Application of glue to strips of material for the tobacco processing industry

A technology of processing industry and material tape, applied in the application field of scraper in gluing device, can solve problems such as interruption, vacancy of gluing system, insufficient gluing of coated paper tape, etc., and achieve the effect of extending acceptance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the following figures, the same or identical elements or corresponding parts are each marked with the same reference numerals, so that no corresponding reintroduction is necessary.

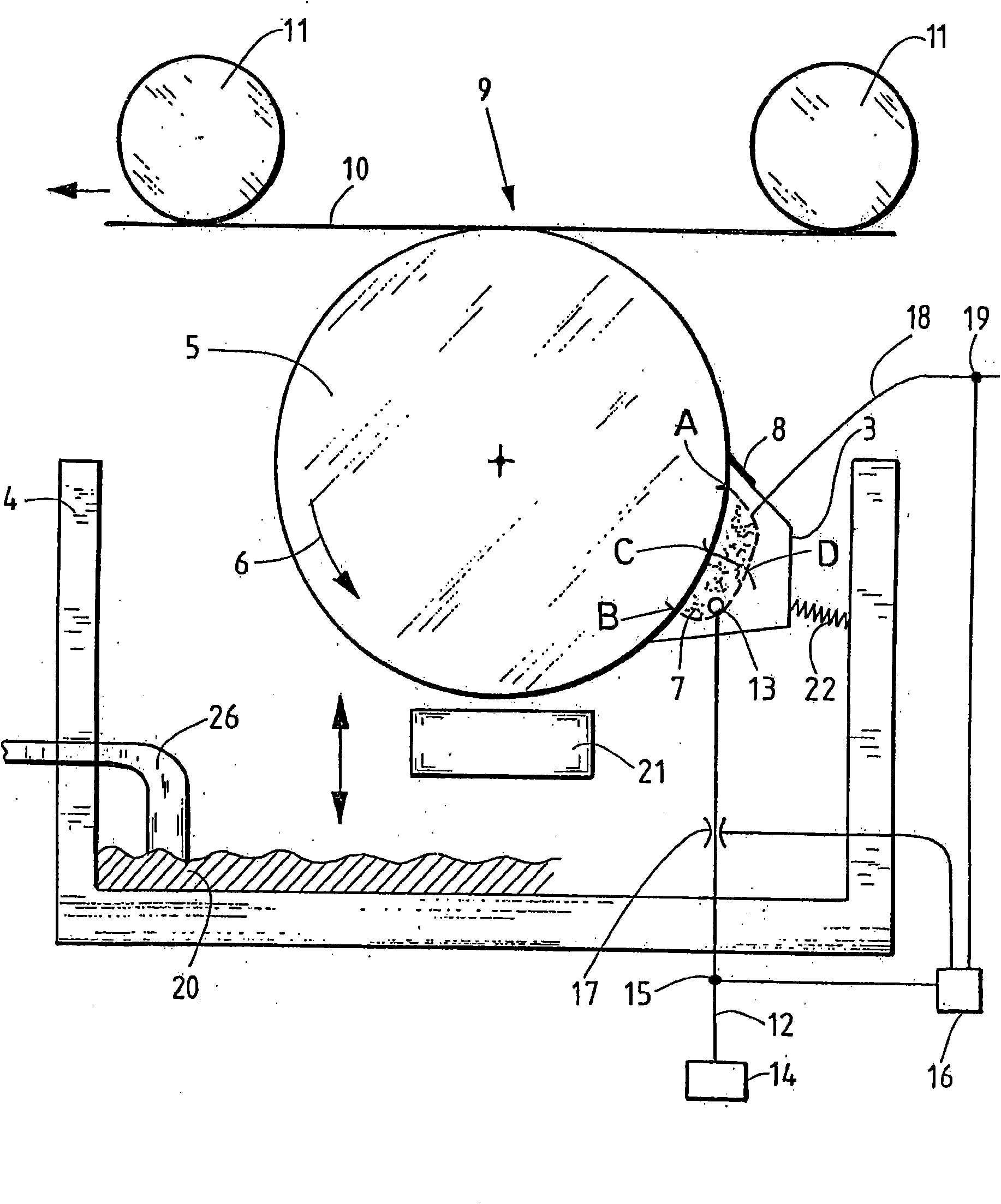

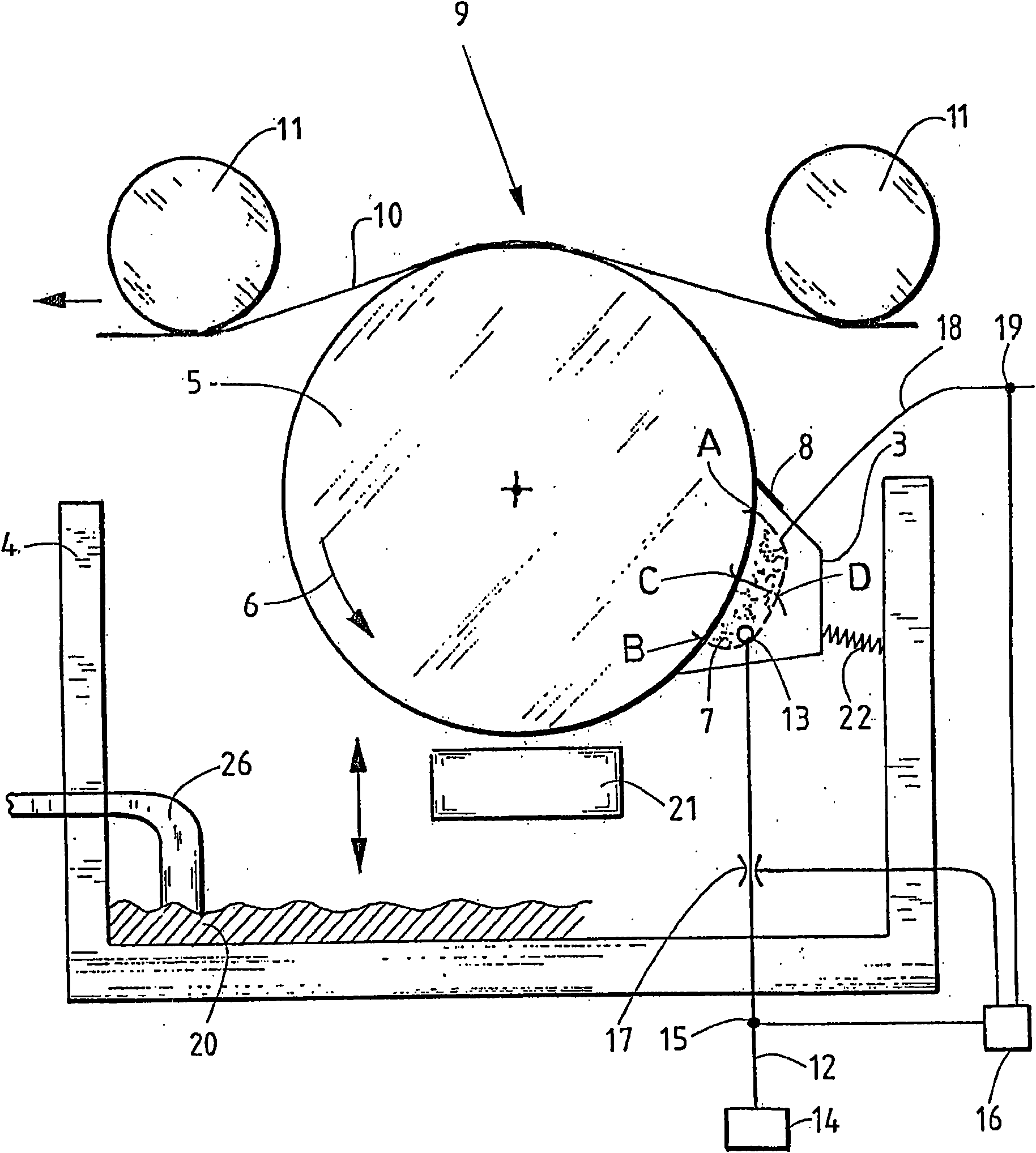

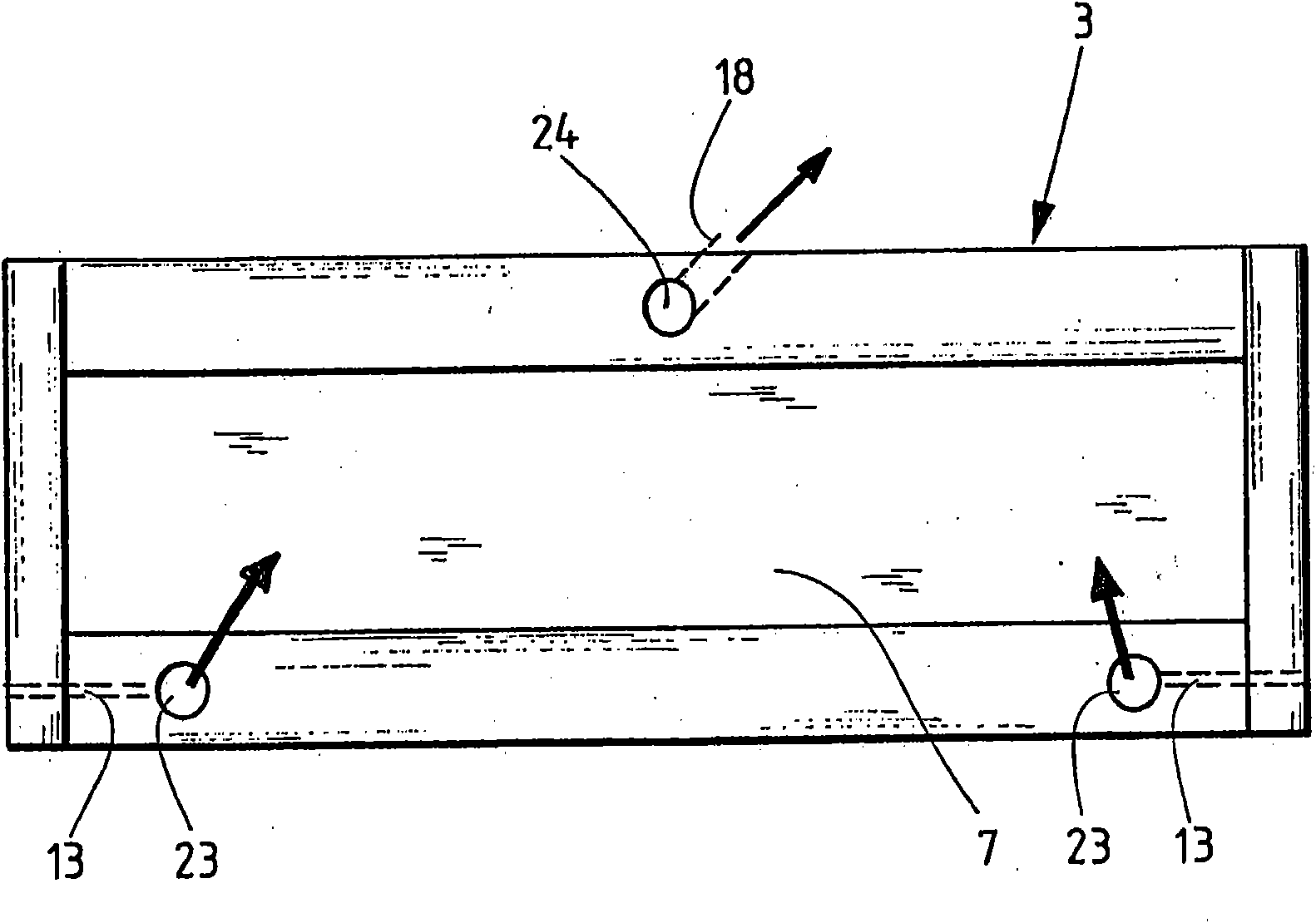

[0059] Figure 1a and Figure 1b In each case, a gluing device is shown in longitudinal section, wherein a plurality of elements or parts are drawn in this schematic representation. It is possible within the scope of the invention that the gluing device according to the invention can be equipped with one or more of the described or illustrated elements.

[0060]The gluing device has an engraved roller 5 arranged in the glue tank 4 and driven in rotation, which is driven in rotation in the direction of the arrow 6 drawn. The shallow groove of the screen roller 5 enters the glue distribution chamber 7 of a glue chamber 3, and accepts the glue entering the glue distribution chamber 7, and exits in the area of an upper scraper or scraper 8. The slots filled with glue are then conveyed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com