Patents

Literature

120results about How to "Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

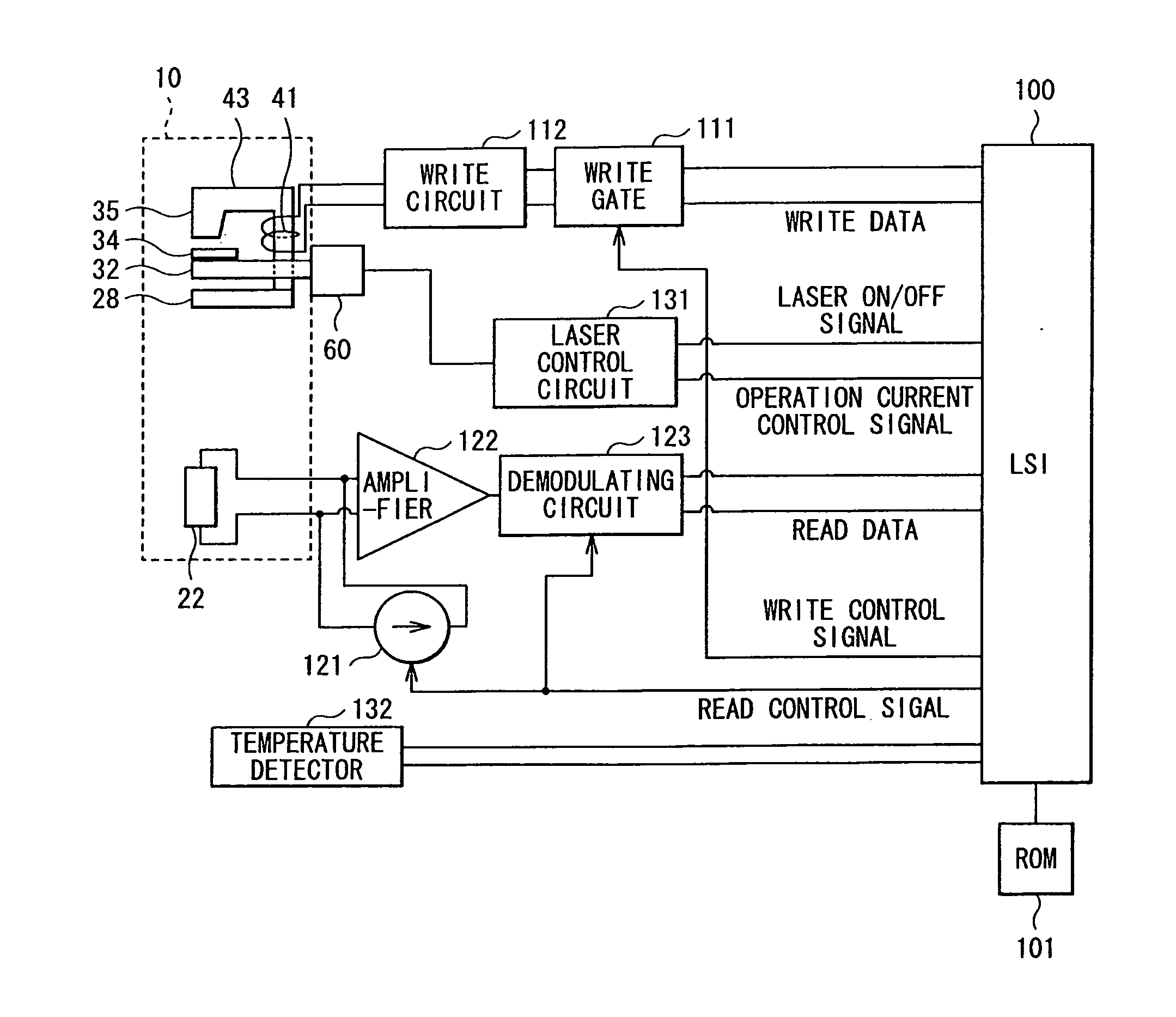

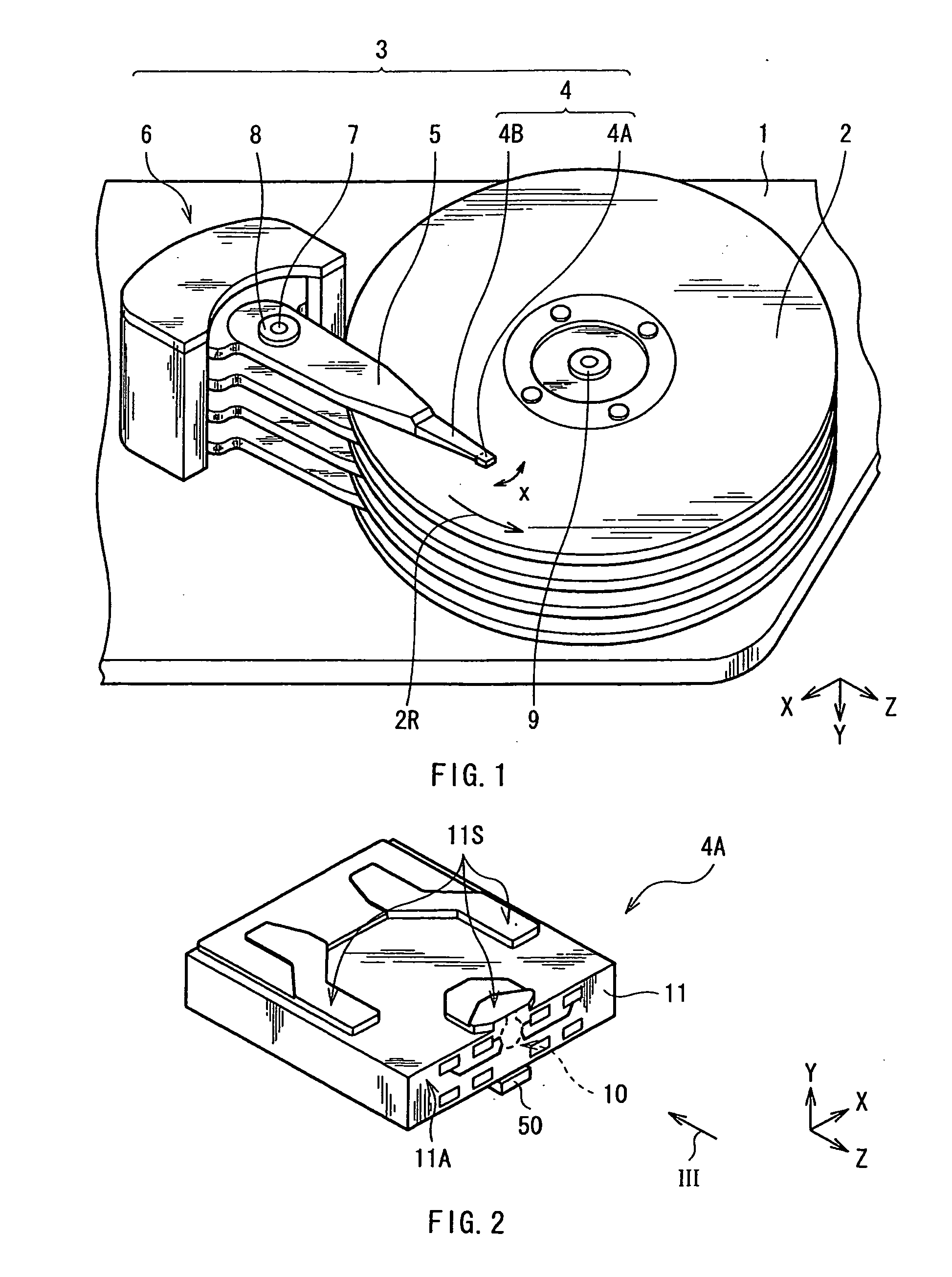

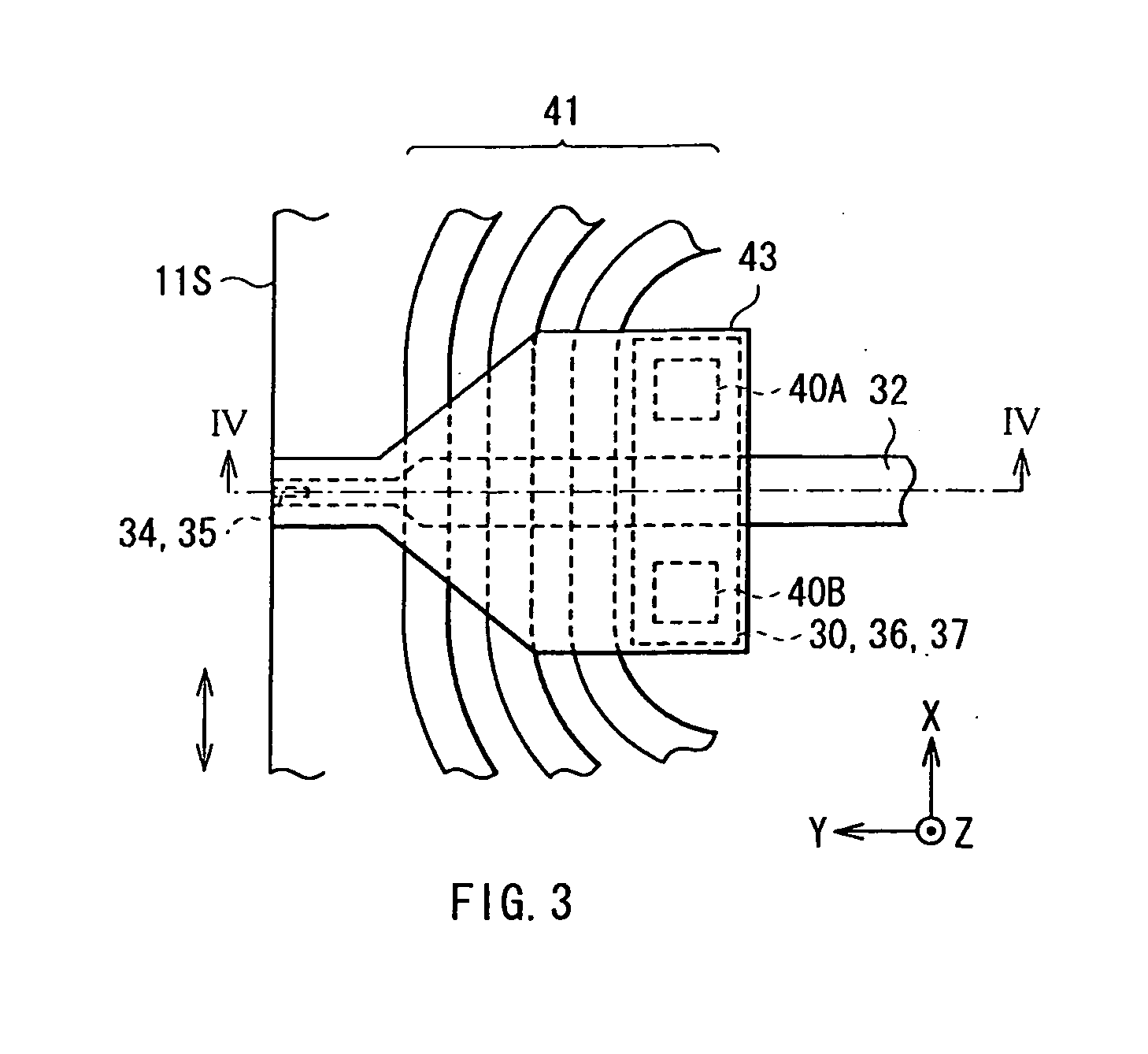

Heat-assisted magnetic write head, head gimbals assembly, head arm assembly, and magnetic disk device

ActiveUS20120213042A1Improve cooling efficiencyCorrosionCombination recordingRecord information storageMagnetic disksAir bearing surface

A heat-assisted magnetic write head includes a magnetic pole having an end surface exposed at an air bearing surface, a waveguide extending toward the air bearing surface to propagate light, and a plasmon generator provided between the magnetic pole and the waveguide, and generating near-field light from the air bearing surface, based on the light propagated through the waveguide. The plasmon generator has an end portion exposed at the air bearing surface or located in close proximity to the air bearing surface, the end portion having a minimum thickness in a region close to the waveguide.

Owner:TDK CORPARATION

Fracturing fluid prepared by recovery waste water of crude oil and preparation method of fracturing fluid

ActiveCN103074049AAlleviate needsSolve processing problemsDrilling compositionCross-linkFracturing fluid

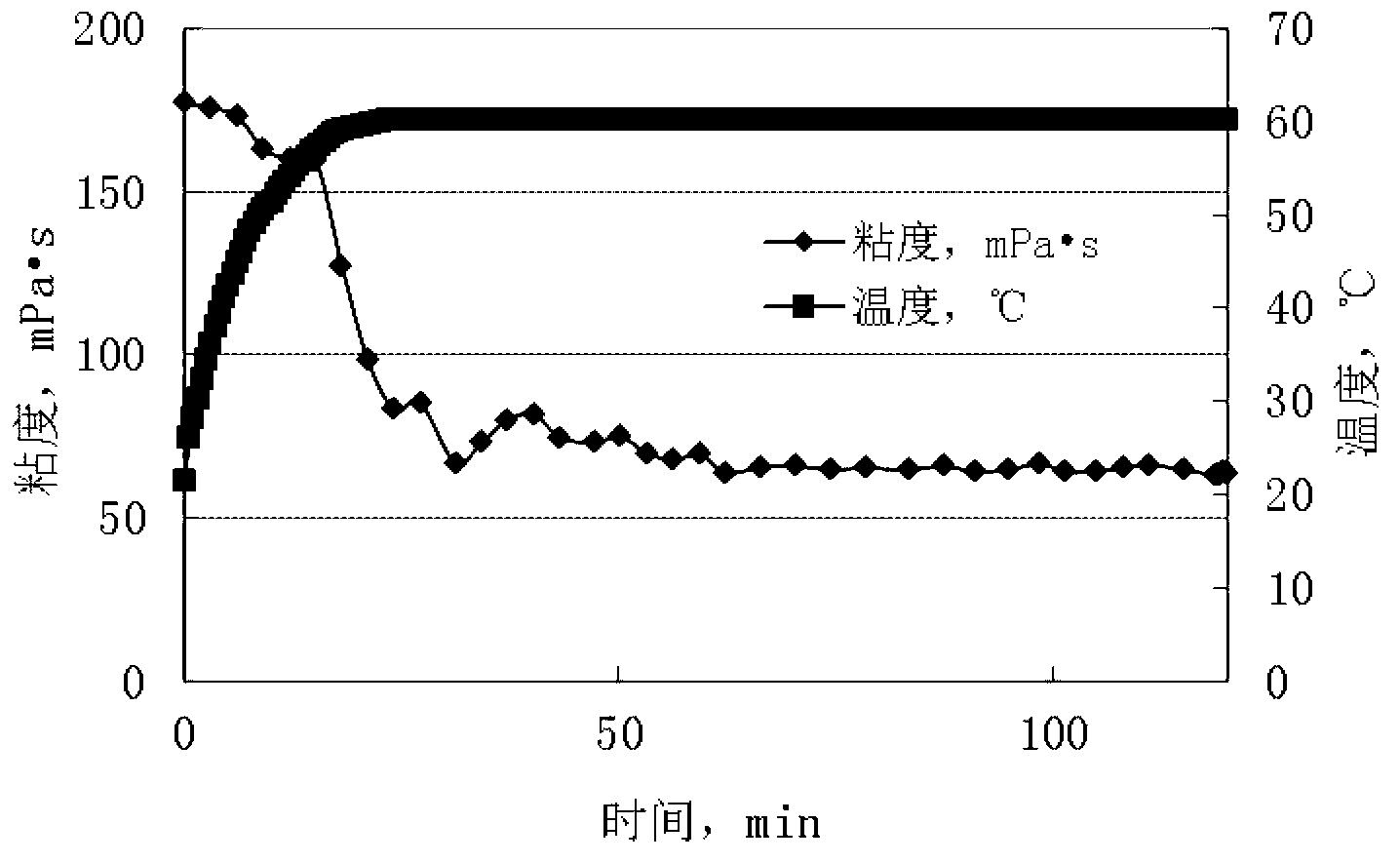

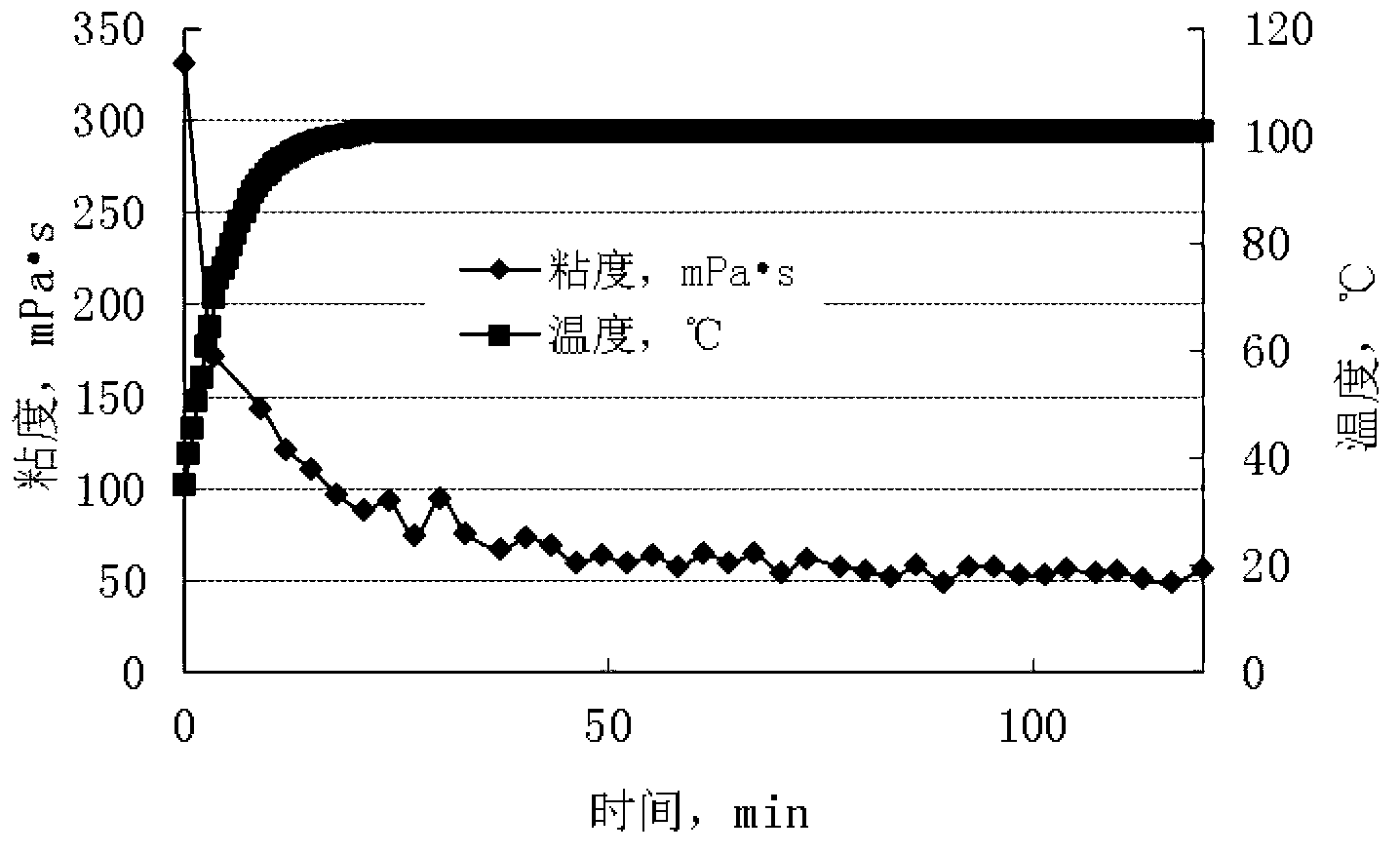

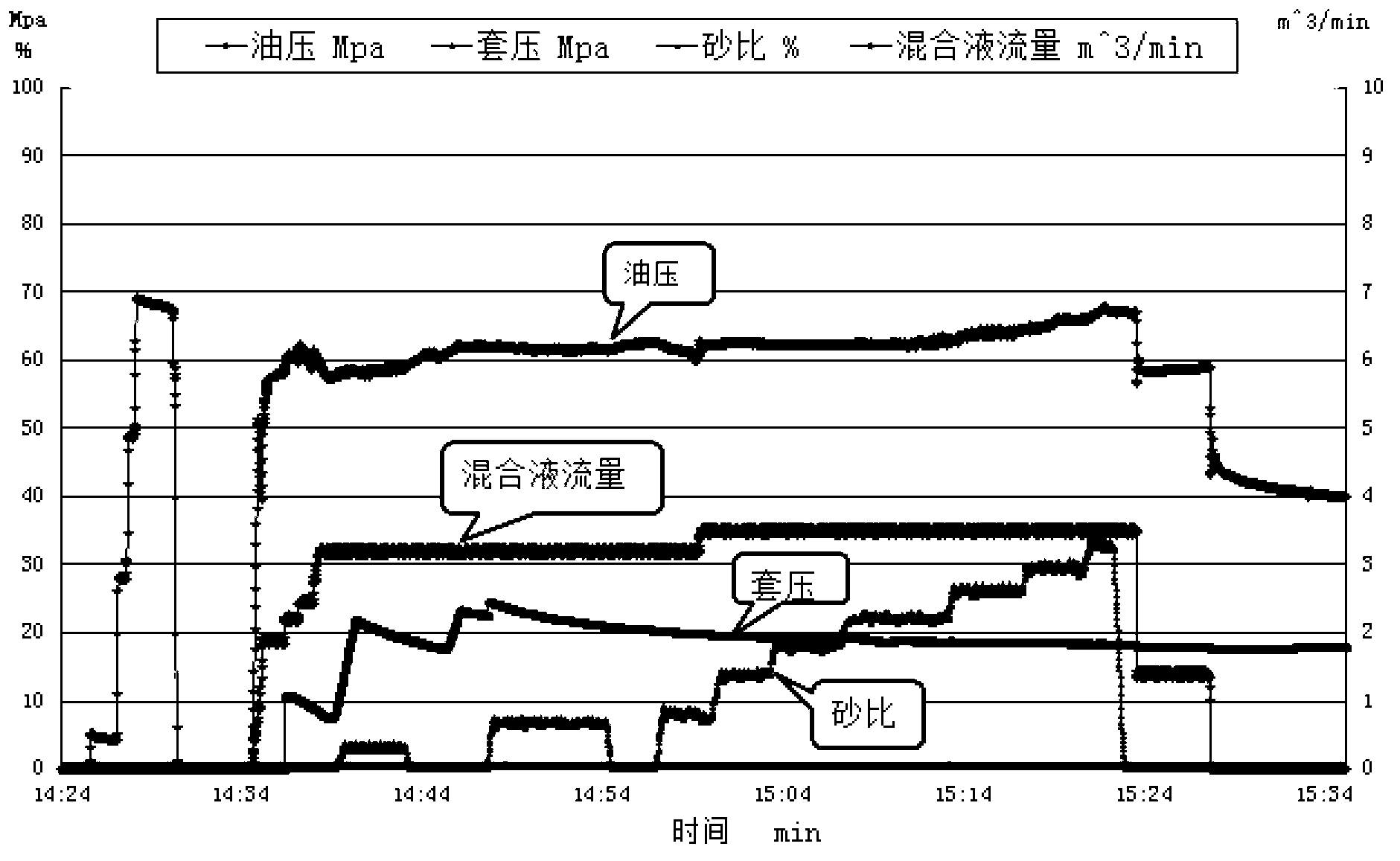

The invention discloses an association polymer fracturing fluid prepared by recovery waste water of crude oil. The fracturing fluid comprises the following components: 0.2-1.4wt% of thickening agent, 0.01-0.1wt% of thickening assistant, 0.05-0.1% of metal ion stabilizing agent, 0.02-0.05wt% of water block preventive, 0.05-0.2wt% of high-temperature stabilizing agent, 1-2wt% of clay stabilizing agent and the balance of the recovery waste water of the crude oil. Compared with the prior art, the fracturing fluid has the benefits that the fracturing fluid system adopts an association polymer as a primary thickening agent, no cross-linking agent is used, structural viscosity is formed by the synergetic effect of the association polymer and an ampholytic surfactant, and the fracturing fluid has the characteristics of temperature resistance, good salt tolerance, shear resistance, bacterial corrosion resistance and low friction, and has a good solid carrying behavior when the viscosity is greater than 20mPa*s.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Water-based metal-degreasing cleaning agent

The invention discloses a water-based metal-degreasing cleaning agent. The water-based metal-degreasing cleaning agent comprises the components in percent by weight: 10-30% of composite surface active agent, 5-10% of cleaning additive, 2-5% of corrosion inhibiting agent, 0.4-0.8% of hard-water resistant agent, 0.05-0.2% of defoaming agent and the balance of deionized water. By mass, the composite surface active agent is a mixture compounded by LAS (sodium alkyl benzene sulfonate), AEO-9 (Fatty alcohol polyoxyethylene ether) and TX-10 (alkylphenol ethoxylates) according to the mass ratio of 1:2:1; the corrosion inhibiting agent is a mixture compounded by benzotriazole (BTA) and benzimidazole (BIA) according to the mass ratio of 1:1; the cleaning additive is a mixture compounded by 4A zeolite, sodium metasilicate and sodium carbonate according to the mass ratio of 1:1:1; the defoaming agent is a polyether-modified organic silicon defoaming agent. The water-based metal-degreasing cleaning agent disclosed by the invention has the characteristics of low surface tension, fast defoaming, long foam-inhibiting time, low cost and less use amount and the like.

Owner:SUZHOU LOTTE CHEM TECH

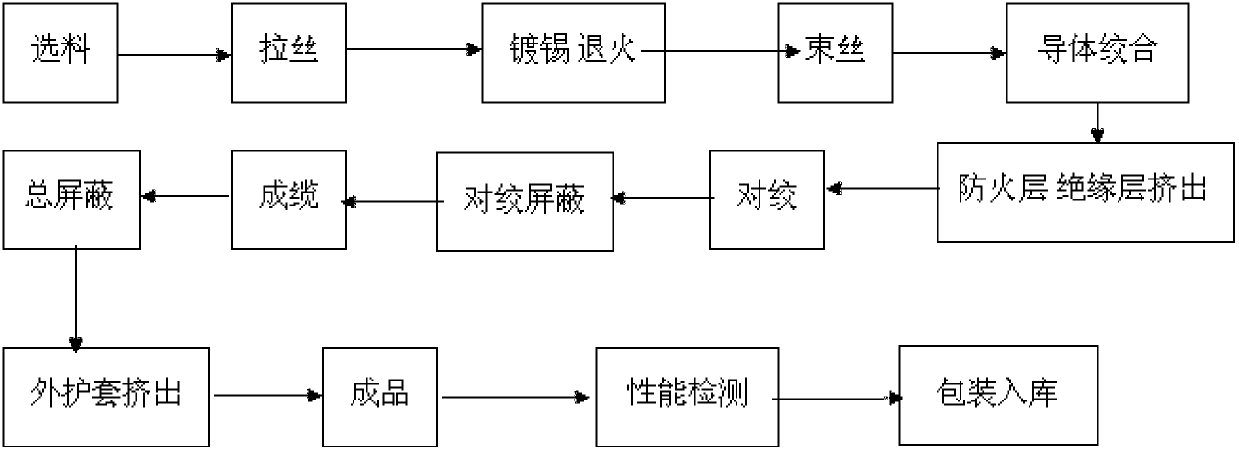

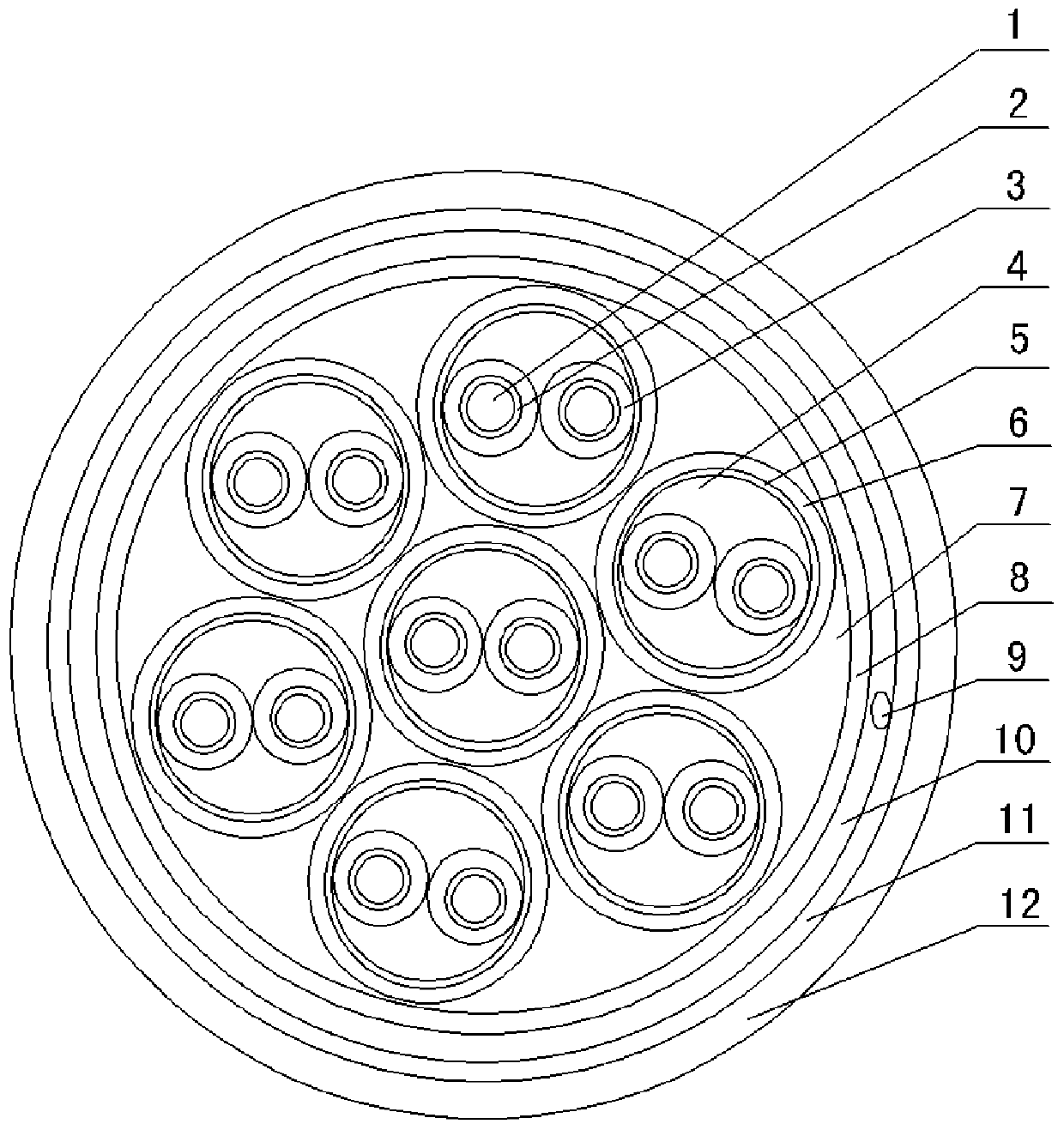

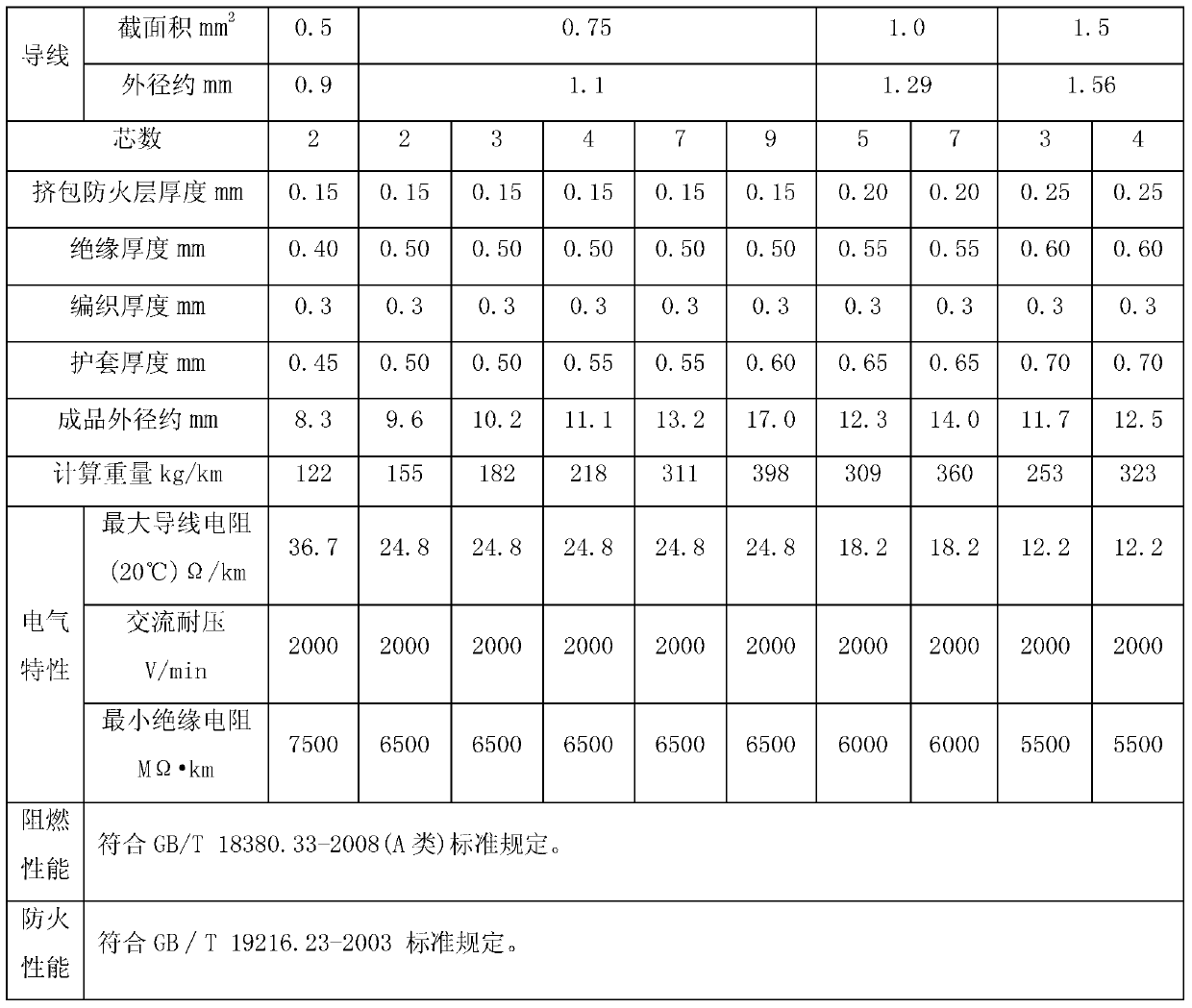

Heat-resistant instrument cable for ships and manufacturing process of heat-resistant instrument cable

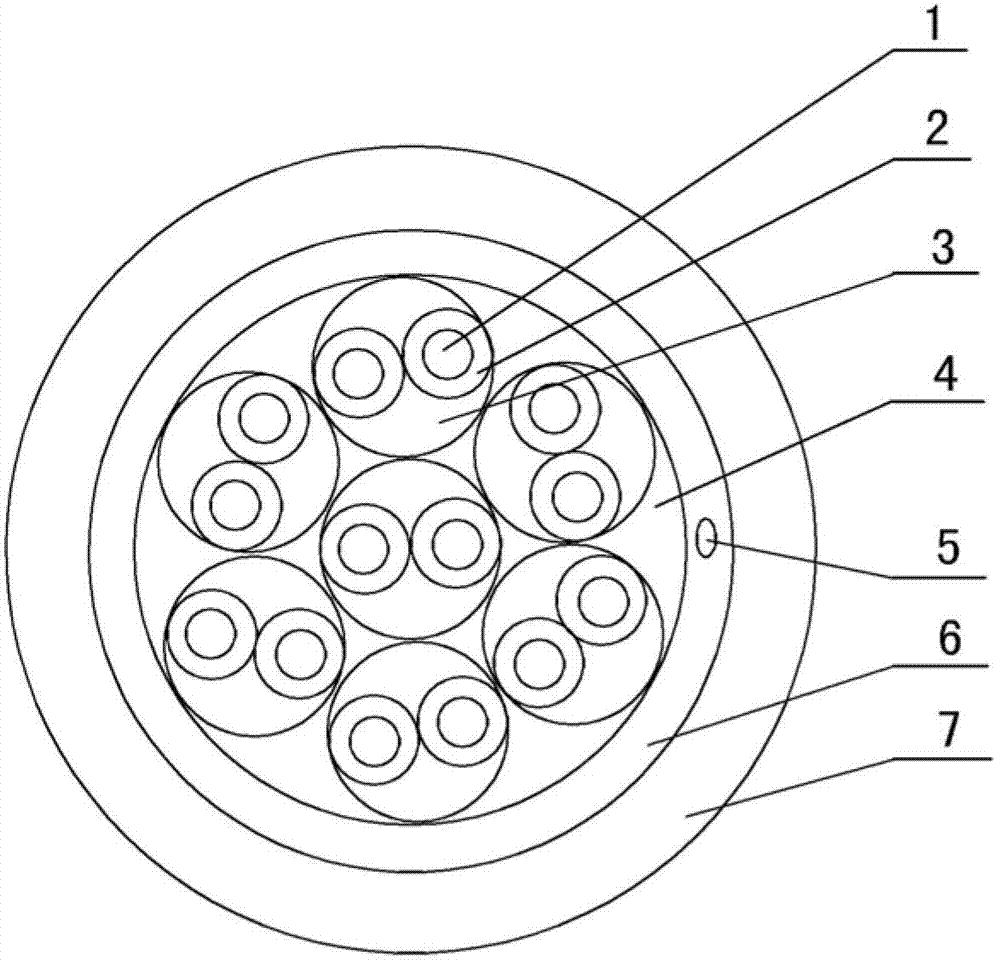

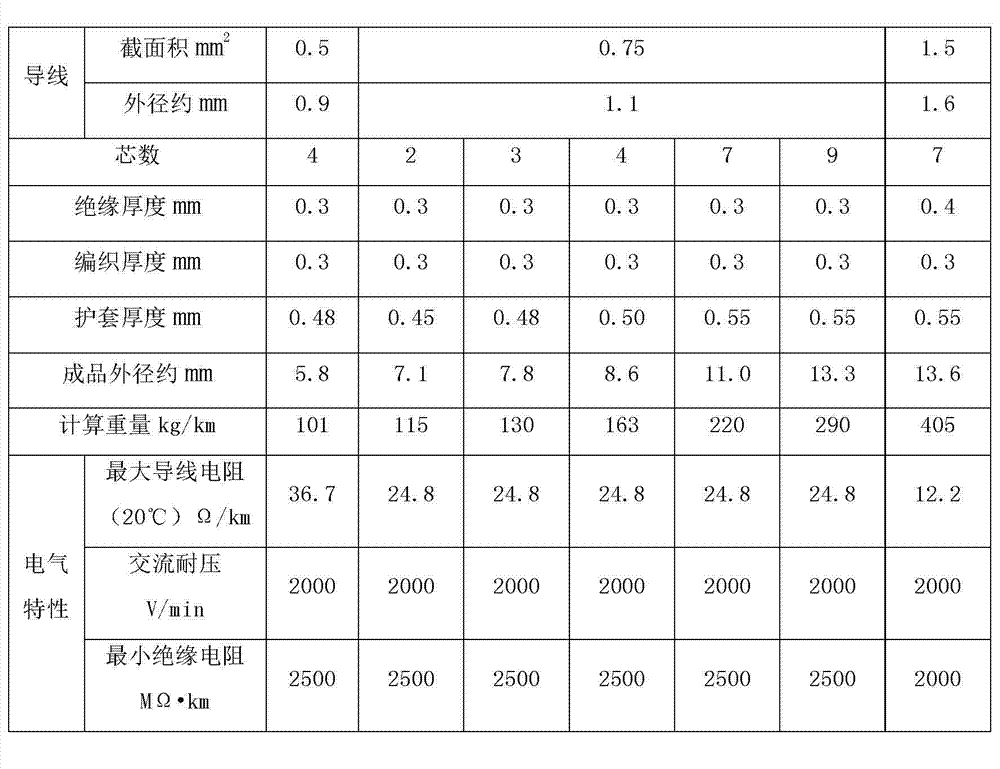

ActiveCN102760517ASmall structure sizeImprove electrical performanceNon-insulated conductorsInsulated cablesElectrical conductorCopper wire

The invention discloses a heat-resistant instrument cable for ships and a manufacturing process of the heat-resistant instrument cable, and is characterized in that a cable conductor is formed by twisting a plurality of tin-plated copper wires which are drawn by a copper rod and are treated by annealing and tin plating; the conductor is extruded with an insulating layer to form an insulating cable core; a twisted-pair unit is formed by two insulating cable cores; a cable core is formed by twisting a plurality of twisted-pair units; the outer surface of the cable core is provided with a longitudinally-added drainage wire, a shielding layer weaved by the tin-plated copper wires and an extrusion sheath layer in sequence; and the insulating layer and the outer sheath layer are respectively made of fluororesin extruding materials. The heat-resistant instrument cable is suitable to be used as an electric instrument connecting line under the severe high-temperature environments such as near diesel engines and in control chambers, and has the advantages of small structural size, high temperature resistance, water vapor resistance, flame retardance, acid-alkaline chemical agent resistance, fire resistance and excellent electric performance and mechanical performance.

Owner:ANHUI GUODIAN CABLE GRP

Vibration-damping heat-insulation paint and preparation method thereof

ActiveCN101709188AGood adhesionIncreased durabilityFireproof paintsAnti-corrosive paintsAdhesiveData recording

The invention discloses a vibration-damping heat-insulation paint which comprises the following components by mass percent: 9.5-11.5% of chlorine ether resin, 5-6% of adhesive, 3.5-4.5% of melamine urea copolymerization resin, 18-21% of environment-friendly solvent, 14.5-16.5% of soft filler I, 13-15% of soft filler II, 18-20% of soft filler III, 3.8-5.8% of plasticizer, 1.5-2.3% of titanium pigment and 4-6% of hollow micro-bead. The invention also discloses a preparation method of the vibration-damping heat-insulation paint. The high-efficiency vibration-damping heat-insulation paint can be coated on various substrates, has advantages in various aspects such as heat insulation, heat preservation, fire prevention, water prevention, crack prevention, noise prevention, weather resistance, acid / alkali resistance, salt-fog resistance, corrosion resistance, vibration damping, durability and the like, is suitable for thermal protection and vibration damping at the external surfaces of spaceflight instruments and data recording instruments of aerospacecrafts and can be used for damping the impact friction and the like of containers and the like.

Owner:WUXI HUHUANG PAINT

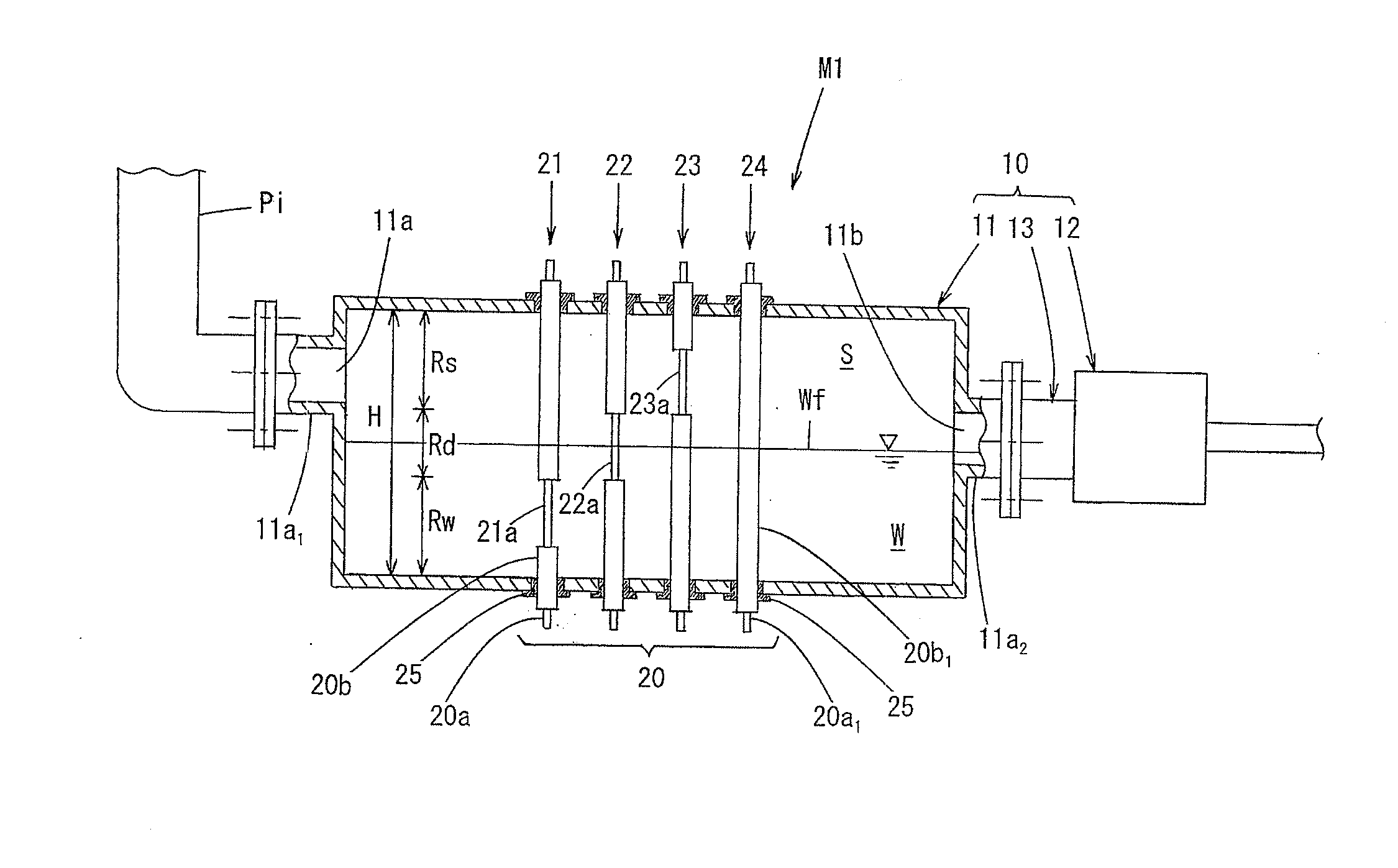

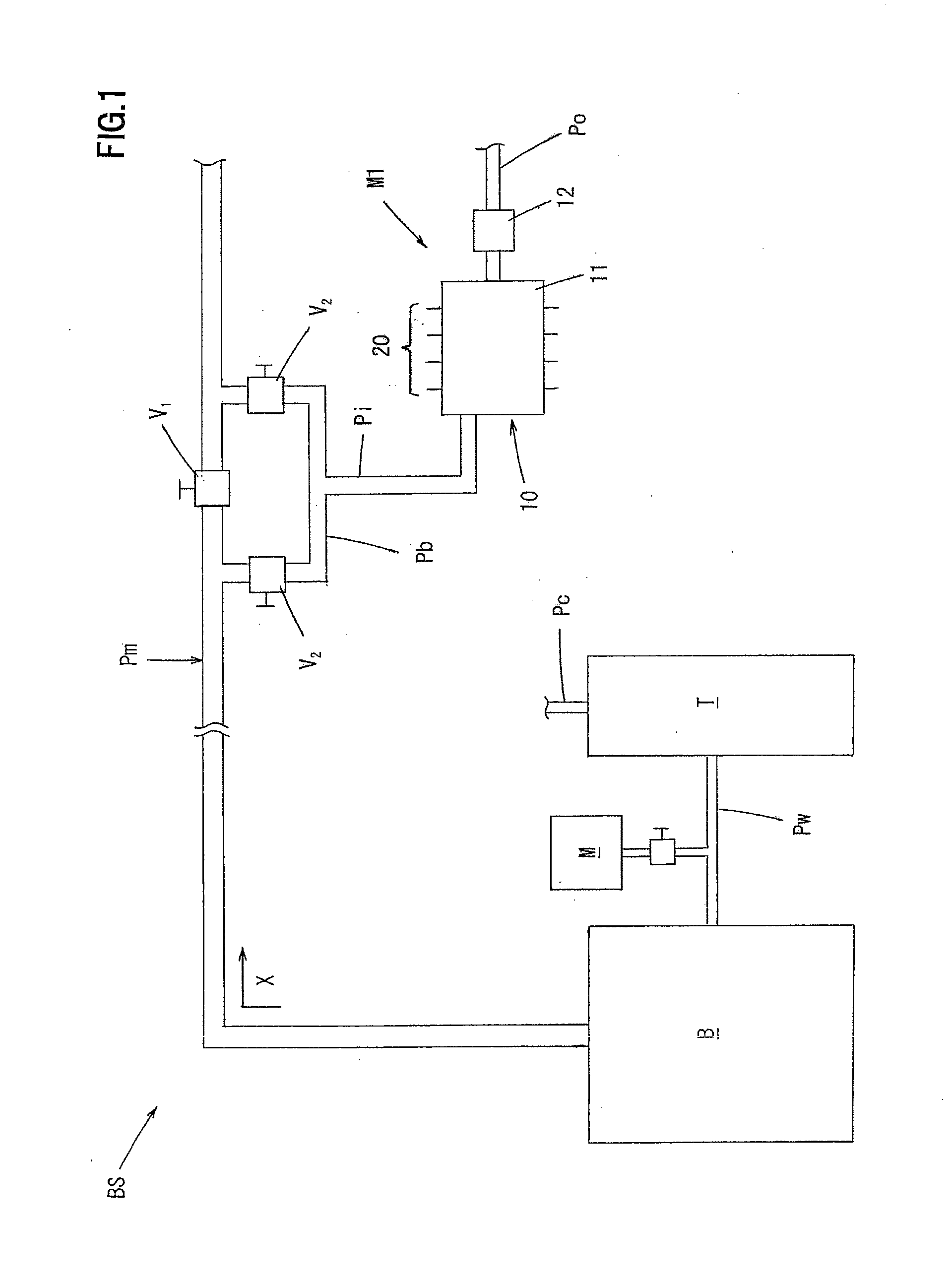

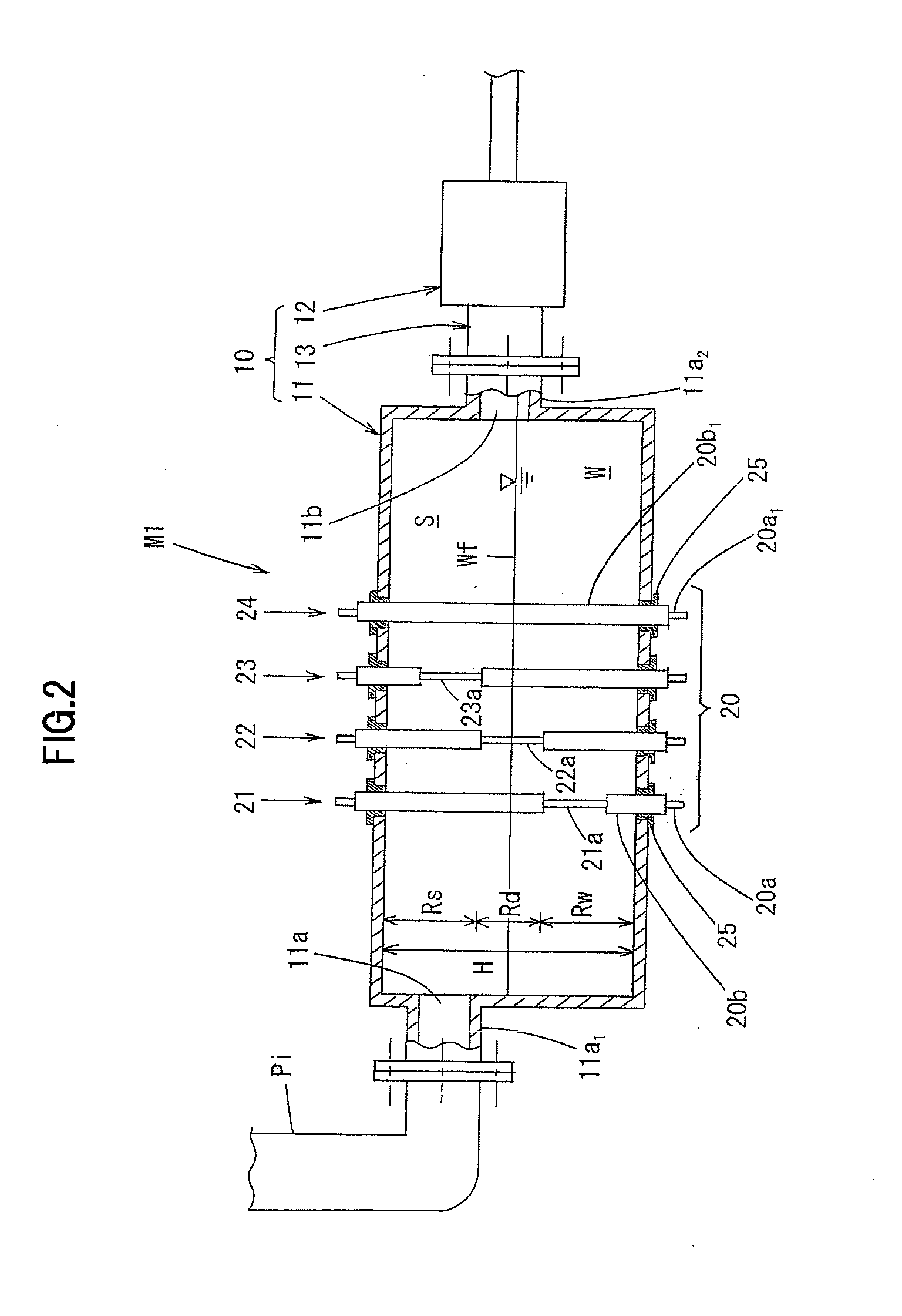

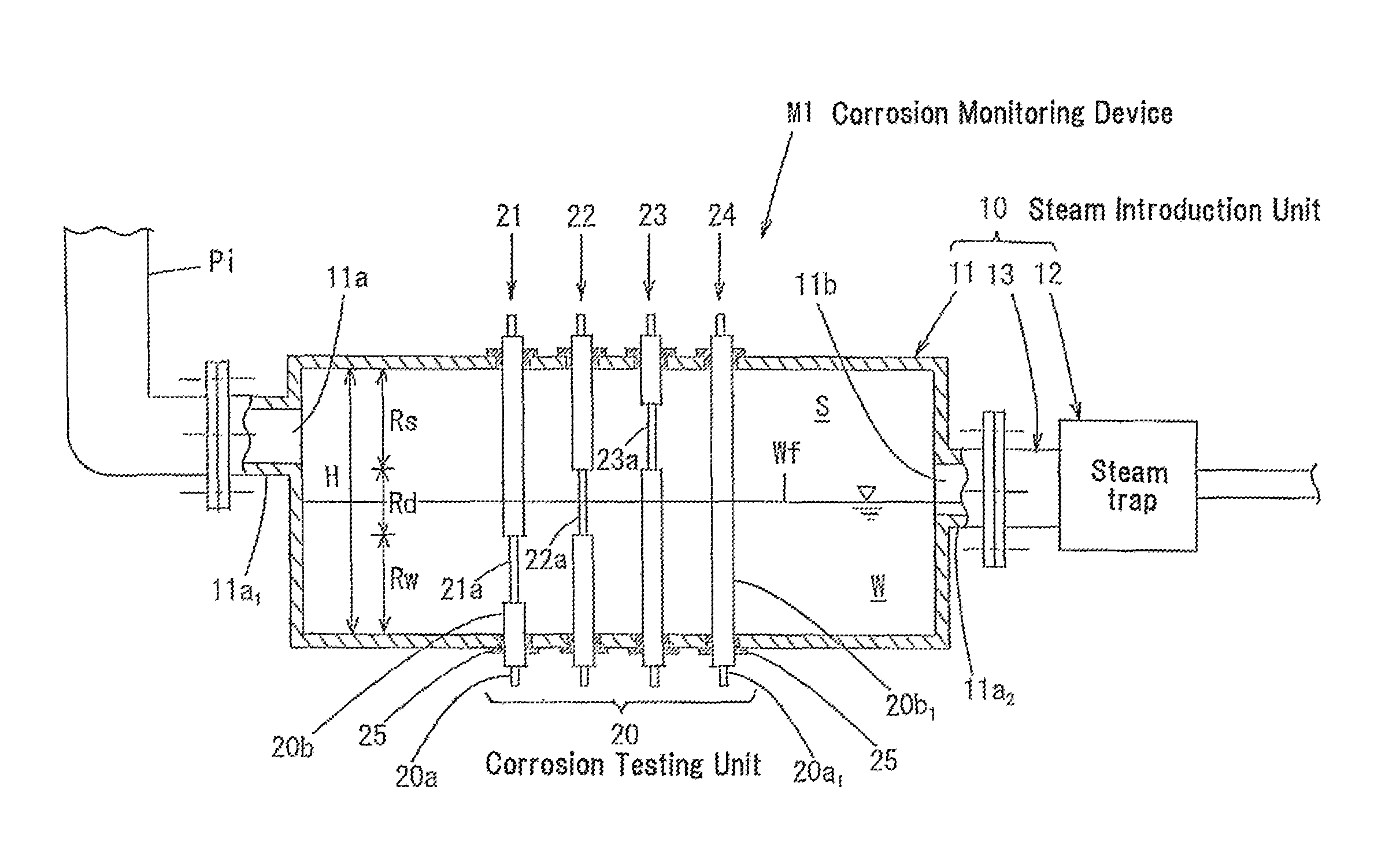

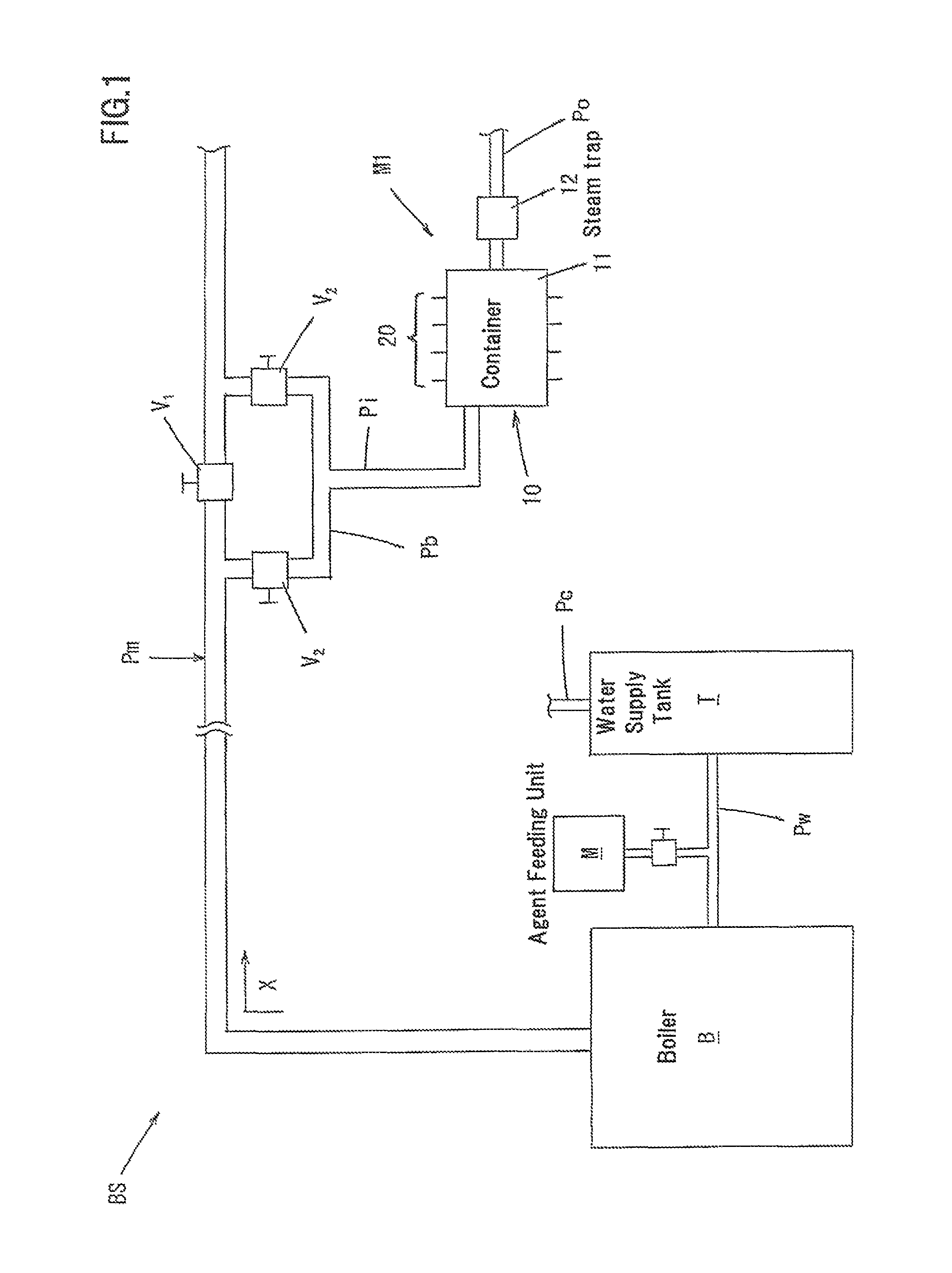

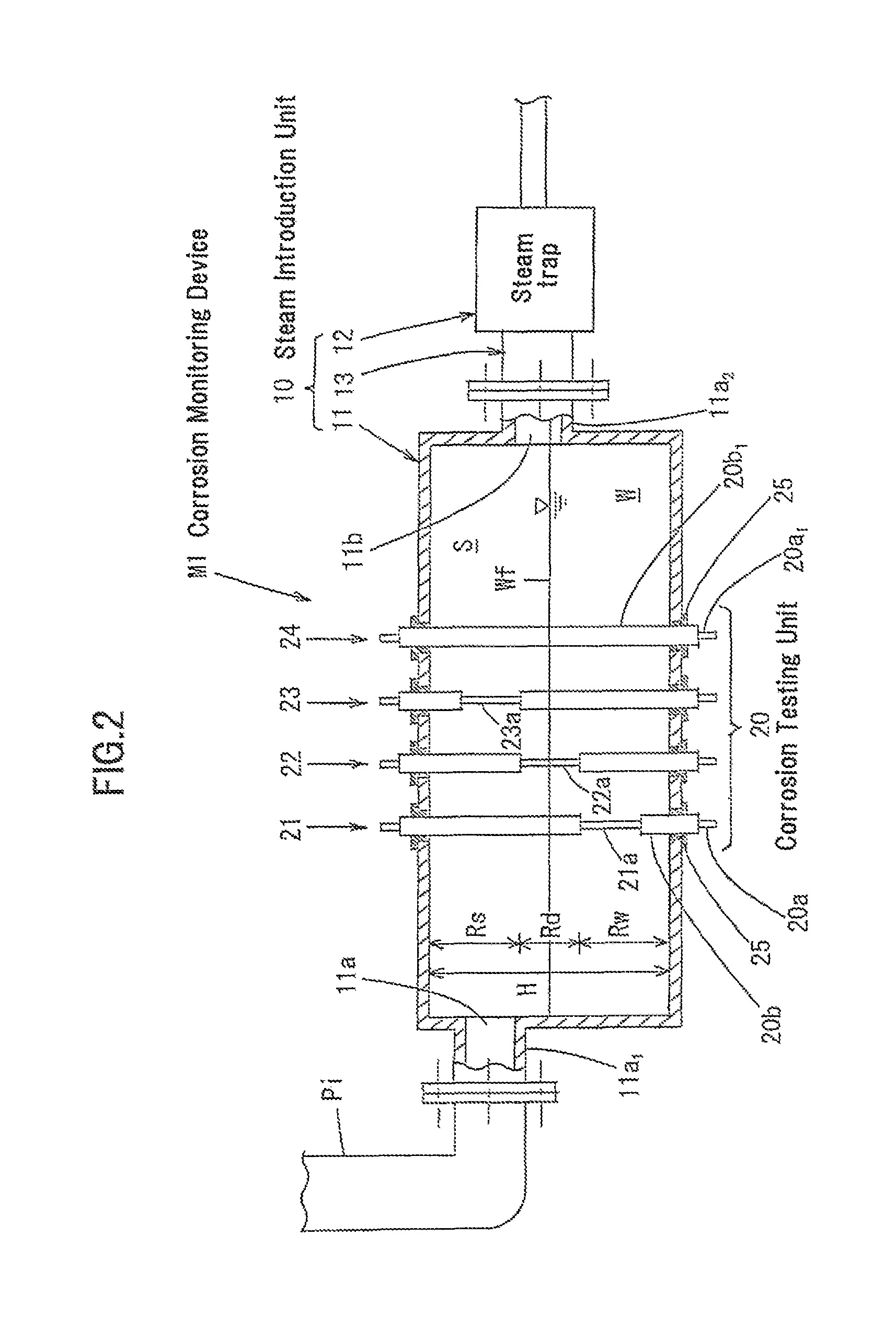

Metal pipe corrosion monitoring device and use thereof

ActiveUS20140306726A1Stable reproductionCorrosionWeather/light/corrosion resistanceResistance/reactance/impedenceCondensed waterVapor phase

A metal pipe corrosion monitoring device includes a steam introduction unit for introducing thereinto steam flowing through a metal pipe; and a corrosion testing unit provided in the steam introduction unit, characterized in that the steam introduction unit is configured to generate condensed water by condensing some of the steam to create a simulated environment similar to an actual environment in the metal pipe and discharge the condensed water above a predetermined water level to the outside. The corrosion testing unit has one or more contact members that contact with a water line region around a water surface of the condensed water in the steam introduction unit, a water phase region on a condensed water side and a vapor phase region on a steam side, and is configured to be able to measure an electric resistance of the one or more contact members.

Owner:NAIGAI KAGAKU SEIHIN

Water-based paint for pipeline and preparing method of water-based paint

InactiveCN105255332ACorrosionStrong adhesionAntifouling/underwater paintsPaints with biocidesSODIUM METAPHOSPHATEMelamine phosphate

The invention relates to water-based paint for a pipeline. The water-based paint for the pipeline is prepared from modified phenolic resin, pitch, alcohol acid emulsion, chromium oxide green, an anti-rusting agent, low polymer polyhydric alcohols, maleic anhydride, methyl methacrylate, hydroxyl ethyl acrylate, hydroxylated fiber resin, polyether sulfone resin, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, crosslinked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine phosphate, pentaerythritol, aluminum silicate fibers, silicon dioxide, antibacterial preservative, titanium dioxide, Ni, Zn, water and other raw materials. Due to the fact that the ingredients such as Ni and Zn are contained in the water-based paint for the pipeline, the water-based paint for the pipeline has the high-temperature resisting and corrosion resisting performance, is suitable for coating demands of various occasions, does not contain toxic organic solvents, is free of pollution and has the advantages that a paint surface cannot crack, and the paint is resistant to aging, high in adhesive force and the like.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

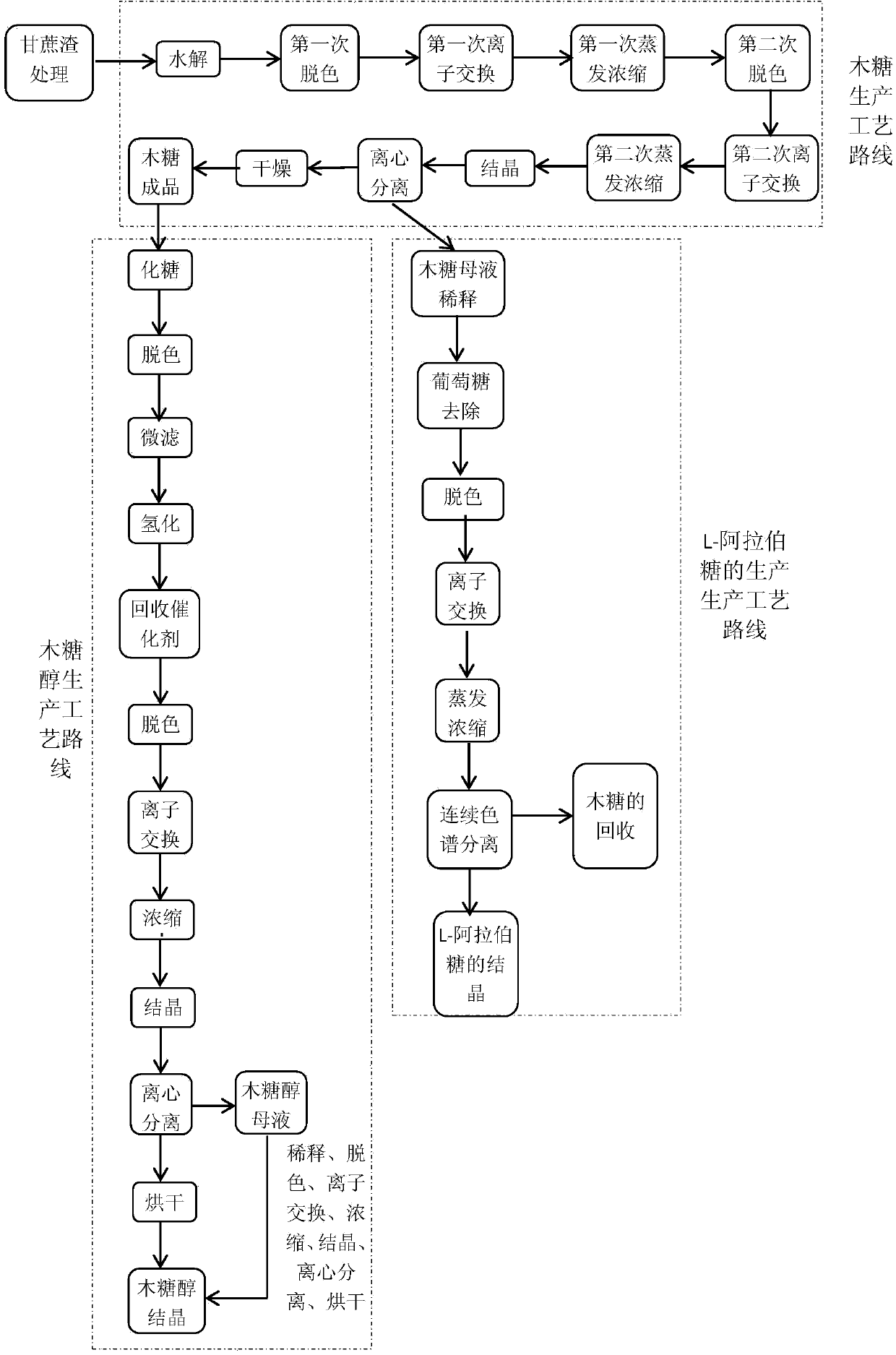

Method of producing xylose and xylitol and co-producing L-arabinose by bagasse

InactiveCN104046705AIncrease profitIncrease added valueSugar derivativesOrganic compound preparationRare sugarAlcohol sugars

The invention relates to a method of producing xylose and xylitol and co-producing L-arabinose by bagasse. The method comprises the following steps: first, treating the bagasse; then, producing xylose by the bagasse; and respectively producing xylitol and arabinose by the product xylose and a xylose mother liquid. By using the bagasse as a raw material, the method provided by the invention obtains crystallized xylose and further products of xylitol and L-arabinose which are high in additional value and are widely applied to the fields of foods and medicines through a whole set of process line. The method provided by the invention is simple to operate, novel in technology, low in cost, diversified in product and high in economic value, is a process method which is initiated at home for co-producing functional sugar alcohols and rare sugar products by bagasse, and has an extremely wide application value.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

Amorphous alloy scalpel and manufacture method thereof

The invention relates to the technical field of amorphous alloy application and particularly relates to an amorphous alloy scalpel and a manufacture method thereof. The scalpel is an amorphous alloy scalpel manufactured by a zirconium-based amorphous alloy, a copper-based amorphous alloy, a titanium-based amorphous alloy, a nickel-based amorphous alloy, a palladium-based amorphous alloy or an iron-based amorphous alloy. The Vickers hardness of the scalpel is 400-600, the yield strength is 1000-3000 MPa, the elastic limit is 2-3%, and the nickel release amount is 0-0.015 mg / cm2 / week; the surface of the scalpel is not corroded after a salt spray test is done for 500-2000 hours. The manufacture method comprises the steps of preparing an integral outline shape of the scalpel through a die-cast formation method, and molding the knifepoint part through TPF or RDF to obtain the amorphous alloy scalpel. The amorphous alloy scalpel has the advantages of high precision, high strength, high elasticity, high hardness, scratch-resistance, corrosion-resistance, and sharp and long service life.

Owner:DONGGUAN PROMETAL TECH CO LTD

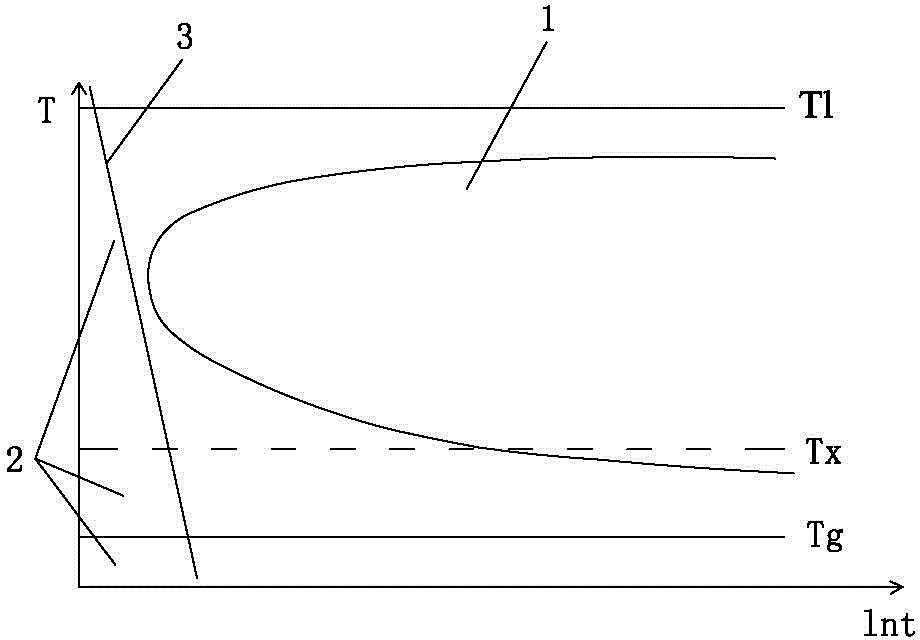

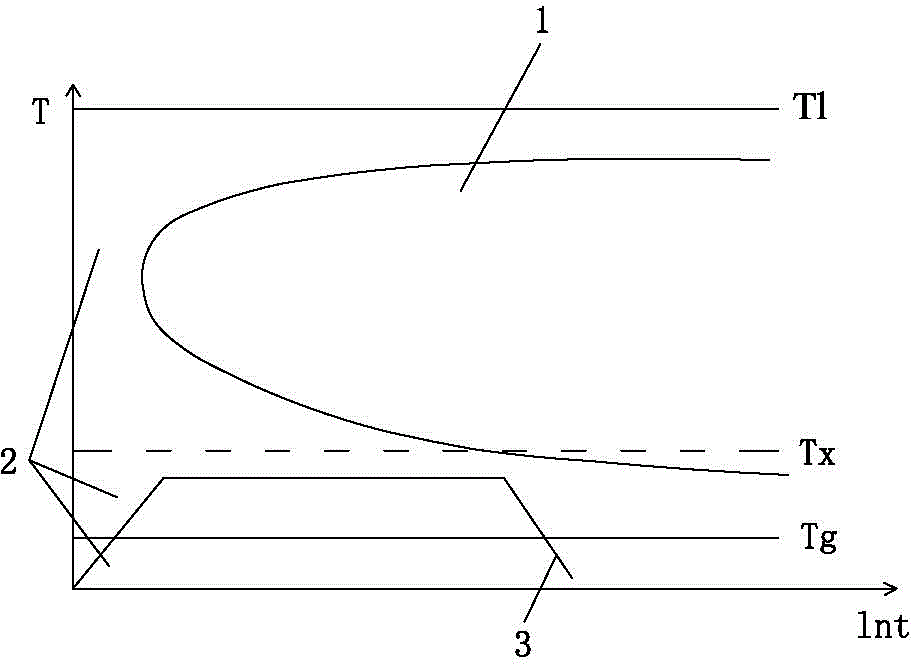

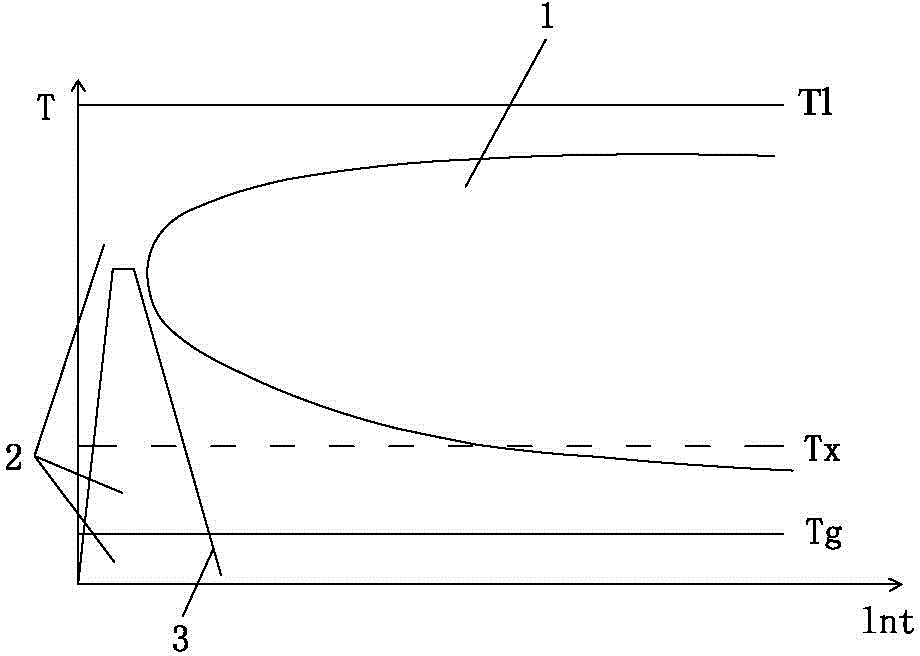

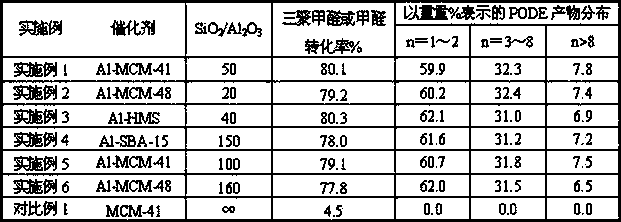

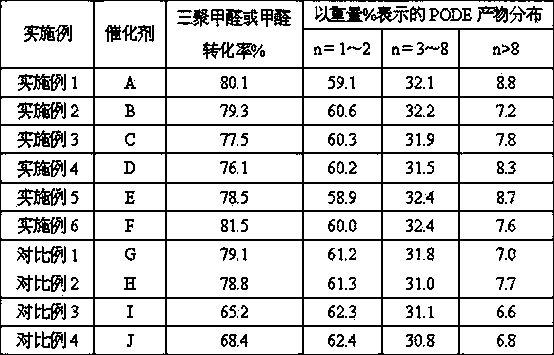

Preparation method of polyoxymethylene dimethyl ethers

ActiveCN103739458ANot corrosiveHigh selectivityOrganic chemistryOrganic compound preparationReaction temperatureMCM-41

The invention relates to a preparation method of polyoxymethylene dimethyl ethers, mainly solving a problem that catalysts are corrosive in the prior art. According to the technical scheme adopted by the preparation method, methanol or dimethyl ether, and formaldehyde or trioxymethylene are adopted as raw materials, the molar ratio of the methanol or the dimethyl ether to the formaldehyde or the trioxymethylene is 1:(0.1-10), the raw materials are contacted with a catalyst and reacted at 50-200 DEG C under 0.1-10 MPa to produce the polyoxymethylene dimethyl ethers, and the catalyst is at least one selected from Al-MCM-41, Al-MCM-48, Al-SBA-15, Al-HMS, Al-MSU-1 or Al-MSU-2. By the scheme, the problem is solved well and the preparation method can be used in industrial production of the polyoxymethylene dimethyl ethers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Industrial heat-resisting fireproofing instrument cable and manufacturing technology thereof

ActiveCN103345964ASmall structure sizeGood mechanical and electrical propertiesInsulated cablesCable/conductor manufacturePolyesterCopper foil

The invention discloses an industrial heat-resisting fireproofing instrument cable which is characterized in that a conductor is formed by a plurality of tinned copper wires in a twisting mode, a fireproofing layer wraps the conductor in a pressing mode, an insulating layer wraps the fireproofing layer in a pressing mode to form an insulating wire core, a pair twisting set is formed by two insulating wire cores, a polyester belt wraps the outer surface of the pair twisting set in a lapping mode, and a shielding layer knitted by tinned copper wires is arranged on the outer surface of the polyester belt to form a pair twisting unit. A cable core is formed by the multiple pair twisting units in a twisting mode. A polyester belt lapping wrapping layer, a longitudinal drainage wire, a tinned copper wire knitting total shielding layer, a copper foil lapping wrapping layer and an outer jacket layer formed in a pressing wrapping mode are sequentially arranged on the outer surface of the cable core from inside to outside, and the insulating layer and the outer jacket layer are made of fluororesin. The industrial heat-resisting fireproofing instrument cable has excellent fireproof performance and high-temperature-resisting performance, has excellent electrical performance and bending performance, is light and handy in cable structure, and meets the requirement for serving as an electric instrument connecting wire under the harsh high temperature environment.

Owner:安徽虹都电缆集团有限公司

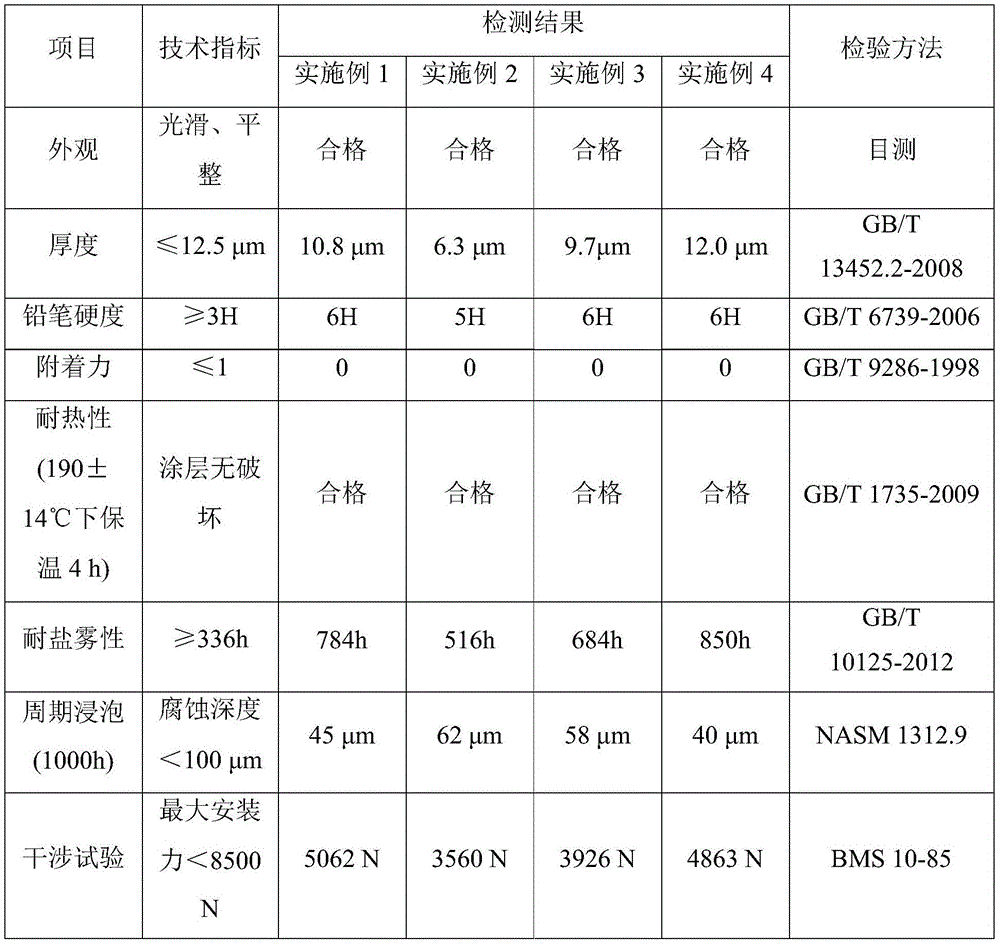

Graphene paint for steel fastening parts and preparation method of graphene paint

InactiveCN105585930ACorrosionReduce corrosionAnti-corrosive paintsFrictional coefficientMelamine formaldehyde resin

The invention discloses graphene paint for steel fastening parts and a preparation method of the graphene paint. The graphene paint is prepared from, by mass, 20-50 parts of urea formaldehyde resin, 1-10 parts of melamine-formaldehyde resin, 0.1-5 parts of graphene, 5-30 parts of aluminum paste, 5-30 parts of zinc powder, 2-10 parts of packing, 1-8 parts of an auxiliary and 10-70 parts of solvent. The paint can be applied to the surfaces of the steel fastening parts, a coating formed through heating curing has the advantages of being small in thickness, high in hardness, resistant to wear, good in adhesive force, low in frictional coefficient and excellent in corrosion resistance, therefore, corrosion of the steel fastening parts can be effectively delayed, and the service life of the steel fastening parts is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Antibiosis and bacteriostat underwear cloth

InactiveCN102125312AImprove breathabilityMoisture-proofSynthetic resin layered productsUndergarmentsAntibiosisTetrafluoroethylene

The invention discloses an antibiosis and bacteriostat underwear cloth, the thickness of which is between 15 and 85 mum. The antibiosis and bacteriostat underwear cloth is made of a fluoroplastic electret film; the micropore diameter of the fluoroplastic electret film is between 0.1 and 0.5 mum; the fluoroplastic electret film is made of a composite material of polytetrafluoroethylene (PTFE), fluoroethylenepropylene (FEP) and ethylene- tetrafluoroethylene copolymer (ETFE) or a composite material of polytetrafluoroethylene (PTFE) and fluoroethylenepropylene (FEP); and the fluoroplastic electret film is made by using the corona-method electret processing technology or the breakdown-method electret processing technology. The antibiosis and bacteriostat underwear cloth can be used in manufacturing of underlinens, underpants, underwaists, briefs, shirts and brassieres.

Owner:徐国元

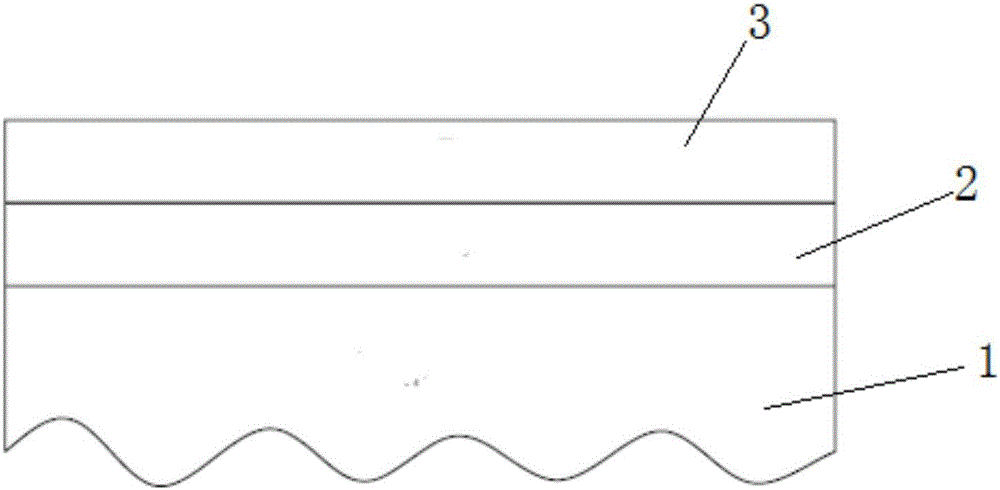

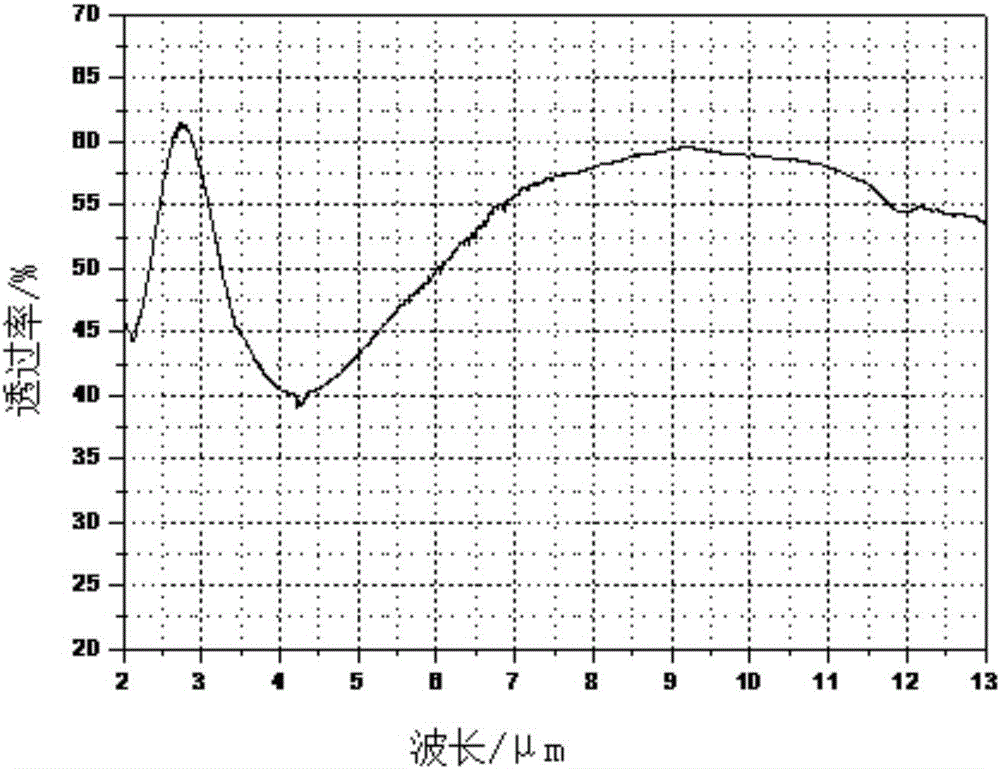

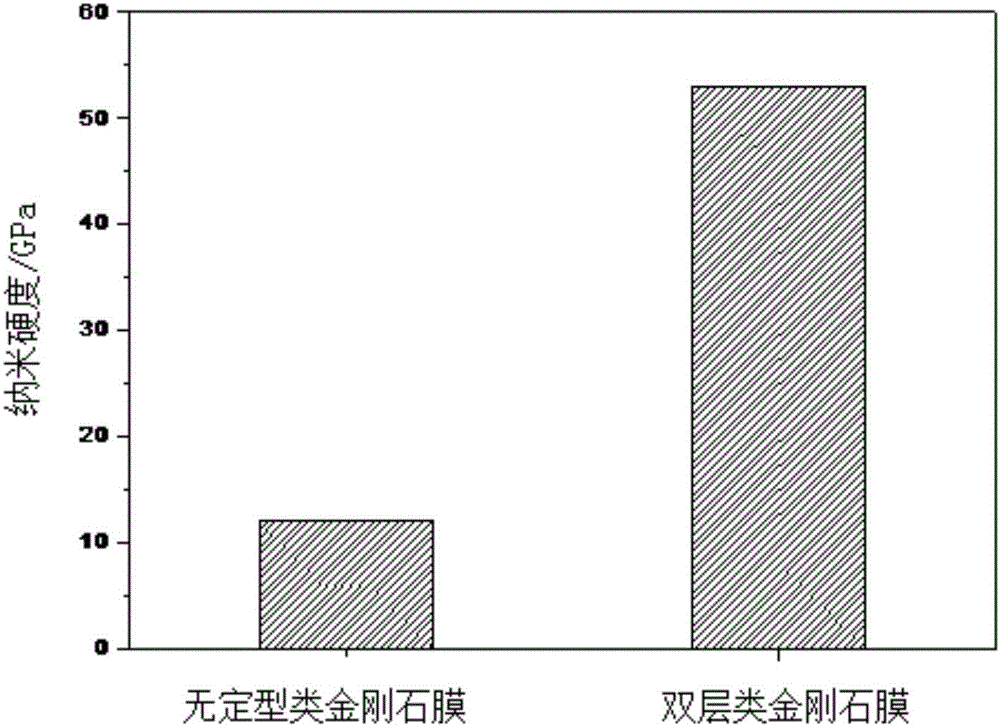

Ultra-hard diamond-like antireflection film, infrared material comprising antireflection film as well as preparation method and application of antireflection film

ActiveCN106521414APlay heavy frictionCorrosionVacuum evaporation coatingSputtering coatingTransmittanceAmorphous diamond

The invention discloses an ultra-hard diamond-like antireflection film, an infrared material comprising the antireflection film as well as a preparation method and application of the antireflection film and belongs to the field of an optical material, wherein the antireflection film comprises an amorphous diamond-like film layer and a tetrahedral diamond-like film layer; and the tetrahedral diamond-like film layer is a surface layer of the antireflection film. The antireflection film disclosed by the invention has the advantages of being resistant to heavy friction and also high in infrared transmittance.

Owner:CHINA BUILDING MATERIALS ACAD

Heat and sound insulation wood plastic material

The invention provides a heat and sound insulation wood plastic material, belonging to the technical field of decorative wood plastic material. The material is composed of 80-100 parts of wood fibre, 20-35 parts of polyurethane plastic, 1-3 parts of a foaming agent, 3-5 parts of a plasticizer, 1-3 parts of fire retardant, 1-2 parts of an anti-oxidant, 1-2 parts of a flexibilizer and 0.5-1 part of a dispersant. According to the invention, the raw materials are easily available and cheap; and the prepared sheet materials has excellent performances of fire resistance, water resistance, corrosion resistance, humidity resistance, insect resistance, fungi resistance, acid and alkali resistance, no toxicity and no pollution; has higher hardness, longer life and higher strength than plastics do; and uses urethane foam, thereby not only being good in the heat insulation effect, but also having the sound insulation effect. The material can be used for decorating metope and base plate, and being made into furniture at the same time, and is beautiful and durable.

Owner:张庆之

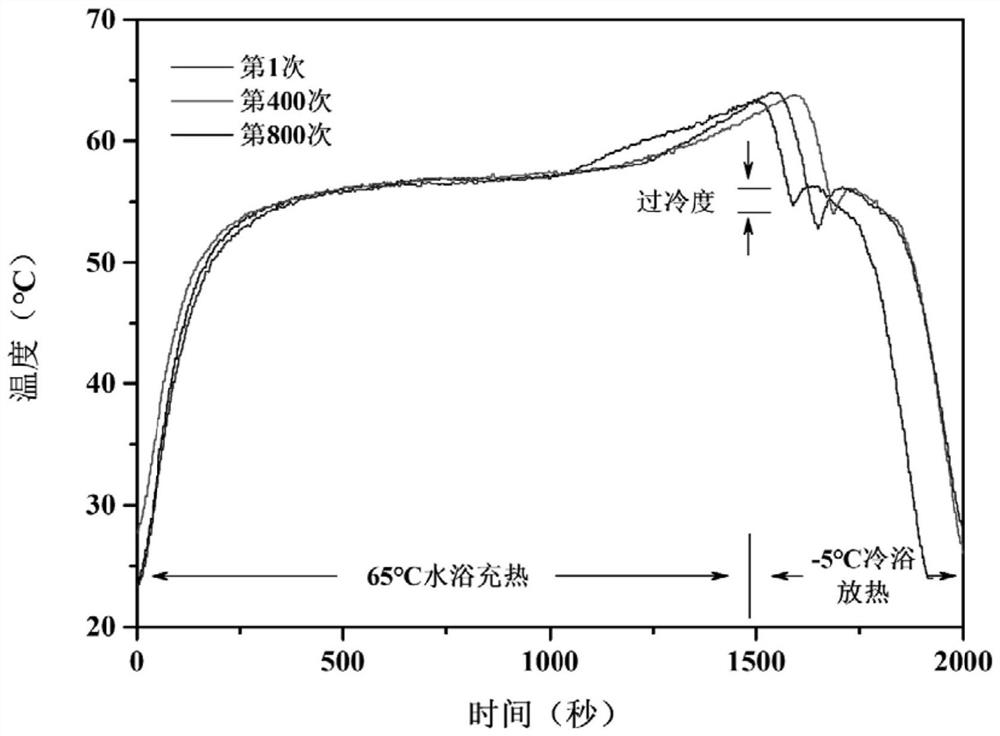

Nano-modified sodium acetate trihydrate phase change heat storage material and preparation method thereof

ActiveCN111621264AReduced nucleation workHigh viscosityHeat-exchange elementsCelluloseChemical reaction

The invention discloses a nano-modified sodium acetate trihydrate phase change heat storage material and a preparation method thereof. The material is composed of, by mass, 90-99 parts of sodium acetate trihydrate, 0.5-2 parts of nano-particles, 0.5-2.5 parts of cellulose and 5-10 parts of graphite, wherein the nano-particles are at least one or a composition of neutral particles and polar particles, the nano-particles do not chemically react with water, and the average particle size of the nano-particles is smaller than 50nm. The phase change temperature is 54-58 DEG C, the degree of supercooling is less than 4 DEG C, and the latent heat of phase change is more than 200kJ / kg. The nano-particles are adopted for modification, the thermal cycle stability of the sodium acetate trihydrate phase change material is improved, and no thermal performance attenuation exists after the material is subjected to 800 times or more of heat charging and discharging cycle tests. The phase change material is green and environmentally friendly, the preparation method is simple, batch production is easy to achieve, stable access of heat is facilitated, and the heat conversion efficiency is improved.

Owner:NARI TECH CO LTD

Medicament for treating empyrosis and scalding and preparation method thereof

ActiveCN102228554AReduce scarsGood curative effectAnthropod material medical ingredientsHydroxy compound active ingredientsSesame OilsMedicine

The invention relates to a medicament for treating empyrosis and scalding and a preparation method thereof. The medicament of a formula comprises the following components in percentage by weight: 25 to 40 percent of bee glue, 2 to 5 percent of golden thread, 1 to 3 percent of phellodendron, 1 to 3 percent of pangolin scales, 1 to 2 percent of borneol, 30 to 55 percent of colza oil and 15 to 32 percent of sesame oil. The preparation method comprises the following steps of: grinding the golden thread, the phellodendron, the pangolin scales and the borneol into 80 to 100-mesh powder for later use; putting the colza oil and the sesame oil into a container, and heating to the temperature of between 180 and 240 DEG C; adding the bee glue, and after the bee glue is dissolved completely, cooling naturally to the temperature of between 60 and 80 DEG C; and adding the powdery medicaments ground in advance, heating, stirring and decocting at the heating temperature of between 60 and 80 DEG C for200 to 240 minutes, and concentrating to form paste. The medicament can produce an effect quickly in inflammation diminishing and detumescence and has an obvious effect of easing pain, and a physiological structure of skin hair follicles can be reconstructed. By the preparation method, active ingredients of each medicament can be kept effectively, so that the prepared medicament is high in curative effect.

Owner:李亚

Light ceramic materials and preparation process and use thereof

The invention relates to a lightweight ceramic material, which is prepared from magnesium soil and pore former through the steps of proportioning, ball grinding, squeezing, forming, drying and sintering. The material has the advantages of light weight, quench resistance, high intensity, strong corrosion stability, non-deformation, good heat-insulating property, and sound insulation performance.

Owner:萍乡市新安工业有限责任公司

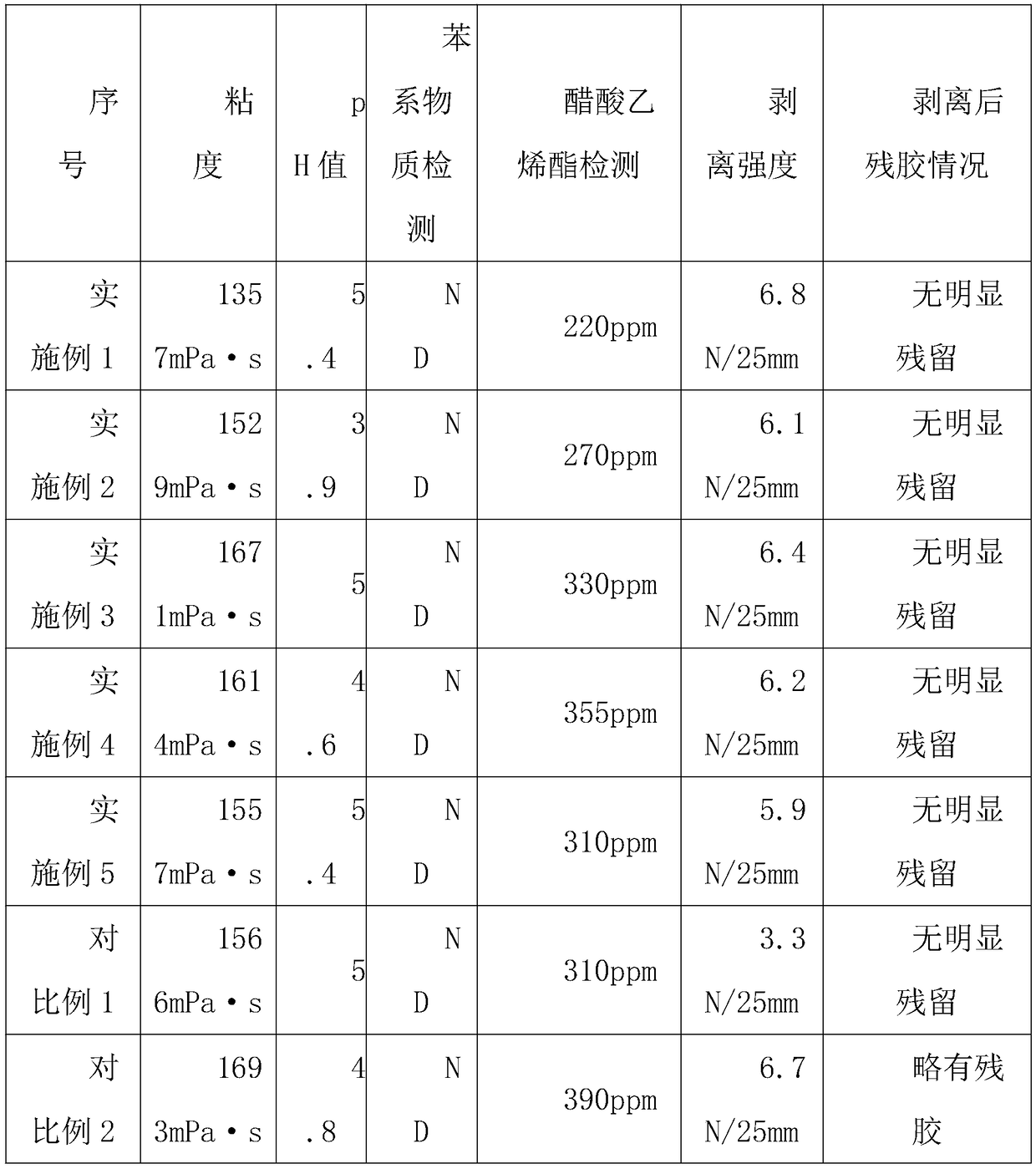

Water-based laser packaging glue used for cigarettes and preparation method thereof

ActiveCN109294488AFast dryingStrong adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemistryCalcium

The invention relates to a water-based laser packaging glue used for cigarettes and a preparation method thereof. The water-based laser packaging glue consists of the following components: a VAE emulsion, nano alumina / crystal alumina, calcium chloride, polyvinyl alcohol, alcohol, a nonionic emulsifier, an environmental protection agent, a preservative, and water. Compared with the prior art, the water-based laser packaging glue has the characteristics of fast drying speed, strong cohesive force, good fluidity, no toxicity, no odor, no corrosion, no burning, and storage resistance. The productquality and various technical performance indicators are superior to similar products, especially in terms of drying speed, bond strength and fluidity, which can be increased by 60% based on the past.The water-based laser packaging glue strictly implements the requirements of the People's Republic of China tobacco industry standard-Volatile and semi-volatile components of tobacco water-based glue, formaldehyde is less than 20ppm, ethyl acetate is less than 400ppm, and the water-based laser packaging glue is inspected by the National Tobacco Quality Supervision and Inspection Center.

Owner:湖北恒阳科技发展有限公司

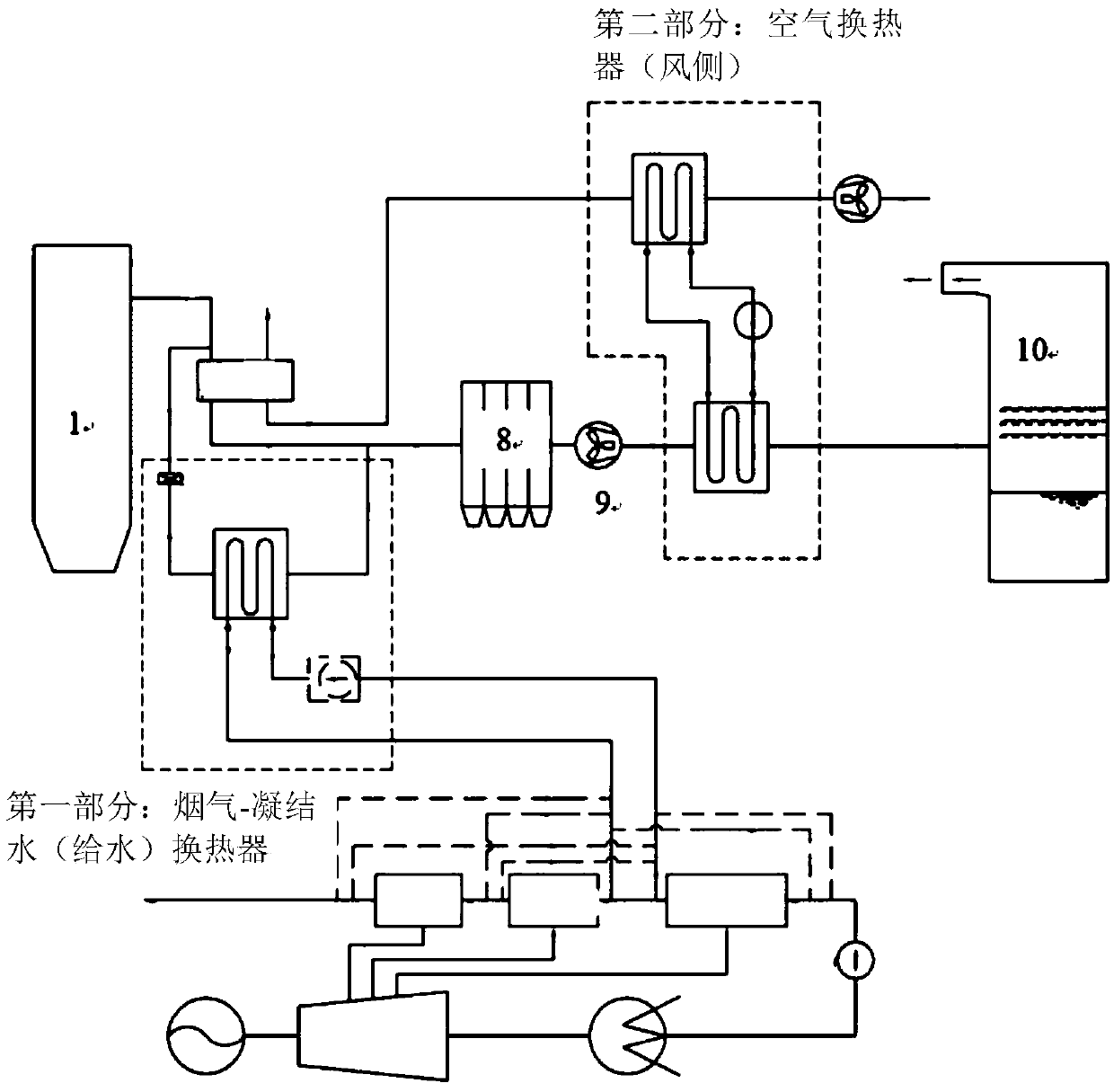

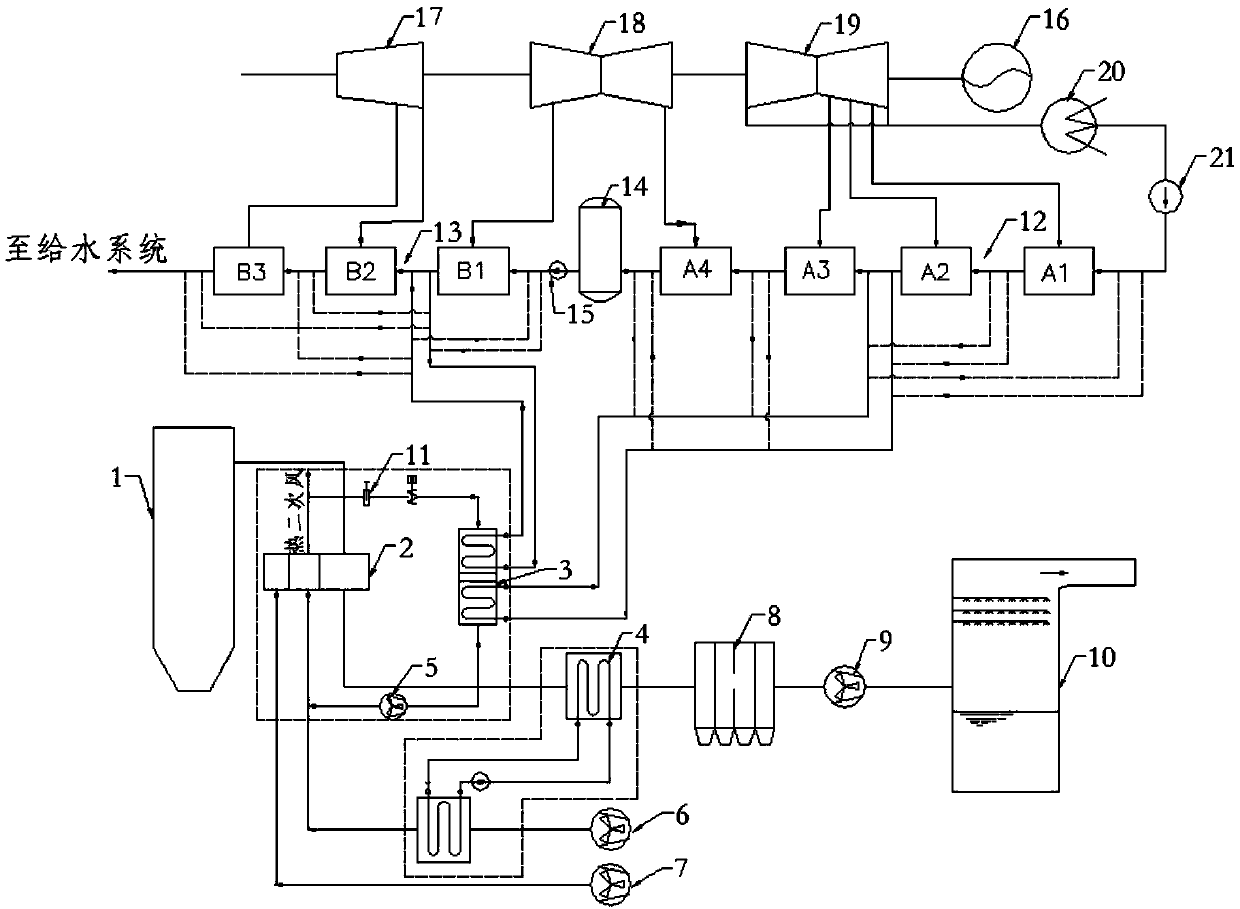

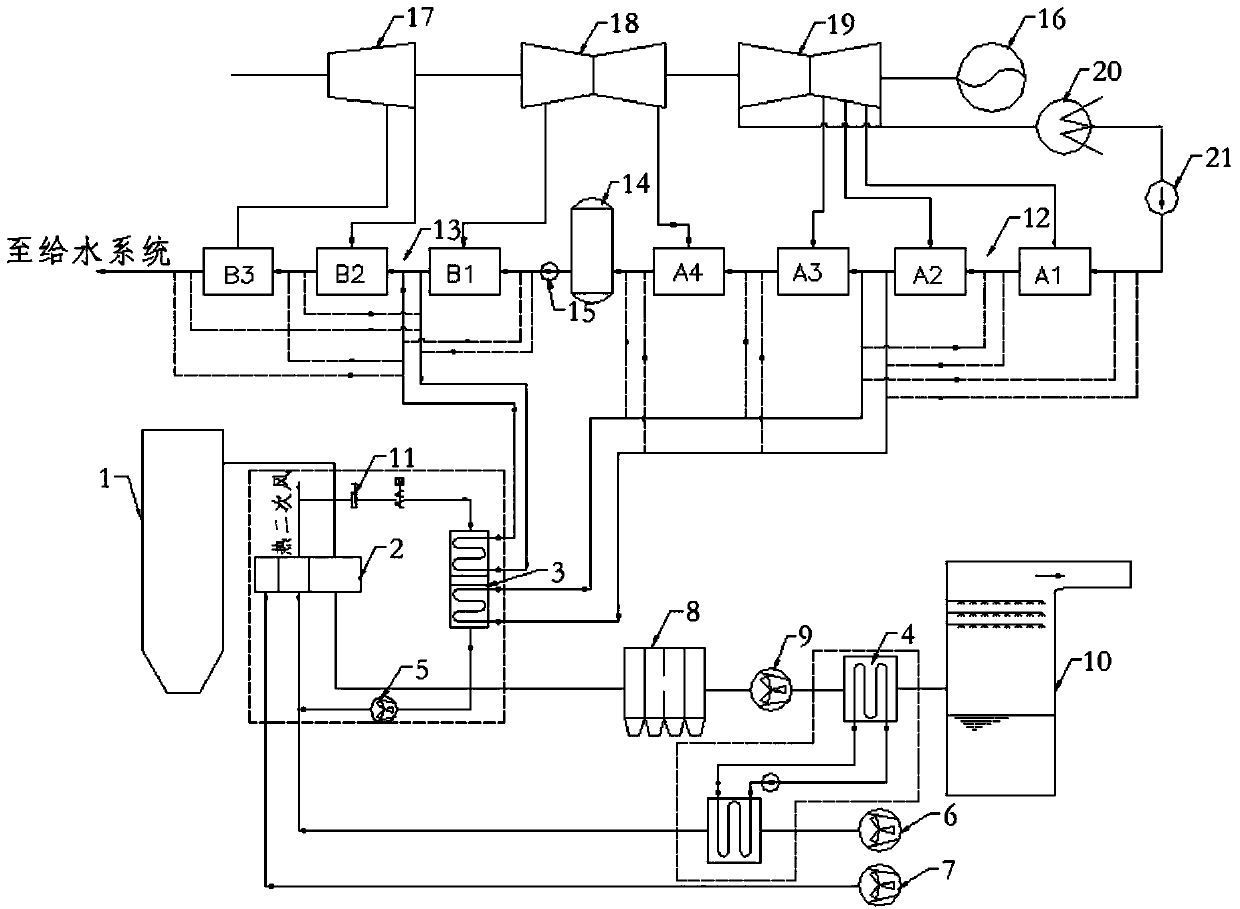

Hot secondary air and flue gas waste heat utilization system and thermal power generating unit

PendingCN109668165AImprove waste heat utilizationImprove qualityCombustion processIndirect carbon-dioxide mitigationAir preheaterRecuperator

The invention belongs to the technical field of flue gas waste heat utilization and relates to a hot secondary air and flue gas waste heat utilization system and a thermal power generating unit. The hot secondary air and flue gas waste heat utilization system comprises an air preheater, a dedustor, an absorption tower, a hot secondary air-feedwater / condensate heat exchanger and a flue gas-air heatexchanger; a hot secondary air outlet of the air preheater is connected with a hot secondary air bypass, the hot secondary air bypass is connected with the hot secondary air-feedwater / condensate heatexchanger, and feedwater / condensate is heated by means of hot secondary air; and the flue gas-air heat exchanger is arranged in an inlet of the dedustor, and cold air is heated by means of low-temperature flue gas at the inlet of the dedustor; or the flue gas-air heat exchanger is arranged in an inlet of the absorption tower, and the cold air is heated by means of low-temperature flue gas at theinlet of the absorption tower. The hot secondary air and flue gas waste heat utilization system and the thermal power generating unit are high in flue gas waste heat utilization rate, and have the characteristics of being clean, free of abrasion, free of corrosion and the like, no soot blowing system is needed, the equipment cost is low, and operation is safe and reliable.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

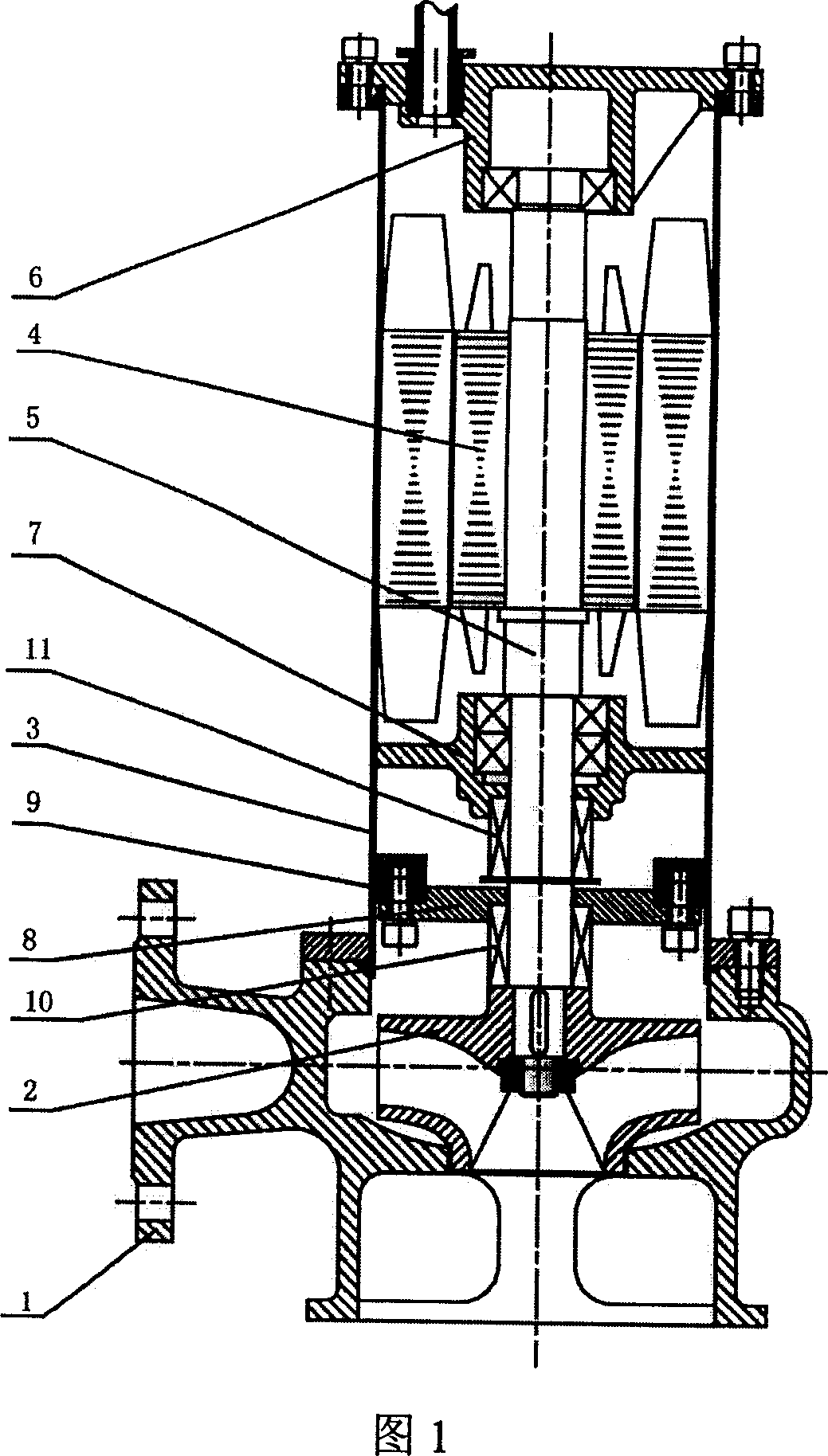

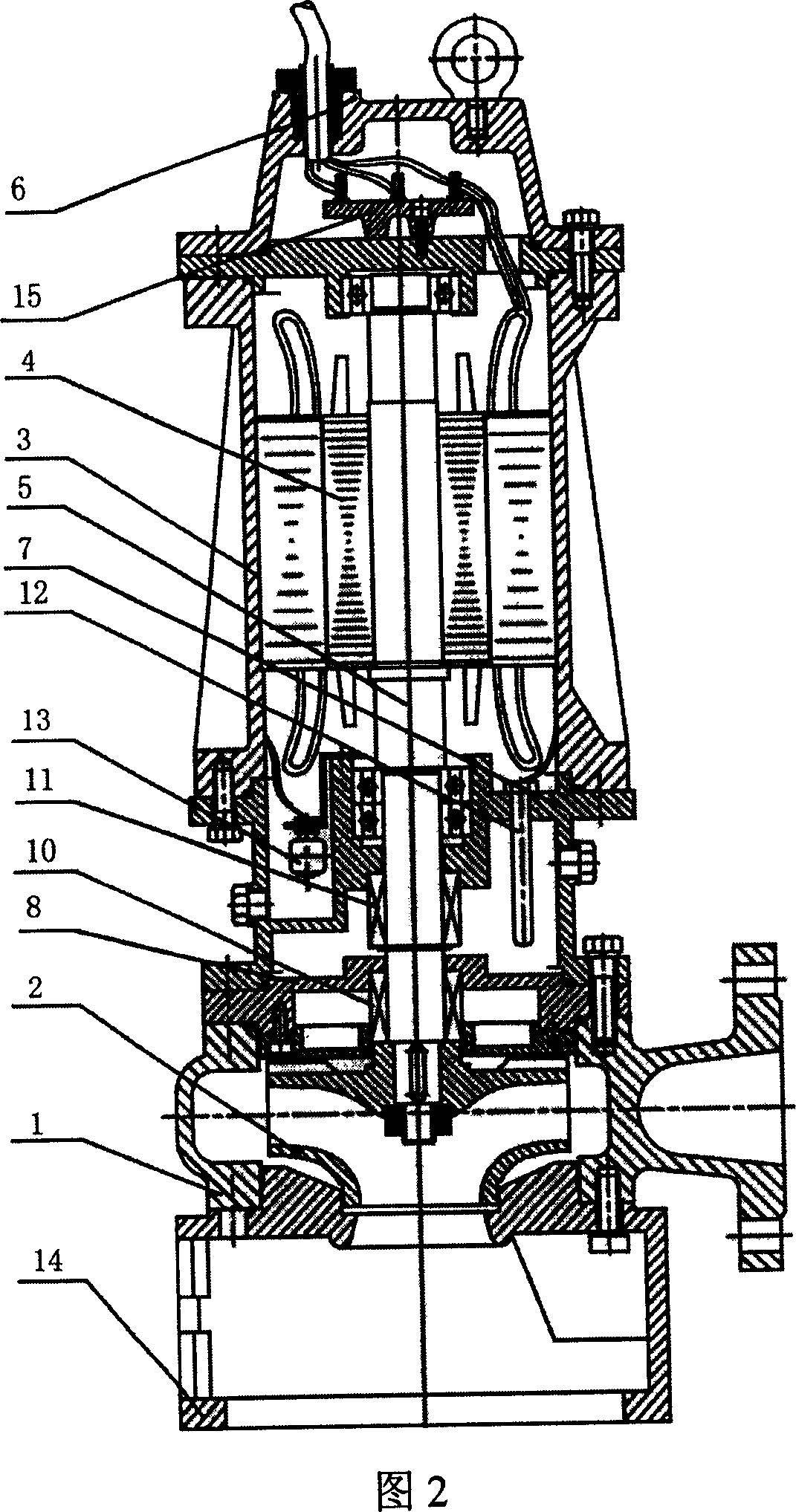

No-blocking pollution discharging pump

InactiveCN1945021ARelieve pressureGuaranteed reliabilitySpecific fluid pumpsPump componentsImpellerFlange

The no-blocking dredge pump includes a pump body, an impeller, a motor, a sealed oil chamber and a mechanical seal. The impeller is one double flow passage structure set inside the pump body; the motor includes stainless steel casing, rotor, shaft, flange type upper bearing seat on the casing and lower bearing seat inside the casing. The upper bearing seat and the lower bearing seat support the rotating rotor and shaft; the sealed oil chamber is constituted with a gland, the casing and the lower bearing seat; and the casing has lower end connected to the pump body. Compared with available technology, the present invention has the advantages of less blocking, reliable sealing, high efficiency high running smoothness and reliability.

Owner:上海山川泵业制造有限公司

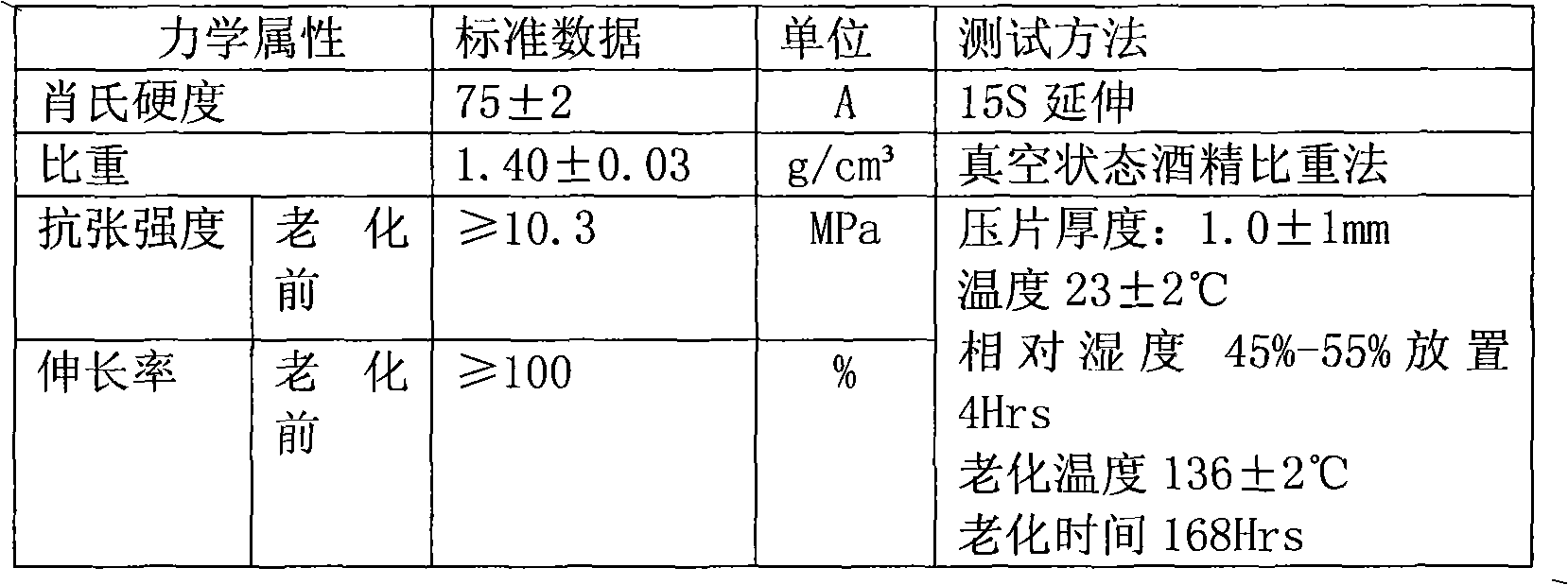

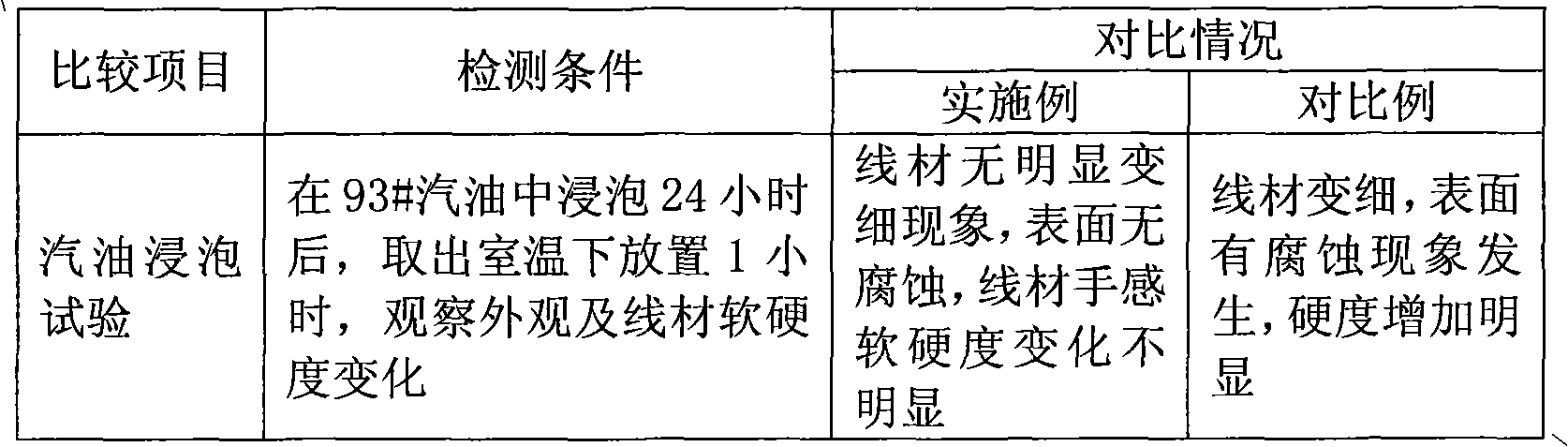

Oil-proof PVC sheath material for earphone wire

InactiveCN101585949AHas ultrafine activityEasy Ultrafine ActiveEarpiece/earphone attachmentsOrganic solventMaterials processing

The invention discloses an oil-proof PVC sheath material for earphone wire, which is obtained by evenly mixing and then, in a double screw extruder, extrusion-granulating the following raw materials, based on weight part, of: 45-50 parts of WS-1300, 25-35 parts of W-2050, 20-25 parts of mixed filler, 2-5 parts of YC-300 and 0.5-2.0 parts of LOCK, the mixed filler is formulated by HD-2500 and CCR-603 in accordance with weight ratio of 1:1-2; the sheath material is not liable to be extracted by organic solvent like oil product after being processed to the earphone wire, has preferable corrosive resistance to organic solvent like oil product, and still has good elasticity and softness after being immersed in organic solvent like oil product. Therefore, the invention is oil-proof PVC sheath material for earphone wire that has preferable oil product resistance and softness stability.

Owner:浙江富舜科技股份有限公司

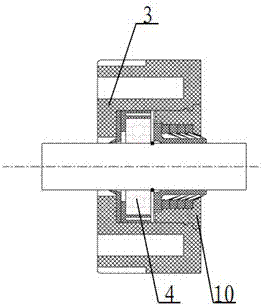

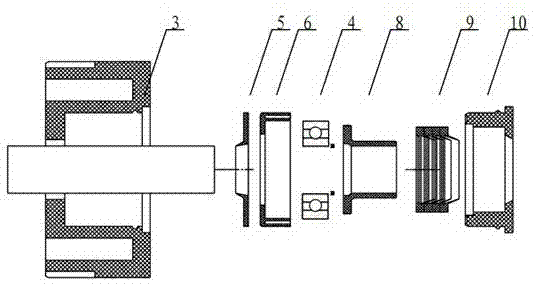

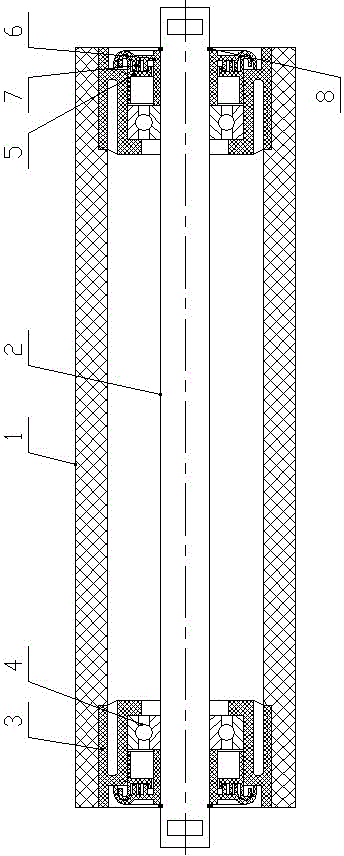

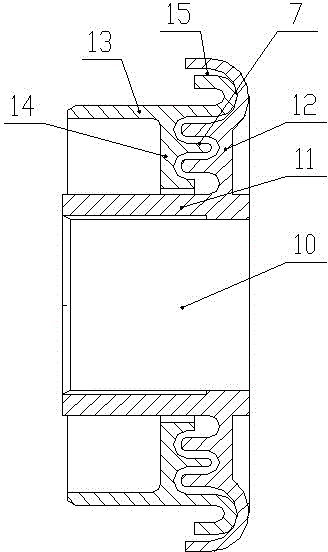

Carrier roller bearing assembly and carrier roller with bearing assembly

The invention discloses a carrier roller bearing assembly and a carrier roller with the bearing assembly. The carrier roller bearing assembly comprises a bearing base, a bearing and a sealing assembly, wherein the bearing is installed on the bearing base. The sealing assembly comprises a bottom sealing ring, a shaft sleeve, a shaft sleeve sealing ring and a sealing outer cover, the bottom sealing ring is arranged on one side of the bearing in the axial direction of the carrier roller, the shaft sleeve, the shaft sleeve sealing ring and the sealing outer cover are arranged on the other side of the bearing in the axial direction of the carrier roller, and the shaft sleeve, the shaft sleeve sealing ring and the sealing outer cover are coaxially arranged. The bearing assembly has good sealing performance, and when used, the carrier roller with the bearing assembly is low in noise and good in sealing performance and has good mechanical strength.

Owner:河南省华北工业塑料有限公司

Anticorrosion termite-insect-resistant power cable material and preparation method thereof

InactiveCN105037893AReduce injectionReduce aggregationDecabromobiphenyl etherDecabromodiphenyl ether

The invention discloses an anticorrosion termite-insect-resistant power cable material. The power cable material is prepared by adopting the following raw materials in parts by weight: 94 to 96 parts of high-density polyethylene, 15 to 17 parts of decabromodiphenyl ether, 7 to 9 parts of antimonous oxide, 2 to 3 parts of metallocene polyethylene, 2 to 3 parts of nano magnesium hydroxide, 4 to 5 parts of cyclohexane, 0.2 to 0.3 part of gamma-aminopropyltriethoxysilane, 1.5 to 2 parts of antioxidant 1024, 1 to 2 parts of methylparaben, 4 to 6 parts of glass fibers, 0.2 to 0.3 part of permethrin, 2 to 3 parts of garlic powder, 10 to 12 parts of diatomite, 0.8 to 1 part of palmitoleic acid lauryl ester, 4 to 6 parts of clarified limewater, 3 to 4 parts of coumarone and 7 to 9 parts of natural rubber. Components such as permethrin, garlic powder, clarified limewater and the like are added and are synergistic, so that the power cable material has an insecticidal function, resists insects and termites, resists corrosion and ensures that a laid cable is prevented from being damaged by insects and termites. The component formula is a halogen-free flame-retardant anticorrosion formula and harmless to the environment, the mechanical performance is good, and the service life is long.

Owner:安徽吉安特种线缆制造有限公司

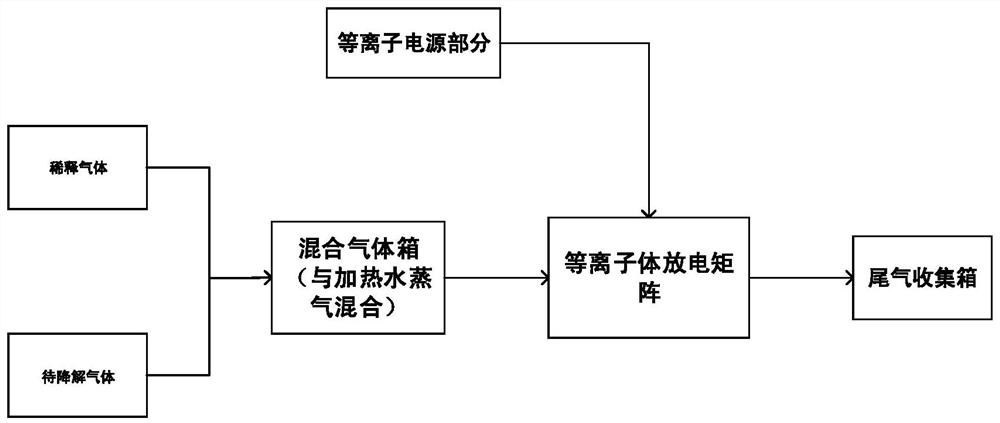

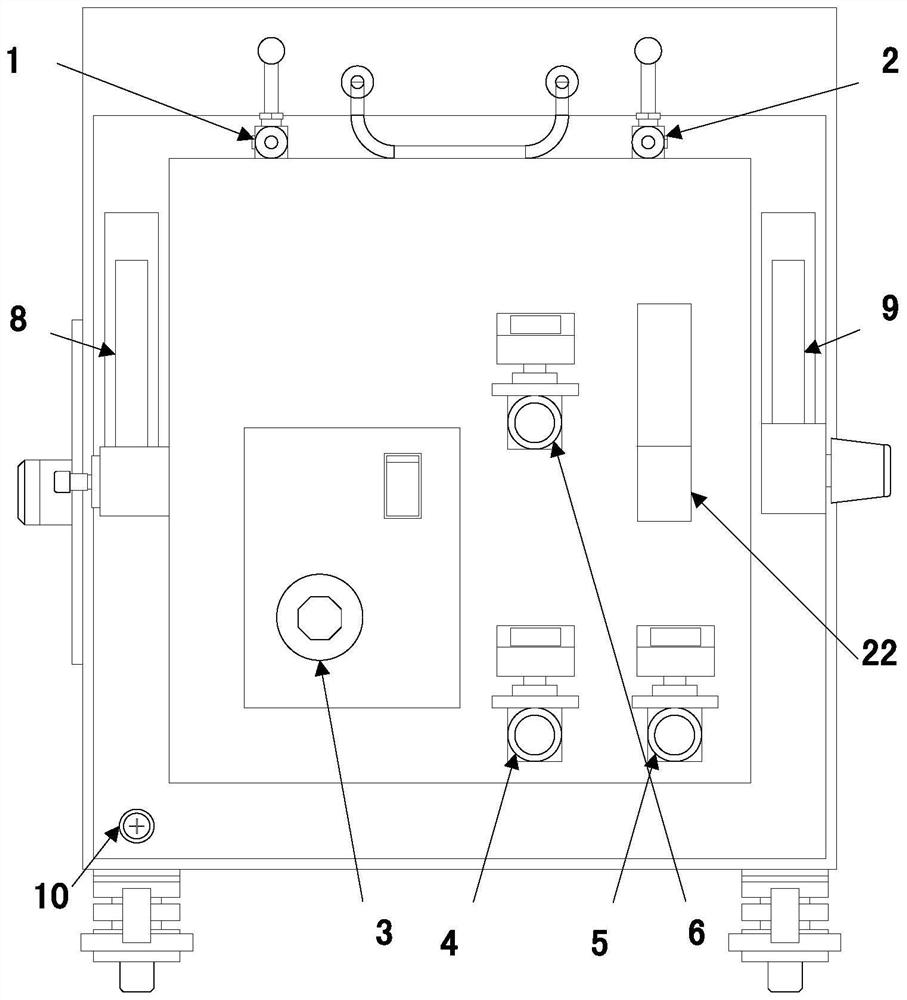

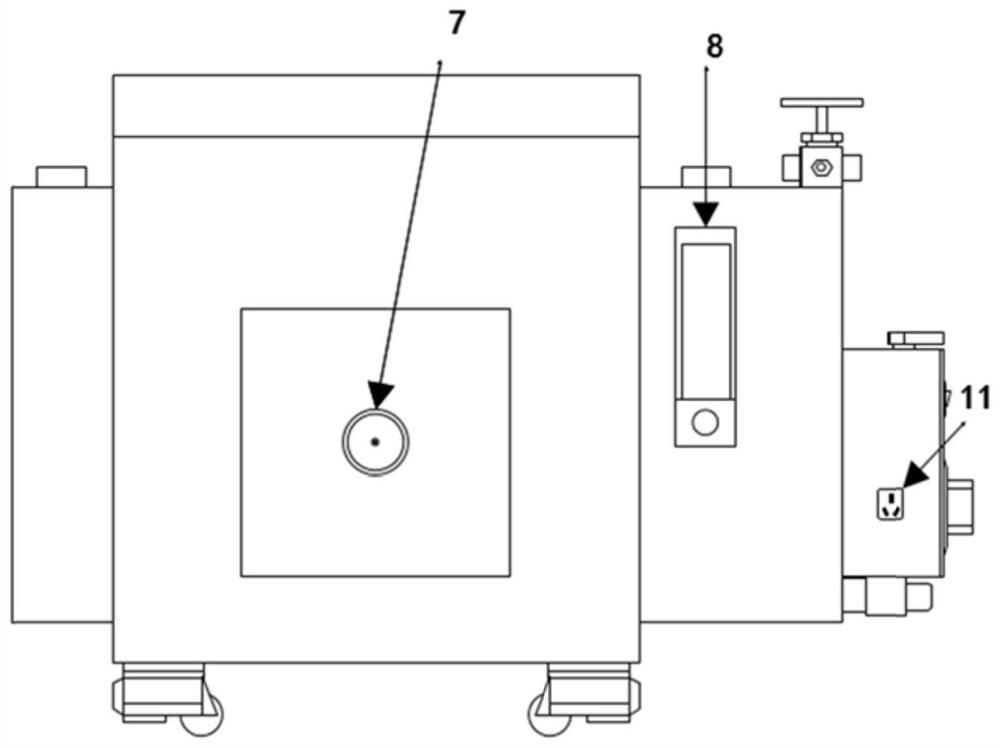

Mixed gas treatment equipment based on plasma technology

PendingCN113181744AControl the severity of the reactionResistant to acid gas corrosionGas treatmentDispersed particle separationPlasma technologyWater vapor

The invention discloses mixed gas treatment equipment based on a plasma technology. The equipment comprises an SF6 degradation host machine and a power supply part; the host machine comprises a mixed gas box, a plasma discharge matrix and a tail gas collection box which are densely assembled together; purified water fills the bottom of the mixed gas box, and gas to be degraded in the mixed gas box is mixed with diluent gas and water vapor to form mixed gas; one end of the plasma discharge matrix is connected with the mixed gas box, so that the plasma discharge matrix can be used for carrying out plasma degradation treatment on the mixed gas; the tail gas collection box is connected with the other end of the plasma discharge matrix, and alkaline absorption liquid is contained in the tail gas collection box, and the tail gas collection box is used for washing the degraded gas and then discharging the gas through an exhaust pipe. The gas mixing device for mixing SF6 gas to be degraded and diluent gas and the washing and collecting device for tail gas subjected to discharge degradation are integrated in front of and behind the discharge matrix, so that the main part of the whole equipment can be formed, and the equipment is small and portable and can be used in various occasions.

Owner:WUHAN UNIV +1

Preparation method of polymethoxy methylal

ActiveCN103539645AIncrease profitIncreased focus capacityOrganic chemistryMolecular sieve catalystsMolecular sieveMicrometer

The invention relates to a preparation method of polymethoxy methylal, which mainly solves the problem of corrosiveness of the catalyst in the prior art. The method comprises the following step: contacting raw materials methanol or dimethyl ether and formaldehyde or trioxymethylene in a mol ratio of 1:(0.1-10) with a catalyst to react at the reaction temperature of 50-200 DEG C under the reaction pressure of 0.1-10MPa to obtain the polymethoxy methylal, wherein the catalyst is a ZSM-5 molecular sieve of which the crystal grain diameter is smaller than or equal to 5 micrometers, the ZSM-5 molecular sieve is treated in a 0.01-2 mol / L alkali solution at 30-100 DEG C for 0.1-10 hours, and the weight ratio of the alkali solution to the molecular sieve is 1-20. The technique scheme provided by the invention well solves the problem, and can be used for industrial production of polymethoxy methylal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Seal carrier roller

ActiveCN102795459BExtended service lifeImprove wear resistanceRollersPulp and paper industryFire resistance

Owner:河南省华北工业塑料有限公司

Metal pipe corrosion monitoring device and use thereof

ActiveUS9239282B2Stable reproductionCorrosionWeather/light/corrosion resistanceResistance/reactance/impedenceElectrical resistance and conductanceEngineering

A metal pipe corrosion monitoring device includes a steam introduction unit for introducing thereinto steam flowing through a metal pipe; and a corrosion testing unit provided in the steam introduction unit, characterized in that the steam introduction unit is configured to generate condensed water by condensing some of the steam to create a simulated environment similar to an actual environment in the metal pipe and discharge the condensed water above a predetermined water level to the outside. The corrosion testing unit has one or more contact members that contact with a water line region around a water surface of the condensed water in the steam introduction unit, a water phase region on a condensed water side and a vapor phase region on a steam side, and is configured to be able to measure an electric resistance of the one or more contact members.

Owner:NAIGAI KAGAKU SEIHIN

A retardant and a retardant acid working solution

ActiveCN105837749AReduce releaseSlow release rateDrilling compositionMannich reactionPhosphoric acid

A retardant is provided. The retardant is prepared through steps of A) subjecting formaldehyde, an amine and phosphoric acid to a Mannich reaction to obtain a monomer, and B) copolymerizing the monomer and acrylic acid to obtain the retardant. The retardant is prepared through copolymerizing the monomers. One molecular chain of the retardant after the polymerization contains a plurality of releasable Hs and the Hs can be slowly released in stratums, thus achieving an effect of acidifying the stratums and improving stratum corrosion capability of the admixture. The invention also provides a retardant acid working solution comprising the retardant. Test results prove that the retardant acid working solution has good slow release effects, and is turned into a spent acid after 30-90 min.

Owner:SOUTHWEST PETROLEUM UNIV +1

Super-pure aluminum microscopic tissue form etching agent and etching method thereof

ActiveCN108240933ACorrosionImprove conductivityPreparing sample for investigationElectrode potentialHydrofluoric acid

The invention relates to the technical field of etching methods and particularly discloses a super-pure aluminum microscopic tissue form etching agent and an etching method thereof. The etching agentis a mixture of hydrofluoric acid, nitric acid and purified water, wherein the volume ratio of hydrofluoric acid to nitric acid to purified water is (5-10) to 10 to (80-85). A reagent adopted in the preparation method is simple and capable of corroding novel high-conductivity hard aluminum leads, and a grain boundary is selectively etched according to the difference between the grain boundary andthe internal electrode potential in a grain in the premise that second-phase particles and other compounds in the tissue are not etched, so that a clear microscopic tissue can be displayed, and the compounds generated in the material and the separated second-phase particles can be preserved, and the reagent can be applied to the etching of a microscopic tissue of a hard aluminum lead used in existing projects.

Owner:囯网河北省电力有限公司电力科学研究院 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com