Seal carrier roller

A roller and outer sealing technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems affecting the normal operation and conveying efficiency of the conveyor, poor sealing effect, short service life, etc., and achieve superior sealing performance , wide temperature adaptability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

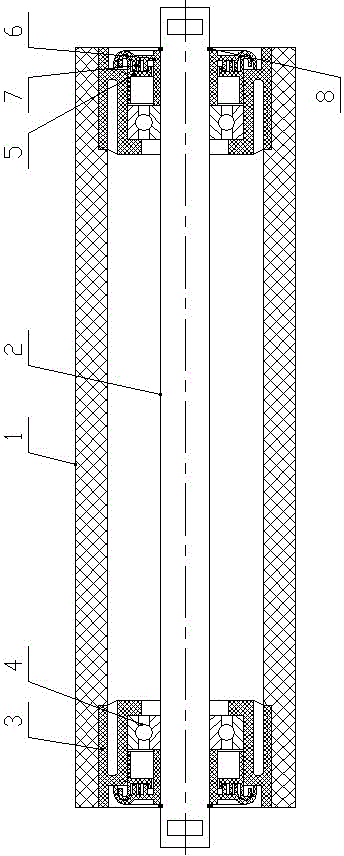

[0023] Such as figure 1 with figure 2 As shown, a sealed idler roller of the present invention includes a roller body 1 and a central shaft 2, the roller body 1 is made of ultra-high molecular weight polyethylene material, and the inner rings at both ends of the roller body 1 are respectively provided with a bearing seat 3, and the center Two bearings 4 are arranged between the shaft 2 and the two bearing housings 3 , and a set of sealing devices between the roller body and the central shaft 2 are respectively arranged on the outer sides of the two bearings 4 .

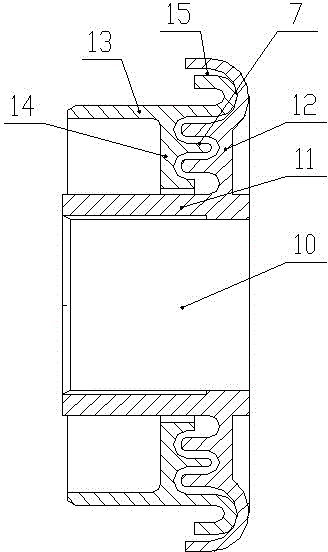

[0024] The sealing device includes an inner seal 5 and an outer seal 6. The outer seal 6 includes a small cylinder 11 with a cylindrical hole 10 and an outer sealing plate 12 arranged outside one end of the small cylinder 11. The inner seal 5 includes a large cylinder 13. And the inner sealing plate 14, the inner sealing plate 14 is arranged on the inner wall of the large cylinder 13 and cooperates with the outer ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com