Preparation method of polymethoxy methylal

A technology of polymethoxymethylal and paraformaldehyde, applied in the preparation of organic compounds, chemical instruments and methods, molecular sieve catalysts, etc., can solve problems such as catalyst corrosion, improve coke capacity, increase utilization, The effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix 40% silica sol, sodium metaaluminate, tetrapropylammonium bromide TPABr, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put it into a reaction kettle, and crystallize dynamically at 170°C (200 rpm). 3 days. The crystallized product was quenched, filtered, washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain the original ZSM-5 molecular sieve powder. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =80.0,H 2 O / SiO 2 =50.8, NaCl / SiO 2 =0.68, NaOH / SiO 2 =0.15, TPABr / SiO 2 =0.40. The average grain diameter is 0.5 micron.

[0020] Get 50 grams of ZSM-5 molecular sieves (SiO 2 / Al 2 o 3 =80), put into 250 grams of concentration and be 0.5 mol / liter of sodium hydroxide aqueous solution, under reflux, stir at 80 ℃ of constant temperature for 0.5 hour, filter, wash with distilled water, then use the ammonium nitrate aqueous solution of 10% mass concentration in 80 Exchanged three...

Embodiment 2

[0024] Get 50 grams of grain diameter and be the ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 =40), put 100 grams of concentration into an aqueous sodium hydroxide solution of 1 mol / liter, stir at a constant temperature of 60° C. for 3 hours under reflux, filter, wash with distilled water, exchange with [Example 1] ammonium, dry, roast , molding, to obtain catalyst B.

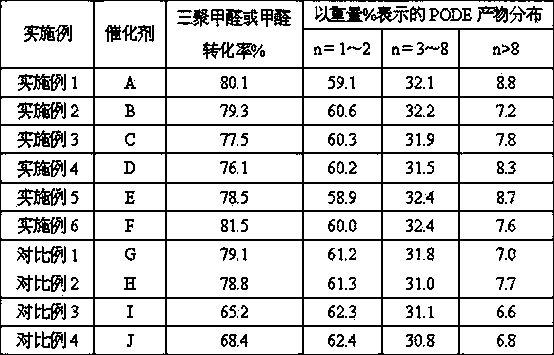

[0025] The performance evaluation of the catalyst was carried out on a 300ml autoclave reaction device. Add 1.5 grams of catalyst, 80 grams of dimethyl ether, and 100 grams of paraformaldehyde in the autoclave, react for 4 hours at 110 ° C and make the pressure 4 MPa by filling nitrogen, filter and separate the catalyst and the reaction product, and analyze by gas chromatography to obtain The composition of the mixture is shown in Table 1.

[0026]

Embodiment 3

[0028] Get 50 grams of ZSM-5 molecular sieves (SiO 2 / Al 2 o 3 =100), put 500 grams of concentration into the potassium hydroxide aqueous solution of 0.2 mol / liter, stir at a constant temperature of 50° C. for 3.5 hours under reflux, filter, wash with distilled water, exchange with [Example 1] ammonium, dry, roast , molding, to obtain catalyst C.

[0029] The performance evaluation of the catalyst was carried out on a 300ml autoclave reaction device. Add 1.2 grams of catalyst, 50 grams of methanol, 50 grams of dimethyl ether, and 100 grams of paraformaldehyde in the autoclave, and react for 5 hours at 100 ° C and a pressure of 1 MPa by filling nitrogen, and filter and separate the catalyst and the reaction product. Chromatographic analysis, the composition of the obtained mixture is shown in Table 1.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com