Bi-component acrylic ester structure adhesive and preparation method thereof

A technology of structural adhesives and acrylates, applied in adhesives, non-polymer organic compound adhesives, etc., can solve the problems of slow initial fixation speed and fast curing speed, and achieve wide application range, low cost, and high technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

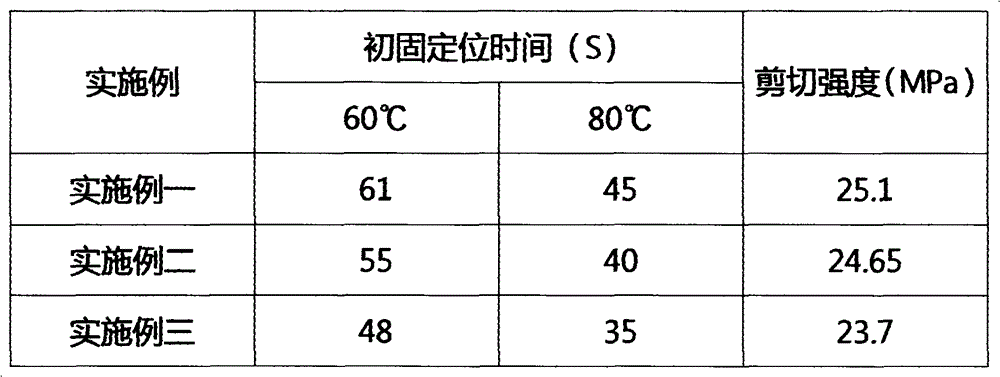

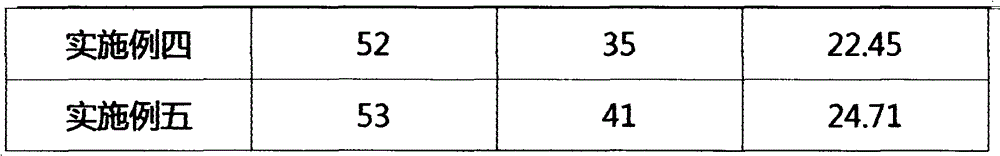

Examples

Embodiment 1

[0012] Mix 20g of 1,6-hexanediol diacrylate, 20g of acryloyl morpholine, 40g of polyurethane prepolymer, and 3g of methacrylic acid, put them into the reaction kettle and stir at 62°C for 14 hours to make it a uniform liquid. When returning to room temperature, add 5 g of γ-methacryloxypropyltrimethoxysilane, 1.5 g of N,N-dimethyl-p-toluidine, and 2 g of cumene hydroperoxide, and stir for 9 hours to obtain the main ingredient.

[0013] Put 2.1g of cobalt isooctanoate or 7.4g of bisphenol A type epoxy resin into the reactor, stir at normal temperature for 1.2 hours, drop into 2.1g of vanadium pentoxide salt, and continue to stir for 2 hours to obtain the accelerator;

[0014] Put 60g of methyl methacrylate, 25g of ethylene propylene rubber, 10g of ABS, and 25g of polyurethane prepolymer into the reaction kettle and stir at 63°C for 11 hours to make it a uniform liquid, then return to room temperature and add 1.5g of the accelerator prepared above , aluminum hydroxide 10g, stirr...

Embodiment 2

[0016] Mix 10g of methyl methacrylate, 20g of acryloyl morpholine, 15g of N-methylolacrylamide, 10g of ABS, 20g of polyurethane prepolymer, and 15g of methacrylic acid, put them into a reaction kettle and stir at 68°C for 11 hours to make It becomes a uniform liquid, and when the temperature returns to room temperature, add 8 g of γ-methacryloxypropyltrimethoxysilane, 1.2 g of N, N-dimethyl-p-toluidine, and 1 g of cumene hydroperoxide, and stir for 8.1 h , to get the main agent.

[0017] Put bisphenol A type epoxy resin 7.3 into the reaction kettle, stir at normal temperature for 1.1 hours, drop into 2.7g of vanadium pentoxide salt, and continue to stir for 2 hours to obtain an accelerator; 68g of methyl methacrylate, ethylene-propylene rubber Put 28g of polyurethane prepolymer and 15g of polyurethane prepolymer into the reaction kettle and stir at 67°C for 13 hours to make it a uniform liquid. Return to room temperature and add 1.5g of accelerator obtained in the above proces...

Embodiment 3

[0019] Mix 20g of acryloylmorpholine, 20g of N-methylolacrylamide, 10g of PMMA, 40g of polyurethane prepolymer, and 3g of methacrylic acid, put them into the reaction kettle and stir at 63°C for 7.4 hours to make it a uniform liquid, and the temperature is restored When it reaches room temperature, add 5 g of γ-methacryloxypropyltrimethoxysilane, 1.5 g of N,N-dimethyl-p-toluidine, and 1.5 g of cumene hydroperoxide, and stir for 6.9 hours to obtain the main ingredient.

[0020] Put 60g of methyl methacrylate, 27g of ABS, and 5g of polyurethane prepolymer into the reaction kettle and stir at 63.5°C for 7.2 hours to make it a uniform liquid. After returning to room temperature, add 2g of vanadium pentoxide in proportion, and stir for 6.5h to obtain Hardener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com