A recovery device and recovery method for catalytic cracking catalyst fine powder

A catalytic cracking and recovery device technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve problems such as air pollution, waste of energy, etc., to reduce procurement costs and avoid environmental pollution , the effect of controlling the severity of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

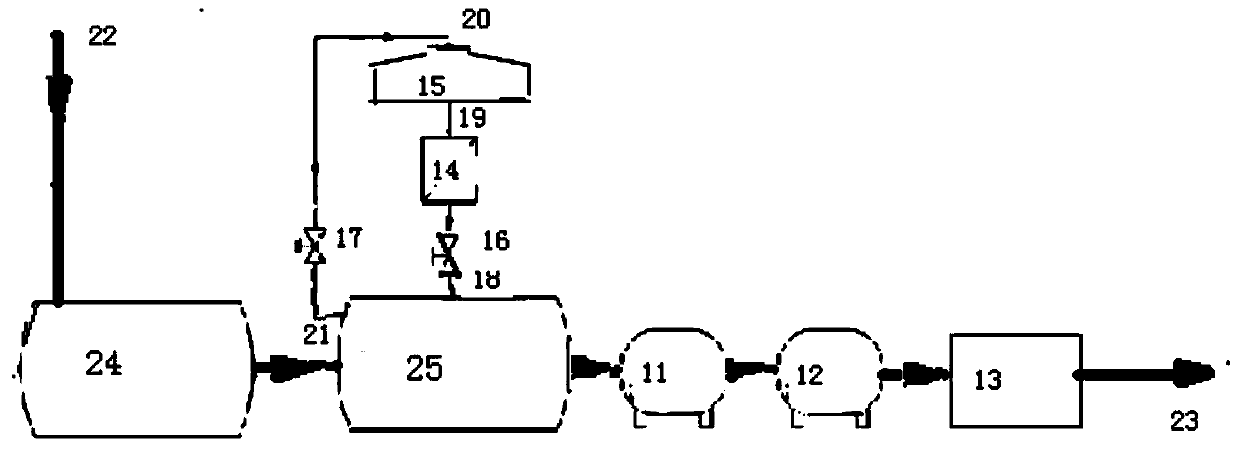

[0045] Such as figure 2 As shown, the recovery device of catalytic cracking catalyst fine powder includes: catalyst fine powder collector, first acid container, second acid container, fine powder grinder, double rubber beater, spray dryer, iron impurity filter and removal Iron soaking liquid pH adjustment tank; wherein, the catalyst fine powder collector, the first acid container, the second acid container, the fine powder grinder, the double glue beater and the spray dryer are sequentially connected; the second acid container, iron removal soaking liquid The pH adjustment tank, the iron impurity filter and the second acid container are connected in circulation in sequence.

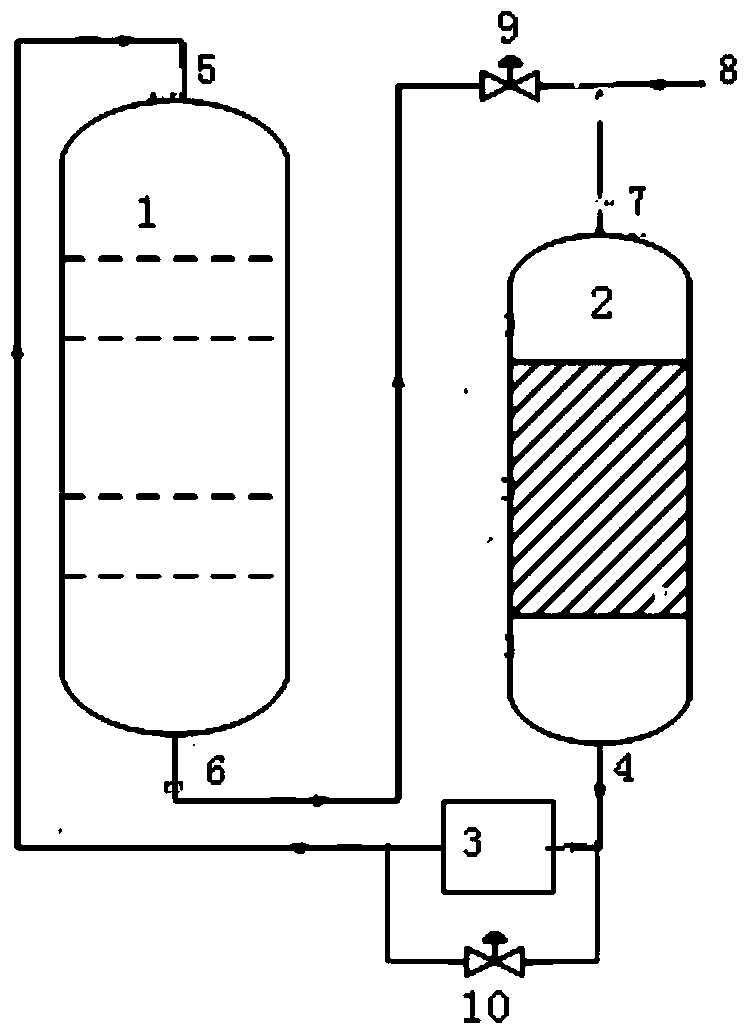

[0046] Such as figure 1 Shown: The FCC catalyst enters from the reactor inlet 5, and after passing through the reactor 1 of the FCC device, it changes from gray to black, flows through the pipeline from the reactor outlet 6, and enters the FCC catalyst regeneration tower (device) from the regenerator in...

Embodiment 2

[0050] The apparatus was the same as in Example 1.

[0051] (1) Open the second valve 10, the regenerated catalyst directly returns to the reactor 1, stops the operation of the fine powder collector 3, and samples and collects FCC fine powder less than 20 μm from the catalyst fine powder collector 3.

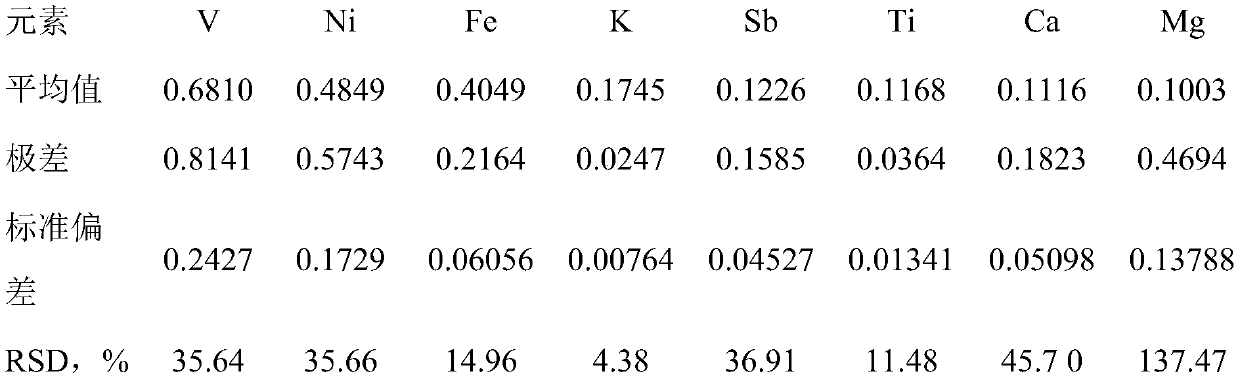

[0052] (2) Step (1) gained fine powder is dropped into the first acid container 24, and in the container, the hydrochloric acid that volume concentration is 25% submerges the fine powder, continues at stirring speed 60r·min -1 Soak for 4min, filter.

[0053] (3) Put the fine powder after filtering from the first acid container into the second acid container, and there is a sodium oxalate solution with a mass concentration of 5% in the container, stir for 8 min at a rotating speed of 60 r / min, then leave standstill for 7 min, filter, After soaking in the first and second acid containers, heavy metal FCC poisoning elements such as Ni, V, Fe basically reached the removal target. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com