Preparation method of modified starch adhesive

A starch adhesive and modification technology, applied in the direction of starch-derived adhesives, adhesives, adhesive types, etc., can solve the problems of low adhesive performance, complicated process, high cost, etc., and achieve fast drying speed, Simple process and good machine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

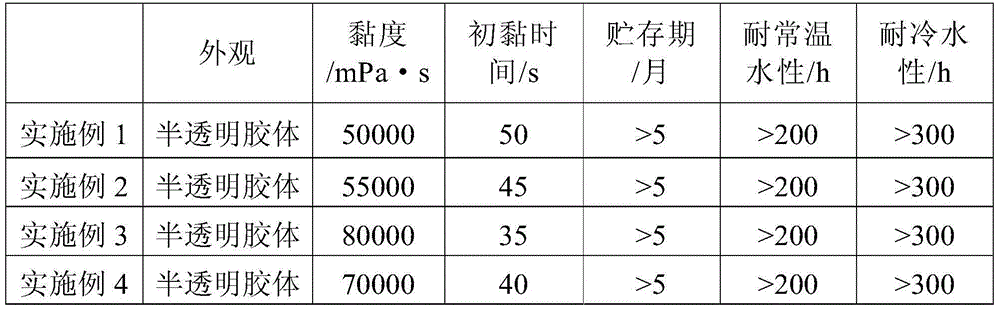

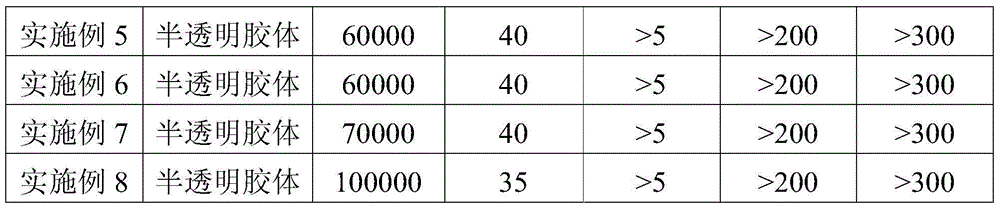

Examples

preparation example Construction

[0011] The preparation method of the modified starch adhesive according to the present invention comprises the steps: (1) adding deionized water to a three-necked flask as a solvent, adding cornstarch to the deionized water, stirring and heating up, so that the cornstarch is fully swollen; (2) ) adding hydrochloric acid and heating up, adding an oxidizing agent, keeping warm to make the oxidizing agent fully react with cornstarch; (3) adding polyvinyl alcohol and heating up; (4) adding boric acid solution, keeping warm after heating up so that boric acid and polyvinyl alcohol fully carry out coupling reaction; (5) Adding formaldehyde solution to keep warm; (6) Adding sodium hydroxide to terminate the reaction; (7) Adding surfactant, drier and preservative, cooling and discharging to obtain modified starch adhesive.

[0012] The difference between the preparation method of modified starch adhesive of the present invention and traditional technology is:

[0013] First, in the tr...

Embodiment 1

[0039] Add 10g of cornstarch into a three-necked flask filled with 100g of deionized water, stir and heat up to 50°C to make the cornstarch fully swell; g oxidant potassium permanganate, keep it warm for 1h to fully react potassium permanganate and cornstarch; add 10g polyvinyl alcohol (alcoholysis degree is 88%), and heat up to 80°C; add 10g pre-prepared concentration of 0.1 % boric acid solution, warm up to 95°C and keep it warm for 0.5h, so that the boric acid and polyvinyl alcohol can fully carry out the coupling reaction; add 10g of formaldehyde solution with a concentration of 10%, and continue to keep warm for 1h; add sodium hydroxide to terminate the reaction, sodium hydroxide The amount is used to control the pH of the solution to be 6-8; finally add tributyl phosphate, calcium chloride, sodium benzoate, and Schiffen compound essence, cool down to 75°C and discharge, and then obtain the modified starch adhesive.

Embodiment 2

[0041] Add 10g of cornstarch into a three-necked flask filled with 150g of deionized water, stir and heat up to 50°C to make the cornstarch fully swell; g oxidant potassium permanganate, keep it warm for 4 hours to fully react potassium permanganate and cornstarch; add 40g polyvinyl alcohol (alcoholysis degree is 88%), and heat up to 80°C; add 10g pre-prepared concentration of 0.1 % boric acid solution, heated up to 90°C and kept warm for 1h, so that the boric acid and polyvinyl alcohol can fully carry out the coupling reaction; add 10g of formaldehyde solution with a concentration of 10%, and keep warm for 1h; add sodium hydroxide to terminate the reaction, The amount is used to control the pH of the solution to be 6-8; finally, tributyl phosphate, calcium chloride, sodium benzoate, and Schiffen compound flavor are added, the temperature is lowered to 75°C and the material is discharged to obtain a modified starch adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com