Butane isomerization catalyst and preparation method and application thereof

A catalyst and isomerization technology, applied in the field of butene isomerization catalyst and its preparation, can solve the problems such as not many reports on the influence of molecular sieve catalytic performance, short product selectivity activity period, complicated preparation steps and difficult control, etc. , to achieve the effect of improving the anti-coking inactivation ability, reducing operating costs and long conversion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

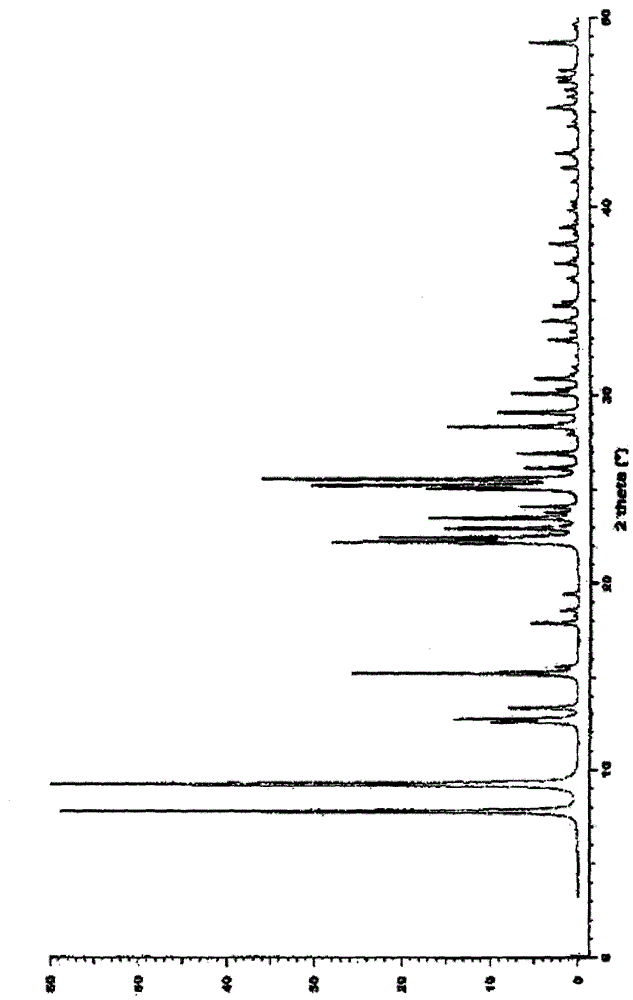

[0042] In a 1L stirred tank under stirring at 100 rpm, add 20 mL of sodium aluminate (industrial product, Sichuan Leshan Runhe Catalytic New Material Co., Ltd., Na 2 O 150g / L, Al 2 o 3 100g / L) and 600mL water, slowly add 110 grams of silica gel (industrial product, Qingdao Ocean Chemical Co., Ltd.), stir for 1 hour, then slowly add 30mL of sodium hydroxide solution (industrial product, Sichuan Leshan Runhe Catalytic New Material Co., Ltd., Na 2 (2300g / L), form colloidal solution, add 60mL pyridine (analytical grade, Beijing Chemical Reagent Company) as templating agent, stir and make reaction mixture. After raising the temperature of the reaction mixture to 150° C. and crystallizing under autogenous pressure for 120 hours, the crystallization reaction was stopped. Solid product is separated by filtration, its XRD collection of patterns and figure 1 The ZSM-35 standard XRD spectrum line peak positions are the same, and the white powder of the resulting product is ZSM-35 mol...

Embodiment 2

[0048] In a 1L stirred tank under 120 rev / min stirring state, add 80mL sodium aluminate (same as above), 650mL water and 2g of the ZSM-35 molecular sieve powder that embodiment 1 obtains as crystal seed, add 110 grams of white carbon black (industrial product, Qingdao Ocean Chemical Co., Ltd.) stirred for 1 hour, then slowly added 20mL of sodium hydroxide solution (same as above) to form a colloidal solution, added 60mL of pyridine (same as above) as a template, and stirred evenly to obtain a reaction mixture. After raising the temperature of the reaction mixture to 170° C. and crystallizing under autogenous pressure for 50 hours, the crystallization reaction was stopped. Solid product is separated by filtration, its XRD collection of patterns and figure 1 The ZSM-35 standard XRD spectrum line peak positions are the same, and the white powder of the resulting product is ZSM-35 molecular sieve.

[0049] Add 400mL of water to the wet filter cake, add sodium aluminate solution (...

Embodiment 3

[0051] In a 1L stirred tank under stirring at 120 rpm, add 40 mL of sodium aluminate (same as above), 630 mL of water and 5 g of the ZSM-35 molecular sieve powder obtained in Example 2 as a seed crystal, add 110 g of silica gel (same as above) and stir for 2 hours , forming a colloidal solution, adding 60 mL of pyridine (same as above) as a template and stirring evenly to prepare a reaction mixture. After raising the temperature of the reaction mixture to 160° C. and crystallizing under autogenous pressure for 80 hours, the crystallization reaction was stopped. Solid product is separated by filtration, its XRD collection of patterns and figure 1 The ZSM-35 standard XRD spectrum line peak positions are the same, and the white powder of the resulting product is ZSM-35 molecular sieve.

[0052] Add 400mL of water to the wet filter cake, add sodium aluminate solution (same as above) and aluminum sulfate solution (same as above) dropwise under stirring, and control the dropping sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com