Double-component glue spreading machine applied to hollow glass production

A two-component, gluing machine technology, applied in coatings, devices for coating liquid on surfaces, etc., can solve the problems affecting the long-term development of insulating glass, unstable quality of insulating glass, and affecting the bonding strength of glue, etc. The effect of convenient gluing work, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

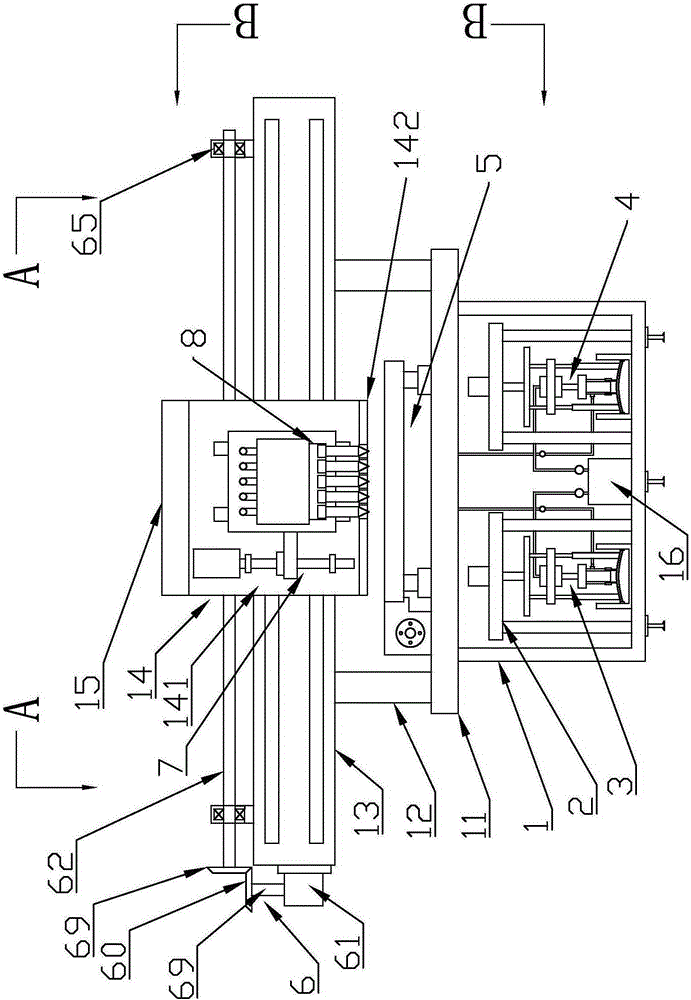

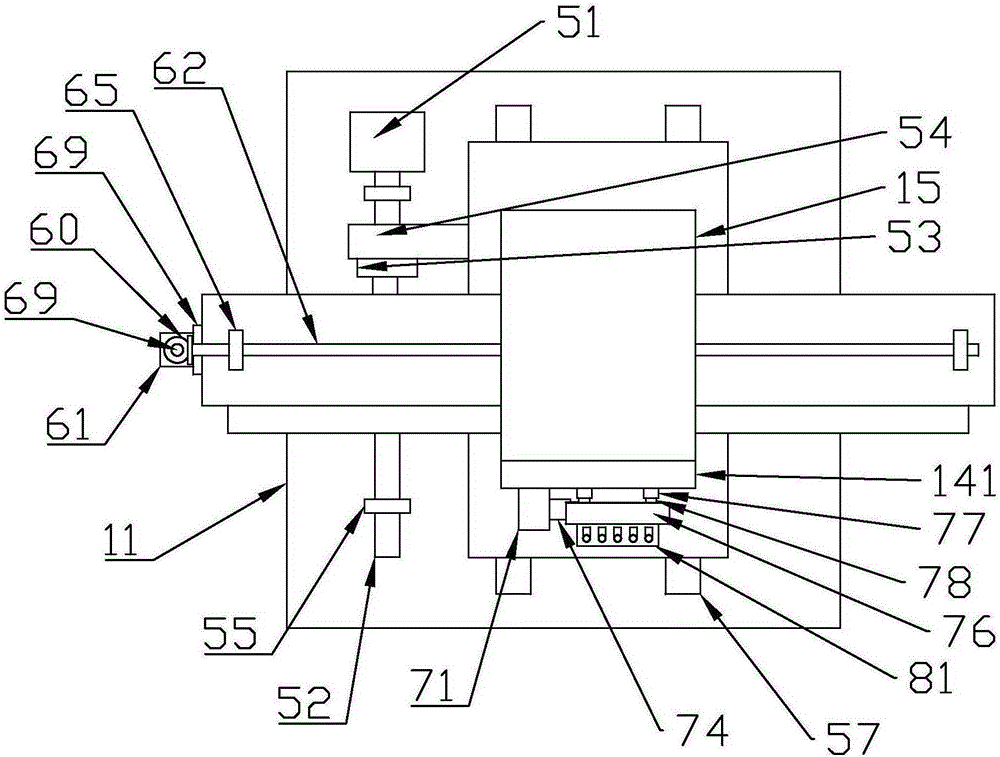

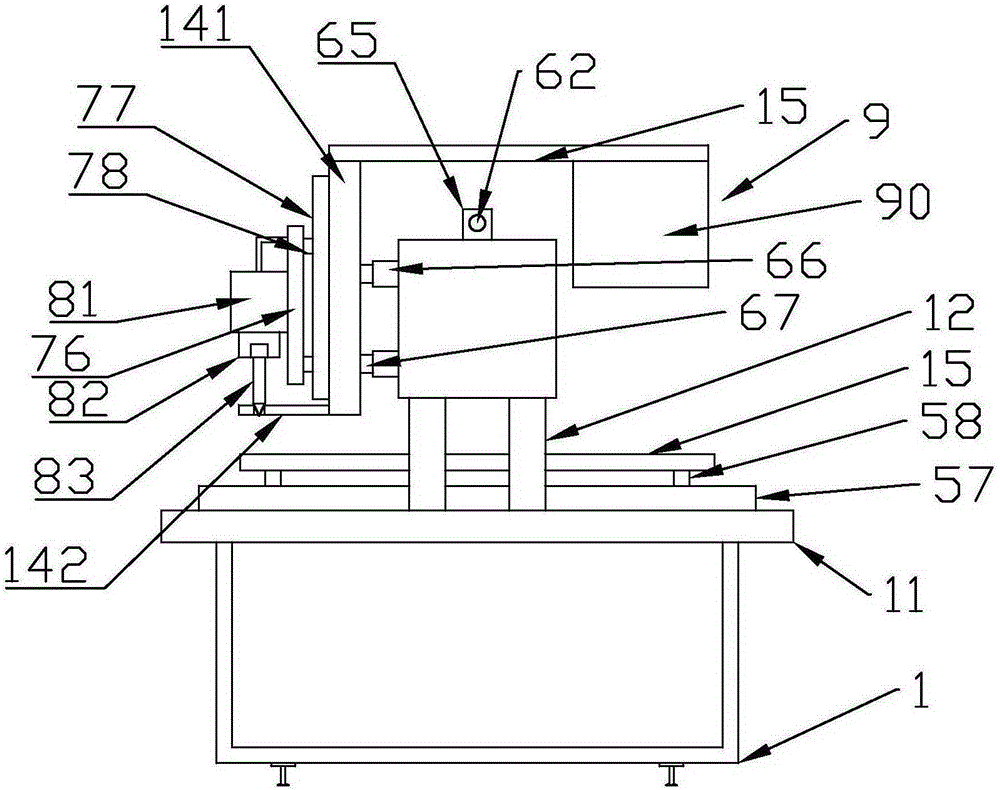

[0036] Such as Figure 1 to Figure 13 As shown, a two-component gluing machine applied to the production of insulating glass includes a frame 1 and a middle workbench 11, and the middle workbench 11 is located on the frame 1. A support frame 12 and a Y-direction conveying device 5 are provided on the middle workbench 11 , a beam 13 is provided on the support frame 12 , and an X-direction moving device 6 is provided at the front end of the beam 13 . The X-direction mobile device 6 is connected with a gluing trolley 14, the gluing trolley 14 includes a vertical connecting seat 141 and a horizontal baffle 142, the vertical connecting seat 141 is connected to the horizontal baffle 142, and the vertical connecting seat 141 is provided with a Z-direction movement. Device 7 and gluing device 8. The upper end of the vertical connecting seat 141 is provided with a connecting plate 15 , and the connecting plate 15 is connected with a glue mixing device 9 , which is located at the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com