Moisture-curable polyurethane hot melt adhesive for automobile roof pendants and preparation method of the moisture-curable polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and car roof technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor stability of hot-melt adhesives, achieve adjustable opening time, low The effect of construction temperature and excellent high and low temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

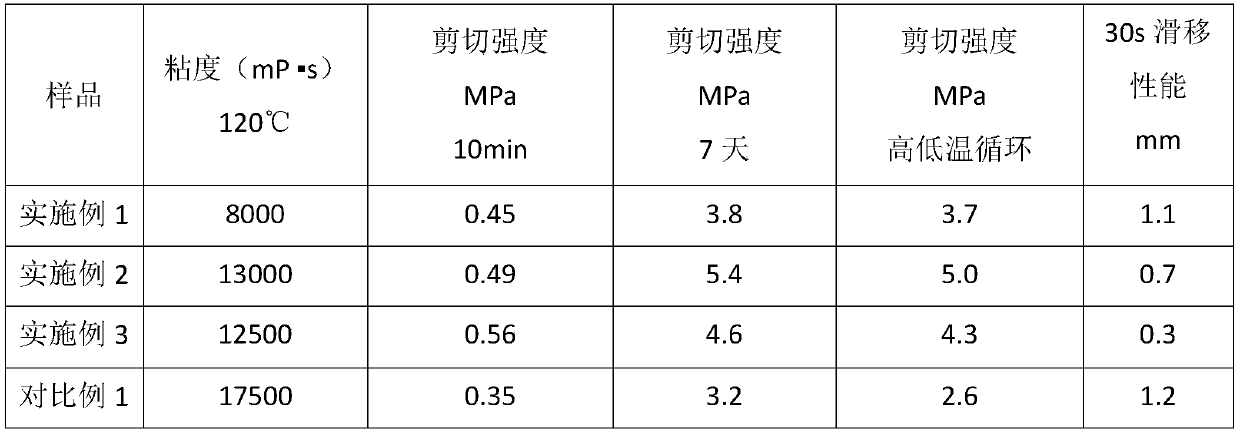

Examples

Embodiment 1

[0026] A kind of moisture-curing polyurethane hot-melt adhesive for automobile ceiling pendant, including the following raw materials composed by weight: 10 parts of polyester polyol, 10 parts of polyether polyol, 5 parts of high molecular weight saturated polyester resin, terpene resin 5 parts, 8 parts of isocyanate, 0.1 part of antioxidant.

[0027] The polyester polyols are crystalline polyester diols and liquid polyester polyols with a molecular weight of 2000-8500, specifically Dynacoll 7360, Dynacoll 7361, Dynacoll 7380, Dynacoll 7381, XCP-2000B, Dynacoll 7230, Dynacoll 7210, Dynacoll One of 7250, Dynacoll 7231 or XCP-2000D.

[0028] The polyether polyol is polypropylene oxide diol with a molecular weight of 400.

[0029] The molecular weight range of the high-molecular-weight saturated polyester resin is 10,000-100,000, the softening point is -30-100° C., and the hydroxyl value is 1-11.

[0030] The terpene resin is a modified terpene resin. The softening point range...

Embodiment 2

[0037] A kind of moisture-curing polyurethane hot-melt adhesive for automobile ceiling pendant, including the following raw materials composed by weight: 30 parts of polyester polyol, 30 parts of polyether polyol, 10 parts of high molecular weight saturated polyester resin, terpene resin 25 parts, 15 parts of isocyanate, 0.5 part of antioxidant.

[0038] The polyester polyols are crystalline polyester diols and liquid polyester polyols with a molecular weight of 2000-8500, specifically Dynacoll 7360, Dynacoll 7361, Dynacoll 7380, Dynacoll 7381, XCP-2000B, Dynacoll 7230, Dynacoll 7210, Dynacoll One of 7250, Dynacoll 7231 or XCP-2000D.

[0039] The polyether polyol is polypropylene oxide diol with a molecular weight of 1000.

[0040] The molecular weight range of the high-molecular-weight saturated polyester resin is 10,000-100,000, the softening point is -30-100° C., and the hydroxyl value is 1-11.

[0041] The terpene resin is a modified terpene resin. The softening point r...

Embodiment 3

[0047] A kind of moisture-curing polyurethane hot-melt adhesive for automobile ceiling pendant, including the following raw materials composed by weight: 40 parts of polyester polyol, 50 parts of polyether polyol, 15 parts of high molecular weight saturated polyester resin, terpene resin 40 parts, 25 parts of isocyanate, 1 part of antioxidant.

[0048] The polyester polyols are crystalline polyester diols and liquid polyester polyols with a molecular weight of 2000-8500, specifically Dynacoll 7360, Dynacoll 7361, Dynacoll 7380, Dynacoll 7381, XCP-2000B, Dynacoll 7230, Dynacoll 7210, Dynacoll One of 7250, Dynacoll 7231 or XCP-2000D.

[0049] The polyether polyol is polypropylene oxide diol with a molecular weight of 2000.

[0050] The molecular weight range of the high-molecular-weight saturated polyester resin is 10,000-100,000, the softening point is -30-100° C., and the hydroxyl value is 1-11.

[0051] The terpene resin is a modified terpene resin. The softening point ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com