A preparation process of 3-15t/d large-scale solid sodium chlorite

A sodium chlorite and preparation process technology, applied in chlorous acid and other directions, can solve the problems of hidden safety and environmental protection, poor control of production indicators, low production capacity of a single production line, etc., to save manpower, improve the effect of reducing agent, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

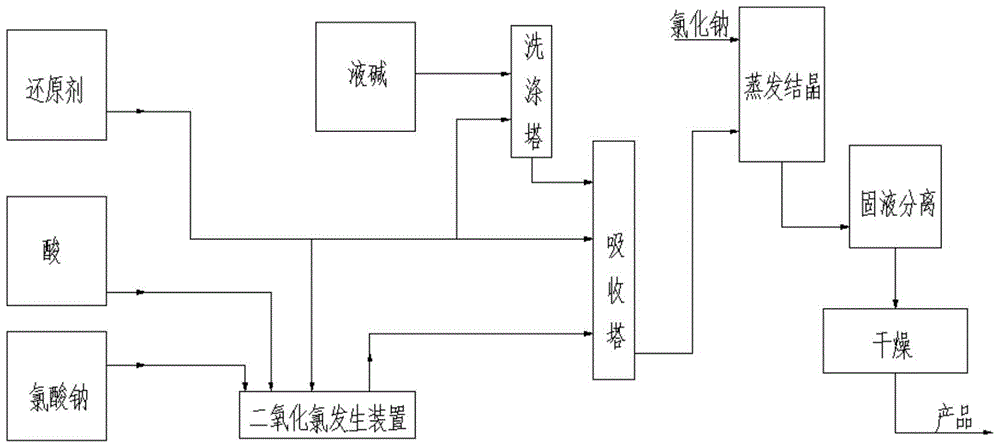

Method used

Image

Examples

Embodiment 1

[0040] At first, sodium chlorate (concentration is 600g / l) joins reactor 1# room, sulfuric acid (mass fraction 93%) joins reactor 1#, 2# room in two ways, hydrogen peroxide (mass fraction 35%) ) into chambers 1#, 2#, and 3# in three ways, the reaction temperature is controlled at 50°C, and the reaction pressure is controlled at 97Kpa to produce a mixed gas of chlorine dioxide and air.

[0041] Secondly, in the absorption tower, the mixed solution of sodium hydroxide (32% by mass fraction) and hydrogen peroxide (27.5% by mass fraction) is used to absorb the mixed gas of chlorine dioxide and air, and the absorption temperature is controlled at 20°C. A finished solution of sodium chlorite is obtained.

[0042]Finally, add sodium chloride (the addition amount is 0.25 times of the quality of sodium chlorite in the liquid) to the finished solution of sodium chlorite, and the mixed solution of sodium chlorite and sodium chloride is evaporated and crystallized, filtered, and dried to ...

Embodiment 2

[0044] First, sodium chlorate (concentration is 500g / l) is added to reactor 1# chamber, sulfuric acid (mass fraction 98%) is divided into two roads and joins reactor 1#, 2# chamber, methanol (mass fraction 20%) divides Three ways are added to 1#, 2#, 3# chambers, the reaction temperature is controlled at 65°C, and the reaction pressure is controlled at 96Kpa to produce a mixed gas of chlorine dioxide and air.

[0045] Secondly, in the absorption tower, the mixed solution of potassium hydroxide (mass fraction 30%) and hydrogen peroxide (mass fraction 27.5%) is used to absorb the mixed gas of chlorine dioxide and air, and the absorption temperature is controlled at 10°C. A finished solution of sodium chlorite is obtained.

[0046] Finally, add sodium chloride (the addition amount is 0.2 times of the quality of sodium chlorite in the liquid) to the sodium chlorite finished solution, and the mixed solution of sodium chlorite and sodium chloride is evaporated and crystallized, filt...

Embodiment 3

[0048] A 3-15t / d large-scale solid sodium chlorite preparation process,

[0049] 1) Add sulfuric acid, hydrogen peroxide and sodium chlorate solution into the chlorine dioxide reactor, and react at a temperature of 45°C and a pressure of 95KPa(A) to generate a mixed gas of chlorine dioxide and air;

[0050] The above steps are divided into four steps to complete:

[0051] A) the sodium chlorate (concentration is 500g / l) of 100% theoretical mass, the sulfuric acid (mass fraction 98%) of 50% theoretical mass, the hydrogen peroxide of 40% theoretical mass are added in the reactor, and the reaction time is 4 hours, The degree of control response is 40%;

[0052] b) adding 50% theoretical mass of sulfuric acid to the reactor to maintain the acidity of the reaction, while adding 40% theoretical mass of hydrogen peroxide, the reaction time was 2 hours, and the degree of reaction was controlled to 80%;

[0053] c) 20% hydrogen peroxide was added into the reactor, the reaction time w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com