Patents

Literature

191results about How to "Easy to apply glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

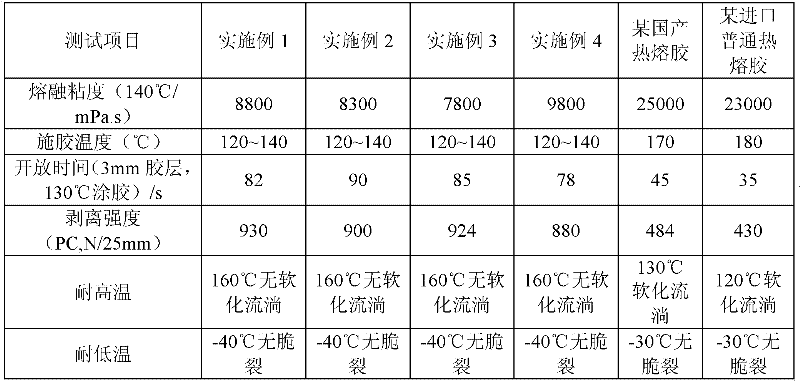

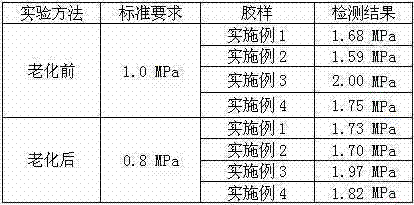

Polyurethane hot-melt adhesive for bonding and preparation method thereof

ActiveCN102585753AExcellent peelabilityEasy to apply glueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a polyurethane hot-melt adhesive for bonding and a preparation method thereof, belonging to the technical field of preparation of automobile hot-melt adhesives. The preparation method comprises the following steps of: firstly, feeding high-crystalline polyester glycol, polyester polyol and tackifying resin into a reactor, heating, dehydrating at vacuum while stirring, andthen cooling; secondly, preheating diisocyanate, adding the preheated diisocyanate to the reactor to uniformly stir and carrying out prepolymerization reaction; after the prepolymerization is finished, sequentially adding weighed catalyst, antioxidant, coupling agent, viscosity stabilizer and grey paste under nitrogen circulation, and stirring till being mixed uniformly; discharging in the nitrogen protection condition, sealing and packaging so as to obtain the product, that is, the polyurethane hot-melt adhesive for bonding automobile lights. The hot-melt adhesive prepared by adopting the preparation method disclosed by the invention can be used for bonding a plurality of base materials such as PP (Polypropylene), PBT (polybutylece terephthalate), ABS (Acrylonitrile Butadiene Styrene), PMMA (polymethyl methacrylate), PC (Poly Carbonate) and inorganic glass.

Owner:WUXI WANLI ADHESION MATERIALS

Environment-friendly and decorative nail-free glue and preparation method thereof

ActiveCN103484043AReduce contentNo pollution in the processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention belongs to environment-friendly and decorative glue, particularly relates to environment-friendly and decorative nail-free glue and a preparation method thereof. The environment-friendly and decorative nail-free glue comprises the following components: 5.0 to 20.0 percent of rubber elastomers, 10.0 to 30.0 percent of tackifying resin, 15.0 to 35.0 percent of reinforcing fillers, 2.0 to 8.0 percent of a thixotropic agent, 10.0 to 40.0 percent of a solvent and 0.1 to 1.0 percent of anti-oxidant; the preparation method of the environment-friendly and decorative nail-free glue comprises the following steps: putting the solvent into a high-speed stirrer, sequentially adding the rubber elastomers and the tackifying resin after a stirrer is started, stirring for 2 to 8 hours until all materials are dissolved to be a uniform liquid, then slowly adding the enhancing fillers and stirring uniformly so as to prepare a flowable slurry mixture, then adding the thixotropic agent and the anti-oxidant, and stirring uniformly so as to prepare the environment-friendly and decorative nail-free glue. The environment-friendly and decorative glue provided by the invention is environmental-friendly, is convenient to use, has high product bonding intensity and is excellent in durability.

Owner:GLEIHOW NEW MATERIALS CO LTD

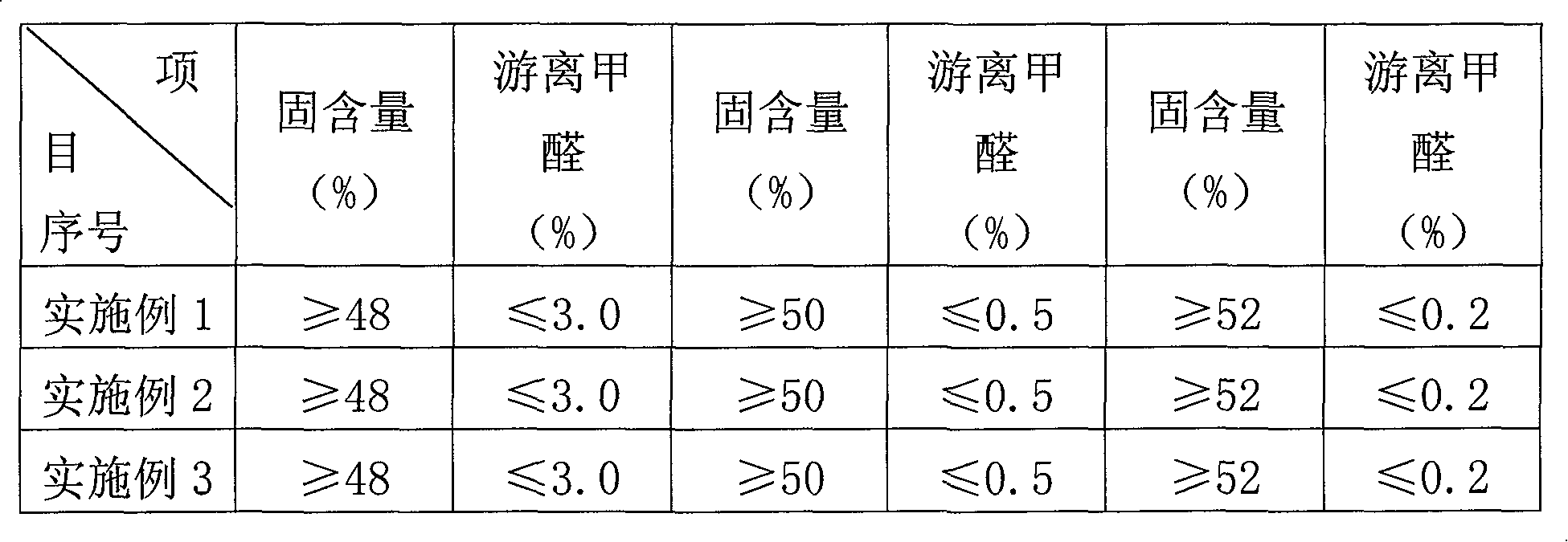

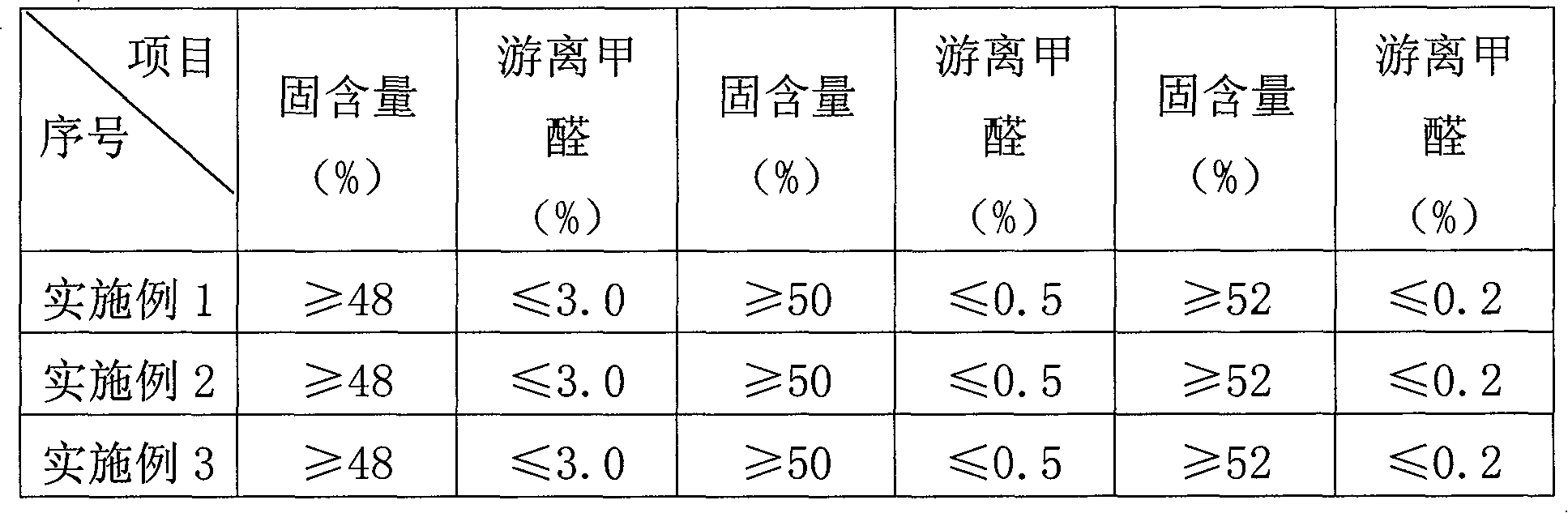

Method for preparing urea-formaldehyde resin adhesive

InactiveCN101191043AImprove permeabilityGood water solubilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotato starchEthylene urea

The invention discloses a preparation method for urea-formaldehyde resin adhesive, which is an adhesive produced by adopting ethylene urea, melamine or polyvinyl alcohol as formaldehyde catching agent and added with urea, potato starch residue and urea-formaldehyde resin to react. The invention has low formaldehyde content, can meet the requirement of low cost for composite sheet adhesive and has all excellent performances of urea-formaldehyde resin adhesive and the production cost is reduced; therefore, a practical adhesive that can be afforded entirely by each composite plate processing enterprises is obtained.

Owner:LANZHOU UNIVERSITY

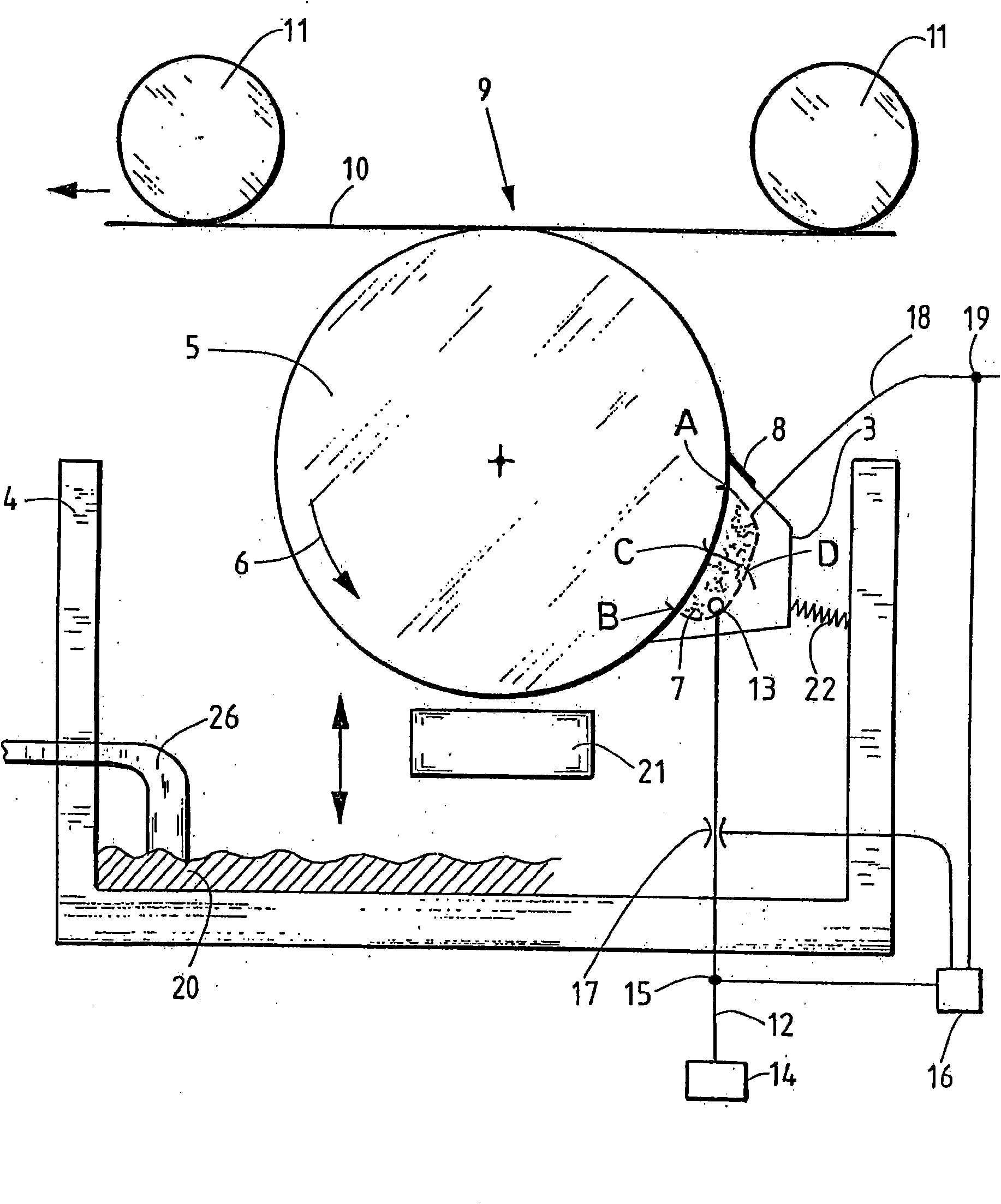

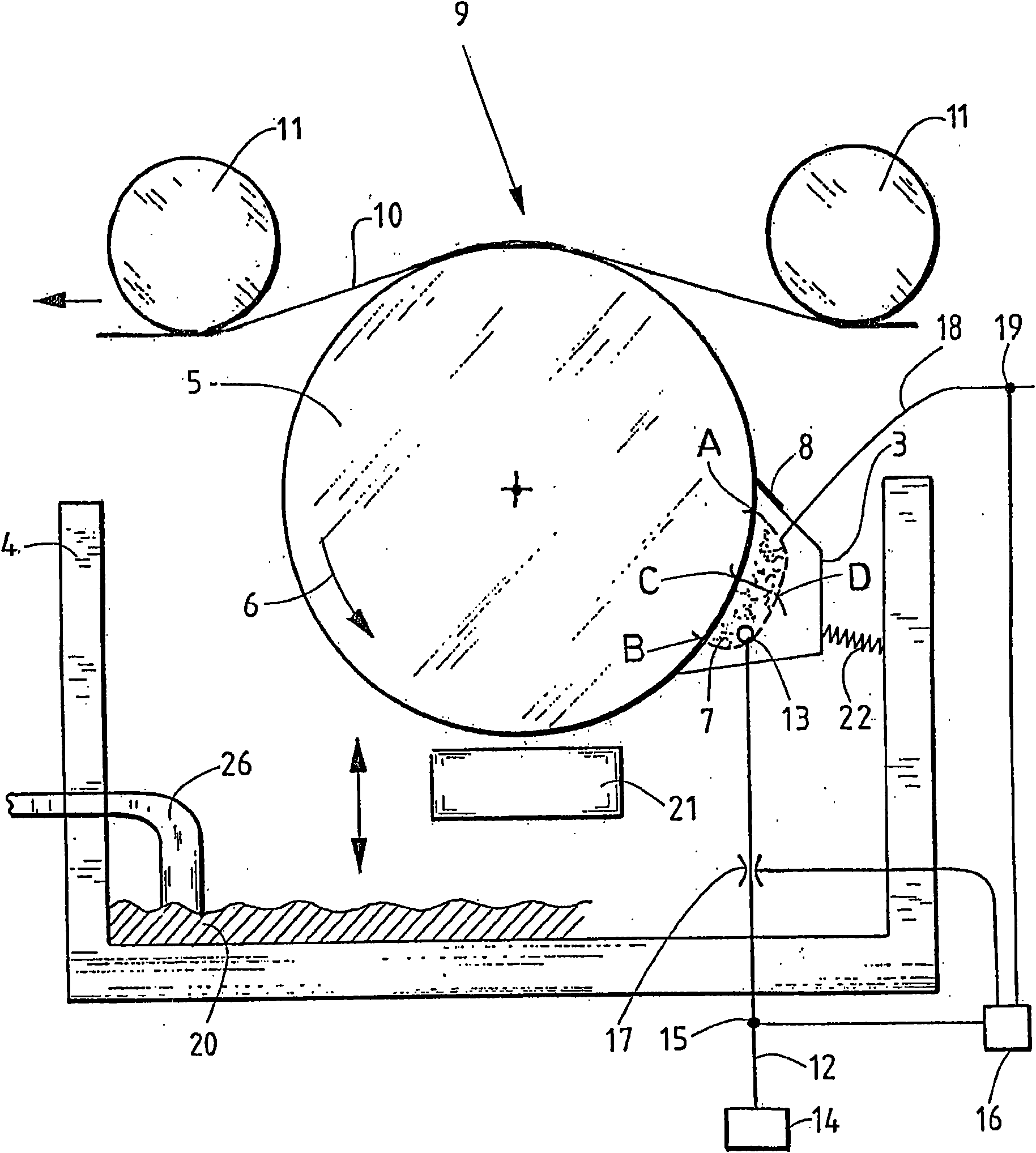

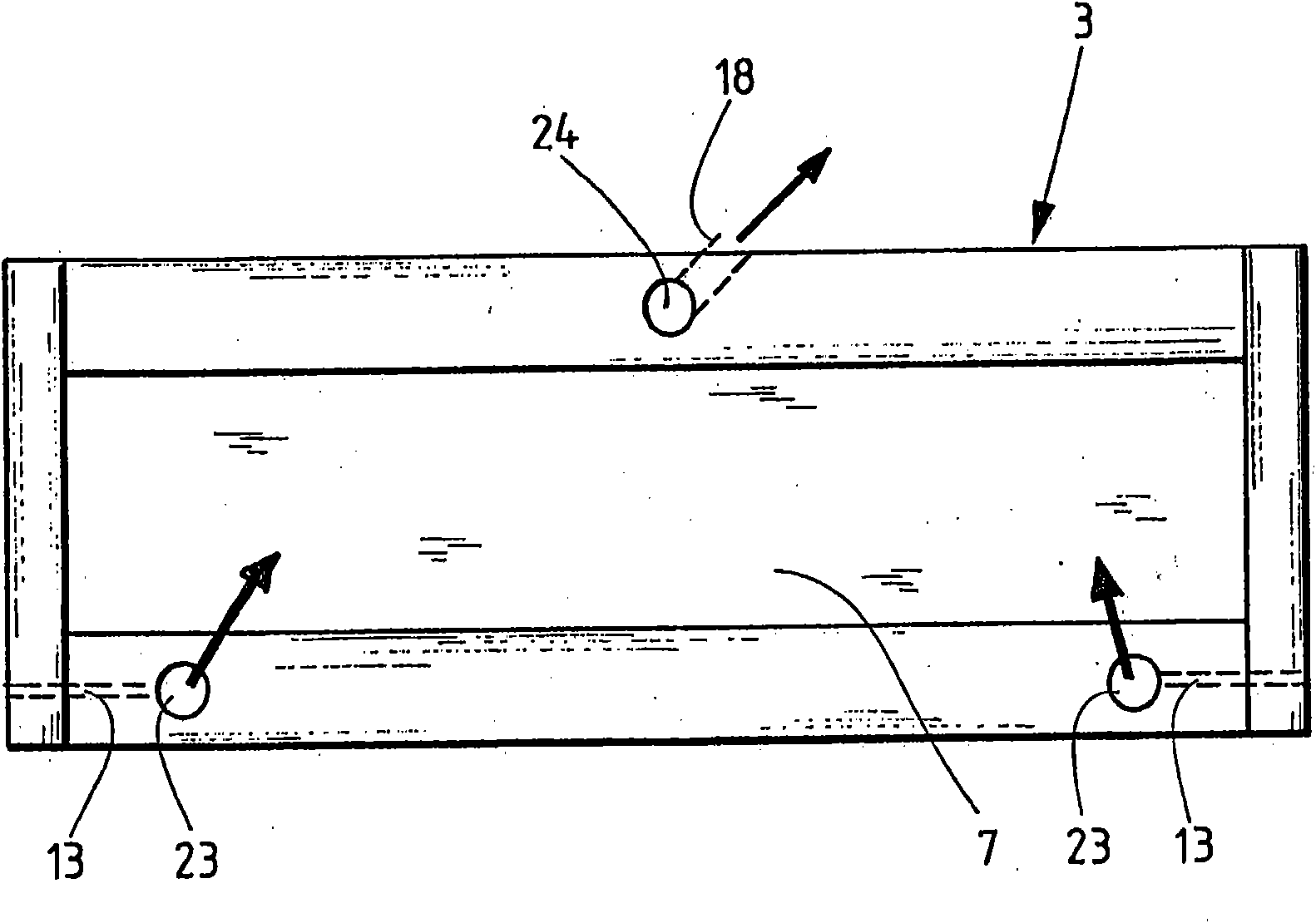

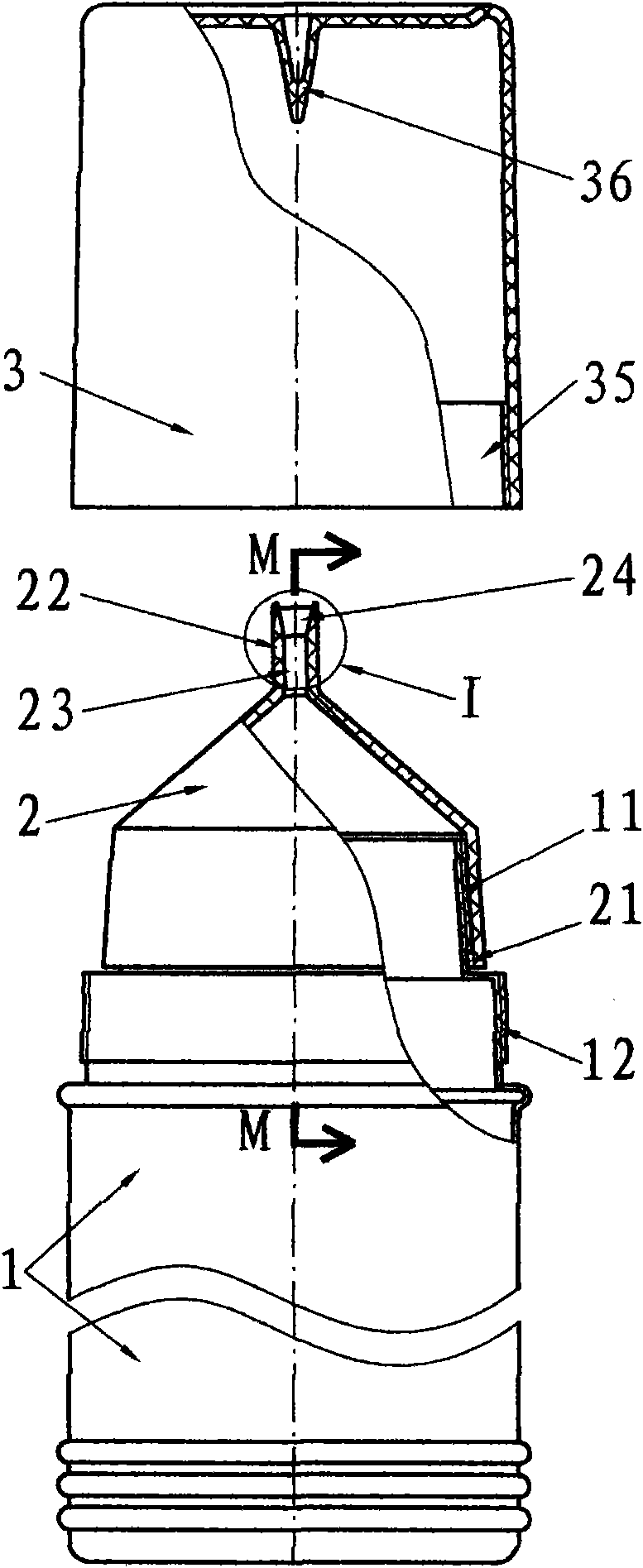

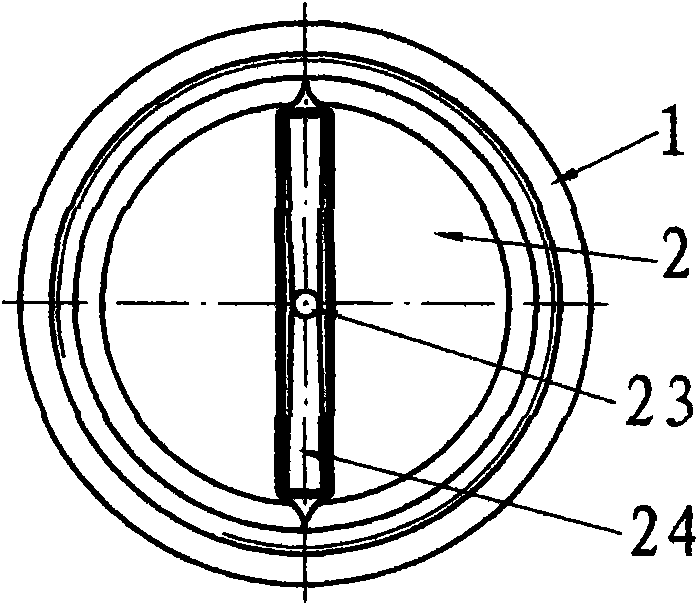

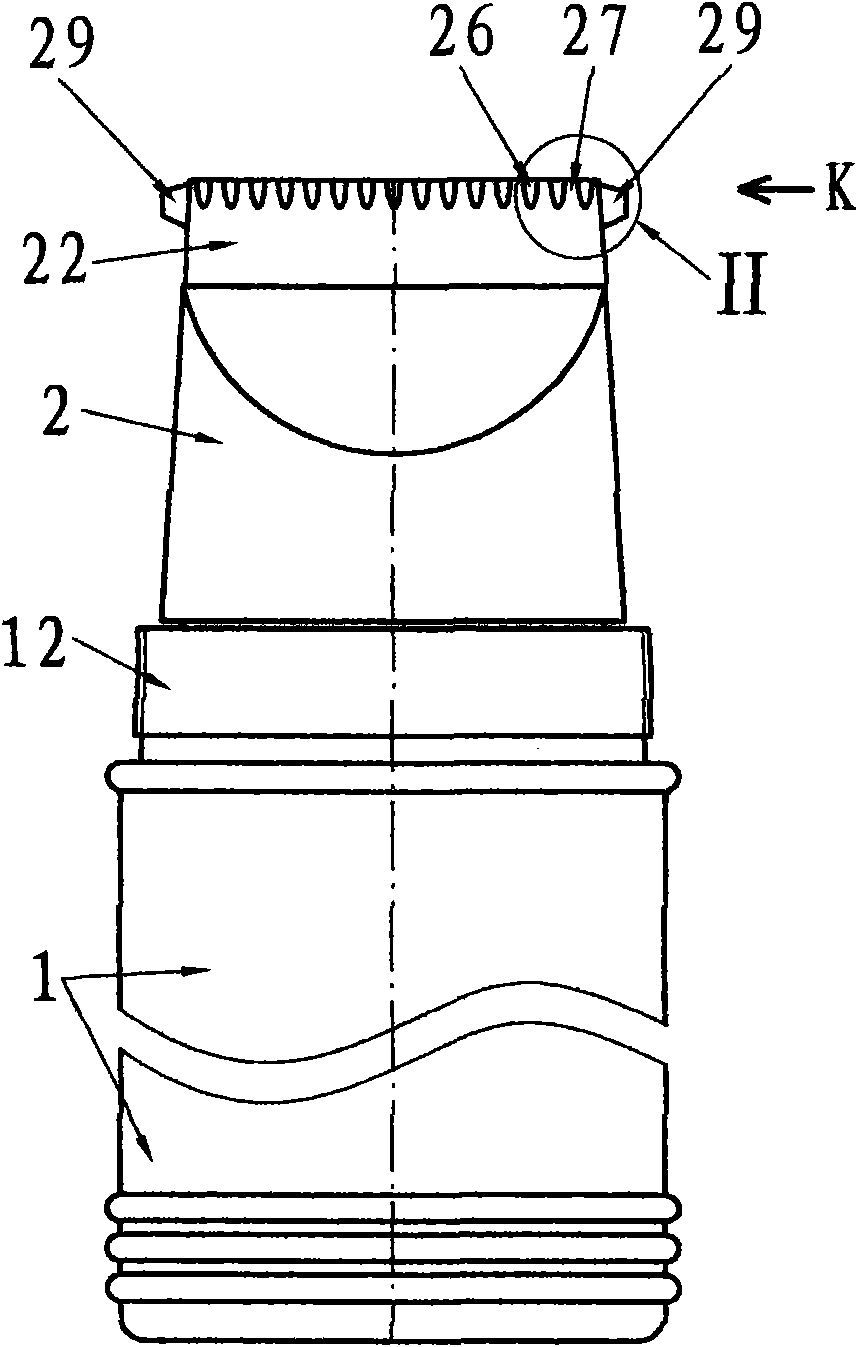

Application of glue to strips of material for the tobacco processing industry

ActiveCN101559417AExtended acceptance timeFirmly connectedLiquid surface applicatorsCigarette manufactureEngineeringMechanical engineering

The present invention relates to application of glue to strips of material for the tobacco processing industry, in particular a device for applying glue (20) to strips (10) of material for tobacco processing industry by means of a raster roller (5) preferably having shallow ridges, wherein a glue processing chamber (7) is arranged at a raster roller (5), glue (20) is removed from the glue processing chamber by using the raster roller. The invention also relates to a method for applying glue (20) to strips (10) of material for tobacco processing industry by means of a raster roller (5) preferably having shallow ridges, wherein the glue (20) is removed from the glue processing chamber by using the raster roller (5). The device is improved, wherein an external conveyor pipe (12) is attached to an internal supply pipe (13) of the glue processing chamber, wherein the glue is delivered by the external conveyor pipe (12) and the internal supply pipe (13) of the glue processing chamber (7). The method according to the invention is characterized in that the glue (20) is conveyed to the chamber (7) through the external conveyor pipe (12) and the internal supply pipe (13) of the glue processing chamber (7) directly connected onto the external conveyor pipe (12).

Owner:HAUNI MASCHINENBAU AG

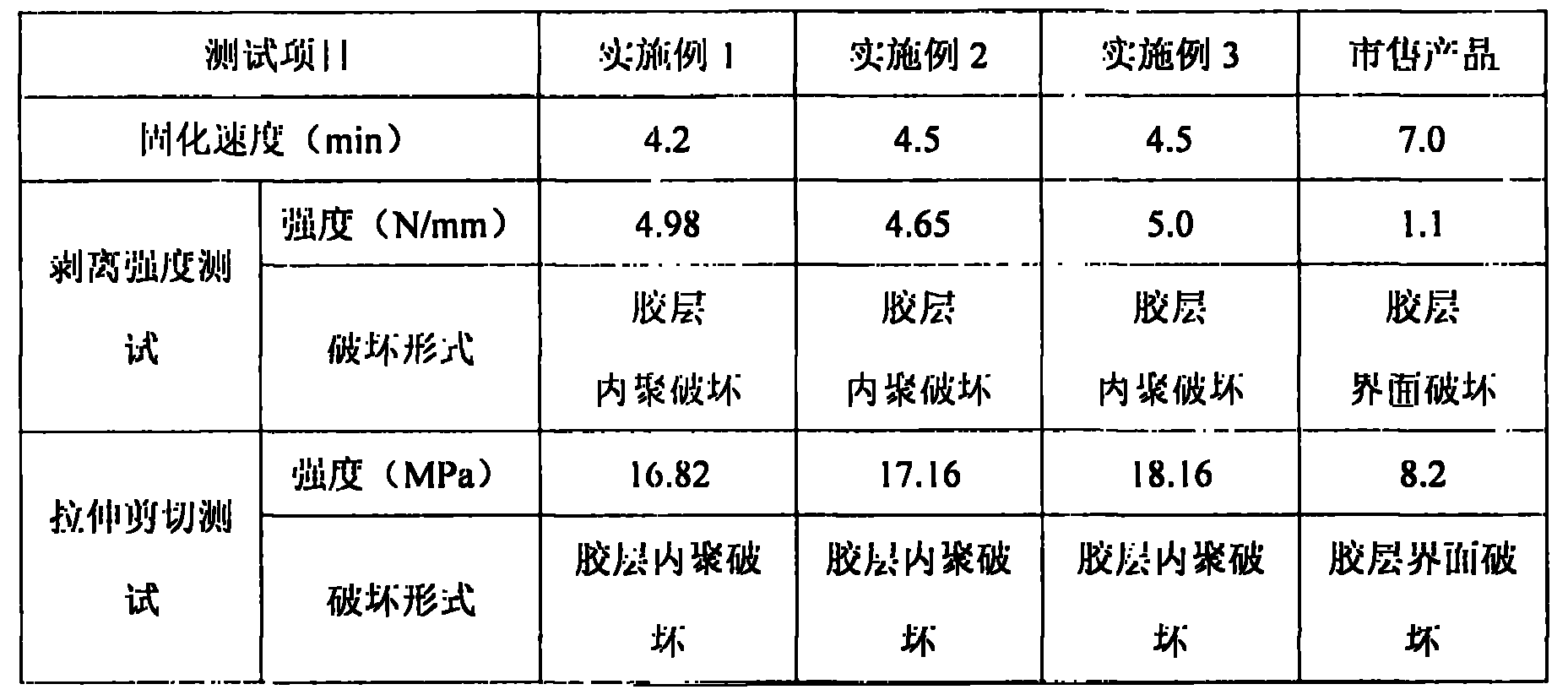

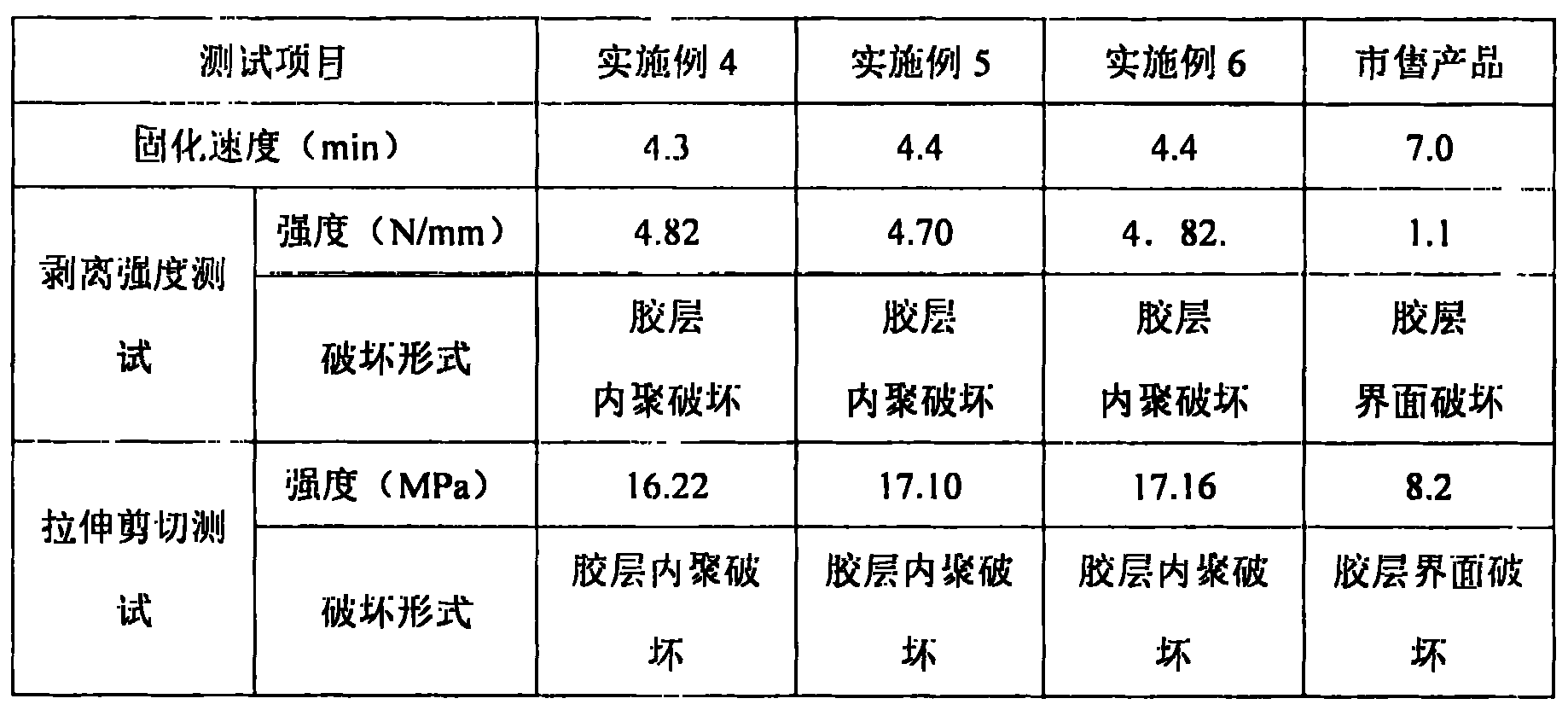

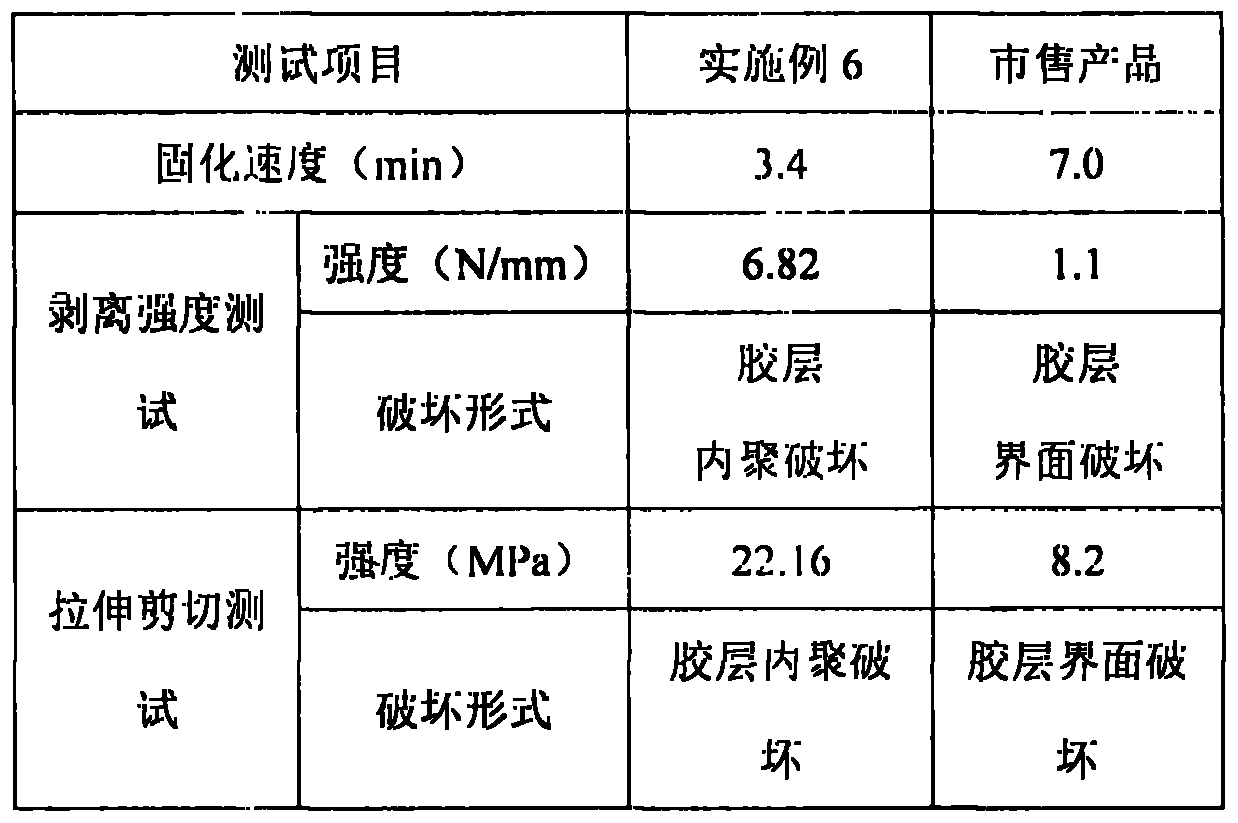

Double-component acrylate structure adhesive for bonding electrophoretic coating materials

ActiveCN104178075AImprove biteEffective bondingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinAdhesive

The invention discloses a double-component acrylate structure adhesive for bonding electrophoretic coating materials and a preparation method of the structure adhesive, belonging to the technical field of adhesives. The structure adhesive is prepared by mixing a component A with a component B according to a volume ratio of 10 : (0.1-2), wherein the component A comprises acrylate monomers, acrylic resin, strongly acidic monomers, non-polar rubber, flexible rubber, non-polar organic particles, an accelerator, a stabilizer and paraffin; the component B comprises an initiator, a plasticizer, a thickener and pigment. The structure adhesive can be used for effectively bonding and quickly curing electrophoretic coatings, is high in stripping strength and shear strength, and has the characteristics of being convenient to apply, good in room-temperature storage stability and the like; the bonding surface destruction form is cohesive failure of an adhesive layer.

Owner:TONSAN ADHESIVES INC

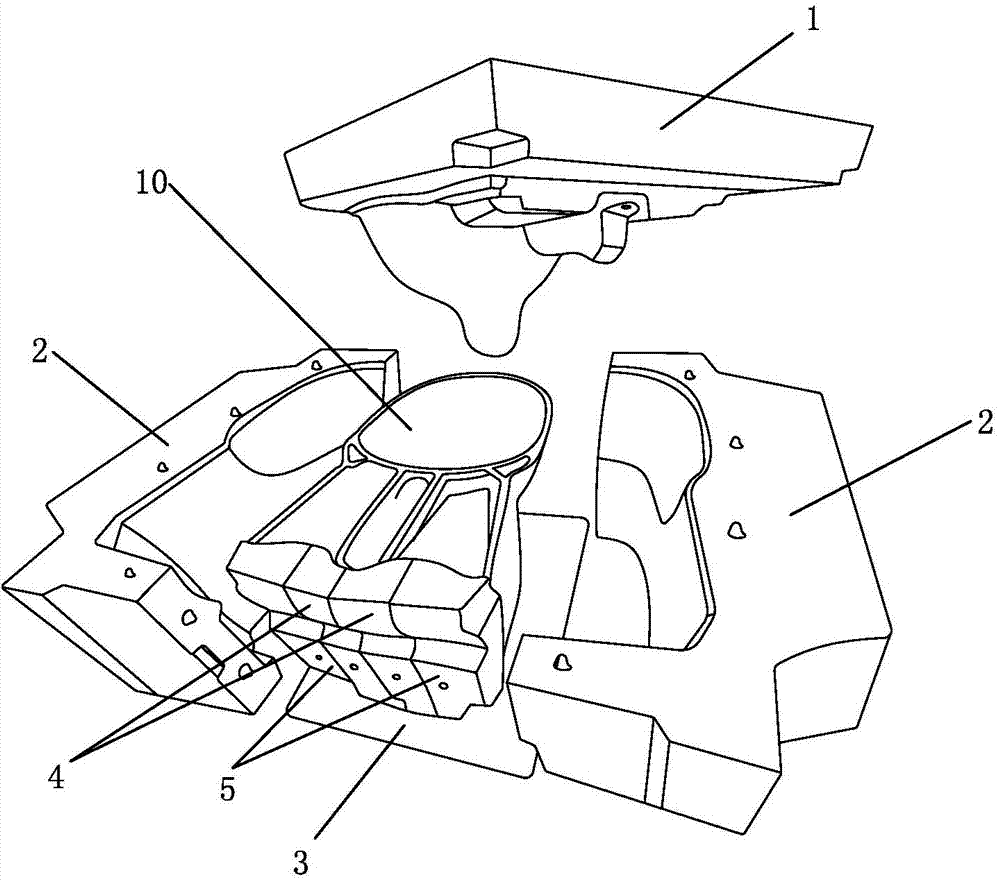

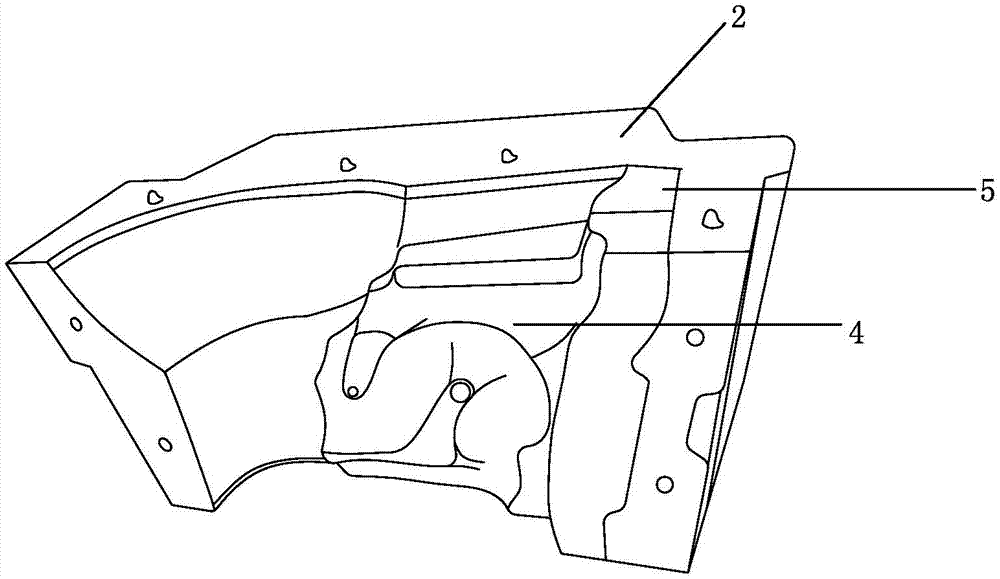

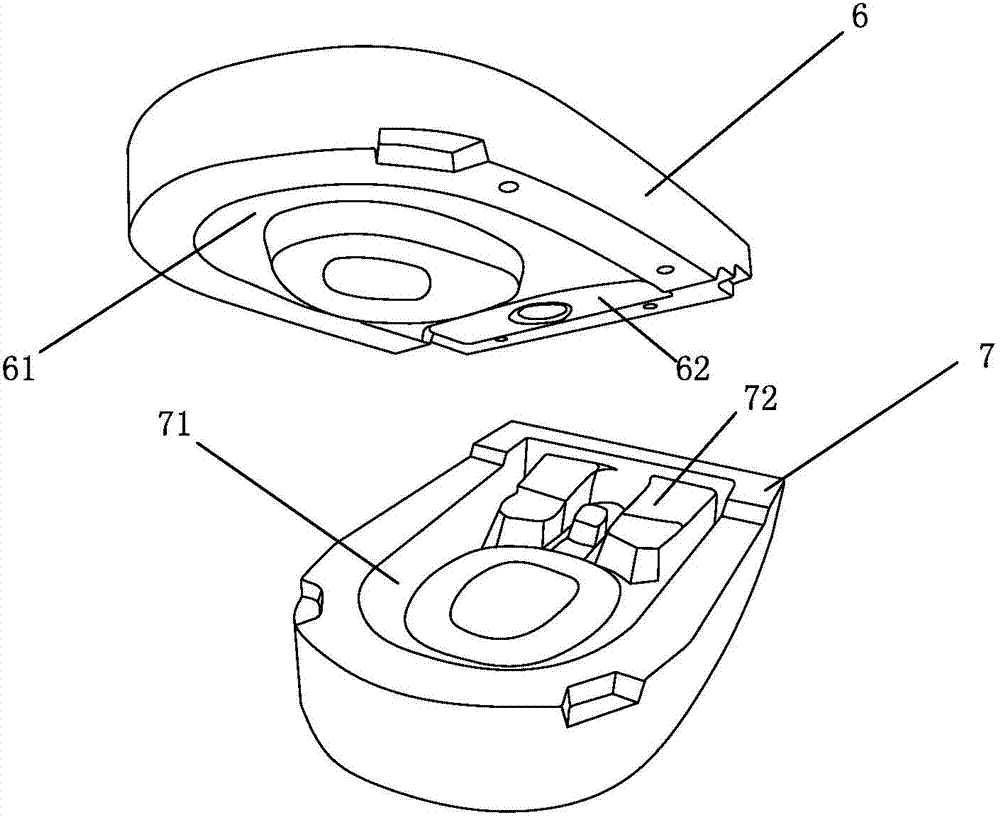

Pedestal pan mold, and mold splitting technology and pedestal pan thereof

InactiveCN103770202AEasy to moldConvenient mold opening operationWater closetsMould separation apparatusSewage treatmentMaterials science

The invention discloses a pedestal pan mold, and a mold splitting technology and a pedestal pan of the pedestal pan mold. The mold comprises a mold body and a seat ring mold, wherein the seat ring mold comprises an upper seat ring mold and a lower seat ring mold, an upper concave ditch is formed in the upper seat ring mold, a lower concave ditch is formed in the lower seat ring mold, and the seat ring mold is used for producing a seat ring with the complete water guide ring. The mold splitting technology comprises the steps that the pedestal pan is split into a pedestal pan body, the mold body and the seat ring mold, and the mold body and the seat ring mold are independently developed from the seat ring; the seat ring mold is divided into the upper seat ring mold and the lower seat ring mold, and is used for producing the seat ring with the complete water guide ring. The pedestal pan comprises a pedestal pan body at least provided with a bed pan, a sewage disposal pipeline and a jetting water way and a seat ring, the pedestal pan body and the seat ring are independently formed, the seat ring is provided with the water guide ring, and the seat ring is stuck to the top end of the pedestal pan body. According to the pedestal pan mold, and the mold splitting technology and the pedestal pan of the pedestal pan mold, the production efficiency can be greatly improved, the labor intensity of workers is reduced, and the production cost is reduced.

Owner:JOMOO KITCHEN & BATHROOM

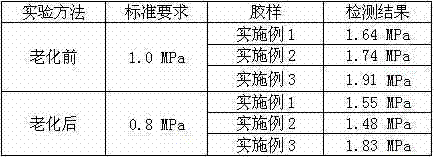

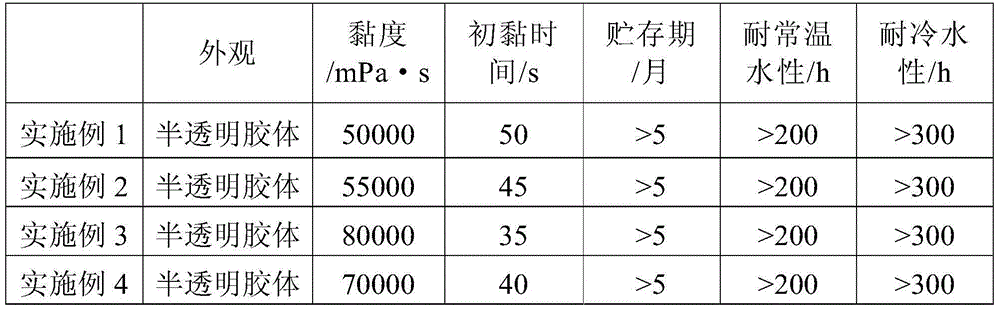

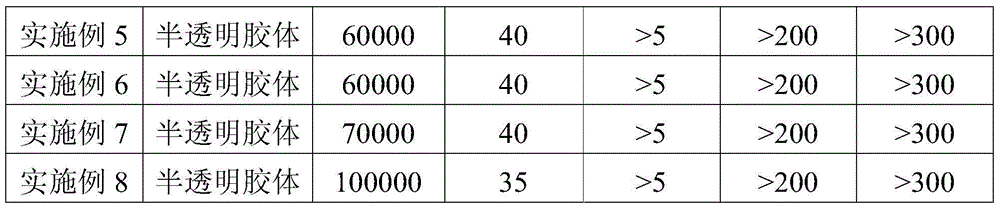

Silyl-terminated polyether sealant and preparing method thereof

ActiveCN105176470AEasy to apply glueGood adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention provides silyl-terminated polyether sealant excellent in waterproof performance and good in adhesion performance. The silyl-terminated polyether sealant is prepared from 30 parts to 50 parts of silyl-terminated polyether, 5 parts to 20 parts of plasticizers, 25 parts to 45 parts of reinforcing fillers, 1 part to 10 parts of pigment, 1 part to 2 parts of ultraviolet absorbers, 1 part to 2 parts of light stabilizers, 1 part to 3 parts of cross-linking agents, 1 part to 3 parts of thickening agents and 0.5 part to 2 parts of catalysts. The sealant is packaged in a single-component mode, sealant sizing is easily carried out, after the sealant is solidified, a sealant layer has high adhesive force to a base material, the adhesion performance is not obviously reduced after the sealant is soaked in water, the adhesive strength of the sealant is higher than the adhesive strength, obtained before and after universal sealant on a stainless steel base material is soaked in water, of the universal sealant, and using reliability is improved.

Owner:YANTAI DARBOND TECH

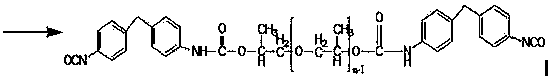

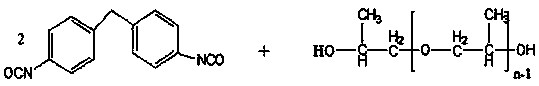

A preparation method of a polyurethane/epoxy resin composite material

ActiveCN103524703AImprove rigidity and comprehensive mechanical propertiesImprove bonding performancePolyureas/polyurethane adhesivesIsocyanateChemistry

A preparation method of a polyurethane / epoxy resin composite material comprises a step of adding a polyether polyol into a reactor to be treated, adding a diisocyanate and heating, controlling the mass content of free -NCO, and obtaining an A component after vacuum deaeration; a step of heating a binary aromatic amine, adding dropwise the liquid epoxy resin and heating again, and reacting to obtain a B component; and a step of stirring and mixing uniformly the A component and the B component stoichiometrically, and reacting and curing to obtain the polyurethane / epoxy resin composite material. When being used as an adhesive, the composite material has good bonding strength, high-temperature resistance, low-temperature resistance, impact resistance and flexibility. The composite material has a wide application scope, and can be prepared into a high-hardness polyurethane elastomer composite material to be applied.

Owner:太原英可奥笔墨科技有限公司

Method for preparing urea-formaldehyde resin adhesive

InactiveCN101191042AImprove permeabilityGood water solubilityAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

The invention discloses a preparation method for urea-formaldehyde resin adhesive. Ethyleneurea and melamine, or polyvinyl alcohol is taken as formaldehyde catching agent, and then added with carbamide, flour and lauxite to react to obtain the urea-formaldehyde resin adhesive. The invention with low formaldehyde content is low cost composite board adhesive that meets the requirements of environmental protection, ensures that all good performances of the urea-formaldehyde resin adhesive are kept and lowers the production cost, thus obtaining a pragmatic adhesive that can be afforded entirely by composite board processing enterprises.

Owner:LANZHOU UNIVERSITY

Paper box folding system

ActiveCN108656625AQuality assuranceIncrease productivityBox making operationsPaper-makingCardboardPulp and paper industry

The invention relates to a paper box folding system. The paper box folding system comprises a paper box folding assembly, a pushing assembly and a conveying line. The paper box folding assembly and the pushing assembly are arranged on the two sides of the conveying line correspondingly. The paper box folding assembly comprises a paper cushion plate, a first folding mechanism, a second folding mechanism, a third folding mechanism, a triangular prism, an installing base, a gas paper suction assembly, a gluing mechanism and an unloading mechanism. The paper box folding system has the beneficial effects that through joint cooperation of the paper box folding assembly, the pushing assembly and the conveying line, the connecting and box forming process can be mechanically finished, the labor intensity can be lowered, the labor cost can be saved, the finished box quality can be guaranteed, and the production efficiency of enterprises is improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

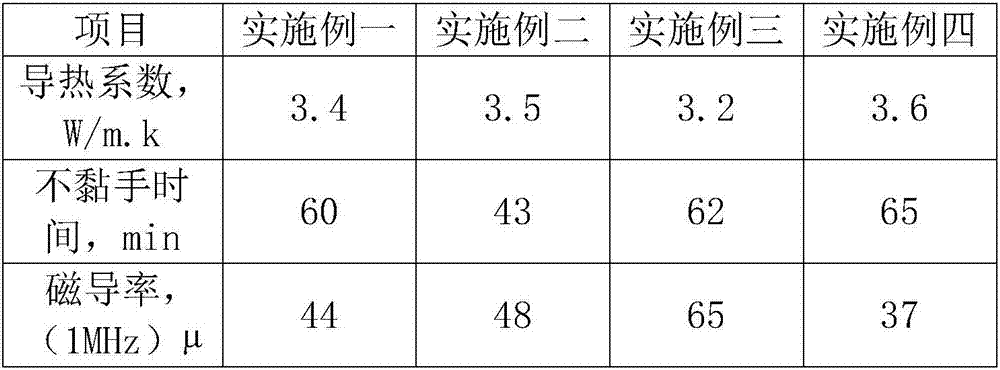

High thermal conductivity interstitial interface material and preparation method thereof

PendingCN107057370AAvoid electromagnetic influenceAvoid electromagnetic interferenceHeat-exchange elementsThermal conductivityElectromagnetic interference

The invention relates to a high thermal conductivity interstitial interface material. The high thermal conductivity interstitial interface material is prepared from a component A and a component B, wherein the component A is prepared from a first main material and a first auxiliary material; the component B is prepared from a second main material and a second auxiliary material; a water absorbing material comprises ferrite. The high thermal conductivity interstitial interface material disclosed by the invention has the advantages that the wave absorbing material is added into the component A, and the component A is enabled to absorb or greatly reduce electromagnetic wave energy of surface, so that electromagnetic influence of an existing electrical element on people is avoided, and hazards of electromagnetic interference, electromagnetic pollution and information leakage are avoided; by means of vinyl silicone oil and thermal conductive filler, a produced gasket has low stress and good pressure absorptivity; on the premise of maintaining high thermal conductivity of the high thermal conductivity interstitial interface material, the stress to the device is greatly reduced; the high thermal conductivity interstitial interface material can adaptively fill various complex spaces; damages to a chip due to pressure in a smaller clearance are effectively avoided; besides, the invention provides a preparation method of the high thermal conductivity interstitial interface material. The preparation method comprises the following steps: preparing the component A, preparing the component B and carrying out vulcanization molding.

Owner:PINGHU ALLIED IND

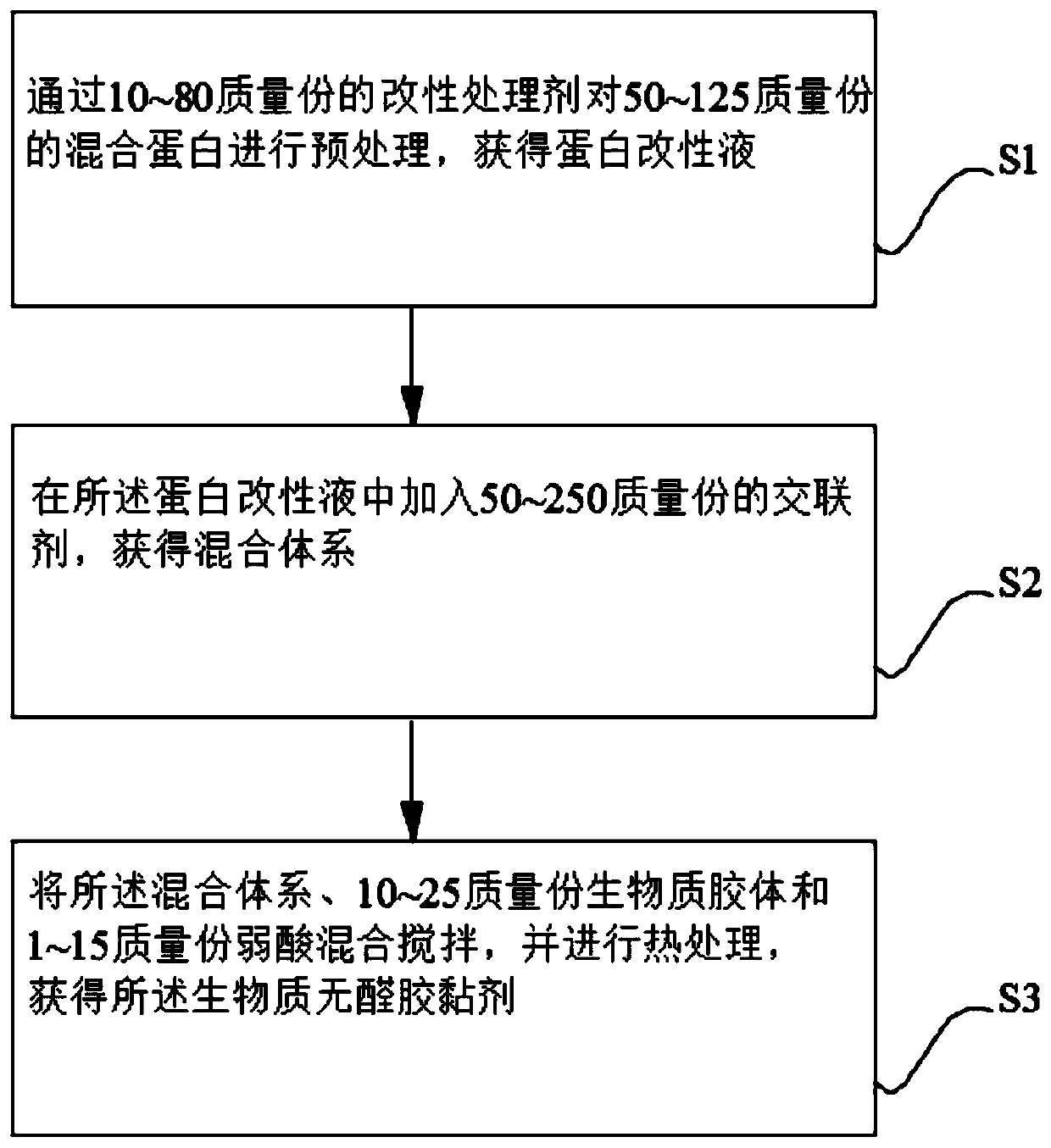

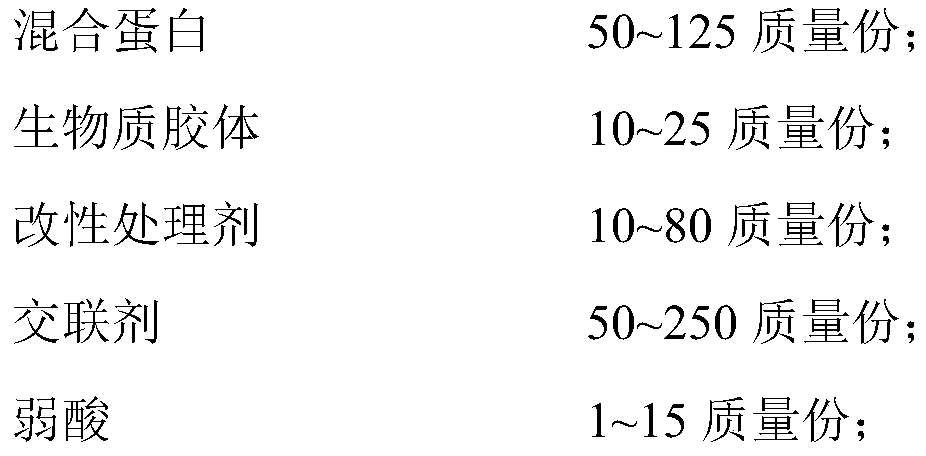

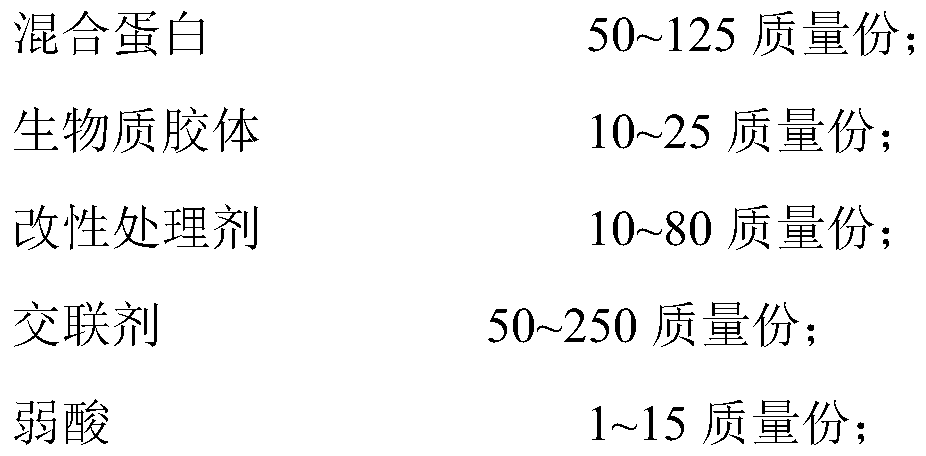

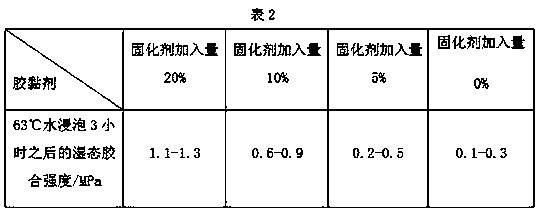

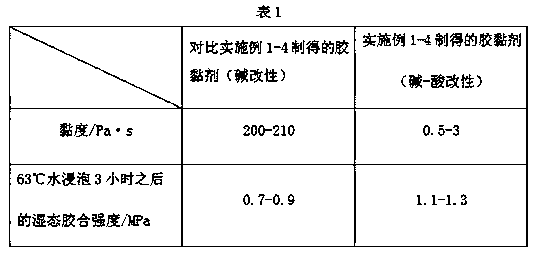

Biomass formaldehyde-free adhesive for artificial board and preparation method thereof

ActiveCN110922941AStable structureAchieve stabilizationProtein adhesivesPolyureas/polyurethane adhesivesAdhesiveCross linker

The invention discloses a biomass formaldehyde-free adhesive for an artificial board and a preparation method thereof. The biomass formaldehyde-free adhesive comprises mixed protein, biomass colloid,a modification treatment agent, a cross-linking agent, weak acid and the like. The biomass formaldehyde-free adhesive has the advantages of zero formaldehyde, high bonding strength, good water resistance, good anti-mildew effect, easiness in sizing and the like.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

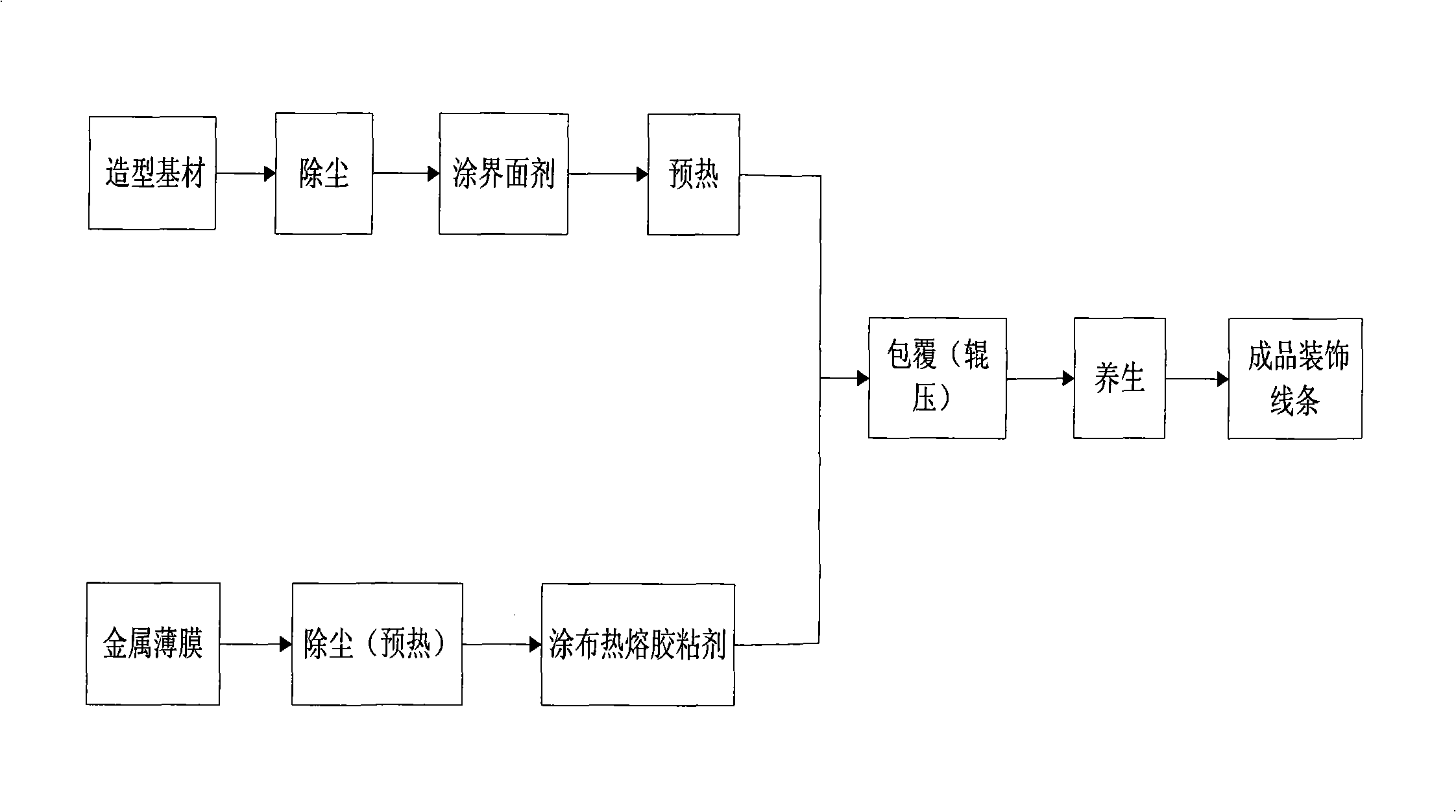

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

Environment-friendly nail-free glue for construction and preparation method thereof

ActiveCN103484040AReduce contentNo pollution in the processMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyvinyl acetate

The invention belongs to environment-friendly glue for construction, and particularly relates to environment-friendly nail-free glue for construction and a preparation method thereof. The nail-free glue comprises the following compositions: 12.0-40.0% of polyvinyl acetate resin, 18.0-40.0% of reinforcing filler, 15.0-40.0% of a solvent, 0.5-8.0% of a thixotropic agent, 0.1-3.5% of a coupling agent, 0.1-5.0% of a plasticizer, and 0.1-0.5% of a dispersing agent. The preparation method comprises the following steps: adding the solvent into a homogenizer, starting the homogenizer, then adding the polyvinyl acetate resin, stirring for 1-3 hours until all the materials are dissolved into a transparent and uniform liquid, further, adding the plasticizer, the coupling agent and the dispersing agent, uniformly stirring, then slowly adding the reinforcing filler, uniformly stirring to prepare a flowing pulpy mixture, then adding the thixotropic agent, and uniformly stirring to prepare the environment-friendly nail-free glue for construction. According to the invention, the environment is protected, the construction is convenient, no nail-holes are bonded, the bonding strength is high, and the ageing resistance is excellent.

Owner:GLEIHOW NEW MATERIALS CO LTD

Basalt-fiber-reinforced soybean-based wood adhesive and preparation method thereof

ActiveCN104817996AFully exposedEnsuring that the spatial structure unfoldsNon-macromolecular adhesive additivesProtein adhesivesAdhesiveNanoparticle

The invention discloses a basalt-fiber-reinforced soybean-based wood adhesive and a preparation method thereof. The wood adhesive is prepared with soybean protein, a soybean protein denaturation agent, a soybean protein modification agent, modified basalt fibers and distilled water. The preparation method includes following steps: 1) uniformly mixing the soybean protein denaturation agent with the distilled water; 2) adding the modified basalt fibers, the soybean protein and the soybean protein modification agent; and 3) finally homogenizing the reaction liquid to prepare the wood adhesive. In the invention, through a grafting reaction between the hydrophilic modified basalt fibers and the denaturated soybean protein, the soybean-based wood adhesive is effectively improved in adhesive water resistance and adhesive strength. Meanwhile, by means of the nano particles for surface-modification to the soybean-based wood adhesive, the compatibility between soybean protein molecules and the basalt fibers is promoted and the solid content of the adhesive is increased. The wood adhesive is convenient to apply, is high in adhesive strength and is excellent in water resistance.

Owner:JIANGSU ACAD OF AGRI SCI

Soybean-protein-containing aldehyde-free adhesive and preparation method thereof

InactiveCN106905919AImprove crosslink strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

To overcome the defects of a soybean adhesive in the prior art, the invention provides a soybean-protein-containing aldehyde-free adhesive and a preparation method thereof, and belongs to the technical field of an aldehyde-free adhesive used for timber. The aldehyde-free adhesive takes soybean protein as a main component, and contains a surfactant, the weight of which is 1-10% of that of soyabean protein, an alkaline compound, the weight of which is 3-15% of that of soyabean protein, metal oxide, the weight of which is 5-20% of that of soyabean protein, polyamide epoxy haloalkane resin, the weight of which is 3-20% of that of soyabean protein, and water the weight of which is 2-5 times of that of soyabean protein. Soybean protein is taken as a substrate, and the surfactant, the modifier of metal oxide and hydroxide and a cross-linking agent are used for comprehensive modification of soybean protein, so that the adhesive strength and water proofness of the soybean protein adhesive are improved.

Owner:UNIV OF SCI & TECH LIAONING

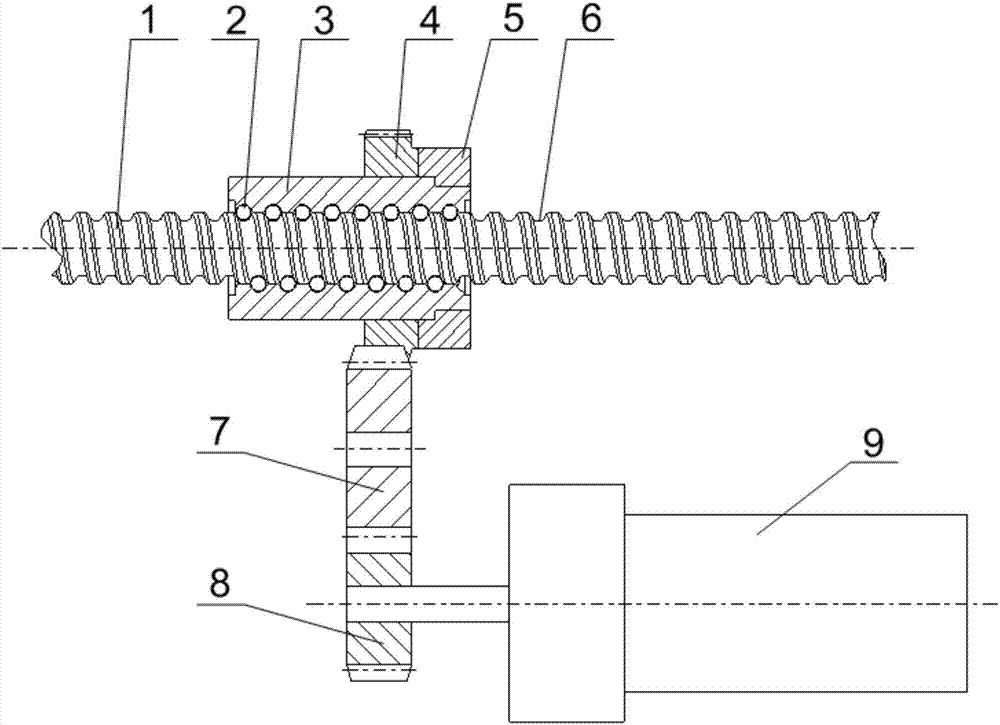

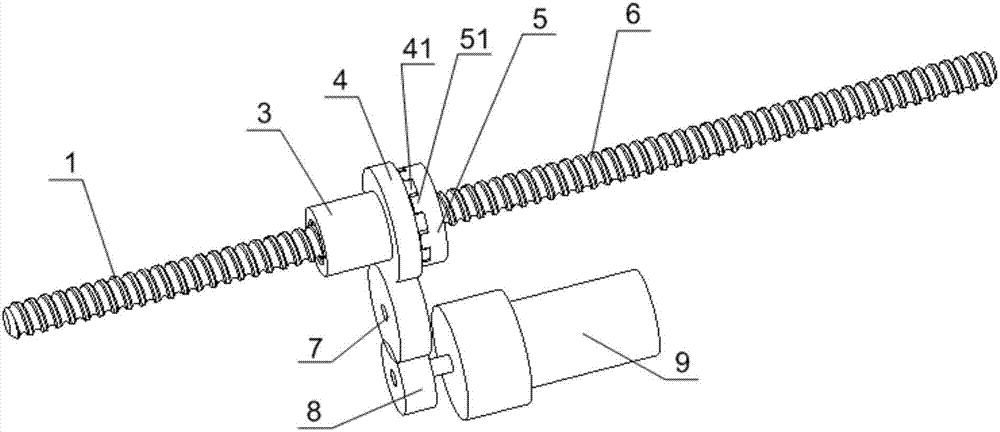

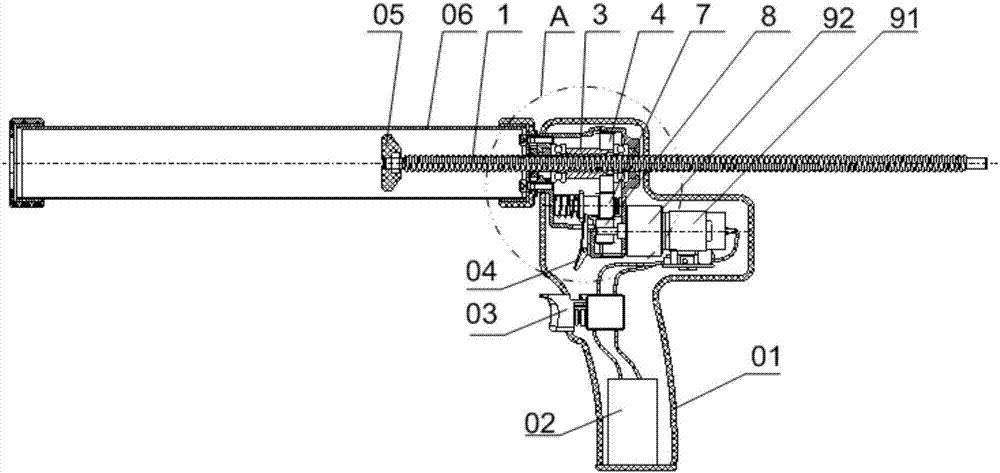

Rubber gun and driving device thereof

ActiveCN107282378ARealize transmissionClutch realizationLiquid surface applicatorsCoatingsEngineeringScrew thread

The invention discloses a rubber gun and a driving device thereof. The driving device of the rubber gun comprises a lead screw, a nut and a first gear, the nut is matched with the lead screw, and balls are arranged between the lead screw and a thread groove of the nut; the periphery of the nut is sleeved with the first gear in a sliding mode, the first gear is connected with the nut in a clutch mode, and a driving tooth used for being connected with the driving device in a driving mode is arranged on the periphery of the first gear. The driving device keeps a complete lead-nut mechanism, is simple in structure, and is provided with few parts; the balls will not fall off from the thread groove and also will not get stuck; the lead screw can move in the front-back direction, power transmission is reliable, large thrust can be provided, and reliable clutch driving can be achieved.

Owner:柏永茂

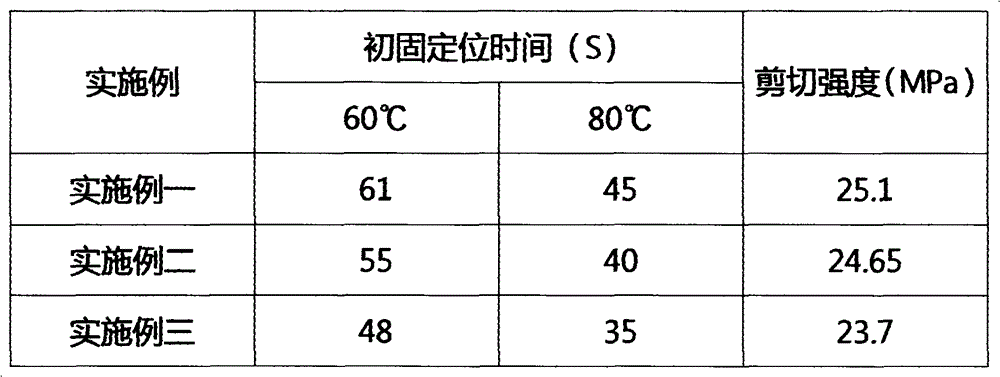

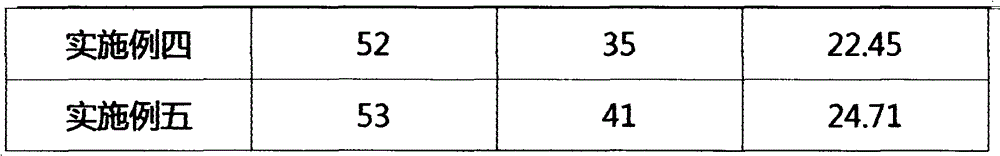

Bi-component acrylic ester structure adhesive and preparation method thereof

The invention discloses a bi-component acrylic ester structure adhesive and a preparation method thereof. According to the invention, a monomer, an elastomer, toughening resin, a polyurethane prepolymer, and methacrylic acid are added into a reaction vessel, such that a uniform liquid can be obtained in the reaction vessel; gamma-methacryloyloxy trimethoxy silane, N,N-dimethyl-p-toluidine, and a peroxide are added to the liquid; the mixture is stirred, such that a main agent is obtained. When a promoting agent comprises two components, biphenyl-A epoxy resin is added into a reaction vessel; the mixture is stirred under normal temperature; vanadium salt is added, and stirring is continued, such that the promoting agent is prepared. A monomer, toughening resin, an elastomer, and a polyurethane prepolymer are added into a reaction vessel, and are stirred, such that a uniform liquid is obtained; the promoting agent and an inorganic filling material are added to the liquid, and the mixture is stirred, such that a curing agent is obtained. The adhesive is advantaged in fast heating positioning. When the adhesive is mixed, a storage life of the adhesive under normal temperature is long, adhesive application is convenient, and a shear strength is high.

Owner:HB FULLER CO

Preparation method of modified starch adhesive

The invention provides a preparation method of a modified starch adhesive, which comprises the following steps: (1) adding deionized water as a solvent into a three-neck flask, adding corn starch into the deionized water, and stirring and heating until the corn starch is sufficiently swollen; (2) adding hydrochloric acid, heating, adding an oxidizer, and keeping the temperature to sufficiently react the oxidizer with the corn starch; (3) adding polyvinyl alcohol, and heating; (4) adding a boric acid solution, heating, and keeping the temperature to sufficiently perform coupling reaction on the boric acid and polyvinyl alcohol; (5) adding a formaldehyde solution, and continuing keeping the temperature; (6) adding sodium hydroxide to terminate the reaction; and (7) adding a surfactant, a drier and a preservative, cooling and discharging to obtain the modified starch adhesive. The preparation method has the advantages of simple technique, accessible raw materials and low cost, and can obtain the modified starch adhesive, which has the advantages of favorable initial viscosity, high drying rate, high viscosity, high mounting performance and stable performance and is convenient for sizing.

Owner:TANGSHAN NORMAL UNIV

Preparation method of formaldehyde-free soybean meal-based wood adhesive for artificial boards

ActiveCN109880586ALow costLow priceNon-macromolecular adhesive additivesProtein adhesivesEpoxyChemical reaction

The invention relates to a preparation method of a formaldehyde-free soybean meal-based wood adhesive for artificial boards, and belongs to the technical field of adhesives. According to the invention, renewable resources, namely soybean meal, are used as raw materials, a water phase is selected as a solvent, and a process step of an alkali-acid two-step method is adopted. Epoxy resin, dicyandiamide, low-molecular-weight polyamide and soybean protein are combined for modification, a chemical reaction is carried out at the same time, and therefore the formaldehyde-free soybean meal-based wood adhesive with very high water resistance and bonding strength is prepared; the adhesive has the advantages of no formaldehyde, low viscosity, good cold pressing performance, low cost, high adhesive strength and the like; the adhesive does not volatilize formaldehyde, phenol or other harmful substances, has the characteristic of no formaldehyde, and is safe and environment-friendly, and the preparedsoybean meal-based wood adhesive is low in viscosity, convenient for applying, good in coating and pre-pressing performance, easy to spray and apply, convenient for repairing of plywood and capable of preventing a shaving board from being scattered, and the problems that a soybean adhesive is high in viscosity and difficult to spray are solved.

Owner:GUANGXI UNIV

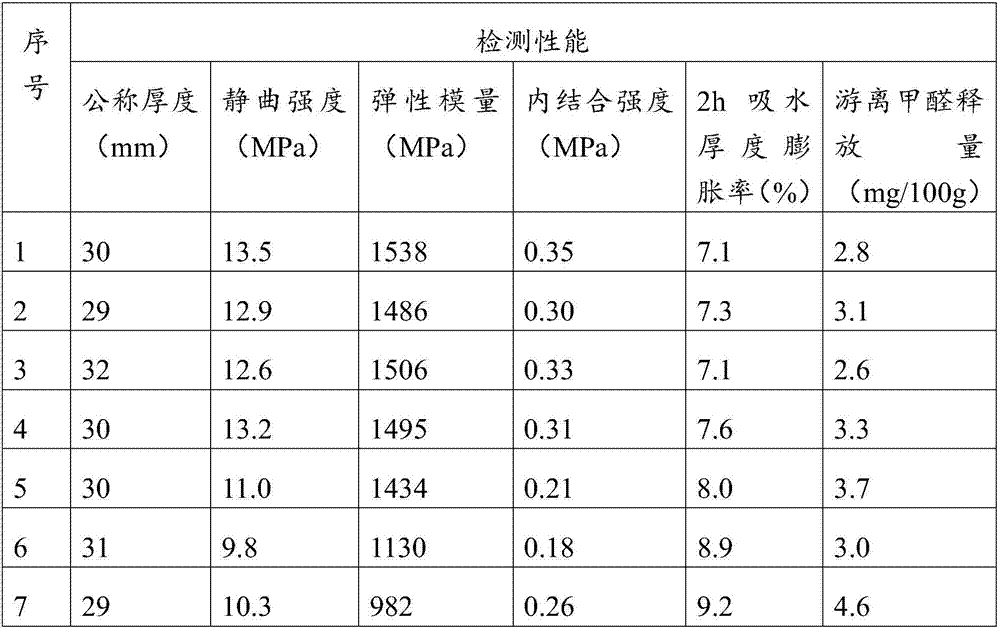

Production method of particleboard

InactiveCN107379205AIncrease profitAdd channelFlat articlesDomestic articlesWood shavingsEngineering

The invention discloses a production method of a particleboard. The production method comprises the following steps of (1) wood shaving preparation; (2), drying and screening; (3) glue application; (4) laying and precompression; (5) hot press molding; and (6) edge sawing and sanding. According to the production method provided by invention, rough core layer wood shavings subjected to glue application are pretreated, and then procedures including laying, precompression and hot press molding are carried out, so that the hot pressing time can be effectively reduced, the hot press molding ratio is increased, and the production efficiency is improved; the particleboard prepared by the production method is low in cost and free formaldehyde releasing quantity and high in strength at the same time; and the production method provided by the invention is capable of effectively improving the quality of a particleboard product and increasing the benefit of an enterprise and is worthy of popularization.

Owner:广西祥盛家居材料科技股份有限公司

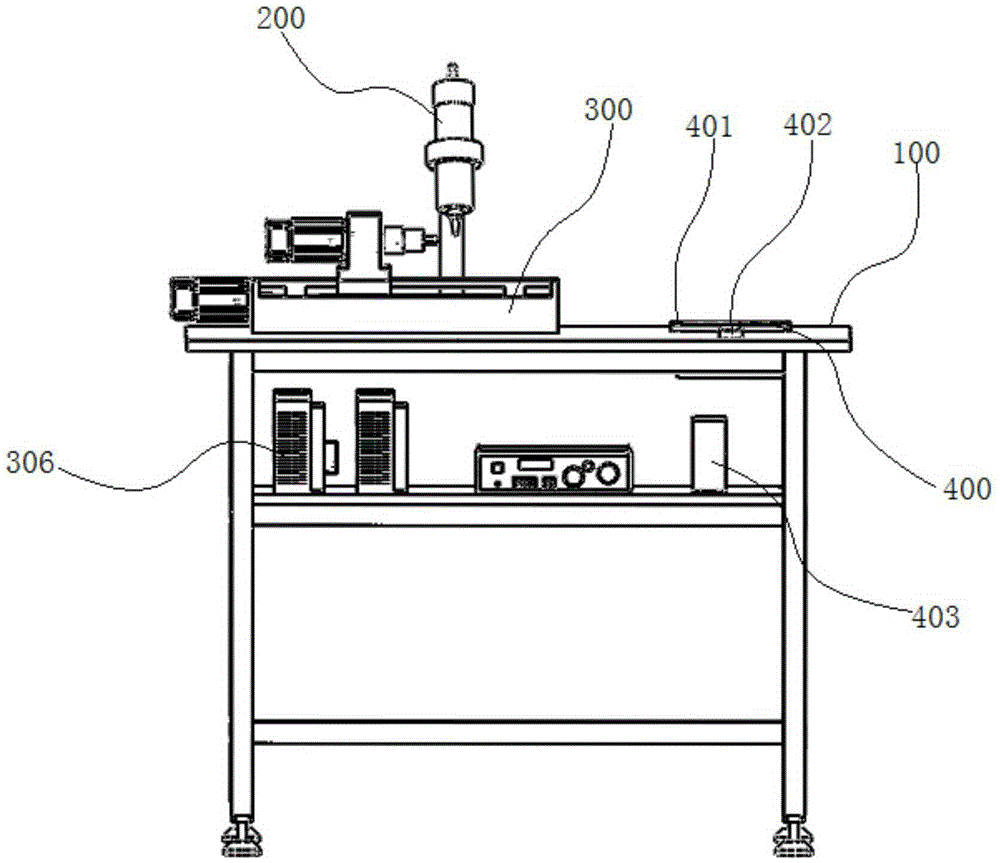

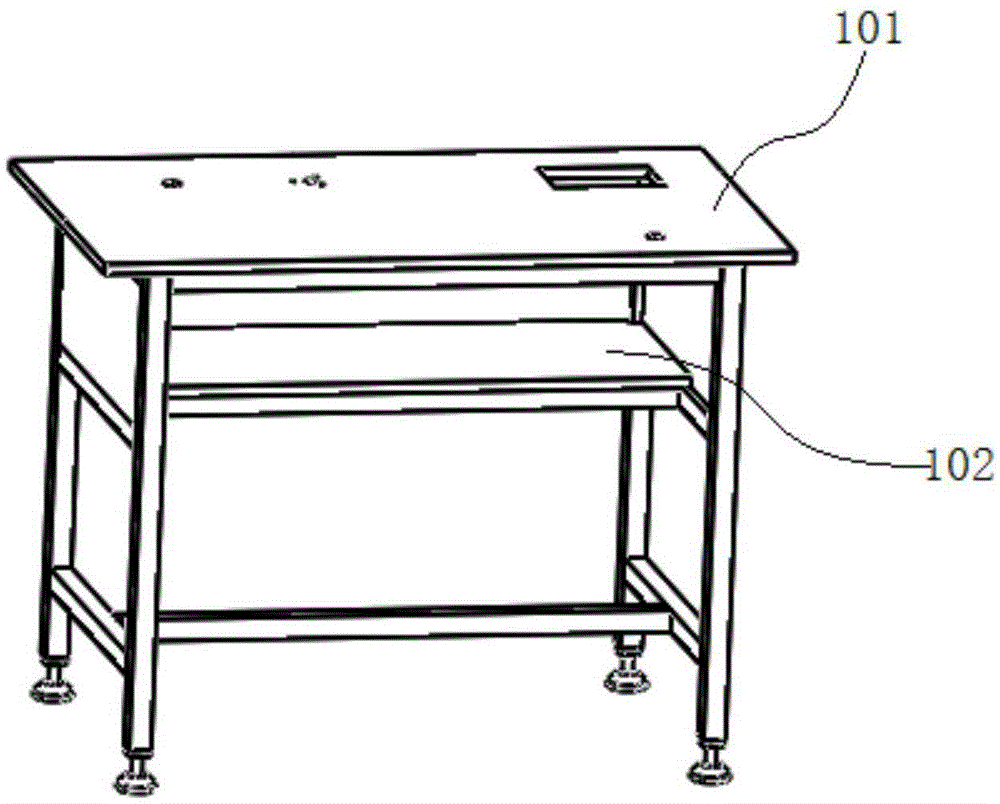

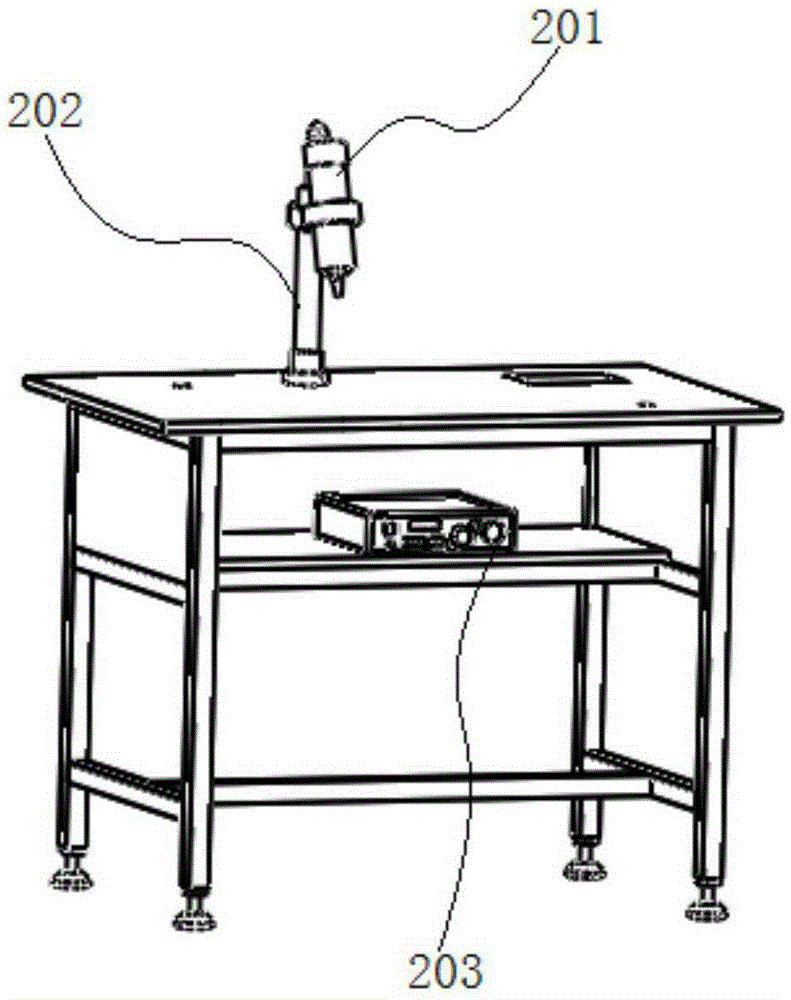

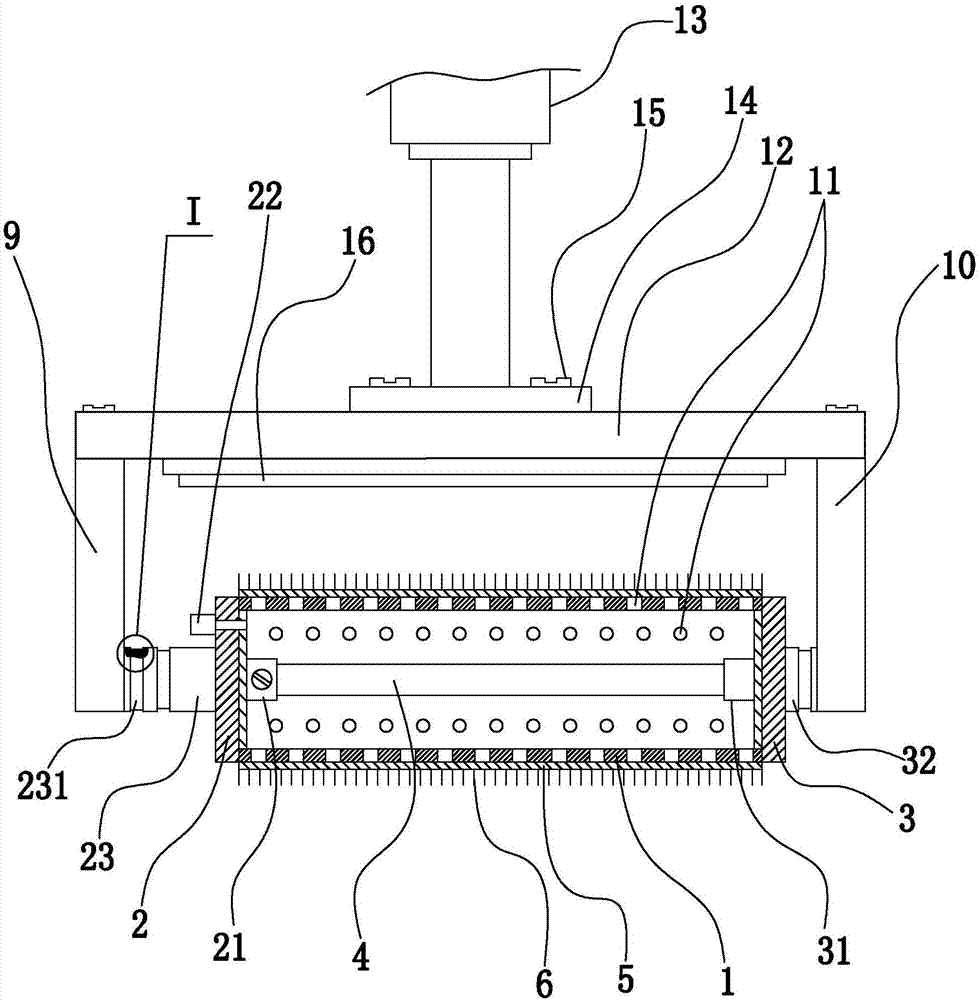

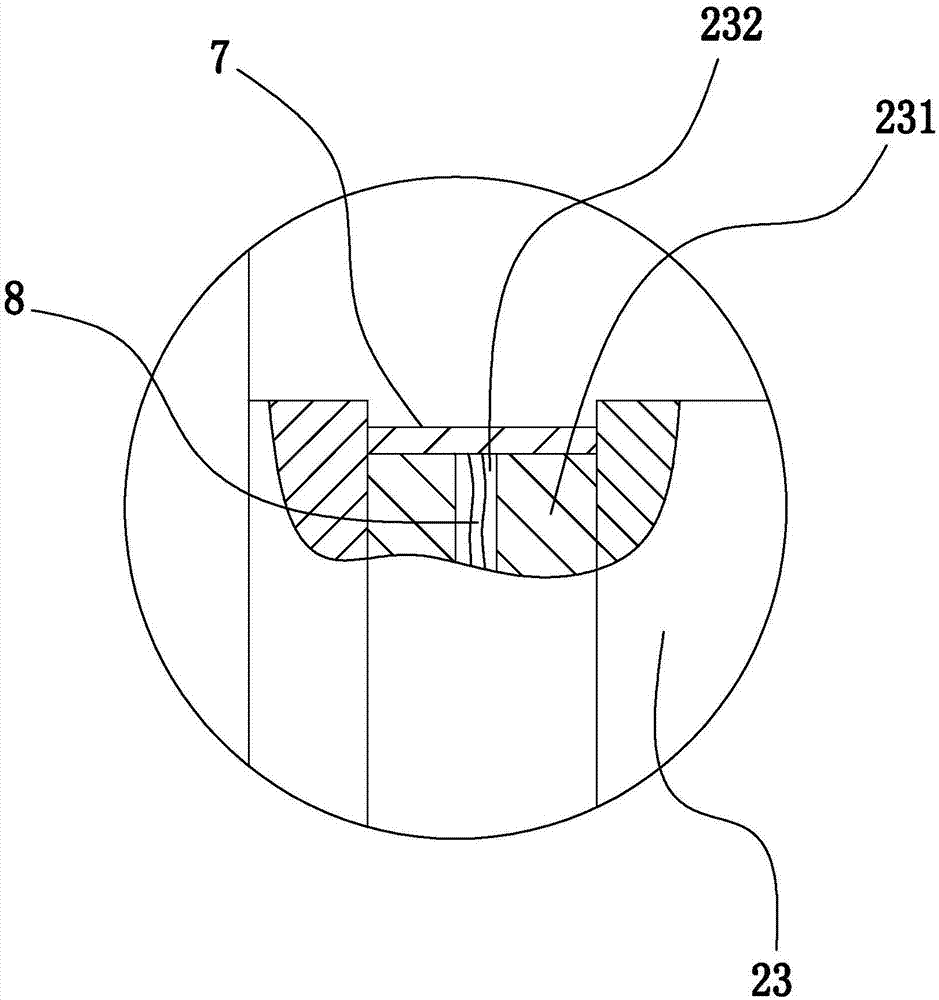

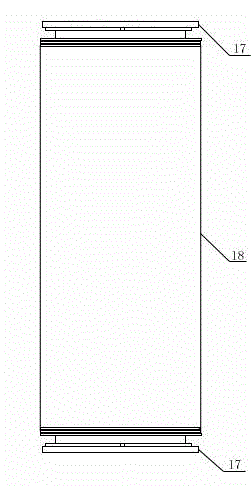

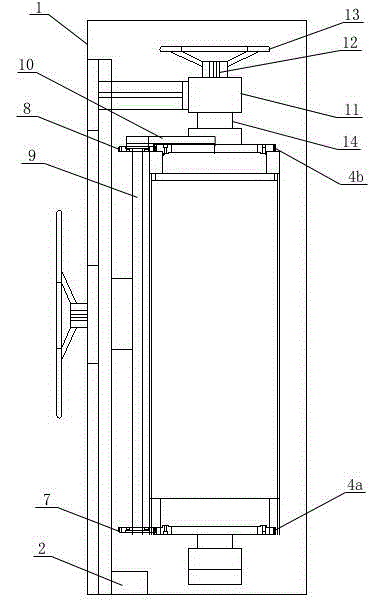

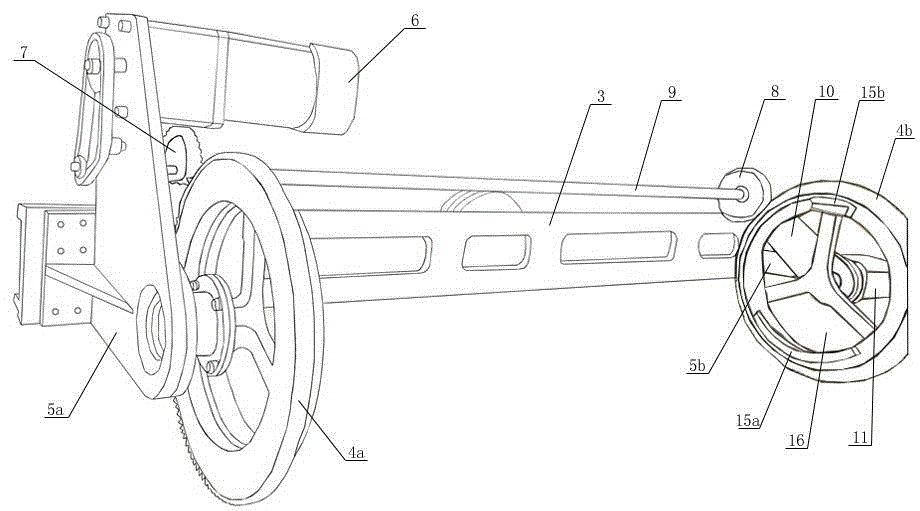

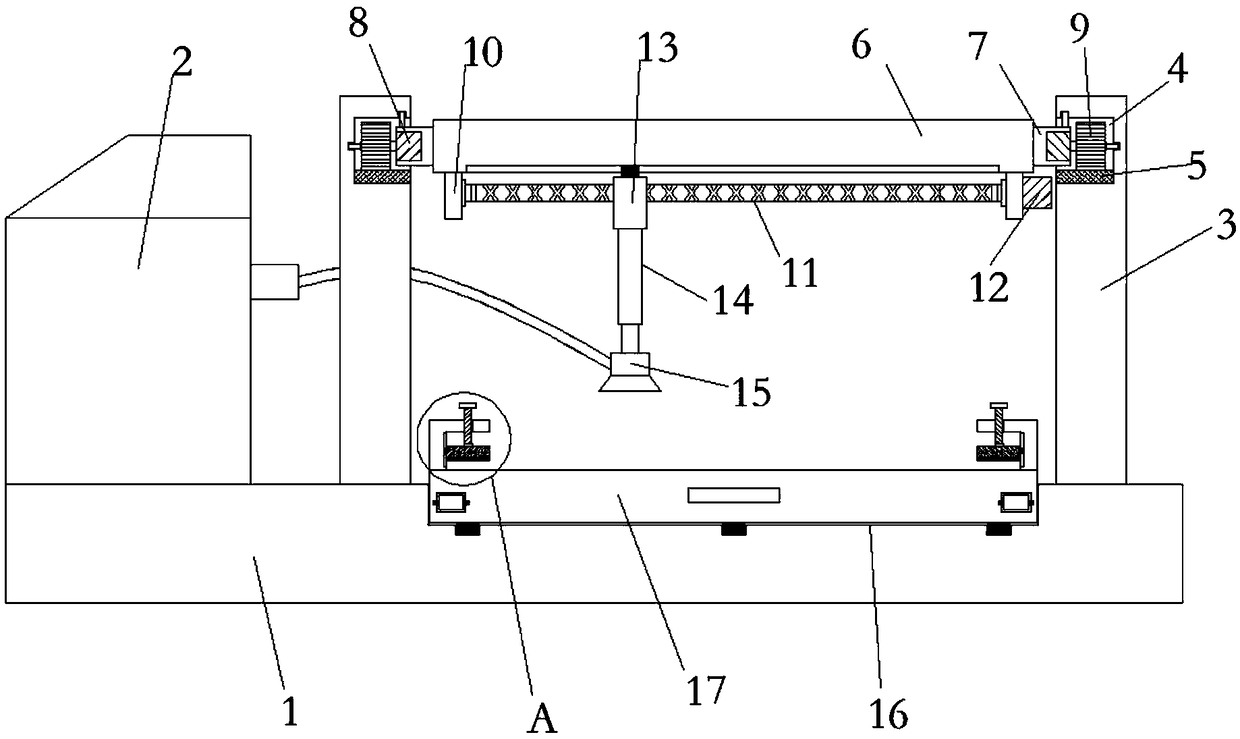

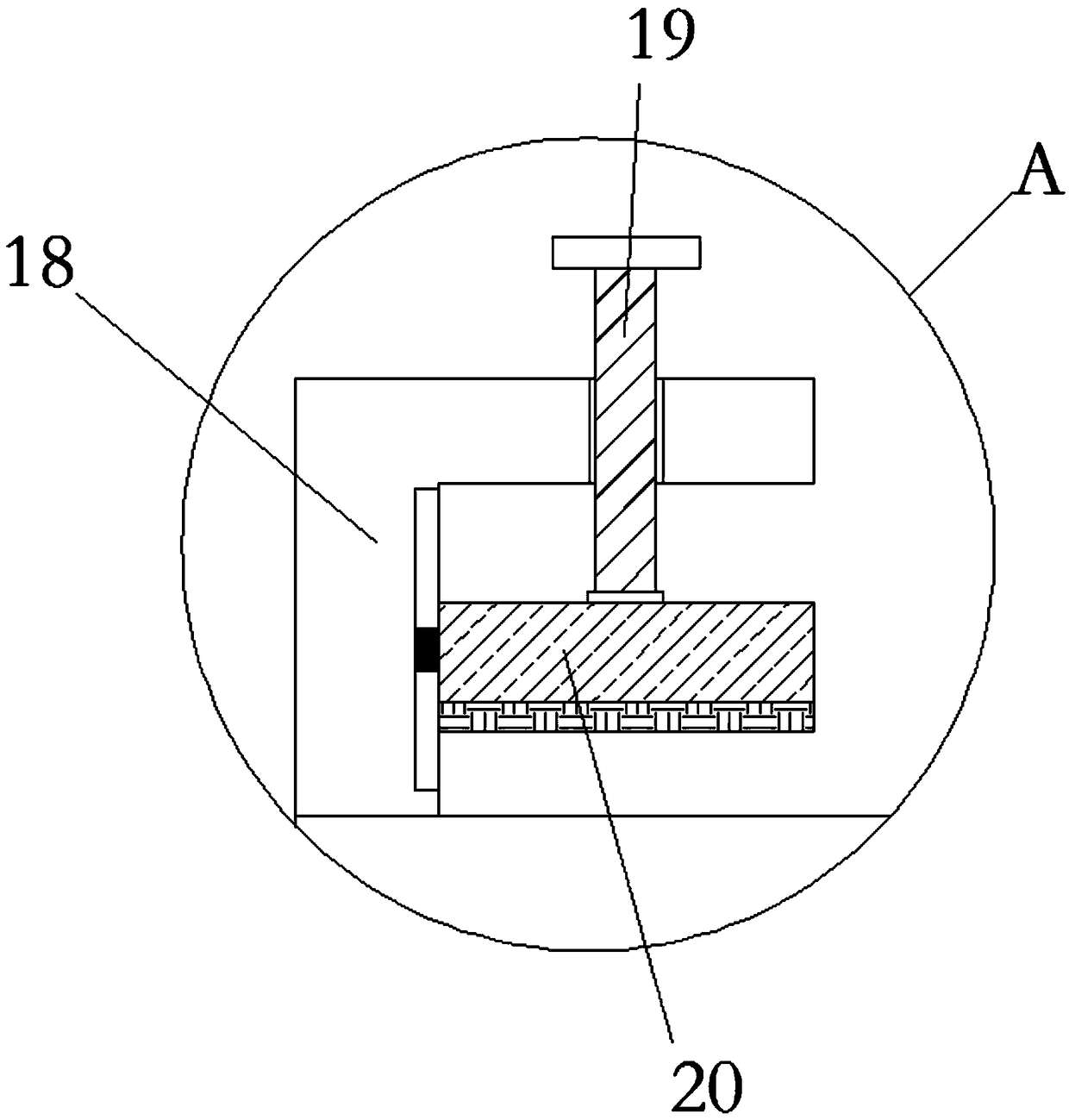

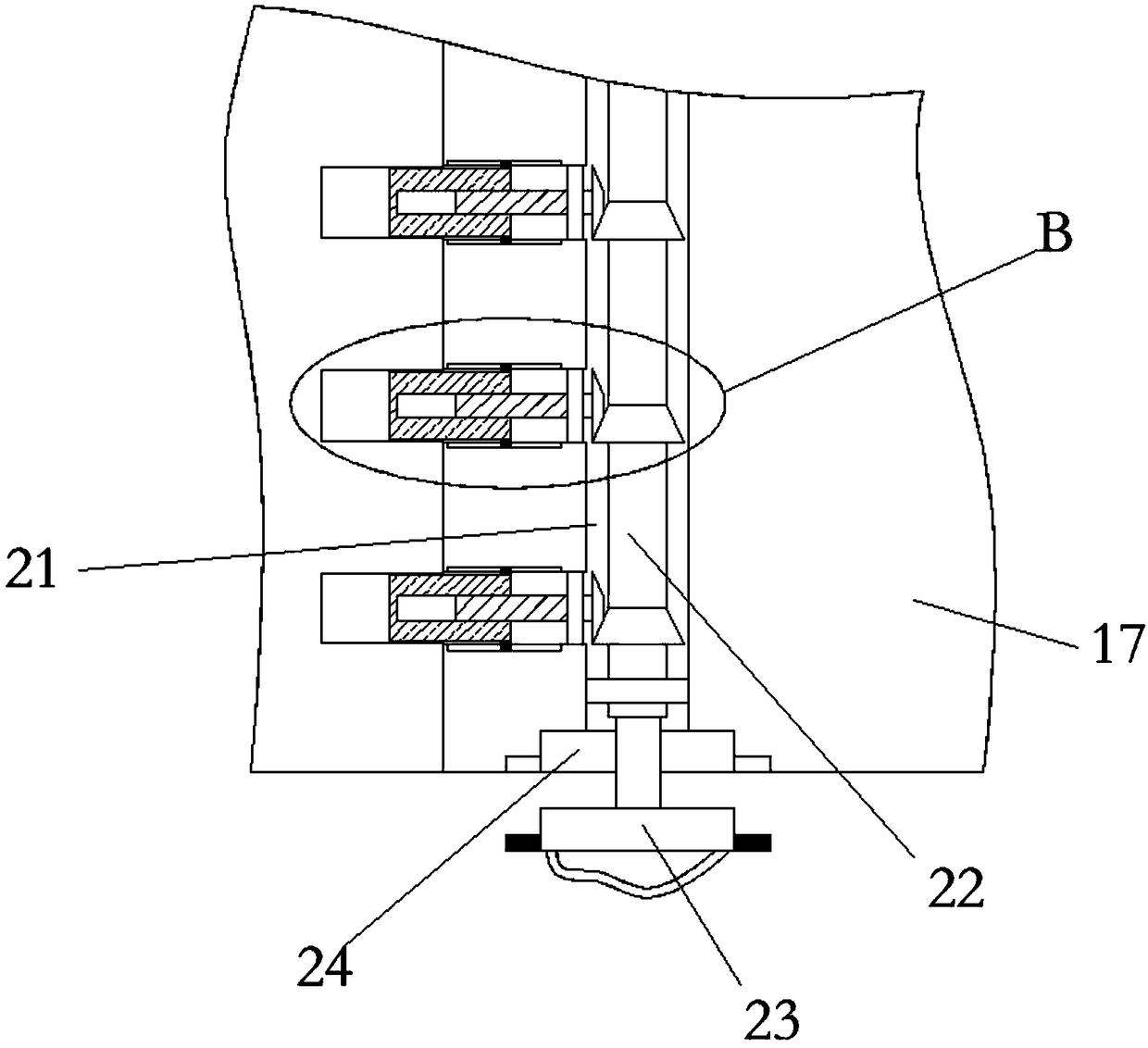

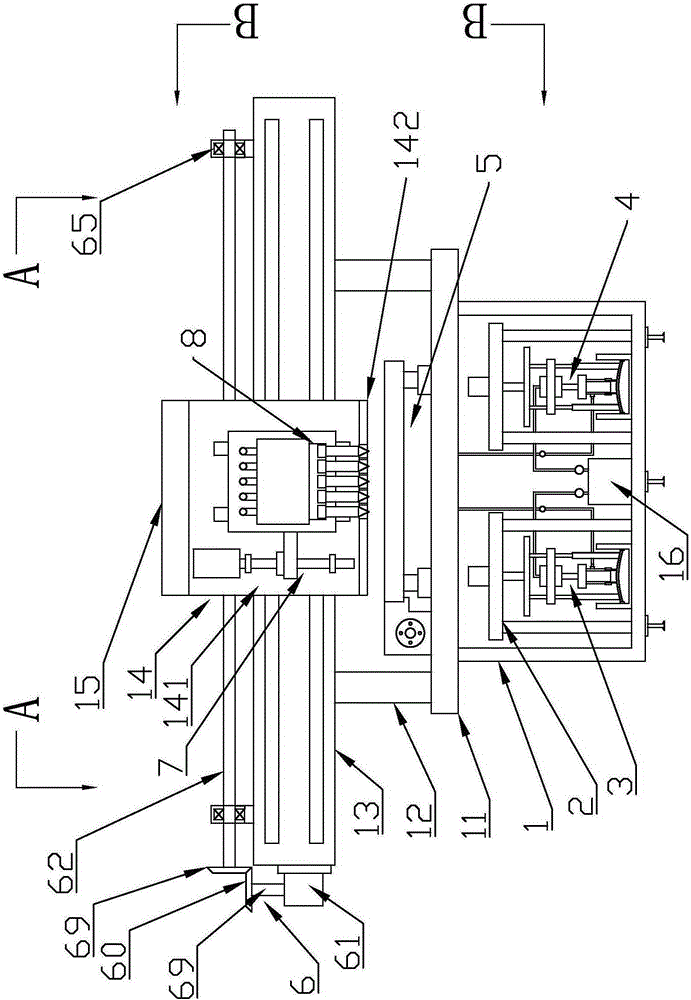

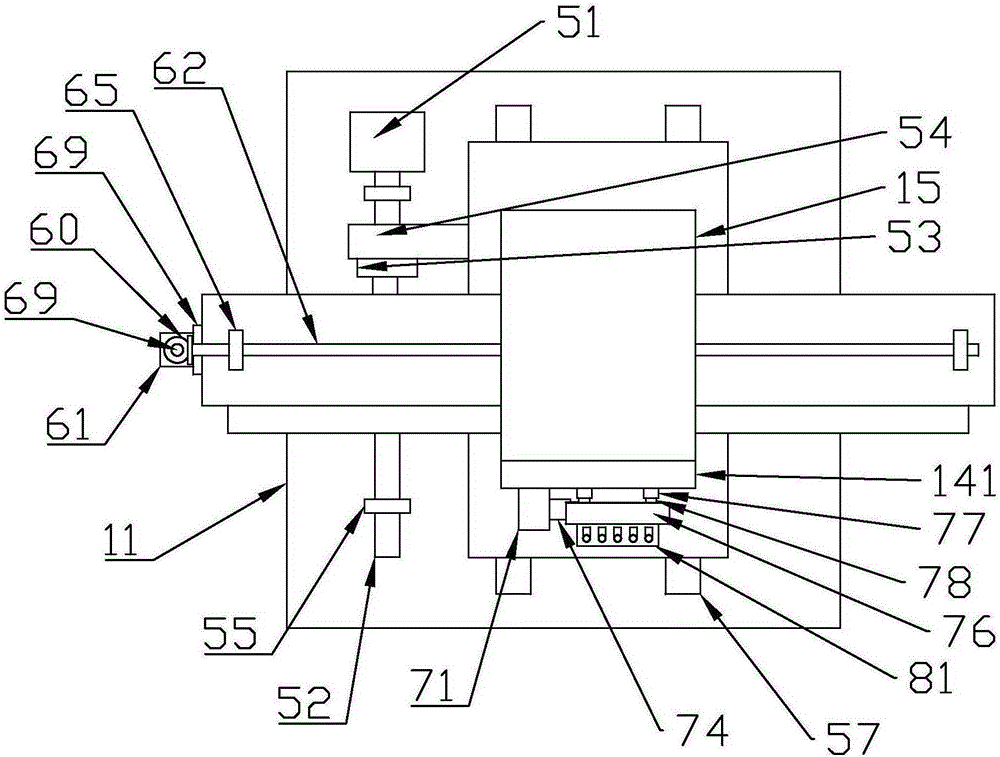

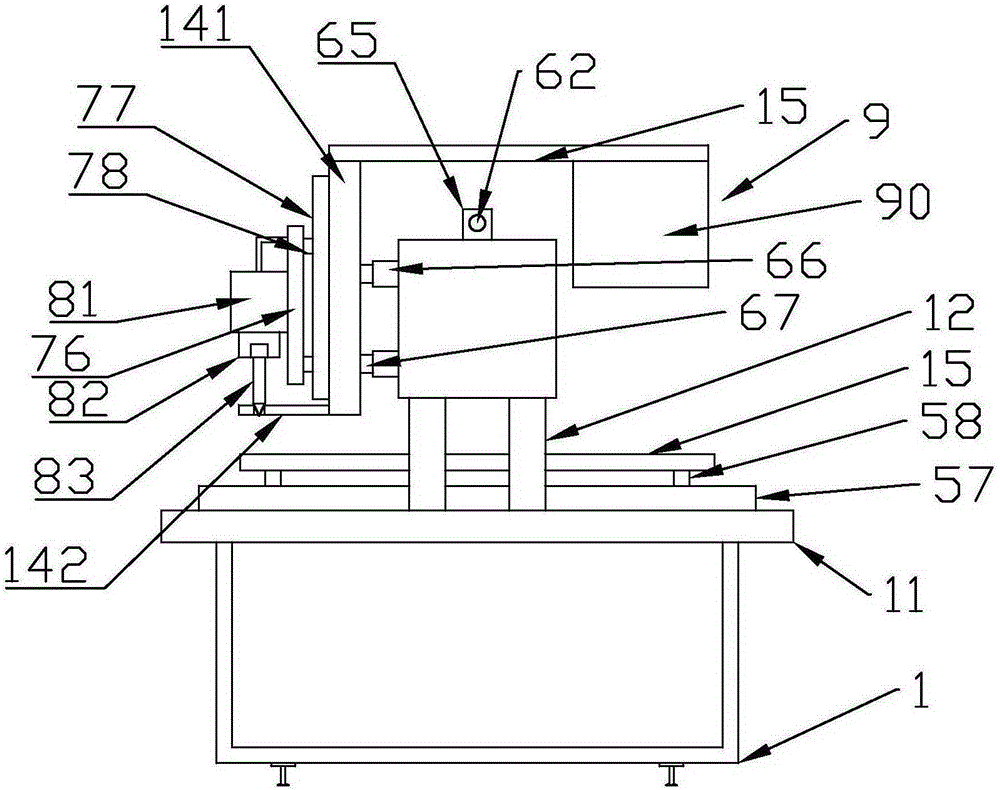

Gluing apparatus and gluing method for gluing magnetic steel for permanent magnet servo motor

ActiveCN105322737AAutomatic glue applicationQuick GlueManufacturing stator/rotor bodiesAtmospheric pressureCooperative work

The invention discloses a gluing apparatus and a gluing method for gluing magnetic steel for a permanent magnet servo motor. The apparatus comprises an equipment table frame, an air pressure gluing apparatus, a rotor clamping and driving apparatus, and a control mechanism; the air pressure gluing apparatus is arranged on the equipment table frame; the rotor clamping and driving apparatus is arranged on the equipment table frame; the driven and clamped rotors helically move relative to the air pressure gluing apparatus, so that the surfaces of the rotors pass through the air pressure gluing apparatus in sequence; the control mechanism is connected with the air pressure gluing apparatus and the rotor clamping and driving apparatus, and controls the air pressure gluing apparatus and the rotor clamping and driving apparatus for realizing cooperative work. In the gluing process, the control mechanism determines a gluing track on the surface of a to-be-glued rotor initially; then the rotor clamping and driving apparatus is controlled based on the track; the rotor clamping and driving apparatus drives the to-be-glued rotors to rotate and move to enable the surfaces of the to-be-glued rotors to pass through the air pressure gluing apparatus in sequence according to the determined gluing track. The rapid gluing in gluing the magnetic steel for the permanent magnet servo motor is realized according to the scheme.

Owner:SHANGHAI LEIZHI MOTOR

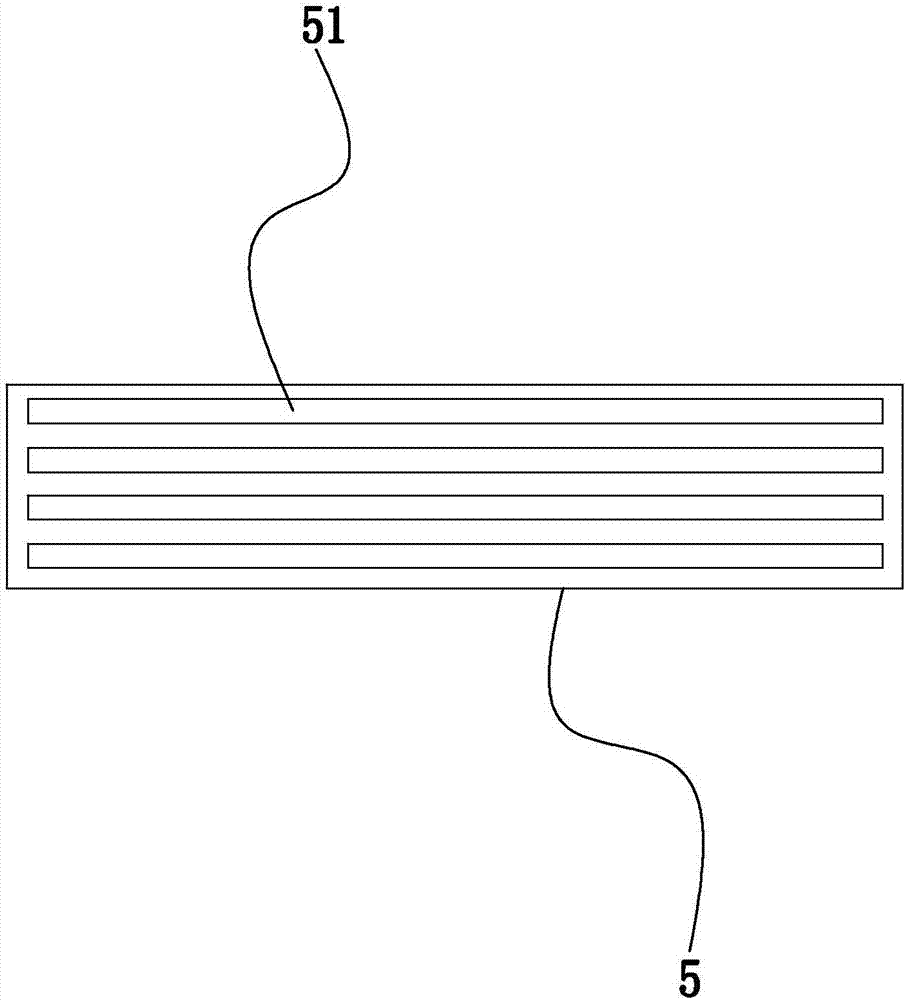

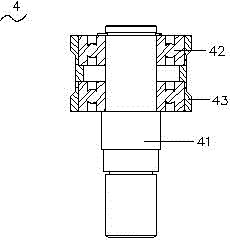

Gumming roller device for hot-melting compound machine

PendingCN107457142AReasonable structureEasy connectionLiquid surface applicatorsCoatingsThreaded pipeAdhesive

The invention relates to a gumming roller device for a hot-melting compound machine. The gumming roller device comprises a roller barrel, wherein a left sealing screw cap is in threaded connection with the left end of the roller barrel; a right sealing screw cap is in threaded connection with the right end of the roller barrel; a threaded pipe is integrally arranged at the middle of the right end surface of the left sealing screw cap; a positioning shaft sleeve is integrally arranged at the middle of the left end surface of the right sealing screw cap; a heating rod is transversely arranged in the roller barrel; the left end of the heating rod is in threaded connection with the threaded pipe; the right end of the heating rod is positioned in the positioning shaft sleeve; a feeding pipe is integrally arranged on the left sealing screw cap; a plurality of discharge holes are formed in the roller barrel; a rubber sleeve is connected onto the outer surface of the roller barrel in a sleeving manner; the inner wall surface of the rubber sleeve is fixed with the outer surface of the roller barrel in an adhering manner; a plurality of rectangular through holes are formed in the rubber sleeve; and a hairbrush layer is fixedly arranged on the outer surface of the rubber sleeve. According to the gumming roller device for the hot-melting compound machine provided by the technical scheme of the invention, the structural design is reasonable, the structure is simple, the uniform gumming is achieved, the heating function is achieved, the flowability of an adhesive is good, and the gumming operation is convenient.

Owner:平湖市新保纺织科技有限公司

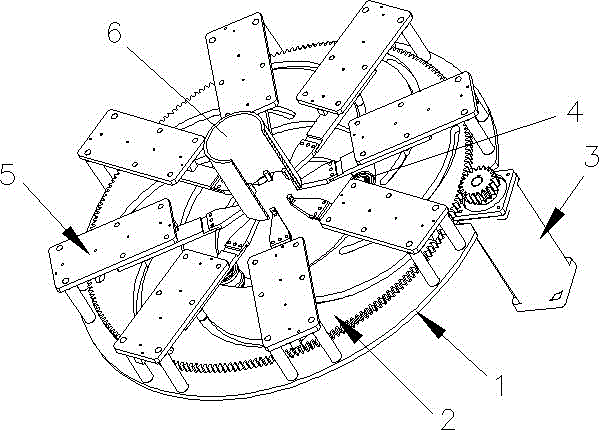

Stencil clamping sizing device and sizing method thereof

The invention discloses a stencil clamping sizing device. The stencil clamping sizing device comprises a sizing cabinet, a stencil clamping unit and a timing heater. The stencil clamping unit comprises a rotating mounting base, a clamping ring assembly and a clamping ring rotation drive mechanism, wherein the rotating mounting base is connected to a rotating mounting base rotation drive mechanism, the clamping ring assembly is composed of a fixed clamping ring and a movable clamping ring which are rotatably connected to a fixed clamping ring mounting base and a movable clamping ring mounting base through rolling bearings respectively, and the clamping ring drive mechanism is used for driving the fixed clamping ring and the movable clamping ring to rotate to the same direction synchronously. A movable clamping ring adjustment mechanism is mounted on the movable clamping ring mounting base. The stencil clamping sizing device uses automatic uniform sizing and sealing heating drying by clamping a money printing stencil, so that an end ring and a stencil cylinder are high in adhesive strength, the deficiency that manual sizing is uneven, low in yield and print run and the like, and the print run rate of the stencil is greatly increased in a printing production process of the stencil.

Owner:CHENGDU BANKNOTE PRINTING

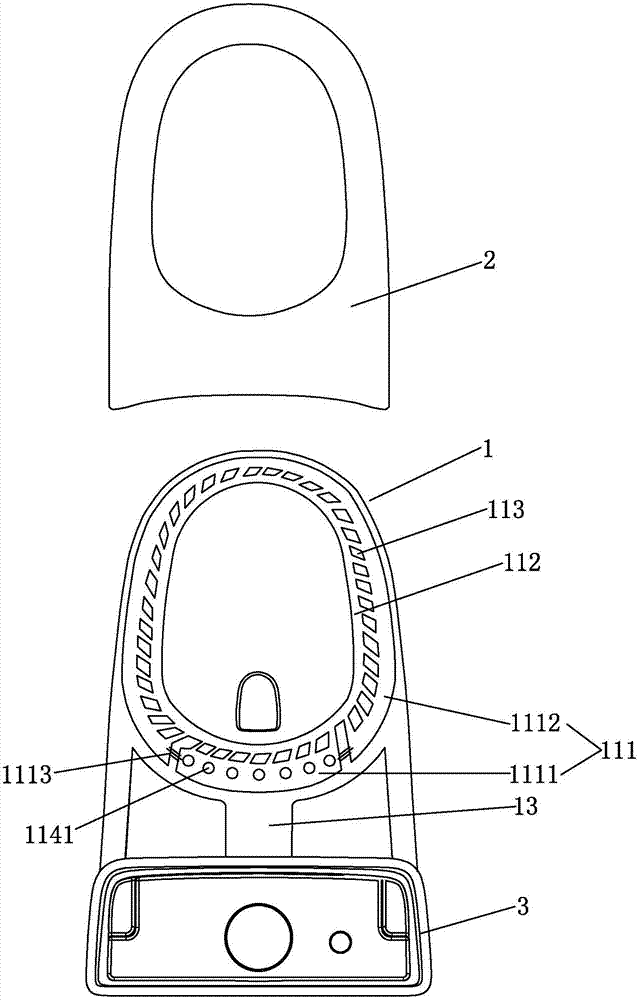

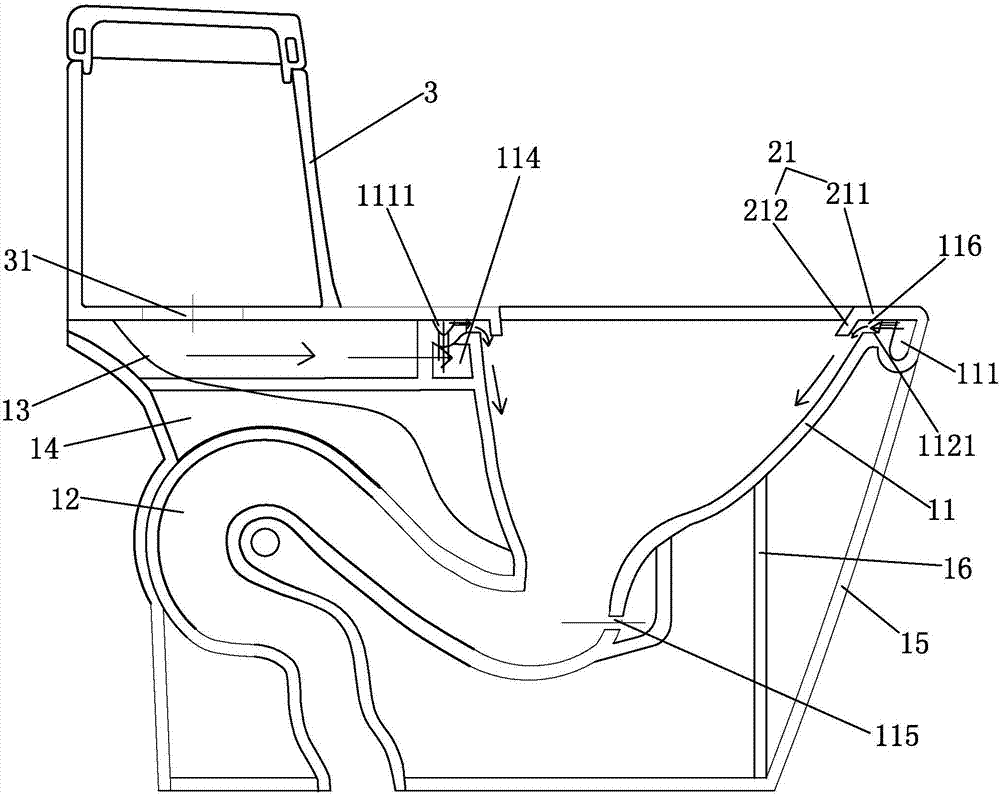

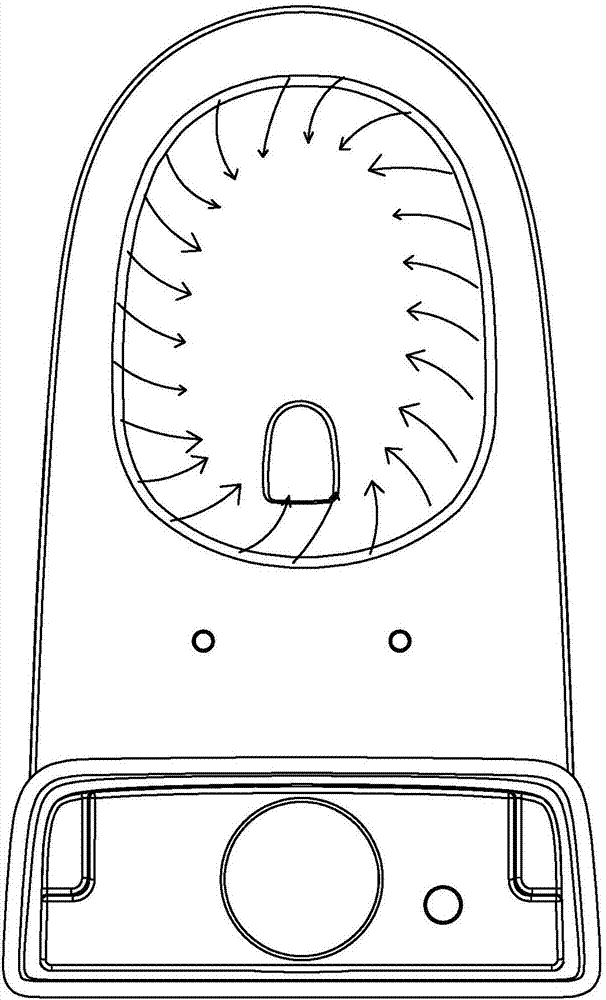

Eddy water curtain type rinsing toilet

ActiveCN107345418AImprove experienceAvoid affecting the cleaning effectUrinalsWater closetsWater trapWater flow

The invention discloses an eddy water curtain type rinsing toilet which comprises a toilet body, wherein the toilet body is provided with a bed pan, a drain pipe and a rinsing water channel. A dirt inlet of the drain pipe is communicated to the bottom of the bed pan; the top of the bed pan is annularly provided with a water guide ring, a lower edge portion located on the inner side of the water guide ring and an upper edge portion, a rinsing seam communicated with the water guide ring is formed between the upper edge portion and the lower edge portion, and a water guide structure is arranged on the lower edge portion to guide a water flow to form an eddy flow. According to the eddy water curtain type rinsing toilet disclosed by the invention, on the one hand, a rinsing hole does not need to be formed in the top of the bed pan, so that the processing technology is simplified and the top of the bed pan is prevented from cracking and the rinsing effect is prevented from being affected; on the other hand, eddy water curtain rinsing can be formed, so that not only is the rinsing vigor improved, but also the rinsing effect is enhanced, the sense of beauty can be added, and the user experience effect is enhanced.

Owner:JOMOO KITCHEN & BATHROOM

Flocking gluing machine

InactiveCN109013195AIncrease the gluing rangeEasy to useLiquid surface applicatorsCoatingsBall bearingPulp and paper industry

The invention relates to the technical field of a gluing machine, and discloses a flocking gluing machine. The flocking gluing machine comprises a bottom plate, a gluing machine body is fixedly arranged at the upper end of the bottom plate, and the upper end of the bottom plate is fixedly connected with two symmetrical stand columns. Wheel grooves are symmetrically formed in the opposite sides, close to the upper end, of the two stand columns, and the inner wall of the bottom of each wheel groove is fixedly connected with a rack. A supporting rod is arranged between the two stand columns, andthe two ends of the supporting rod are both fixedly connected with connecting blocks extending into the wheel grooves. One side, far away from the supporting rod, of each connecting block is fixedly embedded with a first motor, and an output shaft of the first motor is fixedly connected with a gear meshing with the corresponding rack. The lower end of the supporting rod is symmetrically and fixedly connected with two clamping plates, and the opposite sides of the two clamping plates are rotationally connected with a same reciprocating screw rod through ball bearings. A second motor is fixedlyarranged on the surface of one of the clamping plates, and an output shaft of the second motor is fixedly connected with one end of the reciprocating screw rod through a through hole. The flocking gluing machine has the advantage of convenience in gluing.

Owner:嘉善欣达胶业有限公司

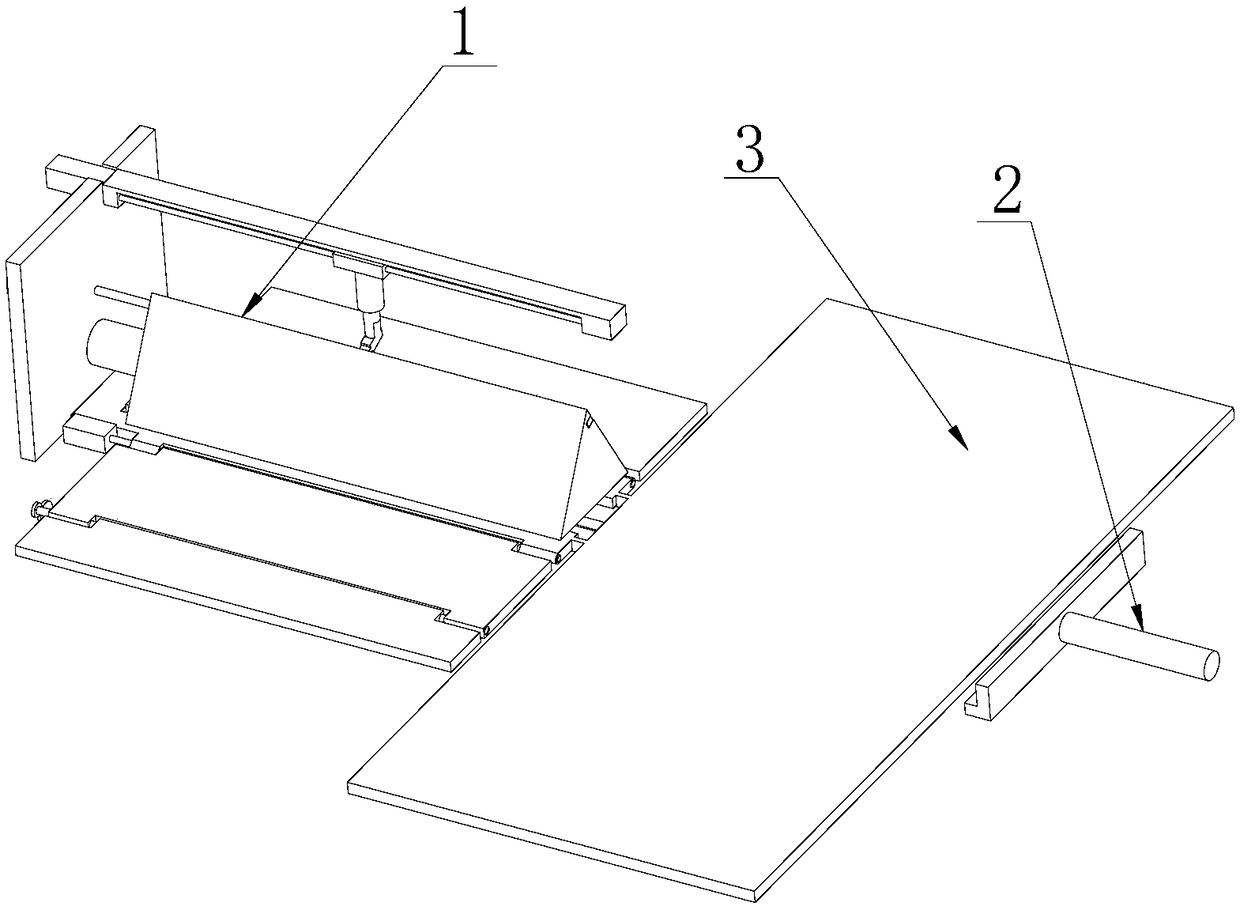

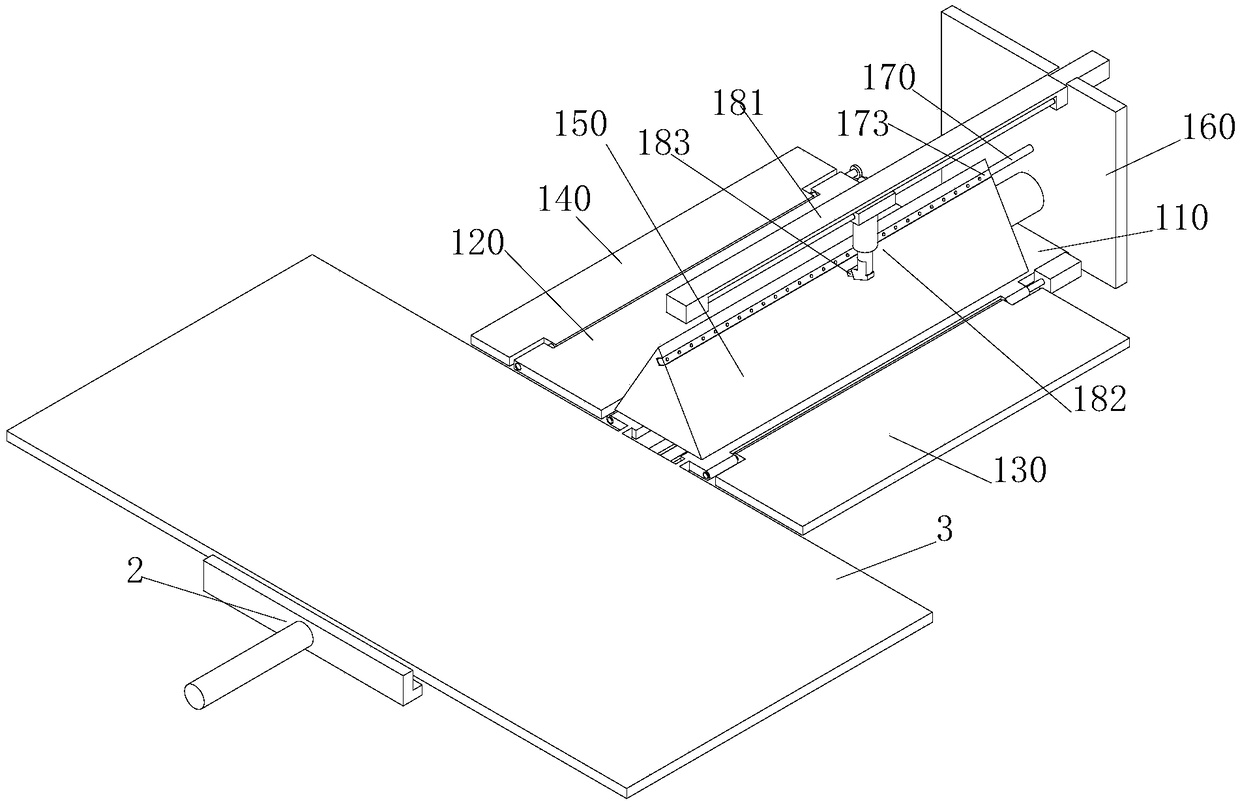

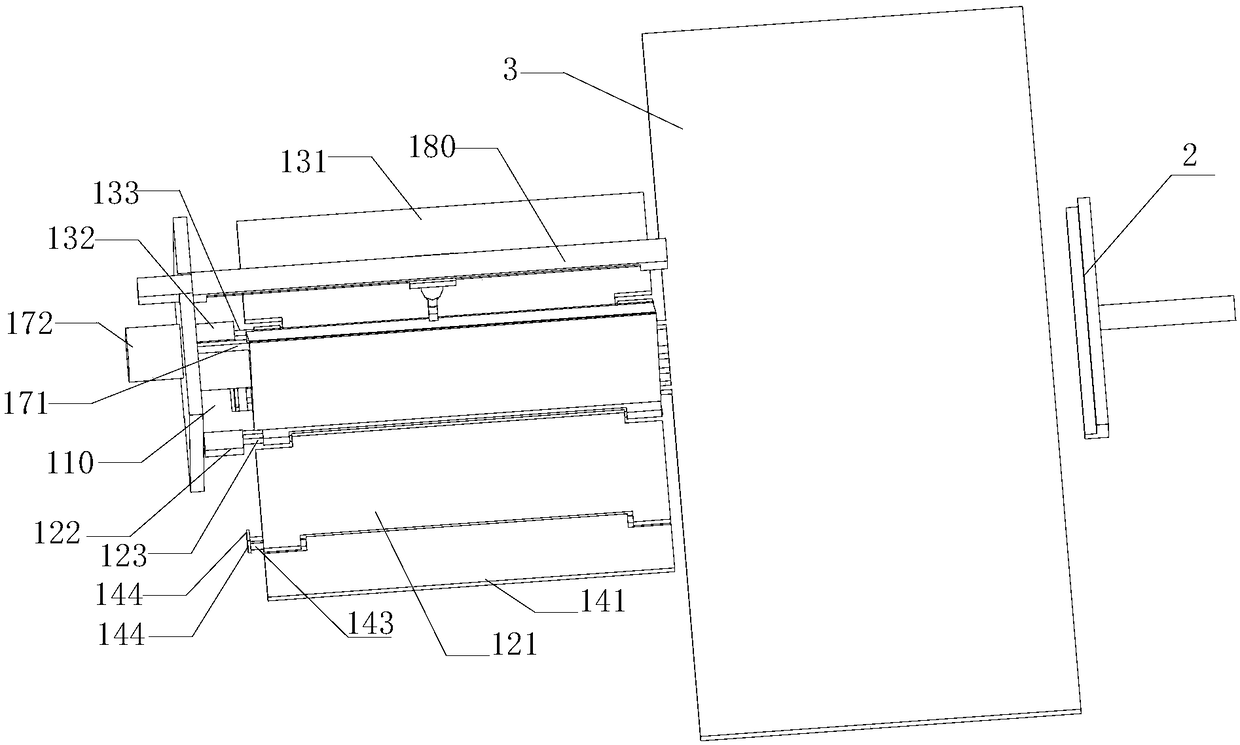

Double-component glue spreading machine applied to hollow glass production

InactiveCN105195379ASolve the glue problemSimple structureLiquid surface applicatorsCoatingsAgricultural engineeringGlass production

The invention discloses a double-component glue spreading machine applied to hollow glass production. The double-component glue spreading machine comprises a frame and a middle workbench, wherein the middle workbench is located on the frame and provided with a support frame and a Y-direction conveying device, a crossbeam is disposed on the support frame, an X-direction moving device is disposed at the front end of the crossbeam and connected with a glue spreading trolley, the glue spreading trolley comprises a vertical connecting seat and a horizontal baffle, the vertical connecting seat is connected with the horizontal baffle, a Z-direction moving device and a glue spreading device are disposed on the vertical connecting seat, a connecting plate is disposed at the upper end of the vertical connecting seat and connected with a glue mixing device, the glue mixing device is connected with an A-type glue supply device and a B-type glue supply device, an air inlet system is disposed at the bottom of the frame, the left side of the air inlet system is connected with the A-type glue supply device, and the right side of the air inlet system is connected with the B-type glue supply device. The double-component glue spreading machine is simple in structure, scientific and convenient, high in pertinence, high in automation level and capable of well solving the glue spreading problems of hollow glass.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

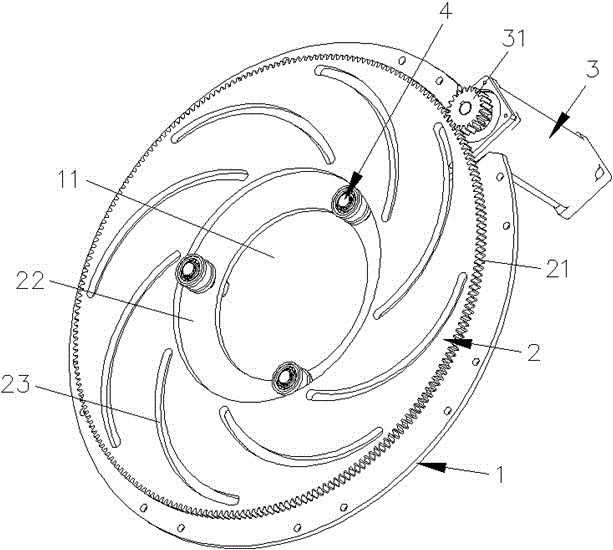

Expanding device

ActiveCN104907426AImprove spraying efficiencyEasy accessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an expanding device. The expanding device comprises a base plate, a rotary disc, a driving system, at least three guide wheel sets and a plurality of chucks. A base plate through hole is formed in the base plate. The rotary disc is arranged above the base plate in parallel, a rotary disc center hole is formed in the rotary disc, and the rotary disc center hole is located above the base plate through hole. The guide wheel sets are arranged on the base plate and are evenly distributed on the periphery of the base plate through hole so as to rotate relative to the inner edge of the rotary disc center hole. Each chuck is provided with a cover plate, a clamping handle and a fixing part, wherein the clamping handle is arranged at one end of the cover plate, the fixing part is downwards arranged at the other end of the cover plate, and the fixing part is arranged on the base plate. Compared with the expanding way that a pipe is held with the hand of a worker and a spray head of a gluing device is plugged into the pipe, the expanding device has the advantages that the process of holding the pipe with the hand of the worker during spraying is omitted, expanding is easy and convenient, and spraying efficiency is high.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Environmentally-friendly filler of adhesive for sheet and application method of filler

InactiveCN110373130ALow costHigh bonding strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCelluloseClay minerals

The invention discloses an environmentally-friendly filler of an adhesive for a sheet. The filler is prepared by uniformly mixing the following raw materials, in percentages by weight: 26%-44% of claymineral powder, 42%-56% of an inorganic filler, 7%-24% of an organic filler, and 1%-5% of a thickening modifier, wherein the clay mineral powder is one or more selected from the group consisting of sepiolite, montmorillonite, attapulgite and kaolinite; the inorganic filler is one or more selected from the group consisting of calcite powder, talcum powder and quartz powder; the organic filler is one or more selected from the group consisting of puffed corn flour, flour, starch and wood flour; and the thickening modifier is one or more selected from the group consisting of cellulose, polyvinylalcohol, polyacrylamide, sodium polyacrylate, sodium silicate and vegetable gum. The invention also provides an application method of the filler. According to the environmentally-friendly filler of the adhesive for the sheet provided by the invention, the finally prepared adhesive has obviously-improved water resistance and bonding strength, and an inhibitory effect on formaldehyde release.

Owner:湘潭海泡石科技有限公司

Multipurpose glue bottle

The invention provides a multipurpose glue bottle which comprises a soft bottle body and a glue brushing head which is connected with the soft bottle body and provided with a glue outlet hole, wherein the glue outlet hole is communicated with the inner cavity of the soft bottle body. The glue bottle is characterized in that the upper end part of the glue brushing head is provided with a flat tongue-shaped brush head; the end part of the flat brush head is provided with a flat mouth-shaped flow storage slot along the longitudinal direction; and the glue outlet hole is arranged on the bottom side part of the flow storage slot to ensure that glue extruded from the soft bottle body flows into the flow storage slot through the glue outlet hole and is stored. When the glue bottle is used in different modes, glue brushing layers with minimum and maximum variation widths can be obtained, and the glue bottle is easy to apply glue into small gaps. The multipurpose glue bottle has reasonable structure, can be produced by a plastic die, is convenient to use, adapts to diversified glue applying requirements to achieve the purpose of one bottle with multiple purposes and can simplify the supply and demand varieties of glue bottles, improves the utilization rate of the glue bottle and is easy to popularize and apply.

Owner:戴永锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com