Mixed gas treatment equipment based on plasma technology

A mixed gas and plasma technology, applied in gas treatment, membrane technology, greenhouse gas capture, etc., can solve the problems of inconvenient portability, bulky size, and reduced device portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

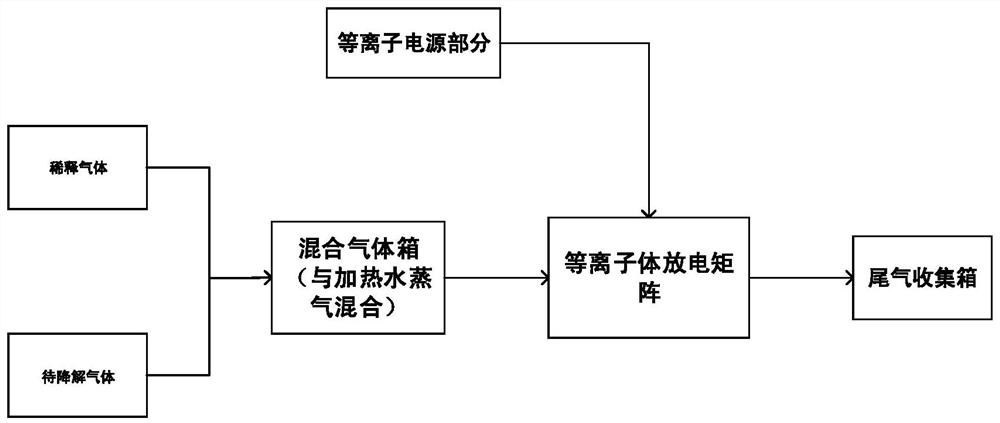

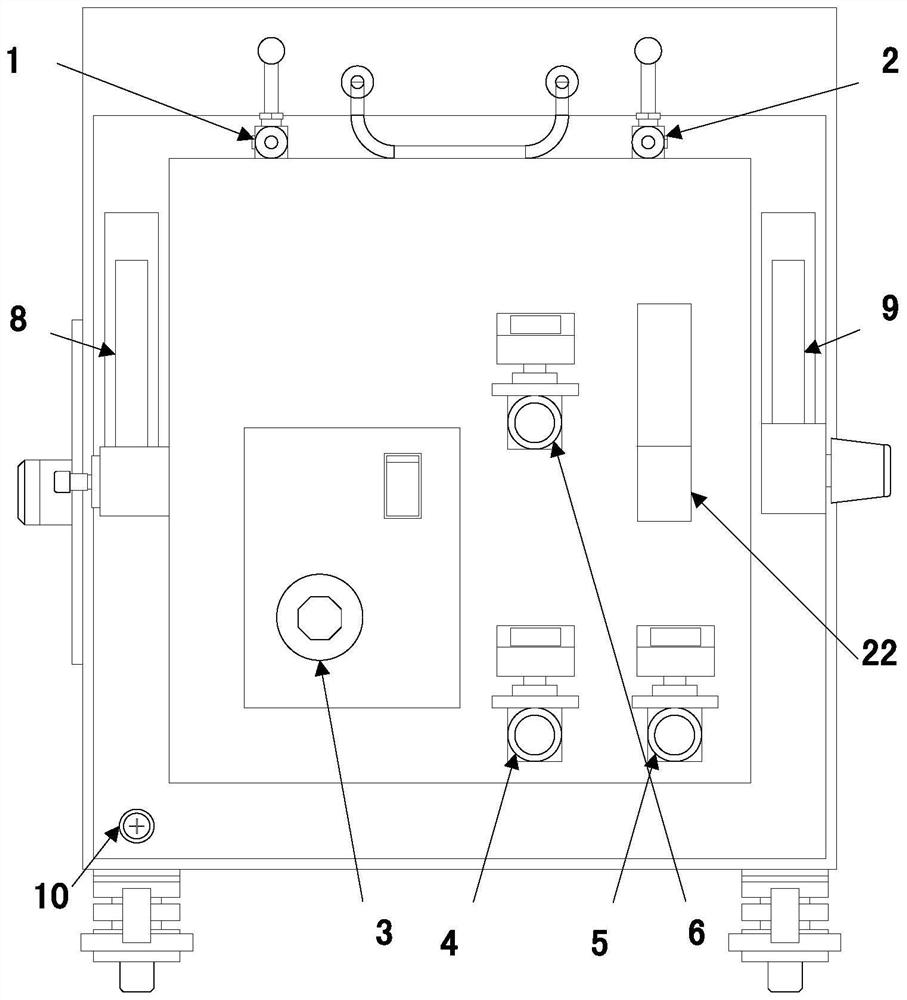

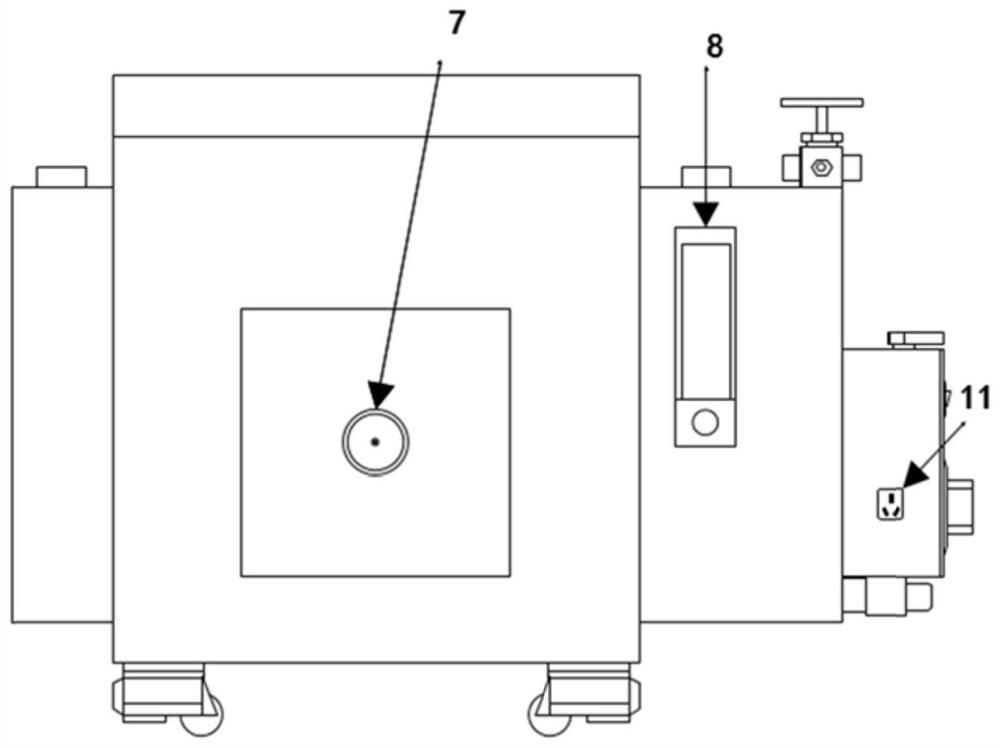

[0040] A mixed gas processing equipment based on plasma technology, with a structural size of 556(L)×350(W)×455(H)mm 3 , with a total volume not exceeding 1m 3 , the structure diagram is shown in Figure 2-4, such as figure 1 Shown is the working flow diagram of the above mixed gas processing equipment, which includes SF 6 Degradation host and power supply part, the host includes a densely assembled mixed gas box, plasma discharge matrix and exhaust gas collection box, and the power supply part includes a plasma power supply and a transformer.

[0041] The size of the mixed gas box is 35 (L) × 15 (W) × 35 (H) cm, and the mixed gas box is connected with two air inlets, one air inlet is the gas inlet 1 to be degraded, and the other air inlet The mouth is the dilution gas inlet 2, the gas to be degraded is also provided with a flowmeter 8 at the gas inlet 1 to be degraded, and the dilution gas flowmeter 9 is also arranged on the dilution gas inlet 2, and the flowmeter is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com