Water-based laser packaging glue used for cigarettes and preparation method thereof

A water-based, packaging adhesive technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc., can solve the problem of poor initial viscosity, poor adhesion of starch glue, slow drying speed, etc. problems, achieve the effect of improving thixotropy, improving initial viscosity and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

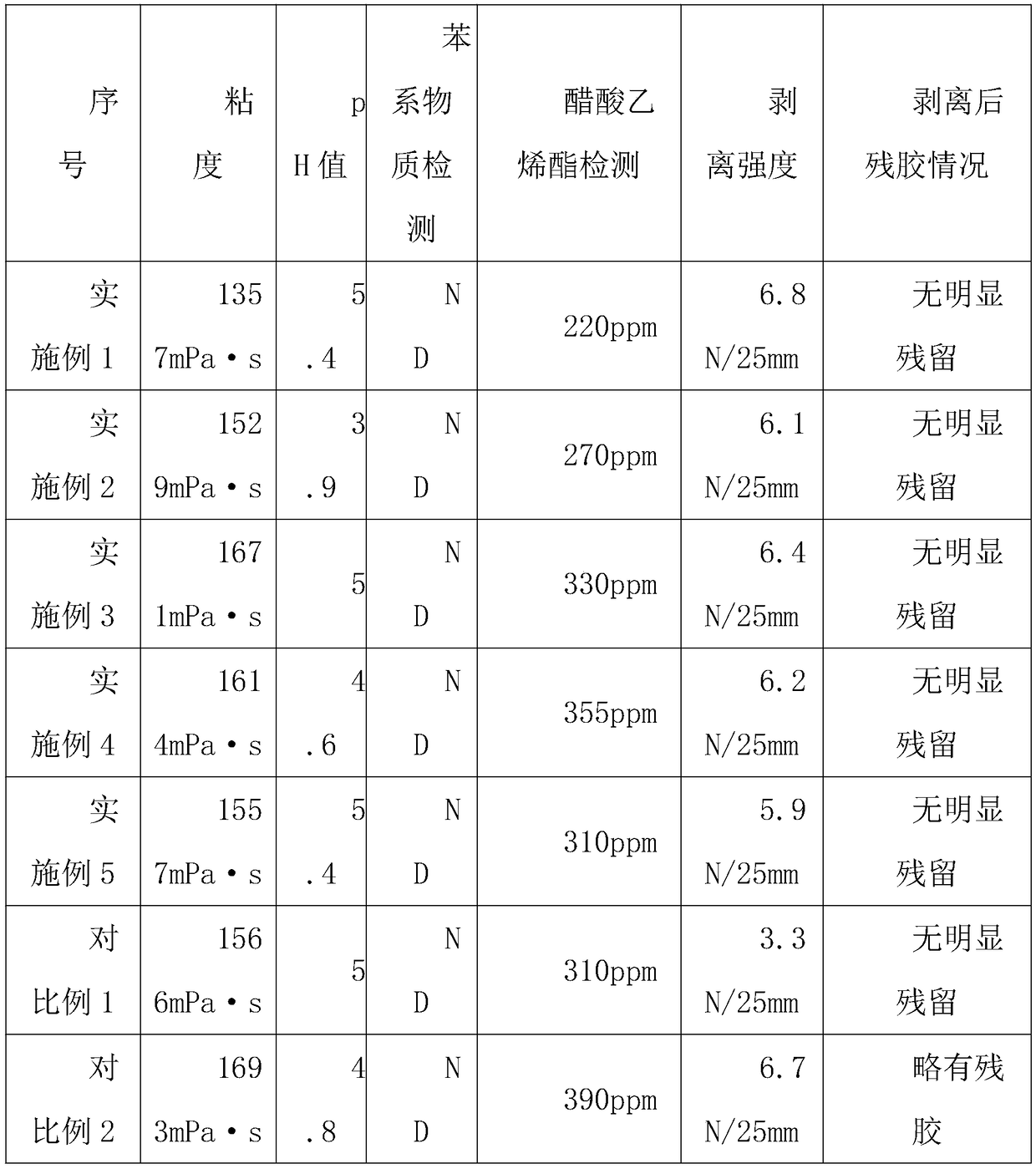

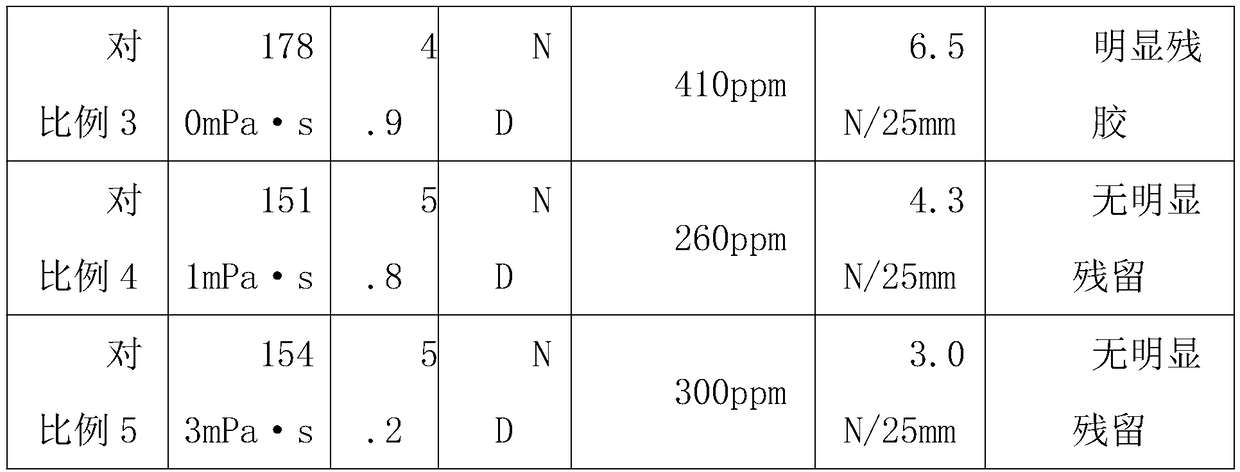

Examples

Embodiment 1

[0024] Add 60kg of VAE emulsion (805c of Beijing Dongfang Petroleum) into the reaction kettle at 20-30℃, turn on the mixer, add 3kg of nano-alumina, 1.5kg of calcium chloride, 5kg of polyvinyl alcohol, 8kg of alcohol, OP-102kg, and environmental protection agent TXIB 5kg, preservative Cathone 2kg, water 20kg, adjust the pH value, stir well and measure the viscosity. Packaging is the finished product.

Embodiment 2

[0026] Add 70kg of VAE emulsion (805c of Beijing Dongfang Petroleum) into the reaction kettle at 20-30℃, turn on the mixer, add 2kg of nano-alumina, 1.5kg of calcium chloride, 5kg of polyvinyl alcohol, 8kg of alcohol, OP-102kg, and environmental protection agent TXIB 5kg, preservative Cathone 2kg, water 20kg, adjust the pH value, stir well and measure the viscosity. Packaging is the finished product.

Embodiment 3

[0028] Add 65kg of VAE emulsion (805c of Beijing Dongfang Petroleum) into the reaction kettle at 20-30°C, start the mixer, add 2.5kg of crystal alumina, 1.5kg of calcium chloride, 3kg of polyvinyl alcohol, 6kg of alcohol, and 1.5kg of OP-10, 5kg of environmental protection agent TXIB, 1.5kg of preservative Kason, 15kg of water, adjust the pH value, stir well and then measure the viscosity. Packaging is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com