Patents

Literature

98results about How to "Larger surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

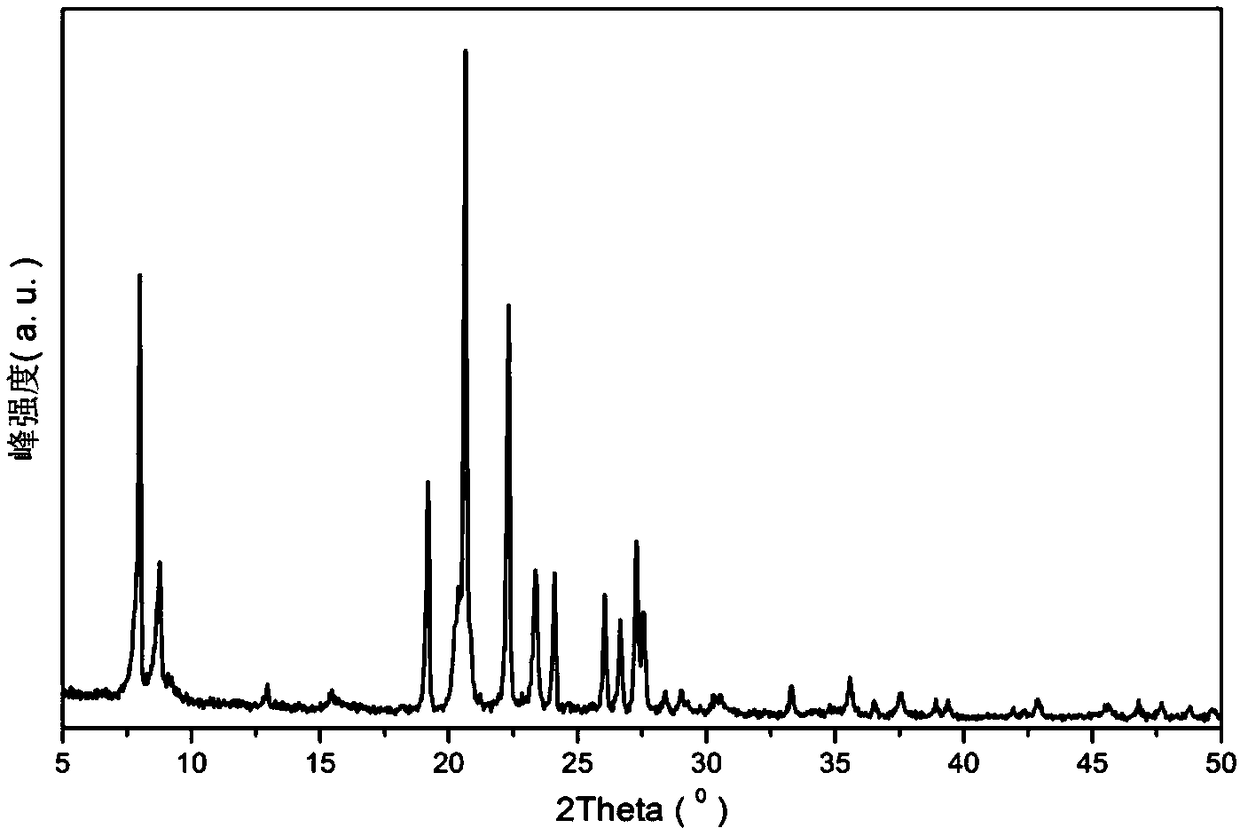

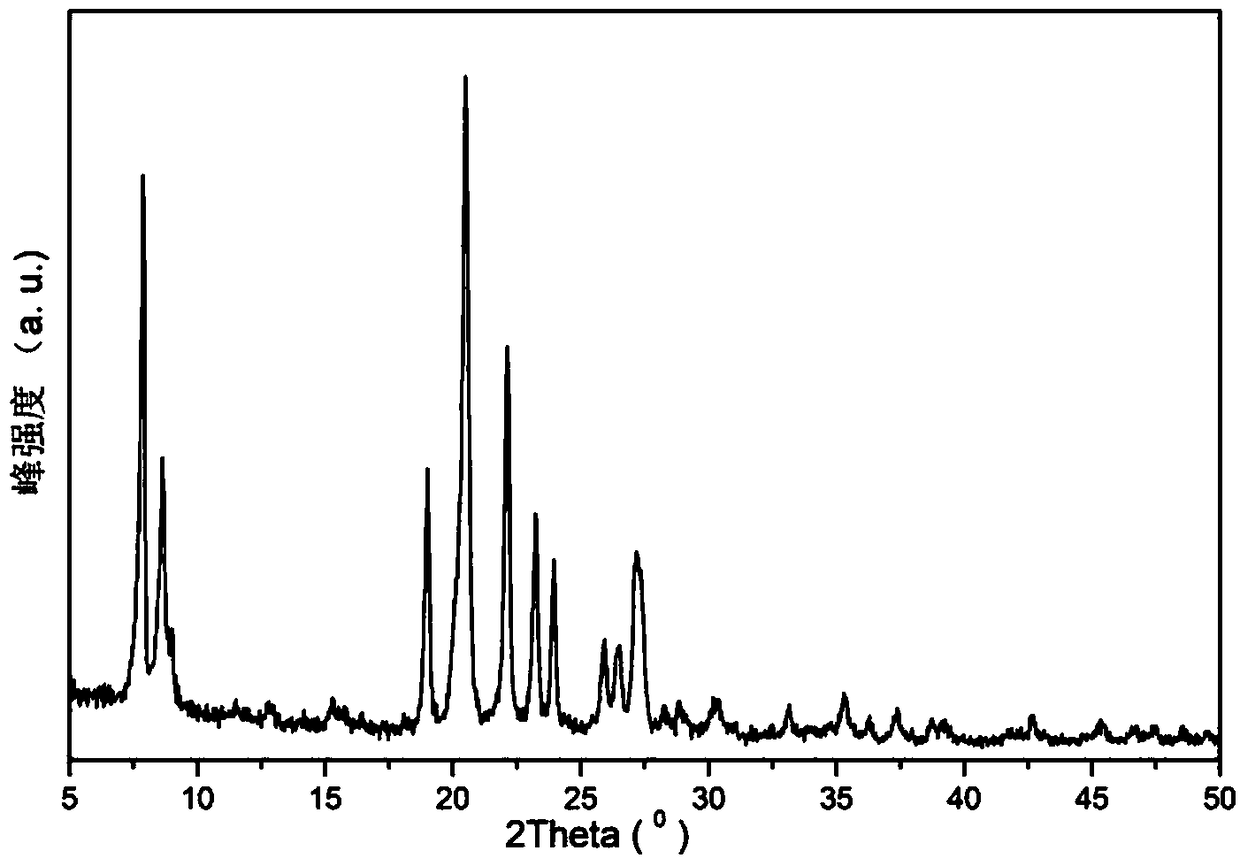

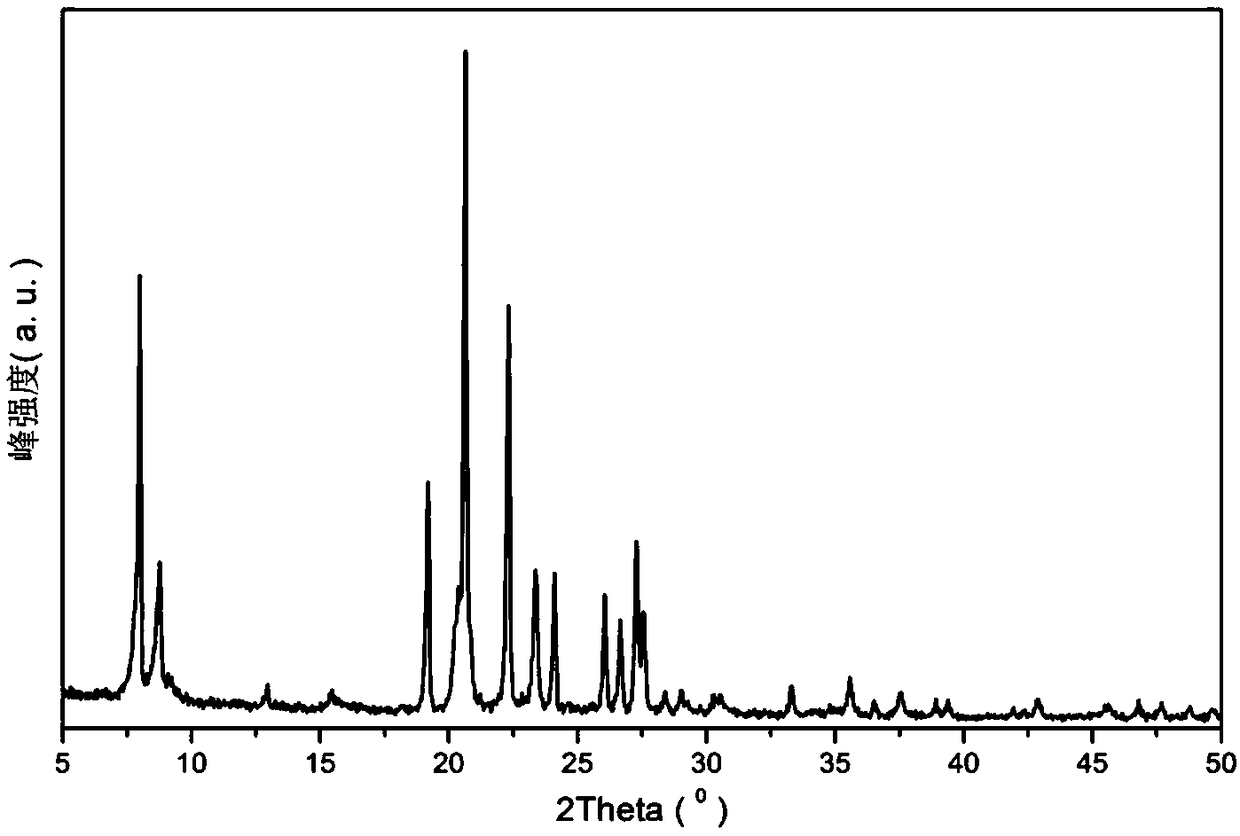

Bifunctional catalyst containing multi-stage pore EUO molecular sieve and preparation method thereof

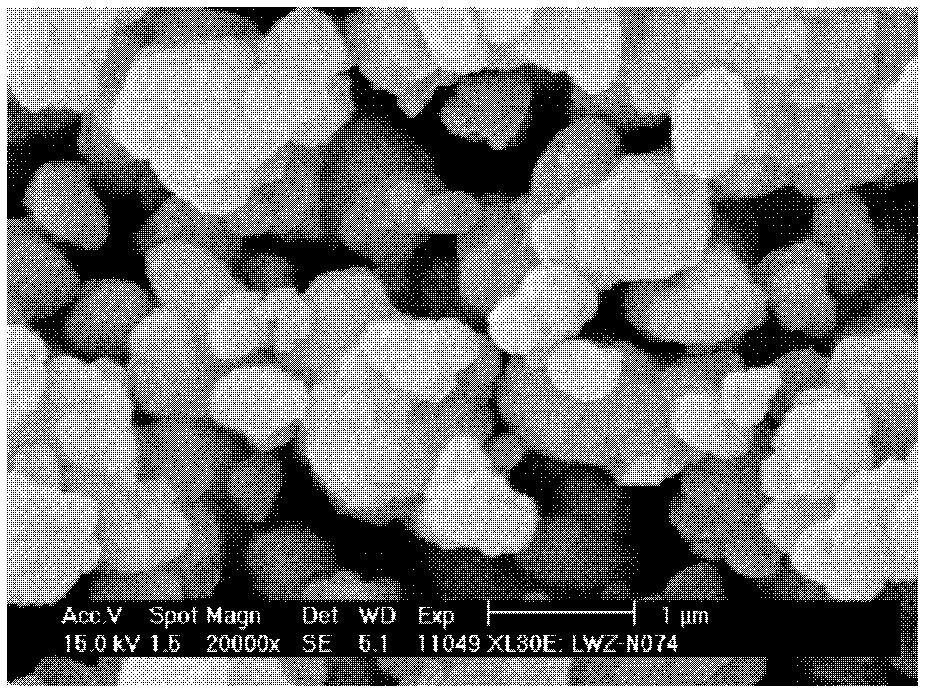

ActiveCN108993585ASmall grain sizeImprove diffusion abilityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneBiological activation

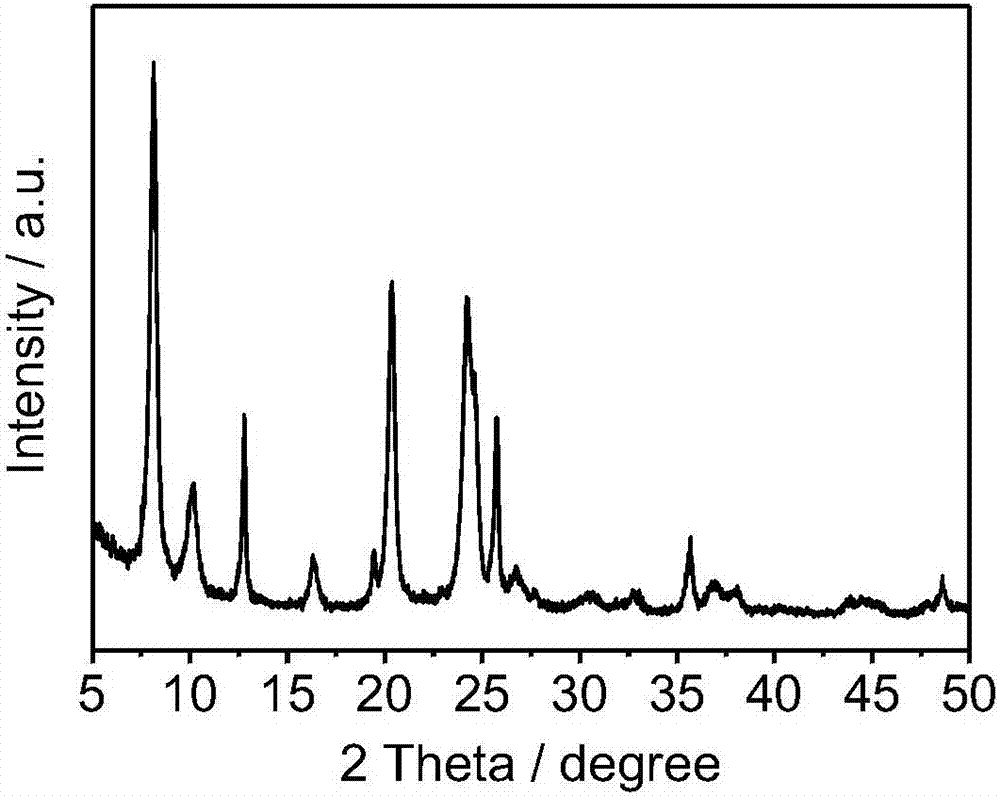

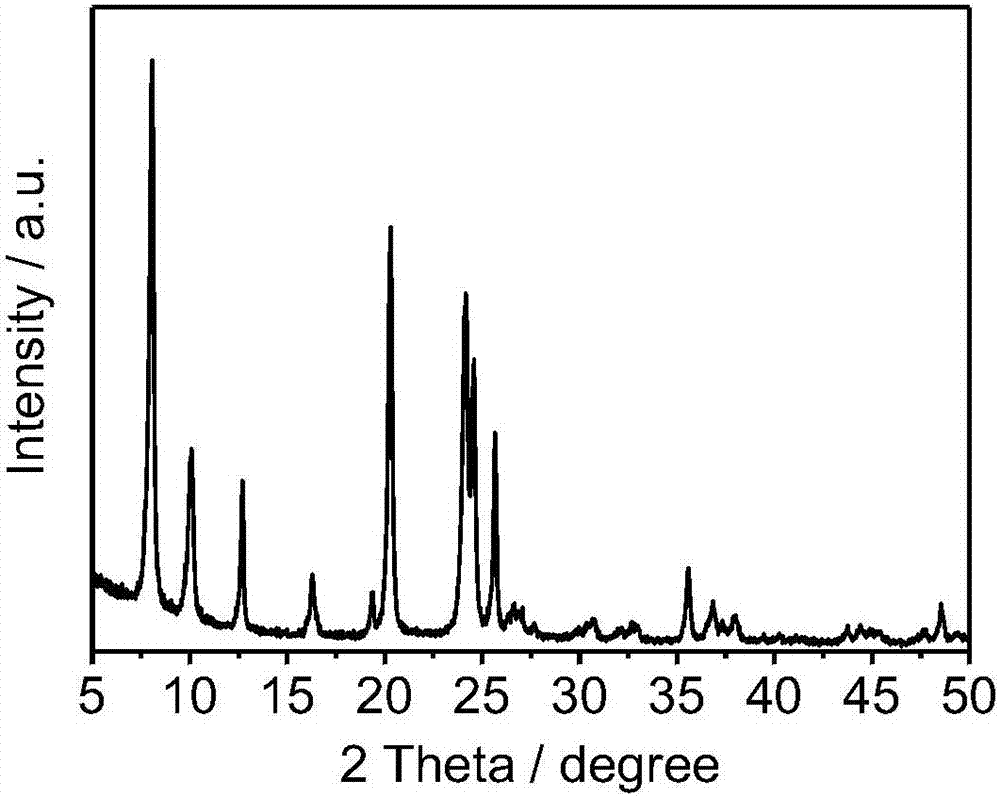

The invention discloses a bifunctional catalyst containing a multi-stage pore EUO molecular sieve and a preparation method thereof. The catalyst comprises 10 to 90wt% of an H-type multi-stage pore structure EUO molecular sieve, 9.9 to 89.9wt% of a matrix and 0.01 to 2.0wt% of a metal active component. The preparation method comprises: mixing multi-stage pore EUO molecular sieve raw powder, the matrix and a pore-expanding agent, adding an acid solution into the mixture, carrying out mixing kneading shaping, carrying out drying and roasting to remove the pore-expanding agent so that a carrier isformed, and dipping the carrier in a mixed solution containing a metal salt for activation to obtain a shaped catalyst. The multi-stage pore EUO molecular sieve is synthesized by crystallization of along-chain silane compound as a crystallization aid and a double-quaternary ammonium salt as an organic template with a double six-membered heterocyclic group substituted alkane structure. The catalyst exhibits good activity and selectivity in the hydroisomerization reaction of a C8 aromatic hydrocarbon and has a good industrial application prospect and economic value.

Owner:CHINA CATALYST HLDG CO LTD

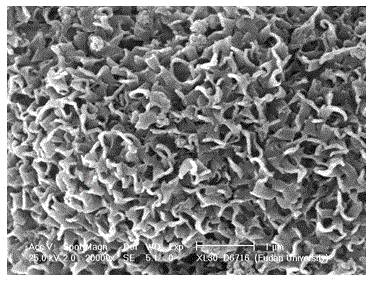

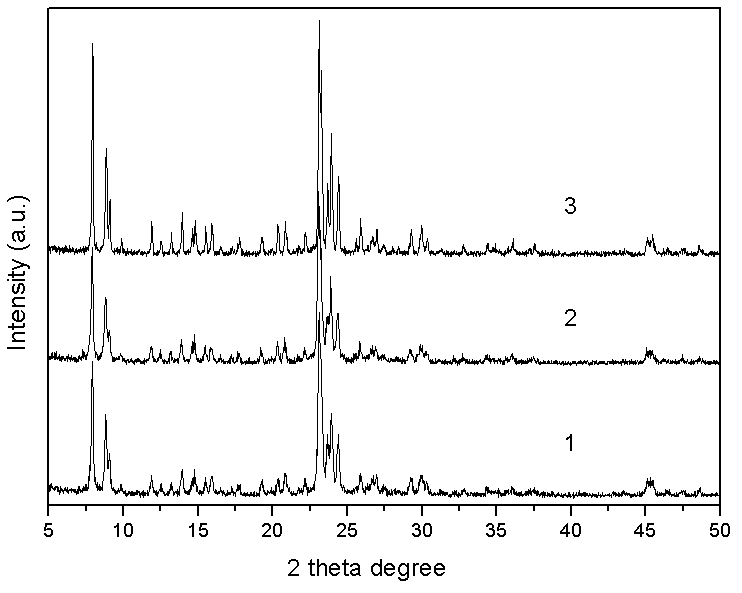

Method for synthesizing novel thin layer ZSM-5 zeolite with boron-containing framework

InactiveCN102942193AUnique lamellar structureHigh crystallinityPentasil aluminosilicate zeoliteStrong acidsAcid strength

The invention belongs to the crossing field of inorganic synthesis chemistry and material chemistry and relates to a method for synthesizing a thin layer ZSM-5 zeolite with a boron-containing framework. The method includes that a silicon source, a boron source, an aluminum source and a biquaternary ammonium salt template agent are mixed with deionized water to synthesize the thin layer ZSM-5 zeolite with a framework simultaneously containing boron and aluminum in one step through a hydrothermal process. The synthesized zeolite has the advantages that the thin layer sheet shaped appearance is achieved, the degree of crystallinity is high, the synthesized zeolite is in a typical MFI structure, a large outer surface area is achieved, a surface acidity site is fully exposed, and acid strength and strong acid site proportion on the surface of the zeolite can be effectively controlled by adjusting a ratio of boron and aluminum in a fed material. The thin layer ZSM-5 zeolite with the boron-containing framework has an excellent application potential in an acid catalyzed reaction and particularly in a macromolecule splitting and polysaccharide hydrolysis reaction.

Owner:中国寰球工程有限公司辽宁分公司 +1

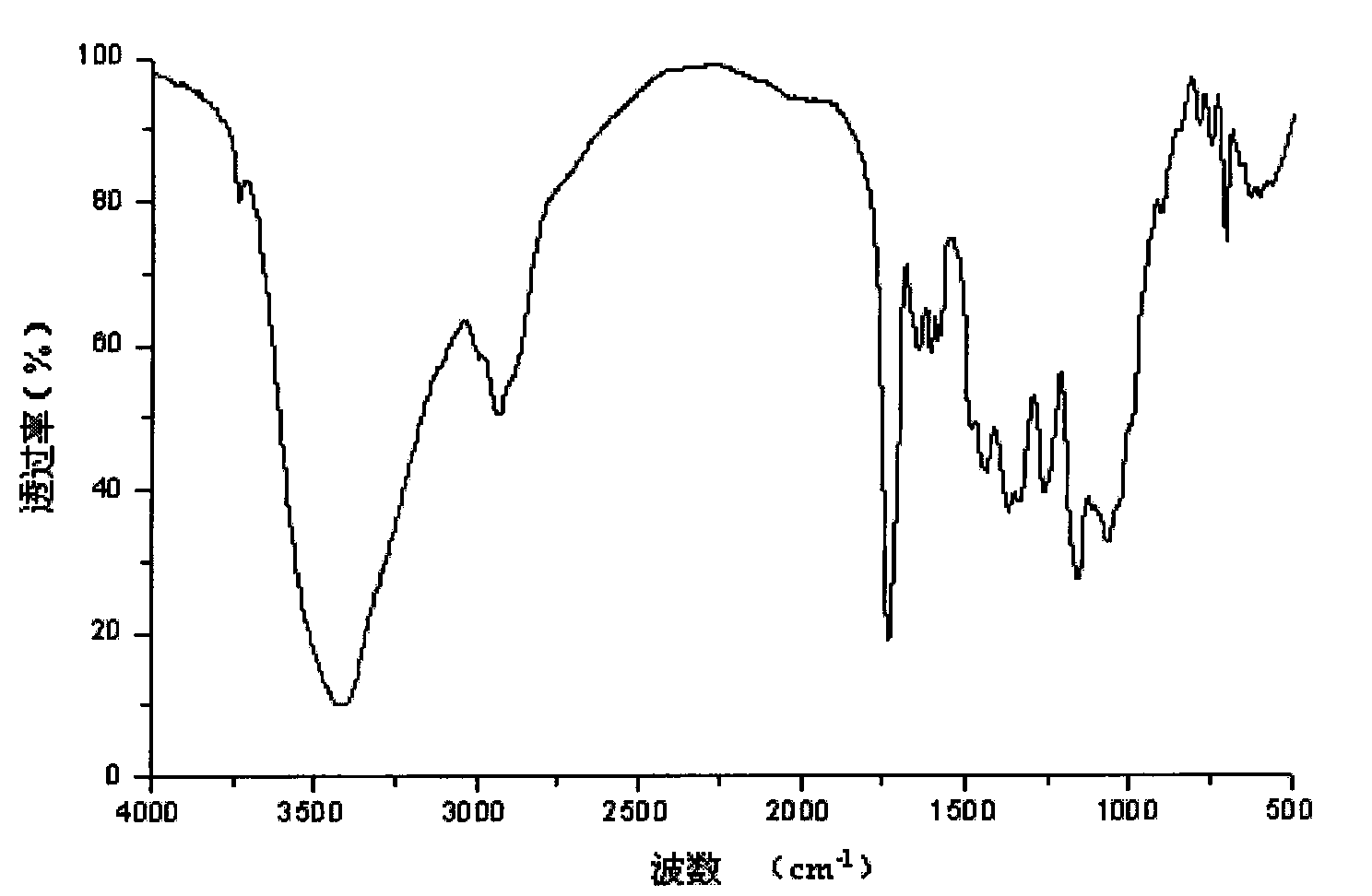

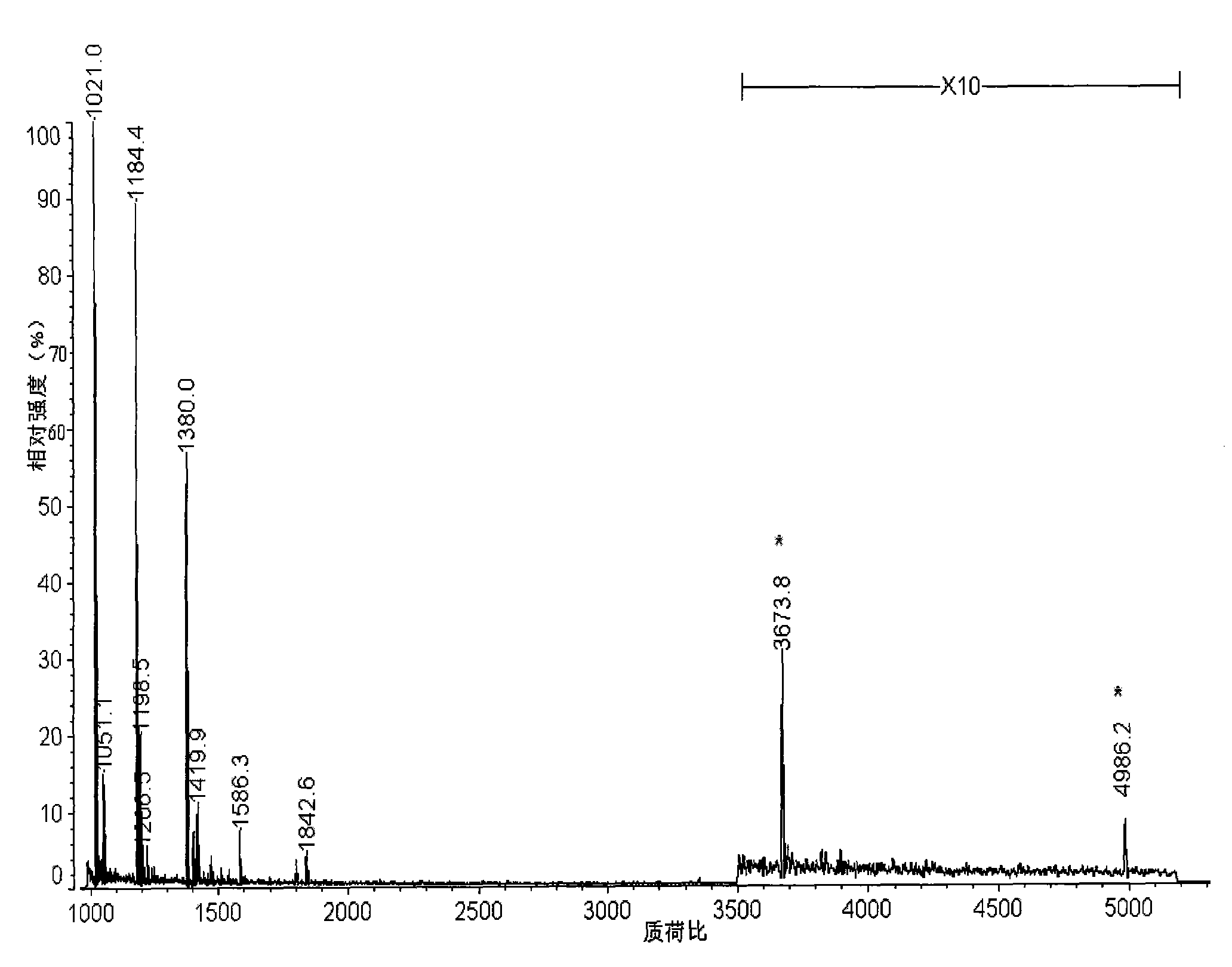

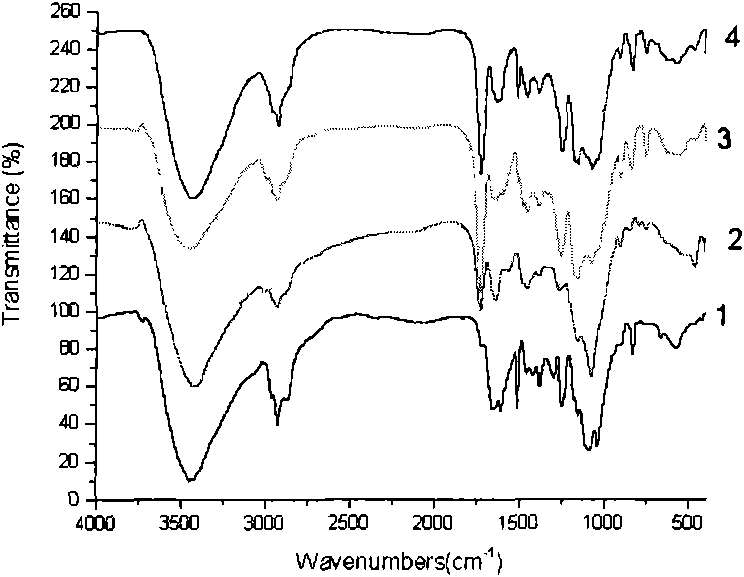

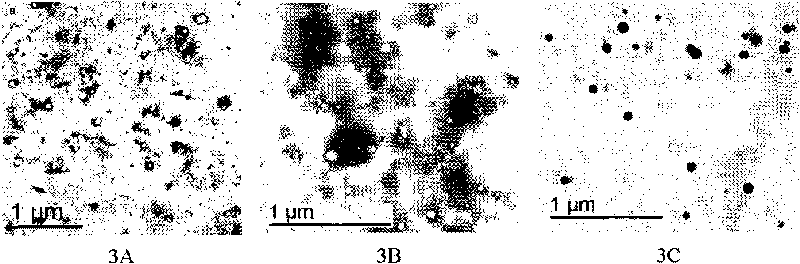

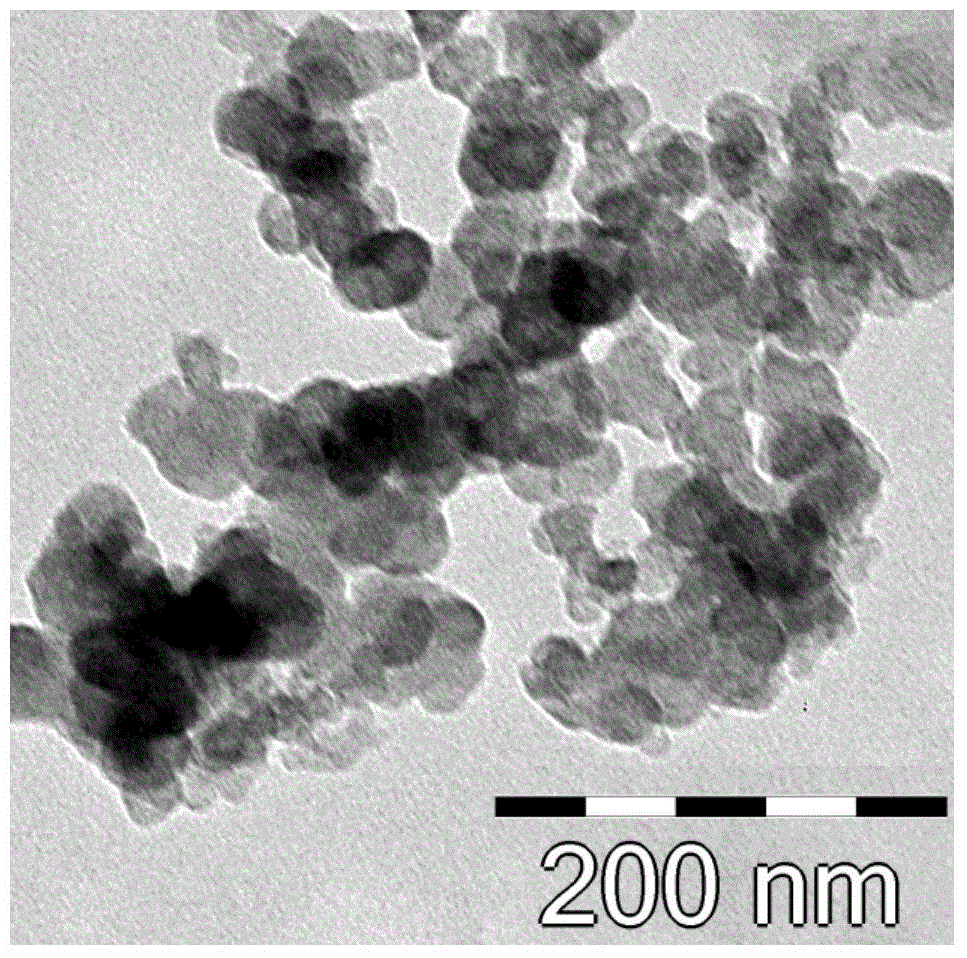

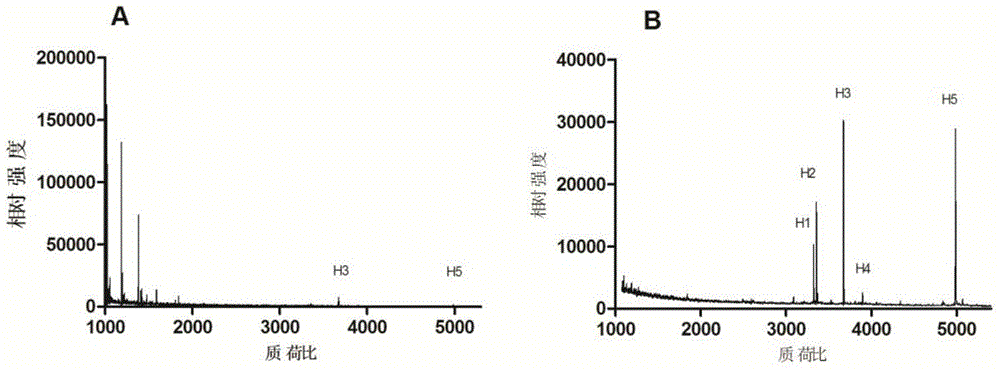

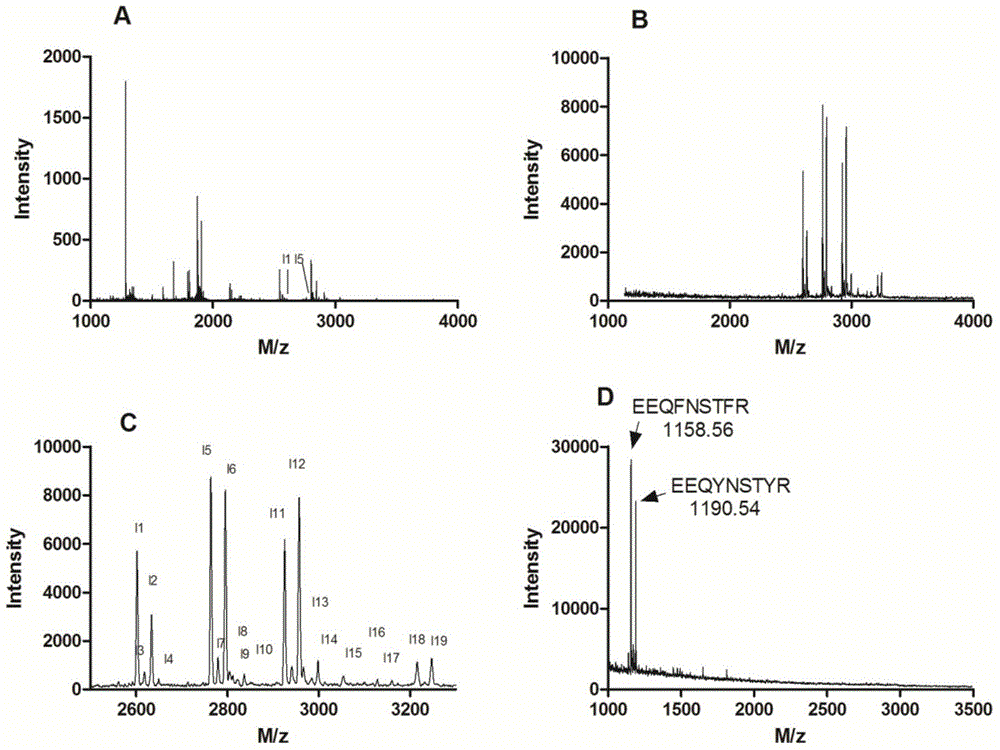

Nano chitosan derivative and preparation method and application thereof

InactiveCN101575384ARealize separation and purificationEasy to optimizePeptide preparation methodsEpoxyCycloaddition

The invention discloses a nano chitosan derivative and a preparation method thereof, belonging to the technical field of biomedical nano materials. The preparation method of the derivative comprises the following steps of: dissolving the chitosan in dilute acid and then mixing the chitosan with methacrylic acid epoxy propyl ester or acrylic acid epoxy propyl ester so as to conduct self-polymerization grafting reaction, thereby obtaining an intermediate with an active epoxy group, then leading the intermediate and an amino group to replace phenylboronic acid to carry out ring-opening addition reaction for finally obtaining the nano chitosan derivative with a boric acid active functional group, with the particle size of 1nm to 300nm. The invention also discloses the application of the chitosan derivative in the aspect of enriching and purifying glycosylated polypeptide / protein. The chitosan derivative has very high specificity, can be used for the enrichment and purification of low-abundance glycosylated polypeptide / protein in biological samples, and can also be used in the biological and medical fields, including clinical diagnosis.

Owner:PEKING UNIV

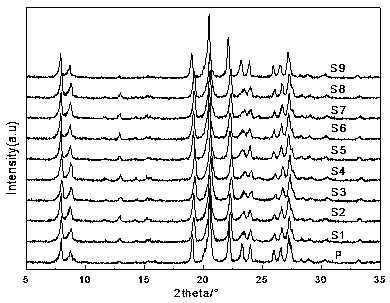

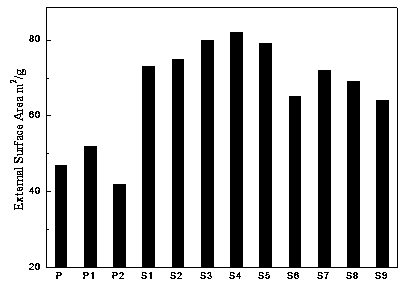

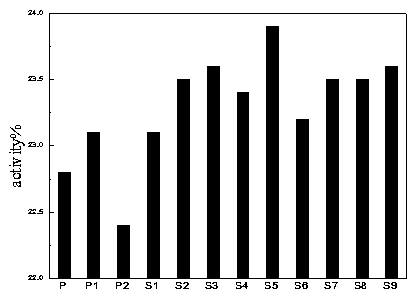

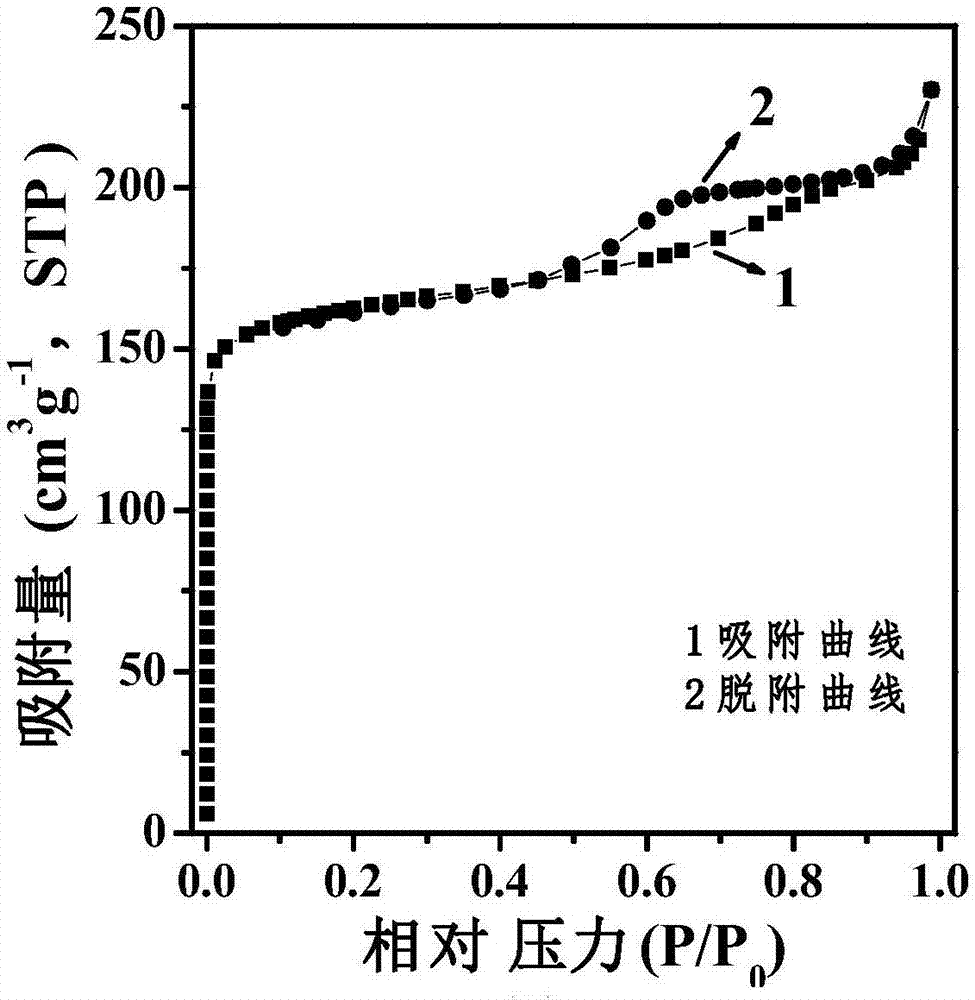

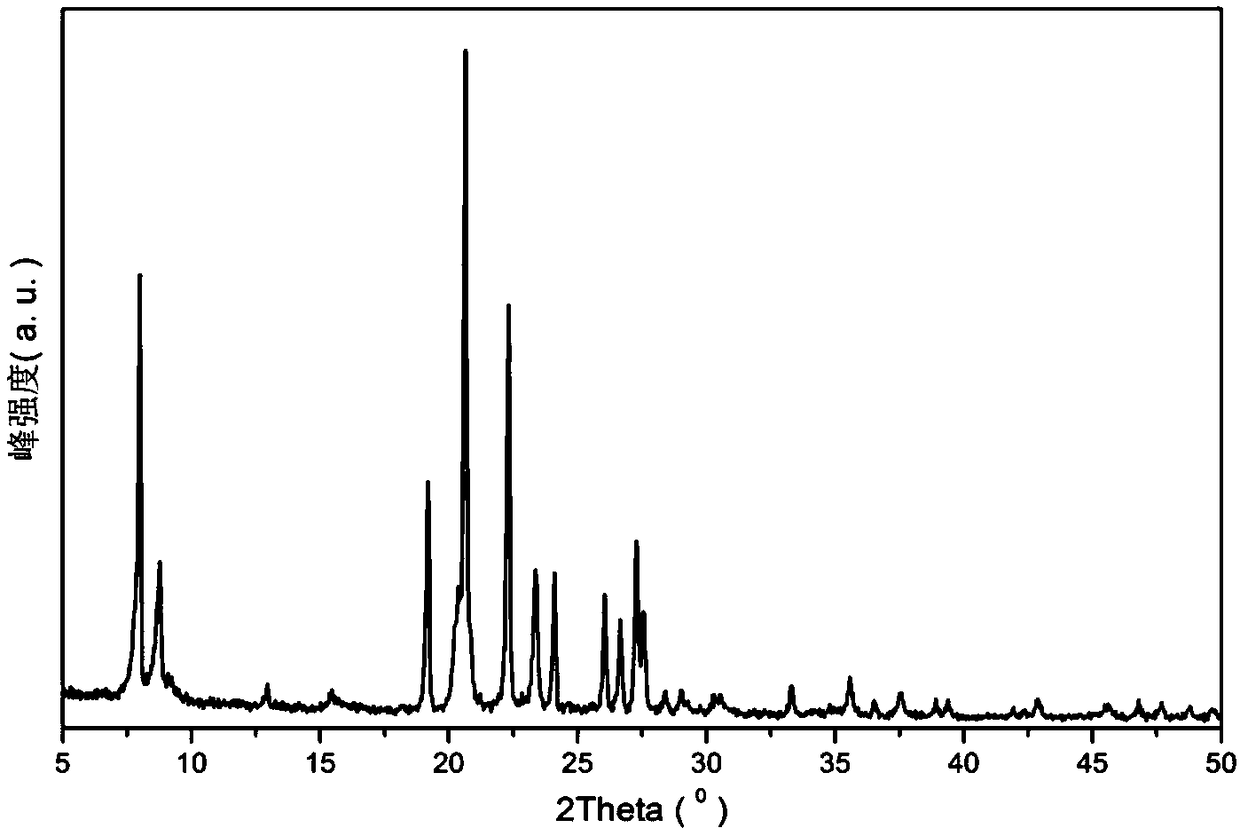

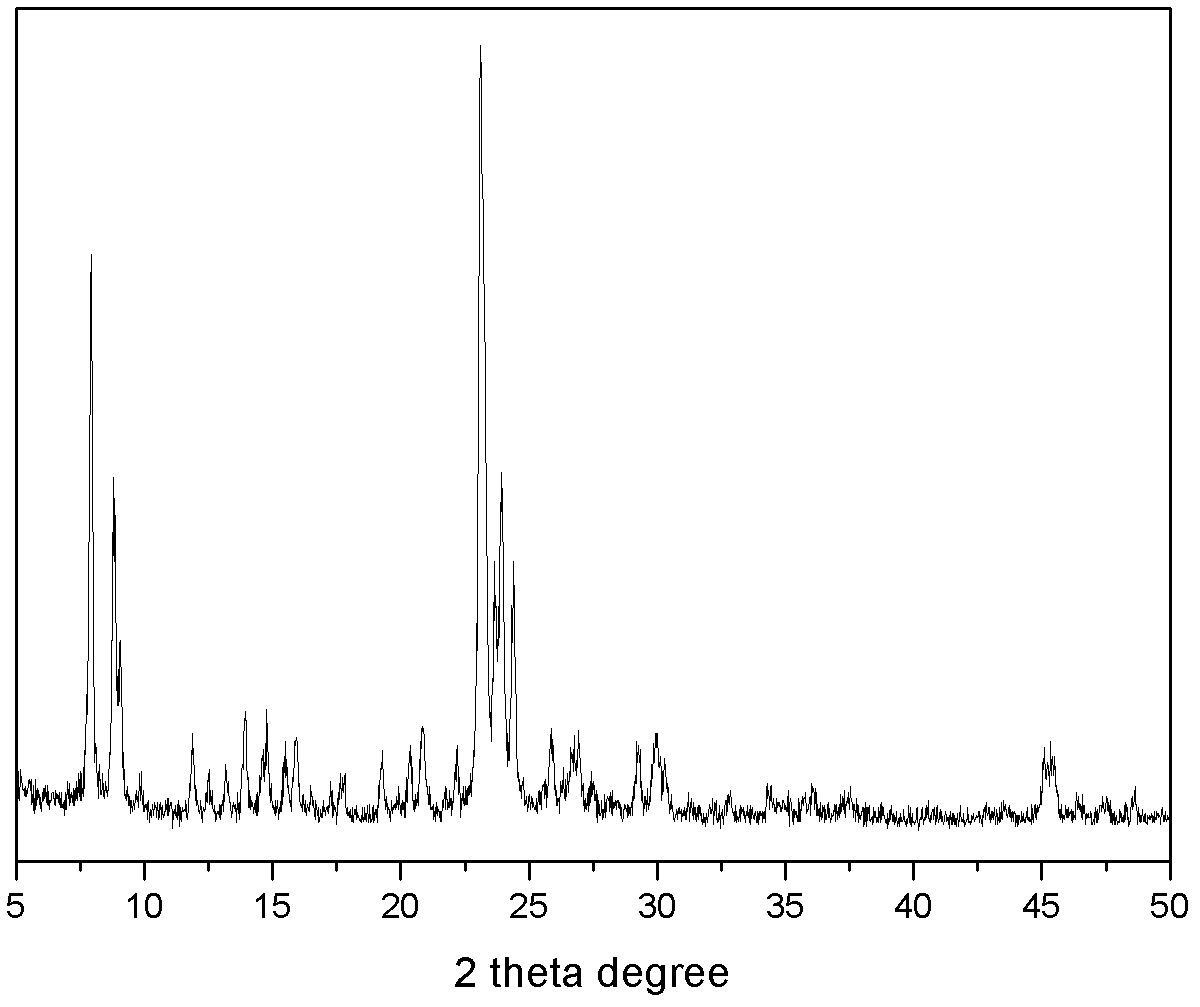

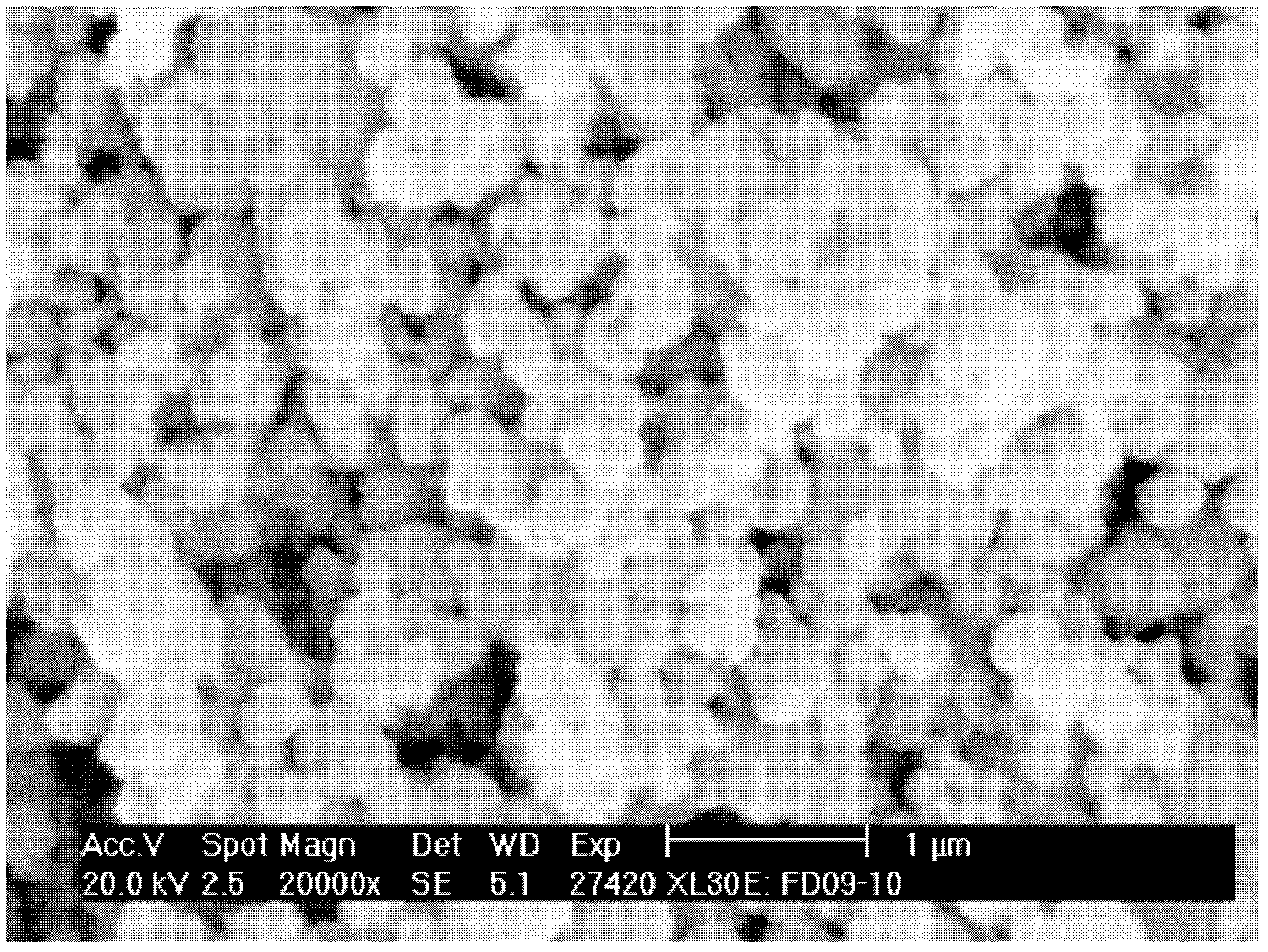

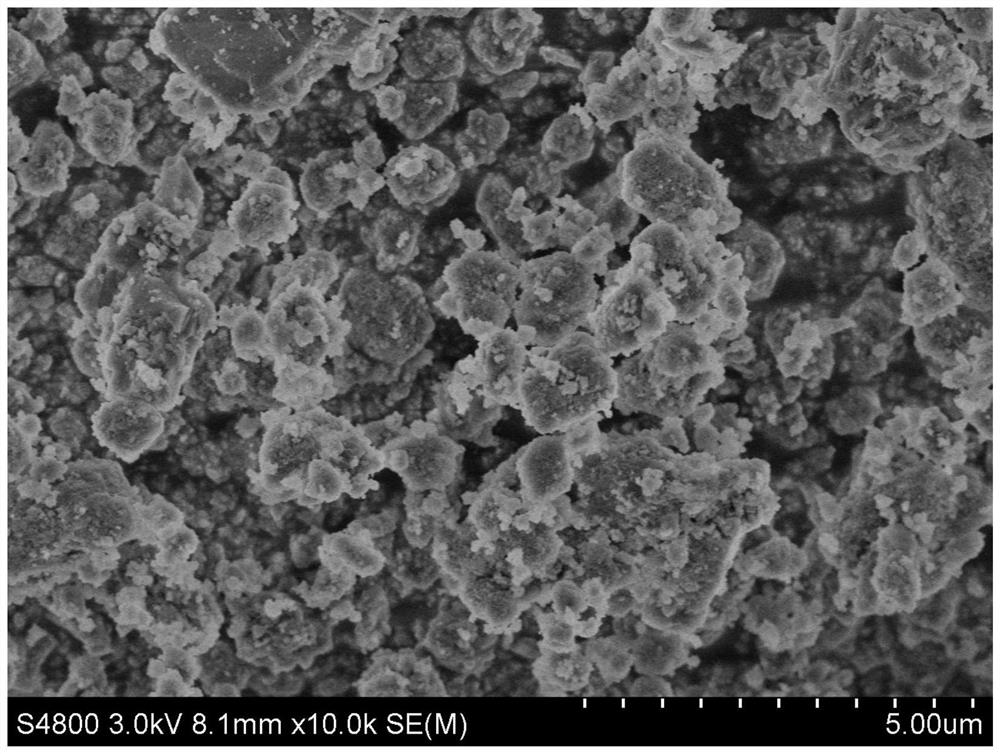

Preparation method of hierarchically porous zeolite molecular sieve

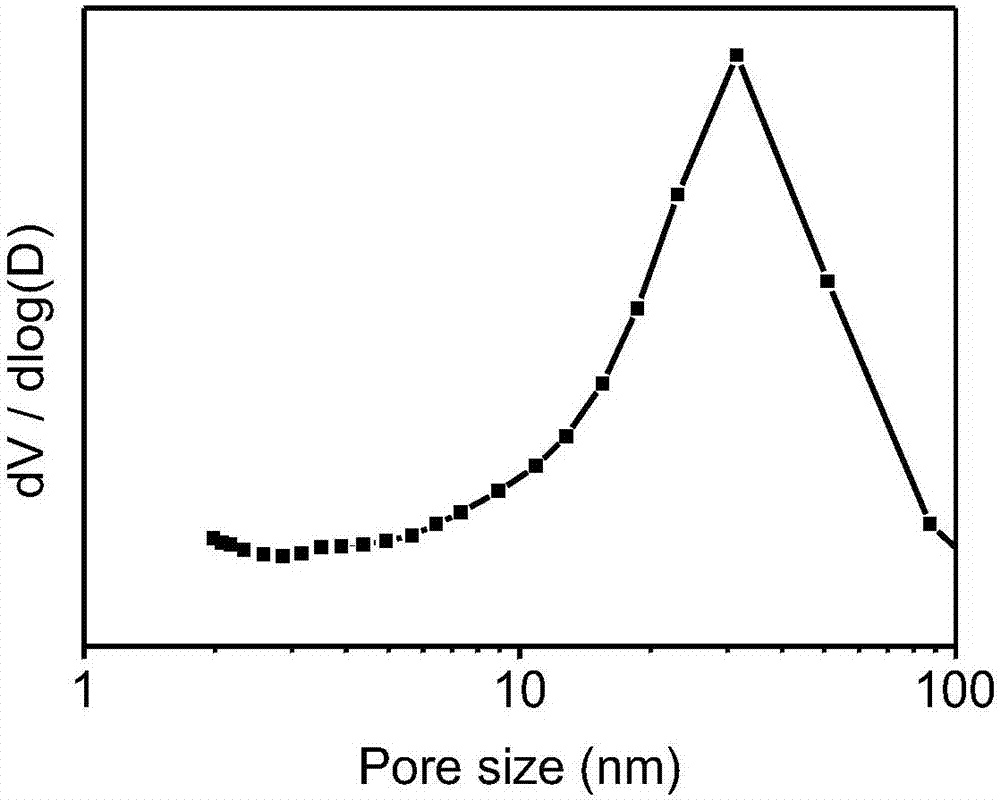

ActiveCN109626390AAvoid it happening againAvoid destructionMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSilicon

The invention relates to the technical field of molecular sieve preparation, and discloses a preparation method of a hierarchically porous zeolite molecular sieve. The specific surface area of a hierarchically porous EU-1 molecular sieve is improved. The method comprises the steps that a template agent part of EU-1 molecular sieve original powder is firstly removed through temperature controlling,then the processed EU-1 molecular sieve is placed in an acid solution to be reacted for 12-48 hours at the temperature of 100-150 DEG C, and finally the EU-1 molecular sieve is placed in an alkali solution where CTAB is dissolved to be reacted for 2-48 hours at the temperature of 80-180 DEG C to obtain the hierarchically porous EU-1 molecular sieve after sintering is conducted. The method has theadvantages that the hierarchically porous molecular sieve is prepared by the joint processing of desilicification and CTAB auxiliary secondary crystallization bonding through sintering temperature controlling and acid treatment, the method is simple, the outer specific surface area of the formed hierarchically porous EU-1 molecular sieve is increased, the dispersing performance of the molecular sieve is improved, and the catalytic activity is further improved.

Owner:TAIYUAN UNIV OF TECH

Preparation method of C10<+> heavyweight aromatic hydrocarbon transalkylation catalyst

ActiveCN104368373AHigh intragranular diffusion rateIncrease profitMolecular sieve catalystsHydrocarbonsSolventMetal salts

The invention discloses a preparation method of a C10<+> heavyweight aromatic hydrocarbon transalkylation catalyst. The preparation method is characterized in that firstly, the catalyst is prepared from a main active component named a HY molecular sieve with the mass percentage of 50-80% and the grain size of 30-100 nanometers, an adhesion agent named aluminum oxide of 15-40% and a modifying agent component named metal or a metallic oxide of 1-8%; secondly, the catalyst is prepared by the following steps: 1) mixing the nano HY molecular sieve with aluminum oxide, adding a squeeze aid, a pore-enlarging agent or an intensity additive with the mass percentage of no more than 5%, carrying out extrusion molding with a dilute nitric acid solution with mass percentage concentration of 4%, airing naturally, drying at 100-120 DEG C for 10-15 hours, then carrying out temperature programming to 550 DEG C, and roasting for 4-6 hours, thereby preparing a semi-finished catalyst; and 2) adding the product in the step 1) into a metal salt solution of the modifying agent component, dipping at room temperature with the equal volume for 6-30 hours, drying at 100-120 DEG C for 10-15 hours, then carrying out temperature programming to 550 DEG C, and roasting for 4-6 hours, thereby obtaining the finished product of the catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Mesoporous ZSM-22 molecular sieve, synthesis method thereof and application thereof

InactiveCN107285331AImproved Diffusion PerformanceImprove adsorption and catalytic performanceCatalyst carriersMolecular sieve catalystsMolecular sieveSorbent

The invention relates to a mesoporous ZSM-22 molecular sieve, a synthetic method thereof and application thereof. The mesoporous ZSM-22 molecular sieve has pore size distribution of 2-150 nanometers, and is high in outer specific surface area; the synthesis method is simple and easy for industrial production; the mesoporous ZSM-22 molecular sieve can be applied as an adsorbent, a catalyst carrier or a catalyst component of organic compound conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special hydrocracking catalyst and preparation method and application thereof

ActiveCN102794203AEvenly dispersedCooperate wellMolecular sieve catalystsCatalyst activation/preparationAfter treatmentMetal

The invention relates to a special hydrocracking catalyst, and a preparation method and application thereof. According to the preparation method for the catalyst, a solution after-treatment method is adopted to ensure that metal is uniformly deposited on a carrier and does not migrate in the subsequent drying process, so that uniform dispersion of the metal is realized; and by the preparation method for the catalyst, the metal is uniformly dispersed, the carrier and the metal are well matched, and the catalytic performance is greatly improved. The hydrocracking catalyst is most suitable for the middle distillate type hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

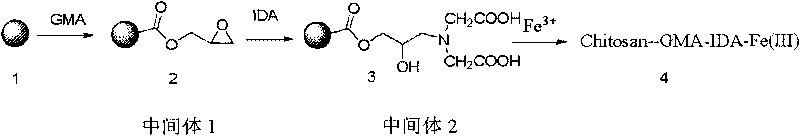

Nano chitosan derivative and preparation method and application thereof

InactiveCN101747448AGood biocompatibilityStable in natureOther chemical processesPeptide preparation methodsCycloadditionPhosphopeptide

The invention relates to the technical field of nano materials in biomedicine. Specifically, the invention provides a nano chitosan derivative, a preparation method and a method of applying the nano chitosan derivative to enrich and purify phosphopeptide highly selectively and specifically. The preparation method comprises the following steps: the chitosan is dissolved in diluted acid and then is mixed with glycidyl methacrylate or glycidyl acrylate to carry out self-polymerization and grafting reaction, thus obtaining a nano composite medium chitosan derivative with active epoxy groups; the composite medium and iminodiacetic acid or aminotriacetic acid or ethylenediamine triacetic acid carry out ring-opening addition reaction to obtain a nano medium chitosan derivative with carboxylic active functional groups; and finally the medium and transition metal ions such as Fe3+, Ti4+, Zr4+, Ga3+ and the like carry out chelation to prepare the final nano chitosan derivative. The nano chitosan derivative has high specificity and can be used for enriching and purifying phosphopeptide with low abundance in the biological samples, thus being used in the fields of biology and medicines, including clinical diagnosis.

Owner:PEKING UNIV

Method for preparing nano molecular sieve by coordinating amino acid assisting and sectional crystallizing through concentrated gel system

InactiveCN106904635APromote crystallizationHigh micropore specific surface areaMaterial nanotechnologyAluminosilicate zeolite type-ANucleationTETRAETHYLAMMONIUM HYDROXIDE

The invention provides a method for a preparing nano molecular sieve by coordinating amino acid assisting and sectional crystallizing through a concentrated gel system, and belongs to the technical field of molecular sieve preparation. The method is characterized in that a traditional hydro-thermal synthesis mode is carried out; tetrapropylammonium hydroxide or tetraethylammonium hydroxide or Na<+> is used as a template; amino acid is added to control crystal nucleation and growth of the molecular sieve, and the sectional crystallizing reaction is carried out through the concentrated gel system, so that the synthesized nano molecular sieve is good in crystal, high in micropore specific surface area, high in external specific surface area and large in micropore volume; the synthesized Beta type molecular sieve is 9.5 nm in average size; an Silicalite-1 type molecular sieve is 30nm in average size; an A type molecular sieve is 50nm in average size. The nano molecular sieve is high in crystalline and monodispersity, and has a certain industrial application prospect.

Owner:JILIN UNIV

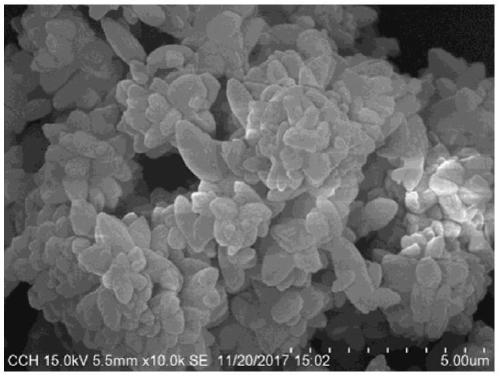

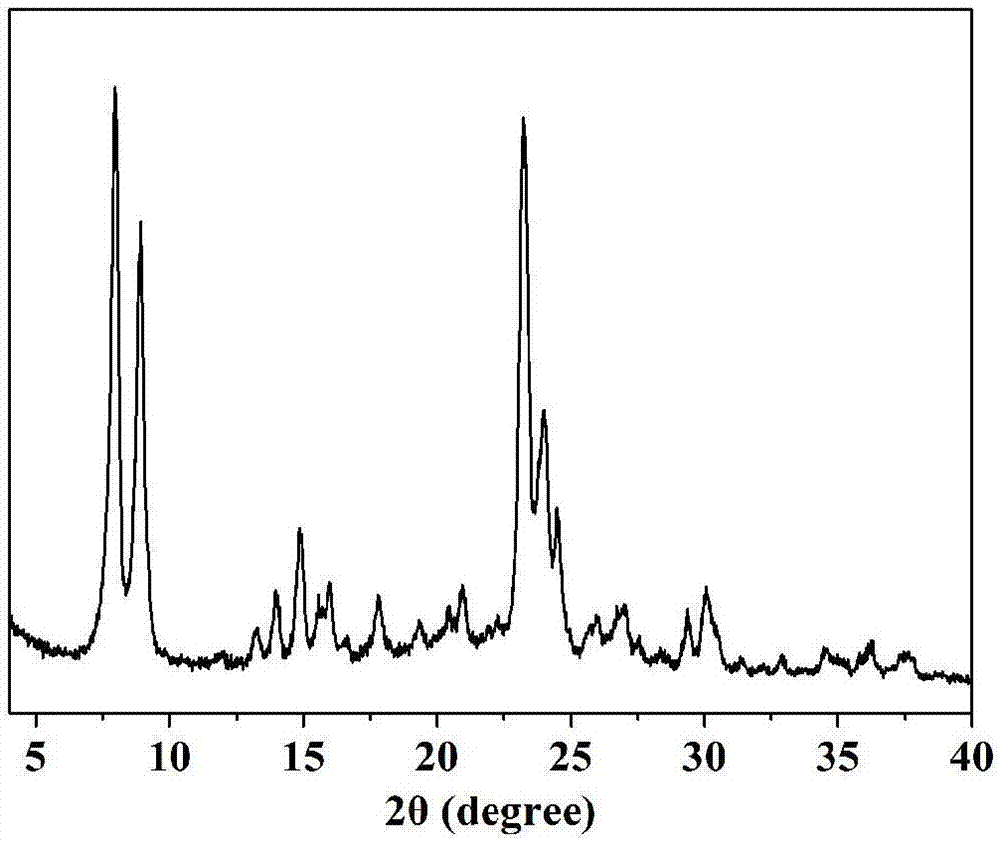

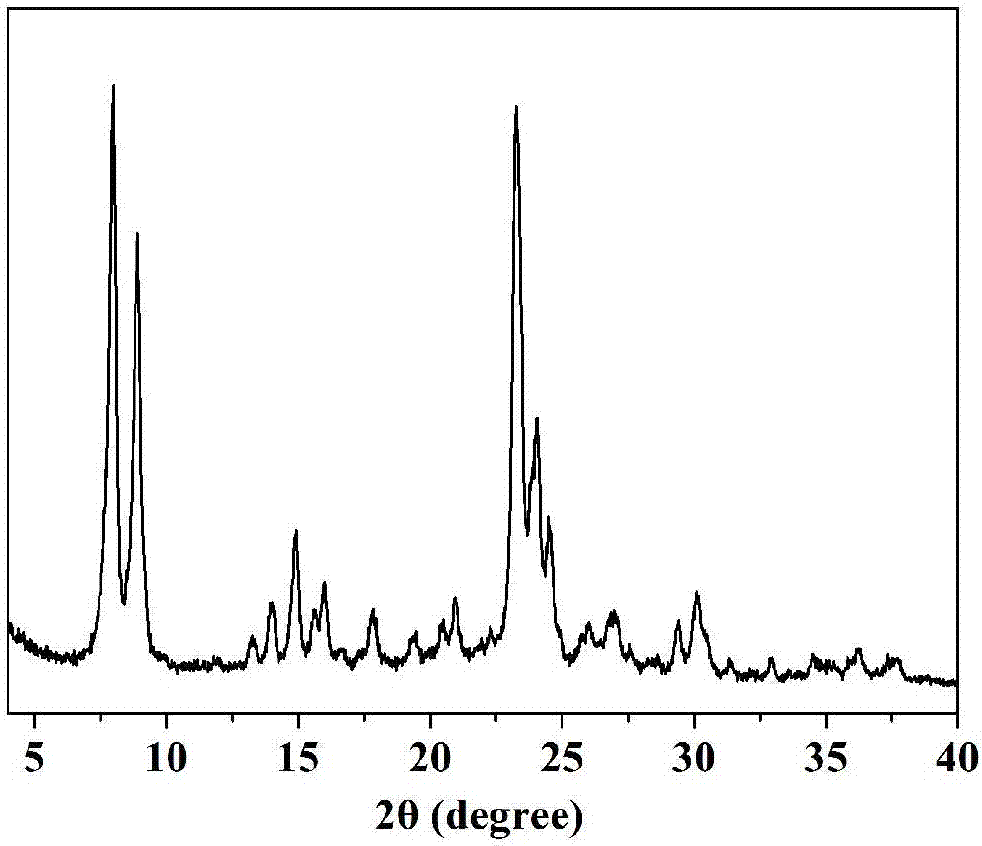

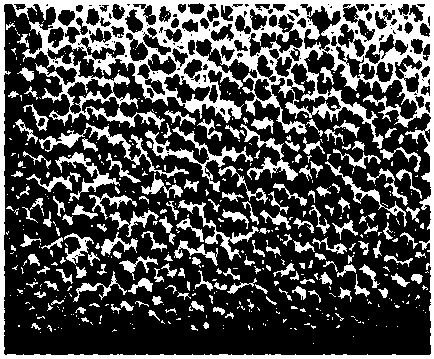

Preparation method of hierarchical pore FAU type zeolite molecular sieve with house-of-cards-like structure

ActiveCN107512728AUniform particle size distributionLarger surface areaFaujasite aluminosilicate zeoliteIonChemistry

The invention discloses a preparation method of a hierarchical pore FAU type zeolite molecular sieve with a house-of-cards-like structure, and belongs to the technical field of inorganic chemistry. The preparation method comprises the following steps: at first, dissolving an inorganic alkali source and an aluminum source into deionized water, slowly adding a silicon source, fully and evenly stirring to obtain uniform sol, and then subjecting the sol to a hydrothermal crystallization treatment to obtain the hierarchical pore FAU type zeolite molecular sieve with a plug-in card structure. The hierarchical pore FAU type zeolite molecular sieve is synthesized in the absence of inorganic / organic templates and an inorganic salt additive, the synthesis cost is greatly reduced, and the preparation method is simple and environmentally friendly. The FAU type zeolite molecular sieve has prominent structural characteristics of micropore, mesopore, and macropore, has the advantages of large external surface, strong acidity, and good stability, and has a wide application prospect in fields such as detergent aid, hard water softening, catalyst, adsorbent, catalyst carrier, and the like.

Owner:SHENZHEN UNIV

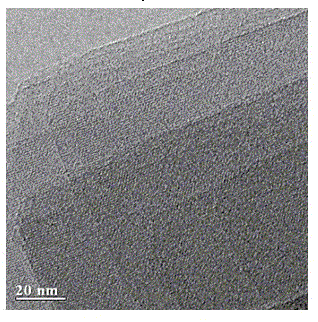

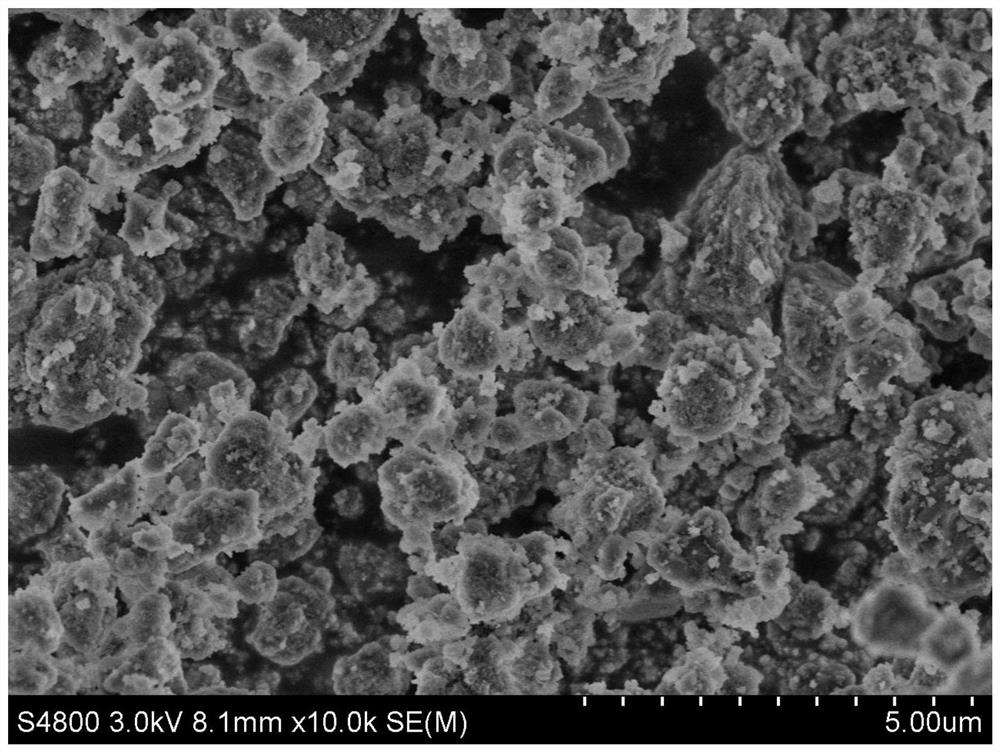

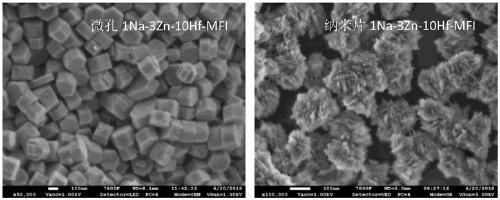

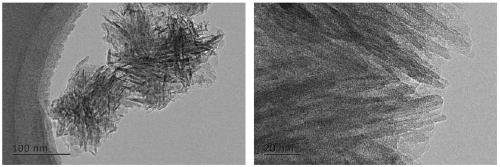

Method for preparing MFI catalyst carrying transition elements and MFI catalyst application

InactiveCN102380412AAvoid inactivationHigh activityMolecular sieve catalystsDispersed particle separationNucleationSodium silicate

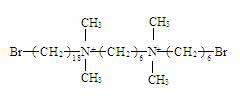

Disclosed are a method for preparing an MFI catalyst carrying transition elements and MFI catalyst application. Cationic gemini surfactant- dibromide-1-(dimethyl hexyl ammonium)-6-(dimethyl octodecyl ammonium) hexane is used as structure directing agent of the MFI catalyst, sodium silicate is used as a silicon source and is subjected to low-temperature hot crystallization under self-generated pressure in a rotationally dynamic manner, and after directional polycondensation, rearrangement, nucleation and growth of inorganic atom Si-Al-Na-O on a two-dimensional plane, and single-structure-cell nano-layer MFI catalytic materials which are in mesoporous and microporous structure with the thickness ranging from 2 nanometers to 5 nanometers only are synthetized. Activity center point number of the MFI catalyst is increased evidently by utilizing two-dimensional single-structure-cell nano MFI carrying transition elements of Fe and Mo, the thickness of the catalyst crystal is reduced effectively, diffusion path is shortened, and molecular diffusion is speeded up. In addition, according to the result of a test of utilizing the selective catalytic reduction (SCR) process to remove tail gas of automobiles, NOx removal rate reaches 99.5%.

Owner:TAIYUAN UNIV OF TECH

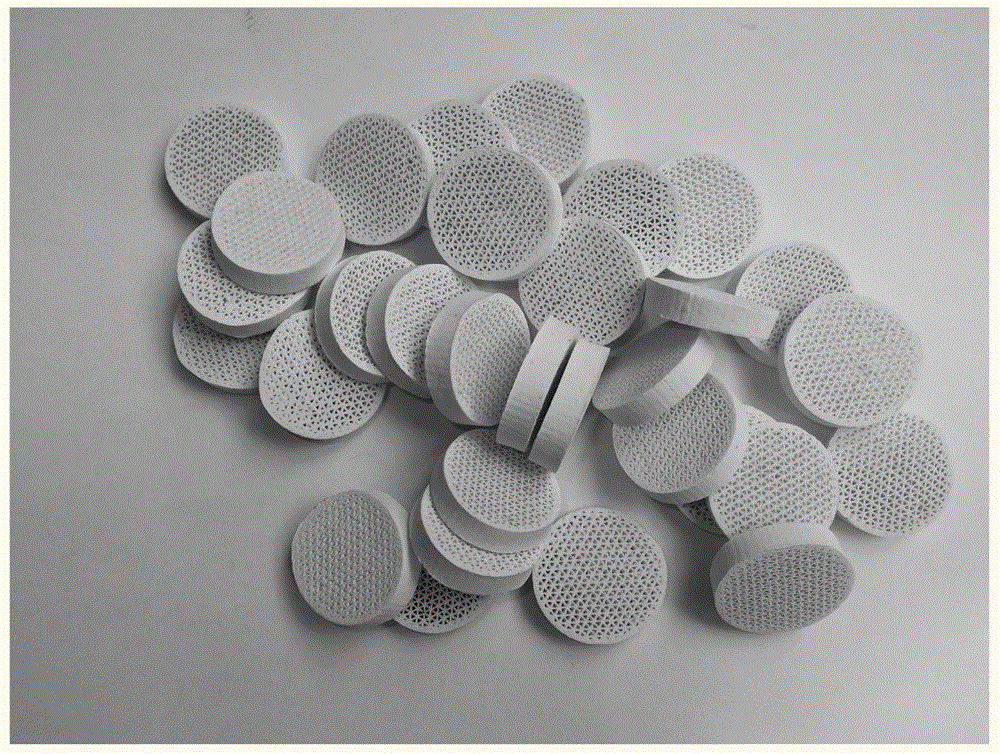

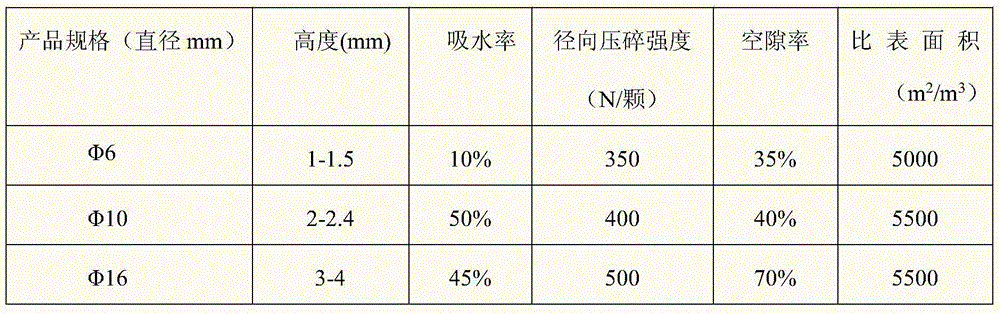

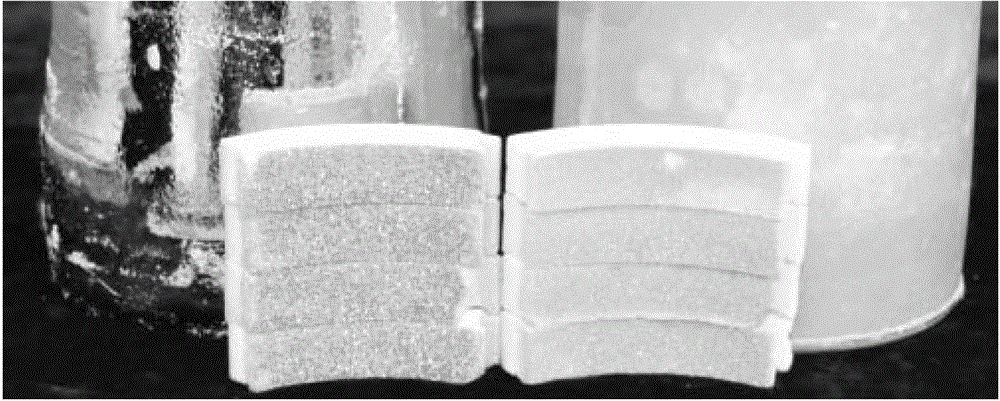

Honeycomb nest hydrogenation protecting agent

ActiveCN104888864AImprove firing pass rateExcellent extrusion formabilityCatalyst carriersHoneycombSolvent

A honeycomb nest hydrogenation protecting agent is prepared from 1-60% of alumina powder, 5-50% of kaolin, 0.1-15% of talcum powder, 5-60% of clay, 0.5-10% of an alkaline solvent, and 0.1-5% of an auxiliary material. The unit cross section area of the above product has more and denser through holes, so the external specific surface area of the product is greatly increased and reaches above 5000m<2> / m<3>, so a reaction raw material and the protecting agent have a larger contact and reaction area. The void fraction of the product reaches 30-70%, the water absorption rate reaches 10-50%, and the appropriate water absorption rate makes the protecting agent adsorb more active substances, so the absorption rate of adsorbed impurities is improved, and the catalysis effect is improved; and the radial crushing strength of the product is 50-500N / granule of the product, the product cannot be fragmented when 50-500N is applied to the two axial ends of the product, and maintains integrity, so the strength is improved, and the service life is prolonged.

Owner:JIANGXI ACICHEMSHUN IND

Preparation method of polymethoxymethylal

ActiveCN103121927AHigh activityIncrease profitOrganic chemistryMolecular sieve catalystsMolecular sieveActive component

The invention relates to a preparation method of polymethoxymethylal, mainly solving the problem that in the prior art, the catalyst has corrosivity. The method comprises the following step: by taking methanol or dimethyl ether and formaldehyde or trioxymethylene as raw materials, contacting the reaction raw materials with a catalyst to generate the polymethoxymethylal under the conditions that the molar ratio of the methanol or the dimethyl ether to the formaldehyde or the trioxymethylene is 1: (0.1-10), the reaction temperature is 50 to 200 DEGC and the reaction pressure of 0.1-10 MPa, wherein a molecular sieve ZSM-5 with the size of less than or equal to 5 microns is adopted as the active component of the used catalyst. through using the technical scheme, the problem is solved well. The method provided by the invention can be applied to industrial production of the poly methoxy methylal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for protecting precious metal crucible by coating crucible with high temperature resistant coating

The invention relates to a method for protecting a precious metal crucible by coating the crucible with a high temperature resistant coating. The method comprises the following steps: carrying out surface pretreatment on the precious metal crucible: blasting the outer surface of the precious metal crucible by using aluminium oxide particles at a high speed in an airtight box, so that ultrafine pits are formed on the outer surface of the precious metal crucible so as to increase the outer specific surface area of the crucible; and carrying out high-temperature plasma spraying of fine zirconium oxide sand on the pretreated outer surface of the precious metal crucible so as to form a dense zirconium oxide protective layer. According to the method, the ultrafine pits are formed on the outer surface of the precious metal crucible by carrying out high-speed fine particle blasting on the outer surface of the precious metal crucible so as to increase the outer specific surface area of the crucible, so that the adsorption capacity between the protective layer and the outer surface of the crucible is increased; and the dense zirconium oxide protective layer is formed through plasma spraying, so that the volatilization of the precious metal crucible is reduced, the using loss is reduced, and the growth cost of crystals is saved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

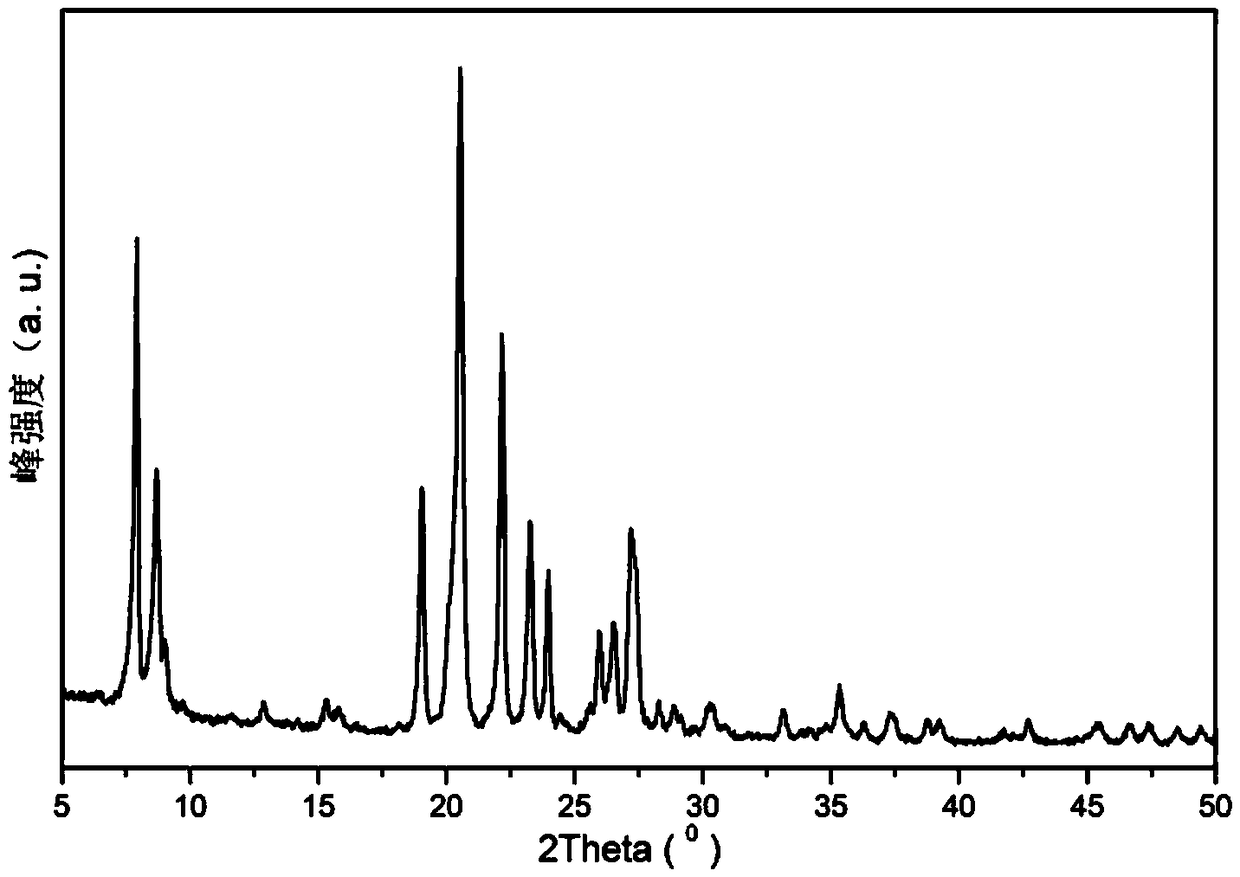

Dual-function catalyst applied to isomerization of C8 aromatic hydrocarbon and preparation method of dual-function catalyst

ActiveCN109046444ASmall grain sizeImprove diffusion abilityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneIsomerization

The invention discloses a dual-function catalyst applied to isomerization of C8 aromatic hydrocarbons and a preparation method of the dual-function catalyst. The catalyst is prepared from the following components: 10-89.9wt% of H type hierarchical-pore structure EUO molecular sieve, 9.9-89.9wt% of matrix and 0.01-2.0wt% of metal active component. The preparation method comprises the following steps: mixing the hierarchical-pore EUO molecular sieve, the matrix and a pore-enlarging agent, then adding an acid solution, kneading and forming, drying and roasting to remove the components such as thepore-enlarging agent to form a carrier, then dipping the carrier in a mixed solution containing metal salt and activating to obtain a formed catalyst. The hierarchical-pore EUO molecular sieve is crystallized and synthesized by taking a long-chain silane compound as a crystallization promoting agent and taking biquaternary ammonium salt with an alkane structure substituted by a di-penta-heterocycle group as an organic template agent. The catalyst shows favorable activity and selectivity in hydroisomerization reaction of C8 aromatic hydrocarbon and has a good industrial application prospect and a good economic value.

Owner:CHINA CATALYST HLDG CO LTD

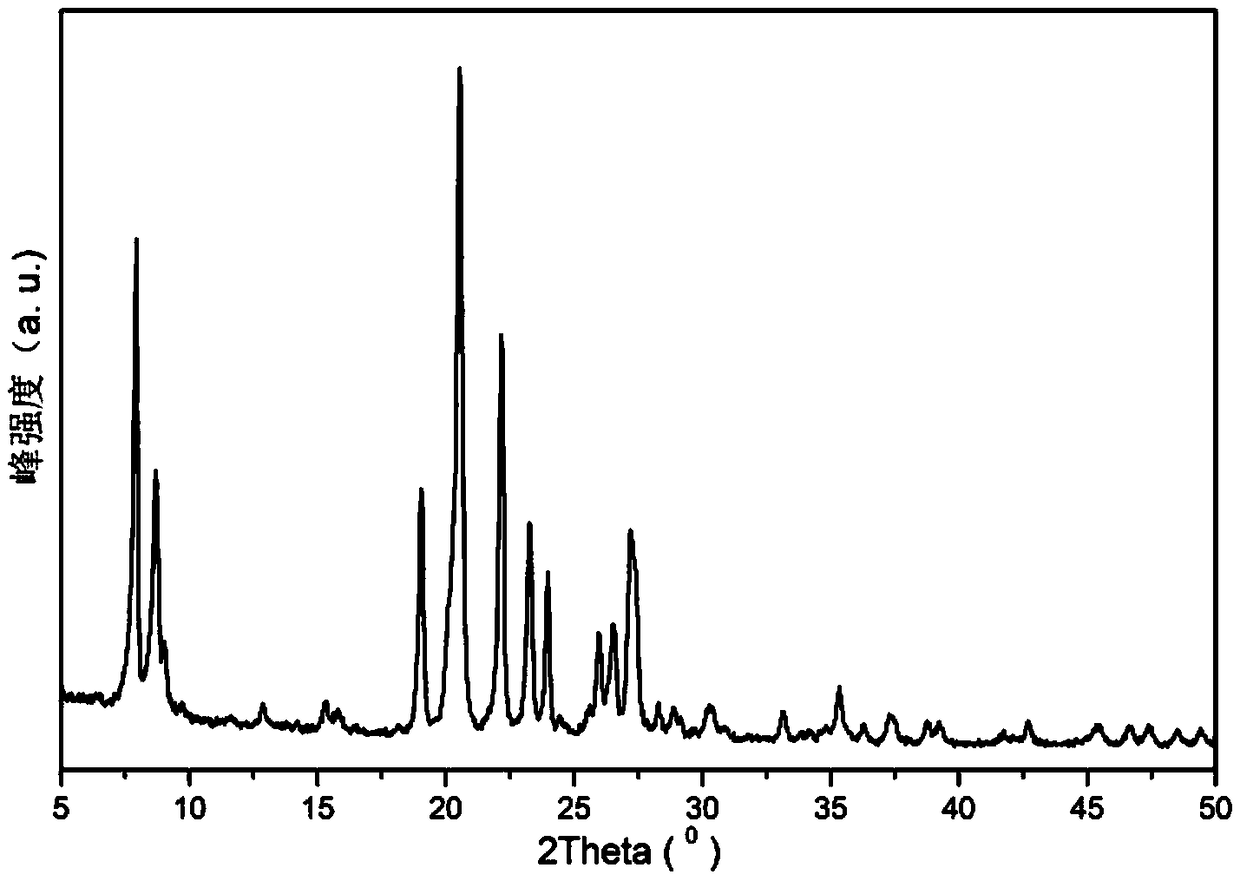

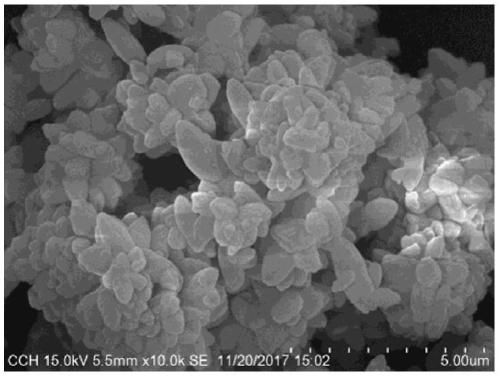

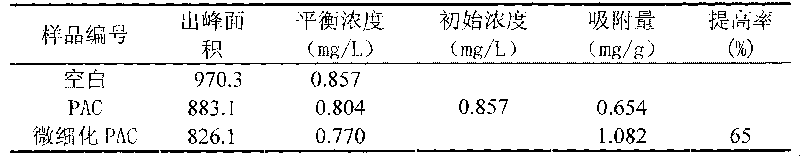

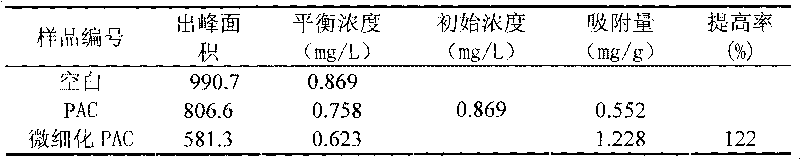

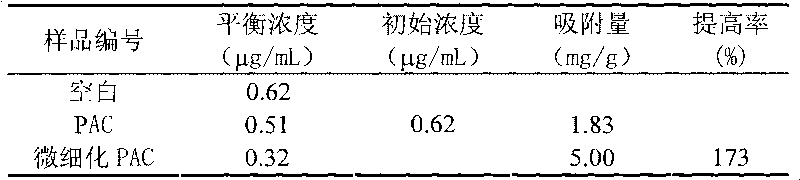

Micronized powder active carbon for water treatment and preparation method thereof

InactiveCN101696008ALarger surface areaShorten the diffusion distanceOther chemical processesWater/sewage treatment by sorptionIonActivated carbon

The invention provides micronized powder active carbon for water treatment and a preparation method thereof. The average particle size of the micronized powder active carbon is less than or equal to 10mu m. The preparation method comprises the following steps that: powder active carbon sold on the market is ground by a dry method until the average particle size is less than or equal to 10mu m to obtain a finished product. The micronized powder active carbon is prepared by a micronized physical method, and the performances of adsorbing odorants and heavy metallic ions can be synchronously improved; and the preparation method is simple, has no secondary pollution, and can be combined with water treatment technique such as an oxidation process and the like.

Owner:TSINGHUA UNIV

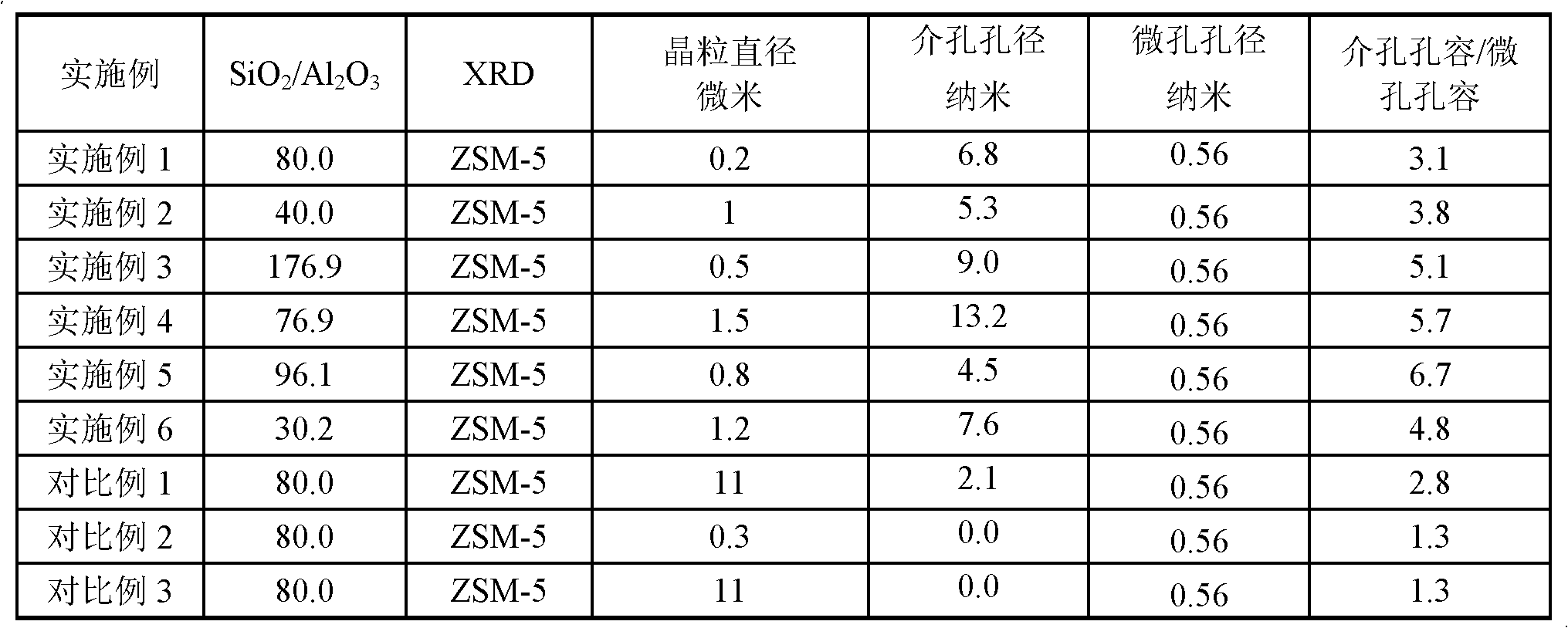

Method for preparing ethylene through ethanol catalytic dehydration

InactiveCN103030489AIncrease profitIncreased focus capacityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureSpace velocity

The invention relates to a method for preparing ethylene through ethanol catalytic dehydration and mainly solves the problem of poor reaction stability in the prior part. According the method, ethanol with the weight percentage concentration being 5 to 100 percent is used as raw materials, reaction raw materials and catalysts are in contact to generate ethylene under the conditions that the reaction temperature is 200 to 400 DEG C, and the volume space velocity relative to the ethanol is 0.1 to 15 h<-1>, wherein the used catalysts are MSM-5 zeolite, the MSM-5 zeolite has the crystal grain diameter being smaller than or equal to 5 microns and simultaneously has mesoporouses and micropores, and the mesoporous volume / micropore volume value of the MSM-5 zeolite is 1.5 to 10. Through the technical scheme, the problems are perfectly solved, and the preparation method can be used in the industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

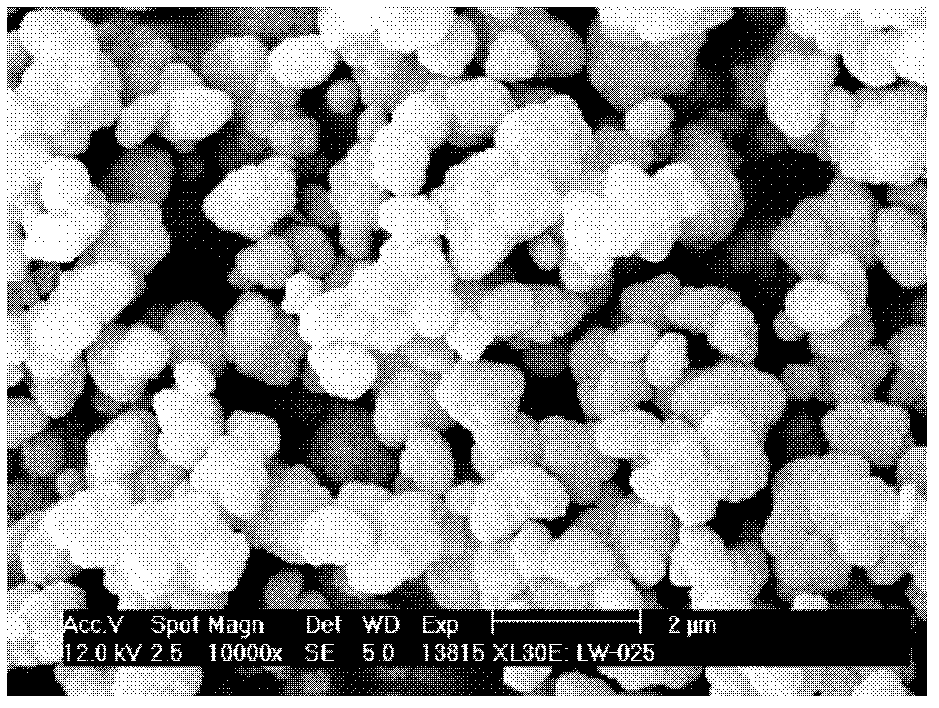

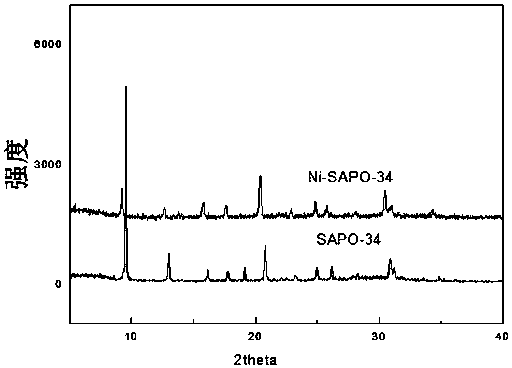

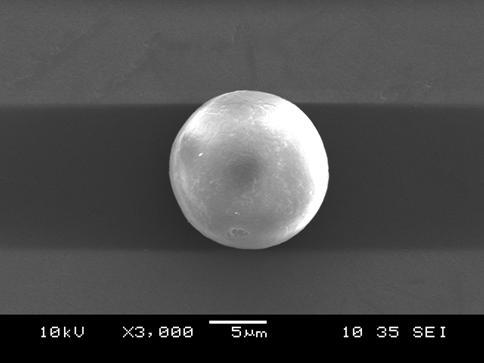

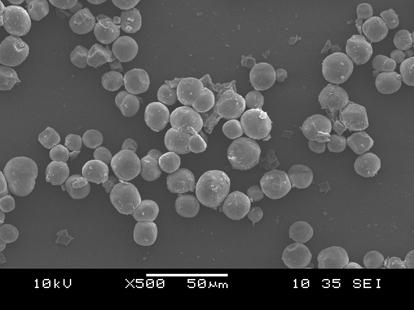

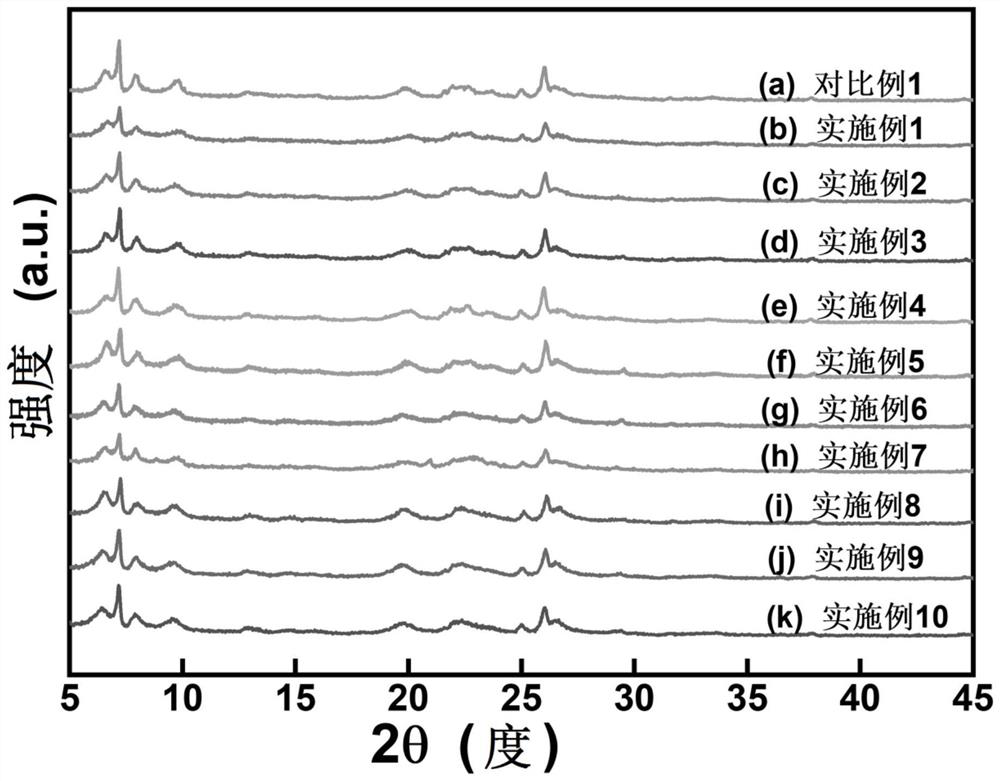

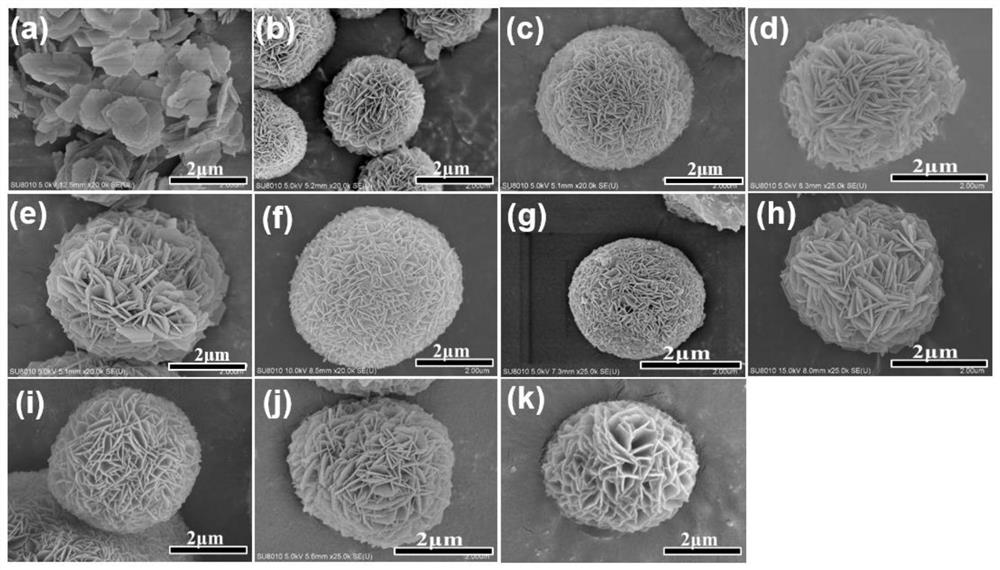

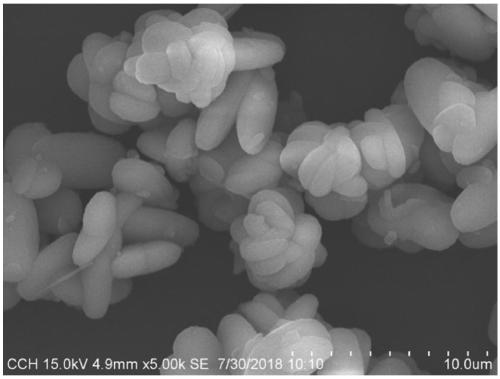

A kind of spherical heteroatom ni-sapo-34 molecular sieve and its preparation and application

ActiveCN107244679BHigh crystallinityRegular shapeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesHydration reactionMolecular sieve

The invention relates to a spherical heteroatom Ni-SAPO-34 molecular sieve, and a preparation method and an application thereof. The preparation method comprises the following synthesis steps: (1) dissolving nickel nitrate hexahydrate in deionized water, and dropwise adding a chelating agent at room temperature while stirring to obtain a Ni chelate solution A; (2) mixing an aluminum source, a phosphorous source, a silicon source, a template and deionized water, and heating and stirring the obtained mixture to obtain an initial sol B; (3) adding the solution A to the initial sol B, and heating and stirring the solution A and the initial sol B to obtain a sol C; and (4) filling a reaction kettle with the sol C, carrying out a crystallization reaction, filtering and washing a product obtained after the reaction is completed until the product is neutral, and drying, calcining and cooling the neutral product to obtain the spherical heteroatom Ni-SAPO-34 molecular sieve. The spherical heteroatom Ni-SAPO-34 molecular sieve with a high crystallinity is synthesized by a sol-hydrothermal synthesis technology, the pressure drop of an accumulated catalyst bed is effectively reduced, the introduction of metallic nickel provides many active sites for the reaction, and the molecular sieve has an important application in an NH3-SCR reaction. The synthesis method has the advantages of simple steps, and easiness in operation.

Owner:SHANTOU UNIV

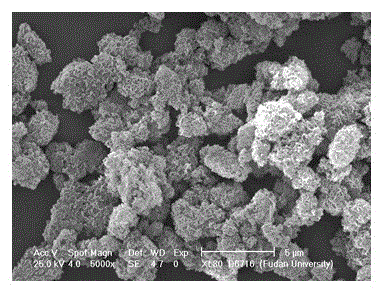

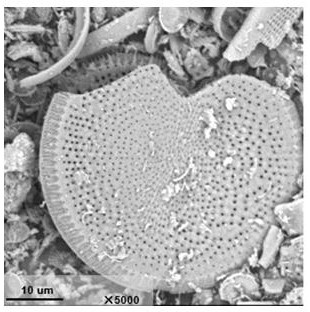

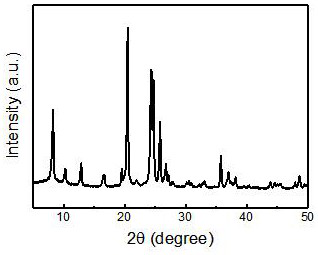

Synthesis method of nano small-grain ZSM-22 molecular sieve

ActiveCN113233472ALarger surface areaImprove the ability of mass transfer and diffusionNanotechnologyMolecular-sieve and base-exchange compoundsMolecular sieveCrystallinity

The invention belongs to the field of synthesis of molecular sieves, and relates to a synthesis method of a nano small-grain ZSM-22 molecular sieve. According to the method, natural diatomite is used as all silicon sources and aluminum sources required for synthesizing the molecular sieve, and in-situ crystallization is carried out under the condition of no template to obtain the nano small-grain ZSM-22 molecular sieve. The composition and skeleton of the diatomite are fully utilized, the original pore structure of the diatomite is reserved in the synthesis process of the molecular sieve, the silicon-aluminum ratio and grain size of the product molecular sieve are regulated and controlled by controlling the silicon-aluminum content of the diatomite and the composition of the initial gel, and the high-crystallinity nano small-grain ZSM-22 molecular sieve with a large external specific surface area and an adjustable silica-alumina ratio is synthesized. The method has the advantages of simple and efficient synthesis process, environmental protection, low cost and great industrialization prospect.

Owner:FUZHOU UNIV

Foam ceramic supporter, TiO2 photocatalyst and preparation method thereof

ActiveCN110871060AImprove performancePlay a role in sterilizationGas treatmentPhysical/chemical process catalystsPhoto catalyticSlurry

The invention discloses a foam ceramic supporter, a TiO2 photocatalyst supported on the foam ceramic supporter and a preparation method thereof. The foam ceramic supporter includes foam ceramic and acomposite oxide, wherein the foam ceramic has a porous foam structure, the pore edges in the foam ceramic contain three-dimensional penetrating micro-scale pore channels, the composite oxides distributing in the surface of the pore edges and the interior of the pore channels. The preparation method of the foam ceramic supporter includes: impregnating the foam ceramic with a composite oxide precursor slurry to obtain the foam ceramic supporter. The TiO2 photocatalyst supported by the foam ceramic supporter is high in photo-catalytic activity, wherein the TiO2 is not liable to lose, so that thephotocatalyst has good activity stability and is especially suitable for photocatalytic purification of gas or liquid.

Owner:中科粤能净(山东)新材料有限公司

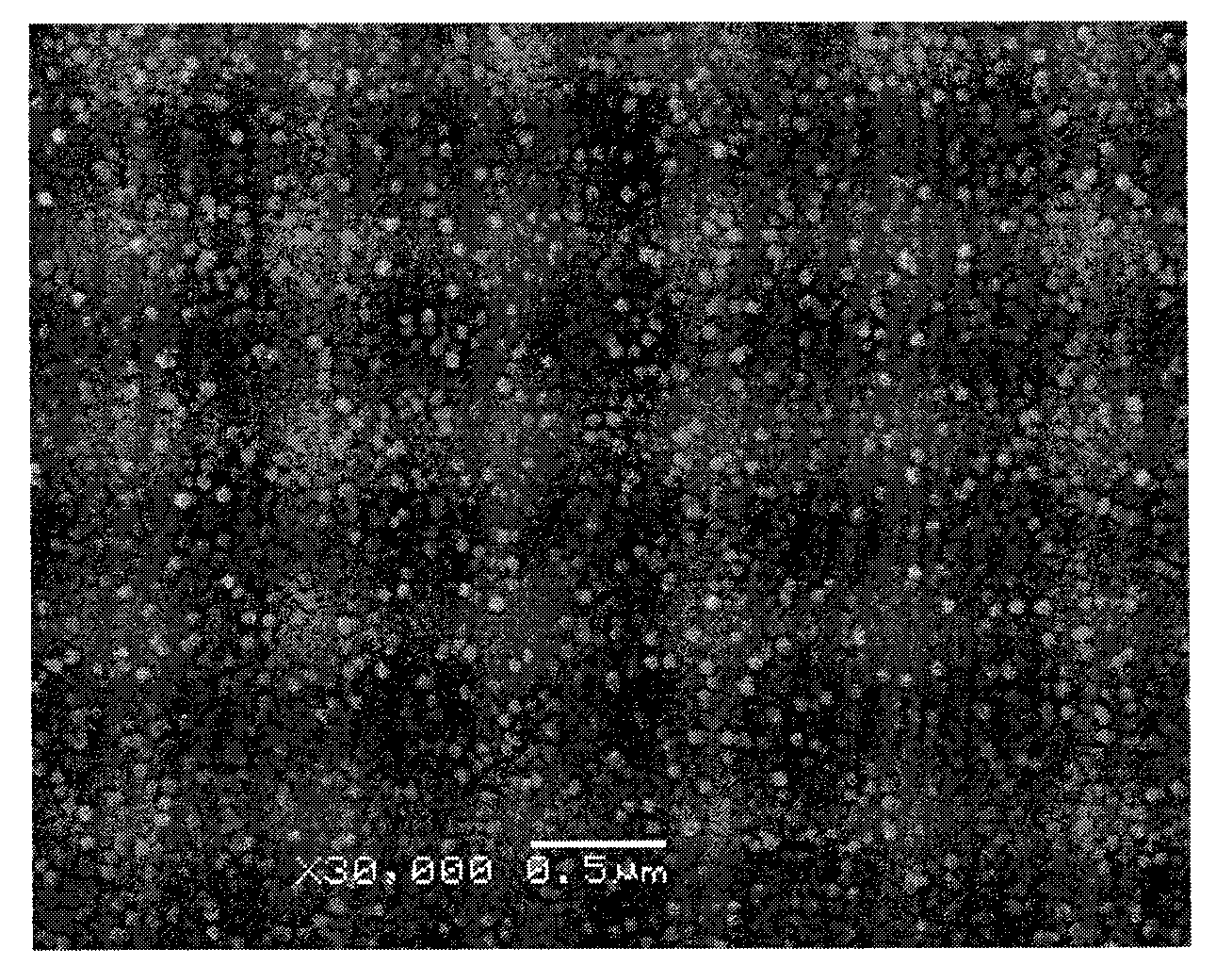

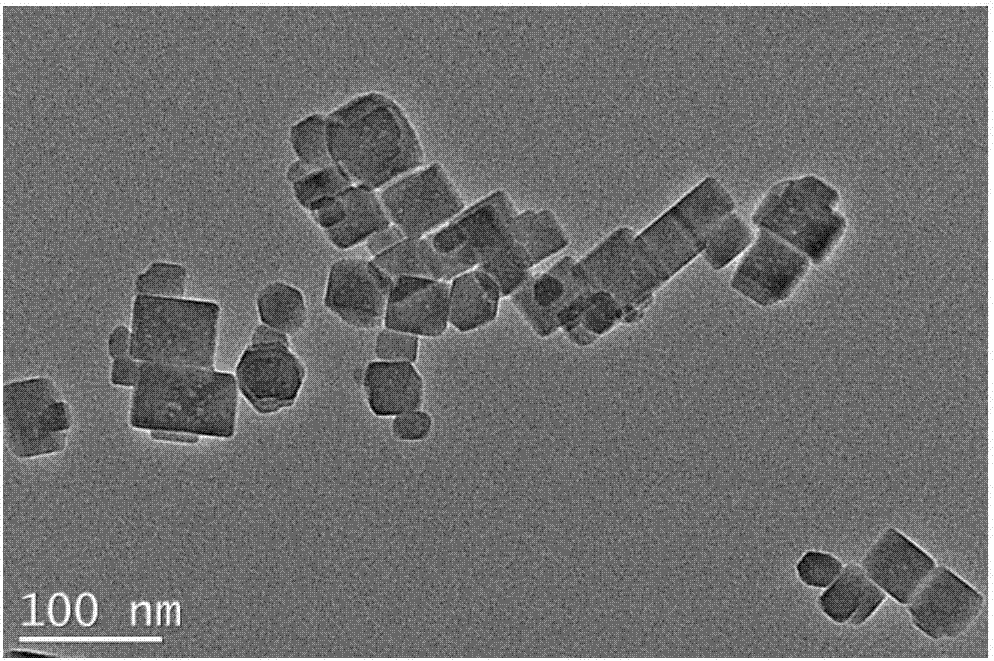

Synthesis method of nano Y zeolite, synthesized nano Y zeolite and application

ActiveCN110562995AImprove thermal stabilityGood nanostructureMaterial nanotechnologyMolecular sieve catalystsMolecular sieveIce water

The invention relates to a synthesis method of nano Y zeolite, the synthesized nano Y zeolite and an application. The method comprises steps as follows: a) an aluminum source and a sodium hydroxide solution make contact at the temperature of 50-95 DEG C to obtain an aluminum source solution; b) a silicon source and the sodium hydroxide solution make contact at the temperature of 70-100 DEG C to obtain a silicon source solution; c) the aluminum source solution and the silicon source solution make contact under the condition of an ice water mixed bath, and a mixture is obtained; and d) the mixture is crystalized to obtain a nano Y molecular sieve. The method can be used for industrial production of the nano Y zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

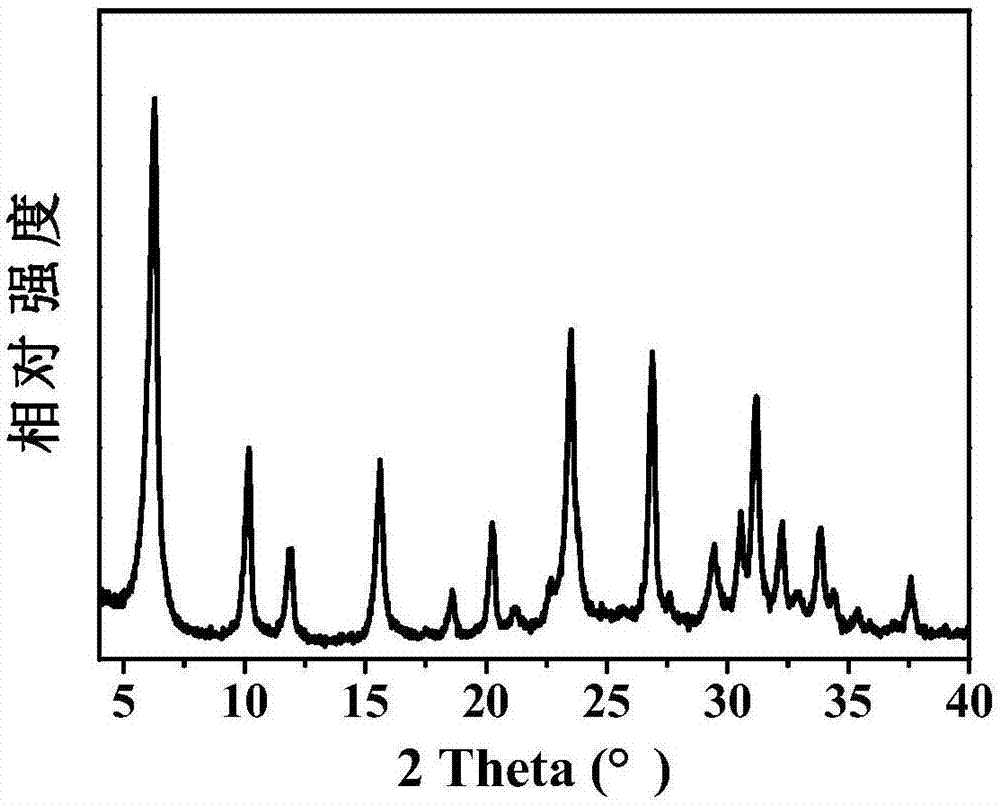

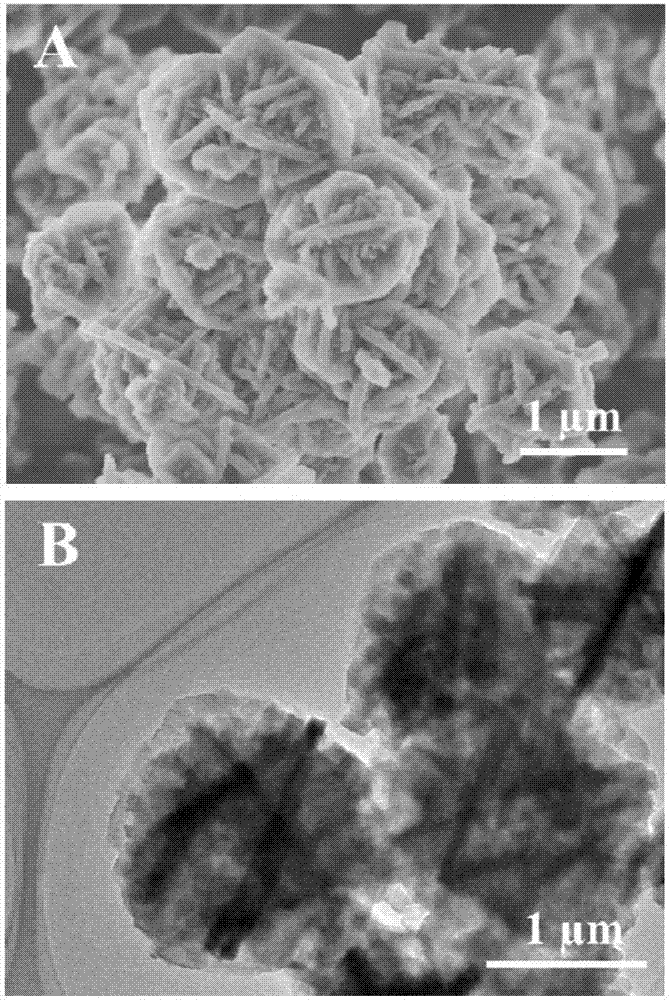

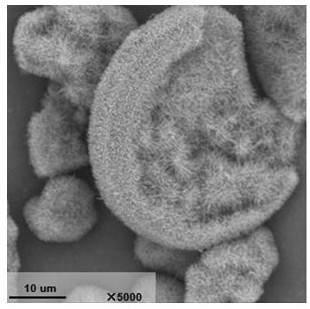

Thin-layer MCM-22 molecular sieve microsphere with microporous/mesoporous structure as well as preparation and application of thin-layer MCM-22 molecular sieve microsphere

ActiveCN114162833AUniform particle sizeImprove responseMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveBenzene

The invention provides a thin-layer MCM-22 molecular sieve microsphere with a microporous / mesoporous structure as well as preparation and application of the thin-layer MCM-22 molecular sieve microsphere. The molecular sieve microspheres have the shape of'desert rose '. The method comprises the following steps: preparing a main template agent, a second template agent and water into a solution A; preparing an aluminum source, NaOH and water into a solution B; mixing and aging the solution A, the solution B and a silicon source to obtain mixed glue; the molar ratio of the components in the mixed glue meets the following conditions: SiO2 / Al2O3 is equal to 5-200, OH <-> / SiO2 is equal to 0.005-1, H2O / SiO2 is equal to 5-100, R1 / SiO2 is equal to 0.01-1, and R2 / SiO2 is equal to 0.005-0.5; and carrying out hydrothermal crystallization on the mixed glue, and then carrying out post-treatment to obtain the MCM-22 molecular sieve microspheres. In a liquid phase alkylation reaction of benzene and ethylene, the molecular sieve prepared by the method shows relatively high benzene conversion rate and ethylene selectivity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

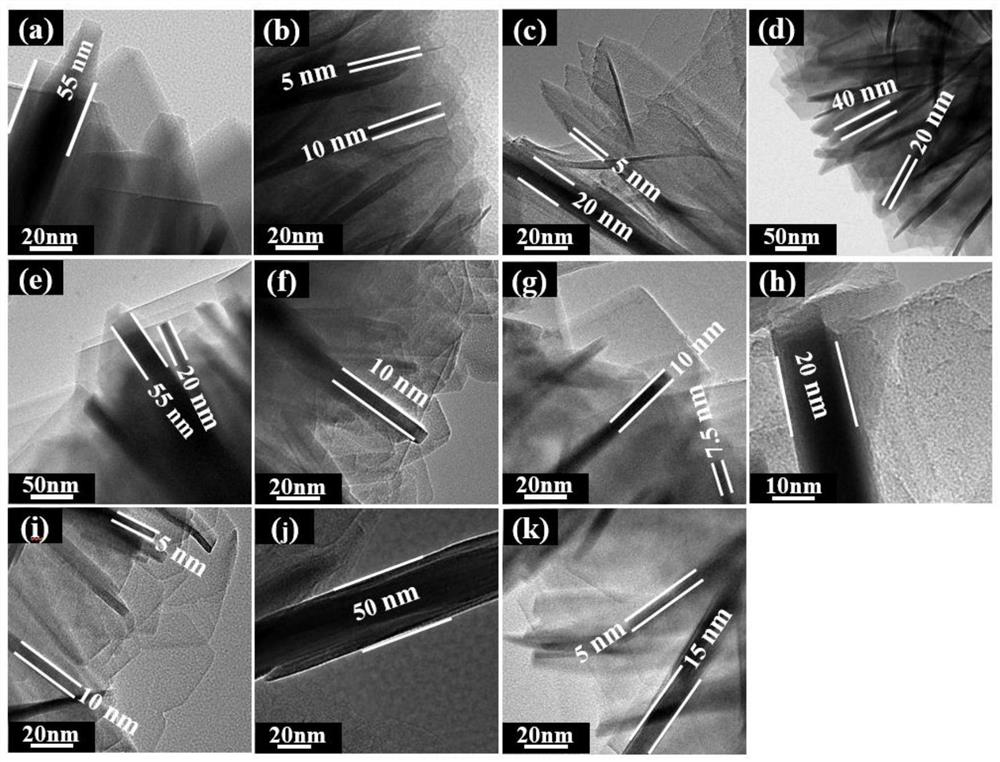

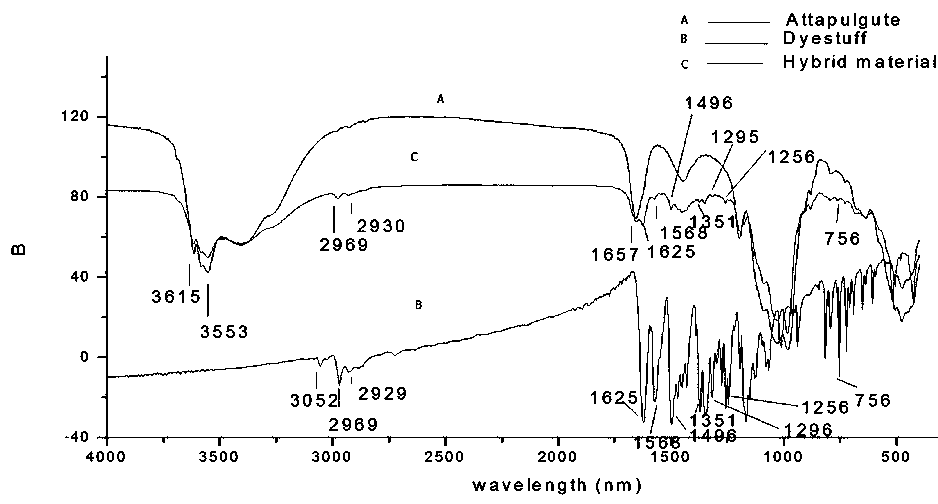

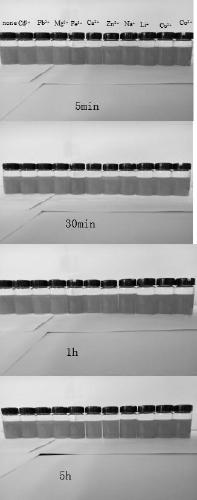

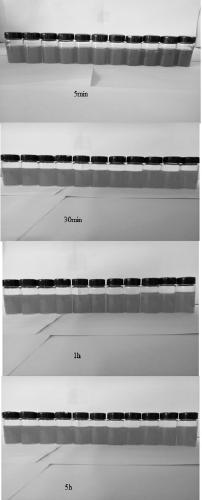

Attapulgite clay-thiocoumarin functional hybrid material and preparation method and application

ActiveCN110389117AImprove stabilityHigh sensitivityFluorescence/phosphorescenceCoumarine dyesHybrid materialColor reaction

The invention discloses an attapulgite clay-thiocoumarin functional hybrid material, which is characterized in that it is prepared by hybridizing a thiocoumarin fluorescent dye having a molecular sizematching the size of an attapulgite clay pore, and the attapulgite clay under a certain condition; the material can be subjected to a specific selective fluorescence reaction with mercury ions, so that the fluorescence intensity at a certain wavelength is significantly improved; further, the material can produce an eye-recognizable color reaction so as to be used in the detection of mercury ionsto detect mercury contamination in water. The invention also discloses a method for preparing the attapulgite clay-thiocoumarin functional hybrid material, comprising an attapulgite clay preprocessingstep and a wet hybridization step. The processed attapulgite clay has a greatly increased specific area. The isopropyl alcohol wet hybridization can effectively promote the dissociation of the attapulgite clay and further promote the combination with the dye. The high-temperature baking promotes the dehydration of the attapulgite clay and promotes the hybridization of the thiocoumarin and the attapulgite clay.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for enriching and purifying glycosylation peptides by nano chitosan derivative

InactiveCN104535381AGood biocompatibilityStable in natureComponent separationPreparing sample for investigationFunction groupHigh selectivity

The invention discloses a method for enriching and purifying glycosylation peptides by a nano chitosan derivative, which belongs to the technical field of biomedical nano-material. The particle size of the nano chitosan derivative is 1-300nm, a solid supported matrix is chitosan, the derivative has an active carboxyl function group and enables complexation with transition metal Ti <4+> ion. The nano chitosan derivative contains a sugar chain and metal Ti <4+> ion, so that glycosylation polypeptides can be enriched and purified with high selectivity and specificity. In addition, the nano chitosan derivative can enrich the glycosylation polypeptides (such as IgG) containing sialic acid as well as enrich polypeptides (such as HRP) of different glycosyls. The nano chitosan derivative can be used for enriching and purifying glycosylation polypeptides with low abundance in a biological sample, and can be used for biological and medical fields comprising clinical diagnosis.

Owner:PEKING UNIV

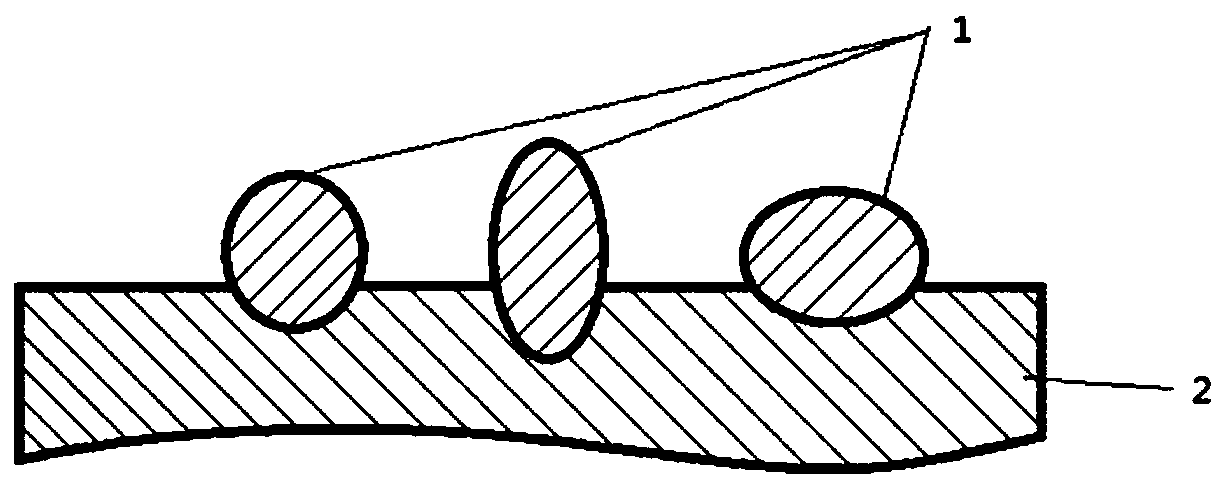

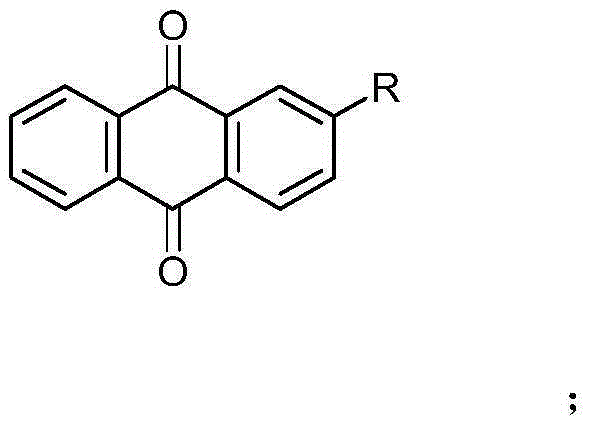

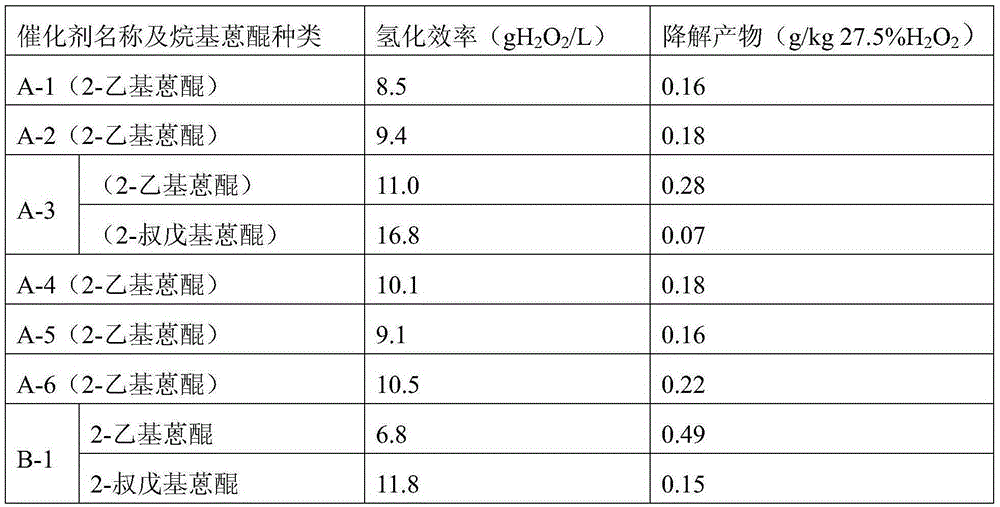

Alkyl anthraquinone hydrogenation catalyst and preparation method thereof

ActiveCN106693958AImprove hydrogenation efficiencyLarger surface areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsDegradation reactionChemistry

The invention discloses an alkyl anthraquinone hydrogenation catalyst and a preparation method thereof. The alkyl anthraquinone hydrogenation catalyst is applied to a technology for producing hydrogen peroxide by an anthraquinone method. The alkyl anthraquinone hydrogenation catalyst is prepared from a catalyst carrier (a CNTs-TiO2 complex) and an active component (palladium atoms) by an equivalent-volume impregnation method, wherein in terms of the elementary palladium atoms, the active component accounts for 0.1-5% of the total weight of the alkyl anthraquinone hydrogenation catalyst; the CNTs-TiO2 complex is prepared from TiO2 and Ni(NO3)2 by a chemical vapor deposition method in the presence of a carbon source gas; the molar ratio of the TiO2 to the Ni(NO3)2 is (0.04-0.25): (0.015-0.2); CNTs accounts for 5-30% of the total weight of the CNTs-TiO2 complex. In the alkyl anthraquinone hydrogenation catalyst, the carrier CNTs-TiO2 complex has a relatively large external specific surface area, so that envelopment of the palladium atoms in the carrier can be effectively reduced, and thus the palladium atoms are fully utilized to improve the activity of the alkyl anthraquinone hydrogenation catalyst; meanwhile, the acidity of the CNTs-TiO2 complex is weaker than Al2O3, and under the action of the TiO2, occurrence of a degradation reaction in the reaction process can be effectively reduced, so that production of a degraded product in a working fluid is reduced. The alkyl anthraquinone hydrogenation catalyst has the characteristics of high hydrogenation efficiency, low anthraquinone degradation and the like in the process of producing the hydrogen peroxide by the anthraquinone method.

Owner:CHINA CATALYST HLDG CO LTD

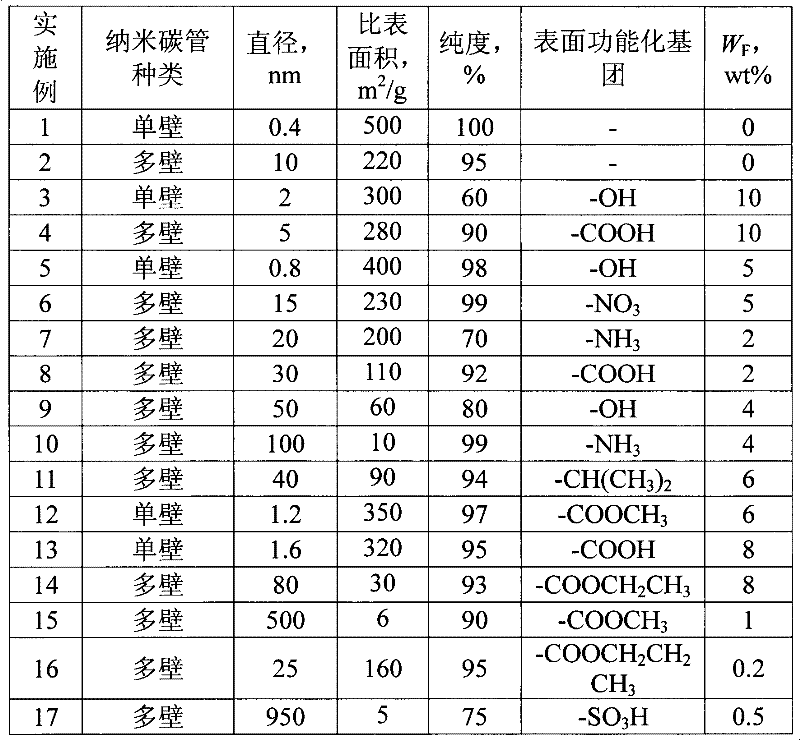

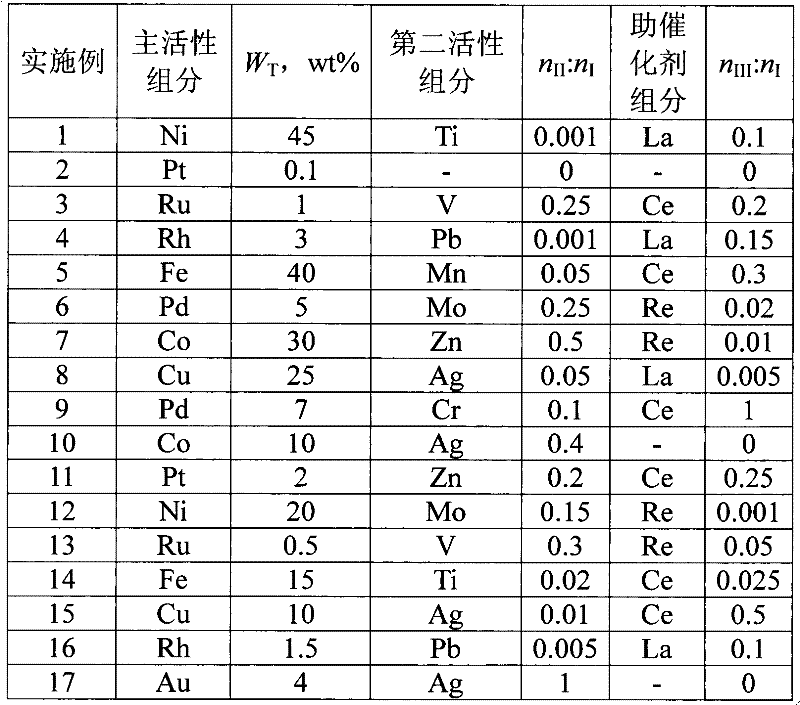

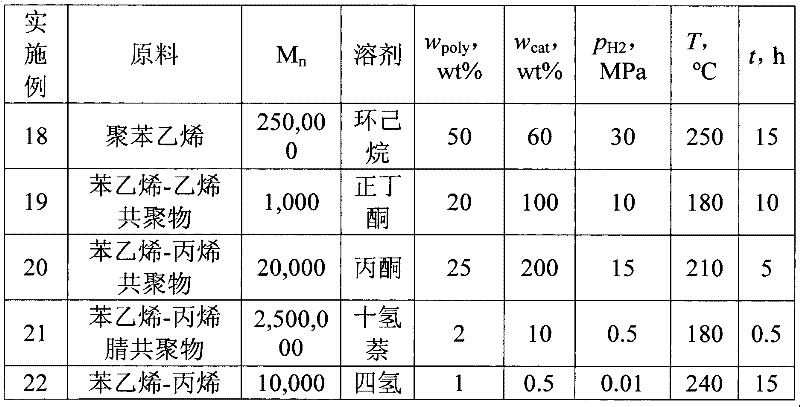

Preparation method for homopolymer or copolymer of cyclohexyl ethylene and catalyst

The invention discloses a catalyst, comprising a carbon nano-tube and a main active hydrogenation component, wherein in the catalyst, the carbon nano-tube is used as a catalyst carrier carried with the main active hydrogenation component, and the main active hydrogenation component is a conventional metal catalyst for catalytic hydrogenation reaction in the field of hydrogenation reaction. The invention further discloses a preparation method for the catalyst, and a preparation method for the homopolymer or copolymer of cyclohexyl ethylene. In the preparation methods disclosed by the invention, hydrogenation can be performed on the polymer solution of polystyrene or styrene copolymer in certain conditions by selecting special catalyst, thereby obtaining the homopolymer or copolymer of cyclohexyl ethylene.

Owner:EAST CHINA UNIV OF SCI & TECH

Hierarchical porous EU-1 molecular sieve and preparation method thereof

ActiveCN109081361AImprove diffusion abilityFacilitated DiffusionMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sieveOrganic base

The invention discloses a hierarchical porous EU-1 molecular sieve and a preparation method thereof. The preparation method includes: putting EU-1 molecular sieve raw powder of 20-200 in silicon oxide / aluminum oxide molar ratio into an inorganic base and piperidine organic base compound mixed basic solution, treating at room temperature for 10-60min according to a solid / liquid mass ratio of 1:(10-50), adding acid to adjust pH value to neutral, filtering, washing, drying, subjecting a sample and an acid solution of 0.01-0.5mol in concentration according to a mass ratio of 1:(10-50) to backflowtreatment at 80-120 DEG C for 0.5-1.2h, filtering, washing, and drying to obtain the hierarchical porous EU-1 molecular sieve. The hierarchical porous EU-1 molecular sieve has good reaction moleculardispersion performance and has great application prospect when serving as a catalyst carrier.

Owner:CHINA CATALYST HLDG CO LTD

Preparation method and application of hierarchical pore SAPO-11 molecular sieve and long-chain alkane isomerization catalyst

ActiveCN112536067AImprove mobilityFacilitate mass transferMolecular sieve catalystsEthylene productionPhosphoric acidMolecular sieve

The invention relates to the technical field of alkane isomerization catalysts, in particular to a preparation method and application of a hierarchical pore SAPO-11 molecular sieve and a long-chain alkane isomerization catalyst. The preparation method comprises the following steps: adding water, low-carbon alcohol, a Gemini surfactant and an organic pore-forming agent into a reaction kettle; thenadding phosphoric acid, a template agent and silica sol, conducting stirring, then putting the stirred material into a kettle for crystallization, washing, drying and roasting a crystallization product, then adding a binder and a molding aid for extrusion molding, loading a certain amount of active components on a carrier obtained by extrusion molding, and conducting drying and roasting to obtainthe long-chain alkane isomerization catalyst. In the preparation process, the low-carbon alcohol, the Gemini surfactant and the organic pore-forming agent are introduced to obtain the hierarchical pore SAPO-11 molecular sieve with small particle size, and the alkane isomerization catalyst prepared by taking the hierarchical pore SAPO-11 molecular sieve as the carrier is developed in pore passage and excellent in mass transfer performance, and has good isomerization activity and selectivity when being used for isomerization of long-chain alkane.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

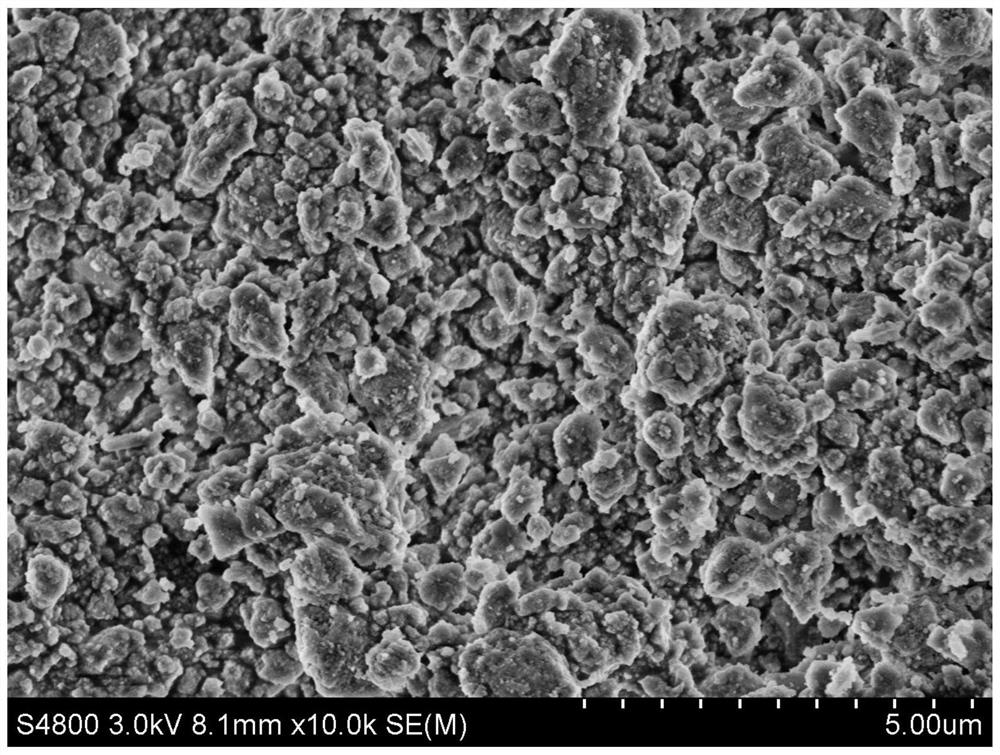

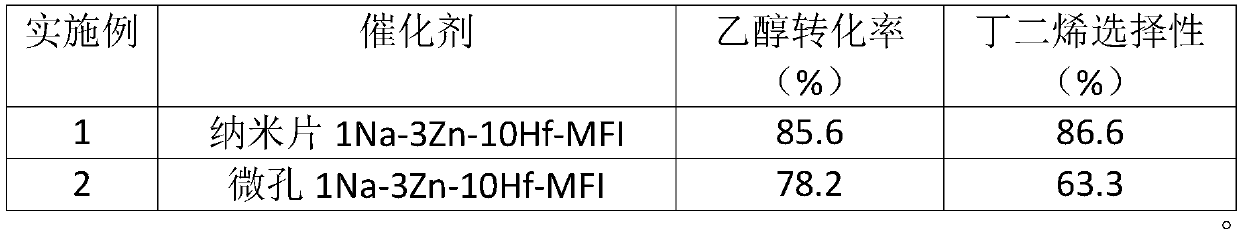

Catalyst for reaction for preparing 1,3-butadiene from ethanol, preparation and applications thereof

ActiveCN111217656AConducive to useInhibit the occurrence of side effectsMolecular sieve catalystsMolecular sieve catalystMolecular sieveButadiene Dioxide

The invention relates to a catalyst for a reaction for preparing 1,3-butadiene from ethanol, a preparation method and applications thereof. The catalyst is an MFI type molecular sieve, which has a nanosheet layer structure, contains two transition metals X and Y and an alkaline earth metal Z, and is formed by cross growth of nanosheet layers, wherein the thickness of the nanosheet layer is 2-50 nm, the metal component X of the catalyst is one or more than two selected from transition metal elements Zn, Ni, Fe, Cu and Ag, the component Y of the catalyst is one or more than two selected from acidic or alkaline metals Zr, Y, Hf, La, Ce, Sn and Ta, and the metal elements are loaded on a molecular sieve carrier in a post-treatment manner. The invention provides a catalyst for preparing 1,3-butadiene by stably and efficiently catalyzing ethanol conversion, a preparation method and applications thereof, wherein the catalyst has obvious industrial application value in a process for preparing butadiene from ethanol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

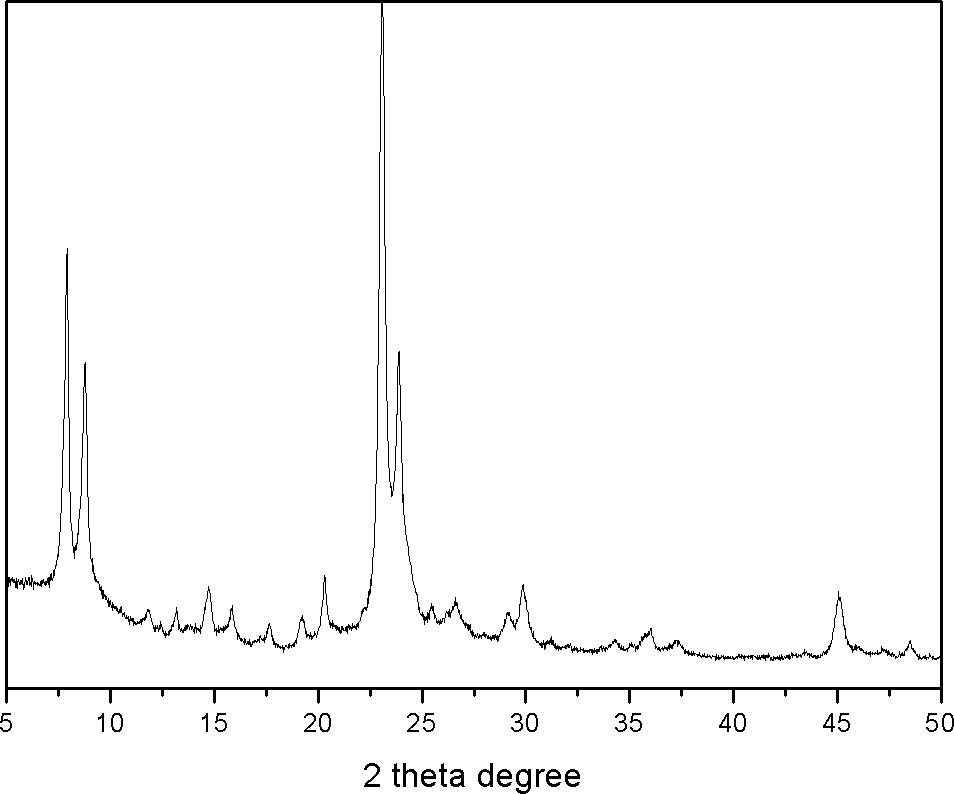

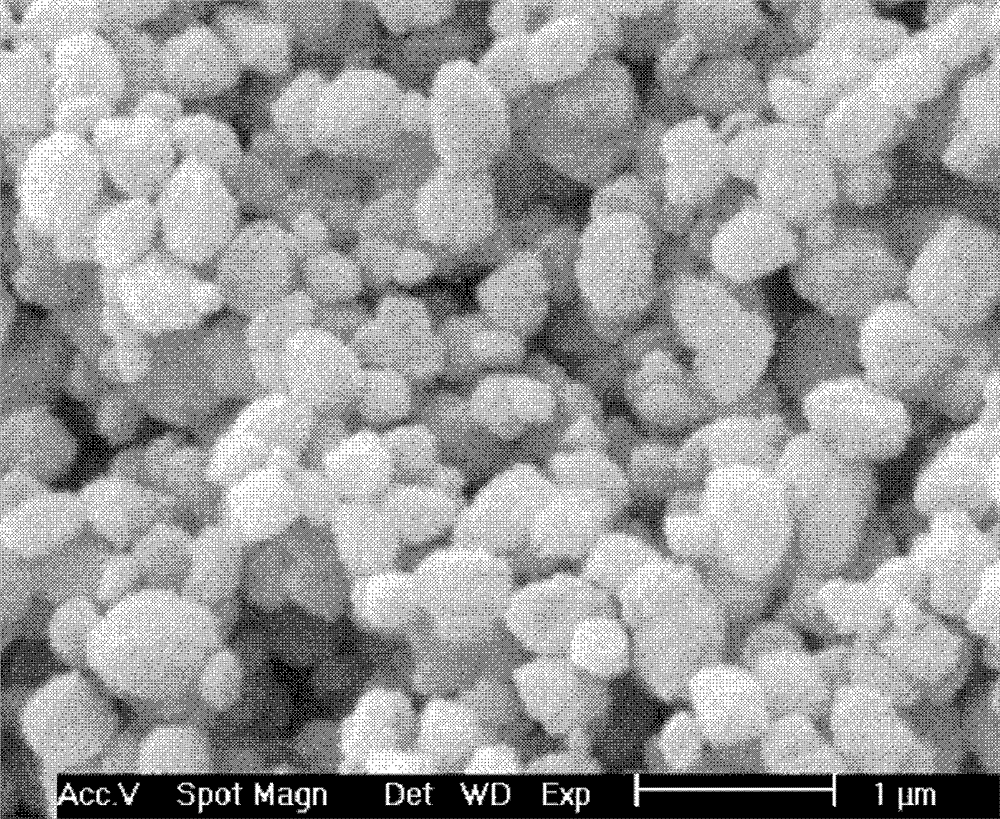

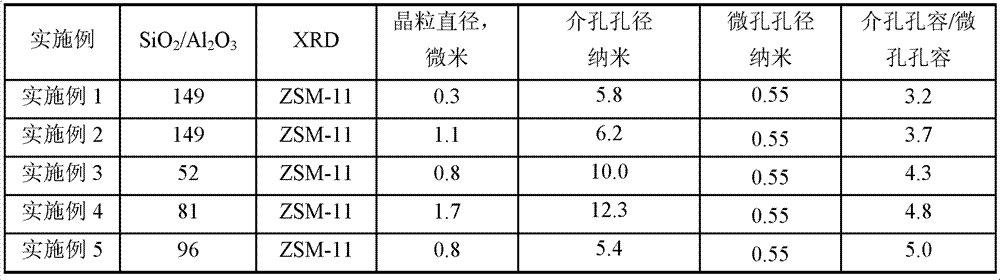

Method for preparing ethylene by dehydrating ethanol

ActiveCN103121903BIncrease profitIncreased focus capacityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureEthylene

The invention relates to a method for preparing ethylene by dehydrating ethanol and mainly aims to solve the problem of poor reaction stability in the prior art. The method comprises the step of making a raw material to contact and react with a catalyst to generate ethylene under the conditions that the temperature is 200-400 DEG C and the space velocity relative to the volume of the ethylene is 0.1-15h<-1>, wherein the raw material is the ethanol with the concentration of 5-100% by mass, and the catalyst is a ZSM-11 zeolite with mesopores and micropores, wherein the ratio of the volume of the mesopores to the volume of the micropores of the ZSM-11 zeolite is 1.5-10, and the diameter of the crystalline grain of the catalyst is not more than 5 microns. The technical scheme well solves the problem of poor reaction stability in the prior art and can be used for the industrial production of the ethylene by dehydrating the ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com