Patents

Literature

873results about How to "Achieve compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive manufacturing device composite powder compacting and spreading device and method

ActiveCN104043830AImprove mechanical propertiesImprove densification performanceIncreasing energy efficiencyMechanical propertyAdditive layer manufacturing

The invention discloses an additive manufacturing device composite powder compacting and spreading device and method. The powder spreading device comprises a pressure powder spreading machine and a vibration system, wherein the pressure powder spreading machine is provided with a coating surface with a certain inclined angle and used for spreading a powder material, and the vibration system is used for vibrating and compacting the spread powder material. According to the powder spreading device, due to the fact that the pressure powder spreading machine is provided with the coating surface with the certain inclined angle, in the powder spreading process, after loose powder enters the included angle formed between the coating surface and a powder spreading plane, the heated loose powder is mutually extruded through the gradually-decreasing space, and then gaps between the powder become smaller; the vibration system vibrates and pressurizes the extruded powder, distribution arrangement of the gaps between the extruded powder is stabilized, namely, rebound of the spread powder is reduced, the powder material is elastically deformed and then the flat-spread powder is compacted, so that compactness of three-dimensional forming products is improved, and mechanical performance of the three-dimensional forming products is further improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

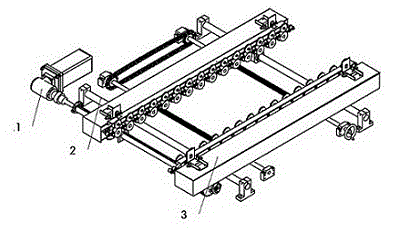

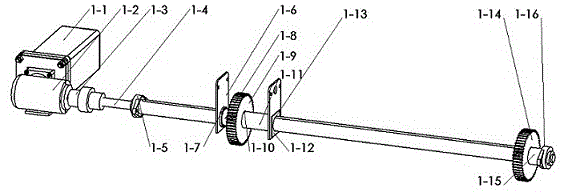

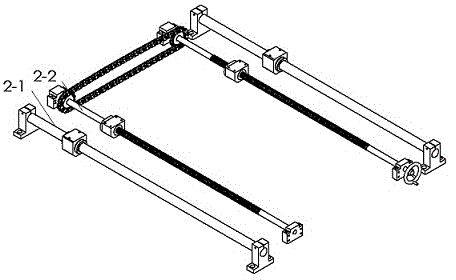

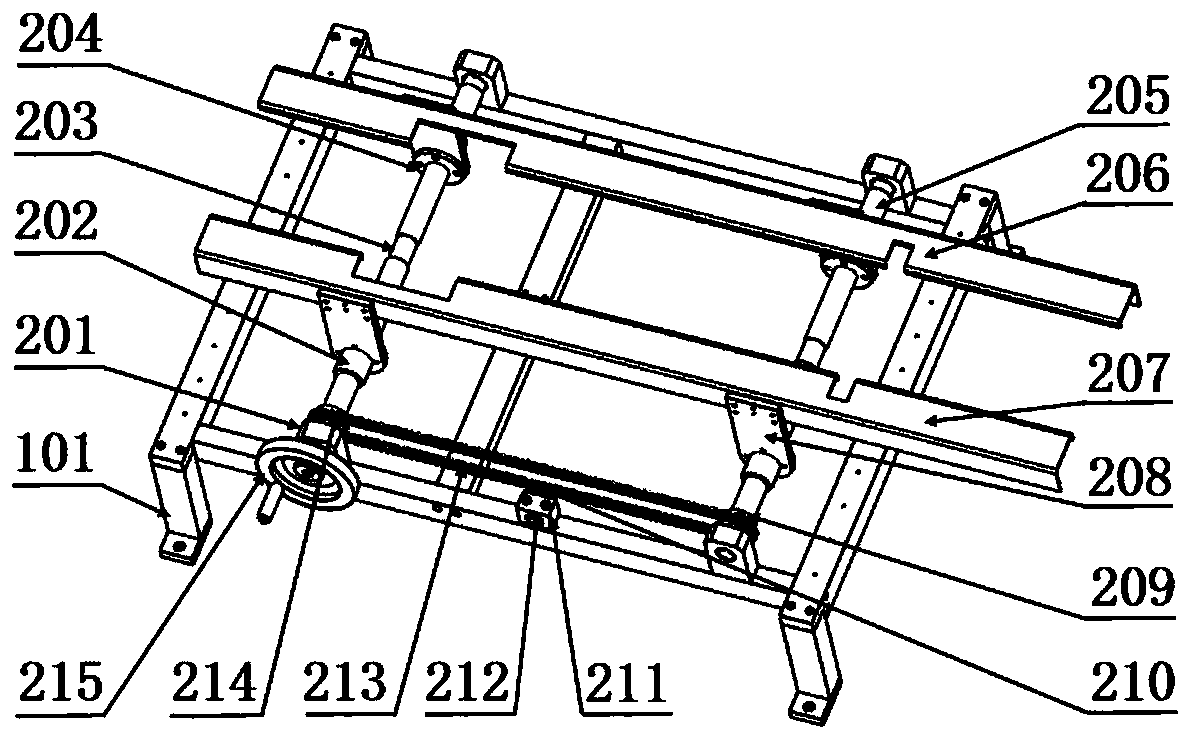

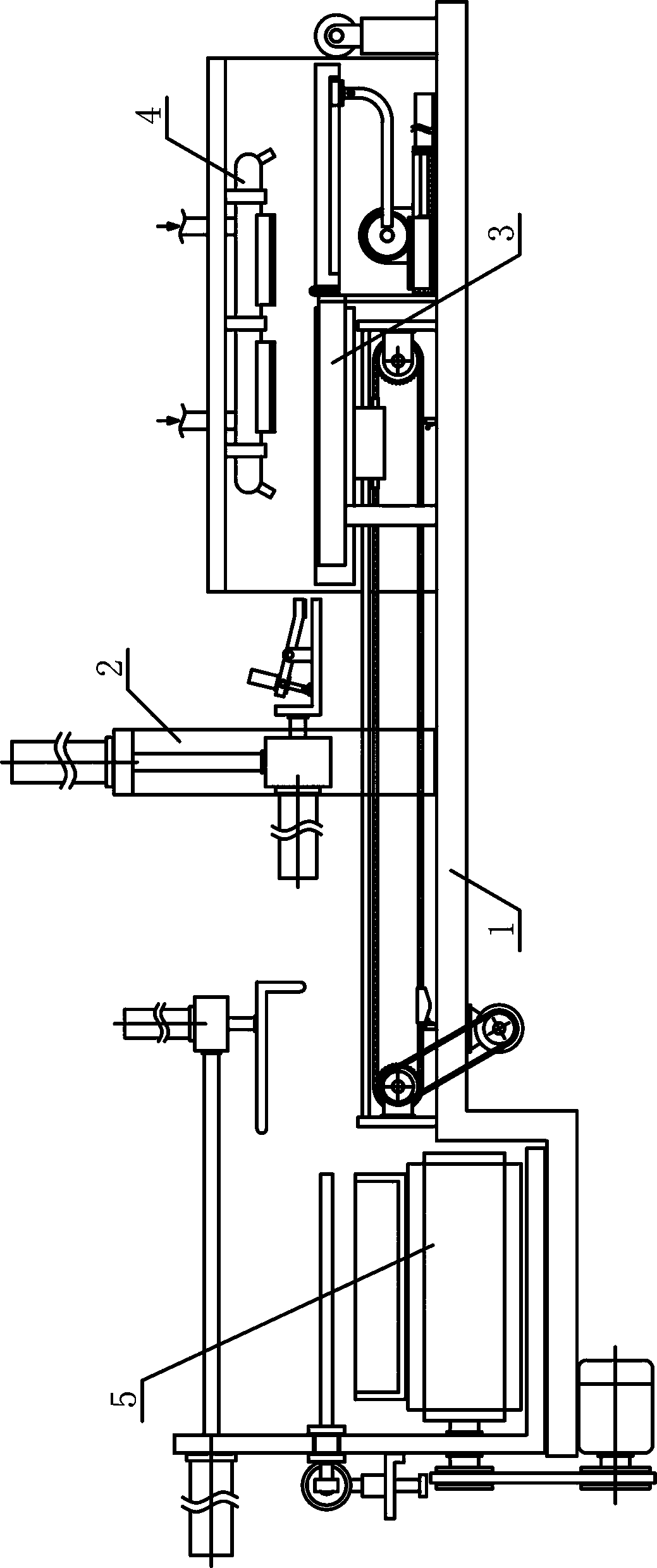

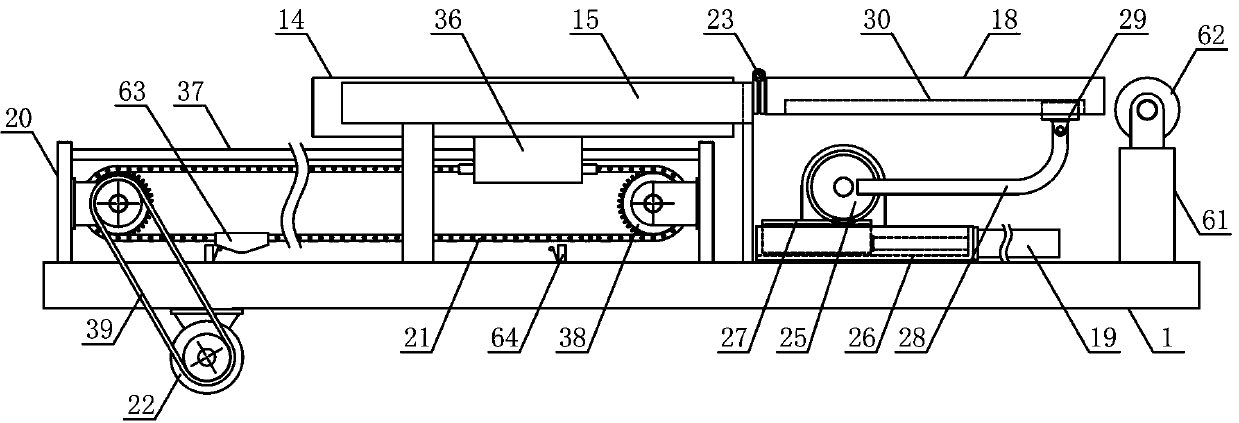

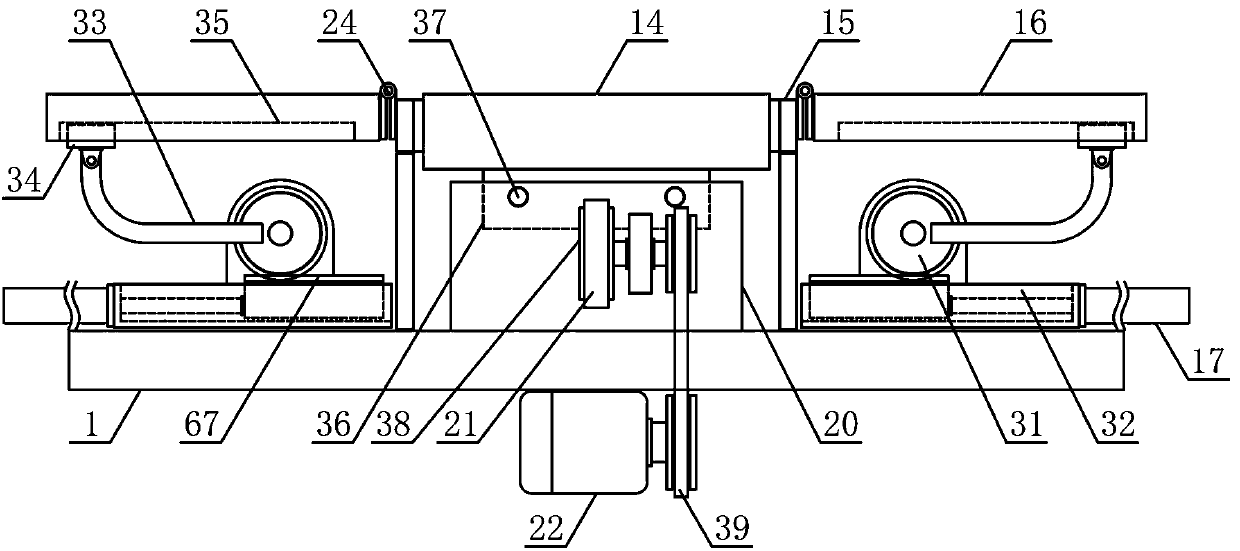

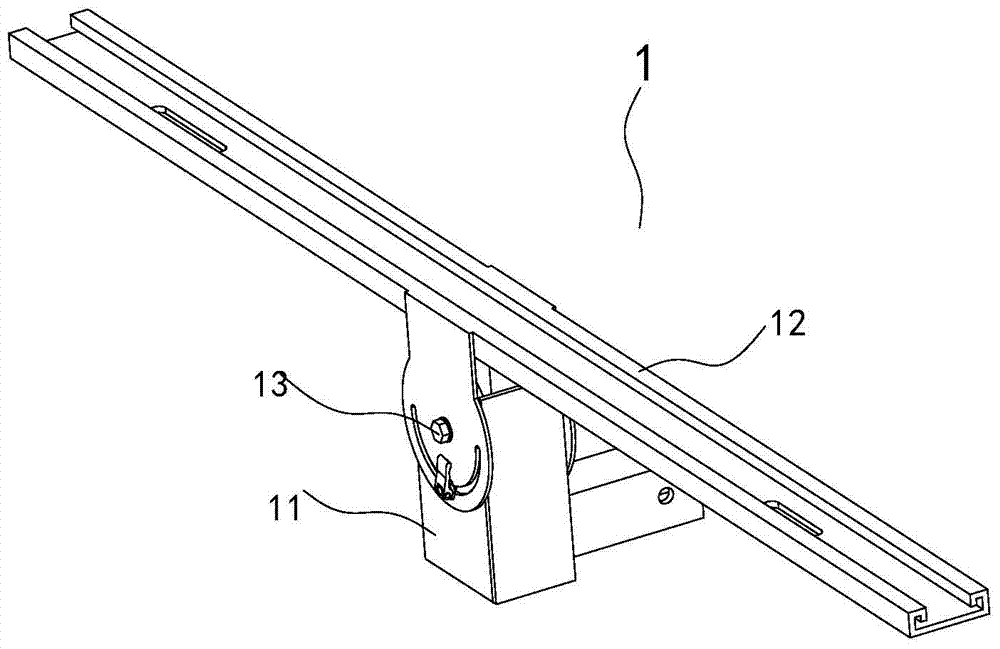

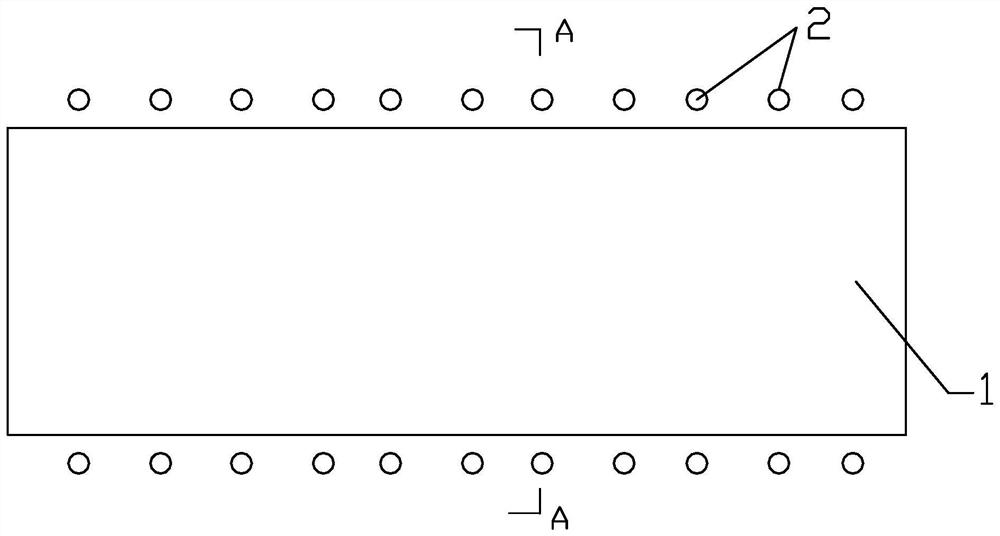

Multifunctional width adjustable conveying device

InactiveCN104401644AAdjustable distanceAchieve cleaningCharge manipulationConveyor partsLinear motionDrive shaft

The invention discloses a multifunctional width adjustable conveying device of a PCB (printed circuit board) and machined component washing device, which is a core part of the washing device. The multifunctional width adjustable conveying device consists of a power input device (1), a supporting width adjusting device (2) and a conveying guide rail compression device (3), wherein a motor (1-1) drives a gear of a conveying guide rail (3-1) to rotate through a transmission shaft (1-4), a gear (1-9) and a gear (1-14), and a chain of the conveying guide rail (3-1) drives a large roller and a small roller to rotate together so as to realize the online washing of a PCB; a groove body of the conveying guide rail (3-1) is connected with a slide bearing sleeve and a nut seat of the supporting width adjusting device (2-1), a handle of a ball screw width adjusting device (2-2) is rotated so as to drive a ball screw to rotate through a chain wheel and the chain, the conveying guide rail (3-1) is driven by the linear motion of the nut seat to make linear movement along the axis direction so as to realize the width adjustment of the conveying guide rail, and the online washing of PCBs in different widths can be satisfied.

Owner:SICHUAN UNIV

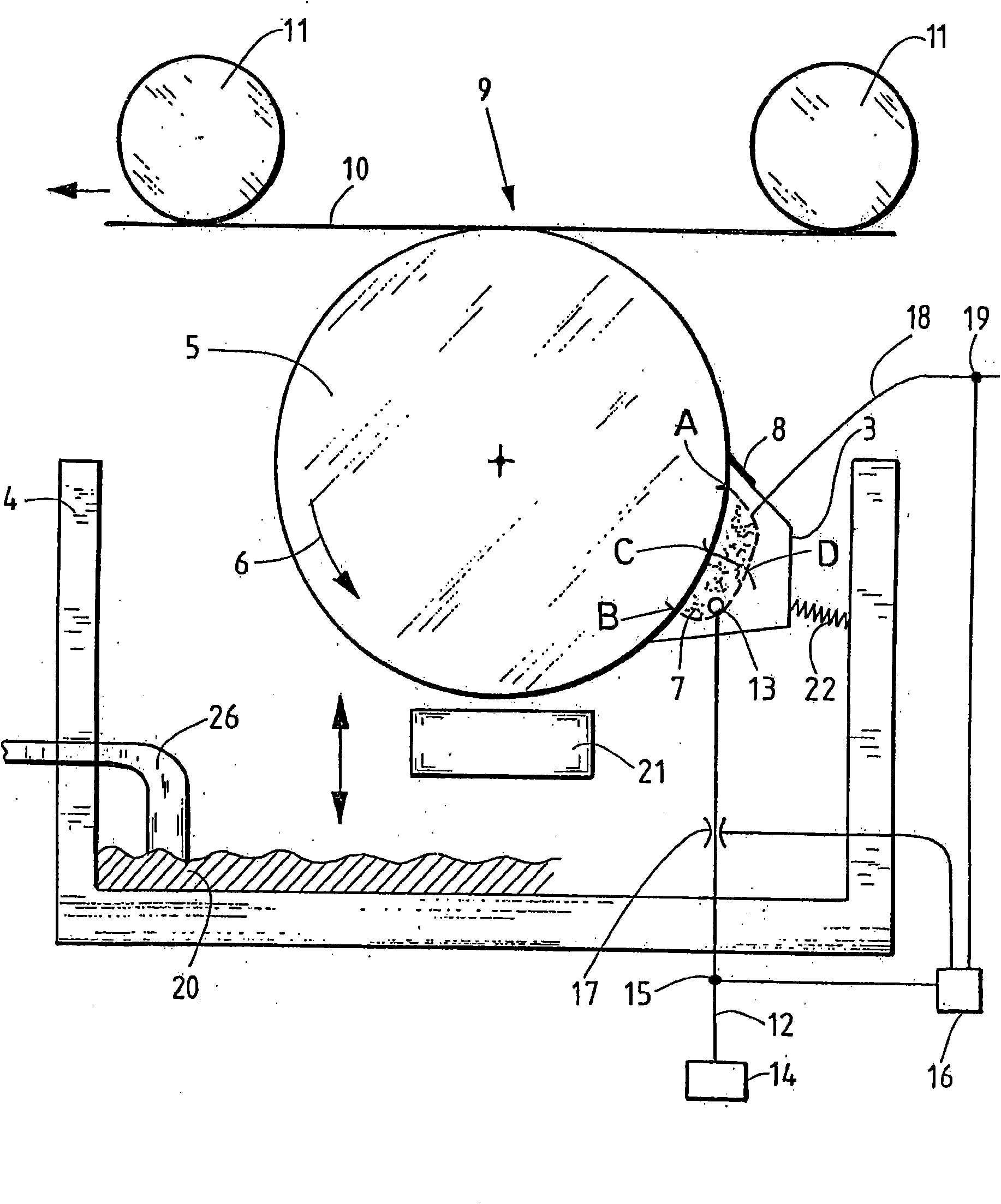

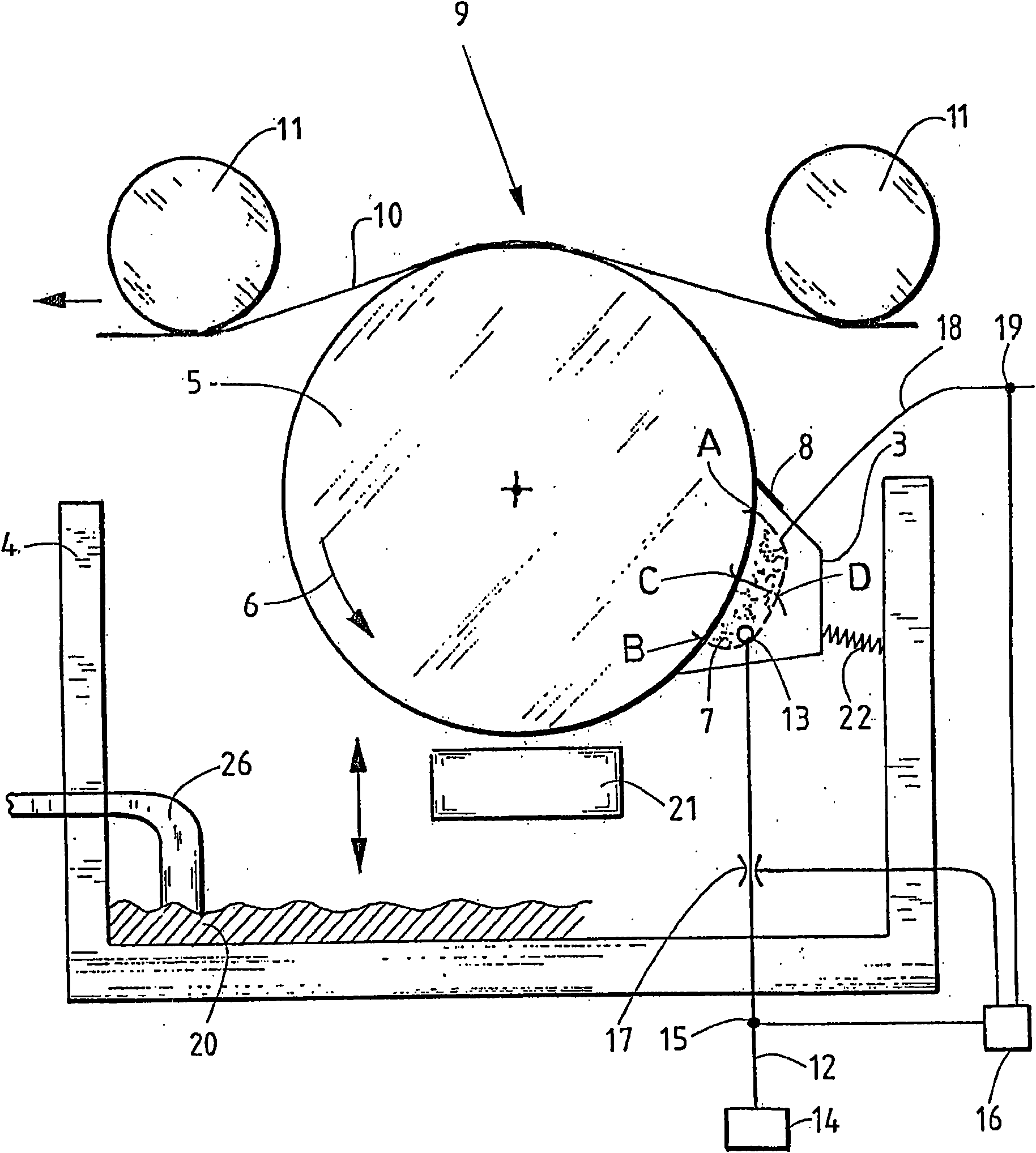

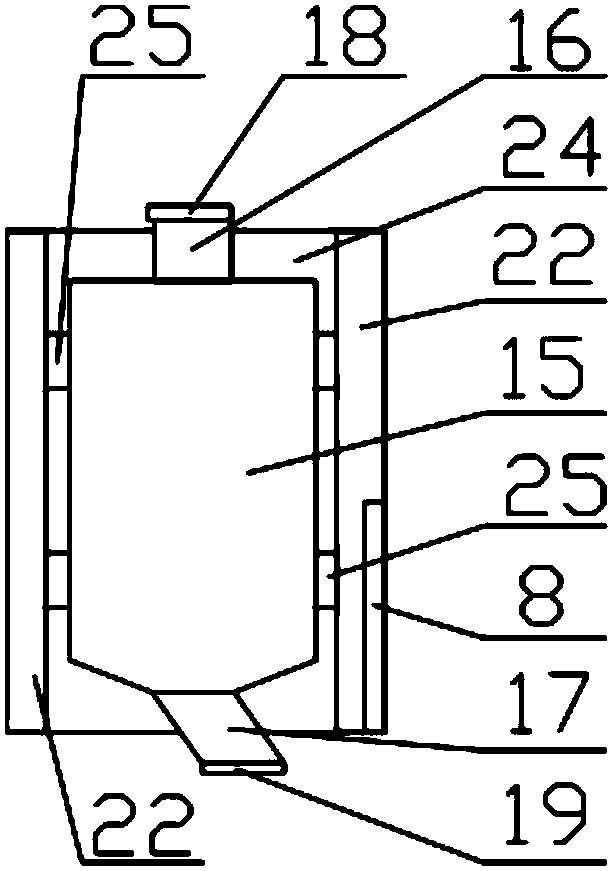

Application of glue to strips of material for the tobacco processing industry

ActiveCN101559417AExtended acceptance timeFirmly connectedLiquid surface applicatorsCigarette manufactureEngineeringMechanical engineering

The present invention relates to application of glue to strips of material for the tobacco processing industry, in particular a device for applying glue (20) to strips (10) of material for tobacco processing industry by means of a raster roller (5) preferably having shallow ridges, wherein a glue processing chamber (7) is arranged at a raster roller (5), glue (20) is removed from the glue processing chamber by using the raster roller. The invention also relates to a method for applying glue (20) to strips (10) of material for tobacco processing industry by means of a raster roller (5) preferably having shallow ridges, wherein the glue (20) is removed from the glue processing chamber by using the raster roller (5). The device is improved, wherein an external conveyor pipe (12) is attached to an internal supply pipe (13) of the glue processing chamber, wherein the glue is delivered by the external conveyor pipe (12) and the internal supply pipe (13) of the glue processing chamber (7). The method according to the invention is characterized in that the glue (20) is conveyed to the chamber (7) through the external conveyor pipe (12) and the internal supply pipe (13) of the glue processing chamber (7) directly connected onto the external conveyor pipe (12).

Owner:HAUNI MASCHINENBAU AG

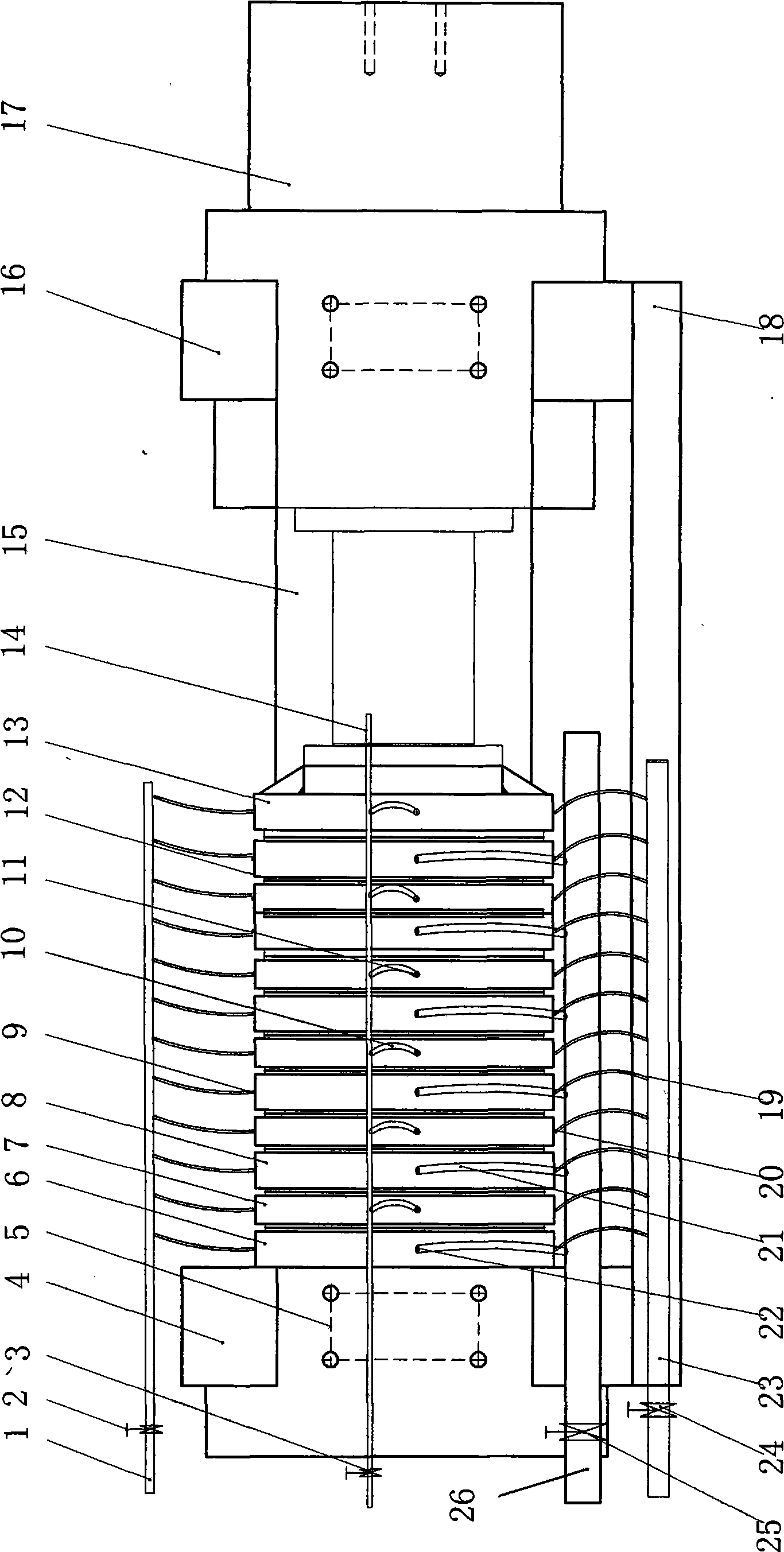

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

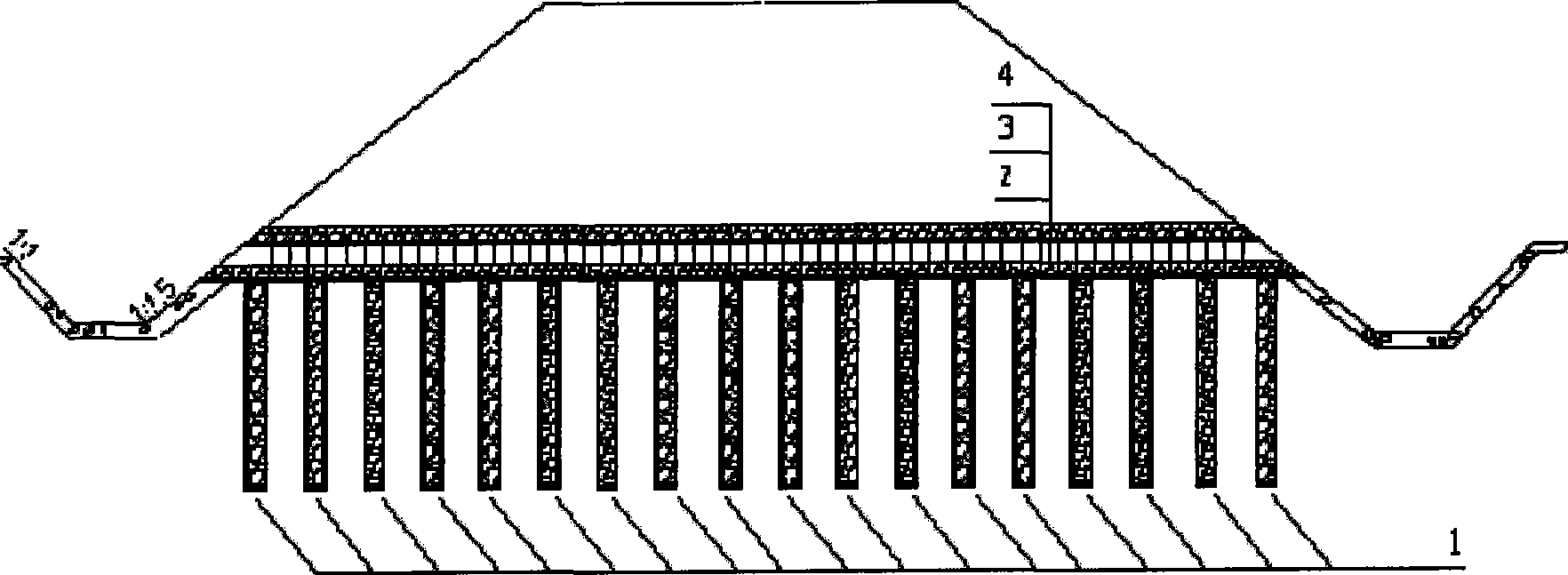

Bidirectional reinforcing and water drainage reinforcing means for highway soft soil foundation

The invention discloses a soft soil foundation two-way reinforcement and drainage reinforcement method for highways. The invention comprises the steps as follows: (1) the site is leveled and the pile positions are set out; (2) the construction is carried out by vibroflotation, hammering method, or vibrating tube sinking method to form a gravel pile; (3) the top of the pile is paved with Geocell coarse sand or gravel hardcore, the main composition body thereof is a Geocell layer with drain holes on the wall, the Geocell is filled with compact coarse sand or gravels, and the upper part and the lower part of the Geocell are respectively paved with drainage layers. By adopting the Geocell coarse sand or gravel hardcore and gravel pile two-way reinforcement and drainage structure, the method can realize a composite action of reinforcement, compaction, replacement and drainage on the soft foundation, effectively improve the strength and stability of the roadbed, reduce the differential settlement of the foundation and satisfy the requirement of traffic load increase on the bearing capacity and deformation of the roadbed.

Owner:HUNAN UNIV

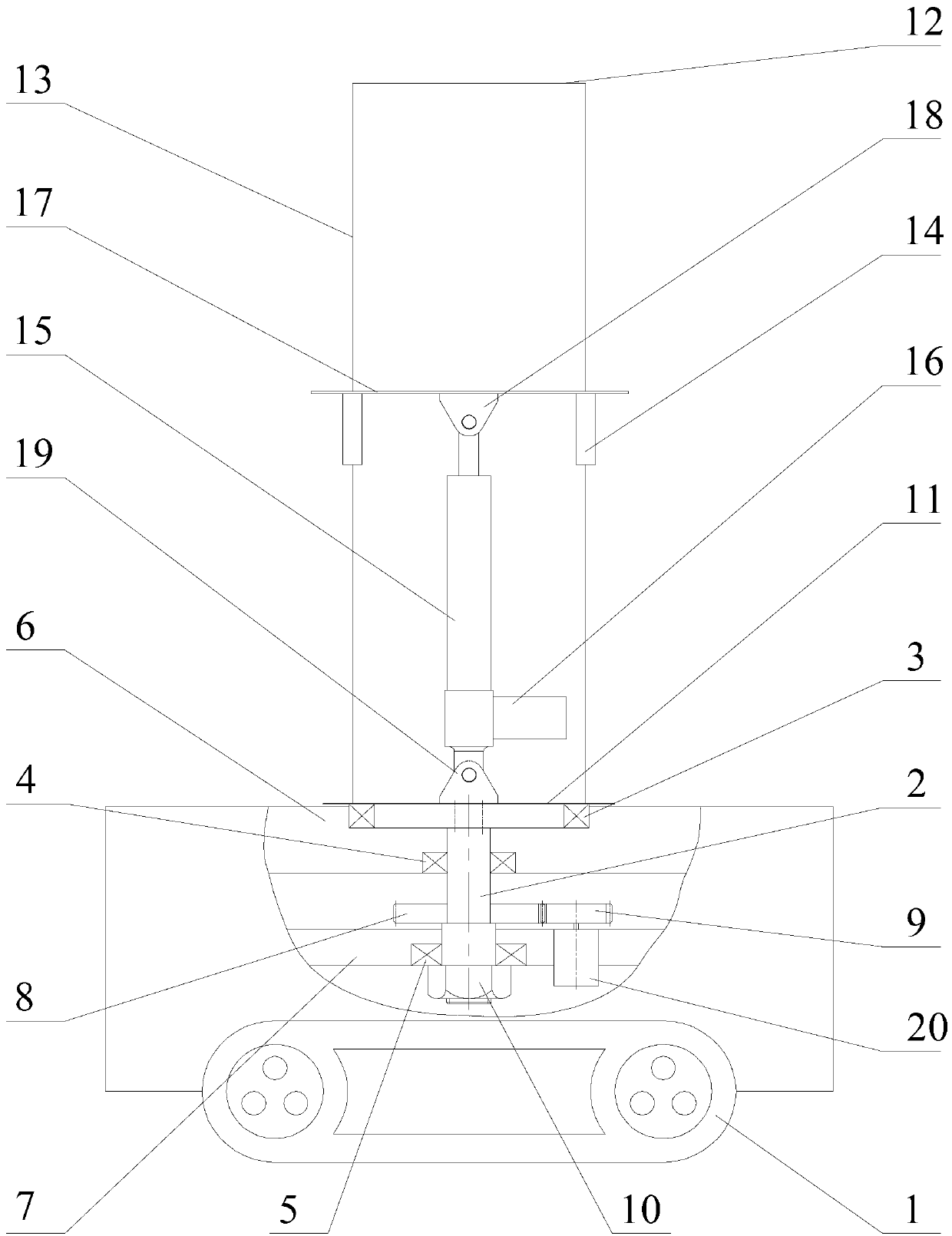

Movable and rotatable lifting platform used for picking agricultural products

ActiveCN103270849AImprove rigidityImprove general performancePicking devicesControl systemAgricultural engineering

The invention discloses a movable and rotatable lifting platform used for picking agricultural products. The movable and rotatable lifting platform comprises a walking mechanism, a rotating mechanism, a lifting platform body and a control system. The rotating mechanism comprises a rotating machine frame, a main shaft, a bearing set, a bearing seat board set, a gear set and a rotating driving motor, wherein the main shaft is connected with the bearing set in a matched mode, the bearing set is fixed on the bearing seat board set, the rotating driving motor transmits rotating power to the main shaft through the gear set, the rotating driving motor is installed on the rotating machine frame, the top end of the main shaft is fixedly connected with the lifting platform body, the bottom of the rotating machine frame is connected with the walking mechanism, and the control system is in signal connection with the rotating driving motor and the lifting platform body. The movable and rotatable lifting platform has the advantages of being capable of bearing larger loads and capsizing moment, small in motion resistance, high in motion precision, large in motion stroke, strong in universality of parts, convenient to produce and maintain, low in manufacturing cost, and the like. Large-load and mass mechanized harvesting of crops can be achieved only through that a corresponding agricultural harvesting operation device is arranged on the movable and rotatable lifting platform.

Owner:SOUTH CHINA AGRI UNIV

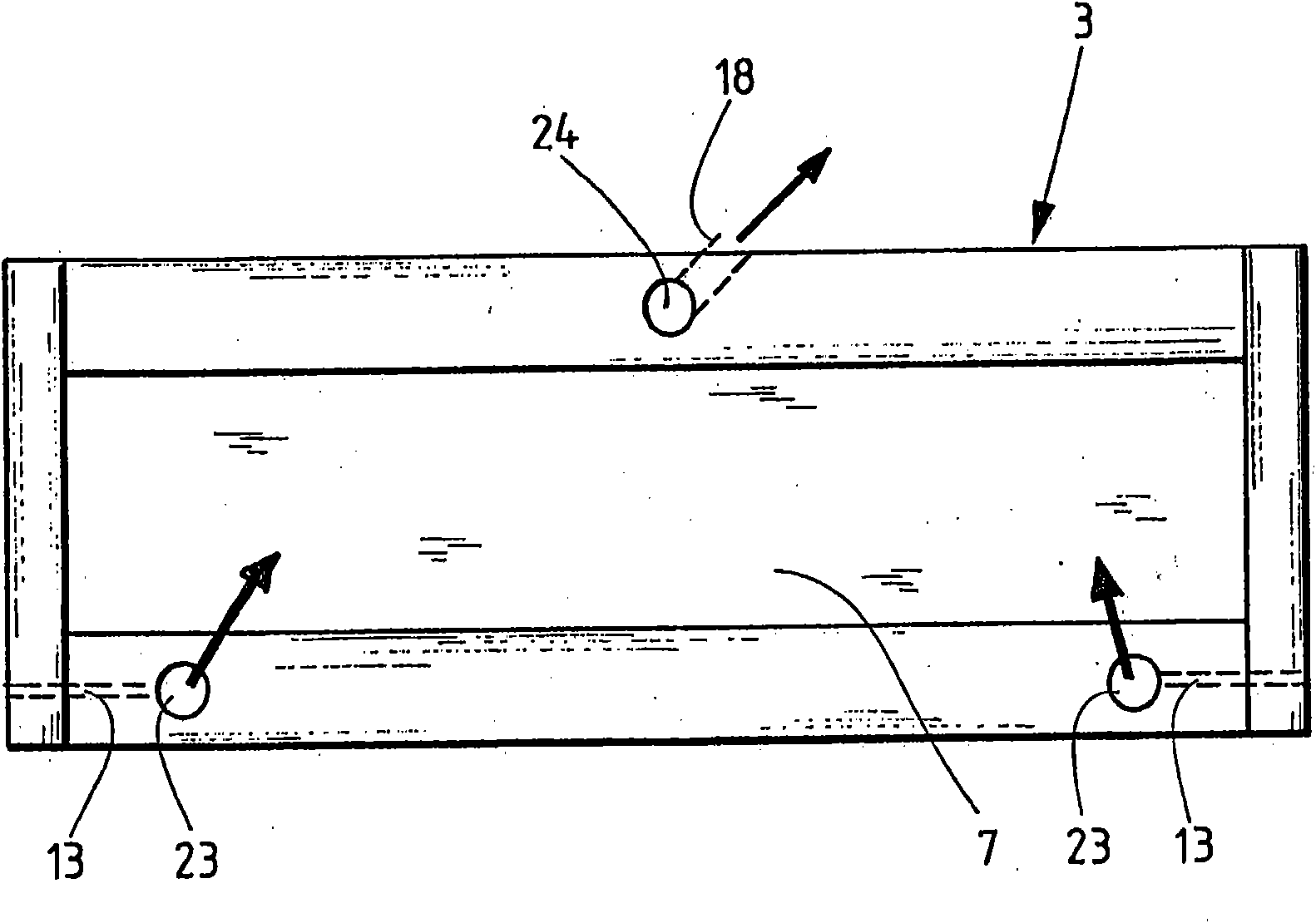

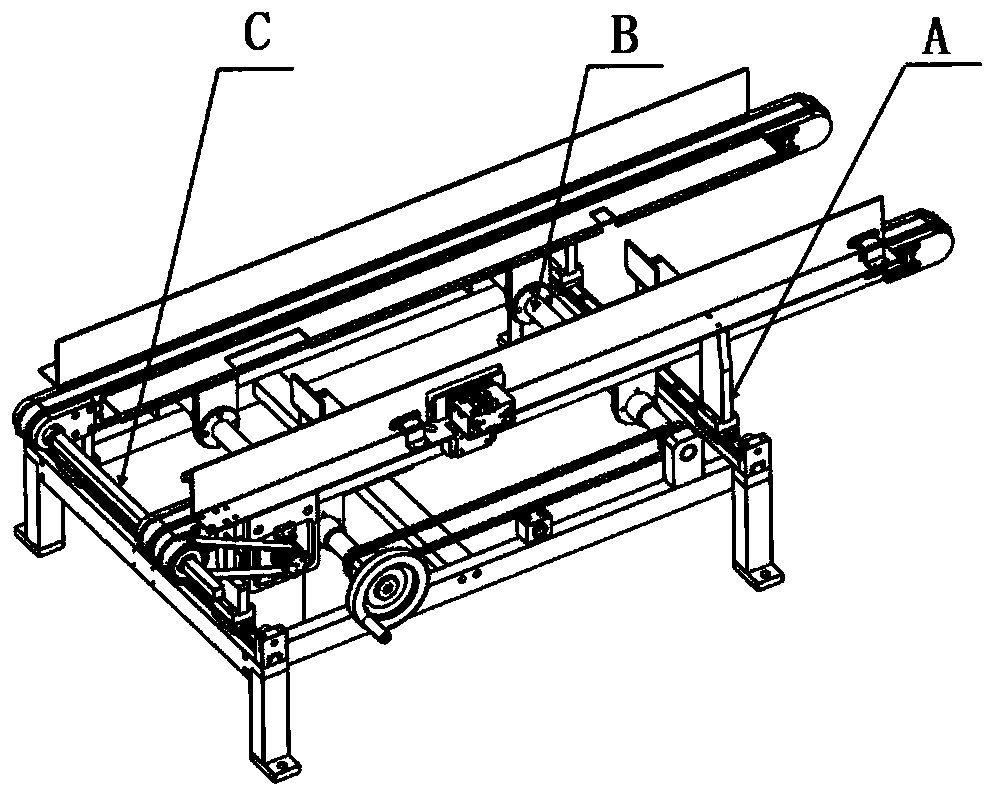

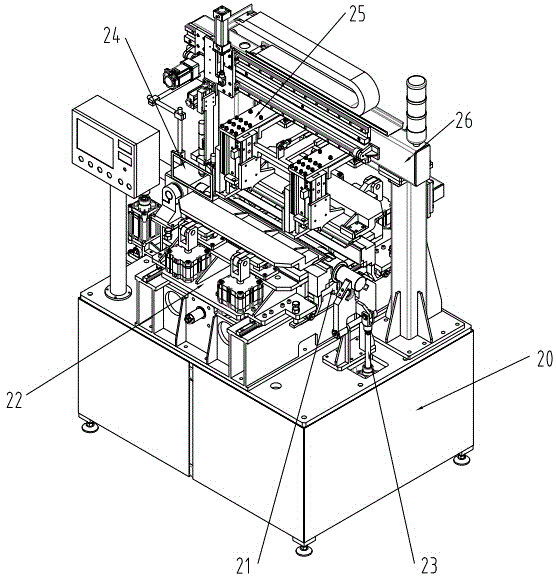

Carton conveying and positioning device with adjustable interval

The invention relates to a conveying device, in particular to a carton conveying and positioning device with adjustable interval. The device comprises a sliding support part, an adjusting screw part,and a dual-synchronous-belt conveying part, dual sliding block guide rails are arranged on the two sides of a rack and are used for supporting sliding of a synchronous belt support, the support is arranged on sliding blocks of the dual sliding block guide rails, two sets of left-handed and right-handed screws are transmitted through a chain, synchronous centered moving is achieved, through a copper nut connecting plate, the synchronous belt support is connected with a left-handed copper nut and a right-handed copper nut, and interval adjusting of the synchronous belt support is achieved; two synchronous belt conveying devices are arranged, through square shaft transmission, stable synchronous rotation is ensured, the interval can be adjusted, interval adjusting of boxing and conveying canbe achieved, the device is suitable for boxing transportation of different sizes, and adaptation is improved; a hollow structure is arranged between the two synchronous belt conveying devices, a blocking air cylinder and a pushing air cylinder are added, and positioning and pressing of cartons on the fixed position of the conveying device can be achieved.

Owner:YANGZHOU MEIDA FILLING MACHINERY

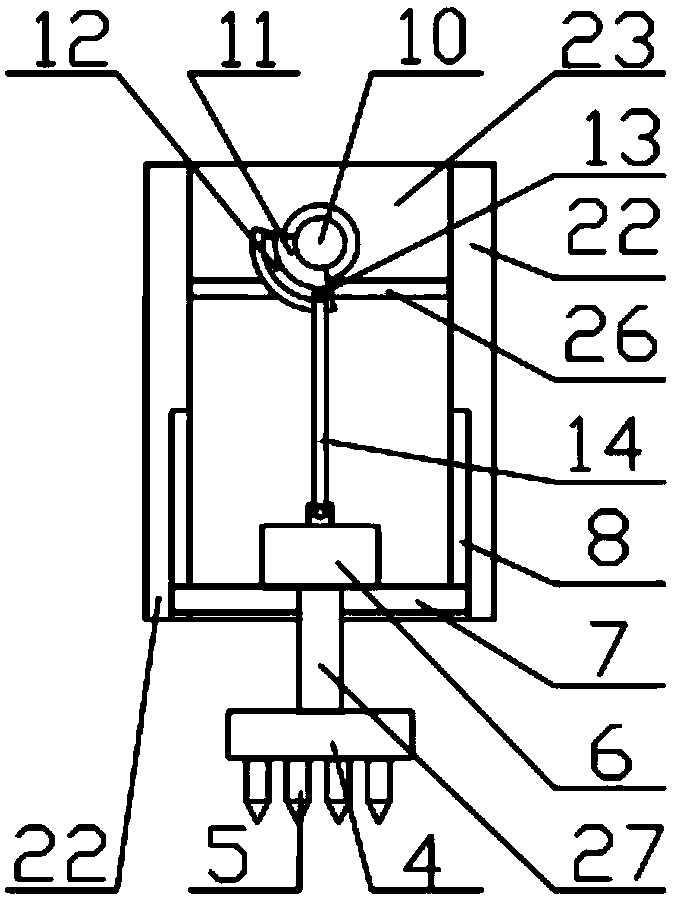

Dead weight type compaction device for road repairing of municipal construction

The invention discloses a dead weight type compaction device for road repairing of municipal construction. The dead weight type compaction device comprises a supporting plate, wherein supporting frames are respectively mounted on two sides of the upper end of the supporting plate; a crossbeam is mounted at the upper end of the supporting frame; a driving motor is mounted at the middle part of theupper end of the crossbeam; a driving shaft is mounted at the lower end of the driving motor; a driving gear is mounted in the middle part of the driving shaft; a rotating gear is meshed with each oftwo ends of the driving gear; a rotating shaft is mounted in the middle part of each rotating gear; a first worm is mounted at the lower end of a left side rotating shaft, and a first worm wheel is meshed with the left end of the first worm; a second worm is mounted at the lower end of a right side rotating shaft, and a second worm wheel is meshed with the right end of the second worm; fixing shafts are respectively mounted in the middle part of the first worm wheel and the middle part of the second worm wheel; a meshing gear is mounted at the middle part of the front end of each fixing shaft;and a lifting rack is meshed with the outer side of each meshing gear. According to the dead weight type compaction device disclosed by the invention, the up-and-down reciprocating movement of a compaction plate is realized, so that the compaction effect to road surfaces is realized by the gravity of the compaction plate, and the compaction requirements for different road surfaces are also met.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

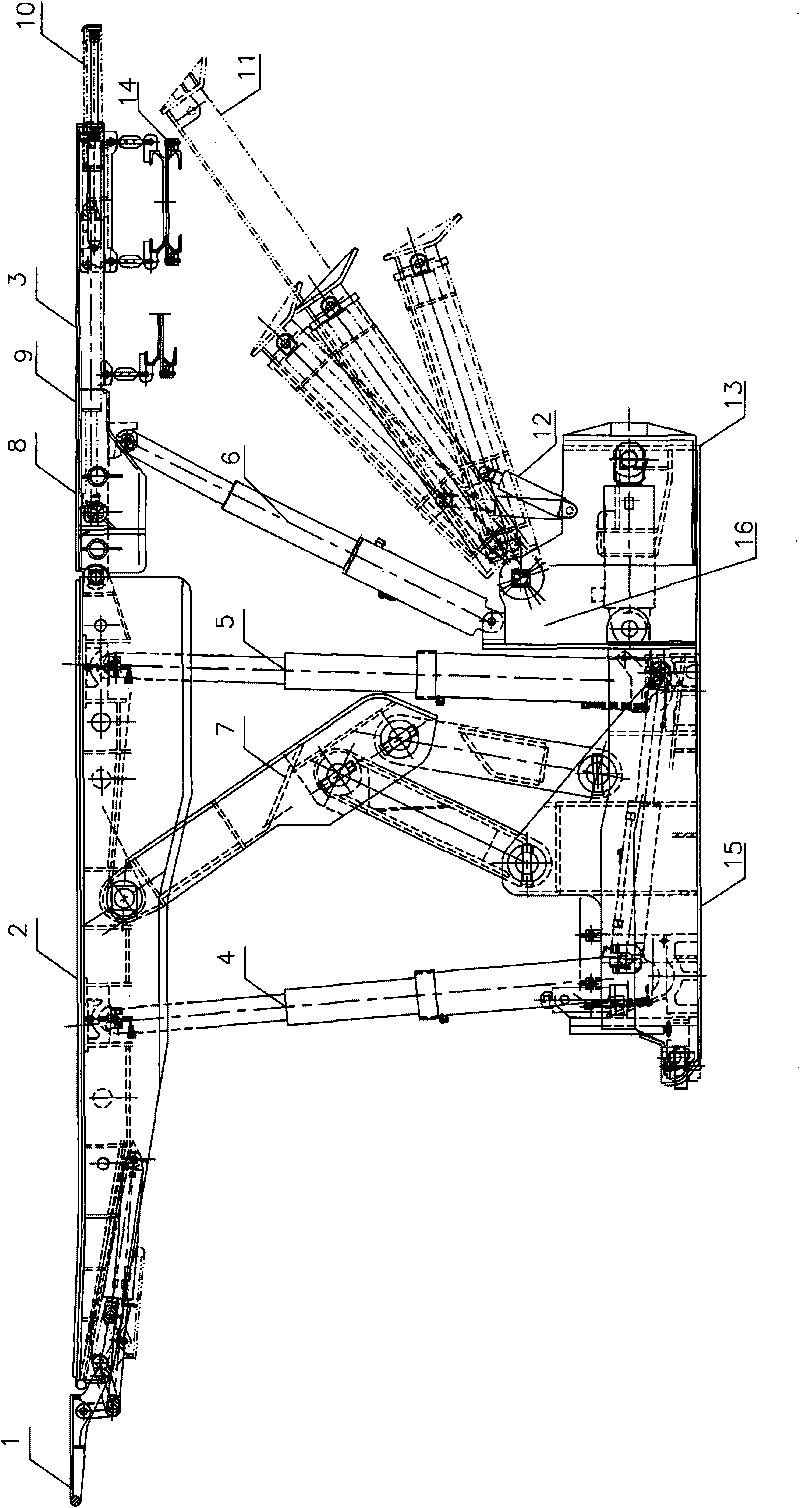

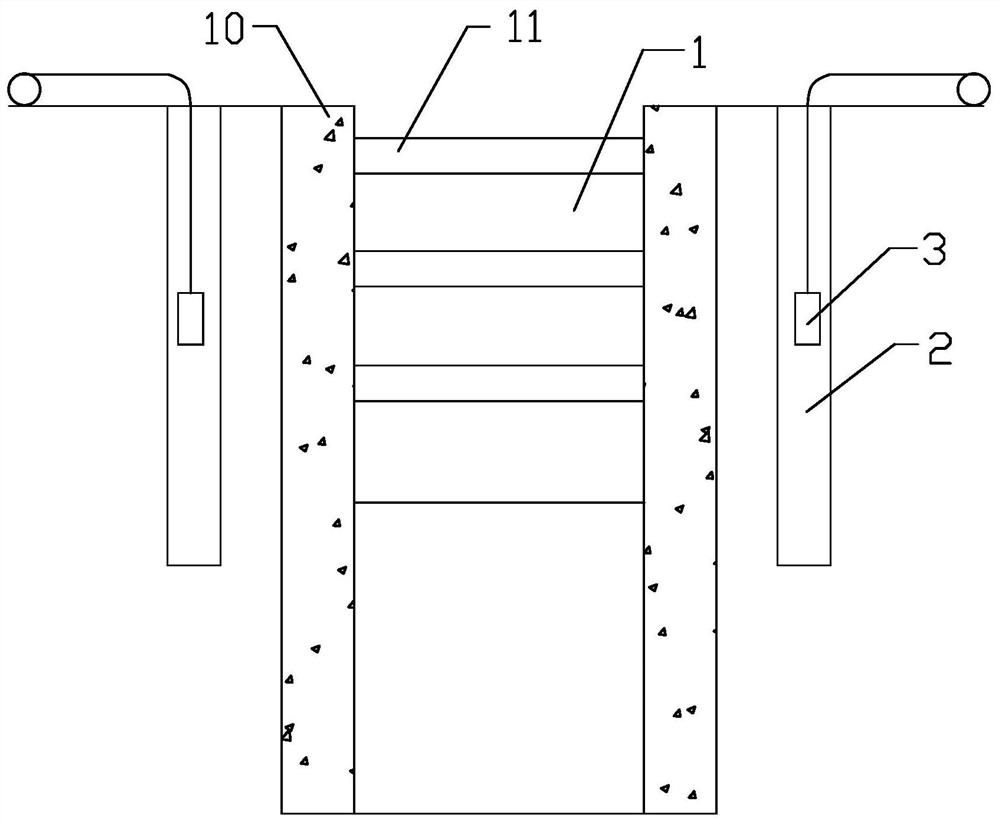

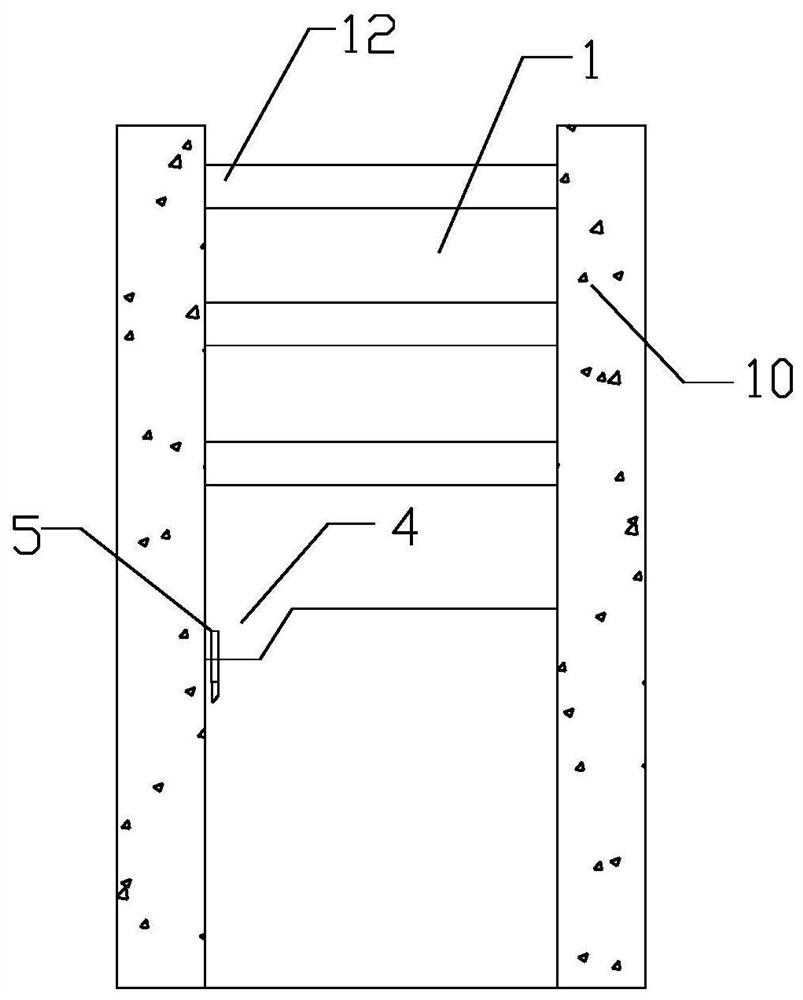

Hexastyle supporting type coal mining and filling hydraulic bracket

InactiveCN101725365ARealize fillingAchieve compactionMaterial fill-upMine roof supportsEngineeringWork space

The invention relates to a hexastyle supporting type coal mining and filling hydraulic bracket which comprises a telescopic girder, a front top girder, a rear top girder, a front upright post, a middle upright post, a rear upright post, a four bar mechanism, a middle upper part compaction mechanism, a height-regulating jack, a lower box type compaction mechanism, a slide way, a pulling jack, a rear-inserting type top protection device, a filling and mining conveyer and a base, wherein the front top girder is supported through the front upright post and the middle upright post and maintains the balance through the four bar mechanism; the rear top girder is mutually hinged with the front top girder and supported through the rear upright post, bears the pressure of a top plate, controls the deflection of the top plate before filling and can overhang the filling and mining conveyer to realize filling solid fillers in a goaf; and the rear top girder is provided with the slide way and can maintain a working space for normal mining of a working surface, realize the full filling of the goaf and meanwhile compact the fillers by clean mining within a high range. The hexastyle supporting type coal mining and filling hydraulic bracket has compact structure, strong supporting force, convenient operation and good filling effect on the goaf and can adapt to the filling and the mining under a complicated geological condition.

Owner:CHINA UNIV OF MINING & TECH

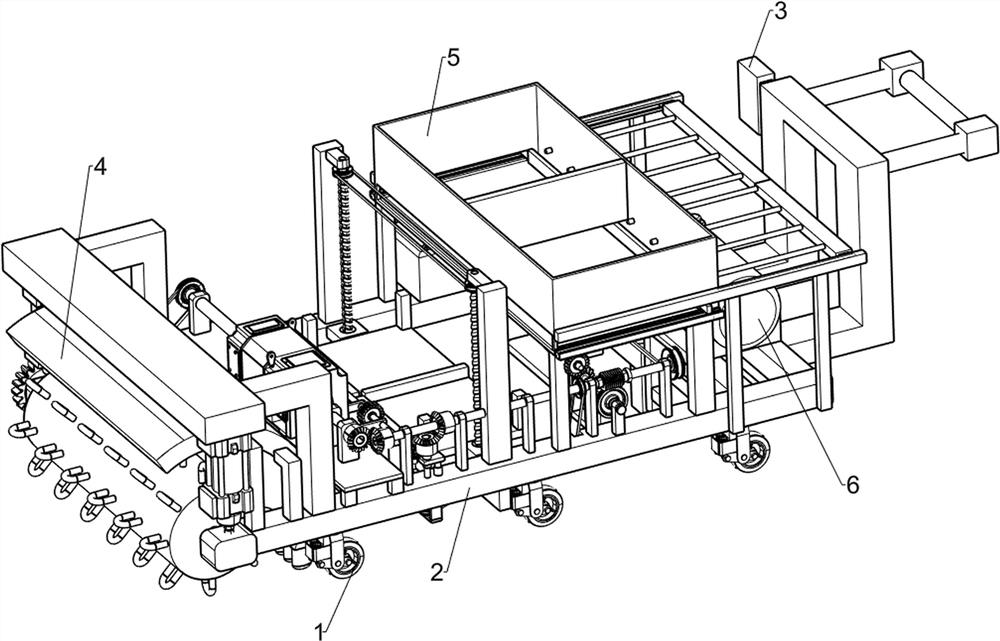

Road repairing device

ActiveCN108842580AVibration crushingGuaranteed to be completely brokenRoads maintainenceElectric machineryRoad surface

The invention discloses a road repairing device, and belongs to the technical field of road repairing. The road repairing device comprises a vehicle body, a breaking and flat ramming mechanism, an asphalt filling mechanism and a compacting roller, wherein the breaking and flat ramming mechanism, the asphalt filling mechanism and the compacting roller are sequentially mounted on the vehicle body from the front end to the rear end in the marching direction of the vehicle body; the breaking and the flat ramming mechanism comprises a flat ramming gravity plate, and a drill bit which is fixed to the lower surface of the flat ramming gravity plate; the upper part of the flat ramming gravity plate is connected to a vibrating motor; a rotating shaft and a sector turntable which is fixed to one side of the rotating plate are arranged right above the vibrating motor; an arc-shaped hole is formed in the sector turntable; a moving rod which vertically passes through the arc-shaped hole is arrangedin the arc-shaped hole; a connecting rod is connected between the moving rod and the vibrating motor; two ends of the connecting rod are correspondingly hinged with the moving rod and the vibrating motor. According to the road repairing device, a broken and old pavement can be hammered and vibrated to realize combined breaking through one mechanism, and the broken pavement can be completely rammed, levelled and compacted; in addition, related acting strength is high; the breaking effect and the flat ramming effect are good.

Owner:ANHUI NORMAL UNIV

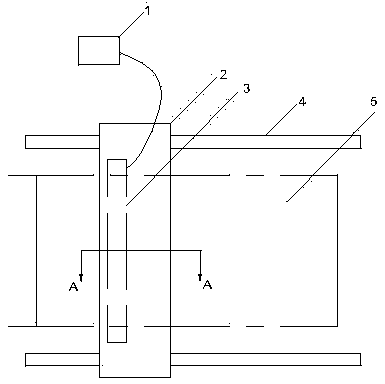

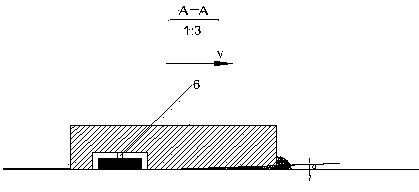

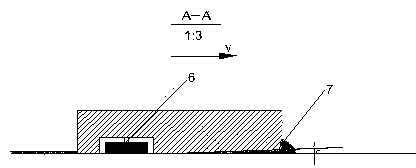

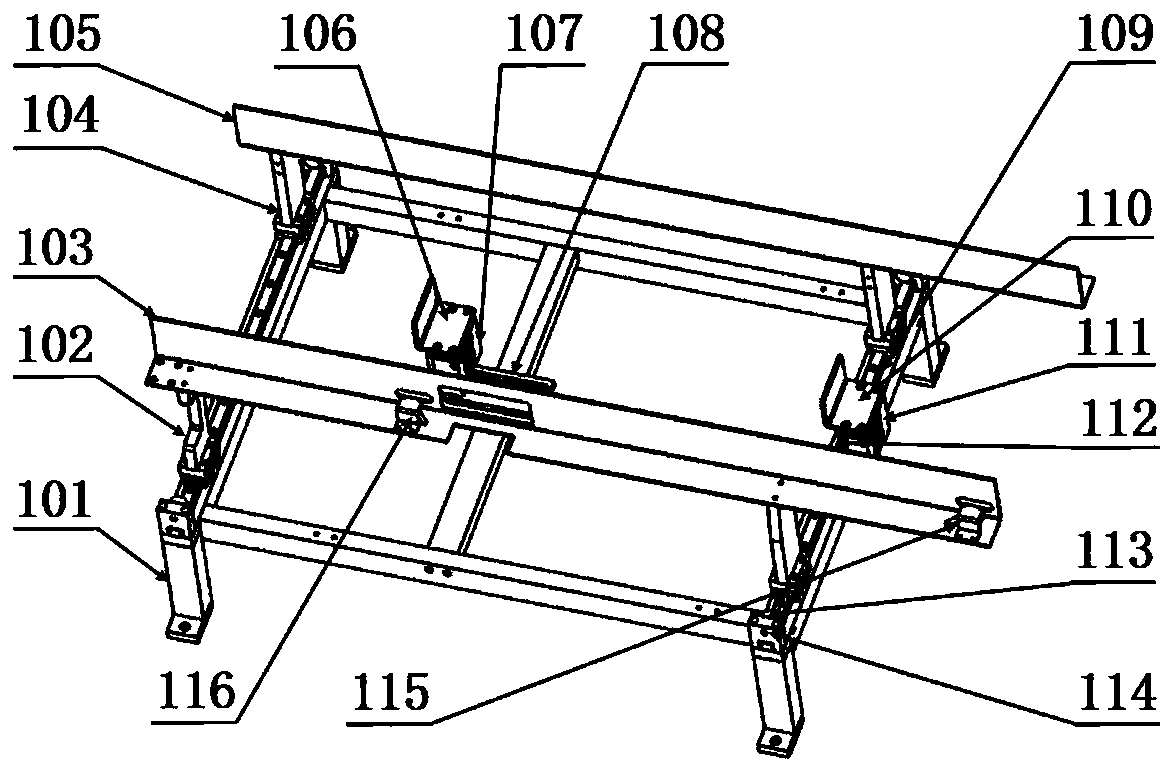

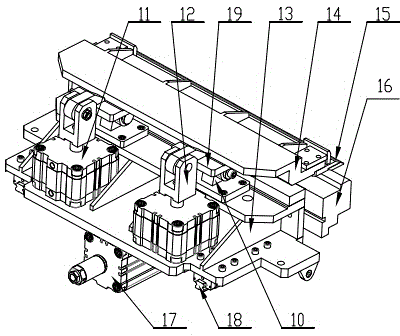

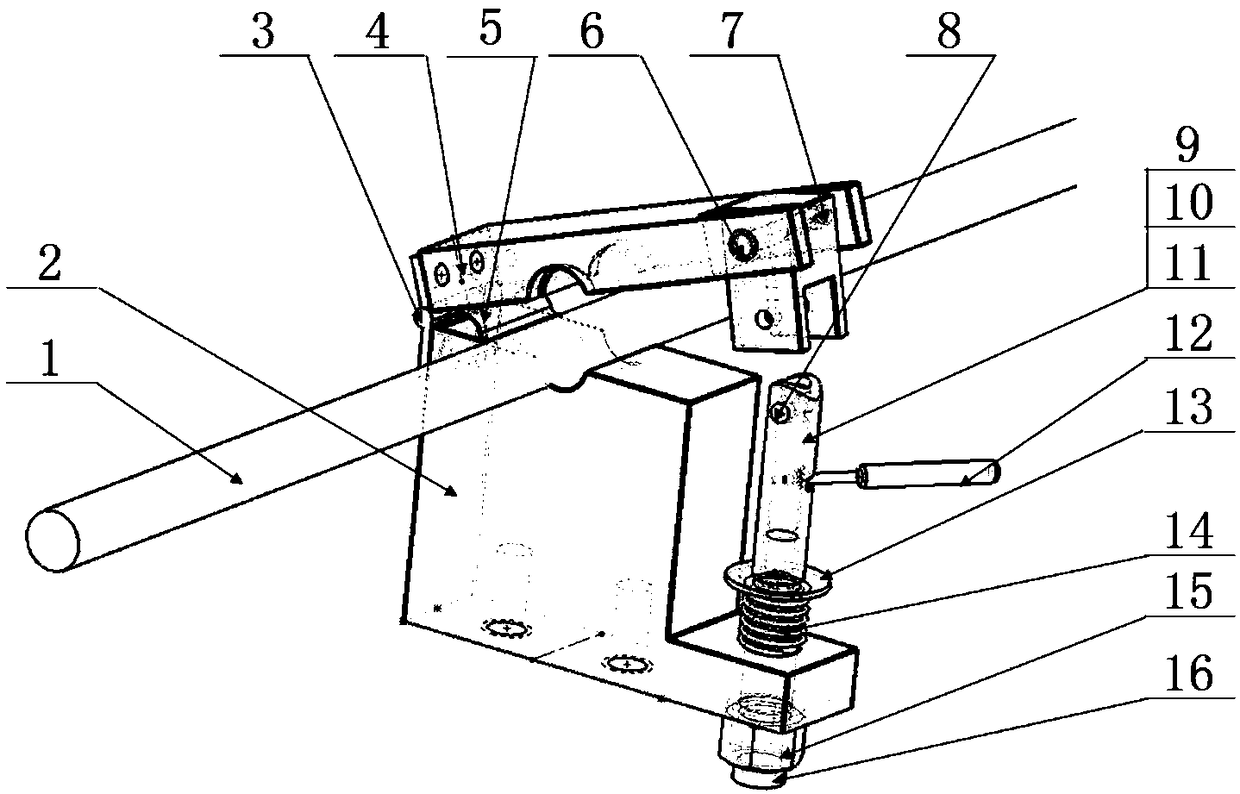

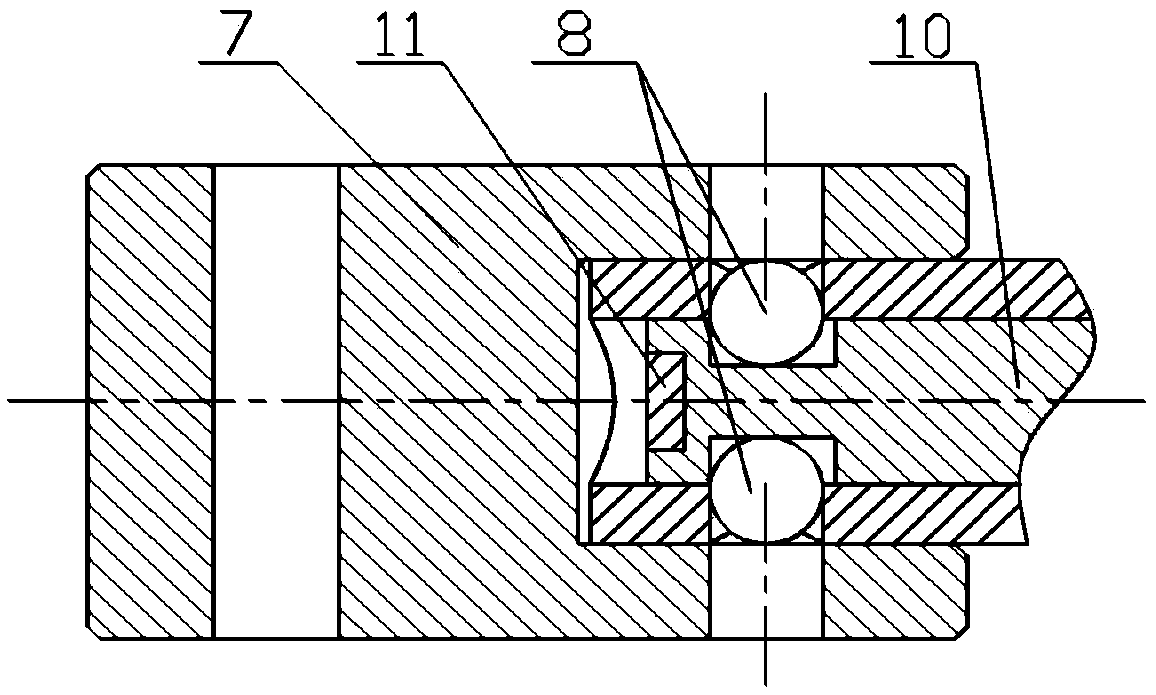

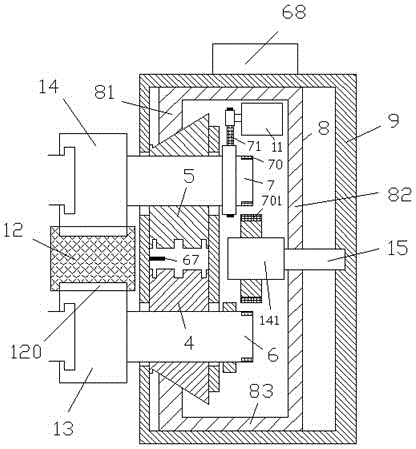

Longitudinal seam welding machine suitable for thin-wall small-diameter suspended single-face welding and double-face forming

ActiveCN104128736AGuaranteed straightnessAvoid positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention relates to welding equipment, in particular to a longitudinal seam welding machine suitable for thin-wall small-diameter suspended single-face welding and double-face forming. The longitudinal seam welding machine comprises a rack. The rack is provided with a work-piece locating device, folding and pressing devices, a central spindle supporting device, a central spindle device, a centering device and a walking gantry welding device. The first folding and pressing device and the second folding and pressing device are located on a sliding rail and connected with a horizontal air cylinder. The central spindle device is located above the locating device. According to the technical scheme, acting force is exerted on a longitudinal seam of a rolling pipe from left and right, under the effect of the misalignment-preventing centering device, seam alignment of a work-piece can be finished without manual adjustment, the straightness of butt seams can be ensured, and the phenomena that positions of the butt seams need to be manually adjusted many times and misalignment is corrected in the past production process can be avoided.

Owner:CHENGDU AIGRE TECH

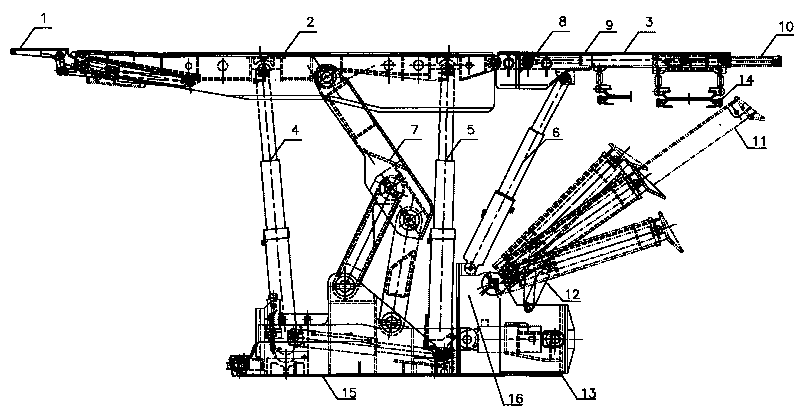

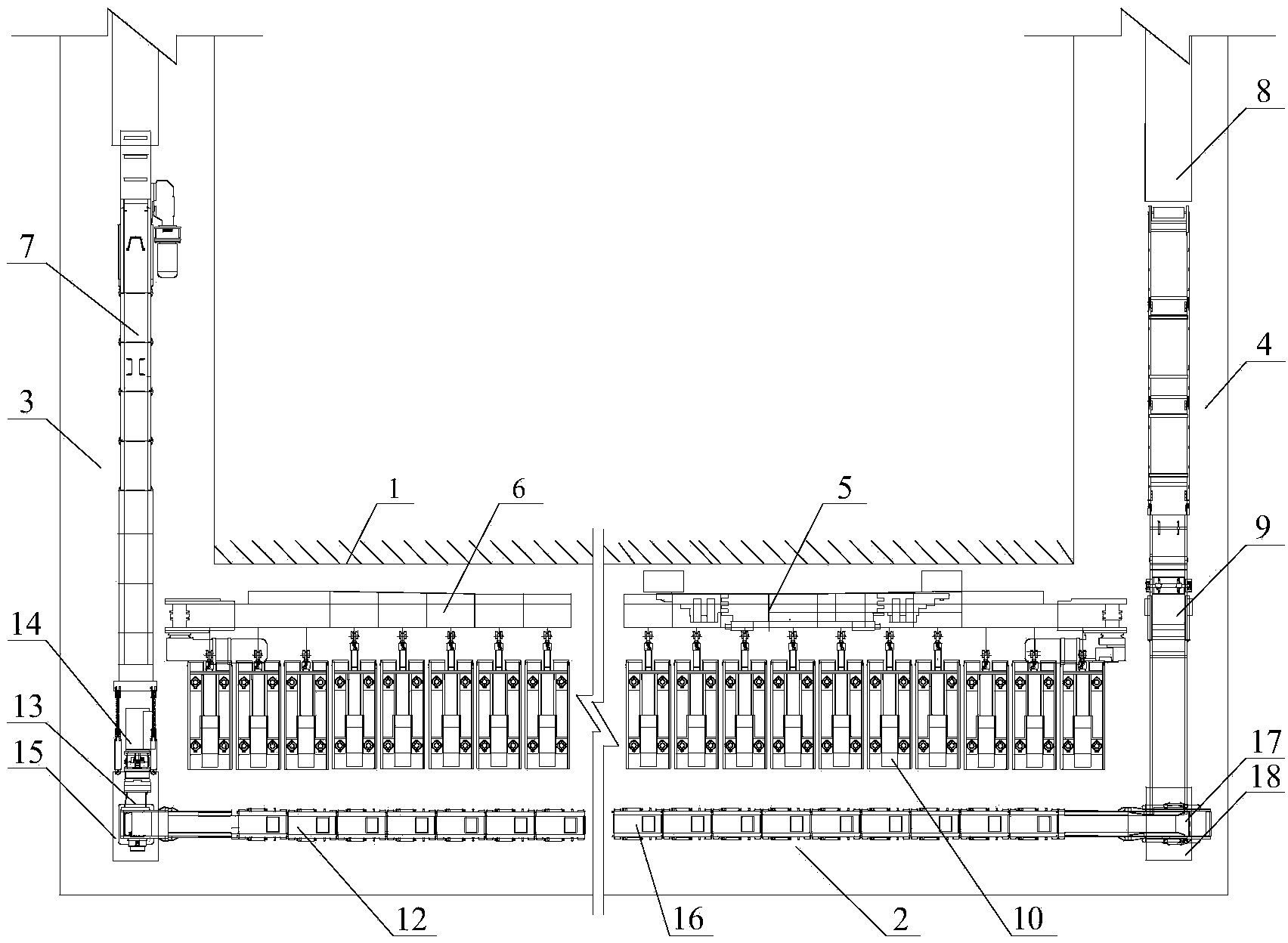

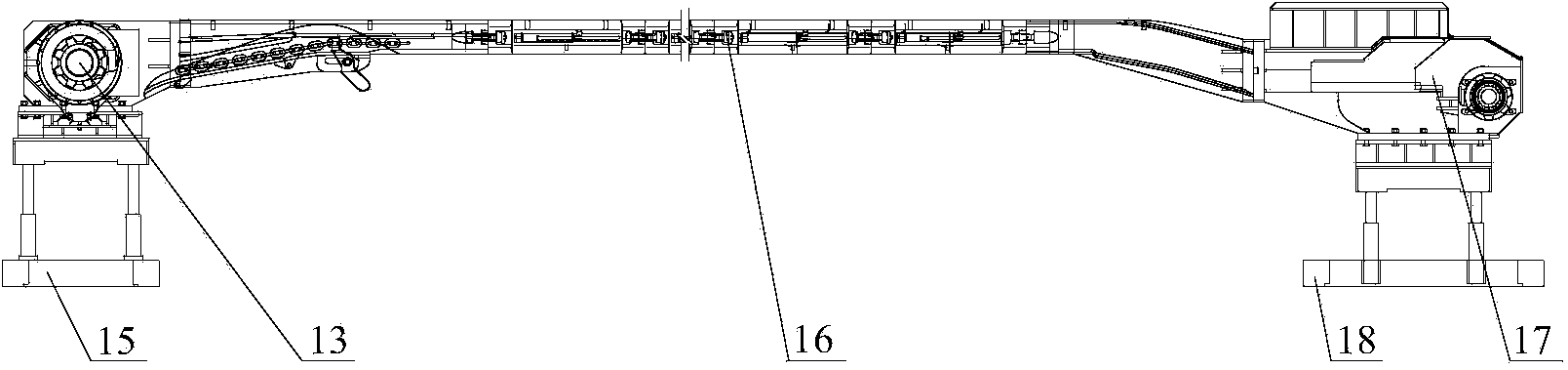

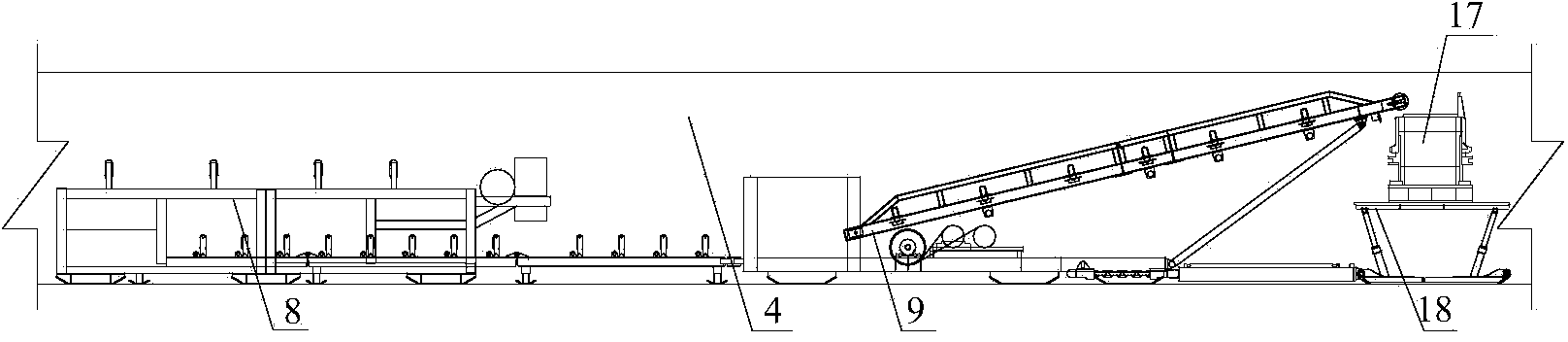

Equipment matching method for solid-filling coal face of coal mine

ActiveCN103939139AEfficient miningImprove resource recoveryMaterial fill-upUnderground transportIntegrated operationsEngineering

The invention provides an equipment matching method for a solid-filling coal face of a coal mine and belongs to coal mining with filling methods. According to the equipment matching method, equipment is composed of a coal cutter, a scraper conveyer, a milling with filling hydraulic support, a coal conveying device, a machine head, a drive motor, a machine head lifting platform, a gangue belt conveyer, a self-moving transfer conveyer, a machine tail, a machine tail lifting platform, a punning mechanism and a conveyer middle section, wherein the coal cutter, the scraper conveyer and the milling with filling hydraulic support are arranged on the coal face; the coal conveying device, the machine head, the drive motor and the machine head lifting platform are arranged in a coal conveying roadway; the gangue belt conveyer, the self-moving transfer conveyer, the machine tail and the machine tail lifting platform are arranged in a gangue conveying roadway; the punning mechanism and the conveyer middle section are arranged in the milling with filling coal face. The conveyer middle section and the punning mechanism are arranged on the rear portion and the bottom of the mining with filling hydraulic support respectively. The self-moving transfer conveyer is in lap joint with the gangue belt conveyer and the machine tail. The machine tail is arranged on the machine tail lifting platform. The machine head and the drive motor are arranged on the machine head lifting platform. A delayed shoring method is used for achieving management of a coal face transition section. By the adoption of the equipment matching method, integrated operation of filling and mining of a comprehensively mechanical solid filling work face is achieved, and the recovery rate of a resource exhaustion type mine is greatly increased.

Owner:CHINA UNIV OF MINING & TECH

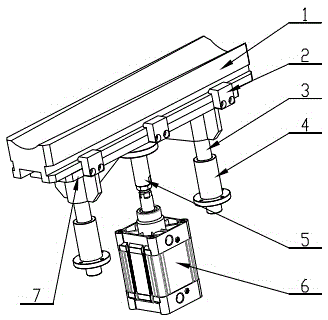

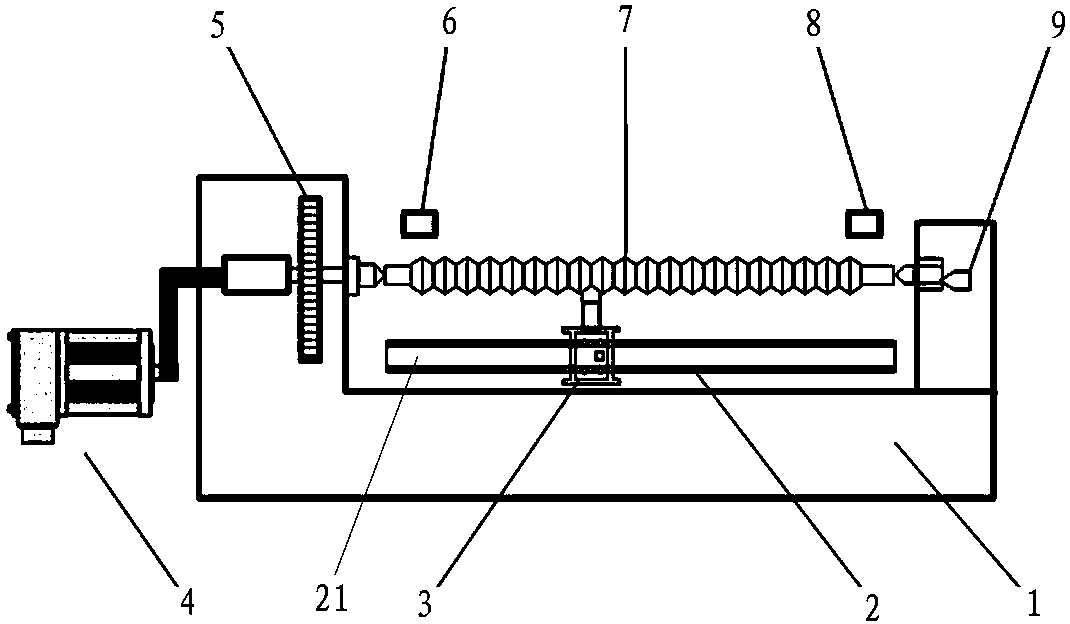

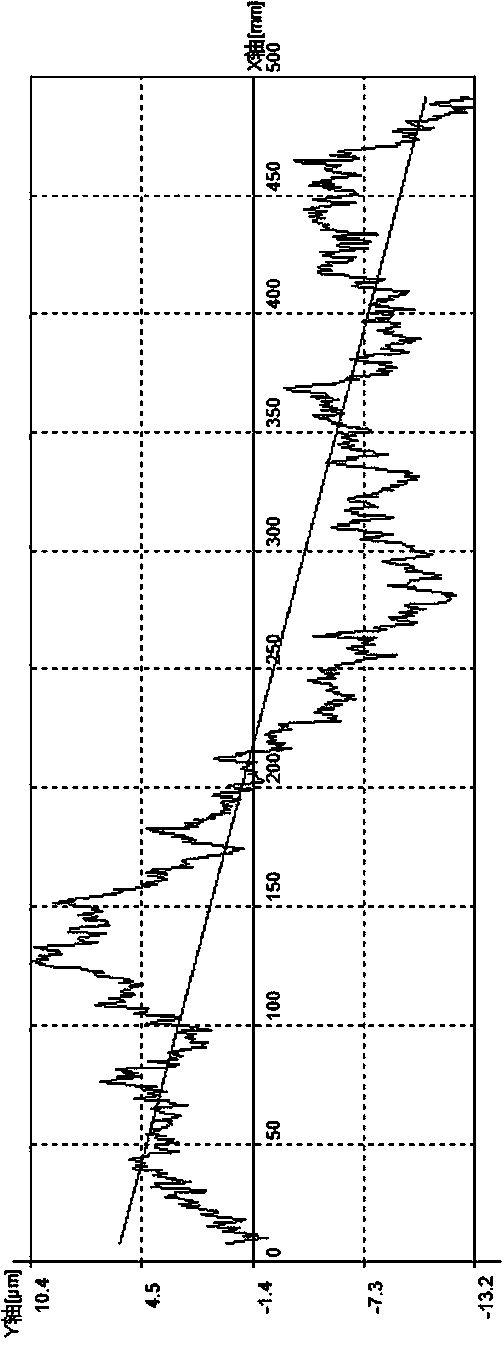

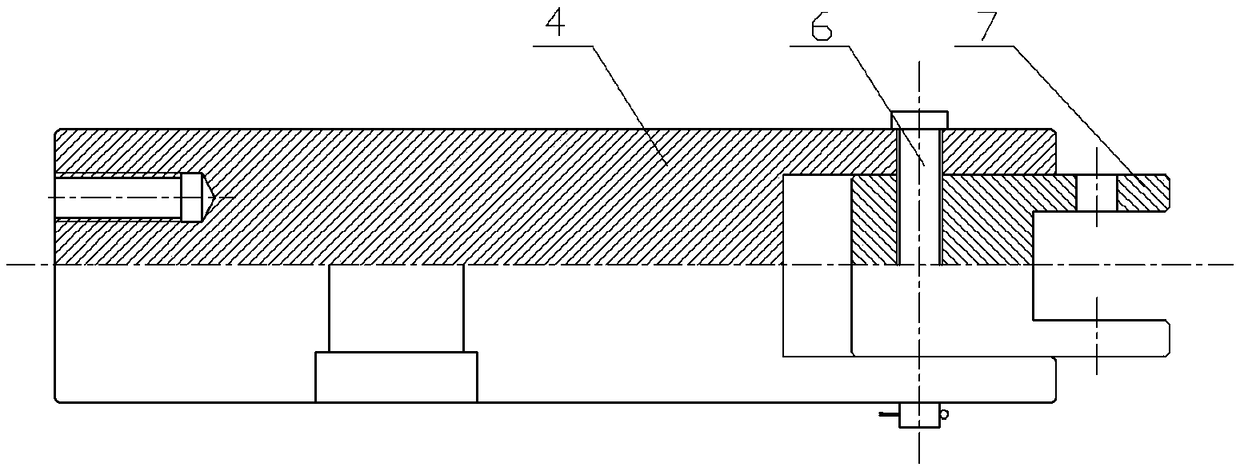

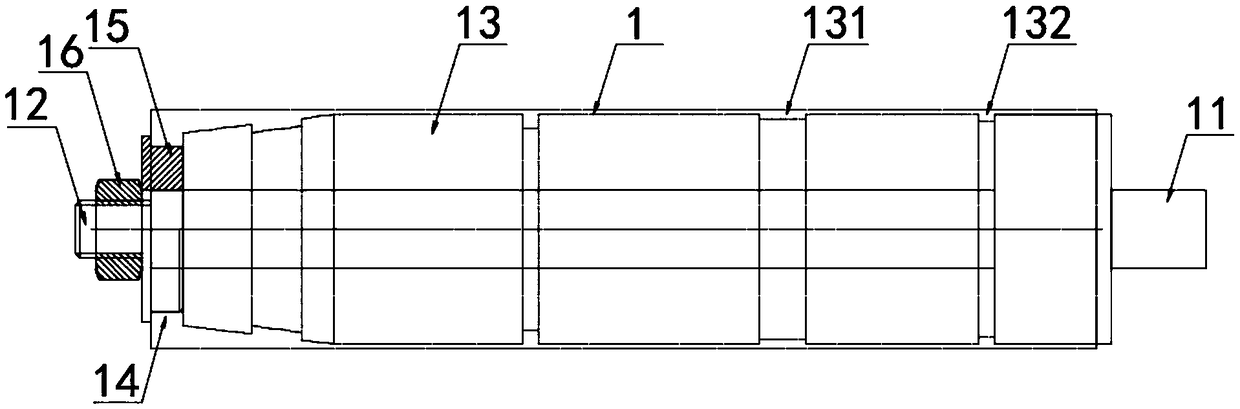

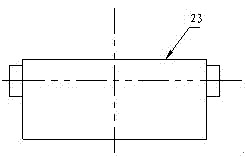

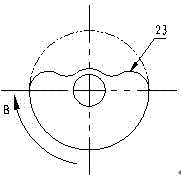

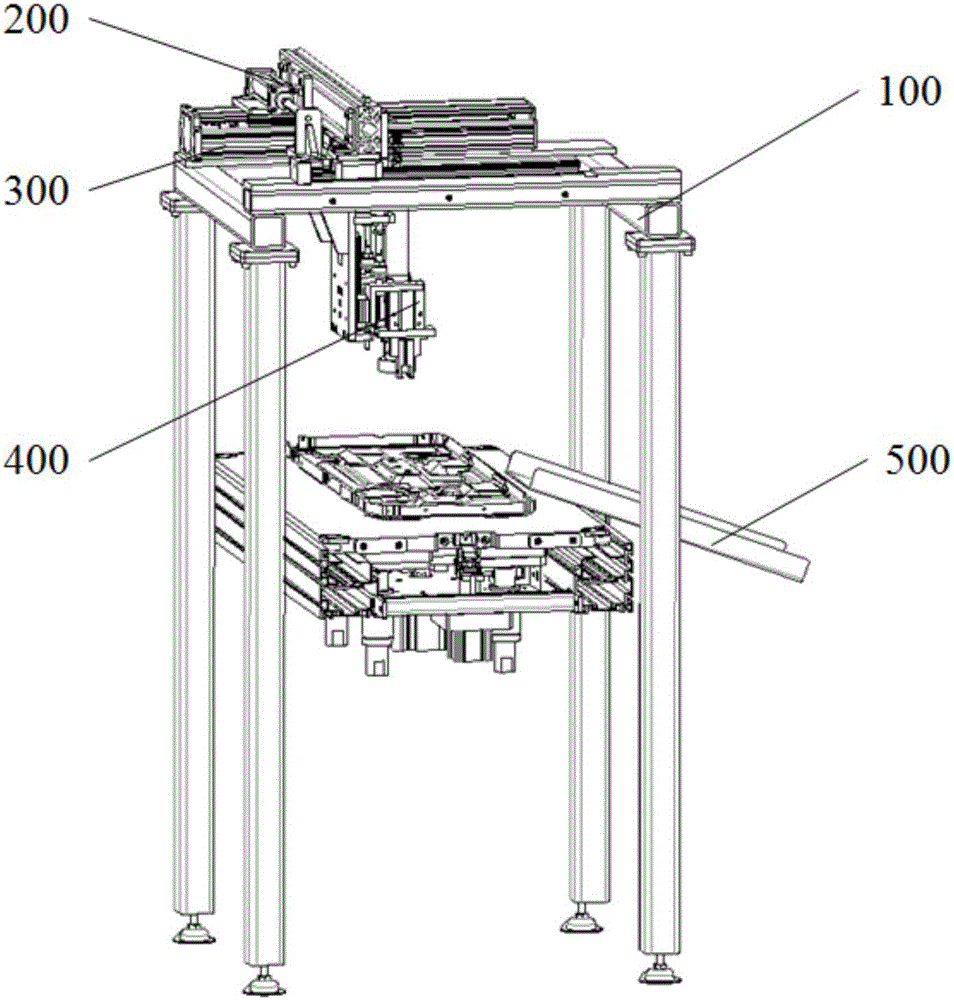

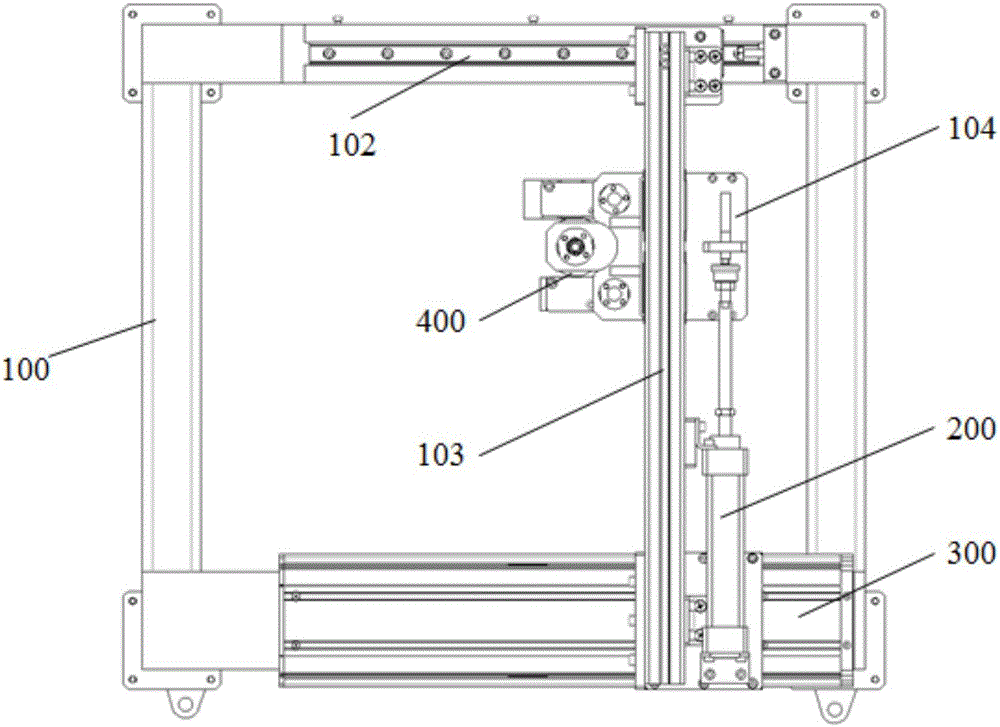

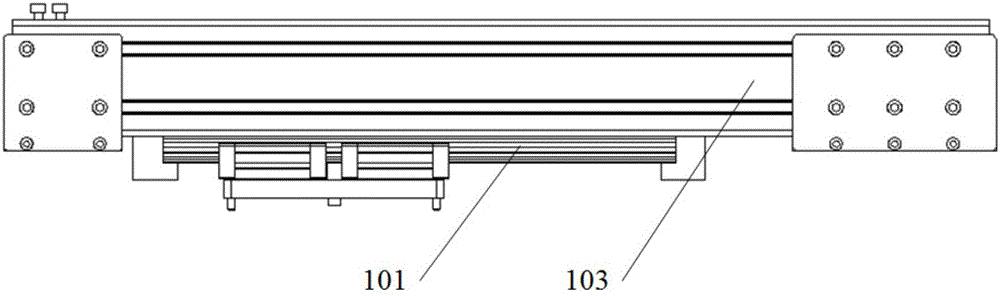

Lead screw lead accuracy detection device and detection head device thereof

InactiveCN103411543AImprove inspection accuracyFast and efficient real-time detectionUsing optical meansMovement controlCollections data

The invention relates to the field of lead screw detection, in particular to a lead screw lead accuracy detection device. The lead screw lead accuracy detection device comprises a mechanical portion, a movement control portion, a data collection portion and a computer. The mechanical portion comprises an instrument main frame, a detection rail, a linear grating ruler, a circular grating pair and a detection head device. The movement control portion comprises a motor, a motor driver and a movement control card. The data collection portion comprises a data collection card and a signal transferring board. Detection software is arranged on the computer, the computer is connected with the movement control card and the data collection card through a data bus, and the computer controls the motor in real time, conducts data collection of grating signals of the circular grating pair and grating signals of the linear grating ruler in real time, and displays a result and an error curve after conducting processing through the algorithm in the detection software. The lead screw lead accuracy detection device is used for detecting the accuracy of the lead of a lead screw.

Owner:XIAMEN UNIV

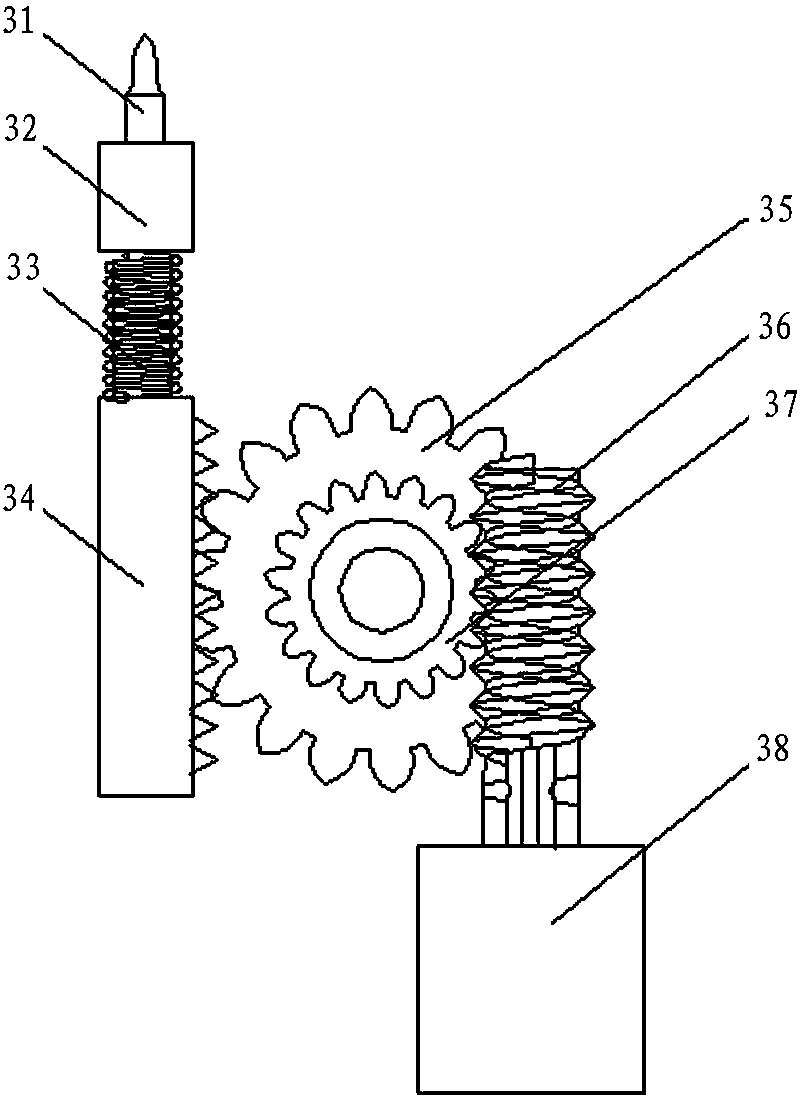

Split-type hopkinson torsion bar energy storing and releasing device as well as operation method thereof

ActiveCN108645696AGuaranteed repeatabilityPracticalMaterial strength using steady torsional forcesEngineeringEnergy analysis

The invention discloses a split-type hopkinson torsion bar energy storing and releasing device as well as an operation method thereof, which can realize impact torsion energy storing and releasing bya simple mechanical structure. The apparatus comprises a hopkinson incident bar, a clamping mechanism, a releasing mechanism, and a guiding mechanism. The operating method is characterized in that theHopkinson incident bar is clamped by the clamping mechanism and guiding mechanism, the torque storage is realized, by designing the releasing device, the stored torsion energy is subjected to instantrelease, so that the shock loading effect can be simulated, and the impact experiment simulation condition is provided; and at the same time, the loaded shock loading is determined by torsion turns numbers, which is conveniently controlled; the split-type hopkinson torsion bar energy storing and releasing device is suitable for different loading devices, and is repeatedly usable without materialconsumption. The device has the advantages of simple structure, low cost, easy control, and convenient operation.

Owner:XI AN JIAOTONG UNIV

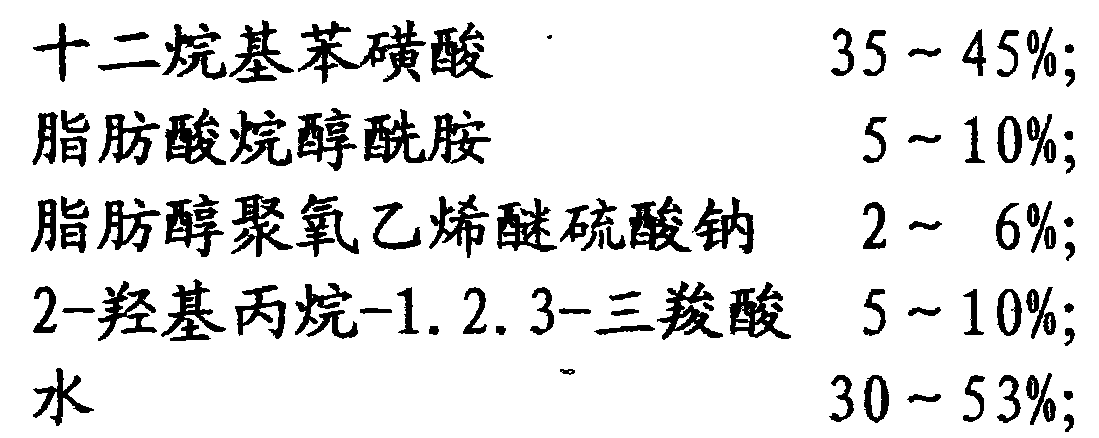

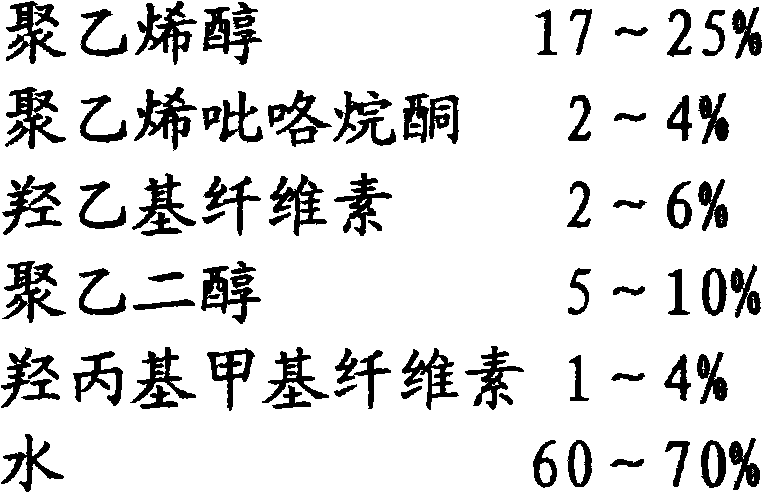

Swelling soil modifier

InactiveCN102079980AUse foreverHigh densityBuilding constructionsOrganic fertilisersRational useSwelling ratio

The invention relates to a material for regulating and improving the soil structure, soil compactness, and soil chemical properties and physical properties of a swelling soil roadbed. The technical scheme is that: a swelling soil stabilizer comprising a main component of dodecylbenzene sulfonic acid and a swelling soil firming agent comprising a main component of polyvinyl alcohol are combined to improve the chemical and physical properties of swelling soil. The swelling soil stabilizer regulates the components and molecular structure of the swelling soil so as to improve the structure, compactness and expansion and shrinkage performance of the swelling soil, and recombine the structure of the swelling soil; the firming agent is used to firm swelling-shrinking soil, reduce the swelling ratio, improve bearing capacity and reduce construction cost so as to reasonably use human, financial and material resources, and the aim that civil engineering including road engineering is durable is fulfilled; and after being rolled, the soil can be compressed to achieve high compactness, reduce an osmotic coefficient and improve soil consolidation capacity, so that the damage of water to the roadbed is reduced and the frost boiling phenomenon of the roadbed is effectively prevented.

Owner:钟维安 +2

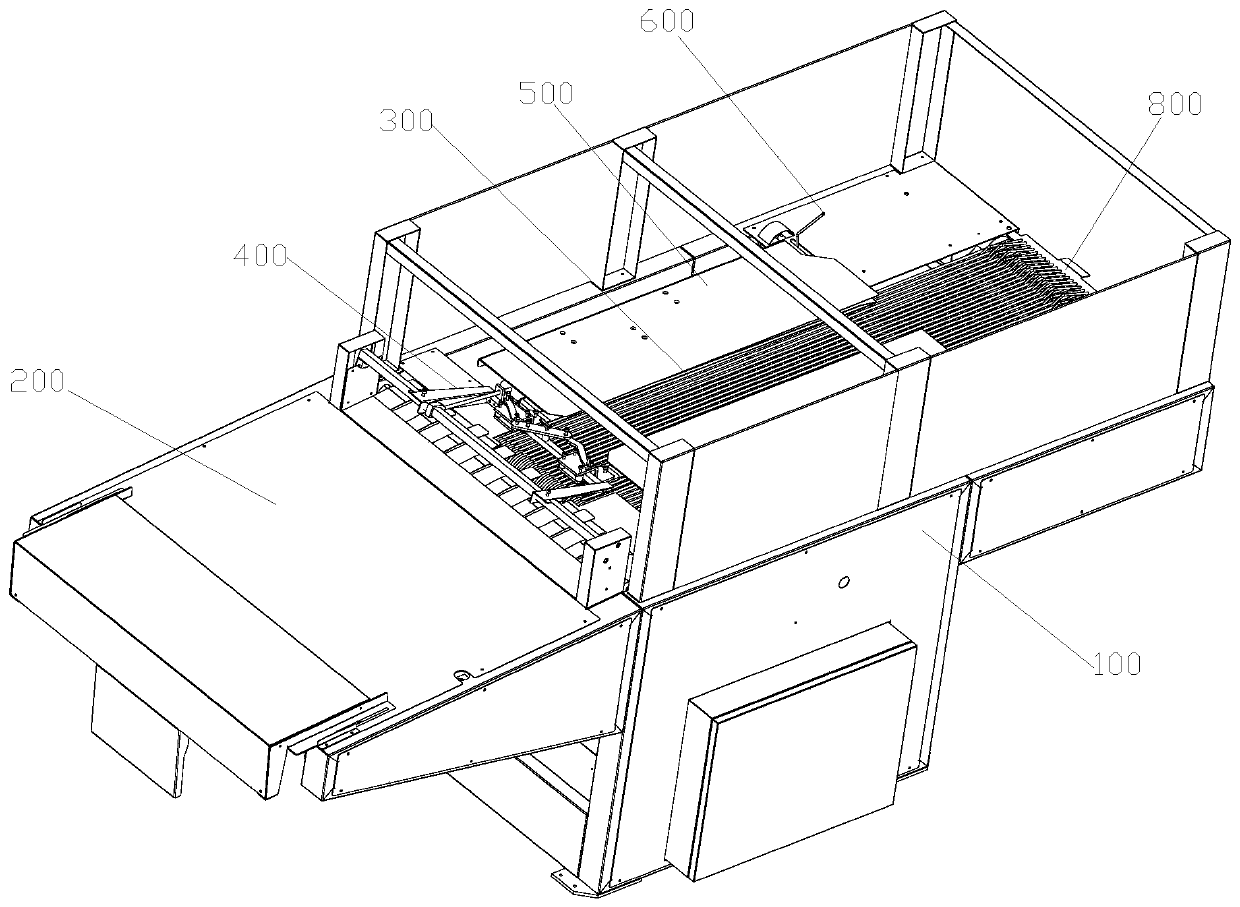

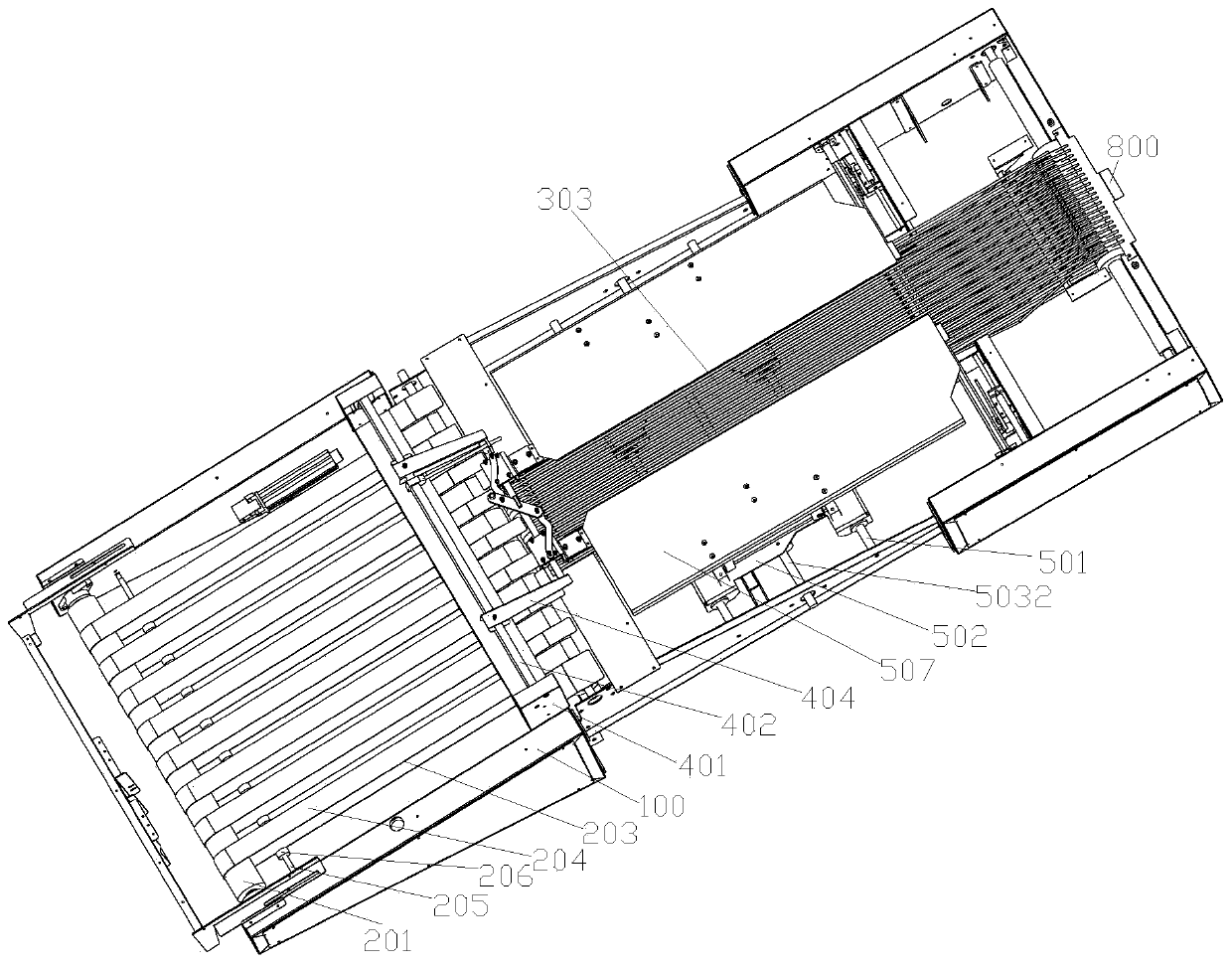

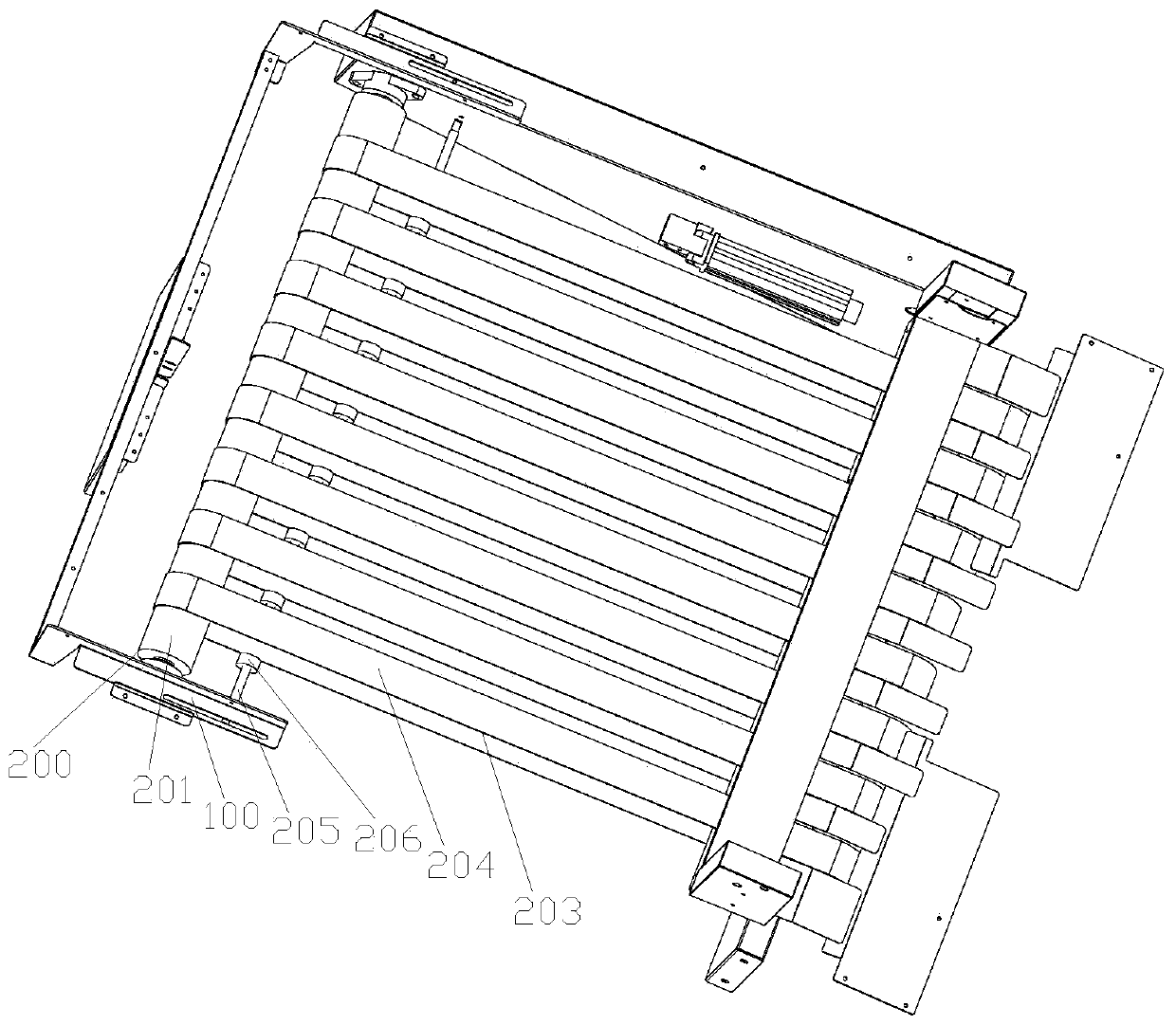

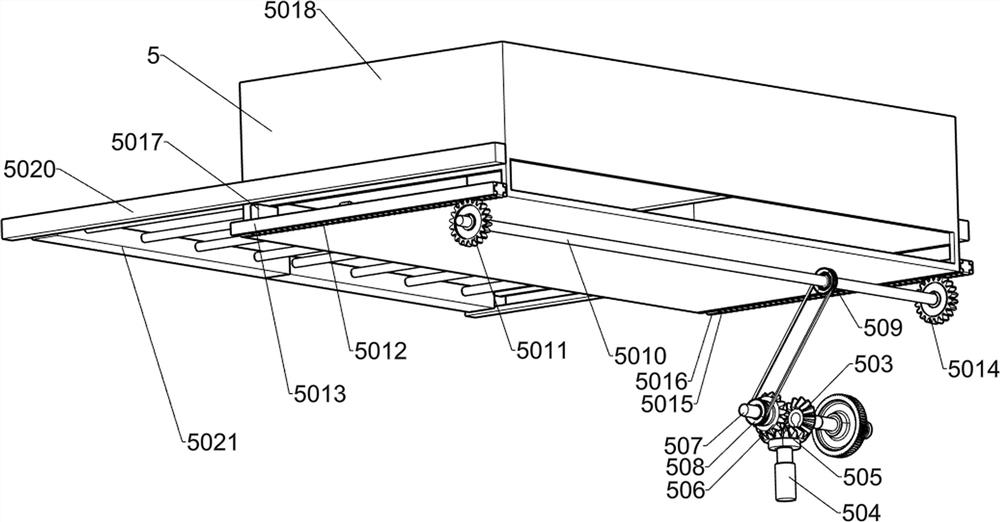

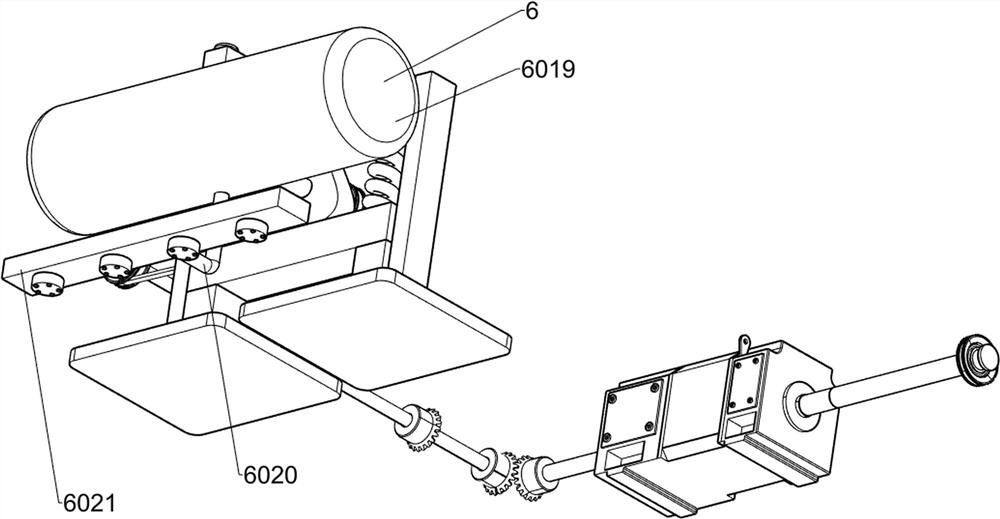

Full-automatic clothes folding machine

InactiveCN110589136AAchieve horizontal foldAchieving Vertical FoldingConveyorsFolding thin materialsEngineeringAutomation

The invention relates to the technical field of clothes packaging, and specifically discloses a full-automatic clothes folding machine. The full-automatic clothes folding machine comprises a machine frame, wherein a first conveying mechanism, a second conveying mechanism, a cloth pressing mechanism, a cloth folding mechanism, a positioning mechanism, a cloth turning mechanism and an output sectionare arranged on the machine frame, the cloth pressing mechanism is positioned above the second conveying mechanism, the position of the cloth folding mechanism on the machine frame corresponds to theposition of the cloth pressing mechanism, the positioning mechanism is located on the machine frame at the position where the clothes are away from the cloth folding mechanism, the cloth turning mechanism is at the position where the machine frame corresponds to the positioning mechanism, and the output section is located at the position where the machine frame is located at the output end of thesecond conveying mechanism. The full-automatic clothes folding machine has the characteristics of no deviation of a conveying strip, good conveying effect, convenient adjustment of the folding width,better adjustment precision, better folding flatness, better folding consistency, better appearance, higher degree of automation, higher production efficiency, low labor intensity and ability of adapting to large-yield demand.

Owner:浙江雅力士自动化设备科技有限公司

Automatic clothing stacking equipment

ActiveCN110451039ARealize automatic finishing and processingAchieve compactionPackagingBiochemical engineering

The invention discloses automatic clothing stacking equipment, and belongs to the field of clothing production and finishing processing. A laminating translation mechanism, a clamping and clothes pulling mechanism and a clothes placing and conveying mechanism are sequentially and fixedly arranged on the upper side of a clothes stacking support in the horizontal direction, a clothes clamping pressing plate is arranged on the upper side of a clothes clamping bearing plate, a main folding plate is arranged on one side of the middle of the clothes stacking frame, side folding plates are symmetrically arranged on the two sides of the clothes stacking frame correspondingly, a clothes placing plate is horizontally arranged in the clothes stacking frame, the clothes placing plate is arranged on atranslation guide rod in a sliding mode, a flattening ring tube is arranged on an arrangement support on the upper side of the clothes stacking frame, and a material falling mechanism is horizontallyarranged on a clothes conveying support on the upper side of a clothes conveying belt. According to the automatic clothing stacking equipment, the structural design is reasonable, the clothes can be stably and efficiently folded and processed, the clothes which can be folded and processed can be conveniently and smoothly placed into a packaging box in a convenient and smooth manner, automatic finishing processing of the clothes is realized, and the requirements of production and use are met.

Owner:亘美集团有限公司

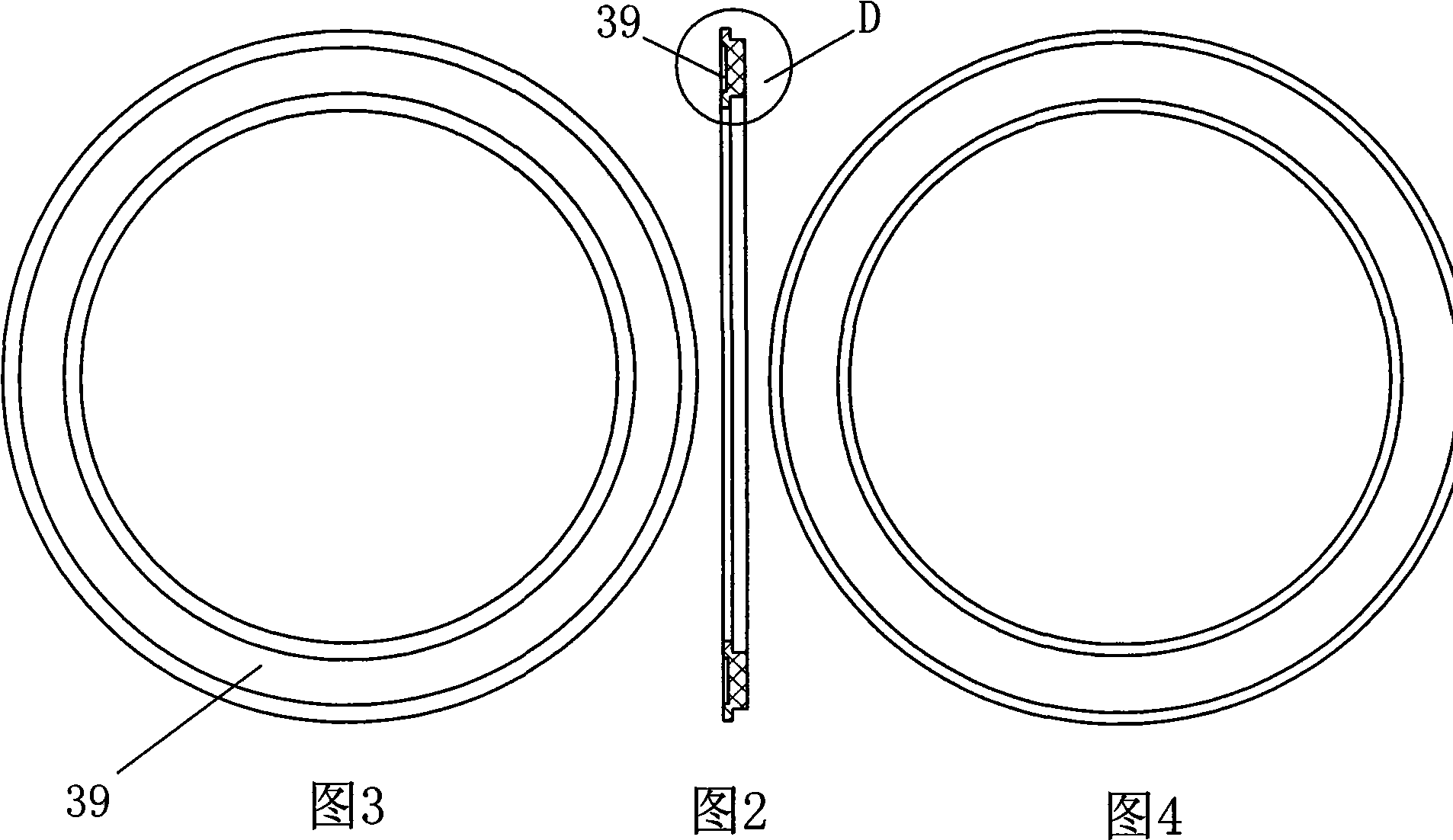

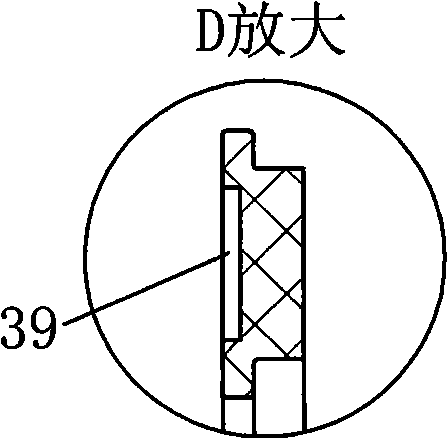

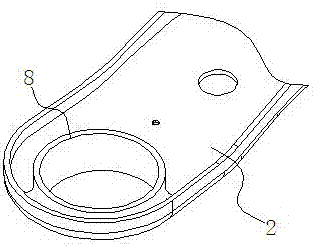

Thin-wall shell processing method

ActiveCN109396766ARestricted degrees of freedomGuarantee quality requirementsWork clamping meansPositioning apparatusEngineeringThermal treatment

The invention discloses a thin-wall shell processing method which comprises a tool clamp, wherein the tool clamp comprises a mandrel; one end of the mandrel is equipped with a mounting column; the outer part of the mandrel is fixedly equipped with an outer ring body in a sleeving mode; a wide ring-shaped slot and a narrow ring-shaped slot are formed in the outer ring body; a step is arranged between one end of the outer ring-shaped body and the mandrel; an auxiliary pressure plate is arranged on the outer part of the step in the sleeving mode; one side of the auxiliary pressure plate is equipped with a nut; and the nut is in threaded connection with the mounting column. The thin-wall shell processing method comprises the following specific steps: step I, outer wall rough turning; step II,high-temperature tempering; step III, left end surface turning; step IV, right end surface turning; step V, clamp mounting; step VI, outer wall fine turning; and step VII, appearance processing. The thin-wall shell processing method performs processing through a high-efficiency machine tool, and a thermal-treatment tempering distressing process is added to release part processing inner stress; andthe necessity of designing a special clamp is combined, so that processing deformation is prevented, and part processing quality requirements are guaranteed.

Owner:河南红宇精密机械有限公司

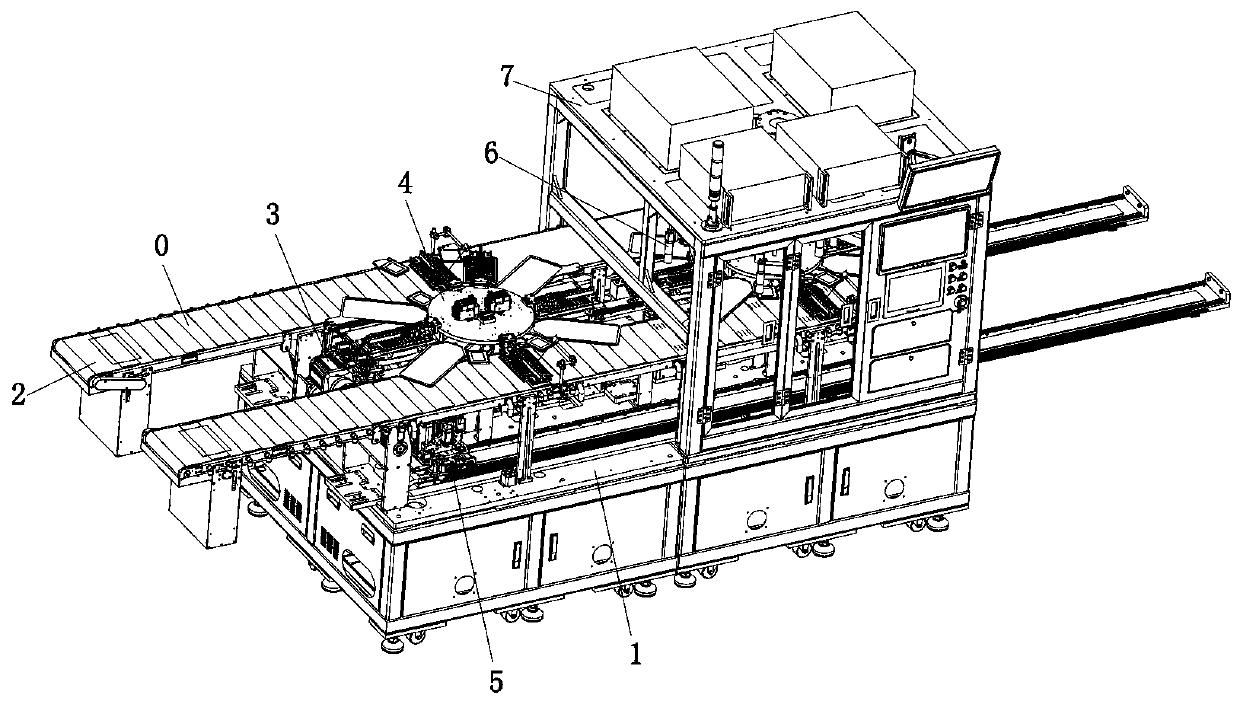

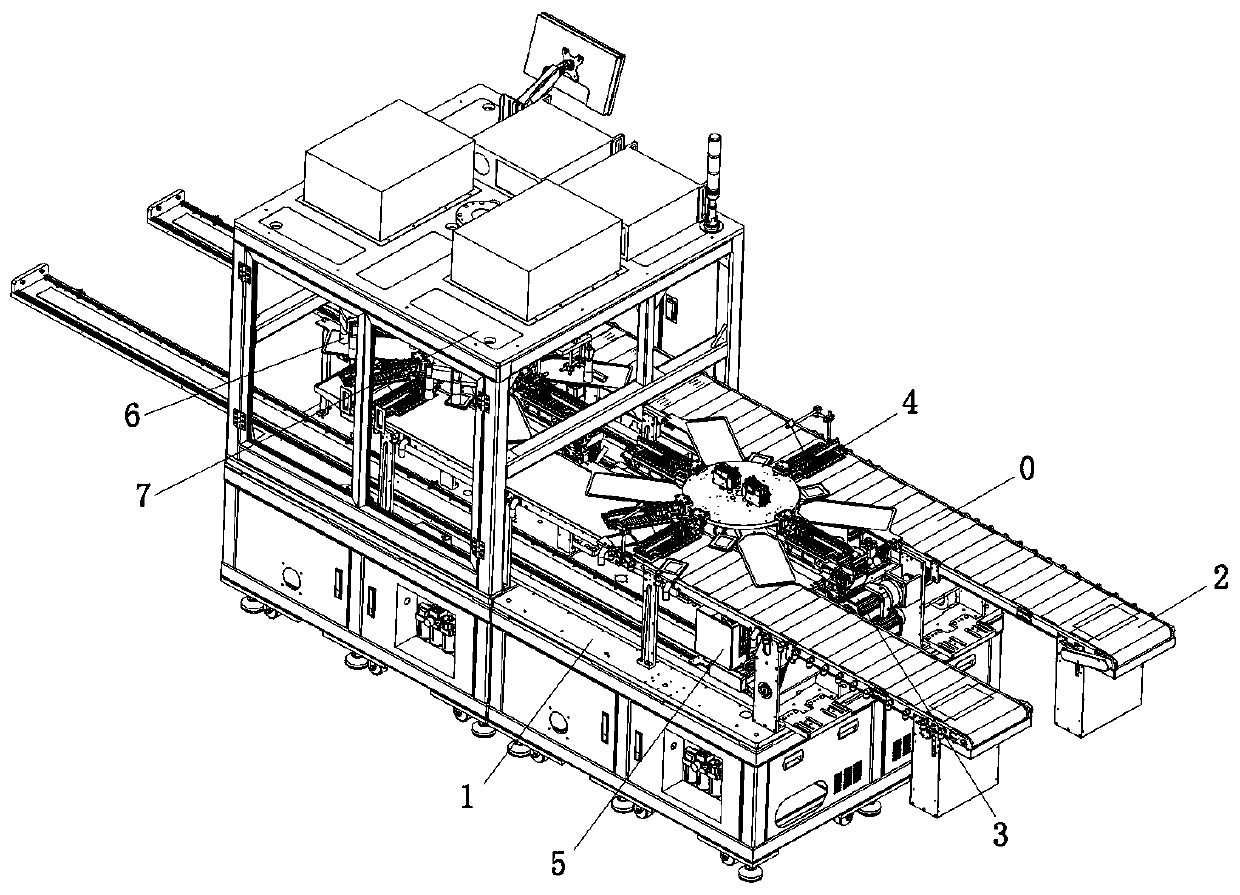

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

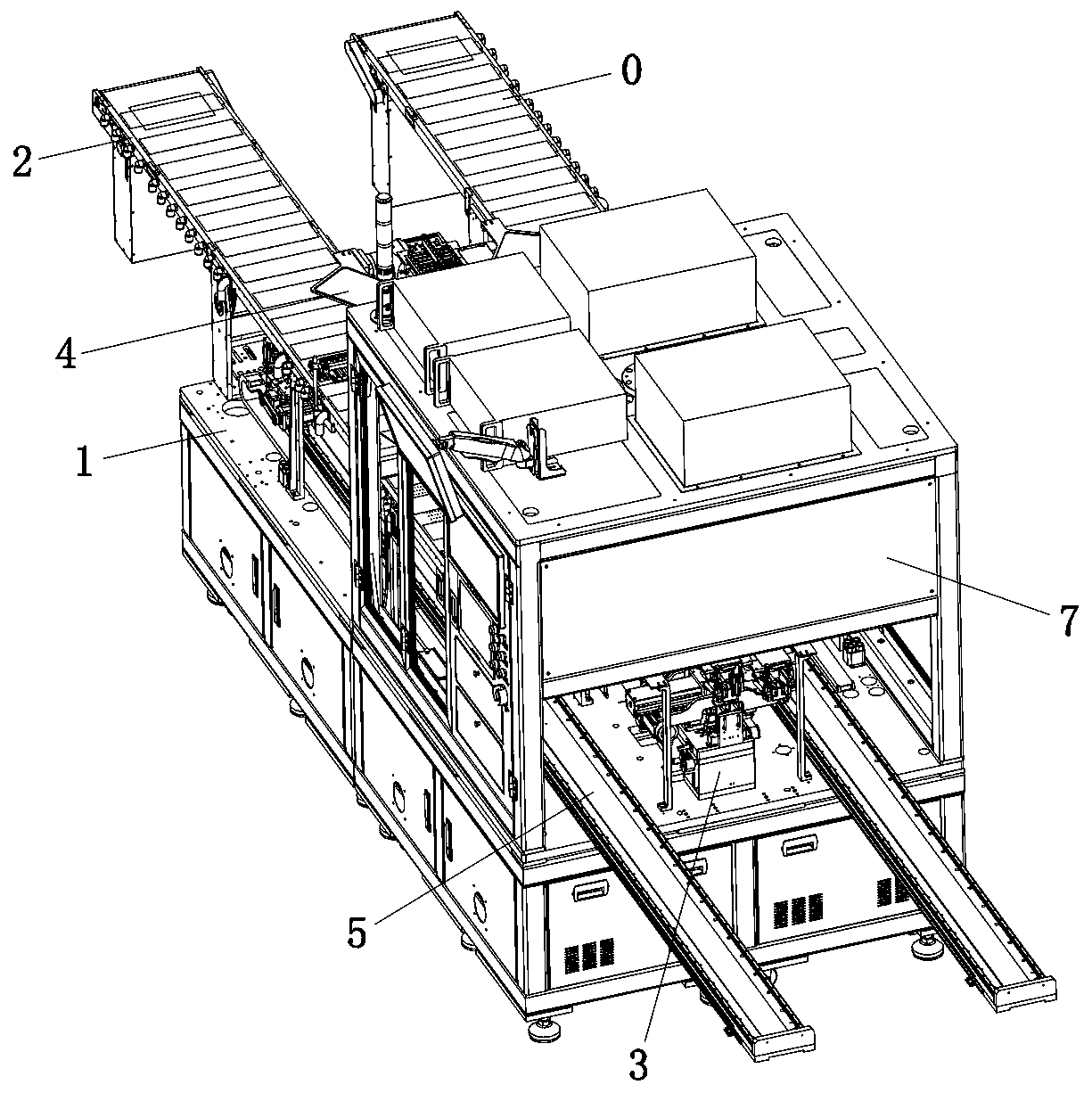

Welding press-fit mold

The invention discloses a welding press-fit mold, and relates to the technical field of plastic welding. The welding press-fit mold comprises an upper mold and a lower mold; the upper mold includes an upper mold base; a fixed plate is fixedly connected under the upper mold base; at least two ultrasonic welding heads are uniformly and fixedly connected under the fixed plate and are used for connecting a first plastic part and a second plastic part in a welding manner; an upper pressing plate is connected below the upper mold base through elastic pieces, and is provided with through holes through which the ultrasonic welding heads can penetrate; two limiting bars are symmetrically arranged on two sides of the upper pressing plate; the lower mold includes a lower mold base and a lower template fixed above the lower mold base; and limiting grooves matched with the limiting bars are formed in two sides of the top of the lower template. According to the welding press-fit mold, accurate positioning and firm pressing are achieved, and the problem that plastic parts are easily misplaced during welding is effectively avoided; and meanwhile, the at least two ultrasonic welding heads are adopted to uniformly contact with the plastic parts, so that the multi-point welding of the plastic parts is realized, the production procedures are greatly simplified, and the working efficiency is improved.

Owner:SUZHOU ANTONGLIN AUTOMOBILE INNER DECORATION CO LTD

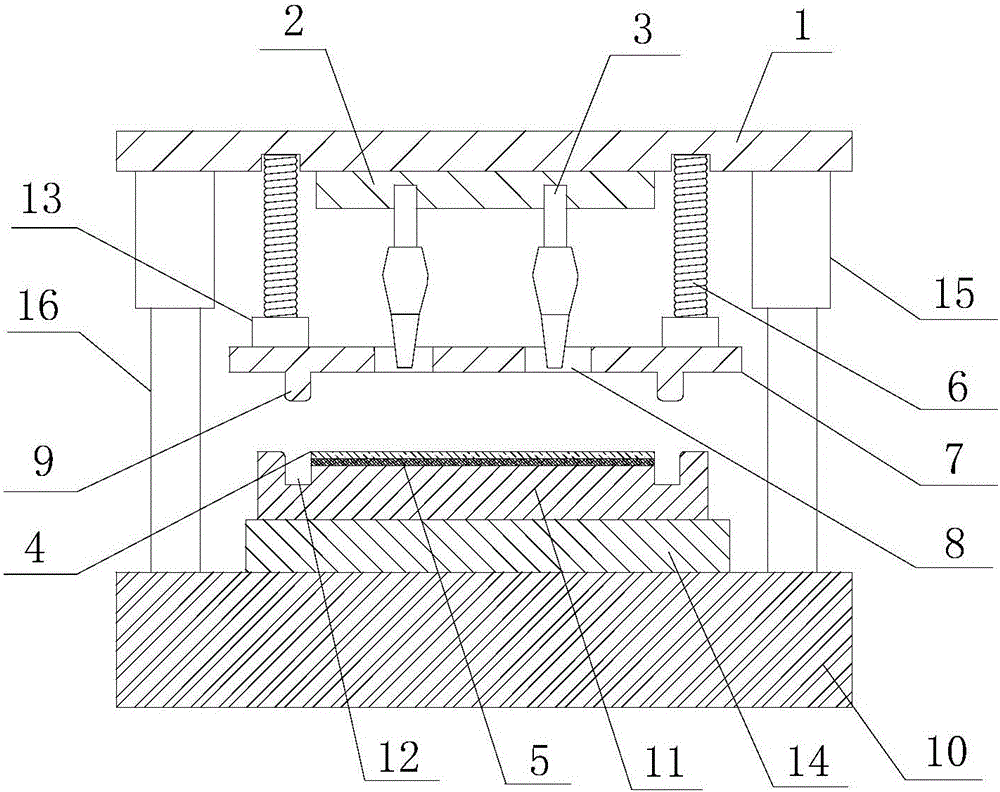

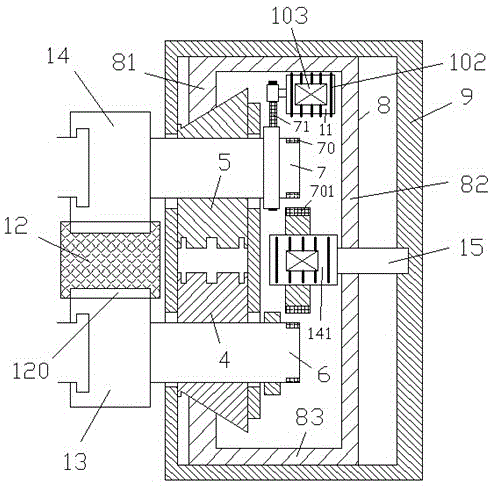

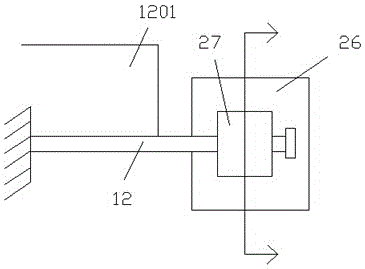

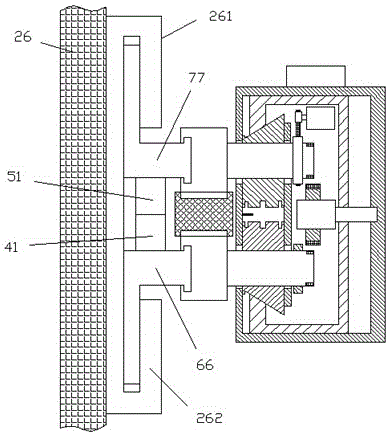

Installing assembly provided with radiator fan and applied to LED display device

InactiveCN105090714AReliable structureSimple equipment structureStands/trestlesIdentification meansComputer fanCantilever

An installing assembly provided with a radiator fan and applied to an LED display device comprises a rail beam (12), a lower idler wheel (13), an upper idler wheel (14), an LED display device installing and connecting part (261) and a driving box (27). The rail beam is fixed to a building (1201), extends outwards in a cantilever manner and is provided with an upper rail groove (120) and a lower rail groove (120); the lower idler wheel and the upper idler wheel can roll in the two rail grooves (120); and the LED display device installing and connecting part and the driving box are respectively connected to the two sides of the lower idler wheel (13) and the two sides of the upper idler wheel (14).

Owner:YIWU CITY GECE COMMODITY

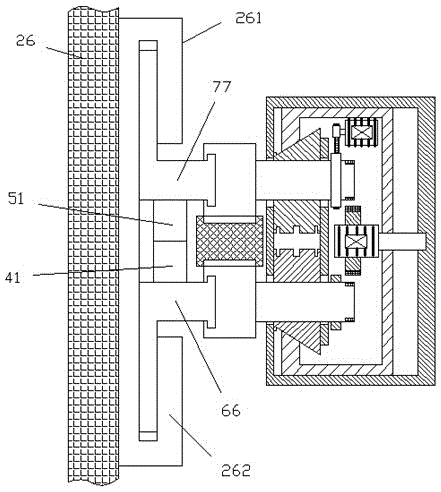

Mounting component provided with alarm and used for LED display device

The invention discloses a mounting component provided with an alarm and used for an LED (Light-emitting Diode) display device (26). The mounting component comprises a rail beam (12), a lower roller (13), an upper roller (14), an LED display device mounting connecting piece (261) and a driving box (27), wherein the rail beam (12) is fixed to a building (1201), stretches out in a cantilever manner, and is provided with two rail grooves (120) formed up and down; the lower roller (13) and the upper roller (14) can roll in the two rail grooves (120) respectively; and the LED display device mounting connecting piece (261) and the driving box (27) are connected with the two sides of the lower roller (13) and the upper roller (14).

Owner:TONGXIANG CITY AOPEIOU GARMENTS

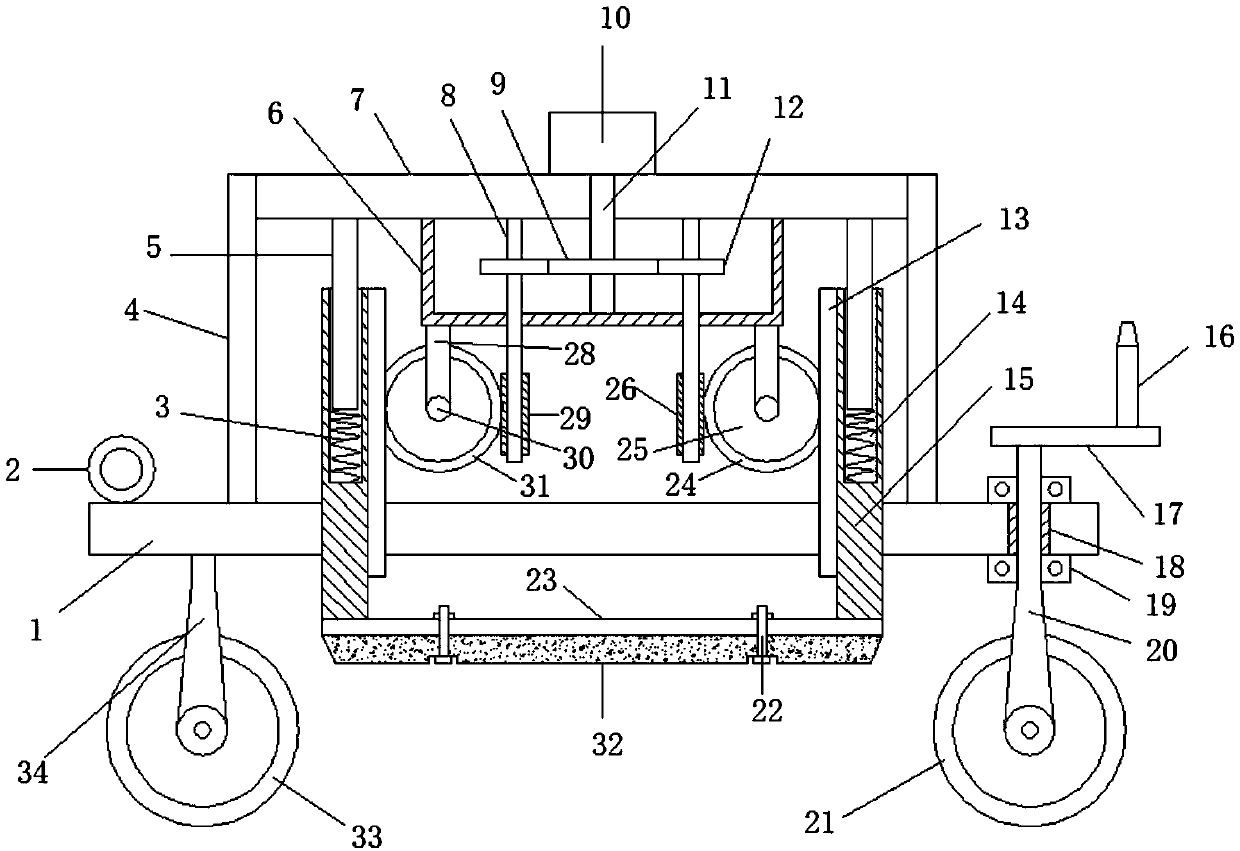

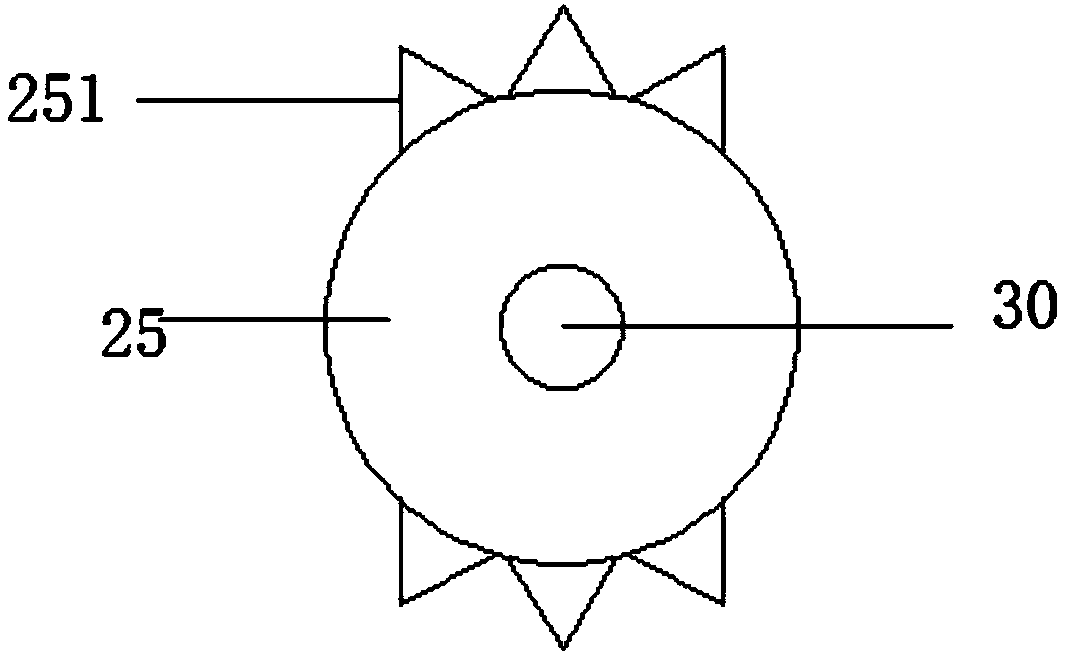

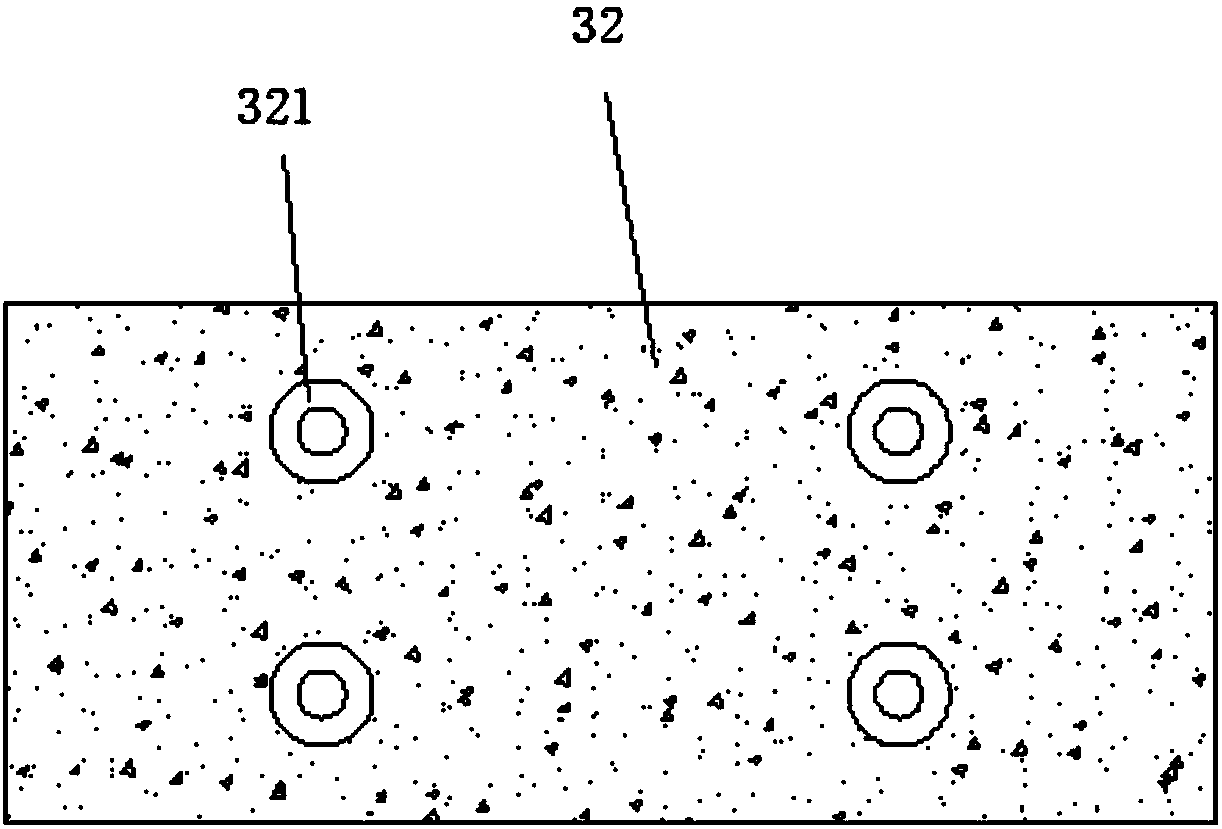

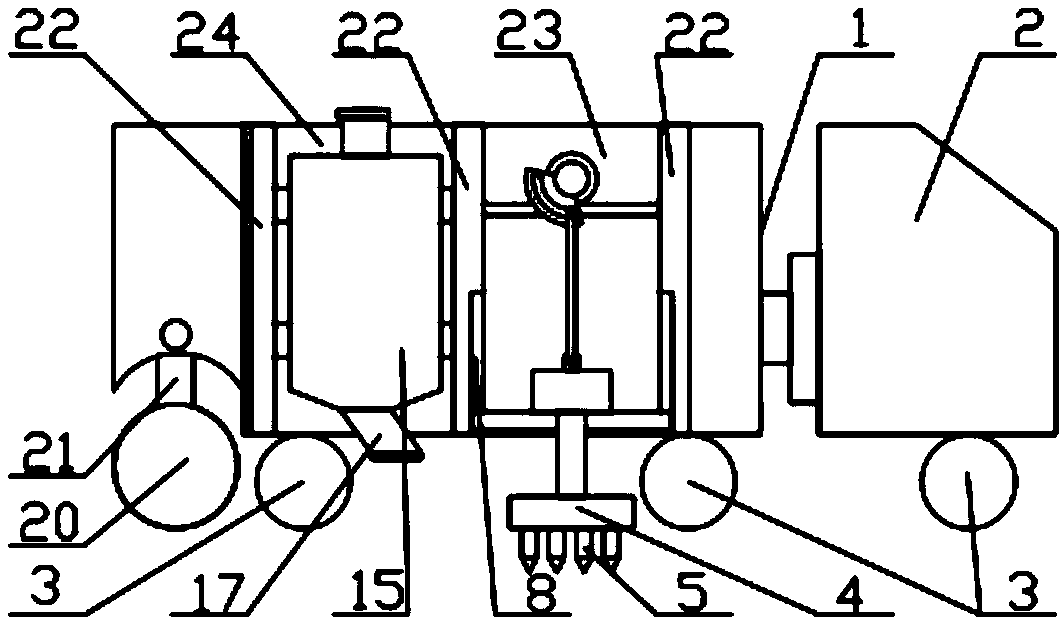

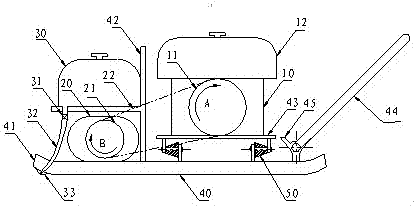

Portable plate tamper

InactiveCN102561157ACompact structureImprove the effectRoads maintainenceEngineeringVibration damper

The invention relates to a portable plate tamper comprising a power device, a vibration generator, a watering device, a plate tamper body and a vibration damper, wherein the plate tamper body is provided with a smooth bottom surface, the power device; the vibration generator, the watering device and the vibration damper are arranged on the plate tamper body; the vibration generator comprises an eccentric vibration generating body, the vibration generating body rotates to drive the plate tamper to vibrate up and down; the watering device is arranged at the advancing front end of the plate tamper; and the vibration damper comprises at least one vibration damping body which is an elastic piece, the vibration damper is fixed on the plate tamper body, and the power device is arranged above the vibration damper. The portable plate tamper disclosed by the invention has a compact structure; the eccentric vibration generating body rotates to drive the whole plate tamper to vibrate up and down so that a pavement is tamped. The plate tamper is further provided with the watering device and the vibration damper so that not only further the effect of pavement tamping is improved and simultaneously the service life of the plate tamper is prolonged.

Owner:ANHUI SANJING ENG MACHINE

Grass block laying device capable of adapting to different laying places

InactiveCN112535072AImplement preprocessingAchieve compactionSpadesHops/wine cultivationPublic FacilityGrass land

The invention relates to the field of public facilities, in particular to a grass block laying device capable of adapting to different laying places. The technical problem to be solved by the invention is to provide the grass block laying device capable of adapting to the different laying places. According to the technical scheme, the grass block laying device capable of adapting to the differentlaying places comprises a supporting bottom frame, a storage battery, a leveling and positioning system and the like; and the supporting bottom frame is connected with the storage battery. The grass block laying device is designed for the situation that artificial grassland manufacturing is generally needed in large industrial production places and stadiums; by combining the characteristic that grass blocks are small in area, the problem that a large amount of manpower needs to be consumed in the large-area construction field and the like are solved, the problem that the grass blocks cannot beattached to land due to the fact that only simple arrangement and combination are carried out in the manual laying process is solved, the effective utilization rate of the grass blocks is increased,and the grassland generation quality is improved; and the current situation that the grass block laying device suitable for different environments cannot be found is changed.

Owner:徐丹

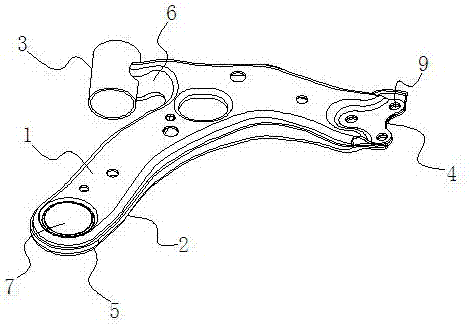

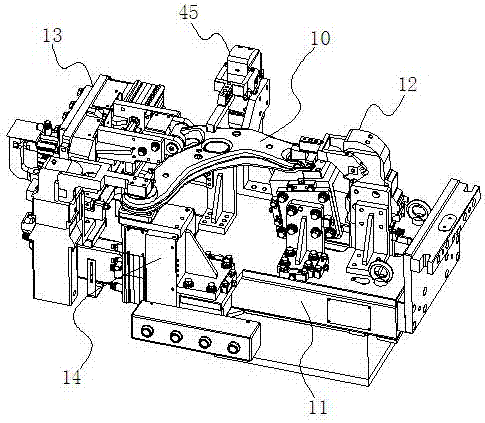

Welding clamping method for automotive suspension control arm

ActiveCN107971676AImprove processing efficiencyGuaranteed machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a welding clamping method for an automotive suspension control arm. The welding method comprises the steps that a ball head connecting end clamping mechanism, a sleeve connecting end clamping mechanism and a ball head pin mounting end clamping mechanism are arranged on a working platform; before welding, firstly, a top cover and a bottom cover are clamped together through the ball head connecting end clamping mechanism and the ball head pin mounting end clamping mechanism, wherein the top cover and the bottom cover are located at a ball head connecting end and a ball head pin mounting end; then, a sleeve is tightly pressed onto a sleeve connecting end through the sleeve connecting end clamping mechanism; and then, welding is conducted. By means of the welding clamping method, machining precision of the automotive suspension control arm can be guaranteed; the operation is convenient and fast to conduct; and machining efficiency is improved.

Owner:ZHUZHOU KAIFENG IND

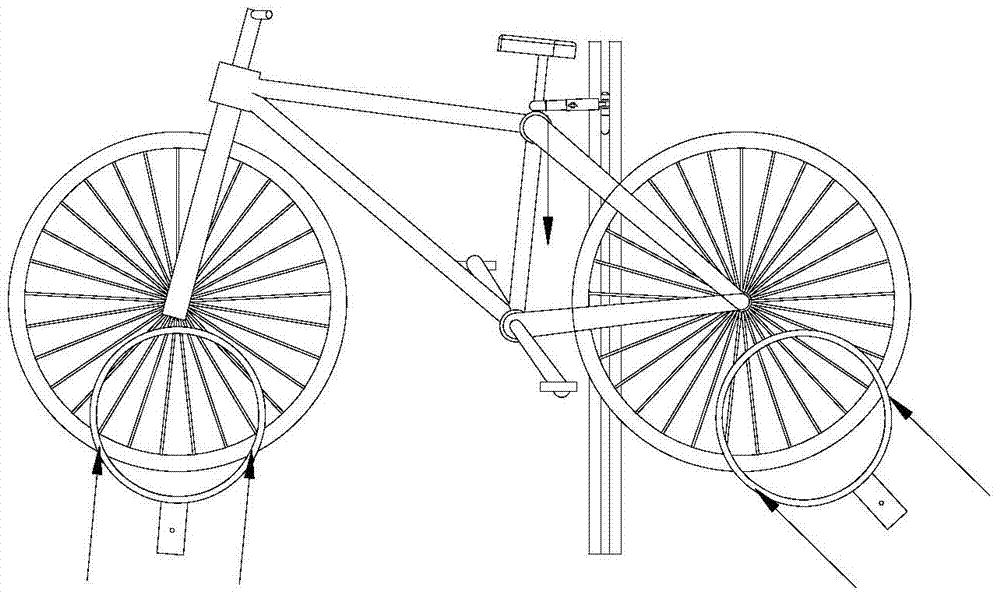

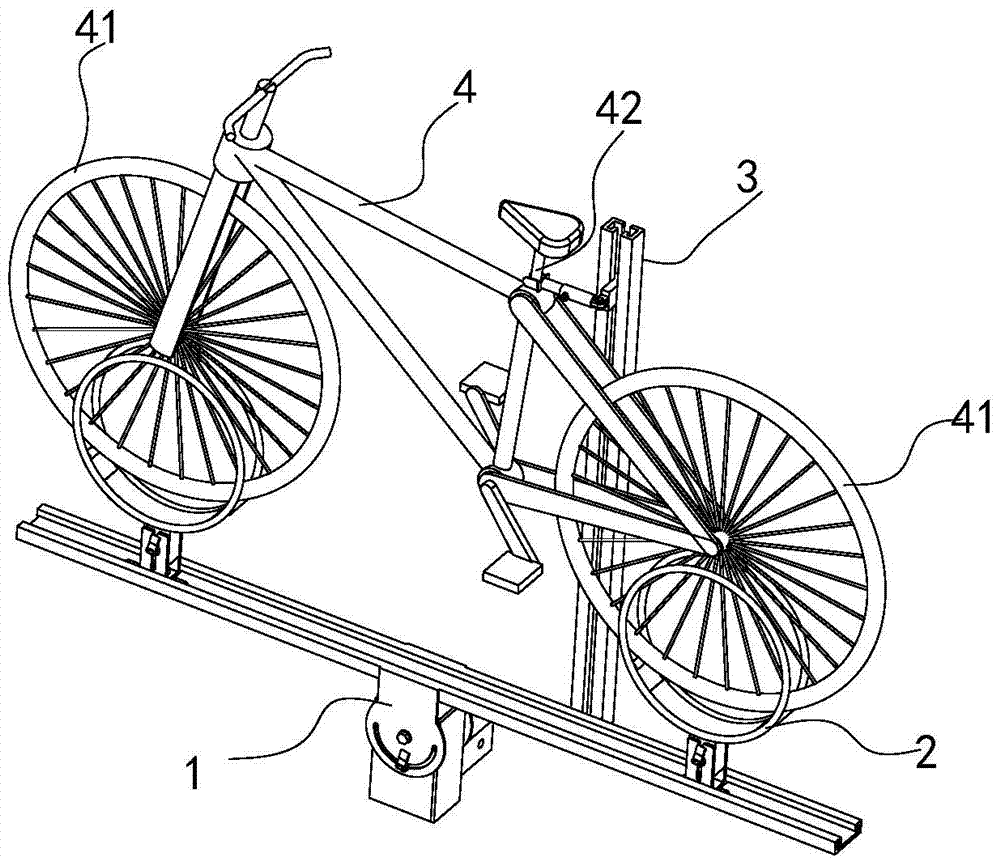

Vehicle-mounted bicycle rack

Owner:GREAT WALL MOTOR CO LTD

Intelligent rubber plug removing device

InactiveCN105936023AIncrease productivityReduce manufacturing costMetal-working hand toolsEngineeringMechanical engineering

The invention belongs to the field of outdoor unit dismounting equipment of air conditioners, and discloses an intelligent rubber plug removing device. The device comprises a rack, a cross beam, a second horizontal guide rail, a first horizontal guide rail, a moving rack, a position adjusting cylinder, a servo motor, a ball screw mechanism and a rubber plug removing mechanism, wherein the first horizontal guide rail is mounted on the rack; the cross beam is glidingly mounted on the first horizontal guide rail; the second horizontal guide rail on which the moving rack is glidingly mounted is arranged on the cross beam; the position adjusting cylinder and the servo motor are mounted on the rack; the rubber plug removing mechanism, comprising a compressor compressing device, a rubber plug lifting device and rubber plug removing devices, is mounted on the mounting rack. With the adoption of the intelligent rubber plug removing device, the process of removing a rubber plug on the top part of a compressor can be automatically and intelligently carried out during the production of an outdoor unit of an air conditioner, so that the purpose of automatically removing and removing the rubber plug on the top part of the compressor of the air conditioner can be achieved, the production efficiency can be improved, and the production cost can be saved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

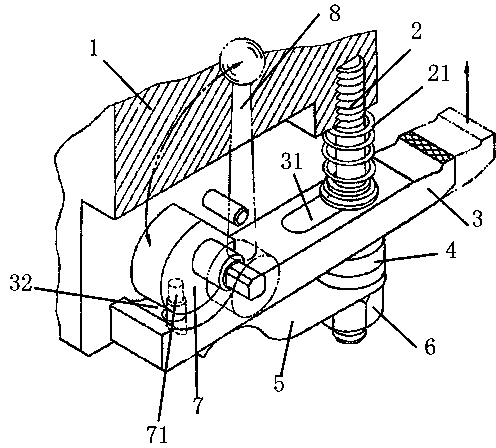

Simple cam press device

The invention relates to a simple cam press device which comprises a fixing seat. A stud is connected to the fixing seat in a threaded mode, a press plate, a spherical washer, a plate spring and a locknut are arranged on the stud in sequence, a bar hole allowing the stud to penetrate through is formed in the middle of the press plate, a claming end is arranged at one end of the press plate, a cam groove is formed in the other end of the press plate, a cam is arranged in the cam groove, a handle is arranged on the cam, and a rotating shaft of the handle is fixedly arranged on the fixing seat. A through hole is formed in the bottom, between the cam and the plate spring, of the cam groove, and a press plate ejector pin inserted into the through hole is arranged on the cam. When the handle is rotated and is rotated in the claming direction, the handle drives the cam to move, the press plate ejector pin arranged on the cam drives the press plate to move horizontally at the moment, the handle is rotated continually when the press plate moves to the bar hole and butts against the stud, the whole press plate rotates with the stud as the rotating shaft under the squeezing of the cam at the moment, and thus pressing of a workpiece is achieved.

Owner:CHONGQING FENGGUO QIYANG TECH DEV

Anti-leakage treatment method for deep foundation pit excavation in water-rich silt stratum

InactiveCN112049115AGels fastAchieve compactionArtificial islandsExcavationsSlurry wallWater leakage

The invention provides an anti-leakage treatment method for deep foundation pit excavation in a water-rich silt stratum. The treatment method comprises the following specific steps that firstly, WSS slurry injection is adopted at the joint position of a continuous wall outside a foundation pit, then dewatering wells are arranged outside the foundation pit to reduce water pressure, a water pump isplaced in each dewatering well, manual exploration and excavation are started from second-layer earth excavation in the deep foundation pit, a Luoyang shovel is adopted for exploration and excavationto explore the water leakage situation of the joint positions of the underground continuous wall at the underground wall joints, and plugging measures are taken according to the water leakage situation; and after it is confirmed that all underground continuous wall joints of a manual exploration and excavation bin section are free of the water leakage situation, a slurry injection platform is arranged beside the foundation pit, meanwhile, multiple sand backfill windows are formed in the outer side of the foundation pit, and in the mechanical excavation process of the foundation pit, emergencytreatment is carried out in a slurry injection and concrete backfill manner under the water seepage condition. According to the method, the risk of water gushing and sand gushing is avoided, the effect that the subway deep foundation pit is rapidly and stably excavated to expose the bottom is achieved, the construction period is shortened, and the cost is saved.

Owner:CHINA RAILWAY 11TH BUREAU GRP +2

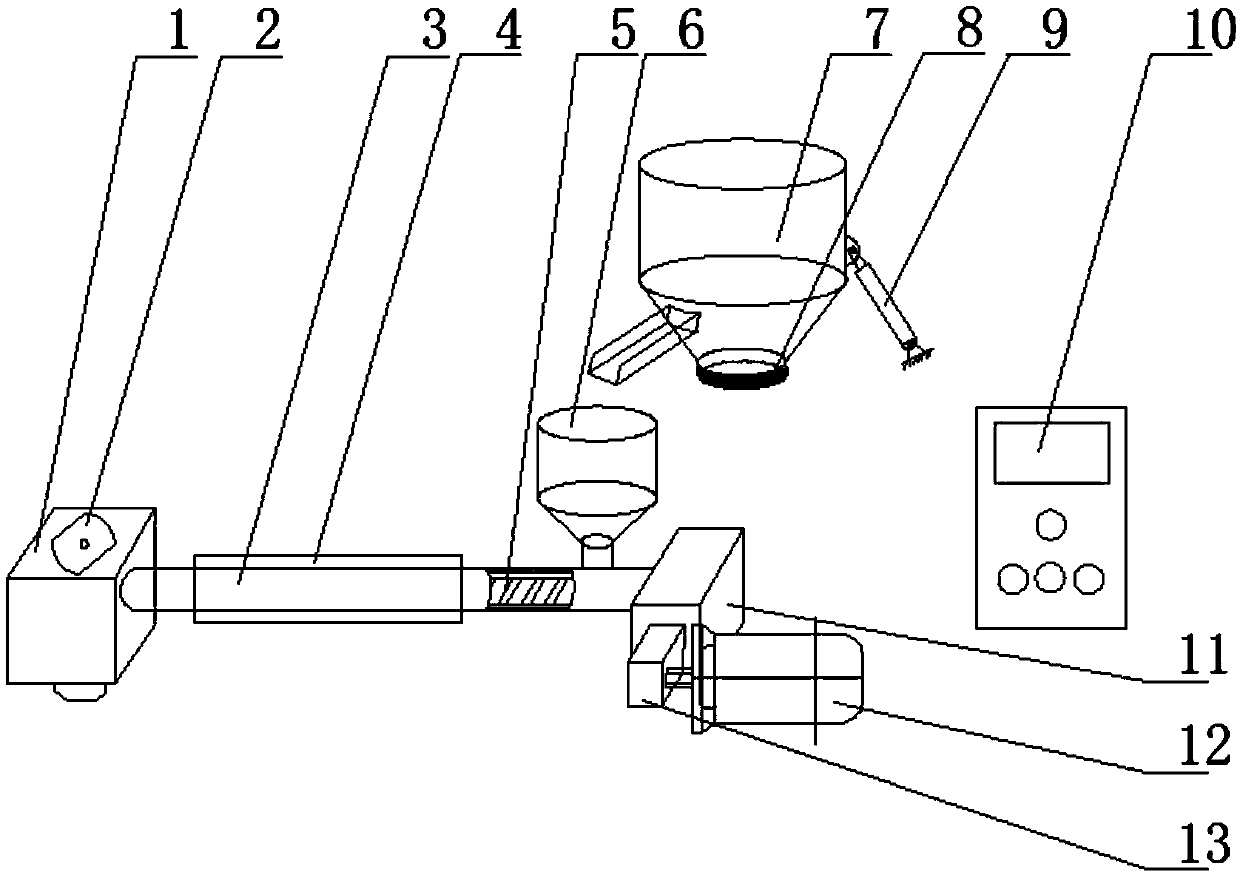

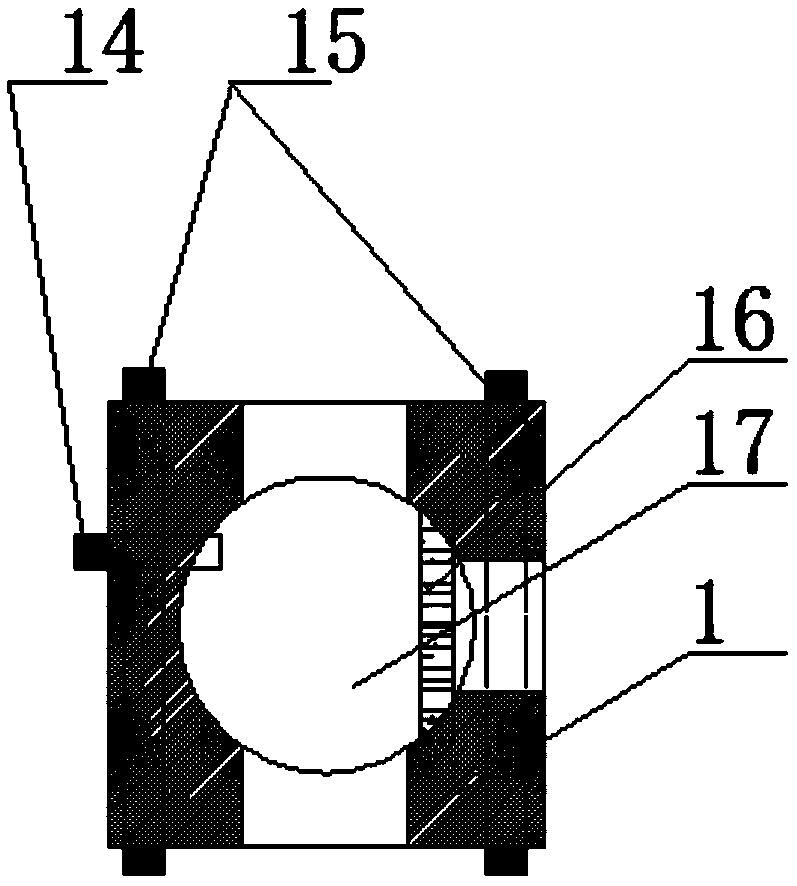

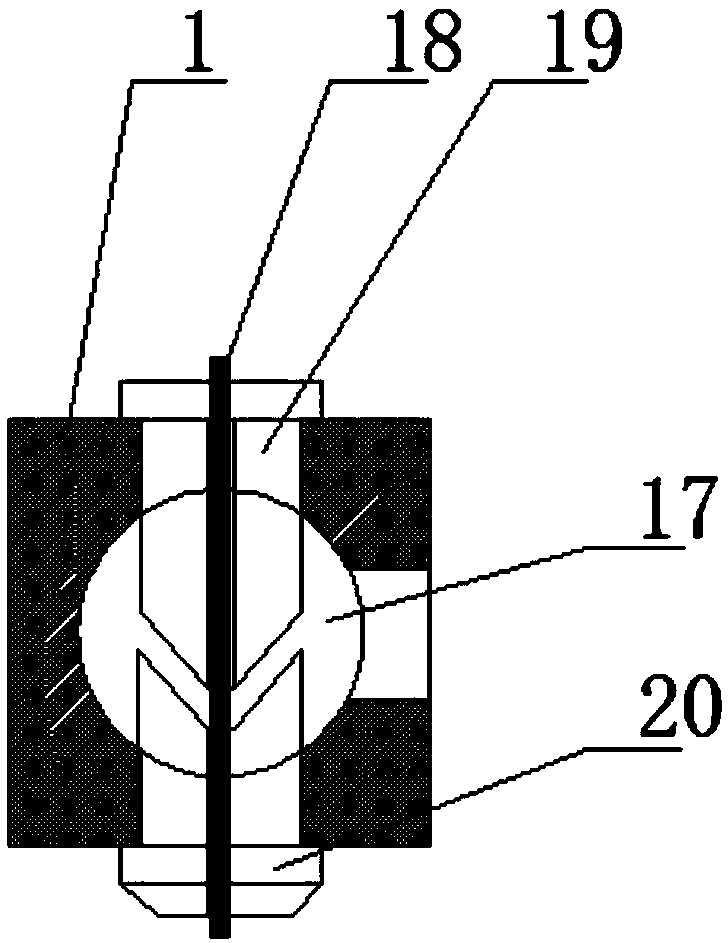

Fiber enhanced composite material annularly coated printing nozzle

ActiveCN109551762AStable quantitative deliveryMonitor quality in real timeManufacturing data aquisition/processingAdditive mnaufacturing with solid and fluidPorosityFiber-reinforced composite

The invention relates to the technical field of 3D printing and provides a fiber enhanced composite material annularly coated printing nozzle. The fiber enhanced composite material annularly coated printing nozzle comprises a feeding part, an extruding mechanism, an impregnating cavity, an annularly coated nozzle and a measuring and controlling part, wherein the feeding part is primarily used forproviding a resin material quantitively at a constant speed and the lower end of the feeding part is connected to the extruding mechanism; the resin is extruded at the constant speed under the actionof a heating ring and a screw to enter the impregnating cavity; in the impregnating cavity, the resin and the fibers are mixed and are extruded and formed through the annularly coated nozzle. The bottom end of the annularly coated nozzle is of a planar structure. The formed surface can be compacted after the composite material is formed, so that the inner porosity is reduced, and the laminar bonding effect is improved. In the printing process, a plurality of temperature and pressure parameters need to be collected and controlled. The printing nozzle mixes the resin and the fibers quickly and efficiently on the one hand, and compacts and prints the resin and the fibers on the other hand, so that the mechanical property of a formed part can be improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com