Mesoporous ZSM-22 molecular sieve, synthesis method thereof and application thereof

A synthesis method and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, other chemical processes, etc., can solve the problems such as no reports of ZSM-22 molecular sieve, and achieve improved adsorption and catalytic performance, obvious effect, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 14.050 grams of deionized water, 0.340 grams of sodium hydroxide (96.0% by weight), 0.047 grams of sodium aluminate (Al 2 O 3 43.0% by weight, Na 2 O 35.0% by weight), 2.85 g of 1-ethylpyridine bromide, 9.0 g of silica sol (SiO 2 40% by weight) is uniformly mixed, and the material ratio (molar ratio) of the reactants is:

[0037] SiO 2 / Al 2 O 3 = 200

[0038] 1-ethylpyridine bromide / SiO 2 =0.25

[0039] H 2 O / SiO 2 = 18

[0040] NaOH / SiO 2 =0.15

[0041] After mixing uniformly, put it into a stainless steel reactor and crystallize at 150°C for 3 days under stirring. After the completion of crystallization, it is filtered, washed and dried to obtain the ZSM-22 molecular sieve precursor.

[0042] 3 grams of the synthesized ZSM-22 molecular sieve precursor was contacted with 90 grams of 1.5% sodium hydroxide aqueous solution at 65° C. for 3 hours, and after the reaction was completed, it was filtered, washed, dried and calcined to obtain mesoporous ZSM-22 molecular sieve.

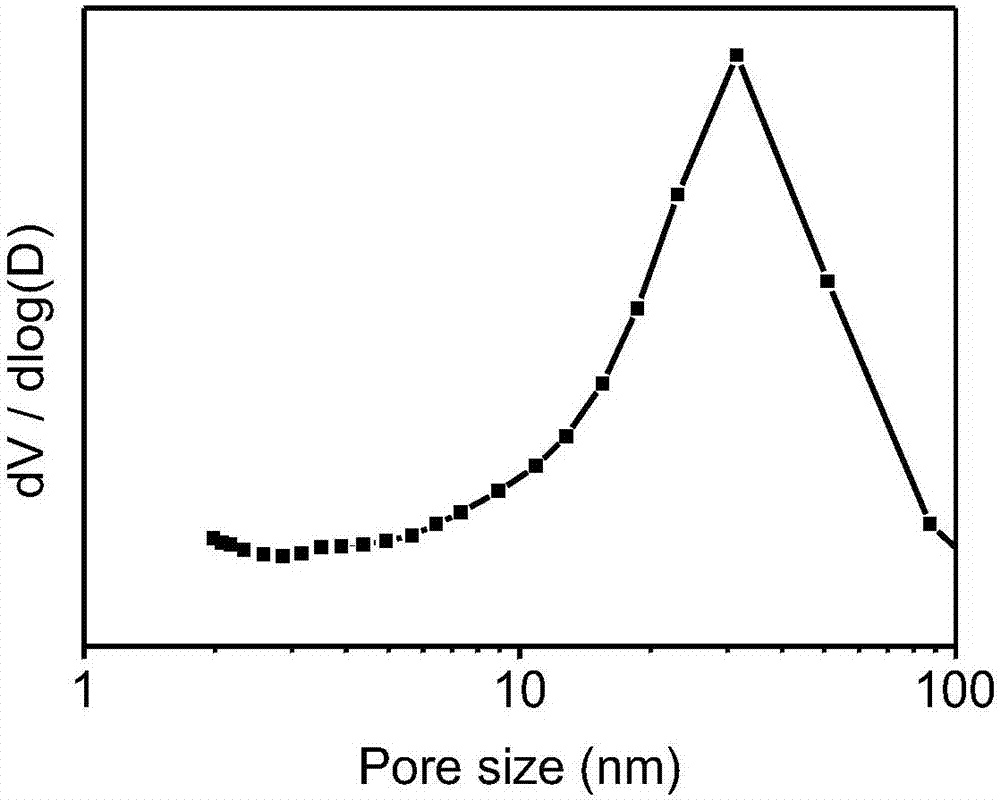

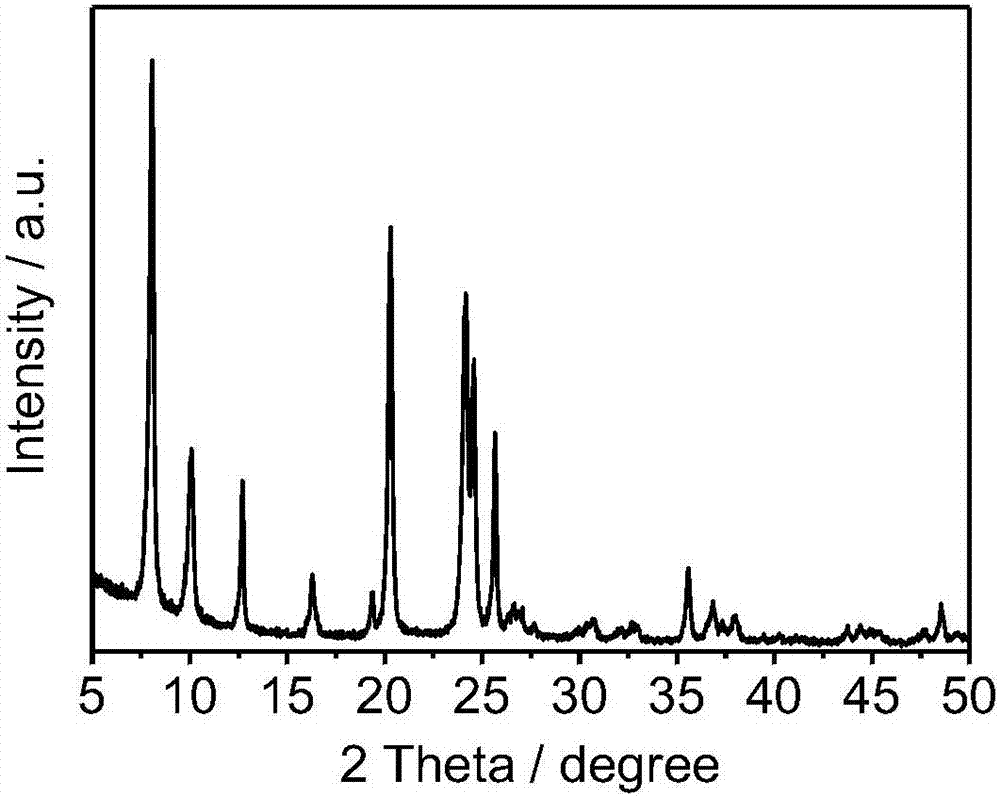

[0043]...

Embodiment 2

[0045] 45.0 grams of deionized water, 0.78 grams of sodium hydroxide (96.0% by weight), 0.119 grams of sodium aluminate (Al 2 O 3 43.0% by weight, Na 2 O 35.0% by weight), 4.75 g of 1-ethylpyridine bromide, 15.0 g of silica sol (SiO 2 40% by weight) is uniformly mixed, and the material ratio (molar ratio) of the reactants is:

[0046] SiO 2 / Al 2 O 3 = 200

[0047] 1-ethylpyridine bromide / SiO 2 =0.25

[0048] H 2 O / SiO 2 = 30

[0049] NaOH / SiO 2 = 0.2

[0050] After mixing uniformly, put it into a stainless steel reactor and crystallize at 150°C for 3 days under stirring. After the completion of crystallization, it is filtered, washed and dried to obtain the ZSM-22 molecular sieve precursor.

[0051] 3 grams of the synthesized ZSM-22 molecular sieve precursor was contacted with 100 grams of a 1.0% sodium hydroxide aqueous solution at 60° C. for 5 hours, and after the reaction was completed, it was filtered, washed, dried and calcined to obtain mesoporous ZSM-22 molecular sieve.

[0052...

Embodiment 3

[0054] Mix 29.5 grams of deionized water, 1.0 grams of potassium hydroxide, 0.455 grams of aluminum sulfate hexadecahydrate, 2.60 grams of 1,8-octane diamine, 11.9 grams of silica sol (SiO 2 30% by weight) is uniformly mixed, and the material ratio (molar ratio) of the reactants is:

[0055] SiO 2 / Al 2 O 3 =90

[0056] 1,8-octanediamine / SiO 2 = 0.30

[0057] H 2 O / SiO 2 = 35

[0058] KOH / SiO 2 = 0.30

[0059] After mixing uniformly, it was aged at room temperature for 24 hours and then put into a stainless steel reactor, and crystallized at 160°C for 3 days under stirring. After the completion of crystallization, it is filtered, washed and dried to obtain the ZSM-22 molecular sieve precursor.

[0060] 2 g of the synthesized ZSM-22 molecular sieve precursor was contacted with 70 g of a 2.0% sodium hydroxide aqueous solution at 40°C for 8 hours, and after the reaction was completed, it was filtered, washed, dried, and calcined to obtain mesoporous ZSM-22 molecular sieve.

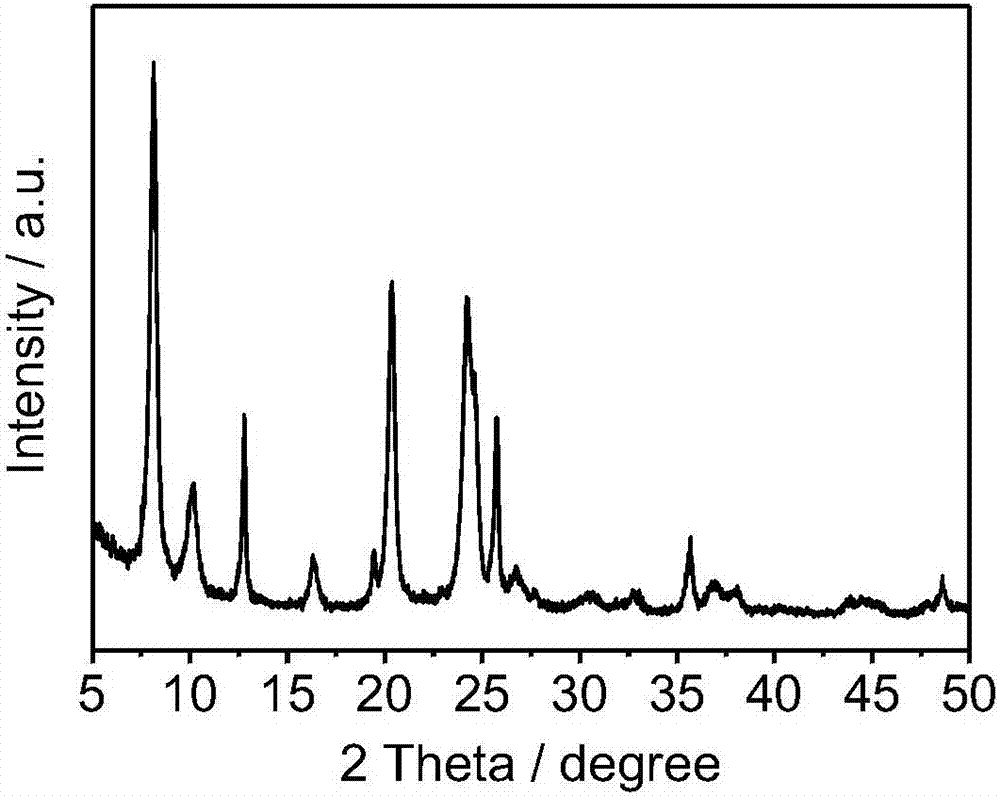

[0061] The XRD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| External specific surface area | aaaaa | aaaaa |

| External specific surface area | aaaaa | aaaaa |

| External specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com