Waterproof proximity switch fixing device

A technology of proximity switches and fixing devices, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of detection components affecting the detection accuracy, difficulty in installing proximity switches, and increasing unit delays, so as to ensure firmness and prevent lower ends from warping Side, to avoid the effect of equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A waterproof proximity switch fixing device of the present invention will be described in detail below with reference to the accompanying drawings.

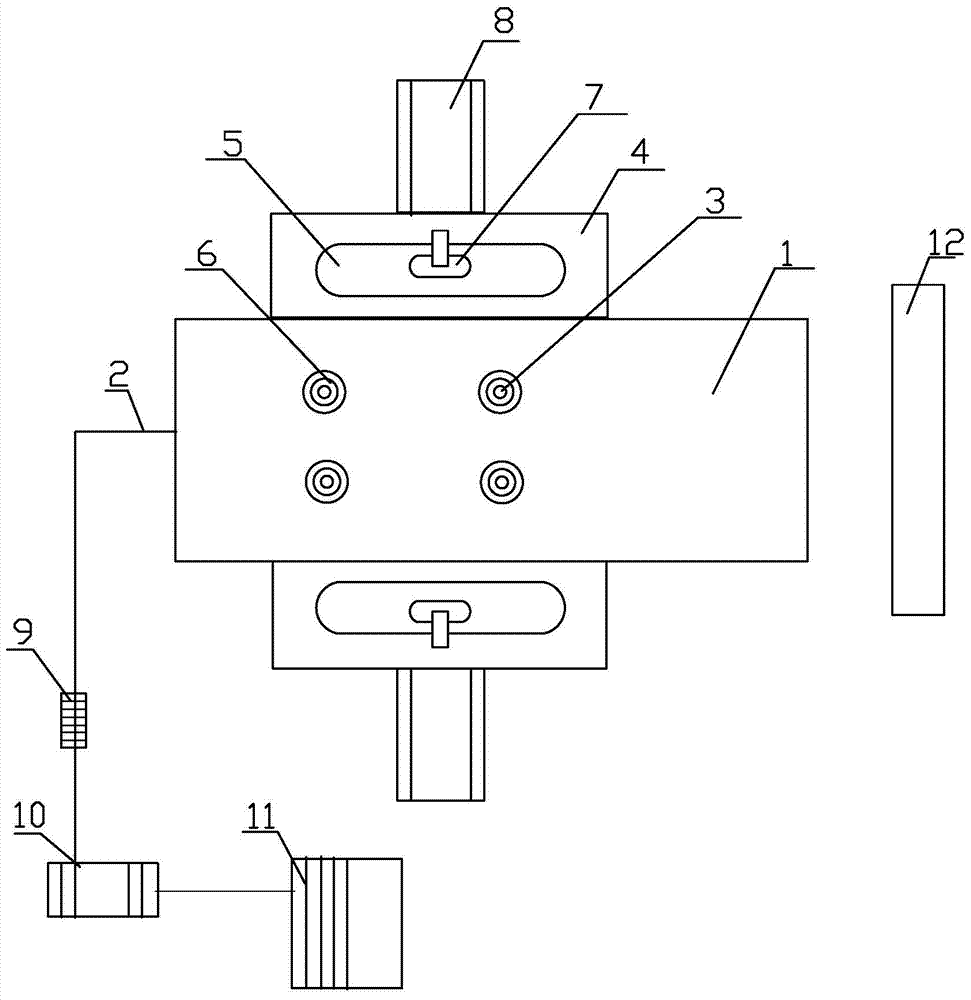

[0015] Such as figure 1 As shown, a kind of waterproof proximity switch fixing device of the present invention, its structure comprises proximity switch body 1, and proximity switch body 1 is provided with connection terminal 9, acquisition system module 10 and VME controller 11, proximity switch body 1 and connection terminal, The acquisition system module and the VME controller are connected by a proximity switch cable 2. The bottom of the proximity switch body 1 is provided with a fixed base plate 4 and a sliding track 8 in turn, and the proximity switch body 1 is connected with the fixed base plate 4 by bolts. The two ends of the above-mentioned fixed bottom plate 4 are respectively provided with adjustment holes 5, and the adjustment holes 5 are provided with oval bolts 7, and the free ends of the oval bolts 7 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com