Method for preparing urea-formaldehyde resin adhesive

A technology for urea-formaldehyde resins and adhesives, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem that the release of free formaldehyde is very low, and the limit of free formaldehyde release has not been reached to protect human health and other issues to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

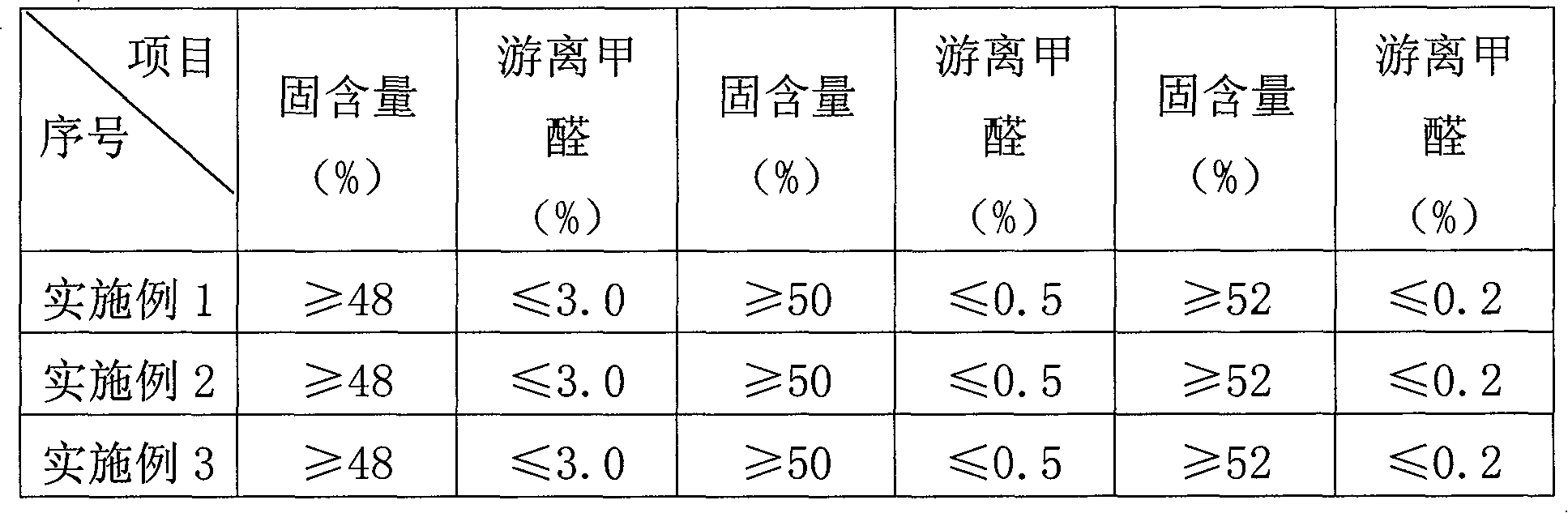

Examples

Embodiment 1

[0023] 1. Add 190g of 36% formaldehyde into a 500ml container, add 1g of 30% sodium hydroxide solution under stirring, then heat up to 40°C, add 56g of urea, the molar ratio of urea to formaldehyde is 1:2.45, and then Raise the temperature to 80°C and stir for 60 minutes. When the pH of the solution is 6.5, add 19g of urea. The molar ratio of urea to formaldehyde is 1:1.84. Keep the temperature of the solution at 80°C for 30 minutes. After 30 minutes, add 20 % ammonium chloride solution 1g, continue to keep the temperature of the solution at 80°C for 60 minutes, and when the pH value of the solution was 5, add 30% sodium hydroxide solution 1g , keeping the temperature of the solution at 80°C for 30 minutes to make the pH of the solution 7 to obtain the raw gum;

[0024] 2. Add 17g of urea to the original gum prepared in step 1 under stirring. The molar ratio of urea to formaldehyde is 1:1.5-1.40. The solution is heated to 90°C and kept at this temperature for 30 minutes. After...

Embodiment 2

[0027] 1. Add 190g of 36% formaldehyde into a 500ml container, add 1g of 30% sodium hydroxide solution under stirring, then heat up to 60°C, add 56g of urea, the molar ratio of urea to formaldehyde is 1:2.45, and then Raise the temperature to 90°C and stir for 60 minutes. When the pH of the solution is 7.5, add 19g of urea. The molar ratio of urea to formaldehyde is 1:1.84. Keep the temperature of the solution at 85°C for 30 minutes. After 30 minutes, add 20 % ammonium chloride solution 1g, continue to keep the temperature of the solution at 85°C for 60 minutes, when the pH value of the solution is 6, add 1g of 30% sodium hydroxide solution, keep the temperature of the solution at 85°C React for 30 minutes, make the pH value of the solution 7 to make the original gum;

[0028] 2. Add 23g of urea to the original gum prepared in step 1 under stirring. The molar ratio of urea to formaldehyde is 1:1.5-1.40. The solution is heated to 96°C and kept at this temperature for 30 minutes...

Embodiment 3

[0031] 1. Add 190g of 36% formaldehyde into a 500ml container, add 1g of 30% sodium hydroxide solution under stirring, then heat up to 40°C, add 56g of urea, the molar ratio of urea to formaldehyde is 1:2.45, and then Raise the temperature to 80°C and stir for 60 minutes. When the pH of the solution is 6.5, add 19g of urea. The molar ratio of urea to formaldehyde is 1:1.84. Keep the temperature of the solution at 80°C for 30 minutes. After 30 minutes, add 20 % ammonium chloride solution 1g, continue to keep the temperature of the solution at 80°C for 60 minutes, when the pH value of the solution is 5, add 1g of 30% sodium hydroxide solution, keep the temperature of the solution at 80°C React for 30 minutes, make the pH value of the solution 7 to make the original gum;

[0032] 2. Add 23g of urea to the raw gum prepared in step 1 under stirring, the molar ratio of urea to formaldehyde is 1:1.5-1.40, heat up the solution to 90°C, keep the temperature for 30 minutes, then cool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com