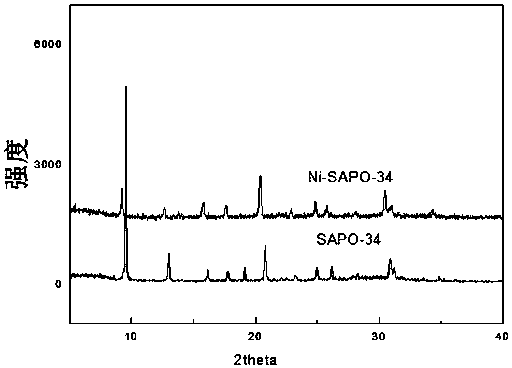

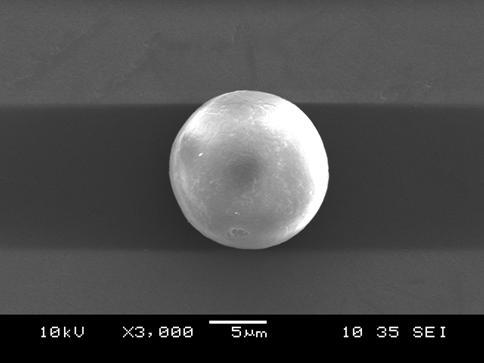

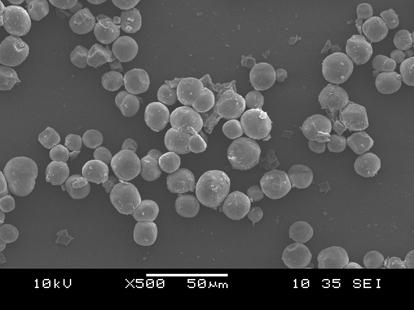

A kind of spherical heteroatom ni-sapo-34 molecular sieve and its preparation and application

A ni-sapo-34, heteroatom technology, applied in the direction of molecular sieve catalyst, molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc. Inexpensive and easy to obtain, the effect of facilitating transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 5ml of deionized water to 0.61g of nickel nitrate hexahydrate, the solution turns green after stirring, then add 0.452ml of diethylenetriamine solution, continue stirring, the solution turns from green to purple, and obtains Ni chelate solution A; Add 2.86g of aluminum isopropoxide, 1.05ml of phosphoric acid solution, 0.938ml of tetraethyl orthosilicate solution, and 2.07ml of morpholine solution into a 50ml glass beaker, then add 8.82ml of deionized water, 40 Stir for 6 hours under the condition of heating in a water bath at ℃, and the stirring speed is 350r / s to obtain the initial sol B; then add the Ni chelate solution A to the initial sol B, and continue to stir for 8 hours under the condition of heating in a water bath at 40°C to obtain sol C . The sol C was transferred into a reaction kettle lined with polytetrafluoroethylene, and after the filling was completed, the reaction kettle was moved into an oven for crystallization at 170° C. for 72 hours. After the...

Embodiment 2

[0032] Add 5ml of deionized water to 0.61g of nickel nitrate hexahydrate, the solution turns green after stirring, then add 0.452ml of diethylenetriamine solution, continue stirring, the solution turns from green to purple, and obtains Ni chelate solution A; Add 2.86g of aluminum isopropoxide, 1.05ml of phosphoric acid solution, 0.938ml of tetraethyl orthosilicate solution, and 2.07ml of morpholine solution into a 50ml glass beaker, then add 8.82ml of deionized water, 40 Stir for 4 hours under the heating condition of water bath at ℃, and the stirring speed is 400r / s to obtain the initial sol B; then add the Ni chelate solution A into the initial sol B, and continue stirring for 10 hours under the heating condition of the water bath at 40℃ to obtain the sol C . The sol C was transferred into a reaction kettle lined with polytetrafluoroethylene, and after filling the kettle, the reaction kettle was moved into an oven for crystallization at 190°C for 48 hours. After the crystal...

Embodiment 3

[0034] The steps in this embodiment are exactly the same as those in Embodiment 1. The difference is: in the raw material sampling and synthesis process, the added aluminum source is changed from 2.86g of aluminum isopropoxide to 1.02g of pseudo-boehmite. The prepared sample was analyzed as spherical heteroatom Ni-SAPO-34 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com