Graphene paint for steel fastening parts and preparation method of graphene paint

A technology of graphene and fasteners, which is applied in the field of graphene coatings for steel fasteners and its preparation, which can solve the problems of low hardness, easy falling off, and damage of Dacromet coatings, so as to ensure reliable use and safety operation, long salt spray resistance time, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

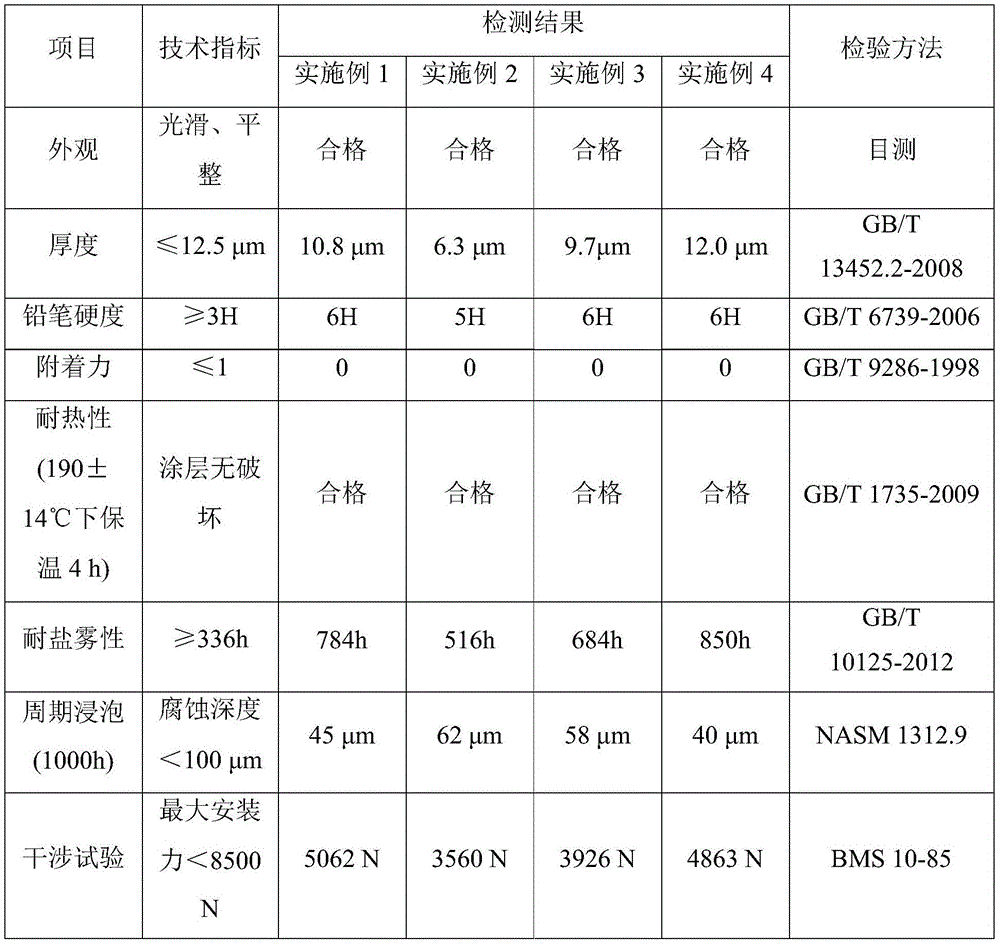

Examples

Embodiment 1

[0020] Urea-formaldehyde resin, 28 parts; melamine-formaldehyde resin, 2 parts; graphene, 0.2 parts; aluminum silver paste, 8 parts; zinc powder, 6 parts; filler, 5 parts; additives, 2 parts; solvent, 20 parts.

[0021] (1) Add 8 parts of aluminum-silver paste and 6 parts of zinc powder into 10 parts of solvent, stir and mix, and let stand for 6 hours to obtain metal powder paste;

[0022] (2) 0.2 parts of graphene, 0.4 parts of zinc phosphate, 2 parts of zinc tungstate, 2.5 parts of bismuth vanadate, 0.1 part of molybdenum disulfide, 28 parts of urea-formaldehyde resin, 2 parts of melamine-formaldehyde resin, 0.5 parts of wetting and dispersing agent , 0.1 part of substrate wetting agent, 0.1 part of defoamer, and 10 parts of solvent are added to the disperser, dispersed at 1000 rpm for 30 minutes, then transferred to a grinder, and ground to a fineness of 7 μm to obtain a resin slurry;

[0023] (3) Transfer the resin slurry in step (2) to a disperser, add the metal powder sl...

Embodiment 2

[0025] Urea-formaldehyde resin, 21 parts; melamine-formaldehyde resin, 9 parts; graphene, 1.5 parts; aluminum silver paste, 6 parts; zinc powder, 9 parts; filler, 8 parts; additive, 3 parts; solvent, 30 parts.

[0026] (1) Add 6 parts of aluminum-silver paste and 9 parts of zinc powder into 15 parts of solvent, stir and mix, and let stand for 4 hours to obtain metal powder paste;

[0027] (2) 1.5 parts of graphene, 5 parts of zinc molybdate, 2.5 parts of aluminum tripolyphosphate, 0.5 parts of polytetrafluoroethylene micropowder, 21 parts of urea-formaldehyde resin, 9 parts of melamine-formaldehyde resin, 1.5 parts of wetting and dispersing agent, 0.2 Add one part of substrate wetting agent, 0.2 part of defoamer, and 15 parts of solvent into a disperser, disperse at 1200 rpm for 30 minutes, then transfer to a grinder, and grind to a fineness of 10 μm to obtain a resin slurry;

[0028] (3) Transfer the resin slurry in step (2) to a disperser, add the metal powder slurry in step...

Embodiment 3

[0030] Urea-formaldehyde resin, 36 parts; melamine-formaldehyde resin, 4 parts; graphene, 4 parts; aluminum silver paste, 24 parts; zinc powder, 8 parts; filler, 16 parts; additive, 6 parts; solvent, 64 parts.

[0031] (1) Add 24 parts of aluminum-silver paste and 8 parts of zinc powder to 32 parts of solvent, stir and mix, and let stand for 8 hours to obtain metal powder paste;

[0032] (2) 4 parts of graphene, 2 parts of zinc phosphate, 3 parts of aluminum tripolyphosphate, 10 parts of zinc tungstate, 1 part of molybdenum disulfide, 36 parts of urea-formaldehyde resin, 4 parts of melamine-formaldehyde resin, 2.5 parts of wet dispersion agent, 0.4 parts of substrate wetting agent, 0.3 parts of defoamer, and 32 parts of solvent were added to the disperser, dispersed at 1200 rpm for 30 minutes, then transferred to a grinder, and ground to a fineness of 13 μm to obtain a resin slurry ;

[0033] (3) Transfer the resin slurry in step (2) to a disperser, add the metal powder slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com