Furnace transmutation glaze dolomitic pottery and preparation technique thereof

A production process and kiln-changing glaze technology, applied in the field of ceramics, can solve the problems of long firing time, high firing temperature of white cloud pottery, single glaze effect, etc., achieve short time, high social and economic benefits, and improve market competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The manufacturing process of the kiln-changed glaze white cloud pottery comprises the following steps:

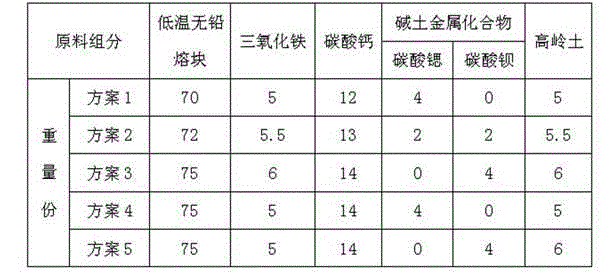

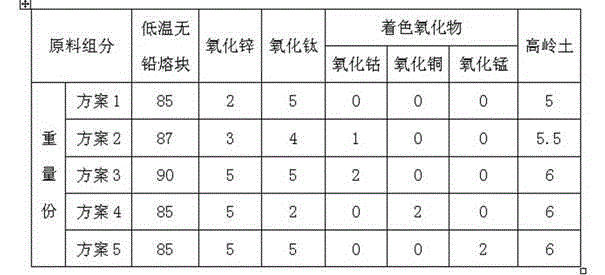

[0016] a) Preparation of glaze: 70-75 parts by weight of low-temperature lead-free frit, 5-6 parts by weight of colored oxides, 12-14 parts by weight of calcium carbonate, 3-5 parts by weight of alkaline earth metal compounds, and 5-6 parts by weight of kaolin Mix evenly to make the bottom glaze mixture, and then make the bottom glaze mixture according to the weight ratio: water=1:0.75~0.85, add water, make the bottom glaze after ball milling; mix 85~90 parts by weight of low-temperature lead-free frit, 2~ 5 parts by weight of zinc oxide, 2~5 parts by weight of titanium oxide, 0~2 parts by weight of colored oxides, and 5~6 parts by weight of kaolin are mixed to make a top glaze mixture, and then the top glaze mixture is prepared according to the weight ratio: water =1: Add water at 0.75~0.85, and make surface glaze after ball milling;

[0017] b) sieving: pass the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com