A retardant and a retardant acid working solution

A technology of retarder and working fluid, applied in the direction of drilling compositions, chemical instruments and methods, etc., which can solve the problems of shortening the effectiveness of production increase, fast reaction rate, short penetration distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

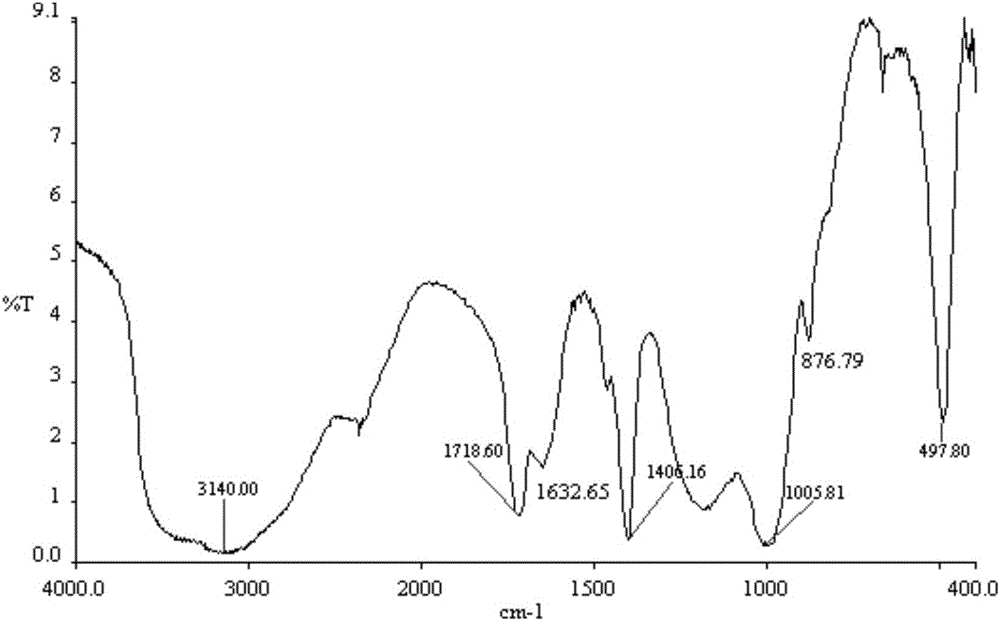

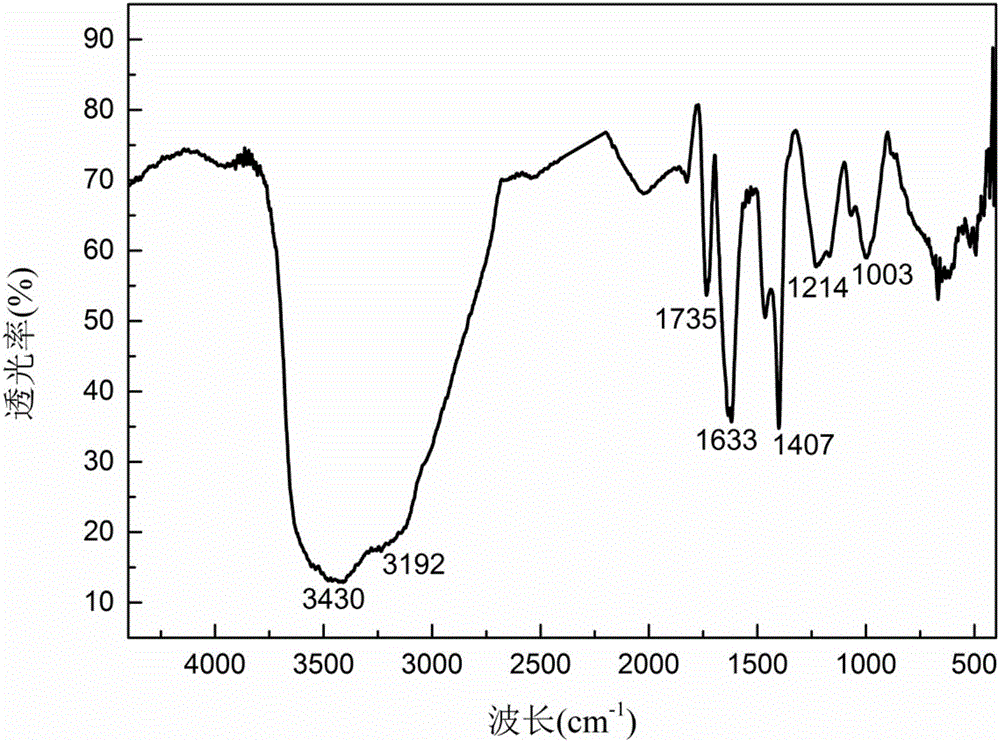

[0054] First, add 8g of acrylamide to 18.7g of formaldehyde solution with a mass fraction of 33%. After it is completely dissolved, put it into a three-necked flask; then add 14g of phosphoric acid with a mass fraction of 85%. After it is completely dissolved, add 0.1g of hydroquinone , under the condition of 90° C., reacted for 14 h while stirring to obtain the product monomer.

[0055] Take 0.84g of acrylic acid in a three-necked flask, add 10.2g of distilled water to dissolve it completely, add 30g of monomer FAP, stir evenly, put it in an oil bath, heat up to 80°C while stirring; then add 0.84g of peroxide Hydrogen, react at 80°C for 1h to obtain retarder.

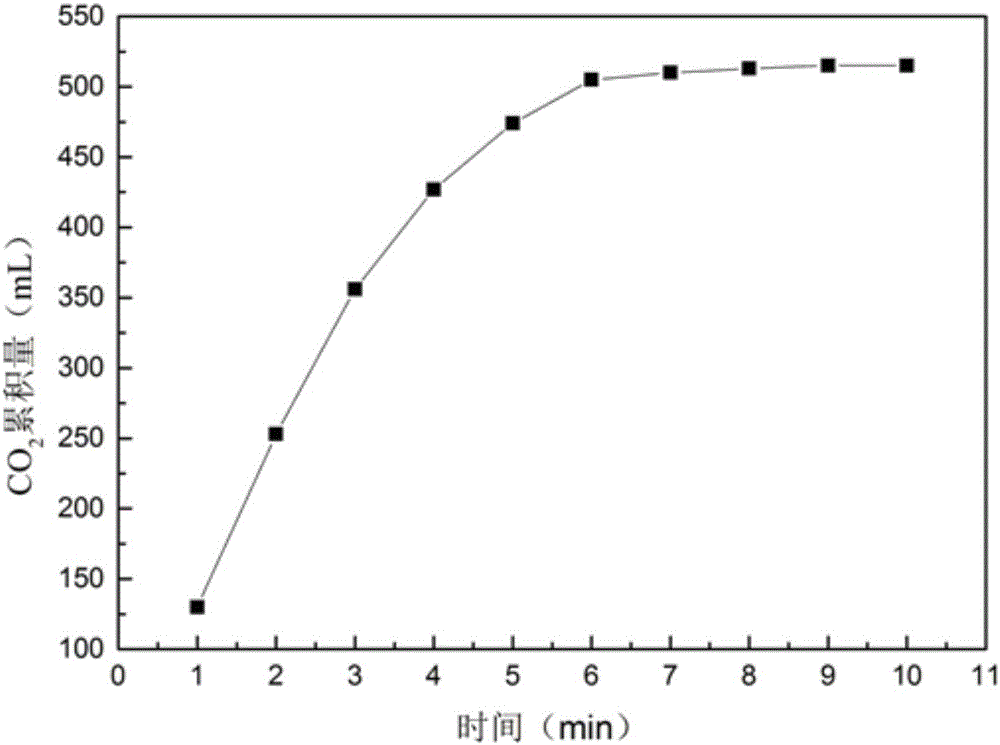

[0056] Take 7.1g of retarder, add it to 30g of HCl with a mass fraction of 17%, add 4g of ammonium chloride, 1g of ammonium fluoride, and 15g of formaldehyde. Agent, 0.86g acidification corrosion inhibitor, after completely dissolving in sequence, you can get slow acid working solution.

[0057] The present invention...

Embodiment 2

[0062] First, add 8g of acrylamide to 18.7g of formaldehyde solution with a mass fraction of 33%. After it is completely dissolved, put it into a three-necked flask; then add 14g of phosphoric acid with a mass fraction of 85%. After it is completely dissolved, add 0.1g of hydroquinone , under the condition of 90° C., reacted for 14 h while stirring to obtain the product monomer.

[0063] Take 1.0g of acrylic acid in a three-necked flask, add 10.2g of distilled water to dissolve it completely, add 30g of monomer FAP, stir evenly, put it in an oil bath, heat up to 90°C while stirring; then add 1.2g of peroxide Hydrogen reacted at 90°C for 2h to obtain a retarder.

[0064] Take 8.4g of retarder, add it to 30g of HCl with a mass fraction of 17%, add 4g of ammonium chloride, 1g of ammonium fluoride, and 15g of formaldehyde. Agent, 0.86g acidification corrosion inhibitor, after completely dissolving in sequence, you can get slow acid working solution.

[0065] In the present inven...

Embodiment 3

[0069] First, add 8g of acrylamide to 18.7g of formaldehyde solution with a mass fraction of 33%. After it is completely dissolved, put it into a three-necked flask; then add 14g of phosphoric acid with a mass fraction of 85%. After it is completely dissolved, add 0.1g of hydroquinone , under the condition of 90° C., reacted for 14 h while stirring to obtain the product monomer.

[0070] Take 1.2g of acrylic acid in a three-necked flask, add 13g of distilled water to dissolve it completely, add 35g of monomer FAP, stir evenly, put it in an oil bath, heat up to 80°C while stirring; then add 1.2g of hydrogen peroxide , Reacted at 80°C for 2h to obtain retarder.

[0071] Take 7.5g of retarder, add it to 30g of HCl with a mass fraction of 17%, add 4g of ammonium chloride, 1g of ammonium fluoride, and 15g of formaldehyde. Agent, 0.86g acidification corrosion inhibitor, after completely dissolving in sequence, you can get slow acid working solution.

[0072] In the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com