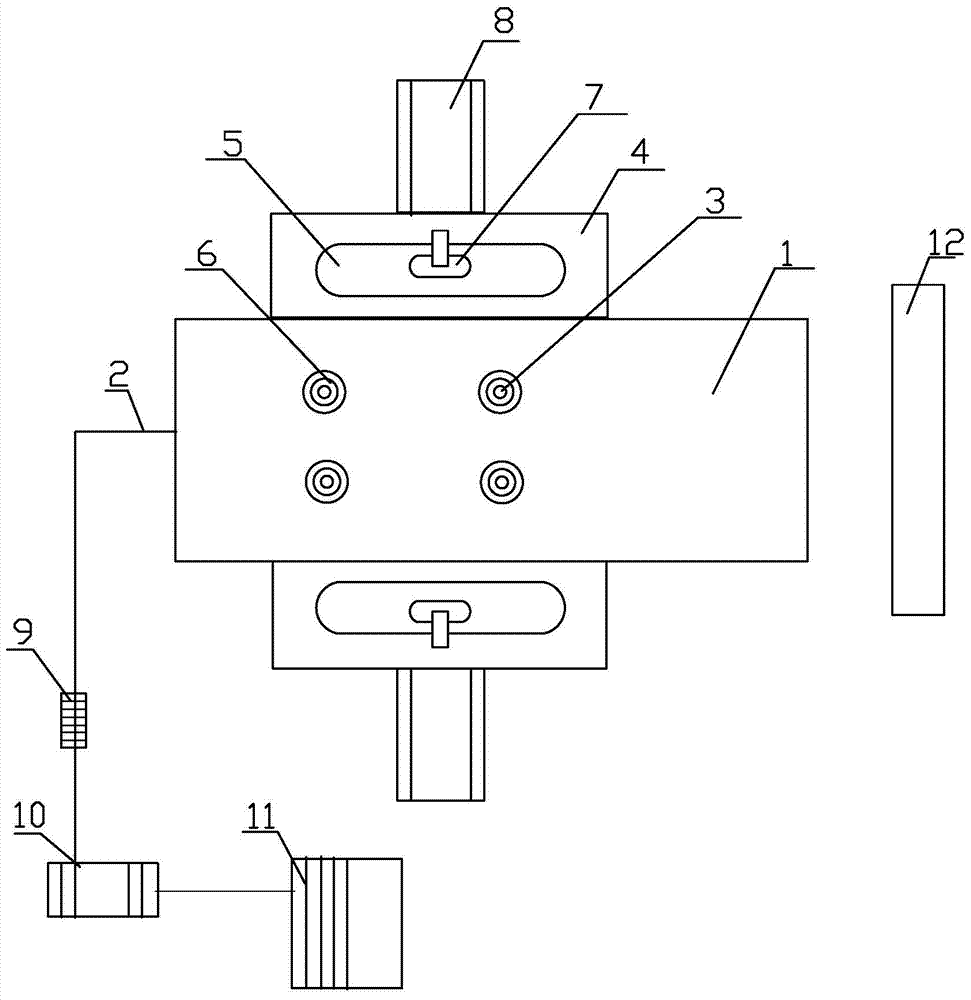

Gluing device for lamination machine

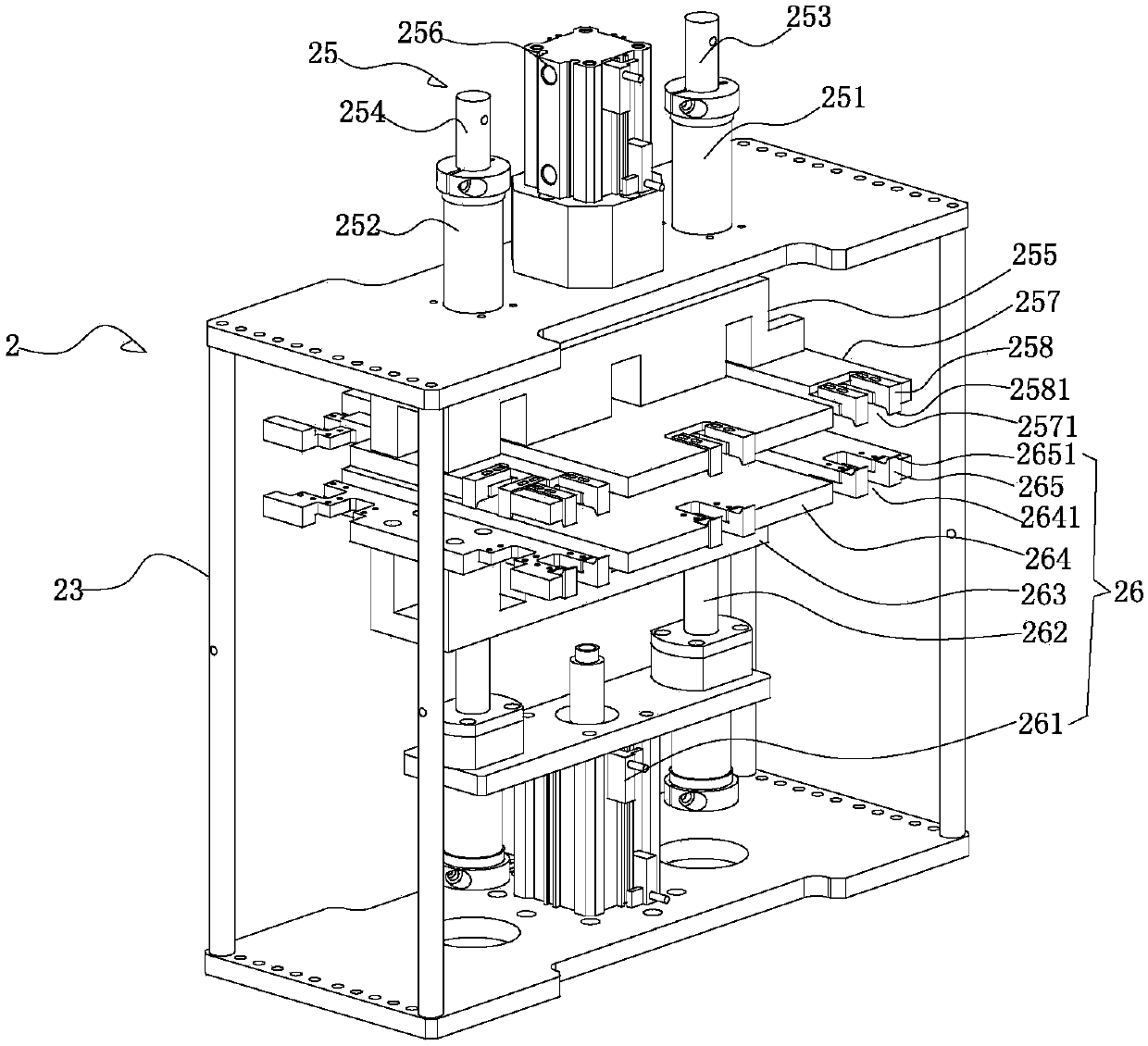

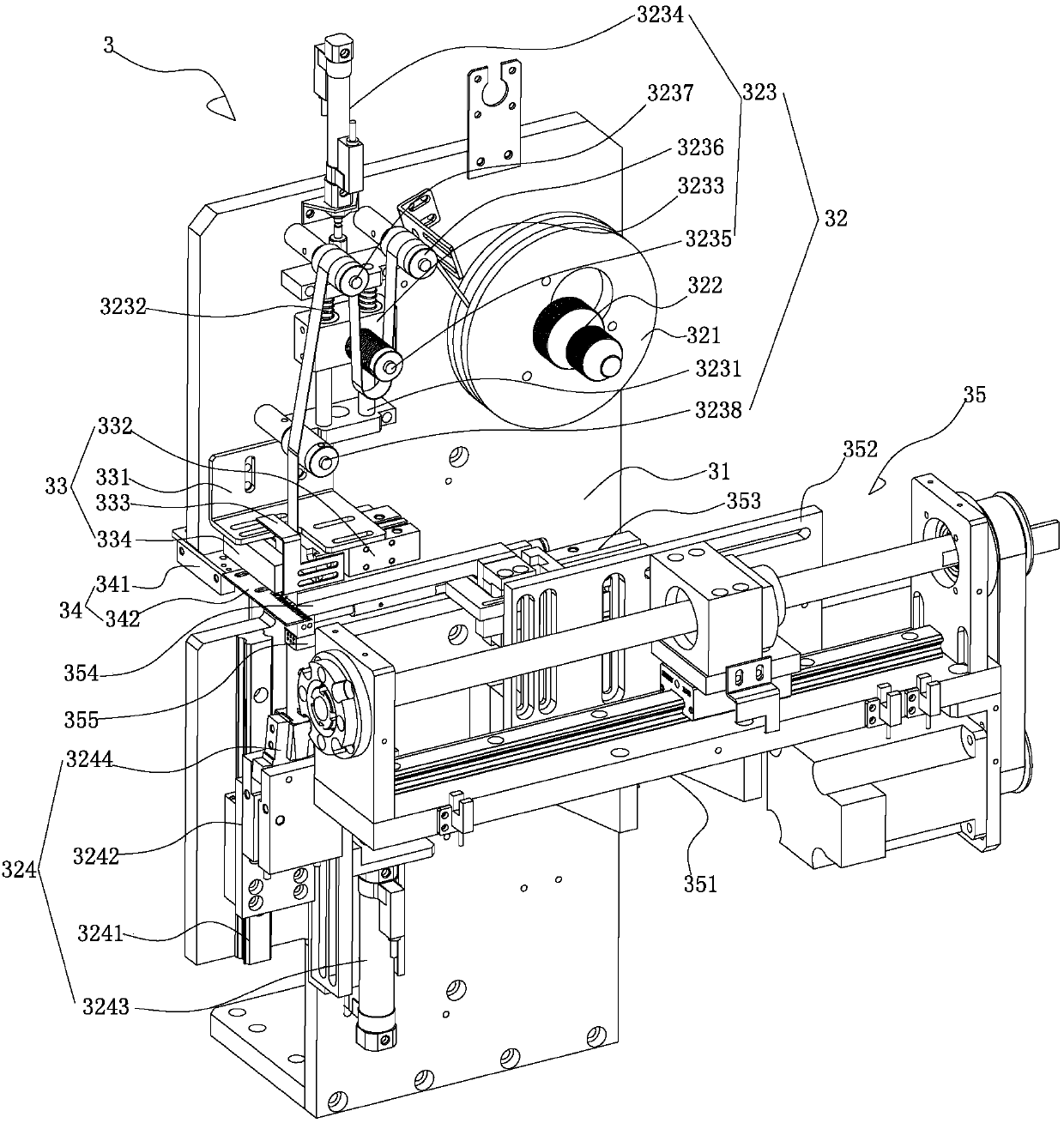

PendingCN107742740AGuaranteed to be firmPrevent wrinkling and reverse edge phenomenonAssembling battery machinesFinal product manufactureLinear driveEngineering

The invention discloses a gluing device for a lamination machine. The gluing device comprises a substrate, a gluing platform module and a gluing mechanism, wherein the gluing platform module comprisesa moving seat, a first linear drive module, a rotating rack, a motor assembly, a first positioning clamping plate module and a second positioning clamping plate module; the moving seat is movably arranged on the substrate; the first linear drive module is arranged on the substrate and is used for driving the moving seat to horizontally move; the rotating rack is mounted on the moving seat; the motor assembly is arranged at the lower end of the moving seat and is used for driving the rotating rack to rotate; the first positioning clamping plate module and the second positioning clamping platemodule are mounted in the rotating rack, and a clamping space used for clamping sheets is formed between the first and second positioning clamping plate modules; the gluing mechanism comprises a vertical plate, a surface sizing module, a degumming module, a cutting module and a gluing module; the vertical plate is arranged on the substrate; the surface sizing module is arranged on the vertical plate and is used for transferring adhesive tapes; the degumming module is arranged on the vertical plate and positioned at the lower end of the surface sizing module; the cutting module is arranged on the vertical plate and is used for cutting off the adhesive tapes; the gluing module is arranged on the vertical plate and is used for adsorbing and positioning the cut adhesive tapes and transferringthe adhesive tapes to be attached to the outer sides of laminated sheets clamped by the first and second positioning clamping plate modules.

Owner:东莞市沈海自动化科技有限公司

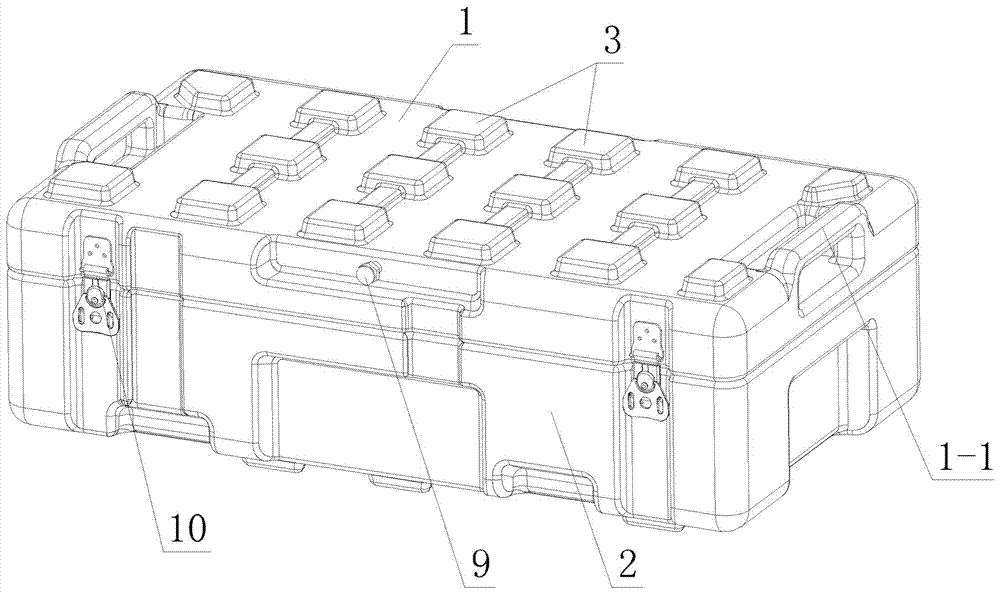

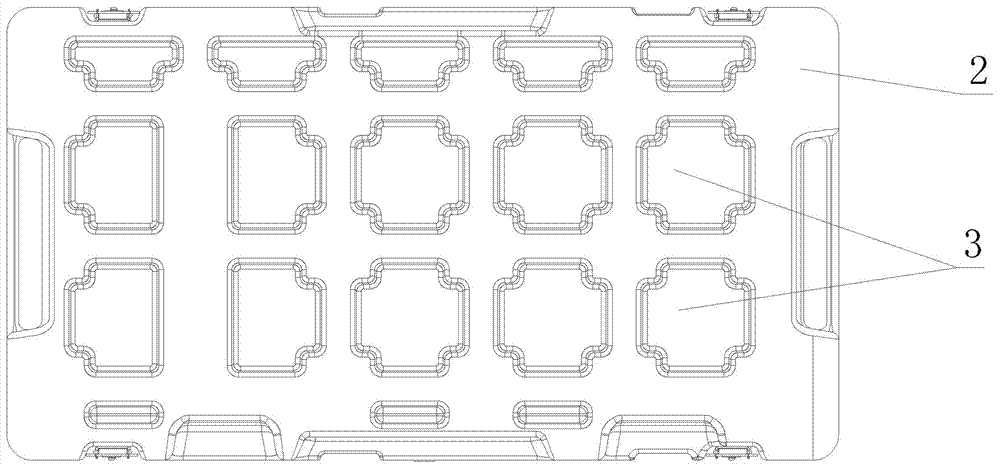

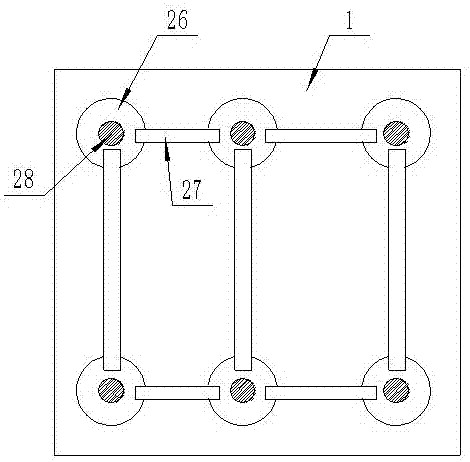

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

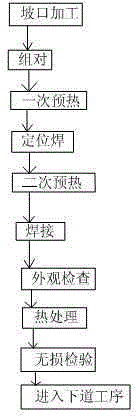

Carbon steel pipe welding technology

InactiveCN104959710AWeld firmlyAvoid repeated solderingArc welding apparatusMetal working apparatusCarbon steelPipe welding

The invention discloses a carbon steel pipe welding technology. The welding technology includes the following steps that groove machining is conducted, the pipe groove form and groove size of a pipe should meet the stipulation of a design document or a welding technology card; grouping is conducted, paint, dirt, burrs and zinc coatings arranged at the position, within the range of being larger than or equal to 10 mm, of a groove and the surfaces of the inner side and the outer side of the groove should be cleaned completely before welding piece grouping is conducted, when the inner-wall alignment tolerance of the pipe or a pipe fitting is 10% smaller than the pipe wall thickness when the pipe or the pipe fitting is in butt joint with a connector; first-time preheating is conducted on welding piece pairs before welding, and the preheating temperature ranges from 100 DEG C to 200 DEG C; positioning welding is conducted on welding assemblies generated after first-time preheating is conducted, the welded assemblies with defects are removed immediately, second-time preheating is conducted after reposition is conducted, and the welding is conducted again. By means of the principle, the alignment tolerance of the inner wall is accurately mastered, the groove is processed accurately, the processing process is optimized, and the mechanical strength of the welding seam position is improved.

Owner:CHENGDU ZHENZHONG ELECTRIC

Automatic filling and leveling device for road cracks

The invention discloses an automatic filling and leveling device for road cracks. The device comprises a rectangular bearing pedestal, the upper surface of the rectangular bearing pedestal is fixedly connected with a rectangular bearing box body, a filling liquid bearing and discharging mechanism is arranged in the rectangular bearing box body, the front surface of the rectangular bearing box body is provided with a pulling mechanism, the rear surface of the rectangular bearing box body is provided with a leveling mechanism, and the lower surface of the rectangular bearing pedestal is provided with a moving mechanism. The device has the advantages of convenience in use, small labor force, convenience in one-man operation, accuracy in crack filling, good surface leveling effect, good adhesion effect and guaranteeing of the firmness of pavements.

Owner:珠海交通工程技术有限公司 +1

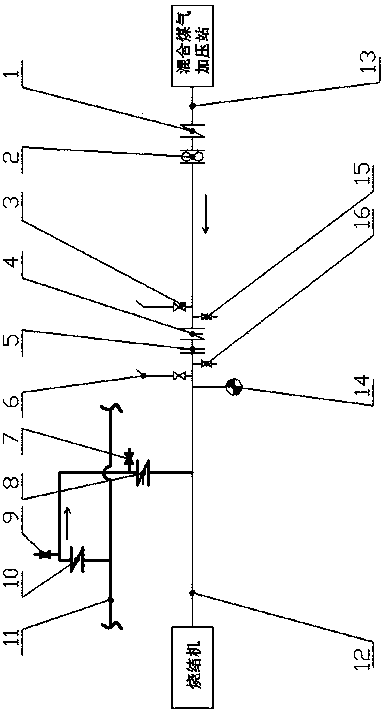

Distribution combustion gas device of sintering machine

InactiveCN103994661AImprove productivityGuaranteed to be firmFuel feedersFurnace typesProduction rateCombustion

The invention provides a distribution combustion gas device of a sintering machine. According to the technical scheme, the distribution combustion gas device comprises a sintering machine inlet pipe communicated with the sintering machine, the sintering machine inlet pipe is communicated with a mixed gas pressure station through a mixed gas pipeline, the sintering machine inlet pipe is further communicated with a coke oven gas distribution combustion pipeline, a gate valve and a coke oven butterfly valve are arranged on the coke oven gas distribution combustion pipeline, and a pressure station outlet butterfly valve and an outlet glasses valve are arranged on the side, close to the mixed gas pressure station, of the mixed gas pipeline. According to the scheme, the gas structure of the sintering machine is provided with two gas sources of coke oven gas and mixed gas through the device, coke oven gas heating can be adopted in a switching mode under the condition of the rich coke oven gas, the rich coke oven gas is consumed, meanwhile, the productivity of the sintering machine is improved, the coke oven gas is automatically adopted in a switching mode when the mixed gas pipeline is repaired, and continuous production of the sintering machine can be guaranteed.

Owner:JIGANG GRP

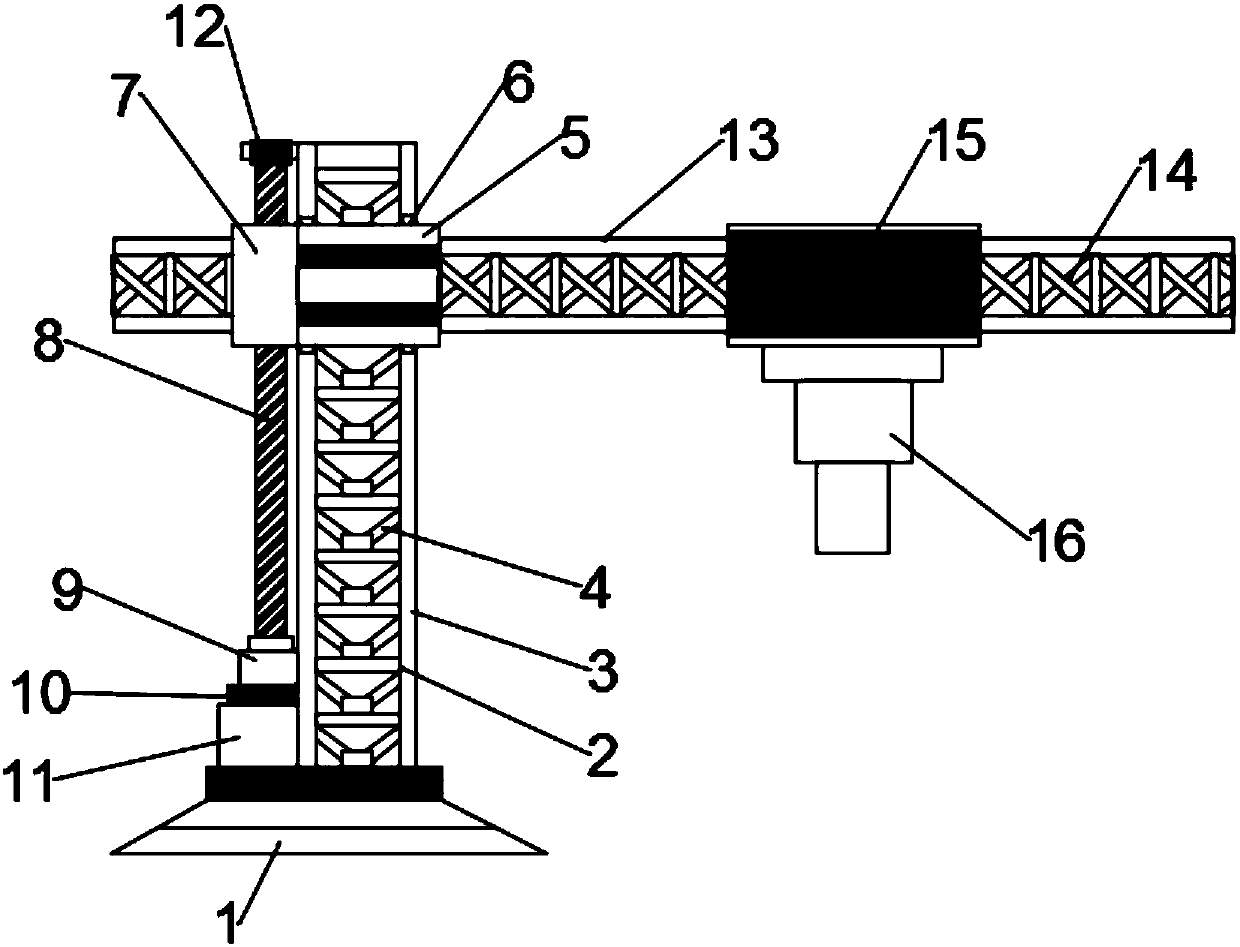

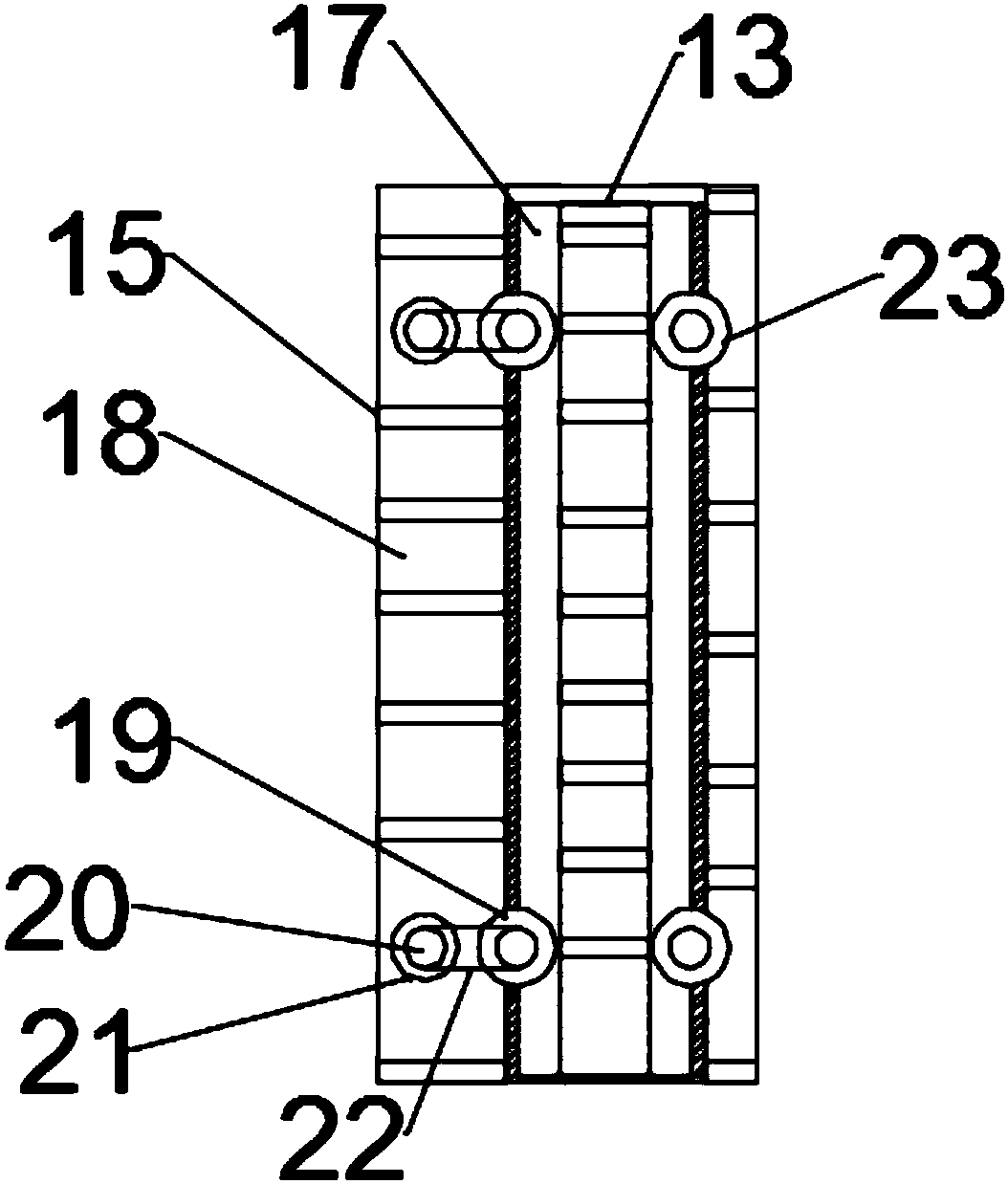

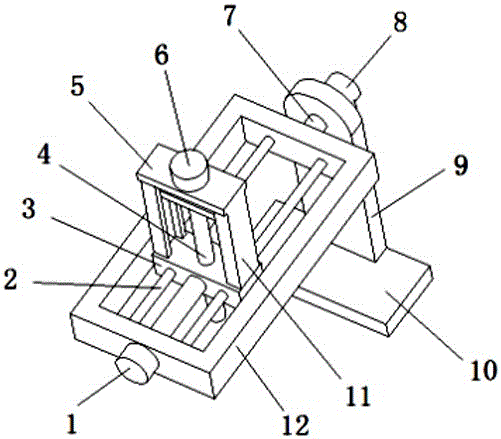

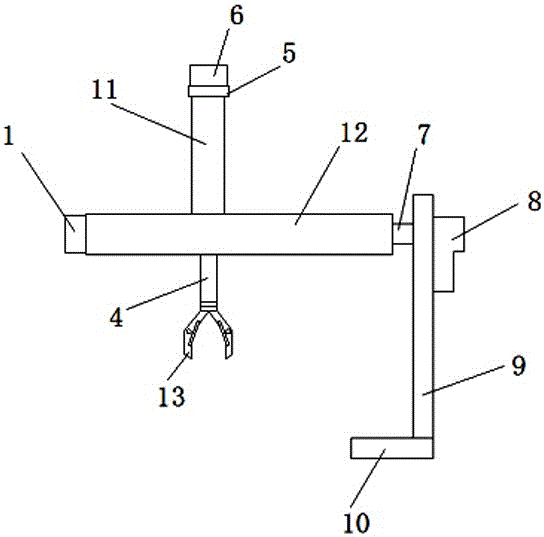

Mechanical hand truss

PendingCN107825404AGuaranteed to be firmEasy to moveProgramme-controlled manipulatorMotor driveRobot position

Owner:WUXI XINGUANG COMP INSTALLATION

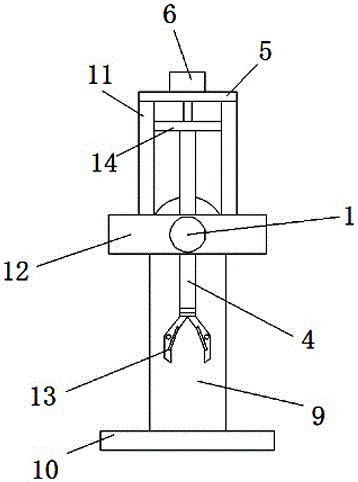

Foreign body forceps for digestive medicine

The invention discloses a foreign body forceps for digestive medicine. The foreign body forces comprise a cannula, wherein the front and rear sides of the top end of the cannula are fixedly connectedwith fixing pieces. A fixing shaft is fixedly connected between the two fixing pieces. The surface of the fixing shaft is sleeved by tow clamping jaws. The bottom of the two clamping jaws are communicated with a rotating rod, and the bottom end of the rotating rod extends to the inside of the cannula, and the bottom of the rotating rod is communicated with a thin pulling tube, which relates to thetechnical field of medical instruments. A foreign body forceps for digestive medicine By pulling the finger ring, the tube can be pulled with the collar, and the foreign body can be clamped by indirectly pulling the clamping jaw by the rotating rod. Also, the cooperation of the latch and the clamping groove can fix the thin-drawn tube after clamping the foreign body, so that the loose clamping caused by the thin-drawn tube when the foreign body is taken out can be avoided, and the harm to the fixed person caused by the secondary clamping is also avoided. Moreover, the thin-drawn tube does notneed to be pulled all the time when the foreign body is pulled out, so that the operation can be completed by one person, and the operation is simple and convenient.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

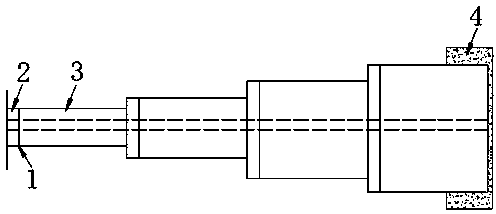

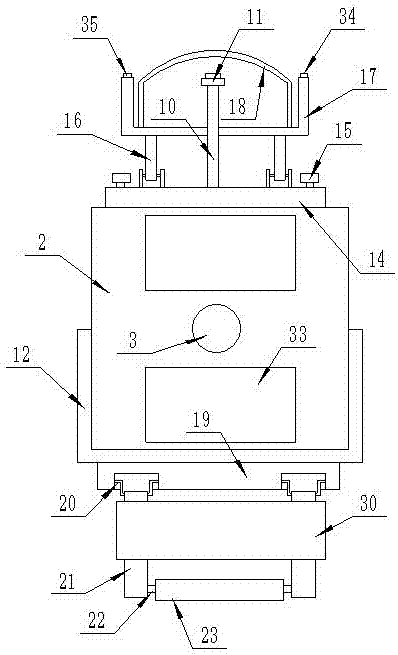

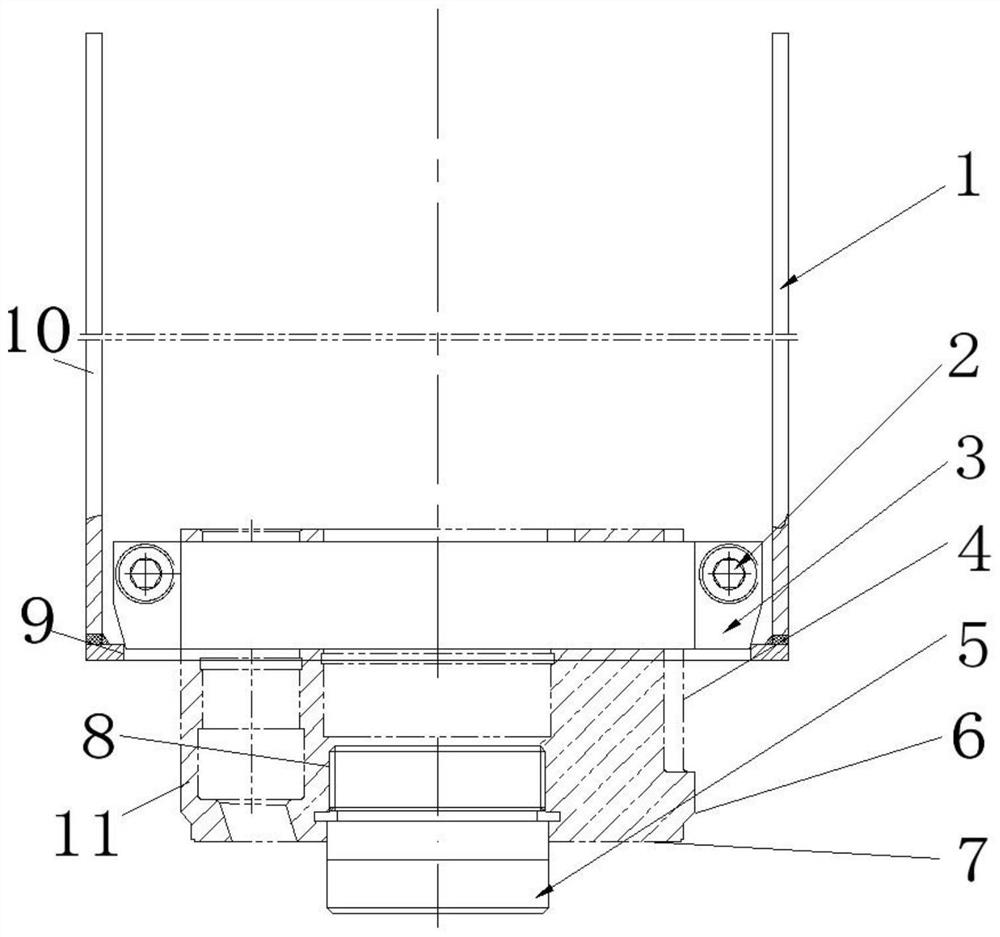

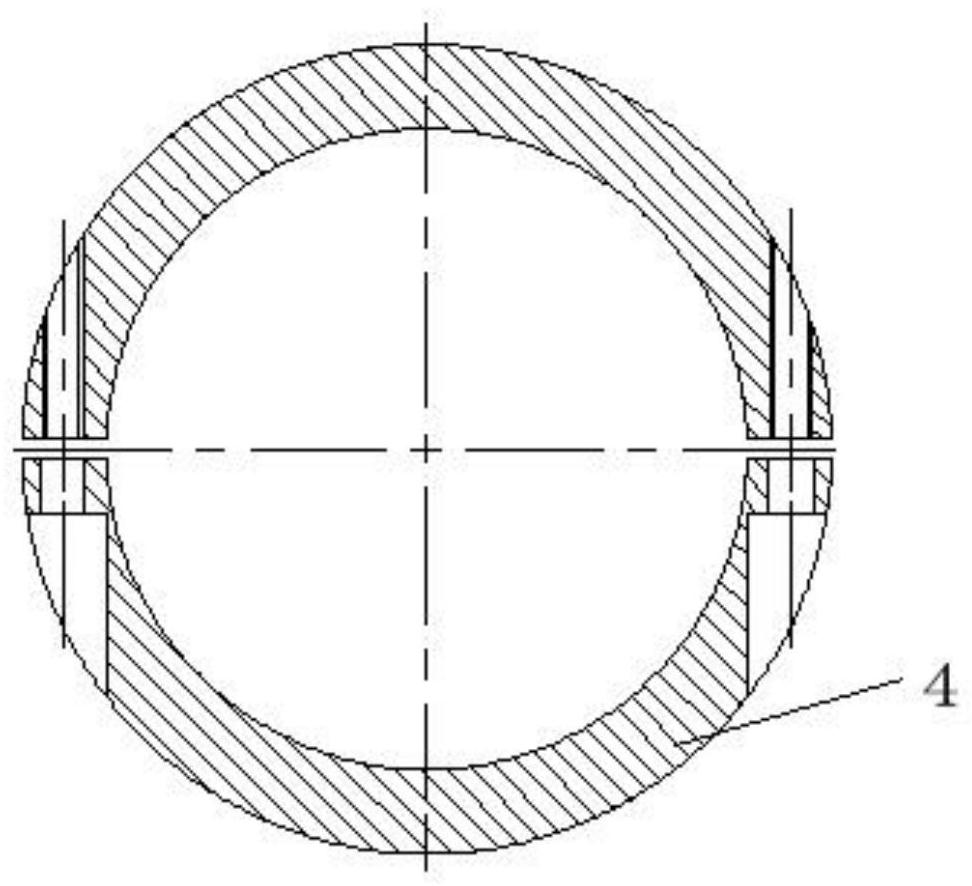

Method for partially electroplating lead-indium alloys on petal-shaped rotors

The invention discloses a method for partially electroplating lead-indium alloys on petal-shaped rotors. The method comprises the following steps: (1) deoiling through an organic solvent; (2) protecting by using insulated rubber tapes, adhesive tapes or tools; and (3) hanging, wherein the step (3) of hanging comprises the following substeps: a substep 3.1 of hanging petal-shaped rotor (11) workpieces by using electroplating tools and then moving the electroplating tools and the workpieces through hoisting rods (10) for electroplating; and a substep 3.2 of hanging the electroplated and dried workpieces by using oil heating tools before oil heating treatment and then placing the oil heating tools and the workpieces into a lubricating oil heat treatment tank for heat treatment through hoisting handles (13). The method for partially electroplating the lead-indium alloys on the petal-shaped rotors has the beneficial effects that the problem that the workpieces are obliquely hung or separated when partially electroplating the lead-indium alloys on the existing petal-shaped rotors is overcome, a method for partially electroplating the lead-indium alloys is provided and is capable of obtaining petal-shaped rotor plating layers which are consistent in color and are uniform and integral, and the method is safe and reliable.

Owner:GUIZHOU HONGLIN MACHINERY

Mechanical arm applied to injection molding machine

InactiveCN106426761ASolve the problem of not being able to stretchGuaranteed to be firmHydraulic cylinderEngineering

The invention discloses a mechanical arm applied to an injection molding machine. The mechanical arm comprises a base. A first fixed plate is arranged at the upper part of the base. The base is perpendicular to the first fixed plate. A first through hole is formed in one side of the first fixed plate. A rotating shaft is mounted in the first through hole. A motor is connected with one end of the rotating shaft, and is fixed on one side of the first fixed plate. A rotating frame is connected to the other end of the rotating shaft, and adopts a cuboid frame structure. Two parallel screw rods are connected between the inner walls, parallel to each other, of the rotating frame. The screw rods are parallel to the rotating shaft. A first sliding block is mounted on the screw rods, and adopts a cuboid structure. Two second through holes are formed in one side, close to the first fixed plate, of the first sliding block. The screw rods are mounted in the second through holes. A first hydraulic cylinder is connected to one side, far from the first fixed plate, of the first sliding block, and is fixed to one side, far from the first fixed plate, of the rotating frame. The mechanical arm has the advantages that the utilization rate of the operation space is high, the processing efficiency is improved, and the safety of an operator is protected.

Owner:ANHUI ZHILIANG INVESTMENT GRP

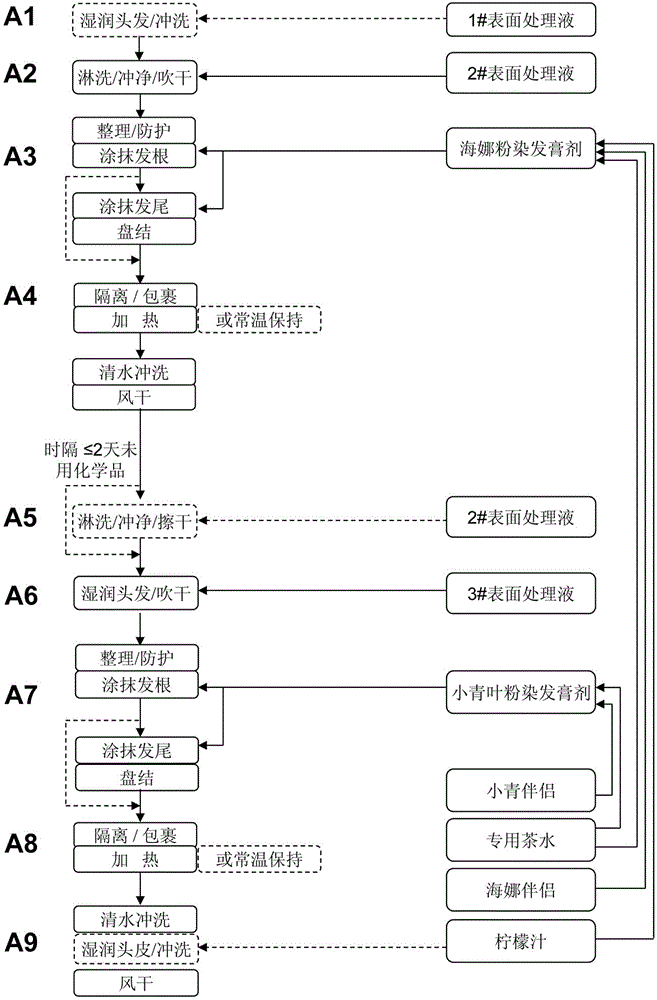

Pure vegetable hair dyeing method and hair dyeing product for dyeing white hair black

ActiveCN104688616AFacilitated releaseTake advantage ofCosmetic preparationsHair cosmeticsBiotechnologyHair dyes

The invention relates to a pure vegetable hair dyeing method and a hair dyeing product for dyeing white hair black. The method sequentially comprises the following steps: leaching hair by using 2# vegetable surface treatment fluid, wherein the 2# vegetable surface treatment fluid comprises any one or two of 0.2-5 weight percent of Indian saponin, 0.2-10 weight percent of tea saponin and 0.2-10 weight percent of soapberry; daubing hair dyeing cream blended by Henna partner, pure Henna leaf powder and special tea water which are respectively packaged on to-be-dyed hair; wetting the hair by using 3# vegetable surface treatment fluid, wherein the 3# vegetable surface treatment fluid comprises 0.2-5 weight percent of poria cocos and 0.2-5 weight percent of coptis chinensis; and daubing hair dyeing cream blended by green leaf partner, pure Indian green leaf powder and special tea water which are respectively packaged on the hair. The pure vegetable hair dyeing method disclosed by the invention has the technical effects that plant pigments can be released in a centralized mode so as to be fully utilized; according to the 3# vegetable surface treatment fluid, an acid-base reaction between indigo blue cream and a Henna dyeing layer can be effectively avoided; and moreover, the 2# vegetable surface treatment fluid has excellent effects of washing and nourishing hair and the like.

Owner:朱绍华

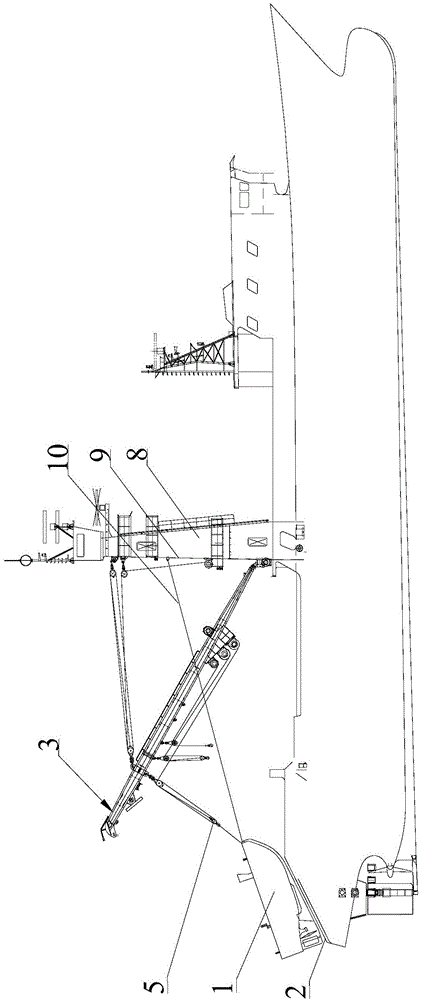

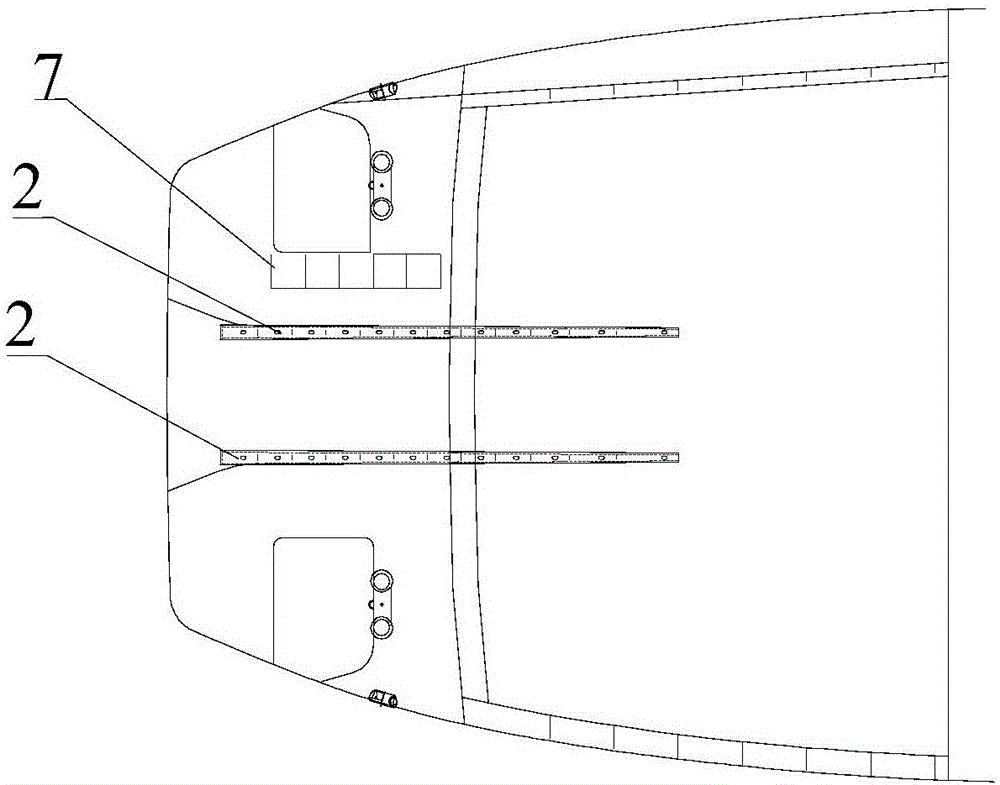

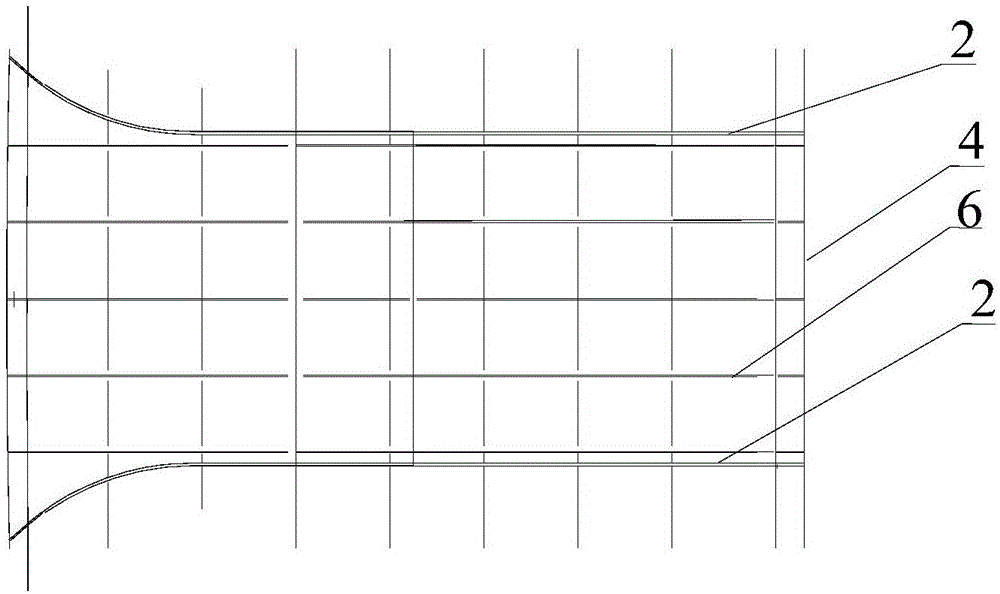

Ship

ActiveCN106005269AAvoid bendingAvoid shear deformationDavitsBoat guiding devicesMarine engineeringBase line

The invention provides a ship capable of quickly and safely retracting and deploying a child ship. The ship comprises a mother ship and the child ship, wherein slideways and a main hanging rod are arranged on the mother ship; the slideways are positioned at the tail part of a cabin of the mother ship; the main hanging rod is positioned in the middle of the mother ship; the slideways are used for placing the child ship; the length extension directions of the slideways are intersected with the length extension direction of the main hanging rod; the included angle of the length extension direction of the slideways and the horizontal base line is 30-60 degrees; a slideway surface is arranged at the bottoms of the slideways; the slideways and the slideway surface are parallel; a first T-shaped material supporting rack is arranged at the bottom of the slideway surface in the longitudinal direction of the slideway surface; openings at the tail end of the slideways are reversed round angles; a pulley block is arranged on the main hanging rod, and comprises hanging hooks.

Owner:FUJIAN MAWEI SHIPBUILDING

Waterproof proximity switch fixing device

InactiveCN104240985AAchieve vertical movementAchieve lateral movementElectric switchesError signalElectrical and Electronics engineering

Owner:SHANDONG IRON & STEEL CO LTD

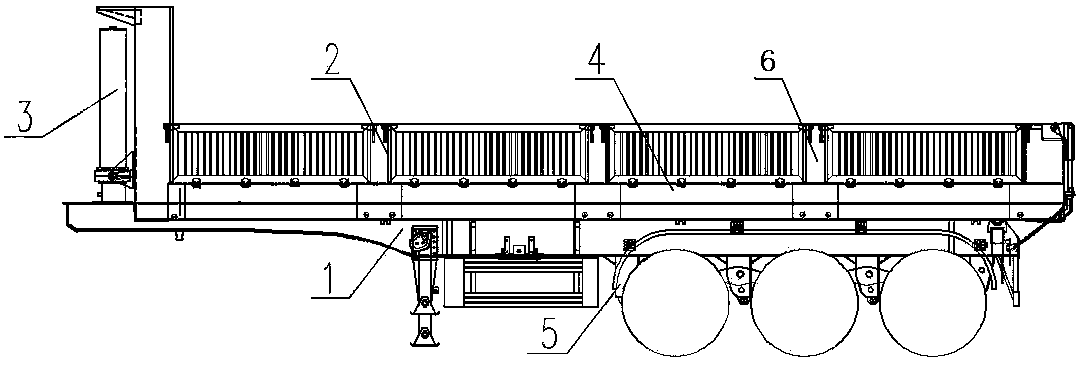

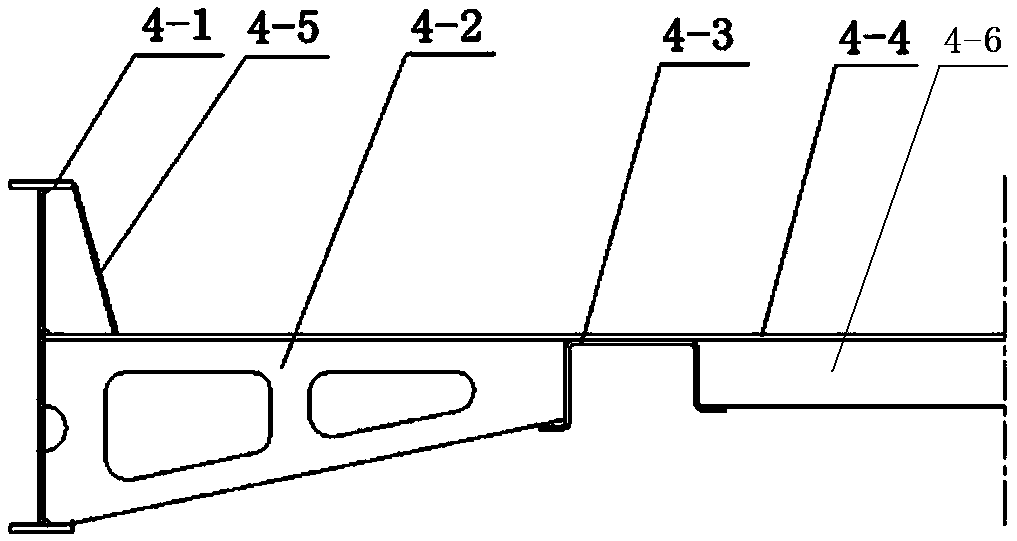

Multi-purpose self-discharging semitrailer

PendingCN108638935AGuaranteed to be firmAchieve tippingTractor-trailer combinationsLoad securingVehicle frameSelf-discharge

The invention discloses a multi-purpose self-discharging semitrailer, and relates to the technical field of automobile manufacturing. The multi-purpose self-discharging semitrailer comprises a frame,carriages, a lifting device and a driving system. A girder of the frame is of a straight beam structure, each bottom plate of each carriage is composed of side longitudinal beams, an inner longitudinal beam, a side cross beam, a middle cross beam and a bottom panel. The side longitudinal beams are arranged at the two ends of the bottom plates, the inner longitudinal beams are arranged on the middle portions of the bottom plates, the side cross beams are arranged between the side longitudinal beams and the inner longitudinal beams, the middle cross beams are arranged between the inner longitudinal beams. The bottom plates are movably provided with a plurality of hinge pin moving position clamping seats. The multi-purpose self-discharging semitrailer can solve the problems that an ordinary semitrailer is single in purpose and cannot transport bulk materials to realize the self-discharging function.

Owner:LIUZHOU CHENGLONG SPECIAL PURPOSE VEHICLE CO LTD

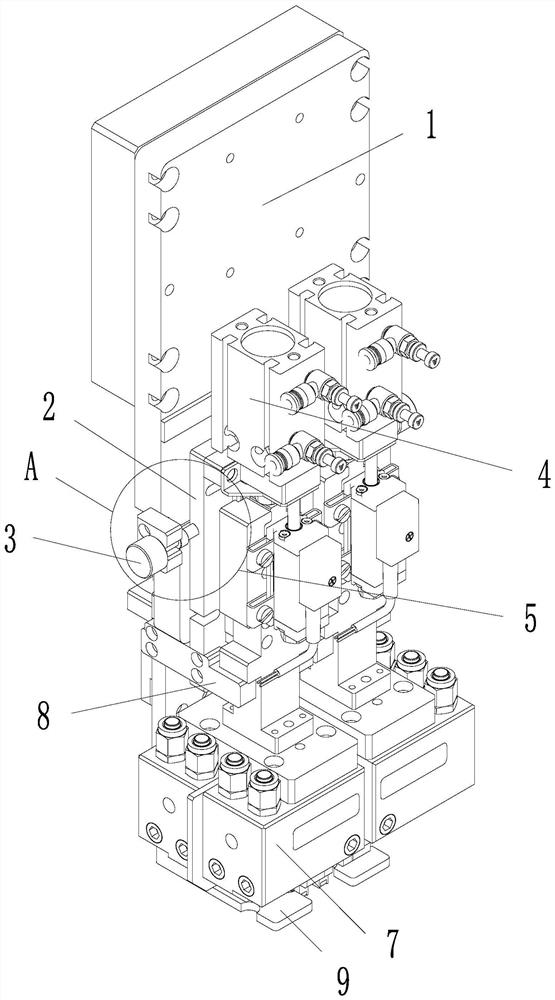

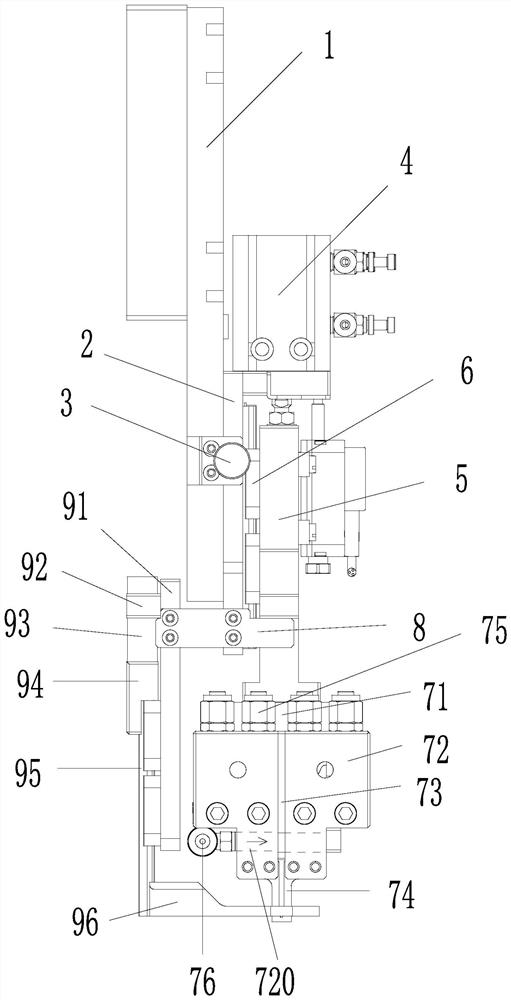

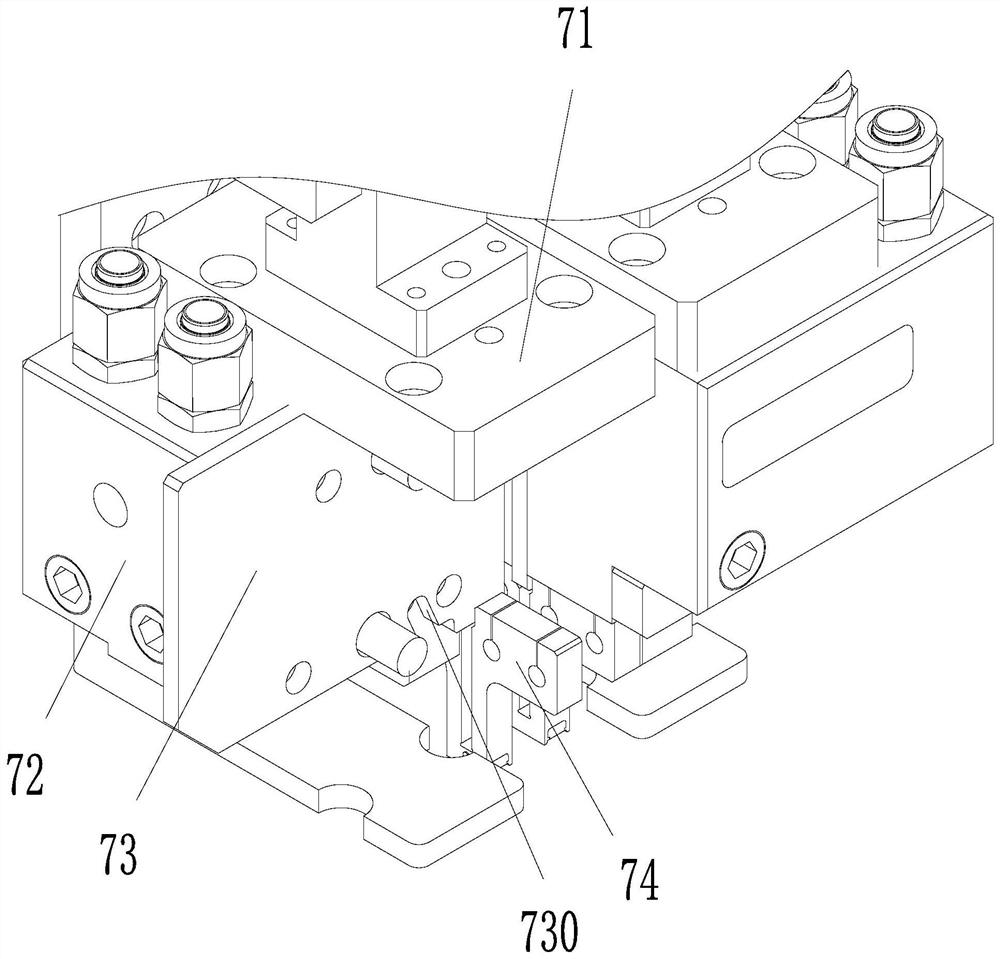

Solar panel junction box shaping welding head assembly

PendingCN112222687AGuaranteed to be firmCompact structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a solar panel junction box shaping welding head assembly. The solar panel junction box shaping welding head assembly comprises a main mounting plate, two horizontal adjusting plates, adjusting assemblies, guided cylinders, a lifting plate, a linear sliding rail, a welding head assembly, a limiting block and a pressing plate assembly, wherein the two horizontal adjusting plates are installed on the main mounting plate, the adjusting assemblies are installed at the two side ends of the main mounting plate, the guided cylinders are installed on the horizontal adjusting plates, piston rods of the guided cylinders are fixedly connected with the lifting plate through connecting blocks, the lifting plate is slidably connected with the horizontal adjusting plates through the vertically-arranged linear sliding rail, the welding head assembly is installed at the lower end of the lifting plate, the pressing plate assembly is arranged below the welding head assembly, and the pressing plate assembly is movably connected with the main mounting plate. By means of the mode, the solar panel junction box shaping welding head assembly is flexible and convenient to operate, fast in temperature rise, high in temperature resistance, capable of guaranteeing that welding spots are firm, wide in the application range, and capable of rapidly cooling the welding head and a weldedproduct, avoiding the damage to the product, and preventing the welding head from being adhered.

Owner:苏州晟成智能装备有限公司

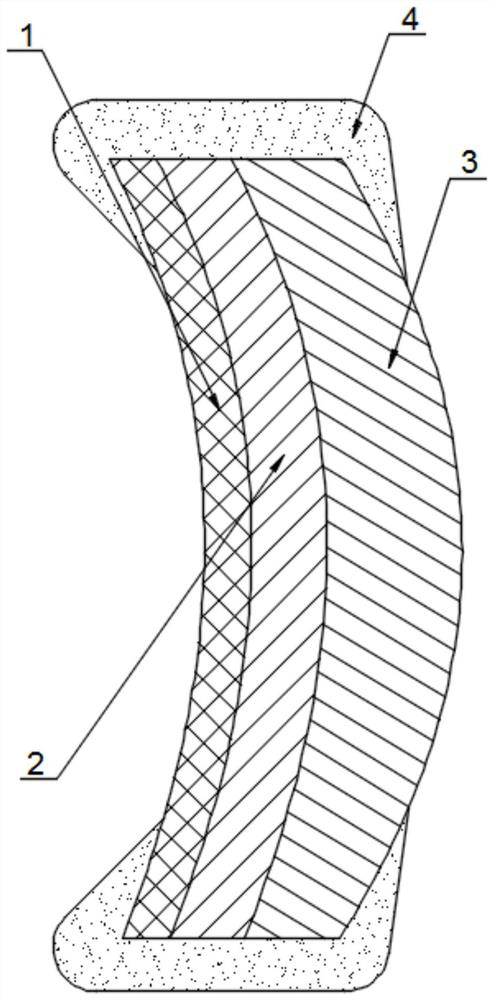

Bra mold cup and preparation method thereof

InactiveCN111904047AGuaranteed to be firmAffect aestheticsBrassieresCorsetsPolymer scienceLatex rubber

The invention discloses a bra mold cup and a preparation method thereof. According to the technical scheme, the bra mold cup comprises a skin-friendly layer, a body layer, a supporting layer and a covered edge; the skin-friendly layer, the body layer and the supporting layer are sequentially distributed from left to right, the covered edge is fixedly arranged on the outer sides of the skin-friendly layer, the body layer and the supporting layer in a sleeving mode, and the skin-friendly layer comprises silk and cotton silk. The body layer comprises 3D vertical cotton, latex and silica gel, andthe supporting layer comprises PU sponge, shaping cotton, rubber cotton and regenerated sponge. The bra mold cup has the beneficial effects that the skin-friendly layer is formed by mutually weaving silk and cotton silk, the body layer isformed by jointly cold-pressing or hot-pressing the 3D vertical cotton, the latex and the silica gel, the supporting layer are made of PU sponge, shaping cotton,rubber cotton and regenerated sponge in a mixed cold pressing or hot pressing mode; the skin-friendly layer, the body layer and the supporting layer are bonded through glue and then sewn in an edge covering mode, firmness of the bra mold cup is guaranteed, and burrs are prevented from leaking out to influence attractiveness after long-term use.

Owner:尹艳梅

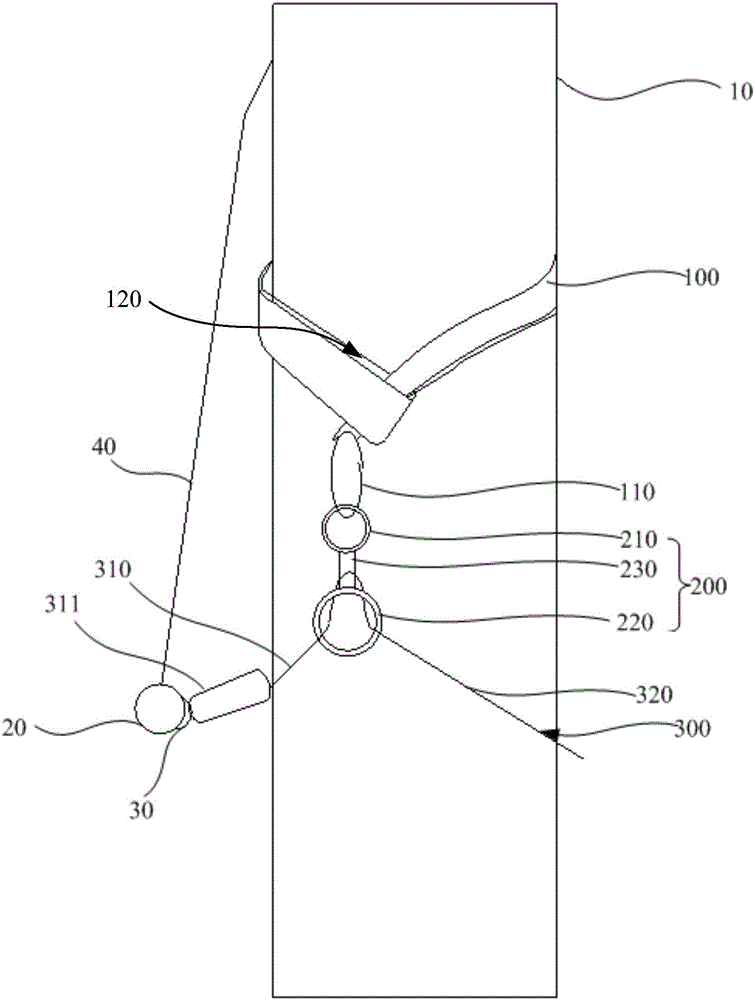

Pole and tower rescuing tool and method

The invention discloses a pole and tower rescuing tool and method. The pole and tower rescuing tool comprises a fixing belt, a connecting ring and a lifting rope, one end of the fixing belt is provided with a first buckling ring, the other end of the fixing belt is provided with a fixing opening, the fixing belt is wound around a pole and tower, and the first buckling ring penetrates the fixing opening; and the connecting ring is detachably buckled on the first buckling ring, one end of the lifting rope is used for being connected with a person to be rescued, and the other end of the lifting roper penetrates the connecting ring to be used for pulling the person to be rescued. According to the pole and tower rescuing tool and method, the fixing belt is bound and fixed to the pole and tower and is used for creating a temporary suspension point, the connecting ring is buckled through the first buckling ring and serves as a bearing body of sliding of the lifting rope, it can be guaranteed that the to-be-rescued person at one end of the lifting rope slowly descends under control of a rescuing person at the other end, and the to-be-rescued person can be downwards transferred to the ground for waiting for emergency treatment. By means of the pole and tower rescuing tool and method, the tool is simple and rapid and convenient to assemble, the rescuing time can be greatly shortened, and the electric shock emergency treatment efficiency is improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

PCB for on-board integration of LED

InactiveCN103517547AImprove luminous performancePlay a supporting rolePoint-like light sourcePrinted circuit detailsBiochemical engineeringLead sheet

The invention discloses a PCB for on-board integration of an LED. The PCB for on-board integration of the LED comprises the PCB, a positive plate and a negative plate, wherein the positive plate and the negative plate are arranged at the two ends of the PCB respectively; a positive electrode lead sheet is arranged on the positive plate and extends to the middle of the PCB; a negative electrode lead sheet is arranged on the negative plate and also extends to the middle of the PCB; the positive electrode lead sheet and the negative electrode lead sheet are respectively provided with a silver coating; the positive plate and the negative plate are respectively provided with gold plating. Compared with the traditional mode that electrodes and pole pieces of the PCB are provided with simplex plating, the PCB for on-board integration of the LED improves the light source effect of an LED lamp body, the stability of the PCB is enhanced, and the overall service life of the LED is prolonged.

Owner:杨睿涵

Construction method of grouting flower tube anchor rods in support process of soft soil slope

ActiveCN111364475AAccurate locationStable structureFoundation testingExcavationsSoil propertiesMesh reinforcement

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com